Experimental Study on the Minimum Required Specimen Width to Maximum Particle Size Ratio in Direct Shear Tests

Abstract

:1. Introduction

2. Previous Laboratory Tests on SSE of Direct Shear Tests

3. Laboratory Tests

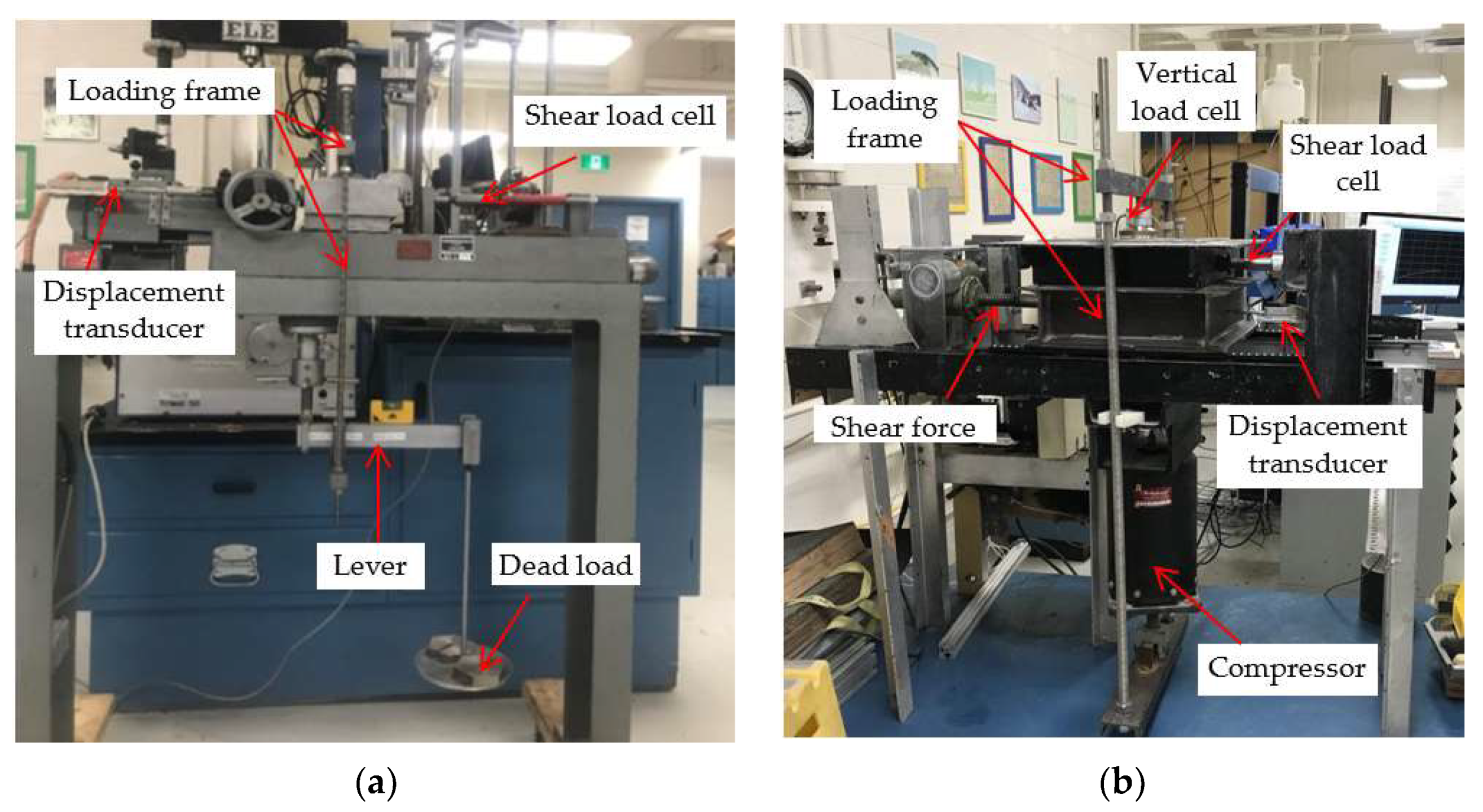

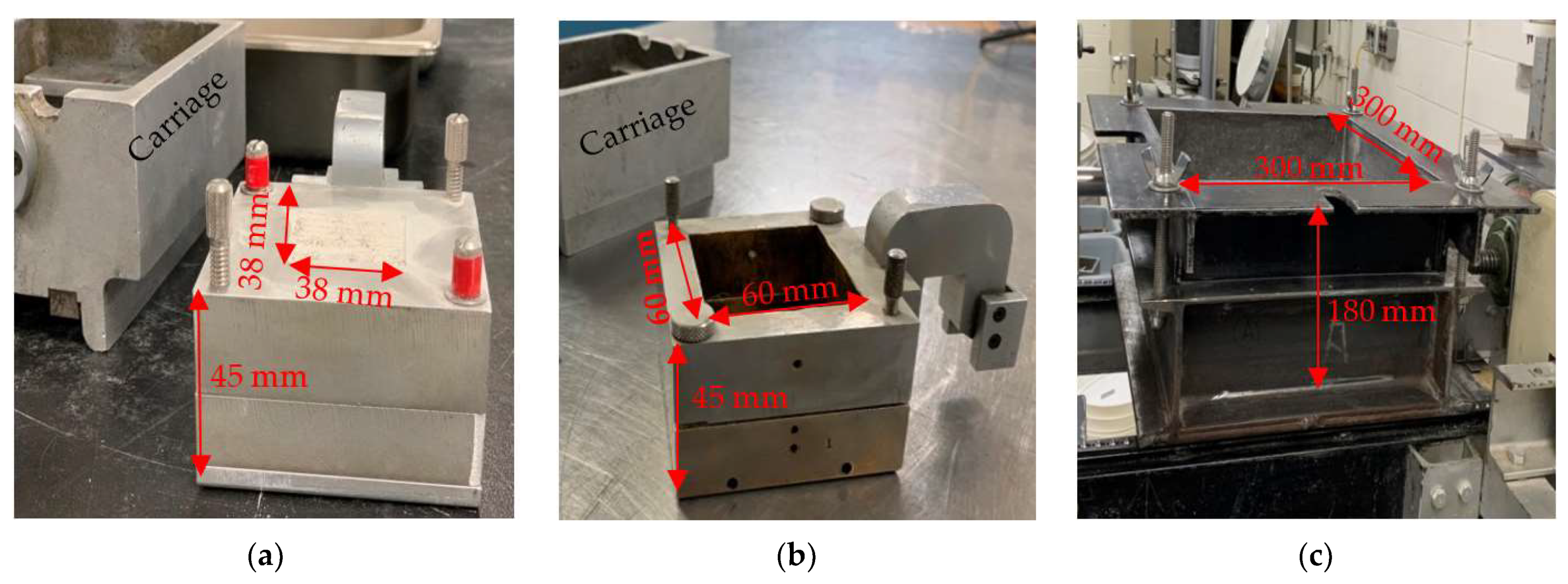

3.1. Test Apparatus

3.2. Materials and Testing Procedure

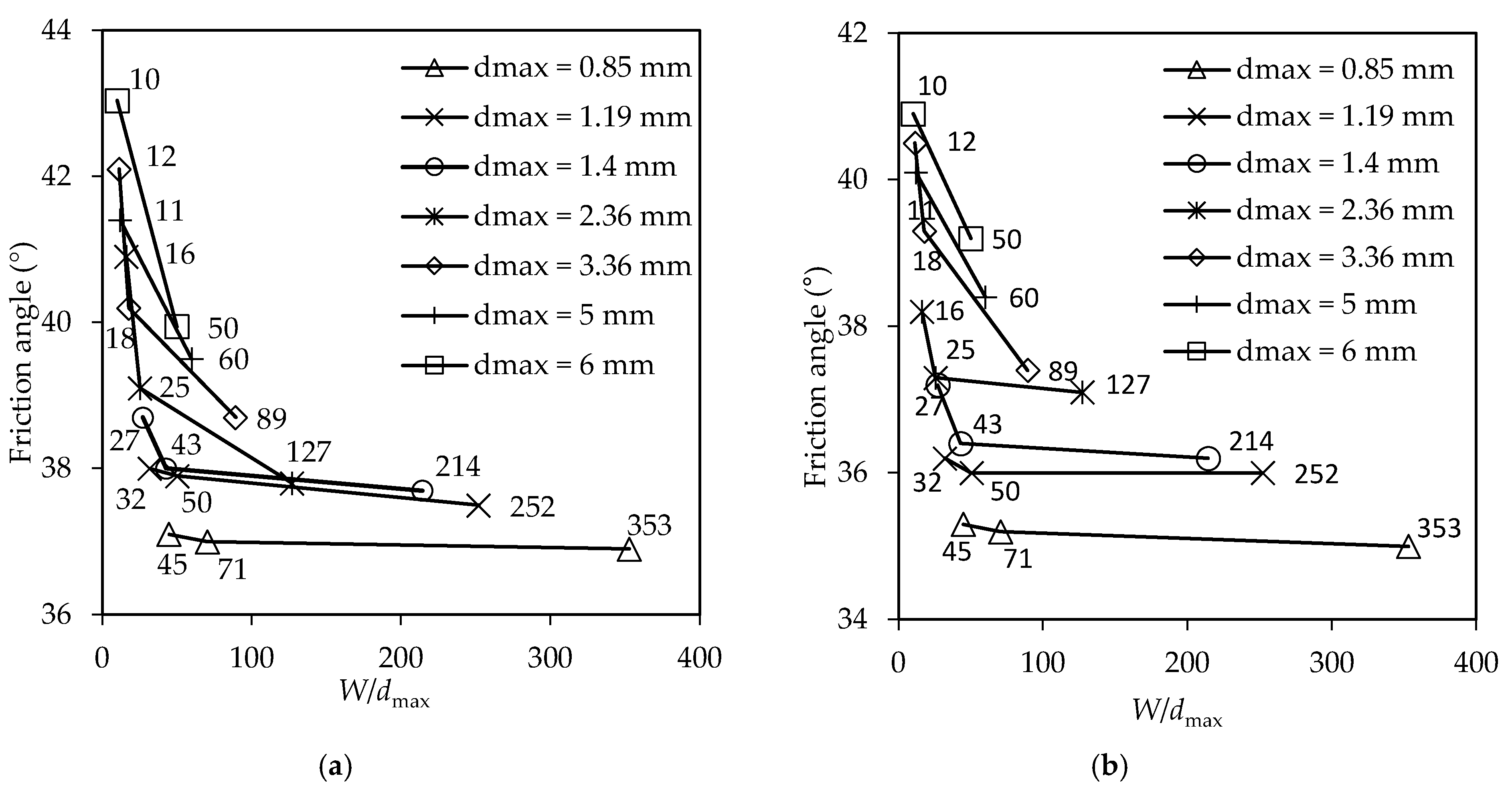

3.3. Test Results

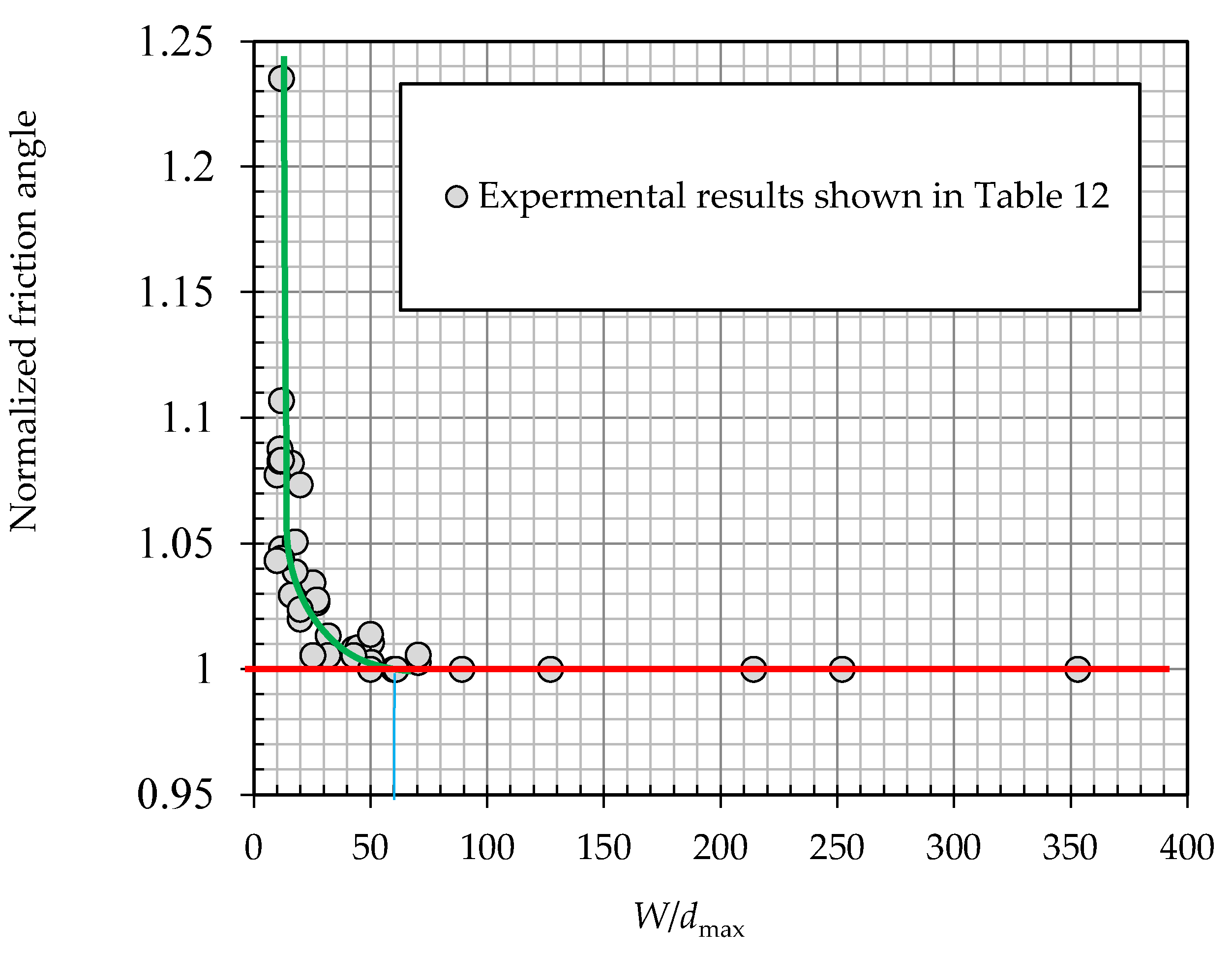

4. Identification of the Minimum Required W/dmax Ratio to Eliminate SSE

5. Discussions

6. Conclusions

- The experimental results confirm what has been reported in [76], who showed that the minimum requirement of ASTM was not validated for fine particle materials due to the lack of experimental data with W/dmax ranging from 10 to 50, but invalidated for coarse particle materials. An update is necessary for the minimum required ratio between specimen sizes and dmax, stipulated by the ASTM D3080/D3080M [42] for direct shear tests.

- The minimum required W/dmax ratio to eliminate the SSE on the shear strengths of granular materials is identified as equal to 60.

- For fine particle materials having a dmax not larger than 1 mm, using the standard shear boxes having W = 60 mm automatically results in W/dmax ≥ 60. The obtained friction angles can be considered as fully representative to that of the tested material in field conditions. The ASTM D3080/D3080M-11 can thus continue to be applied without any problem of SSE.

- For granular materials having dmax larger than 1 mm, applying the minimum requirements of ASTM D3080/D3080M-11 may result in a W/dmax ratio much smaller than the identified minimum required W/dmax ratio. The obtained friction angles can be erroneous.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goodrich, E.P. Lateral earth pressure and related phenomena. Trans. Am. Soc. Civil Eng. 1904, 53, 272–304. [Google Scholar] [CrossRef]

- Casagrande, A.; Albert, S.G. Research on the Shearing Resistance of Soils; Massachusetts Institute of Technology: Cambridge, MA, USA, 1932. [Google Scholar]

- Casagrande, A. Characteristics of cohesionless soils affecting the stability of slopes and earth fills. J. Boston Soc. Civ. Eng. 1936, 23, 13–32. [Google Scholar]

- Terzaghi, K. The shearing resistance of saturated soils and the angle between the planes of shear. In Proceedings of the 1st International Conference on Soil Mechanics and Foundation Engineering, Harvard, Boston, MA, USA, 22–26 June 1936; Volume 2, pp. 54–56. [Google Scholar]

- Cooling, L.F.; Smith, D.B. The shearing resistance of soils. In Proceedings of the 1st International Conference on Soil Mechanics and Foundation Engineering, Harvard, Boston, MA, USA, 22–26 June 1936; pp. 37–41. [Google Scholar] [CrossRef]

- Terzaghi, K.; Peck, R.B. Soil Mechanics in Engineering Practice; Wiley: New York, NY, USA, 1948. [Google Scholar]

- Hutchinson, J.N.; Rolfsen, E.N. Large scale field shear box test and quick clay. Adv. Civ. Eng. 1962, 28, 31–42. [Google Scholar]

- Cerato, A.B.; Lutenegger, A.J. Specimen size and scale effects of direct shear box tests of sands. Geotech. Test. J. 2006, 29, 1–10. [Google Scholar]

- Afzali-Nejad, A.; Lashkari, A.; Shourijeh, P.T. Influence of particle shape on the shear strength and dilation of sand-woven geotextile interfaces. Geotext. Geomembr. 2017, 45, 54–66. [Google Scholar] [CrossRef]

- Afzali-Nejad, A.; Lashkari, A.; Farhadi, B. Role of soil inherent anisotropy in peak friction and maximum dilation angles of four sand-geosynthetic interfaces. Geotext. Geomembr. 2018, 46, 869–881. [Google Scholar] [CrossRef]

- Zhang, Z.; Sheng, Q.; Fu, X.; Zhou, Y.; Huang, J.; Du, Y. An approach to predicting the shear strength of soil-rock mixture based on rock block proportion. Bull. Eng. Geol. Environ. 2019, 79, 2423–2437. [Google Scholar] [CrossRef]

- Cai, H.; Wei, R.; Xiao, J.Z.; Wang, Z.W.; Yan, J.; Wu, S.F.; Sun, L.M. Direct shear test on coarse gap-graded fill: Plate opening size and its effect on measured shear strength. Adv. Civ. Eng. 2020, 5750438. [Google Scholar] [CrossRef]

- Zahran, K.; Naggar, H.E. Effect of sample size on TDA shear strength parameters in direct shear tests. Transp. Res. Rec. 2020, 2674, 1110–1119. [Google Scholar] [CrossRef]

- Motahari Tabari, S.; Shooshpasha, I. Evaluation of coarse-grained mechanical properties using small direct shear test. Int. J. Geotech. Eng. 2021, 15, 667–679. [Google Scholar] [CrossRef]

- Xue, Z.F.; Cheng, W.C.; Wang, L.; Song, G. Improvement of the shearing behaviour of loess using recycled straw fiber reinforcement. KSCE J. Civ. Eng. 2021, 1–17. [Google Scholar] [CrossRef]

- Deiminiat, A.; Li, L. Experimental study on the reliability of scaling down techniques used in direct shear tests to determine the shear strength of rockfill and waste rocks. Civil Eng. 2022, 3, 35–50. [Google Scholar] [CrossRef]

- Jewell, R.A.; Wroth, C.P. Direct shear tests on reinforced sand. Géotechnique 1987, 37, 53–68. [Google Scholar] [CrossRef]

- Jewell, R.A. Direct shear test on sand. Géotechnique 1989, 39, 309–322. [Google Scholar] [CrossRef]

- Shibuya, S.; Mitachi, T.; Tamate, S. Interpretation of direct shear box testing of sands as quasi-simple shear. Géotechnique 1997, 47, 769–790. [Google Scholar] [CrossRef]

- Lings, M.L.; Dietz, M.S. An improved direct shear apparatus for sand. Géotechnique 2004, 54, 245–256. [Google Scholar] [CrossRef]

- Amirpour Harehdasht, S.; Karray, M.; Hussien, M.N.; Roubtsova, V.; Chekired, M. Influence of particle size and gradation on the stress-dilatancy behavior of granular materials during drained triaxial compression. Int. J. Geomech. 2017, 17, 1–20. [Google Scholar] [CrossRef]

- Drugan, W.J.; Willis, J.R. A micromechanics-based nonlocal constitutive equation and estimates of representative volume element size for elastic composites. J. Mech. Phys. Solids 1996, 44, 497–524. [Google Scholar] [CrossRef]

- Kanit, T.; Forest, S.; Galliet, I.; Mounoury, V.; Jeulin, D. Determination of the size of the representative volume element for random composites: Statistical and numerical approach. Int. J. Solids Struct. 2003, 40, 3647–3679. [Google Scholar] [CrossRef]

- Wen, R.; Tan, C.; Wu, Y.; Wang, C. Grain size effect on the mechanical behavior of cohesionless coarse-grained soils with the discrete element method. Adv. Civ. Eng. 2018, 2018, 4608930. [Google Scholar] [CrossRef]

- Parsons, J.D. Progress report on an investigation of the shearing resistance of cohesionless soils. In Proceedings of the 1st International Conference on Soil Mechanics and Foundation Engineering, Harvard, Boston, MA, USA, 22–26 June 1936; Volume 2, pp. 133–138. [Google Scholar]

- Rathee, R.K. Shear strength of granular soils and its prediction by modeling techniques. J. Inst. Eng. 1981, 62, 64–70. [Google Scholar]

- Vucetic, M.; Lacasse, S. Specimen size effect in simple shear test. ASCE J. Geotech. Eng. Div. 1982, 108, 1567–1585. [Google Scholar] [CrossRef]

- Palmeira, E.M.; Milligan, G.W.E. Scale effects in direct shear tests on sand. In Proceedings of the 12th International Conference on Soil Mechanics and Foundation Engineering, Rio De Janeiro, Brazil, 13–18 August 1989; Volume 1, pp. 739–742. [Google Scholar]

- Stone, K.J.; Wood, D.M. Effects of dilatancy and particle size observed in model tests on sand. Soils Found. 1992, 32, 43–57. [Google Scholar] [CrossRef] [Green Version]

- Wu, P.-K.; Matsushima, K.; Tatsuoka, F. Effects of specimen size and some other factors on the strength and deformation of granular soil in direct shear tests. Geotech. Test. J. 2008, 31, 1–20. [Google Scholar]

- Alonso, E.E.; Tapias, M.; Gili, J. Scale effects in rockfill behavior. Géotech. Lett. 2012, 2, 155–160. [Google Scholar] [CrossRef]

- Mirzaeifar, H.; Abouzar, A.; Abdi, M.R. Effects of direct shear box dimensions on shear strength parameters of geogrid-reinforced sand. In Proceedings of the 66th Canadian Geotechnical Conference and the 11th Joint CGS/IAH-CNC Groundwater Conference, GeoMontreal, Montrea, QC, Canada, 29 September–3 October 2013; pp. 1–6. [Google Scholar]

- Amirpour Harehdasht, S.; Hussien, M.N.; Karray, M.; Roubtsova, V.; Chekired, M. Influence of particle size and gradation on shear strength–dilation relation of granular materials. Can. Geotech. J. 2019, 56, 208–227. [Google Scholar] [CrossRef]

- Ziaie Moayed, R.; Alibolandi, M.; Alizadeh, A. Specimen size effects on direct shear test of silty sands. Int. J. Geotech. Eng. 2017, 11, 198–205. [Google Scholar] [CrossRef]

- Potts, D.M.; Dounias, G.T.; Vaughan, P.R. Finite element analysis of the direct shear box test. Géotechnique 1987, 37, 11–23. [Google Scholar] [CrossRef]

- Wang, J.; Dove, J.E.; Gutierrez, M.S. Discrete continuum analysis of shear band in the direct shear test. Géotechnique 2007, 57, 513–526. [Google Scholar] [CrossRef]

- Zhang, L.; Thornton, C. A numerical examination of the direct shear test. Géotechnique 2007, 57, 343–354. [Google Scholar] [CrossRef]

- Jacobson, D.E.; Valdes, J.R.; Evans, T.M. A numerical view into direct shear specimen size effects. Geotech. Test. J. 2007, 30, 512–516. [Google Scholar]

- Wang, J.; Gutierrez, M. Discrete element simulations of direct shear specimen scale effects. Géotechnique 2010, 60, 395–409. [Google Scholar] [CrossRef] [Green Version]

- DeJong, J.T.; Westgate, Z.J. Role of initial state, material properties, and confinement condition on local and global soil-structure interface behavior. J. Geotech. Geoenviron. Eng. 2009, 135, 1646–1660. [Google Scholar] [CrossRef]

- Lashkari, A.; Jamali, V. Global and local sand–geosynthetic interface behaviour. Géotechnique 2021, 71, 346–367. [Google Scholar] [CrossRef]

- ASTM D3080/D3080M-11; Standard Test Method for Direct Shear Test of Soils under Consolidated Drained Conditions (withdrawn 2020). ASTM International: West Conshohocken, PA, USA, 2011.

- Eurocode 7-07; Geotechnical Design; Part 1, General rules: EN 1997-1. The European Union Per Regulation: Brussels, Belgium, 2007.

- AS 1289.6.2.2-98; Soil Strength and Consolidation Tests-Determination of the Shear Strength of a Soil-Direct Shear Test Using a Shear Box. Standards Australia: Sydney, NSW, Australia, 1998.

- BS 1377-90; Methods of Test for Soils for Civil Engineering Purposes. Shear Strength Tests (total stress); Part 7. British Standard Institution: London, UK, 1990.

- McLemore, V.T.; Sweeney, D.; Dunbar, N.; Heizler, L.; Writer, E.P. Determining quantitative mineralogy using a modified MODAN approach on the Questa rock pile materials, New Mexico. In Proceedings of the Society of Mining, Metallurgy and Exploration Annual Convention, Denver, CO, USA, 22–25 February 2009; pp. 9–20. [Google Scholar]

- Zhai, Y.L.; Li, L.; Chapuis, R.P. Analytical, numerical and experimental studies on steady-state seepage through 3D rockfill trapezoidal dikes. Mine Water Environ. 2021, 40, 931–942. [Google Scholar] [CrossRef]

- Azam, S.; Li, Q. Tailings dam failures: A Review of the Last One Hundred Years. Geotech. News 2010, 28, 50–54. [Google Scholar]

- Owen, J.R.; Kemp, D.; Lèbre, É.; Svobodova, K.; Murillo, G.P. Catastrophic tailings dam failures and disaster risk disclosure. Int. J. Disaster Risk Reduct. 2020, 42, 101361. [Google Scholar] [CrossRef]

- Aubertin, M.; Bussière, B.; Bernier, B. Environnement et Gestion des Rejets Miniers; Manuel sur Cédérom; Presses Internationales Polytechnique: Montreal, QC, Canada, 2002. [Google Scholar]

- Azam, S.; Wilson, G.W.; Herasymuik, G.; Nichol, C.; Barbour, L.S. Hydrogeological behavior of an unsaturated waste rock pile: A case study at the Golden Sunlight Mine, Montana, USA. Bull. Eng. Geol. Environ. 2007, 66, 259–268. [Google Scholar] [CrossRef]

- Boudrias, G. Évaluation Numérique et Expérimentale du Drainage et de la Consolidation de Résidus Miniers à Proximité d’une Inclusion de Roches Stériles. Master’s Thesis, Polytechnique Montréal, Montreal, QC, Canada, 2018. [Google Scholar]

- Saleh-Mbemba, F.; Aubertin, M.; Boudrias, G. Drainage and consolidation of mine tailings near waste rock inclusions. In Sustainable and Safe Dams around the World; Taylor & Francis Group: London, UK, 2019; pp. 3296–3305. [Google Scholar]

- Li, L.; Ouellet, S.; Aubertin, M. A method to evaluate the size of backfilled stope barricades made of waste rock. In GeoHalifax; Canadian Geotechnical Society: Halifax, CA, Canada, 2009. [Google Scholar]

- Li, L.; Aubertin, M. Limit equilibrium analysis for the design of backfilled stope barricades made of waste rock. Can. Geotech. J. 2011, 48, 1713–1728. [Google Scholar] [CrossRef]

- Yang, P.Y.; Li, L.; Aubertin, M.; Brochu-Baekelmans, M.; Ouellet, S. Stability analyses of waste rock barricades designed to retain paste backfill. Int. J. Geomech. 2017, 17, 04016079. [Google Scholar] [CrossRef]

- Zhai, Y.L.; Yang, P.Y.; Li, L. Analytical solutions for the design of shotcreted waste rock barricades to retain slurried paste backfill. Constr. Build. Mater. 2021, 307, 124626. [Google Scholar] [CrossRef]

- Hall, E.B. A triaxial apparatus for testing large soil specimens. ASTM Triaxial Test. Soils Bitum. Mix. 1951, 106, 152–161. [Google Scholar]

- Holtz, W.; Gibbs, H.J. Triaxial shear tests on pervious gravelly soils. J. Soil Mech. Found. Div. 1956, 82, 1–22. [Google Scholar] [CrossRef]

- Leslie, D. Large scale triaxial tests on gravelly soils. In Proceedings of the Second Panamerican Conference on Soil Mechanics and Foundation Engineering, Sao Paulo, Brazil, 1 July 1963; Volume 1, pp. 181–202. [Google Scholar]

- Marachi, N.; Seed, H.; Chan, C. Strength characteristics of rockfill materials. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, Mexico City, Mexico, 25–29 August 1969; pp. 217–224. [Google Scholar]

- Marachi, N.D.; Chan, C.K.; Seed, H.B. Evaluation of properties of rockfill materials. J. Soil Mech. Found. Div. 1972, 98, 95–114. [Google Scholar] [CrossRef]

- Varadarajan, A.; Sharma, K.G.; Venkatachalam, K.; Gupta, A.K. Testing and modeling two rockfill materials. J. Geotech. Geoenviron. Eng. 2003, 129, 206–218. [Google Scholar] [CrossRef]

- Hamidi, A.; Azini, E.; Masoudi, B. Impact of gradation on the shear strength-dilation behavior of well graded sand-gravel mixtures. Sci. Iran. 2012, 19, 393–402. [Google Scholar] [CrossRef] [Green Version]

- Chang, W.J.; Phantachang, T. Effects of gravel content on shear resistance of gravelly soils. Eng. Geol. 2016, 207, 78–90. [Google Scholar] [CrossRef]

- Yang, G.; Jiang, Y.; Nimbalkar, S.; Sun, Y.; Li, N. Influence of particle size distribution on the critical state of rockfill. Adv. Civ. Eng. 2019, 2019, 1–7. [Google Scholar] [CrossRef]

- Ovalle, C.; Linero, S.; Dano, C.; Bard, E.; Hicher, P.-Y.; Osses, R. Data compilation from large drained compression triaxial tests on coarse crushable rockfill materials. J. Geotech. Geoenviron. Eng. 2020, 146, 06020013. [Google Scholar] [CrossRef]

- ASTM D3080-72; Direct Shear Test of Soils under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 1972.

- Varadarajan, A.; Sharma, K.G.; Abbas, S.M.; Dhawan, A.K. The role of nature of particles on the behavior of rockfill material. Soils Found. 2006, 46, 569–584. [Google Scholar] [CrossRef] [Green Version]

- Abbas, S.M. Behavior of Rockfill Materials Based on Nature of Particles; Lambert Academic Publishing: Saarbrücken, Germany, 2011. [Google Scholar]

- Pankaj, S.; Mahure, N.; Gupta, S.; Sandeep, D.; Devender, S. Estimation of shear strength of prototype rockfill materials. Int. J. Eng. Sci. 2013, 2, 421–426. [Google Scholar]

- Vasistha, Y.; Gupta, A.K.; Kanwar, V. Medium triaxial testing of some rockfill materials. Electron. J. Geotech. Eng. 2013, 18, 923–964. [Google Scholar]

- Honkanadavar, N.P.; Kumar, N.; Ratnam, M. Modeling the behavior of alluvial and blasted quarried rockfill materials. Geotech. Geol. Eng. 2014, 32, 1001–1015. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y. Shear strength of granular materials based on fractal fragmentation of particles. Powder Technol. 2018, 333, 1–8. [Google Scholar] [CrossRef]

- Dadkhah, R.; Ghafoori, M.; Ajalloeian, R.; Lashkaripour, G.R. The effect of scale direct shear test on the strength parameters of clayey sand in Isfahan city. Can. J. Appl. Sci. 2010, 10, 2027–2033. [Google Scholar] [CrossRef] [Green Version]

- Deiminiat, A.; Li, L.; Zeng, F.; Pabst, T.; Chiasson, P.; Chapuis, R. Determination of the shear strength of rockfill from small scale laboratory shear tests: A critical review. Adv. Civ. Eng. 2020, 2020, 8890237. [Google Scholar] [CrossRef]

- ASTM C29/C29M-17a; Standard Test Method for Bulk Density (unit weight) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2007.

- Hight, D.W.; Leroueil, S. Characterisation of soils for engineering purposes. Characterisation Eng. Prop. Nat. Soils 2003, 1, 255–360. [Google Scholar]

- ASTM D4767; Standard Test Method for Consolidated Undrained Triaxial Compression Test for Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2011.

| Standard | Required Shear Box Size | Maximum Allowed dmax | ||

|---|---|---|---|---|

| W (mm) | T (mm) | W/T | ||

| ASTM D3080/D3080M-11 [42] | ≥50 | ≥13 | ≥2 | Min{T/6, W/10} |

| Eurocode 7 [43] | Not specified | Not specified | Not specified | T/10 |

| AS 1289.6.2.2 [44] | Not specified | ≥12.5 | Not specified | T/6 |

| BS 1377–7 [45] | 60 | 20 | 3 | 2 mm |

| 100 | 25 | 4 | 2.5 mm | |

| 305 | 150 | ≈2 | 15 mm–20 mm | |

| L (mm) × W (mm) | W/dmax | ϕ (°) | |

|---|---|---|---|

| Crushed Quartz | Ottawa Sand | ||

| 60 × 60 | 71 | 31.5 | 31.0 |

| 120 × 100 | 119 | 31.1 | 29.6 |

| 200 × 120 | 143 | 30.7 | 28.5 |

| L (mm) × W (mm) × T (mm) | W/dmax | T/dmax | ϕ (°) |

|---|---|---|---|

| 60 × 60 × 32 | 50 | 27 | 50.1 |

| 252 × 152 × 152 | 127 | 127 | 50.2 |

| 1000 × 1000 × 1000 | 833 | 833 | 49.4 |

| W (mm) × W (mm) × T (mm) | W/dmax | T/dmax | ϕ (°) | ||

|---|---|---|---|---|---|

| Dr = 25% | Dr = 55% | Dr = 85% | |||

| 59.9 × 59.9 × 26.4 | 12 | 5 | 42.0 | 44.5 | 45.5 |

| 101.6 × 101.6 × 40.64 | 20 | 8 | 36.5 | 41.0 | 43.0 |

| 304.8 × 304.8 × 177.8 | 61 | 36 | 34.0 | 40.2 | 42.0 |

| Void Ratio | W (mm) × W (mm) × T (mm) | W/dmax | T/dmax | ϕ (°) |

|---|---|---|---|---|

| 0.654 | 40 × 40 × 20 | 95 | 48 | 45.8 |

| 0.659 | 120 × 120 × 120 | 285 | 285 | 41.8 |

| W (mm) × W (mm) × T (mm) | W/dmax | T/dmax | ϕ (°) | ||

|---|---|---|---|---|---|

| at 1.5 (g/cm3) | at 1.58 (g/cm3) | at 1.67 (g/cm3) | |||

| 60 × 60 × 16 | 46 | 12 | 35.4 | 37.9 | 39.7 |

| 100 × 100 × 30 | 77 | 23 | 33.3 | 34.5 | 35.2 |

| 300 × 300 × 180 | 231 | 138 | 32.6 | 34.0 | 34.5 |

| W (mm) × W (mm) × T (mm) | W/dmax | T/dmax | ϕ (°) | |||

|---|---|---|---|---|---|---|

| Sand 1 | Silty Sand I 2 | Silty Sand II 3 | Silty Sand III 4 | |||

| 60 × 60 × 24.5 | 75 | 30.6 | 43.9 | 39.7 | 34.4 | 30.4 |

| 100 × 100 × 35 | 125 | 43.8 | 39.0 | 31.4 | 31.2 | 31.0 |

| 300 × 300 × 154 | 375 | 192.5 | 34.9 | 33.7 | 30.8 | 31.3 |

| References | Tested W/dmax | Minimum Require W/dmax | Minimum Tested W/dmax Large Enough to Remove SSE | Minimum Required W/dmax of ASTM | |

|---|---|---|---|---|---|

| Parsons [25] | 71, 119, 143 | ~71 | Yes at 71 | Unknown | |

| Rathee [26] | 10, 48 | Unknown | Not at 10 | Invalidated | |

| Cerato and Lutenegger [8] | 12, 20, 61 | Unknown | Not at 20 | Invalidated | |

| Wu et al. [30] | 95, 285 | Unknown | Not at 95 | Invalidated | |

| Mirzaeifar et al. [32] | 46, 77, 231 | ~77 | Not at 46 | Invalidated | |

| Palmeira and Milligan [28] | 50, 127, 833 | ≤50 | Yes at 50 | Unknown | |

| Ziaie Moayed et al. [34] | Sand | 75, 125, 375 | Unknown | Not at 75 | Invalidated |

| Silty sand I | 75, 125, 375 | Unknown | Not at 75 | Invalidated | |

| Silty sand II | 75, 125, 375 | ~125 | Not at 75 | Invalidated | |

| Silty sand III | 75, 125, 375 | ≤75 | Yes at 75 | Unknown | |

| Ranges of Particle Sizes | Masse of Different Portions (g) | ||||||

|---|---|---|---|---|---|---|---|

| dmax = 6 mm | 5 mm | 3.36 mm | 2.36 mm | 1.4 mm | 1.19 mm | 0.85 mm | |

| 5 to 6 mm | 3618 | ||||||

| 3.36 to 5 mm | 5899 | 6190 | |||||

| 2.36 to 3.36 mm | 4314 | 4432 | 5062 | ||||

| 1.4 to 2.36 mm | 3272 | 3227 | 2586 | 4663 | |||

| 1.19 to 1.4 mm | 524 | 721 | 789 | 1334 | 2301 | ||

| 0.85 to 1.19 mm | 1326 | 1379 | 1603 | 2202 | 2220 | 3283 | |

| 0.63 to 0.85 mm | 121 | 125 | 369 | 327 | 1549 | 2401 | 6500 |

| 0.315 to 0.63 mm | 370 | 385 | 291 | 449 | 710 | 853 | 1440 |

| 0.16 to 0.315 mm | 345 | 359 | 408 | 315 | 539 | 568 | 590 |

| 0.08 to 0.16 mm | 1063 | 1105 | 791 | 972 | 771 | 832 | 1300 |

| ≤0.08 mm | 2942 | 3060 | 2531 | 2691 | 2186 | 2324 | 3550 |

| dmax (mm) | emax | 38 mm × 38 mm × 45 mm | 60 mm × 60 mm × 45 mm | 300 mm × 300 mm × 180 mm | ||||

|---|---|---|---|---|---|---|---|---|

| WR 1 | WR 2 | W/dmax | T/dmax | W/dmax | T/dmax | W/dmax | T/dmax | |

| 0.85 | 0.93 | 0.84 | 45 | 53 | 71 | 53 | 353 | 212 |

| 1.19 | 0.87 | 0.79 | 32 | 38 | 50 | 38 | 252 | 151 |

| 1.4 | 0.84 | 0.73 | 27 | 32 | 43 | 32 | 214 | 129 |

| 2.36 | 0.88 | 0.75 | 16 | 19 | 25 | 19 | 127 | 76 |

| 3.36 | 0.85 | 0.74 | 11 | 13 | 18 | 13 | 89 | 54 |

| 5.0 | 0.80 | 0.77 | -- | -- | 12 | 9 | 60 | 36 |

| 6.0 | 0.78 | 0.72 | -- | -- | 10 | 8 | 50 | 30 |

| dmax (mm) | 38 mm × 38 mm × 45 mm | 60 mm × 60 mm × 45 mm | 300 mm × 300 mm × 180 mm | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W/dmax | T/dmax | ϕ (°) | W/dmax | T/dmax | ϕ (°) | W/dmax | T/dmax | ϕ (°) | ||||

| WR 1 | WR 2 | WR 1 | WR 2 | WR 1 | WR 2 | |||||||

| 0.85 | 45 | 53 | 37.1 | 35.3 | 71 | 53 | 37 | 35.2 | 353 | 212 | 36.9 | 35.0 |

| 1.19 | 32 | 38 | 38 | 36.2 | 50 | 38 | 37.9 | 36.1 | 252 | 151 | 37.5 | 36.0 |

| 1.4 | 27 | 32 | 38.7 | 37.2 | 43 | 32 | 38.0 | 36.4 | 214 | 129 | 37.7 | 36.2 |

| 2.36 | 16 | 19 | 40.9 | 38.2 | 25 | 19 | 39.1 | 37.3 | 127 | 76 | 37.9 | 37.1 |

| 3.36 | 11 | 13 | 42.1 | 40.5 | 18 | 13 | 40.2 | 39.3 | 89 | 54 | 38.7 | 37.4 |

| 5 | -- | -- | -- | -- | 12 | 9 | 41.4 | 40.1 | 60 | 36 | 39.5 | 38.4 |

| 6 | -- | -- | -- | -- | 10 | 8 | 43.0 | 40.9 | 50 | 30 | 39.9 | 39.2 |

| Id. of Material | W/dmax | T/dmax | ϕ (°) | Normalized ϕ | Id. of Material | W/dmax | T/dmax | ϕ (°) | Normalized ϕ | References |

|---|---|---|---|---|---|---|---|---|---|---|

| WR 1, dmax = 0.85 mm | 45 | 53 | 37.1 | 1.005 | WR 2, dmax = 0.85 mm | 45 | 53 | 35.3 | 1.009 | This study |

| 71 | 53 | 37.0 | 1.003 | 71 | 53 | 35.2 | 1.006 | |||

| 353 | 212 | 36.9 | 1 | 353 | 212 | 35.0 | 1 | |||

| WR 1, dmax = 1.19 mm | 32 | 38 | 38.0 | 1.013 | WR 2, dmax = 1.19 mm | 32 | 38 | 36.2 | 1.006 | |

| 50 | 38 | 37.9 | 1.011 | 50 | 38 | 36.1 | 1.002 | |||

| 252 | 151 | 37.5 | 1 | 252 | 151 | 36.0 | 1 | |||

| WR 1, dmax = 1.4 mm | 27 | 32 | 38.7 | 1.027 | WR 2, dmax = 1.4 mm | 27 | 32 | 37.2 | 1.028 | |

| 43 | 32 | 38.0 | 1.008 | 43 | 32 | 36.4 | 1.006 | |||

| 214 | 129 | 37.7 | 1 | 214 | 129 | 36.2 | 1 | |||

| WR 1, dmax = 2.36 mm | 16 | 19 | 40.9 | 1.082 | WR 2, dmax = 2.36 mm | 16 | 19 | 38.2 | 1.030 | |

| 25 | 19 | 39.1 | 1.034 | 25 | 19 | 37.3 | 1.005 | |||

| 127 | 76 | 37.8 | 1 | 127 | 76 | 37.1 | 1 | |||

| WR 1, dmax = 3.36 mm | 11 | 13 | 42.1 | 1.088 | WR 2, dmax = 3.36 mm | 11 | 13 | 40.5 | 1.083 | |

| 18 | 13 | 40.2 | 1.039 | 18 | 13 | 39.3 | 1.051 | |||

| 89 | 54 | 38.7 | 1 | 89 | 54 | 37.4 | 1 | |||

| WR 1, dmax = 5 mm | 12 | 9 | 41.4 | 1.048 | WR 2, dmax = 5 mm | 12 | 9 | 40.1 | 1.044 | |

| 60 | 36 | 39.5 | 1 | 60 | 36 | 38.4 | 1 | |||

| Gravel, dmax = 5 mm, Dr = 25% | 12 | 5 | 42.0 | 1.235 | Gravel, dmax = 5 mm, Dr = 55% | 12 | 5 | 44.5 | 1.107 | [8] |

| 20 | 8 | 36.5 | 1.074 | 20 | 8 | 41.0 | 1.020 | |||

| 61 | 36 | 34.0 | 1 | 61 | 36 | 40.2 | 1 | |||

| Gravel, dmax = 5 mm, Dr = 85% | 12 | 5 | 45.5 | 1.083 | ||||||

| 20 | 8 | 43.0 | 1.024 | |||||||

| 61 | 36 | 42.0 | 1 | |||||||

| Sand, dmax = 1.2 mm | 50 | 27 | 50.1 | 1.014 | [28] | |||||

| 833 | 833 | 49.4 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deiminiat, A.; Li, L.; Zeng, F. Experimental Study on the Minimum Required Specimen Width to Maximum Particle Size Ratio in Direct Shear Tests. CivilEng 2022, 3, 66-84. https://doi.org/10.3390/civileng3010005

Deiminiat A, Li L, Zeng F. Experimental Study on the Minimum Required Specimen Width to Maximum Particle Size Ratio in Direct Shear Tests. CivilEng. 2022; 3(1):66-84. https://doi.org/10.3390/civileng3010005

Chicago/Turabian StyleDeiminiat, Akram, Li Li, and Feitao Zeng. 2022. "Experimental Study on the Minimum Required Specimen Width to Maximum Particle Size Ratio in Direct Shear Tests" CivilEng 3, no. 1: 66-84. https://doi.org/10.3390/civileng3010005

APA StyleDeiminiat, A., Li, L., & Zeng, F. (2022). Experimental Study on the Minimum Required Specimen Width to Maximum Particle Size Ratio in Direct Shear Tests. CivilEng, 3(1), 66-84. https://doi.org/10.3390/civileng3010005