Size Effect in FRP Shear-Strengthened RC Beams: Design Models versus Experimental Data

Abstract

:1. Introduction

2. Research Significance

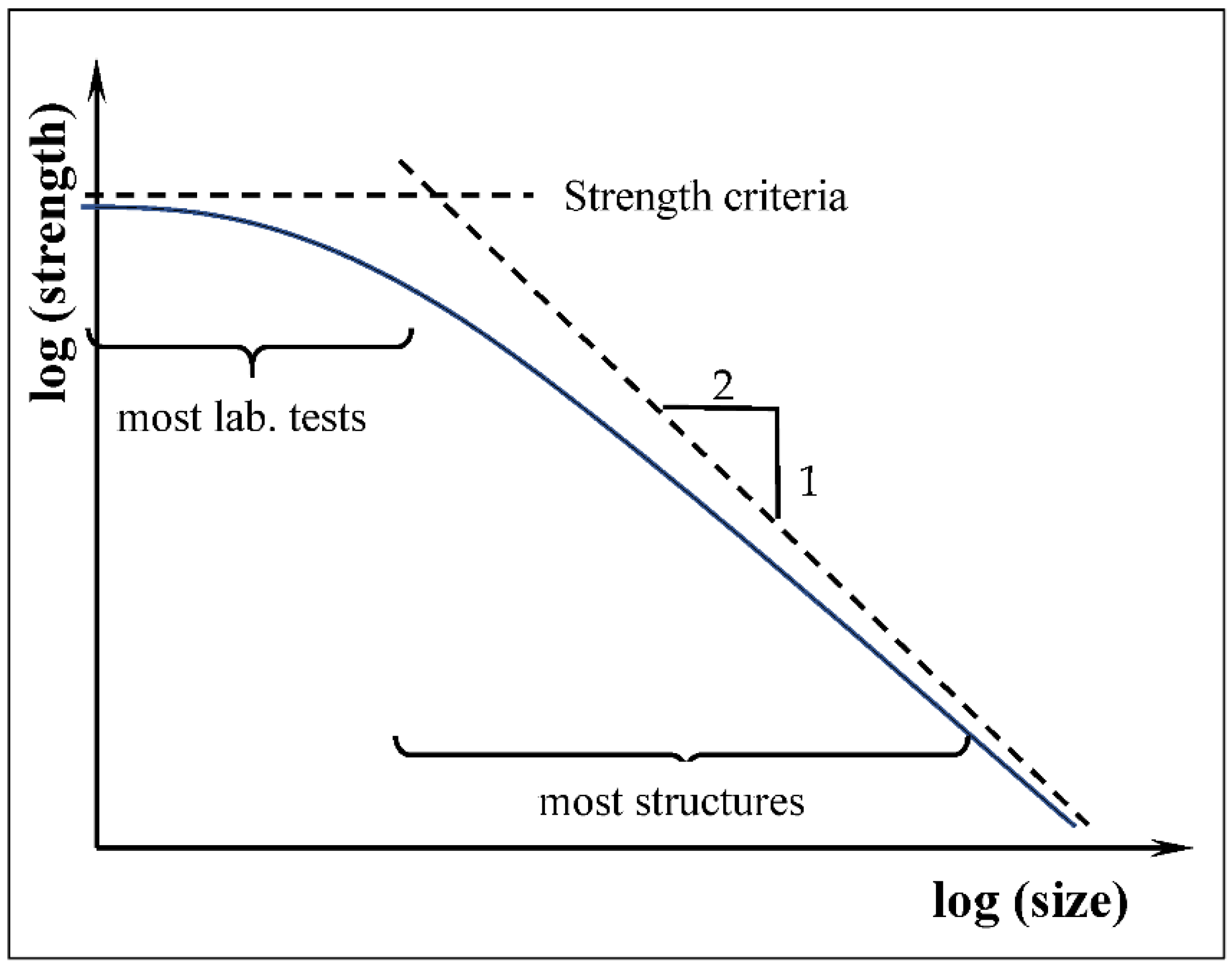

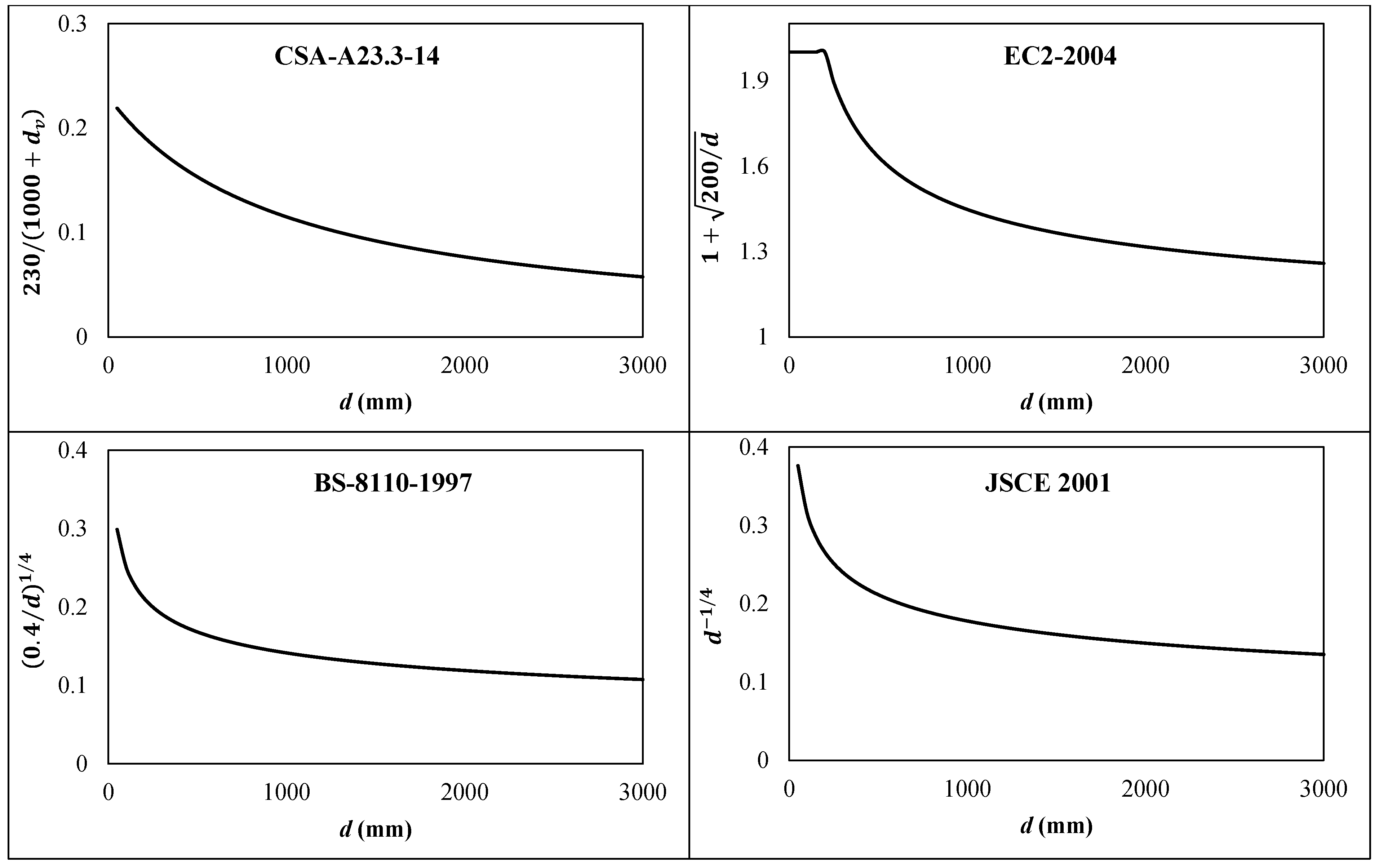

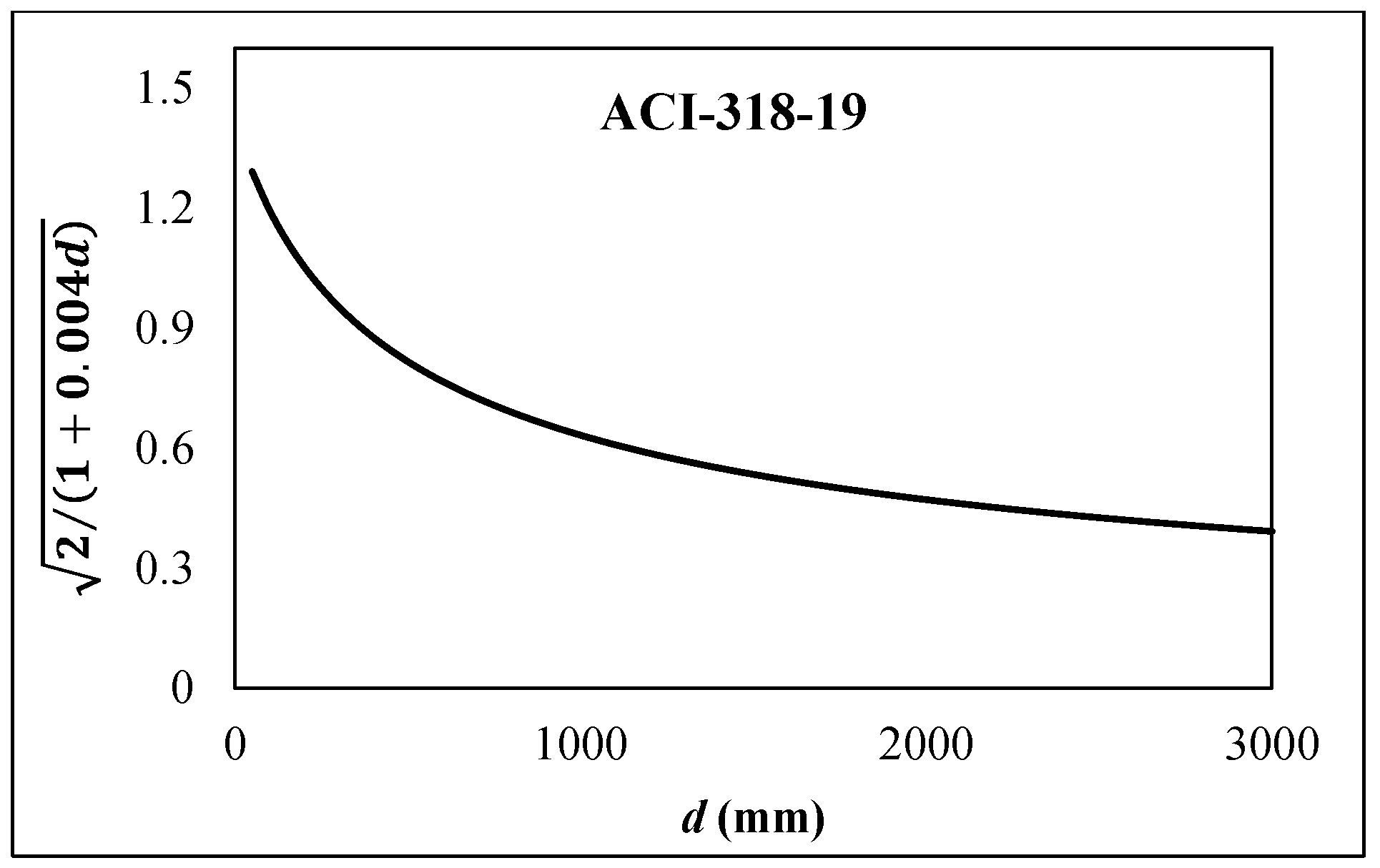

3. Size Effect

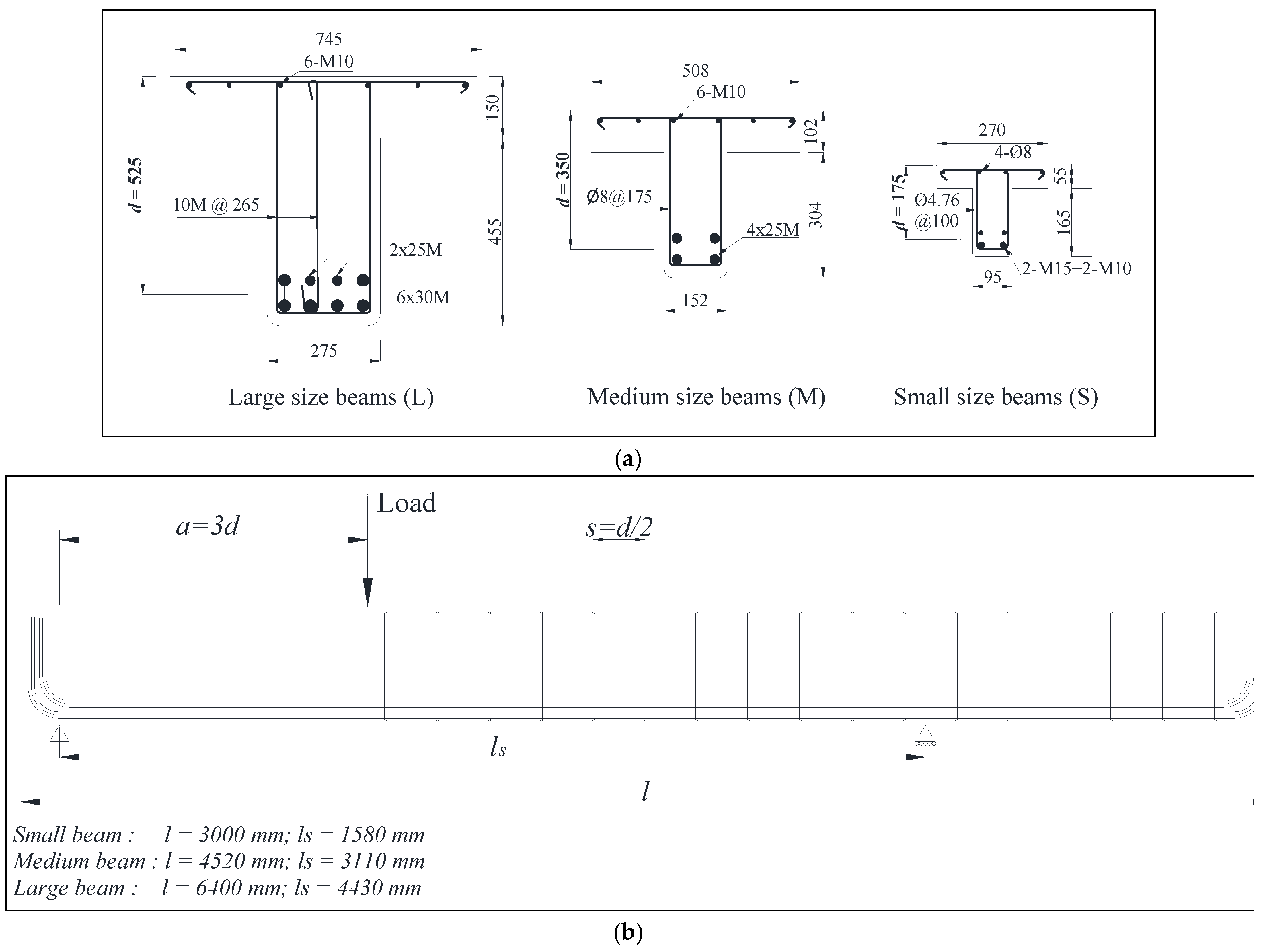

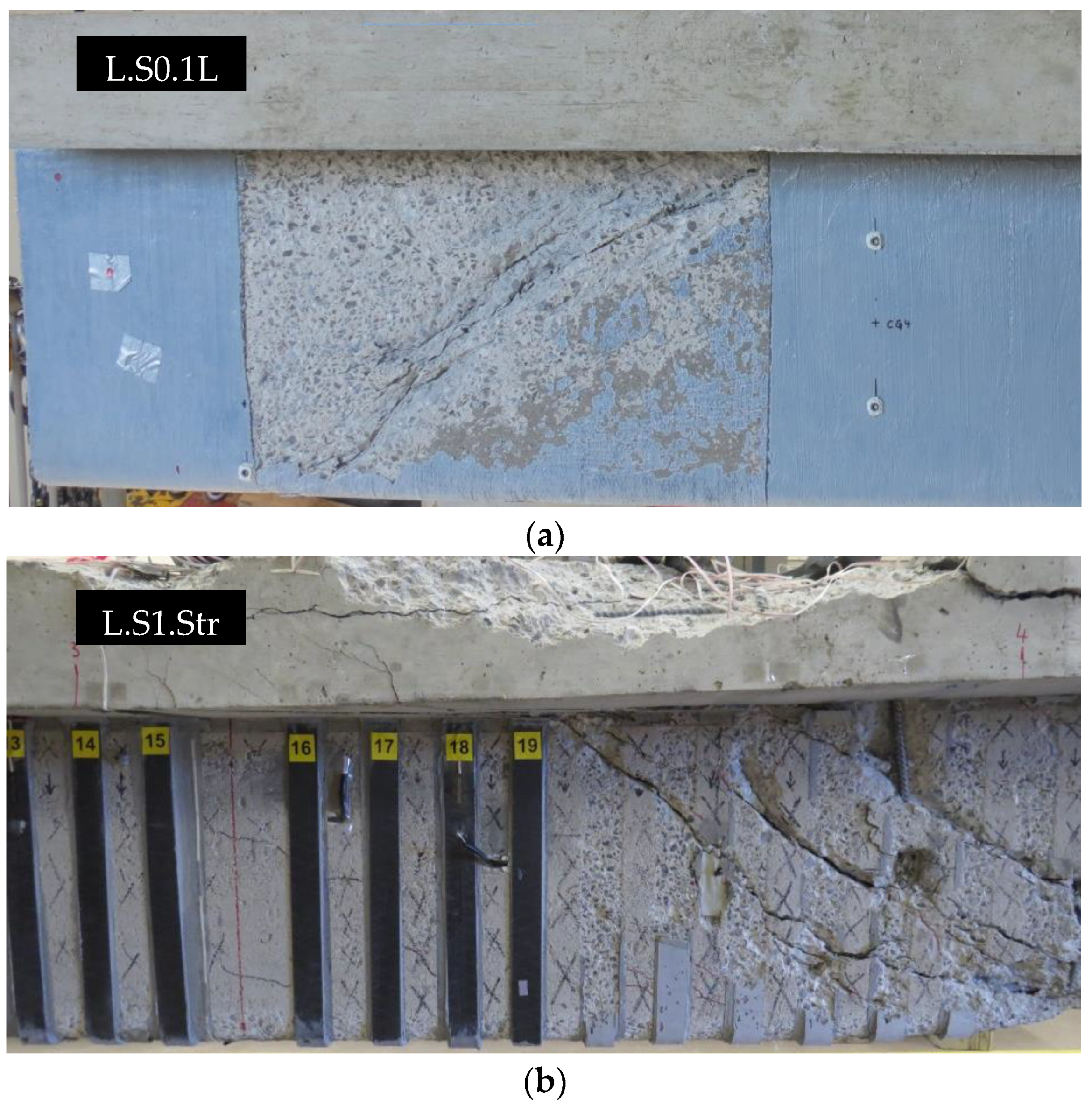

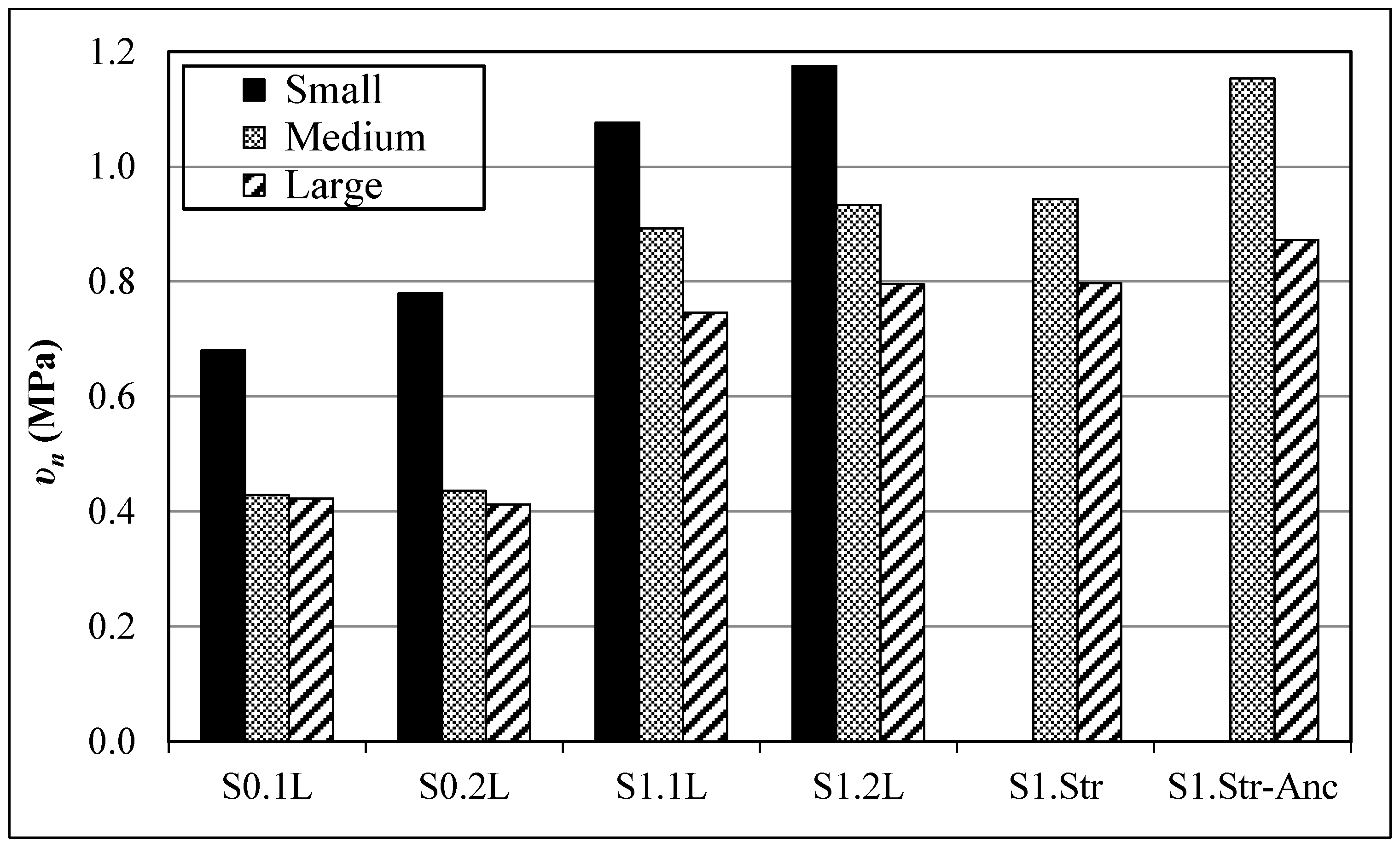

4. Experimental Tests

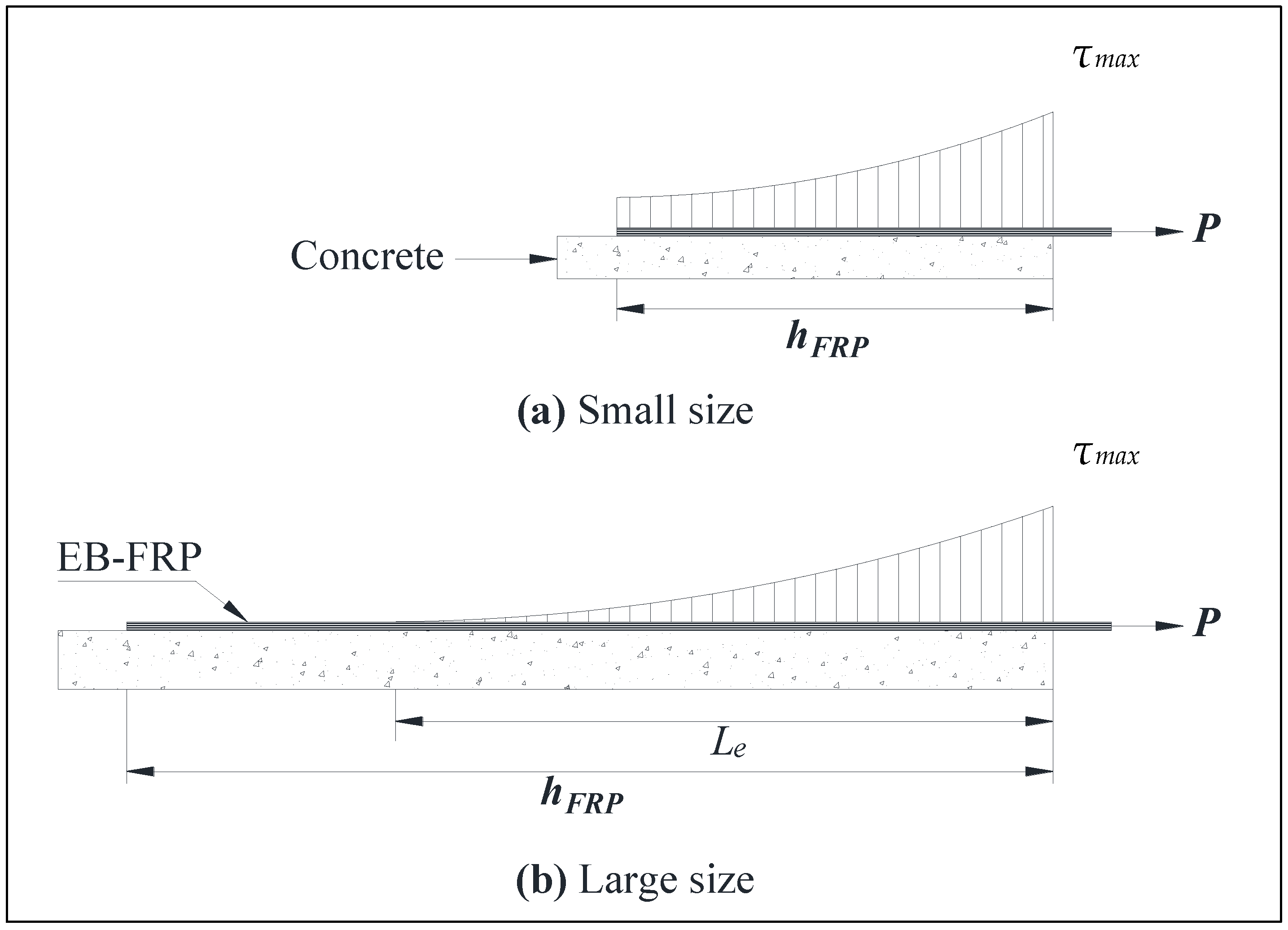

5. Experimental Test Results

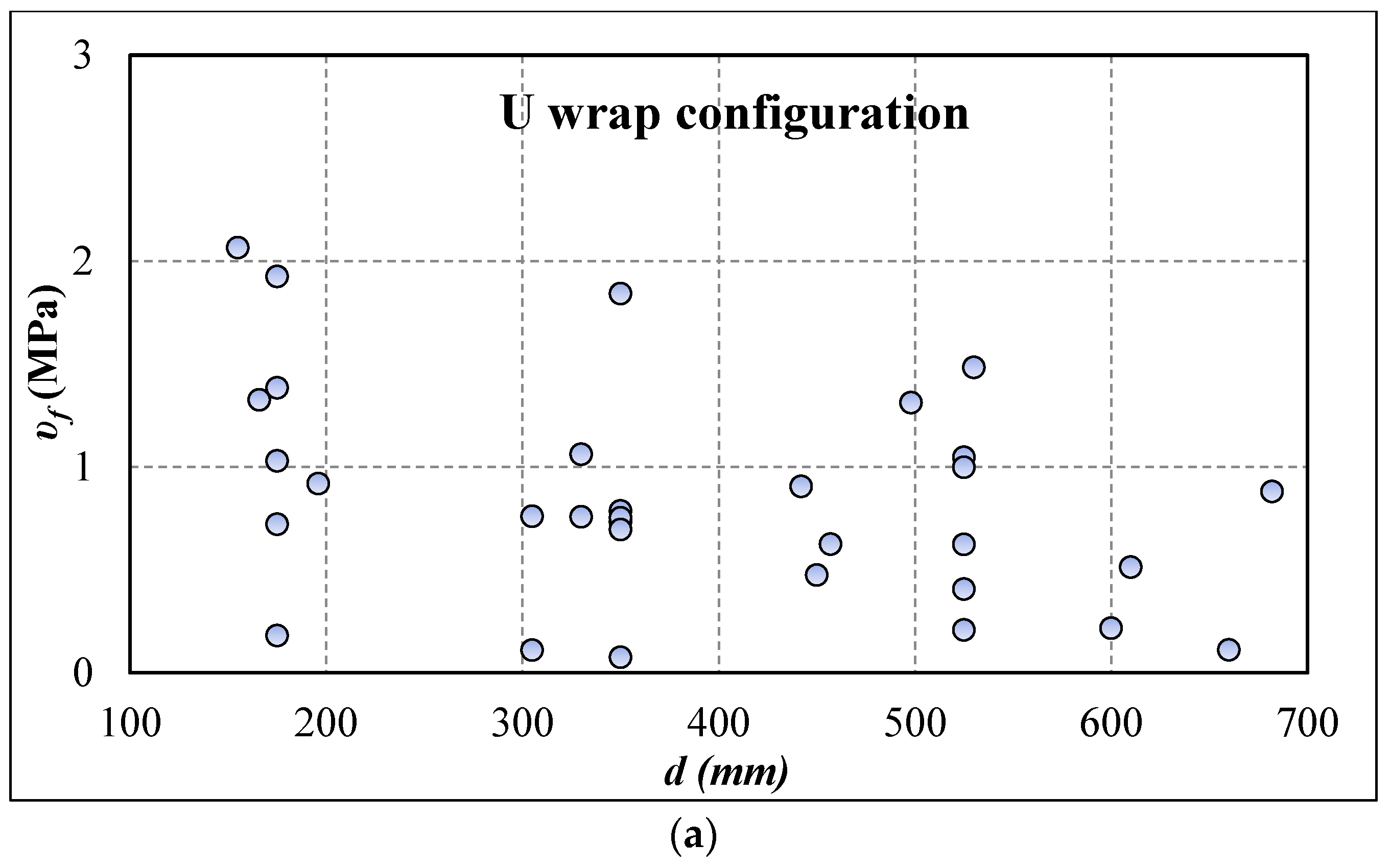

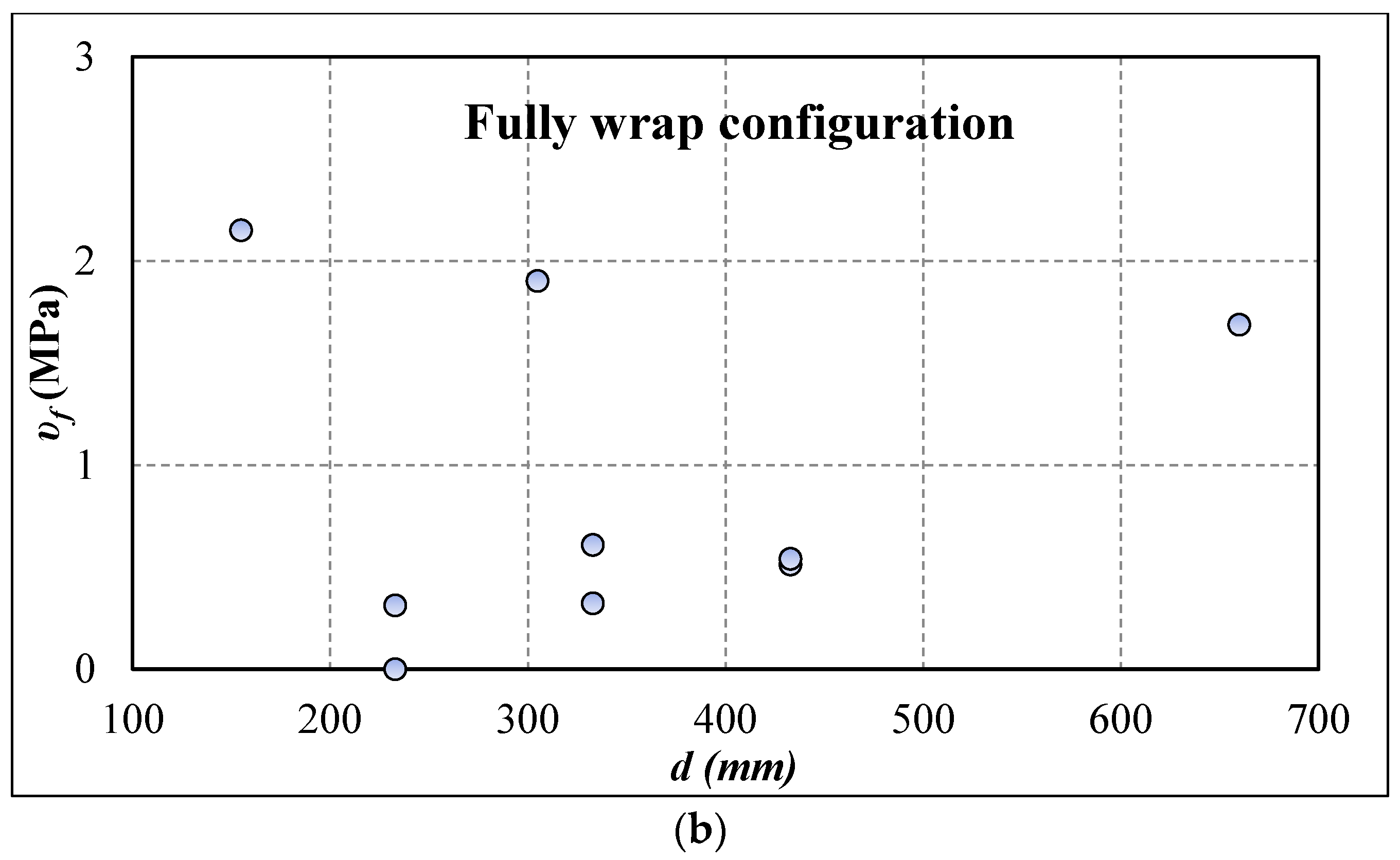

6. Database and Size Effect in EB-FRP-Strengthened RC Beams

7. Current Codes and Design Guidelines

7.1. CSA-S806-12 and CSA-S6-19

7.2. ACI-440.2R-17

7.3. JSCE 2001

7.4. fib-TG9.3 (2001) and fib-TG5.1 (2019)

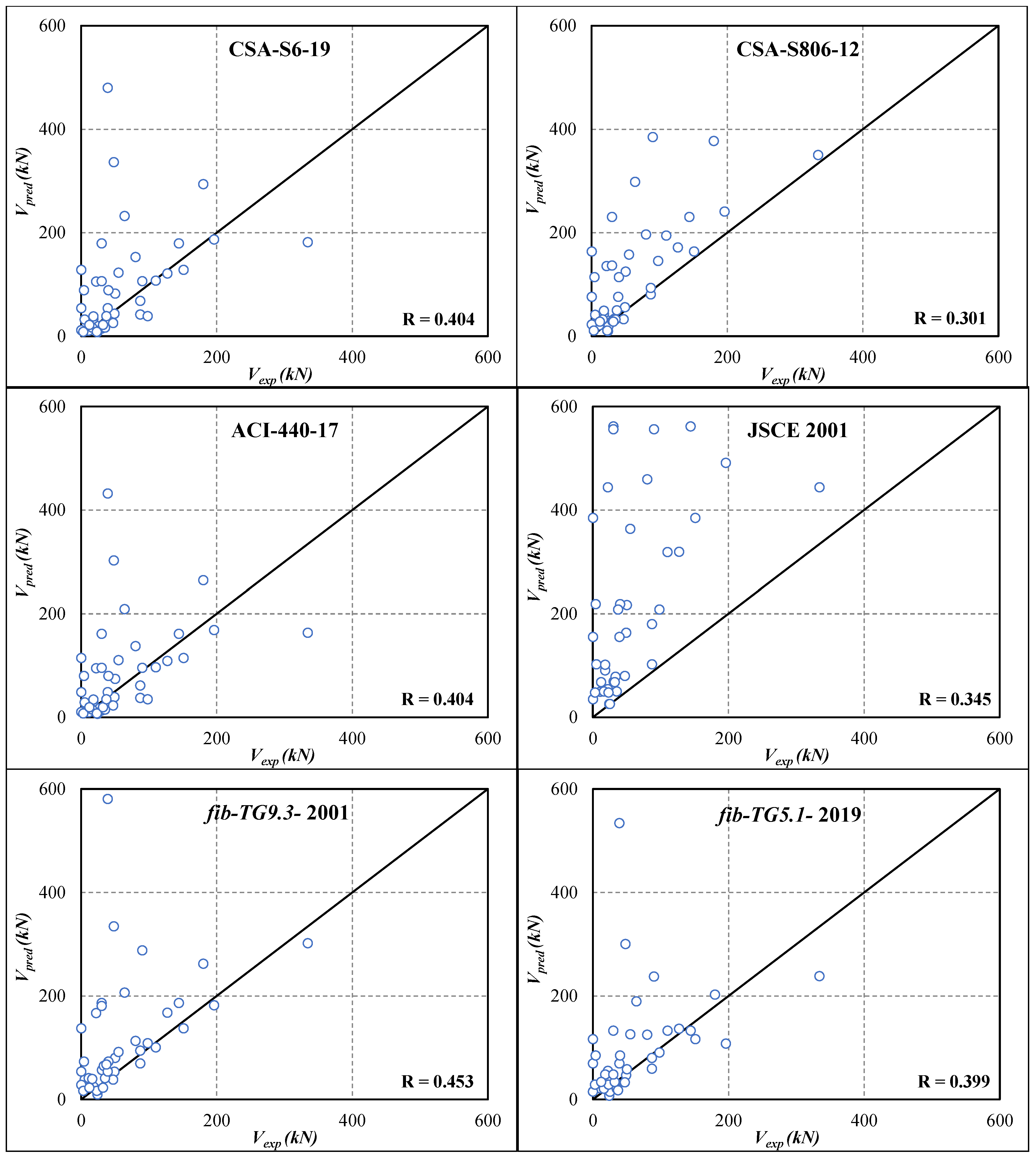

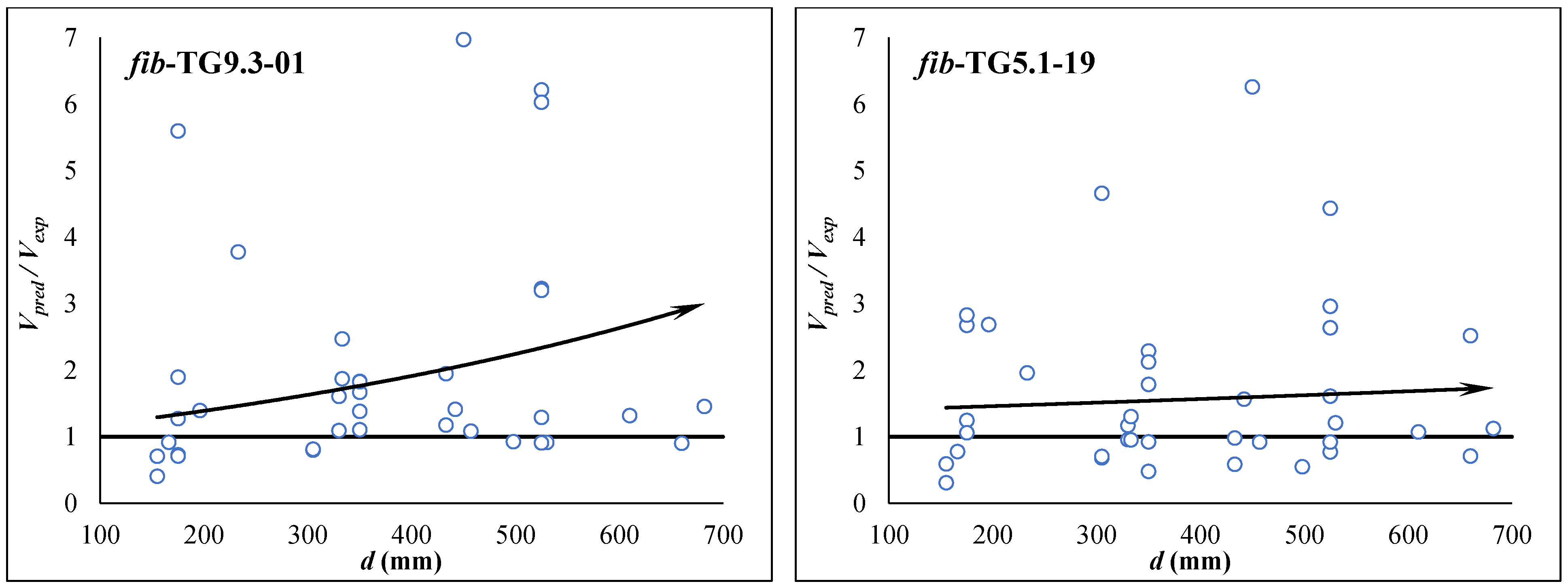

8. Comparison of Experimental Results with Prediction Models of Codes and Design Guidelines

9. Conclusions

- (1)

- The prediction models of EB-FRP contribution to shear resistance do not contain any reducing term to count for size effect, unlike the models of concrete contribution in conventional RC beams, in which a reduction coefficient depending on beam height is provided.

- (2)

- Experimental results on the size effect revealed a presence of an additional size effect related to EB-FRP strengthening that tended to lower the shear strength at failure as specimen size increased.

- (3)

- The EB-FRP contribution to shear resistance predicted by the models considered in the present research study was overestimated in more than 50% of the specimens, particularly when using the JSCE (2001) code, which overestimated almost all specimens in the database.

- (4)

- The influence of the size effect was moderate in the fib-TG5.1-19 (2019), ACI-440.2R-17 (2017), and CSA-S6-19 (2019) prediction models and even more so in the CSA-S806-12 (2012) and fib-TG9.3-01 (2001) models. In contrast, it was very significant in the predictions made using the Japanese code (JSCE (2001).

- (5)

- Compared with the old version of the fib-TG9.3-01 (2001) European code, a clear improvement was observed in the updates in the new version (fib-TG5.1-19 2019) regarding the capture of the influence of the size effect with increasing specimen size.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Symbols

| AFRP | Area of FRP for shear strengthening |

| b | Beam width |

| d | Effective depth of concrete |

| dFRP | Effective shear depth of EB-FRP |

| EFRP | FRP elastic modulus |

| , | Concrete compressive strength |

| fFRP | FRP tensile strength |

| hFRP | FRP bond length |

| Le | Effective anchorage length of EB-FRP |

| SFRP | Spacing of FRP strips |

| S | Spacing of steel stirrups |

| tFRP | FRP ply thickness |

| Vc; Vs; VFRP | Contribution to shear resistance of concrete, steel stirrups, and EB-FRP |

| Vn | Total nominal shear resistance of the beam |

| wFRP | Width of FRP strips |

| αFRP | Inclination angle of FRP fibre |

| FRP strain | |

| ; | FRP ultimate and effective strain |

| FRP strengthening material ratio | |

| Transverse steel reinforcement ratio | |

| Longitudinal steel reinforcement ratio | |

| Normalized shear strength at failure | |

| Resistance factor for FRP material |

References

- Syroka-Korol, E.; Tejchman, J. Experimental investigations of size effect in reinforced concrete beams failing by shear. Eng. Struct. 2014, 58, 63–78. [Google Scholar] [CrossRef]

- ACI-446.1R-99. Fracture Mechanics of Concrete: Concepts Models and Determination of Material Properties; American Concrete Institute: Farmington Hills, MI, USA, 1999. [Google Scholar]

- Benzeguir, Z.E.A.; El-Saikaly, G.; Chaallal, O. Size Effect of RC T-Beams Strengthened in Shear with Externally Bonded CFRP L-Shaped Laminates. J. Compos. Constr. 2020, 24, 04020031. [Google Scholar] [CrossRef]

- Berset, J.-D. Strengthening of Reinforced Concrete Beams for Shear Using FRP Composites. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1992. [Google Scholar]

- El-Saikaly, G.; Godat, A.; Chaallal, O. New anchorage technique for FRP shear-strengthened RC T-beams using CFRP rope. J. Compos. Constr. 2015, 19, 04014064. [Google Scholar] [CrossRef]

- Khalifa, A.; Nanni, A. Improving shear capacity of existing RC T-section beams using CFRP composites. Cem. Concr. Compos. 2000, 22, 165–174. [Google Scholar] [CrossRef]

- Mofidi, A.; Chaallal, O. Tests and design provisions for reinforced-concrete beams strengthened in shear using FRP sheets and strips. Int. J. Concr. Struct. Mater. 2014, 8, 117–128. [Google Scholar] [CrossRef] [Green Version]

- Mofidi, A.; Thivierge, S.; Chaallal, O.; Shao, Y. Behavior of reinforced concrete beams strengthened in shear using L-shaped CFRP plates: Experimental investigation. J. Compos. Constr. 2014, 18, 04013033. [Google Scholar] [CrossRef]

- Triantafillou, T.C. Shear strengthening of reinforced concrete beams using epoxy-bonded FRP composites. ACI Struct. J. 1998, 95, 107–115. [Google Scholar]

- Bae, S.-W.; Tann, B.D.; Belarbi, A. Size effect of reinforced concrete beams strengthened in shear with externally bonded CFRP sheets. In Proceedings of the 6 th International Conference on FRP Composites in Civil Engineering (CICE 2012), Roma, Italy, 13–15 June 2012; pp. 1–8. [Google Scholar]

- Benzeguir, Z.E.A.; El-Saikaly, G.; Chaallal, O. Size Effect in RC T-Beams Strengthened in Shear with Externally Bonded CFRP Sheets: Experimental Study. J. Compos. Constr. 2019, 23, 4019048. [Google Scholar] [CrossRef]

- Deniaud, C.; Cheng, J.R. Review of shear design methods for reinforced concrete beams strengthened with fibre reinforced polymer sheets. Can. J. Civ. Eng. 2001, 28, 271–281. [Google Scholar] [CrossRef]

- Foster, R.M.; Brindley, M.; Lees, J.M.; Ibell, T.J.; Morley, C.T.; Darby, A.P.; Evernden, M.C. Experimental investigation of reinforced concrete T-beams strengthened in shear with externally bonded CFRP sheets. J. Compos. Constr. 2017, 21, 4016086. [Google Scholar] [CrossRef] [Green Version]

- Leung, C.K.; Chen, Z.; Lee, S.; Ng, M.; Xu, M.; Tang, J. Effect of size on the failure of geometrically similar concrete beams strengthened in shear with FRP strips. J. Compos. Constr. 2007, 11, 487–496. [Google Scholar] [CrossRef]

- Nguyen-Minh, L.; Rovňák, M. Size effect in uncracked and pre-cracked reinforced concrete beams shear-strengthened with composite jackets. Compos. Part B Eng. 2015, 78, 361–376. [Google Scholar] [CrossRef]

- Qu, Z.; Lu, X.; Ye, L. Size effect of shear contribution of externally bonded FRP U-jackets for RC beams. In Proceedings of the International Symposium on Bond Behaviour of FRP in Structures (BBFS 2005), Hong Kong, China, 7–9 December 2005; pp. 371–380. [Google Scholar]

- Szymon, C.; Matteo, D.B.; Maurizio, G.; Emanuele, Z. Size Effect in FRP RC Beams with and without Shear Reinforcement. ACI Symp. Publ. 2018, 327, 27.1–27.20. [Google Scholar]

- Chaallal, O.; Shahawy, M.; Hassan, M. Performance of reinforced concrete T-girders strengthened in shear with carbon fiber-reinforced polymer fabric. ACI Struct. J. 2002, 99, 335–343. [Google Scholar]

- Pellegrino, C.; Modena, C. Fiber reinforced polymer shear strengthening of reinforced concrete beams with transverse steel reinforcement. J. Compos. Constr. 2002, 6, 104–111. [Google Scholar] [CrossRef]

- ACI-440.2R-17. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2017. [Google Scholar]

- CSA-S6-19. Canadian Highway Bridge Design Code. In Canadian Standards Association; Canadian Standards Association: Mississauga, ON, Canada, 2019. [Google Scholar]

- CSA-S806-12. Règles de calcul et de construction des structures de bâtiment contenant des polymères renforcés de fibres. In Canadian Standards Association; Canadian Standards Association: Mississauga, ON, Canada, 2012. [Google Scholar]

- fib-TG5.1-19. Externally applied FRP reinforcement for concrete structures. In Fédération Internationale du Béton; Fédération Internationale du Béton: Lausane, Switzerland, 2019.

- fib-TG9.3-01. Externally bonded FRP reinforcement for RC structures. In Fédération Internationale du Béton; Fédération Internationale du Béton: Lausane, Switzerland, 2001.

- JSCE Recommendations for upgrading of concrete structures with use of continuous fiber sheets. In Japan Society of Civil Engineers; Japan Society of Civil Engineers: Tokyo, Japan, 2001.

- Bažant, Z.P. Size effect. Int. J. Solids Struct. 2000, 37, 69–80. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Rajapakse, Y. Fracture Scaling; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Kani, G.N.J. How safe are our large reinforced concrete beams? Proc. ACI J. 1967, 64, 128–141. [Google Scholar]

- Bažant, Z.P.; Ozbolt, J.; Eligehausen, R. Fracture size effect: Review of evidence for concrete structures. J. Struct. Eng. 1994, 120, 2377–2398. [Google Scholar] [CrossRef] [Green Version]

- Bažant, Z.P.; Planas, J. Fracture and Size Effect in Concrete and Other Quasibrittle Materials; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Bousselham, A. Comportement des Poutres en Béton Armé Renforcées en Cisaillement à L’aide de Matériaux Composites Avancés. Ph.D. Thesis, École de Technologie Supérieure, Montréal, QC, Canada, 2005. [Google Scholar]

- ACI-318-19. Building Code Requirements for Structural Concrete and Commentary on Building Code Requirements for Structural Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

- BS-8110. Code of Practice for Design and Construction. In British Standards Institution; British Standards Institution: London, UK, 1997. [Google Scholar]

- CSA-A23. 3-14. Calcul des ouvrages en béton. In Canadian Standards Association; Canadian Standards Association: Mississauga, ON, Canada, 2014. [Google Scholar]

- Eurocode2. Calcul des Structures en Béton: Partie 1-1. In Comité Européen de Normalisation; Comité Européen de Normalisation: Brussels, Belgium, 2004. [Google Scholar]

- Bousselham, A.; Chaallal, O. Experimental investigations on the influence of size on the performance of RC T-beams retrofitted in shear with CFRP fabrics. Eng. Struct. 2013, 56, 1070–1079. [Google Scholar] [CrossRef]

- Li, W.; Li, J.; Ren, X.; Leung, C.K.; Xing, F. Coupling effect of concrete strength and bonding length on bond behaviors of fiber reinforced polymer–concrete interface. J. Reinf. Plast. Compos. 2015, 34, 421–432. [Google Scholar] [CrossRef]

- Lu, X.; Teng, J.; Ye, L.; Jiang, J. Bond–slip models for FRP sheets/plates bonded to concrete. Eng. Struct. 2005, 27, 920–937. [Google Scholar] [CrossRef]

- Benzeguir, Z.E.A.; El-Saikaly, G.; Chaallal, O. Size effect in shear of conventional and shear-strengthened RC beams with EB-FRP: State of knowledge and research needs. Glob. J. Adv. Eng. Technol. Sci. 2017, 4, 1–23. [Google Scholar]

- EMPA. Shear Strengthening with Prefabricated L-Shaped Plates: Test Beams S1 to S6; EMPA, Eidgenössische Materialprüfungs-und Forschungsanstalt: Dübendorf, Switzerland, 2002. [Google Scholar]

- Chalioris, C.E.; Zapris, A.G.; Karayannis, C.G. U-jacketing applications of fiber-reinforced polymers in reinforced concrete T-beams against shear—Tests and design. Fibers 2020, 8, 13. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Hu, C.; Pan, Z.; Peng, W.; Yang, Y.; Xing, F. A proposed strengthening model considering interaction of concrete-stirrup-FRP system for RC beams shear-strengthened with EB-FRP sheets. J. Reinf. Plast. Compos. 2018, 37, 685–700. [Google Scholar] [CrossRef]

| CSA-A23.3-14 (2014) [18] | EC2-2004 [24] | BS-8110 (1997) [15] | JSCE (2001) [28] | ACI-318-19 (2019) [1] | |

|---|---|---|---|---|---|

| Reducing terms |

| Group | Series | Specimen Size d (mm) | ||

|---|---|---|---|---|

| Small (S) 175 | Medium (M) 350 | Large (L) 525 | ||

| CFRP fabric sheets | Without stirrups | S.S0.1L | M.S0.1L | L.S0.1L |

| S.S0.2L | M.S0.2L | L.S0.2L | ||

| With stirrups | S.S1.1L | M.S1.1L | L.S1.1L | |

| S.S1.2L | M.S1.2L | L.S1.2L | ||

| CFRP L-shape laminates | Without anchorage | - | M.S1.Str | L.S1. Str |

| With anchorage | - | M.S1.Str-Anc | L.S1. Str-Anc | |

| Specimen | d (mm) | b (mm) | fc (MPa) | ρw (%) | ρs (%) | Strengthening Configuration | Layers | wFRP (mm) | tFRP (mm) | ρFRP (%) | EFRP (MPa) | εFRPu % | VFRP (kN) | Vr (kN) | νn (MPa) | Loss % | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Group 1—Shear-Strengthened with CFRP Fabric | |||||||||||||||||

| S.S0.1L | 175 | 95 | 30 | 3.6 | 0 | Cont | U-wrap | 1 | – | 0.066 | 0.14 | 231,000 | 1.4 | 23 | 62 | 0.68 | – |

| M.S0.1L | 350 | 152 | 30 | 3.7 | 0 | Cont | U-wrap | 1 | – | 0.107 | 0.14 | 231,000 | 1.4 | 39 | 125 | 0.43 | 37 |

| L.S0.1L | 525 | 275 | 30 | 3.6 | 0 | Cont | U-wrap | 1 | – | 0.167 | 0.12 | 231,000 | 1.4 | 151 | 334 | 0.42 | 38 |

| S.S0.2L | 175 | 95 | 30 | 3.6 | 0 | Cont | U-wrap | 2 | – | 0.132 | 0.28 | 231,000 | 1.4 | 32 | 71 | 0.78 | – |

| M.S0.2L | 350 | 152 | 30 | 3.7 | 0 | Cont | U-wrap | 2 | – | 0.214 | 0.28 | 231,000 | 1.4 | 40 | 127 | 0.44 | 44 |

| L.S0.2L | 525 | 275 | 30 | 3.6 | 0 | Cont | U-wrap | 2 | – | 0.334 | 0.24 | 231,000 | 1.4 | 144 | 326 | 0.41 | 47 |

| S.S1.1L | 175 | 95 | 30 | 3.6 | 0.37 | Cont | U-wrap | 1 | – | 0.066 | 0.14 | 231,000 | 1.4 | 3 | 98 | 1.08 | – |

| M.S1.1L | 350 | 152 | 30 | 3.7 | 0.38 | Cont | U-wrap | 1 | – | 0.107 | 0.14 | 231,000 | 1.4 | 0 | 260 | 0.89 | 17 |

| L.S1.1L | 525 | 275 | 30 | 3.6 | 0.41 | Cont | U-wrap | 1 | – | 0.167 | 0.12 | 231,000 | 1.4 | 0 | 590 | 0.75 | 31 |

| S.S1.2L | 175 | 95 | 30 | 3.6 | 0.37 | Cont | U-wrap | 2 | – | 0.132 | 0.28 | 231,000 | 1.4 | 12 | 107 | 1.18 | – |

| M.S1.2L | 350 | 152 | 30 | 3.7 | 0.38 | Cont | U-wrap | 2 | – | 0.214 | 0.28 | 231,000 | 1.4 | 4 | 272 | 0.93 | 21 |

| L.S1.2L | 525 | 275 | 30 | 3.6 | 0.41 | Cont | U-wrap | 2 | – | 0.334 | 0.24 | 231,000 | 1.4 | 30 | 629 | 0.80 | 32 |

| Group 2—Shear-Strengthened with CFRP L-Shape Laminates | |||||||||||||||||

| M.S1.Str | 350 | 152 | 30 | 3.7 | 0.38 | Laminate | U-wrap | 1 | 40 | 2 | 0.6 | 90,000 | 1.3 | 37 | 275 | 0.94 | – |

| L.S1.Str | 525 | 275 | 30 | 3.6 | 0.41 | Laminate | U-wrap | 1 | 40 | 2 | 0.6 | 90,000 | 1.3 | 30 | 630 | 0.80 | 16 |

| M.S1. Str-Anc | 350 | 152 | 30 | 3.7 | 0.38 | Laminate | U + A | 1 | 40 | 2 | 0.6 | 90,000 | 1.3 | 98 | 336 | 1.15 | – |

| L.S1. Str-Anc | 525 | 275 | 30 | 3.6 | 0.41 | Laminate | U + A | 1 | 40 | 2 | 0.6 | 90,000 | 1.3 | 90 | 690 | 0.87 | 24 |

| Property | Value |

|---|---|

| CFRP Sheet for Group 1 | |

| Tensile strength, fFRPu (MPa) | 3650 |

| Modulus of elasticity, EFRP (GPa) | 231 |

| Elongation at break, εFRPu (%) | 1.4 |

| CFRP L-shape Laminates for Group 2 | |

| Tensile strength, fFRPu (MPa) | 1350 |

| Modulus of elasticity, EFRP (GPa) | 90 |

| Elongation at break, εFRPu (%) | 1.3 |

| Studies | Year | FRP Properties | Anchorage | Transverse Steel | ||

|---|---|---|---|---|---|---|

| Fabric | Laminate | Rigidity | ||||

| Deniaud [12] | 2001 | ✓ | ✗ | ✗ | ✗ | ✗ |

| Qu [16] | 2005 | ✓ | ✗ | ✗ | ✗ | ✗ |

| Leung [14] | 2007 | ✓ | ✗ | ✗ | ✗ | ✗ |

| Bae [10] | 2012 | ✓ | ✗ | ✗ | ✗ | ✗ |

| Nguyen-Minh [15] | 2015 | ✓ | ✗ | ✗ | ✗ | ✗ |

| Foster [13] | 2017 | ✓ | ✗ | ✓ | ✓ | ✗ |

| Szymon [17] | 2018 | ✓ | ✗ | ✗ | ✗ | ✗ |

| Benzeguir [3,11] | 2019 and 2020 | ✓ | ✓ | ✓ | ✓ | ✓ |

| Specimen | Section | d (mm) | b (mm) | fc (MPa) | ρw (%) | ρs (%) | Strengthening Configuration | Layers | wFRP (mm) | tFRP (mm) | ρFRP (%) | EFRP (MPa) | εFRP % | VFRP (kN) | Vr (kN) | νn (MPa) | Loss % * | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Deniaud (2001) [12] | ||||||||||||||||||

| T4S4-G90 | T | 330 | 140 | 29.0 | 2.30 | 0.20 | Cont | U-wrap | 1 | − | 1.80 | 2.60 | 17,700 | 1.5 | 49 | 206 | 0.83 | − |

| T6S4-G90 | T | 530 | 140 | 44.0 | 2.70 | 0.20 | Cont | U-wrap | 1 | − | 1.80 | 2.60 | 17,700 | 1.5 | 110 | 297 | 0.60 | 27 |

| Qu et al. (2005) [16] | ||||||||||||||||||

| U4 | Rect | 166 | 100 | 51.2 | 4.10 | 0.00 | Strips | U-wrap | 1 | 30 | 0.11 | 0.13 | 235,000 | 1.5 | 22 | 101 | 0.85 | − |

| U5 | Rect | 330 | 200 | 51.2 | 4.50 | 0.00 | Strips | U-wrap | 2 | 60 | 0.22 | 0.13 | 235,000 | 1.5 | 50 | 405 | 0.86 | −1 |

| U6 | Rect | 498 | 300 | 51.0 | 4.20 | 0.00 | Strips | U-wrap | 3 | 90 | 0.33 | 0.13 | 235,000 | 1.5 | 196 | 1009 | 0.95 | −11 |

| Leung et al. (2007) [14] | ||||||||||||||||||

| SB-U1 | Rect | 155 | 75 | 27.4 | 5.40 | 0.28 | Strips | U-wrap | 1 | 20 | 0.11 | 0.10 | 235,000 | 1.8 | 24 | 65 | 1.07 | − |

| MB-U1 | Rect | 305 | 150 | 27.4 | 4.40 | 0.28 | Strips | U-wrap | 2 | 40 | 0.22 | 0.10 | 235,000 | 1.8 | 5 | 155 | 0.65 | 39 |

| LB-U2 | Rect | 660 | 300 | 27.4 | 4.10 | 0.28 | Strips | U-wrap | 4 | 80 | 0.44 | 0.10 | 235,000 | 1.8 | 22 | 560 | 0.54 | 49 |

| SB-F1 | Rect | 155 | 75 | 27.4 | 5.40 | 0.28 | Strips | F-wrap | 1 | 20 | 0.11 | 0.10 | 235,000 | 1.8 | 25 | 66 | 1.08 | − |

| MB-F1 | Rect | 305 | 150 | 27.4 | 4.40 | 0.28 | Strips | F-wrap | 2 | 40 | 0.22 | 0.10 | 235,000 | 1.8 | 87 | 236 | 0.99 | 9 |

| LB-F1 | Rect | 660 | 300 | 27.4 | 4.10 | 0.28 | Strips | F-wrap | 4 | 80 | 0.44 | 0.10 | 235,000 | 1.8 | 334 | 872 | 0.84 | 22 |

| Bae et al. (2012) [10] | ||||||||||||||||||

| S-Str | Rect | 305 | 203 | 25.2 | 0.16 | 0.00 | Strips | U-wrap | 1 | 76 | 0.165 | 0.05 | 228,000 | 1.5 | 47 | 113 | 0.36 | − |

| M-Str | Rect | 457 | 305 | 32.0 | 0.16 | 0.00 | Strips | U-wrap | 1 | 152 | 0.165 | 0.05 | 228,000 | 1.5 | 87 | 246 | 0.31 | 14 |

| L-Str | Rect | 610 | 406 | 32.0 | 0.18 | 0.00 | Strips | U-wrap | 1 | 252 | 0.165 | 0.05 | 228,000 | 1.5 | 127 | 371 | 0.26 | 27 |

| Nguyen-Minh and Rovňák (2015) [15] | ||||||||||||||||||

| G1-GFRP-1B | Rect | 175 | 100 | 25.0 | 1.80 | 0.19 | Cont | U-wrap | 1 | − | 1.3 | 2.60 | 26,100 | 2.2 | 18 | 56 | 0.64 | − |

| G1-GFRP-2A | Rect | 350 | 200 | 25.0 | 1.80 | 0.19 | Cont | U-wrap | 2 | − | 2.6 | 2.60 | 26,100 | 2.2 | 55 | 225 | 0.64 | 0 |

| G1-GFRP-3A | Rect | 525 | 300 | 25.0 | 1.80 | 0.19 | Cont | U-wrap | 3 | − | 3.9 | 2.60 | 26,100 | 2.2 | 64 | 459 | 0.58 | 9 |

| G2-GFRP-1A | Rect | 196 | 100 | 23.5 | 2.40 | 0.16 | Cont | U-wrap | 1 | − | 1.3 | 2.60 | 26,100 | 2.2 | 18 | 63 | 0.66 | − |

| G2-GFRP-2A | Rect | 442 | 200 | 23.5 | 2.40 | 0.16 | Cont | U-wrap | 2 | − | 2.6 | 2.60 | 26,100 | 2.2 | 80 | 305 | 0.71 | −7 |

| G2-GFRP-3A | Rect | 682 | 300 | 23.5 | 2.40 | 0.16 | Cont | U-wrap | 3 | − | 3.9 | 2.60 | 26,100 | 2.2 | 180 | 650 | 0.66 | 1 |

| Foster et al. (2017) [13] | ||||||||||||||||||

| SC0.7U | T | 300 | 150 | 62.5 | 4.20 | 0.10 | Cont | U-wrap | 1 | − | 0.5 | 0.7 | 10,500 | 1.0 | 0 | 166 | 0.47 | − |

| MC0.9U | T | 450 | 225 | 61.7 | 2.90 | 0.10 | Cont | U-wrap | 1 | − | 1.0 | 0.9 | 95,800 | 1.0 | 0 | 299 | 0.38 | 19 |

| LB0.7U | T | 600 | 300 | 60.3 | 2.70 | 0.10 | Cont | U-wrap | 1 | − | 1.0 | 0.7 | 105,400 | 1.0 | 0 | 458 | 0.33 | 30 |

| SC1.3U | T | 300 | 150 | 63.2 | 4.20 | 0.10 | Cont | U-wrap | 1 | − | 1.0 | 1.3 | 105,400 | 1.0 | 0 | 153 | 0.43 | − |

| MB1.3U | T | 450 | 225 | 64.1 | 2.90 | 0.10 | Cont | U-wrap | 1 | − | 1.5 | 1.3 | 95,800 | 1.0 | 0 | 306 | 0.38 | 12 |

| LB1.3U | T | 600 | 300 | 62.0 | 2.70 | 0.10 | Cont | U-wrap | 1 | − | 2.0 | 1.3 | 95,800 | 1.0 | 0 | 437 | 0.31 | 28 |

| MB1.3UA | T | 450 | 225 | 61.1 | 2.90 | 0.10 | Cont | U + A | 1 | − | 1.5 | 1.3 | 95,800 | 1.0 | 48 | 370 | 0.47 | − |

| LB1.3UA | T | 600 | 300 | 54.1 | 2.70 | 0.10 | Cont | U + A | 1 | − | 2.0 | 1.3 | 95,800 | 1.0 | 39 | 511 | 0.39 | 17 |

| Cholostiakow Szymon et al. (2018) [17] | ||||||||||||||||||

| GB62 | Rect | 233 | 150 | 52.70 | 0.82 | 0.00 | Strips | F-wrap | 1 | − | − | 0.12 | 65,000 | 2.6 | 10.9 | 48.2 | 0.19 | − |

| GB64 | Rect | 333 | 150 | 47.54 | 0.86 | 0.00 | Strips | F-wrap | 1 | − | − | 0.12 | 65,000 | 2.6 | 30.4 | 61.7 | 0.18 | 6 |

| GB60 | Rect | 433 | 150 | 38.40 | 0.88 | 0.00 | Strips | F-wrap | 1 | − | − | 0.10 | 65,000 | 2.6 | 33.3 | 77.2 | 0.19 | −1 |

| GB63 | Rect | 233 | 150 | 50.91 | 0.82 | 0.00 | Strips | F-wrap | 1 | − | − | 0.04 | 241,000 | 1.7 | 0 | 54.2 | 0.22 | − |

| GB65 | Rect | 333 | 150 | 47.54 | 0.86 | 0.00 | Strips | F-wrap | 1 | − | − | 0.04 | 241,000 | 1.7 | 16.1 | 63.4 | 0.18 | 15 |

| GB61 | Rect | 433 | 150 | 38.40 | 0.88 | 0.00 | Strips | F-wrap | 1 | − | − | 0.03 | 241,000 | 1.7 | 35.1 | 85.4 | 0.21 | 2 |

| Specimens | Vexp | S6-19 | Vpred/Vexp | S806-12 | Vpred/Vexp | AC-I440 | Vpred/Vexp | JSCE 2001 | Vpred/Vexp | fib 2001 | Vpred/Vexp | fib 2019 | Vpred/Vexp |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Deniaud (2001) [12] | |||||||||||||

| T4S4-G90 | 49 | 43.7 | 0.9 | 56.1 | 1.1 | 39.4 | 0.8 | 163.6 | 3.3 | 53.8 | 1.1 | 47.1 | 1.0 |

| T6S4-G90 | 110 | 107.6 | 1.0 | 194.5 | 1.8 | 96.9 | 0.9 | 319.0 | 2.9 | 100.9 | 0.9 | 133.2 | 1.2 |

| Qu et al. (2005) [16] | |||||||||||||

| U4 | 22 | 20.8 | 0.9 | 31.4 | 1.4 | 18.7 | 0.9 | 54.6 | 2.5 | 20.3 | 0.9 | 17.1 | 0.8 |

| U5 | 50 | 82.6 | 1.7 | 125.0 | 2.5 | 74.4 | 1.5 | 217.1 | 4.3 | 80.5 | 1.6 | 58.6 | 1.2 |

| U6 | 196 | 187.0 | 1.0 | 240.9 | 1.2 | 169.0 | 0.9 | 491.4 | 2.5 | 182.0 | 0.9 | 108.1 | 0.6 |

| Leung et al. (2007) [14] | |||||||||||||

| SB-U1 | 24 | 7.9 | 0.3 | 10.1 | 0.4 | 7.1 | 0.3 | 26.1 | 1.1 | 9.8 | 0.4 | 7.5 | 0.3 |

| MB-U1 | 5 | 32.3 | 6.5 | 41.5 | 8.3 | 29.1 | 5.8 | 102.6 | 20.5 | 38.6 | 7.7 | 23.3 | 4.7 |

| LB-U2 | 22 | 105.6 | 4.8 | 135.6 | 6.2 | 95.1 | 4.3 | 444.2 | 20.2 | 167.0 | 7.6 | 55.5 | 2.5 |

| SB-F1 | 25 | 10.7 | 0.4 | 20.6 | 0.8 | 9.6 | 0.4 | 26.1 | 1.0 | 17.7 | 0.7 | 14.9 | 0.6 |

| MB-F1 | 87 | 42.0 | 0.5 | 80.9 | 0.9 | 37.8 | 0.4 | 102.6 | 1.2 | 69.8 | 0.8 | 59.6 | 0.7 |

| LB-F1 | 334 | 181.9 | 0.5 | 350.3 | 1.0 | 163.8 | 0.5 | 444.2 | 1.3 | 302.1 | 0.9 | 238.4 | 0.7 |

| Bae et al. (2012) [10] | |||||||||||||

| S-Str | 47 | 25.6 | 0.5 | 32.9 | 0.7 | 23.1 | 0.5 | 80.2 | 1.7 | 38.4 | 0.8 | 33.3 | 0.7 |

| M-Str | 87 | 68.5 | 0.8 | 93.6 | 1.1 | 61.7 | 0.7 | 180.4 | 2.1 | 94.6 | 1.1 | 80.4 | 0.9 |

| L-Str | 127 | 121.4 | 1.0 | 171.8 | 1.4 | 109.3 | 0.9 | 319.5 | 2.5 | 167.8 | 1.3 | 136.7 | 1.1 |

| Nguyen-Minh and Rovňák (2015) [15] | |||||||||||||

| G1-GFRP-1B | 18 | 33.9 | 1.9 | 43.5 | 2.4 | 30.5 | 1.7 | 91.0 | 5.1 | 23.0 | 1.3 | 48.2 | 2.7 |

| G1-GFRP-2A | 55 | 123 | 2.2 | 157.9 | 2.9 | 110.7 | 2.0 | 364 | 6.6 | 91.9 | 1.7 | 126 | 2.3 |

| G1-GFRP-3A | 64 | 232.4 | 3.6 | 298.4 | 4.7 | 209.2 | 3.3 | 819.0 | 12.8 | 206.7 | 3.2 | 189.7 | 3.0 |

| G2-GFRP-1A | 18 | 38.5 | 2.1 | 49.4 | 2.7 | 34.7 | 1.9 | 101.9 | 5.7 | 25.1 | 1.4 | 48.4 | 2.7 |

| G2-GFRP-2A | 80 | 153.1 | 1.9 | 196.6 | 2.5 | 137.9 | 1.7 | 459.7 | 5.7 | 113.4 | 1.4 | 125.4 | 1.6 |

| G2-GFRP-3A | 180 | 294.0 | 1.6 | 377.6 | 2.1 | 264.8 | 1.5 | 1063.9 | 5.9 | 262.4 | 1.5 | 202.8 | 1.1 |

| Foster et al. (2017) [13] | |||||||||||||

| SC0.7U | 0 | 103.0 | – | 166.8 | – | 92.8 | – | 205.8 | – | 84.4 | – | 91.1 | – |

| MC0.9U | 0 | 279.8 | – | 359.3 | – | 251.9 | – | 617.3 | – | 205.7 | – | 195.0 | – |

| LB0.7U | 0 | 393.6 | – | 505.4 | – | 354.4 | – | 823.1 | – | 333.2 | – | 306.1 | – |

| SC1.3U | 0 | 189.0 | – | 242.7 | – | 170.2 | – | 411.5 | – | 115.0 | – | 100.4 | – |

| MB1.3U | 0 | 347.5 | – | 446.1 | – | 312.9 | – | 926.0 | – | 249.4 | – | 212.0 | – |

| LB1.3U | 0 | 525.8 | – | 675.1 | – | 473.4 | – | 1646.2 | – | 438.0 | – | 350.7 | – |

| MB1.3UA | 48 | 336.5 | 7.0 | 676.2 | 14.1 | 303.0 | 6.3 | 926.0 | 19.3 | 334.8 | 7.0 | 300.6 | 6.3 |

| LB1.3UA | 39 | 480.1 | 12.3 | 1202.2 | 30.8 | 432.3 | 11.1 | 1623.4 | 41.6 | 580.9 | 14.9 | 534.3 | 13.7 |

| Cholostiakow Szymon et al. (2018) [27] | |||||||||||||

| GB62 | 10.9 | 10.9 | 1.0 | 21.0 | 1.9 | 9.8 | 0.9 | 49.6 | 4.6 | 41.2 | 3.8 | 21.4 | 2.0 |

| GB64 | 30.4 | 15.3 | 0.5 | 29.5 | 1.0 | 13.8 | 0.5 | 69.7 | 2.3 | 57.0 | 1.9 | 29.1 | 1.0 |

| GB60 | 33.3 | 17.5 | 0.5 | 33.8 | 1.0 | 15.8 | 0.5 | 78.6 | 2.4 | 65.0 | 2.0 | 32.7 | 1.0 |

| GB63 | 0 | 11.8 | – | 22.7 | – | 10.6 | – | 35.2 | – | 28.3 | – | 15.2 | – |

| GB65 | 16.1 | 16.8 | 1.0 | 32.4 | 2.0 | 15.2 | 0.9 | 50.3 | 3.1 | 39.9 | 2.5 | 21.0 | 1.3 |

| GB61 | 35.1 | 16.8 | 0.5 | 32.5 | 0.9 | 15.2 | 0.4 | 50.4 | 1.4 | 41.3 | 1.2 | 20.7 | 0.6 |

| Benzeguir et al. (2019) [11] | |||||||||||||

| S.S0.1L | 23 | 8.7 | 0.4 | 11.2 | 0.5 | 7.8 | 0.3 | 48.2 | 2.1 | 16.8 | 0.7 | 28.7 | 1.2 |

| M.S0.1L | 39 | 54.5 | 1.4 | 76.3 | 2.0 | 49.0 | 1.3 | 155.6 | 4.0 | 54.1 | 1.4 | 69.8 | 1.8 |

| L.S0.1L | 151 | 128.5 | 0.9 | 163.8 | 1.1 | 114.9 | 0.8 | 385.0 | 2.5 | 137.5 | 0.9 | 116.7 | 0.8 |

| S.S0.2L | 32 | 22.0 | 0.7 | 28.2 | 0.9 | 19.8 | 0.6 | 68.1 | 2.1 | 22.8 | 0.7 | 34.0 | 1.1 |

| M.S0.2L | 40 | 89.1 | 2.2 | 114.4 | 2.9 | 80.2 | 2.0 | 219.0 | 5.5 | 73.4 | 1.8 | 85.1 | 2.1 |

| L.S0.2L | 144 | 179.6 | 1.2 | 230.6 | 1.6 | 161.7 | 1.1 | 562.0 | 3.9 | 186.5 | 1.3 | 133.1 | 0.9 |

| S.S1.1L | 3 | 8.7 | 2.9 | 11.2 | 3.7 | 7.8 | 2.6 | 48.2 | 16.1 | 16.8 | 5.6 | 28.7 | 9.6 |

| M.S1.1L | 0 | 54.5 | – | 76.3 | – | 49.0 | – | 155.6 | – | 54.1 | – | 69.8 | – |

| L.S1.1L | 0 | 128.5 | – | 163.8 | – | 114.9 | – | 385.0 | – | 137.5 | – | 116.7 | – |

| S.S1.2L | 12 | 22.0 | 1.8 | 28.2 | 2.4 | 19.8 | 1.6 | 68.1 | 5.7 | 22.8 | 1.9 | 34.0 | 2.8 |

| M.S1.2L | 4 | 89.1 | 22.3 | 114.4 | 28.6 | 80.2 | 20.0 | 219.0 | 54.8 | 73.4 | 18.3 | 85.1 | 21.3 |

| L.S1.2L | 30 | 179.6 | 6.0 | 230.6 | 7.7 | 161.7 | 5.4 | 562.0 | 18.7 | 186.5 | 6.2 | 133.1 | 4.4 |

| Benzeguir et al. (2020) [3] | |||||||||||||

| M.S1.Str | 37 | 39.0 | 1.1 | 50.1 | 1.4 | 35.1 | 0.9 | 208.5 | 5.6 | 67.7 | 1.8 | 17.9 | 0.5 |

| L.S1.Str | 30 | 106.5 | 3.6 | 136.7 | 4.6 | 95.9 | 3.2 | 556.5 | 18.6 | 181.0 | 6.0 | 48.4 | 1.6 |

| M.S1.Str.Anc | 98 | 39.0 | 0.4 | 145.5 | 1.5 | 35.1 | 0.4 | 208.5 | 2.1 | 108.8 | 1.1 | 90.8 | 0.9 |

| L.S1.Str.Anc | 90 | 106.5 | 1.2 | 385.0 | 4.3 | 95.9 | 1.1 | 556.5 | 6.2 | 288.4 | 3.2 | 237.8 | 2.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benzeguir, Z.E.A.; Chaallal, O. Size Effect in FRP Shear-Strengthened RC Beams: Design Models versus Experimental Data. CivilEng 2021, 2, 874-894. https://doi.org/10.3390/civileng2040047

Benzeguir ZEA, Chaallal O. Size Effect in FRP Shear-Strengthened RC Beams: Design Models versus Experimental Data. CivilEng. 2021; 2(4):874-894. https://doi.org/10.3390/civileng2040047

Chicago/Turabian StyleBenzeguir, Zine El Abidine, and Omar Chaallal. 2021. "Size Effect in FRP Shear-Strengthened RC Beams: Design Models versus Experimental Data" CivilEng 2, no. 4: 874-894. https://doi.org/10.3390/civileng2040047

APA StyleBenzeguir, Z. E. A., & Chaallal, O. (2021). Size Effect in FRP Shear-Strengthened RC Beams: Design Models versus Experimental Data. CivilEng, 2(4), 874-894. https://doi.org/10.3390/civileng2040047