BIM Interoperability Analyses in Structure Design

Abstract

1. Introduction

- Software houses have been admitting an incremental capability of integrating functionalities, referred to as extensions, add-in, and plug-in, based on the native format of the main system;

- The international organization BuildingSMART, which brings together enterprises and professionals of the construction industry from several countries, is responsible for issuing the standard data format, the Industry Foundation Classes (IFC) [9], and has been lunching new versions with increasing efficiency.

- Transfer of models performed on the basis of the native format of data;

- Transfer based on IFC format.

2. Structure Models

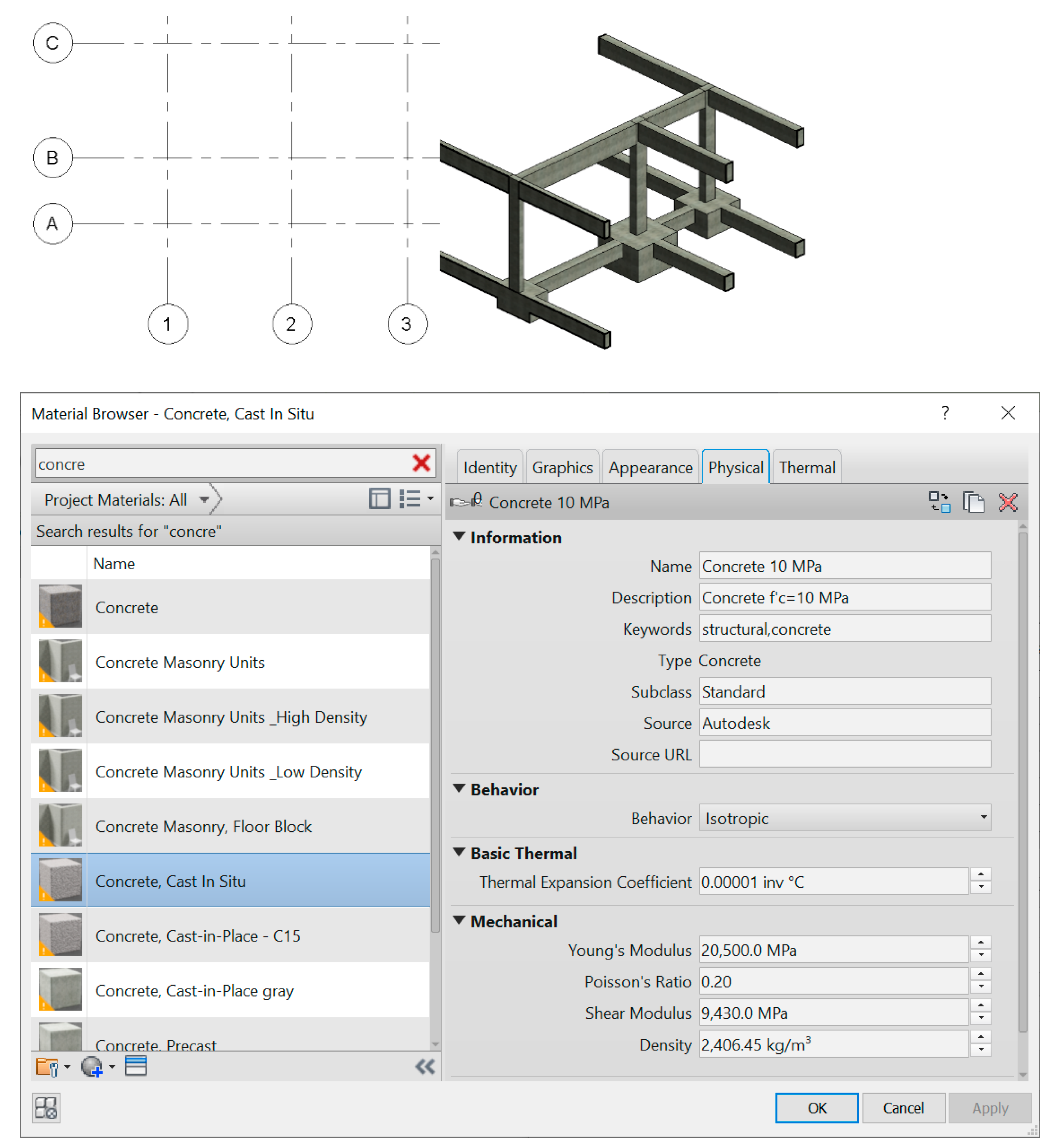

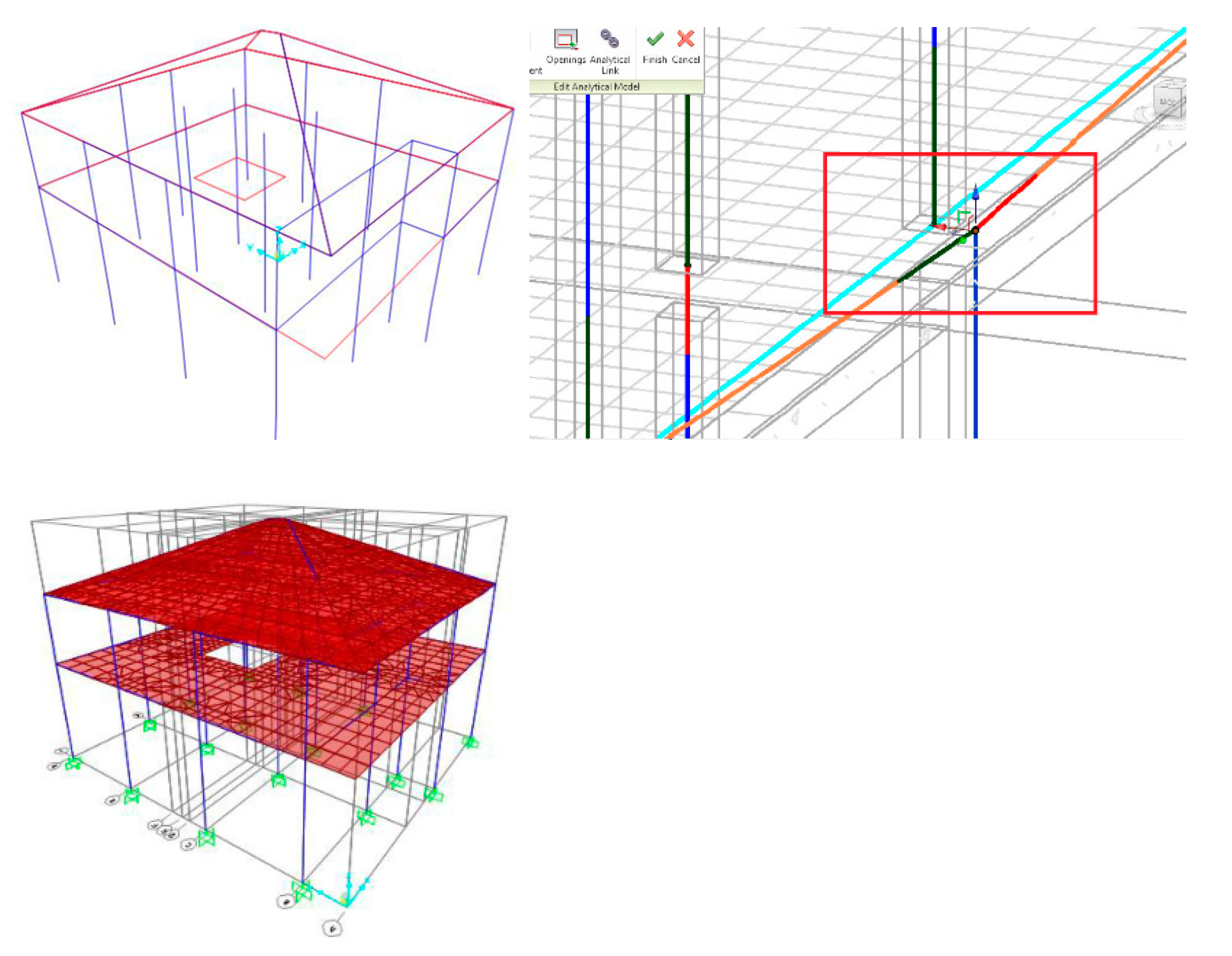

- The first building case is composed of eight elevated floors, located in Lisbon. The structure frame is a concrete beamed solution, and presents a regular distribution of their elements, both in plant and in elevation [16]. The BIM model is generated in Revit using the parametric objects available on the structure library. A physical model is then created, however, as all elements are classified as structure objects, the modelling system incorporates the discretization functionality, allowing the user to visualize the respective analytical model, composed of all components idealized as finite elements. Each of these elements is represented by its axis (beams and columns) or by its middle surface (slabs or walls), and they are associated to the correspondent’s physical properties, that are later required in the structure analyses process, namely, cross-section areas and inertias. Looking at the analytical model, the engineer must verify the consistency of all connections prior to its export to the structure analysis system (Figure 2).

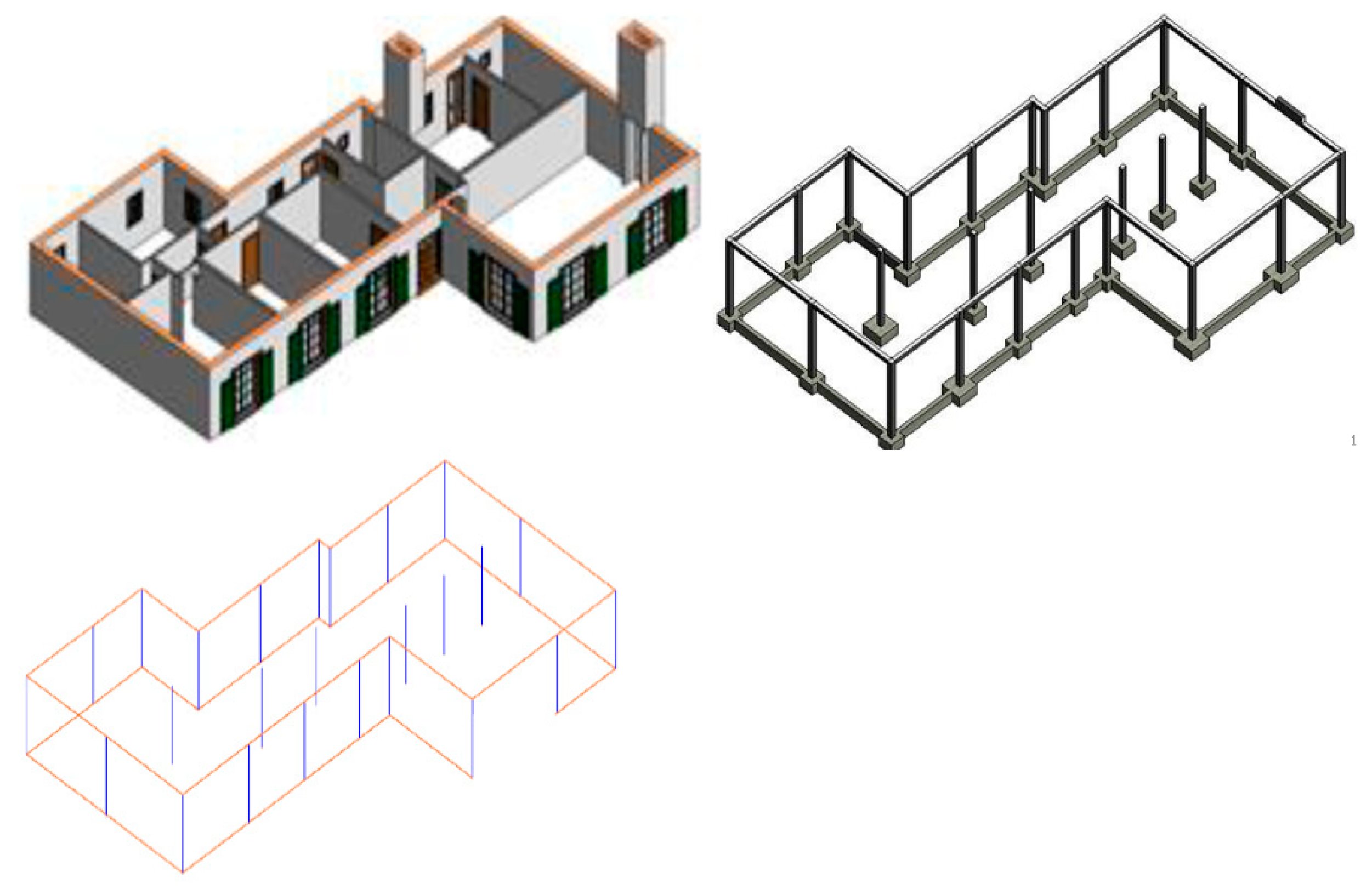

- The second case is a single-family house. The building, located in Santarem, Portugal, is formed of a ground floor. Using the Revit tool, the architecture and structure components of the required BIM model were generated. The structure solution was defined over the architecture design, allowing the engineer to judge the suitability of the structure considering the architecture constraints (Figure 3). The structure solution is composed of a concrete fungiform slab with peripheral beams, a set of internal columns, and a foundation system composed with a linear beam-foundation positioned on the border and individual supports. The analytical model was also performed and the consistency of each node is verified [16].

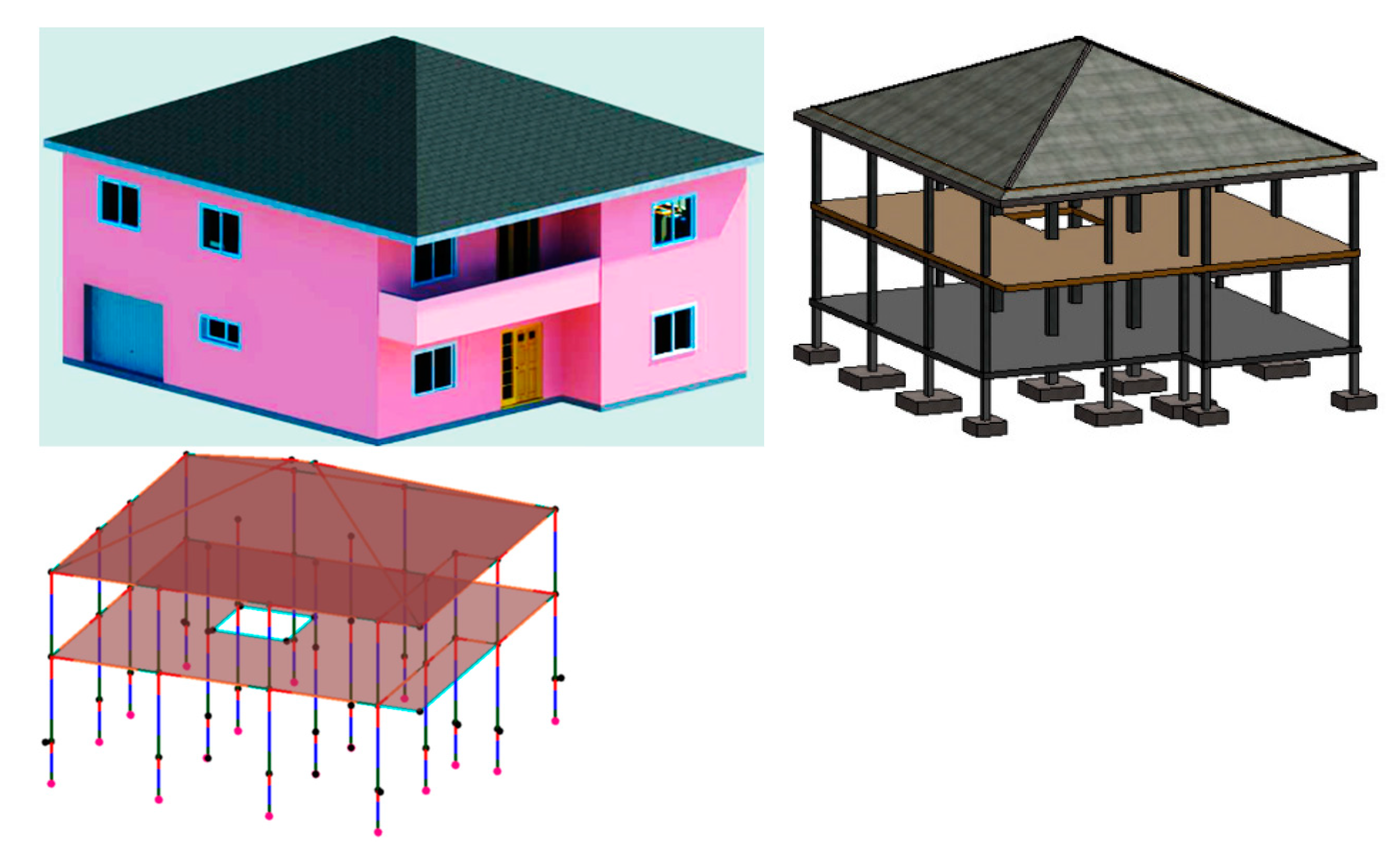

- A two-floor house located in the north of Portugal was analyzed. Using also the Revit system, the components of architecture and structures of the BIM model were generated. The structure frame was considered over the architecture component in order to fulfil all architectural requirements. The structure solution is composed of fungiform slabs, with beams positioned in the boarder at the ground and elevated floors, a foundation system formed with isolated elements and concrete reinforced slabs supporting a pitched roof (Figure 4). An analytical model was also obtained and each connection between elements was checked [17].

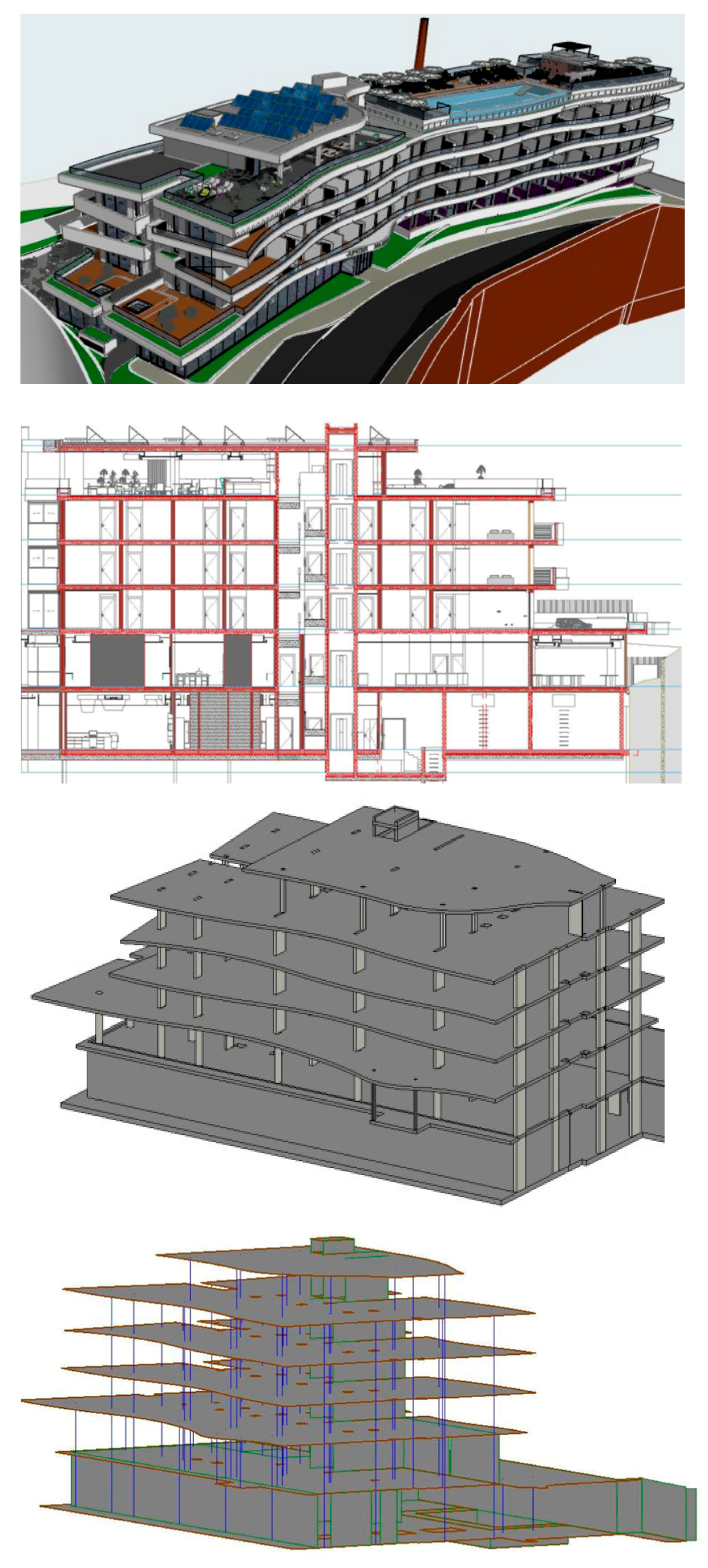

- A hotel building was also considered. The building is located in Algarve, on the south of Portugal, and both architecture and structure components of the BIM model were created using the ArchiCAD system (Graphisoft) [18]. The established structure solution considers concrete fungiform slabs, in order to properly accommodate the networks of hydraulic and air conditioning systems, and to satisfy the organic configuration considered in the architecture design. In addition, isolated columns were placed and, in the periphery of the ground floor, a resistant wall is positioned (Figure 5). The required parametric objects representing structure component were all selected from the BIM system library. This tool also allows the representation of the correspondent analytical model.

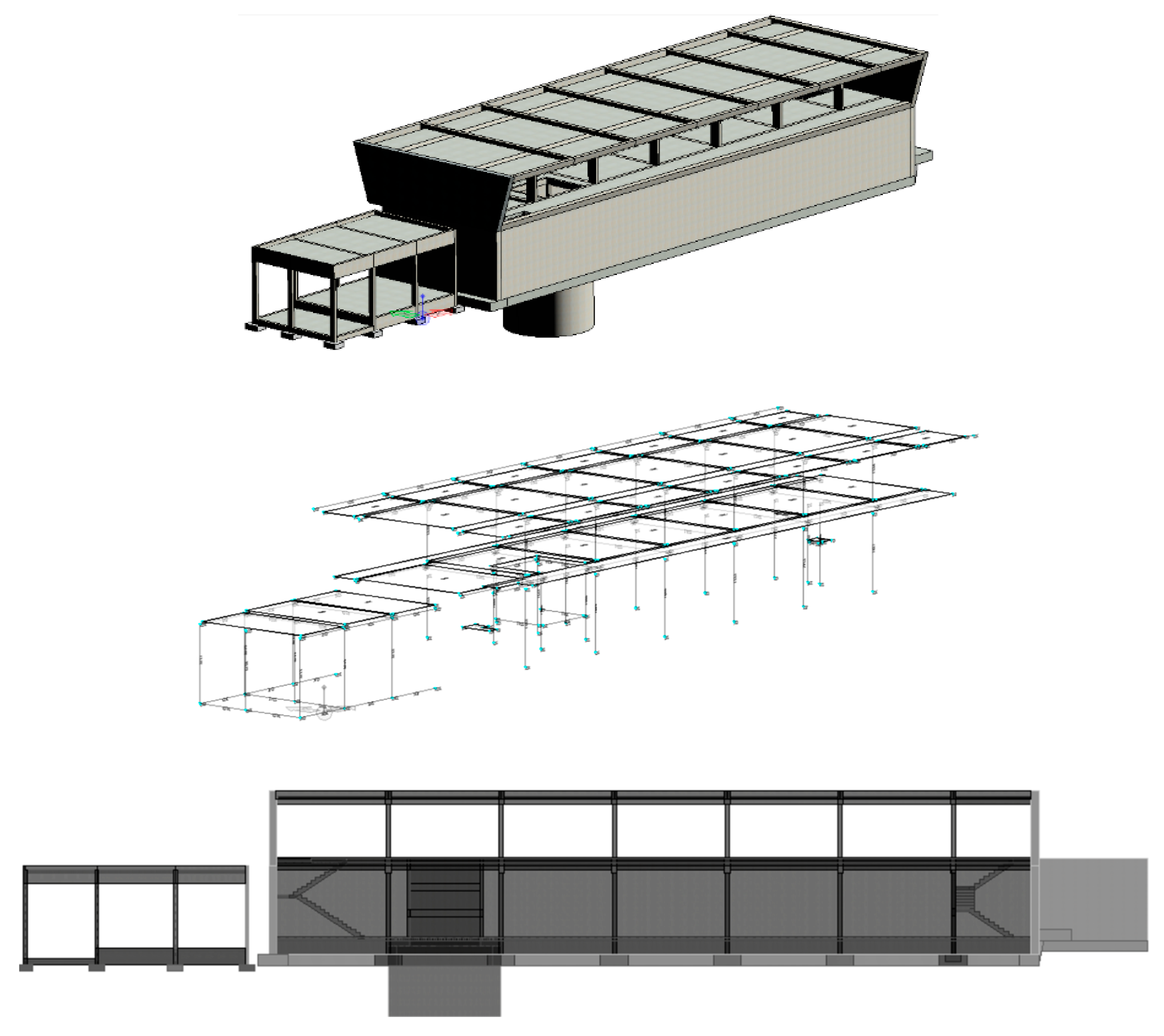

- A technical building of a dam was modeled. The AECOsim Building Designer (Bentley) system was used to generate the structure BIM component, based on dwg drawings of the project made available. The parametric elements, related to reinforced concrete elements, were selected from the tool’s library and adapted according to the established solution (Figure 6) [19]. The system also admits the representation of the analytical model, discretizing the beams and columns through frames of linear elements, and the slabs and walls through shell elements, allowing the engineer to check the consistency of all the connections between elements.

3. Structure Analyses

3.1. Models Export

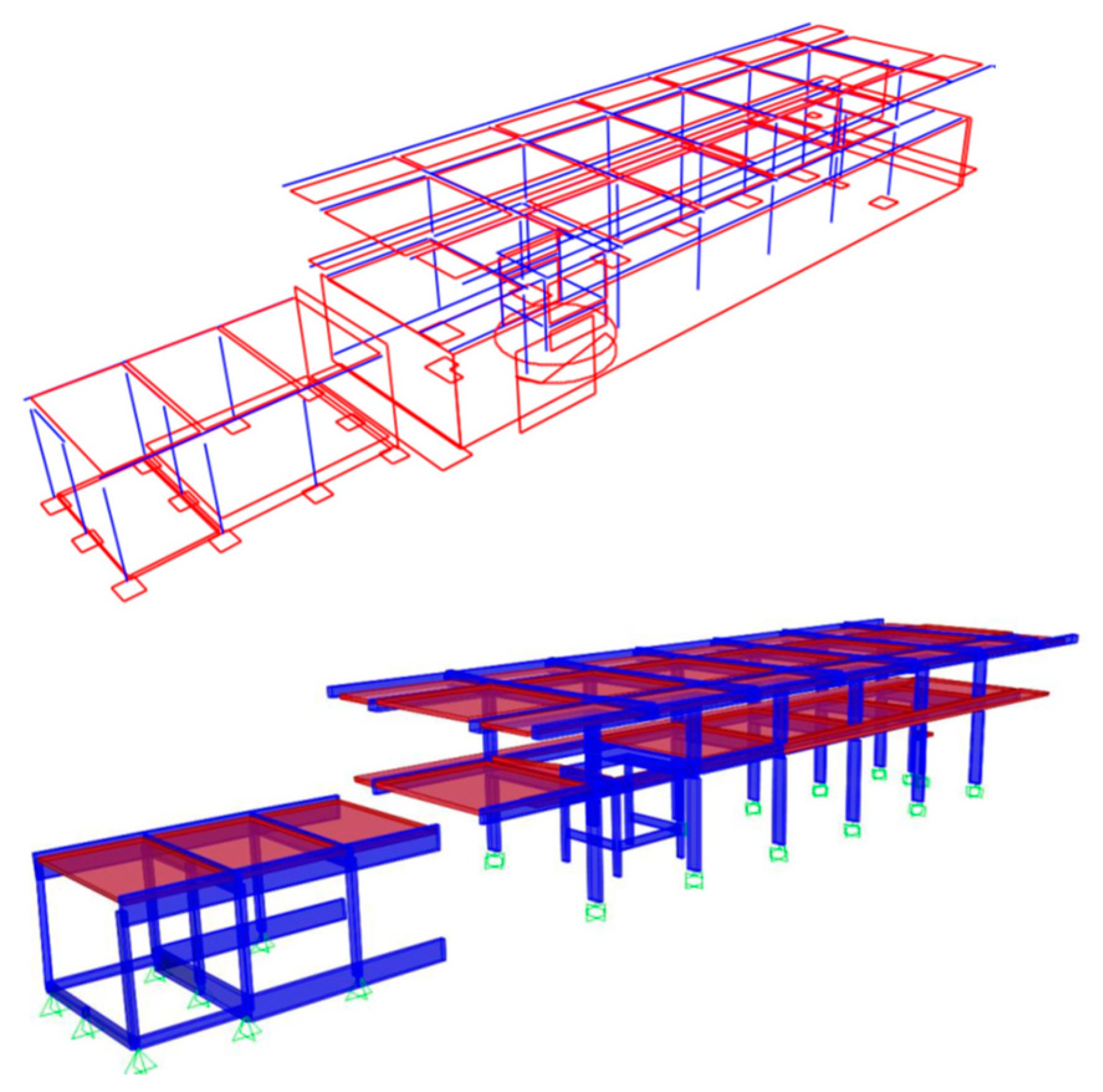

- Revit/Robot export. The model created in Revit is transferred to the Robot software, and the quality of the transferred data is analyzed. The geometry and physical properties of most structure elements have been correctly recognized by the calculation system. However, over the model it was necessary to make some adjustments; the stair elements were not recognized by the system and then sloped slabs were modelled instead, and the foundation elements were not transferred and the correspondent supports were redefined (Figure 7). As both systems, Robot and Revit belong to Autodesk, a high level of interoperability is verified, although not entirely error-free [16].

- Revit/SAP transfer. The process of exporting a Revit model to SAP structure analysis software is made based on the use of a plug-in, named CSIXRevit. After the model is transferred to SAP, the consistency of the model is verified. Most of the structure elements were well transferred, namely, foundations, columns, walls, beams, and slabs, but the stairs and foundations were not. The material, concrete C30/37 and steel A500 NR SD, and the associated mechanical properties were also properly accepted (Figure 8). However, it was necessary to make some corrections over the analytical model, in particular, the axis of linear finite elements and the rigid links established previously on Revit tool, were not well identified by the SAP system [17].

- ArchiCAD/ETABS export. The model created in ArchiCAD was saved in the system using the IFC data standard, in order to allow its transfer to ETABS (CSI) system. Although, previously at ArchiCAD all ifc elements (IfcColumns, IfcWalls, and IfcSlabs) were specifically selected to be transferred, a careful geometric analysis carried out over the transferred model identifies some inconsistency errors (Figure 9). A large number of adjacent elements were disconnected, requiring a relevant volume of adjustments. This additional work is time consuming, but a correct analytical structure model must be obtained to guarantee correct result [18].

- AECOsim/SAP transfer. The model created in AECOsim is saved in IFC format and transferred to SAP. This system identifies some of the ifc elements transferred, namely, ifcStructurePointConnection, ifcBeam, ifcColumn, ifcSlab, ifcStructureCurveMember, and ifcStructureSurfaceMember; but not being recognized foundations, stairs, border conditions, and loads. However, the cross-sections and thicknesses of each element are correctly transferred (Figure 10). The SAP merge joints functionality, allows to join nodes that have a minimum distance between axis ends, but does not check the orthogonality of the resultant adjustments, leading to incorrect situations. The interoperability between the two systems is still limited, however, the possibility of exporting the analytical model from the parametric model is easily performed, contributing to speed all process and to increase productivity [19].

3.2. Analyses Process and Reinforcements

- The death loads relating to the structure own weight (PP) is automatically assumed based on the unit weight of the reinforced concrete;

- The permanent loads (PC) are related to the distinct coating applied according to the type of use per zone of each floor, and with the interior walls applied as distributed weight;

- The variable load (SC) considers the type of use in each floor;

- The seismic action (SISM) is quantified according to the medium spectral response of the building and the seismicity coefficient associated to the house location.

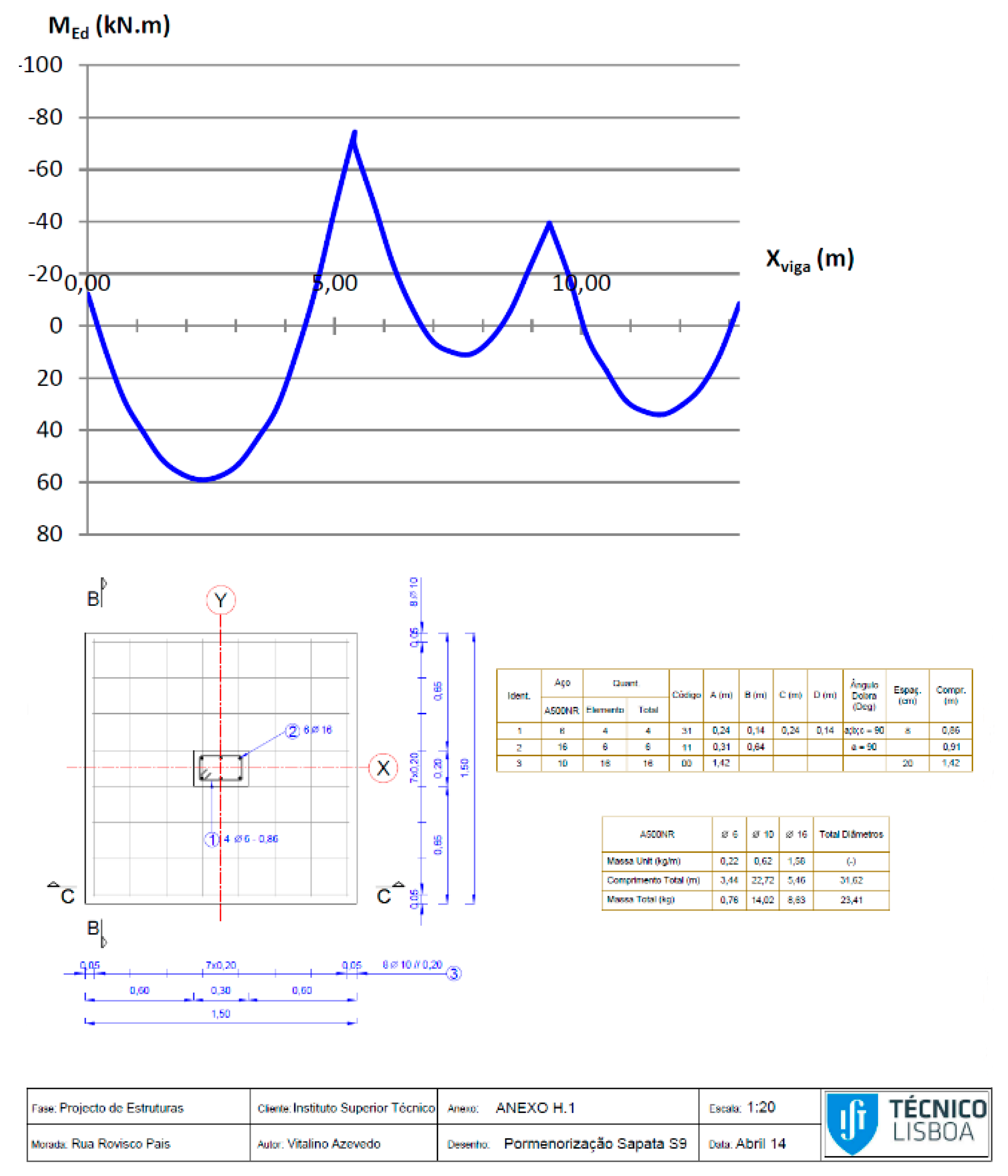

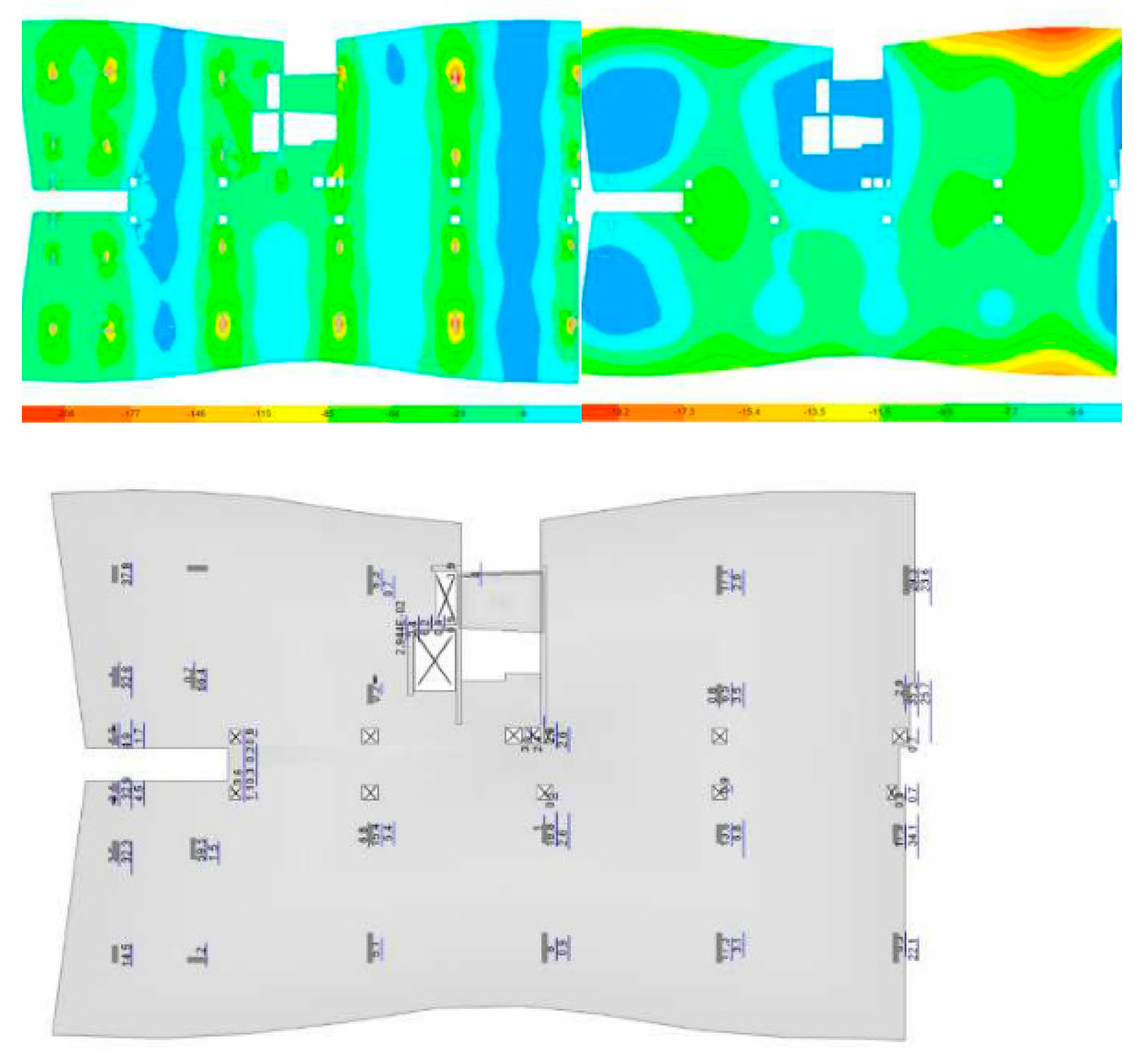

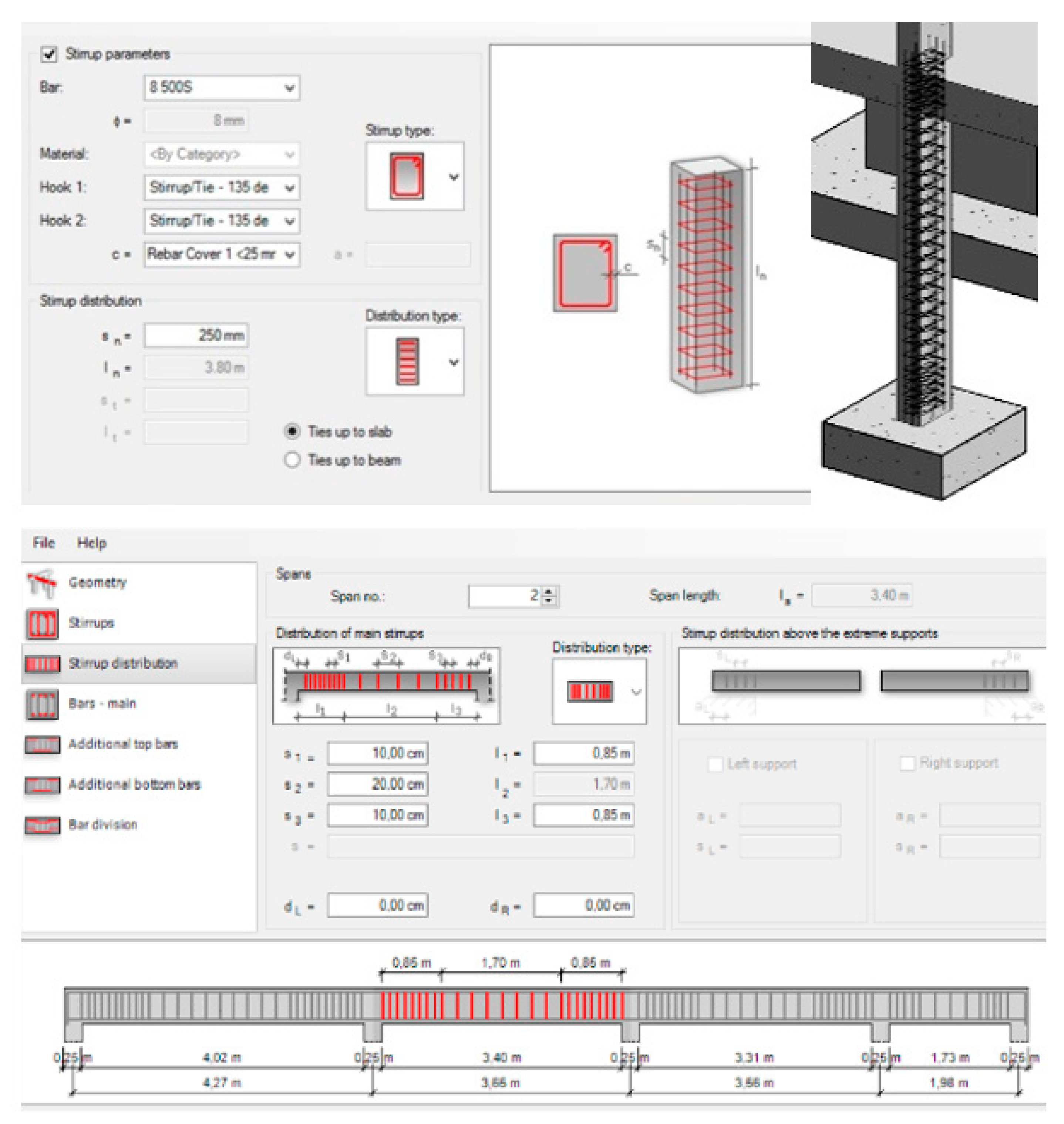

- Robot. To proceed with the analyses, each slab is discretized in finite element mesh surfaces and after calculation, the system automatically set the value of the reinforcement required for each finite element based on the materials and cover applied. For the resistant safety verification of columns, the normal stresses is considered and the detailing of the necessary reinforcement is conducted in an automatic way, based on the spacing between the stirrups and the number of longitudinal bars to be allocated per side. The verification of beams resistance is based on the evaluation of the stresses considering the envelope of the distinct applied loads combinations. Concerning the foundations elements, the system only allows to check the forces acting in the supporting nodes and the user must perform a safety check, based on traditional computational methods (Figure 11).

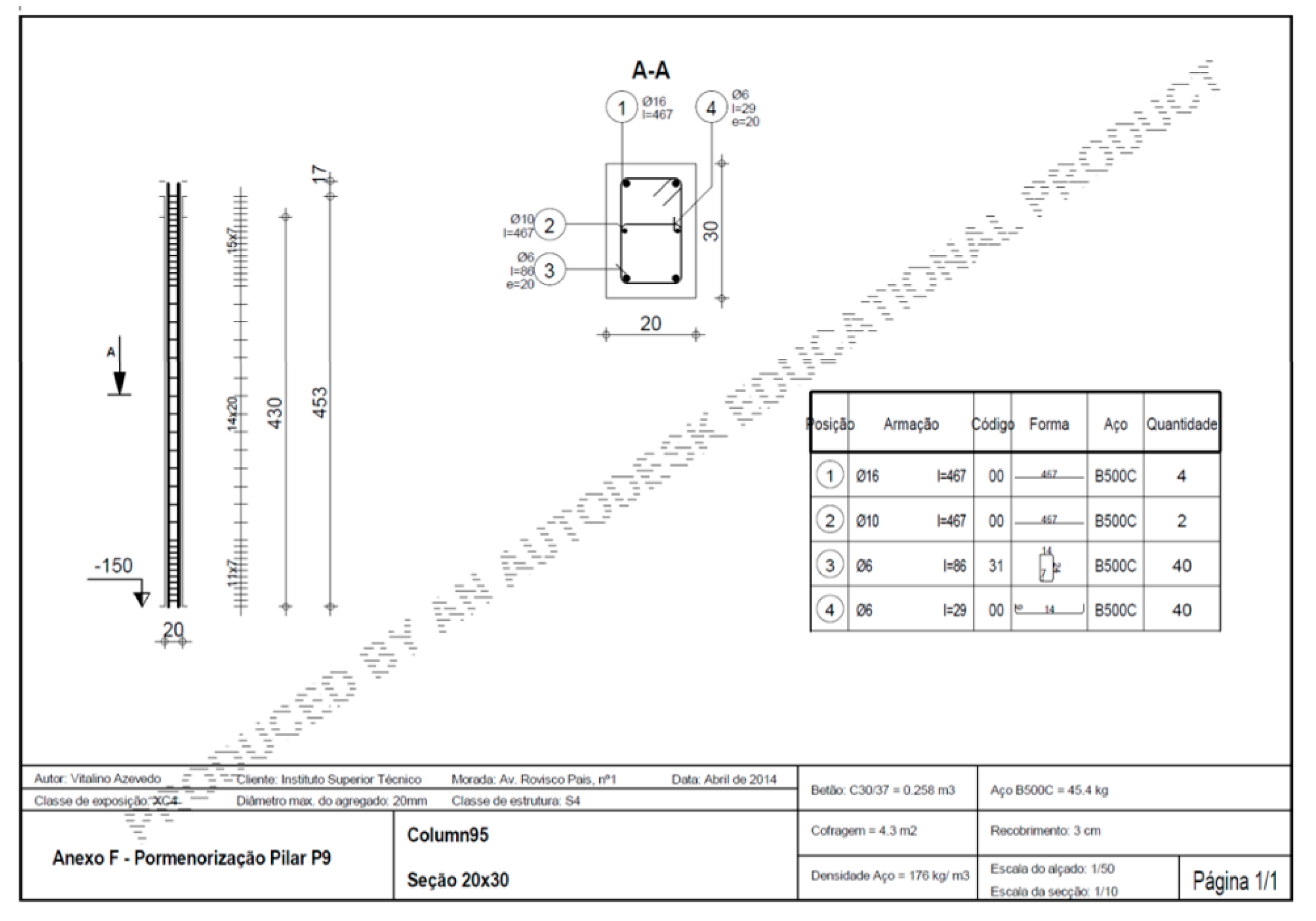

- SAP—Checked the consistency of the imported model, SAP system performs the structure analyses according to the current Eurocode. Based on the diagrams of the analyses results the required quantity of steel is determined and the concrete reinforcement detailing drawings of all elements are generated (Figure 12).

- ETABS—The design of slabs, columns, and beams is carried out in accordance with the current Eurocodes. The system determines stresses and deformations visualized in diagrams and 3D models. Then, the tool is able to determine the necessary reinforcement bars for each structure element and automatically proceeds with the elaboration of the detailing drawings (Figure 13).

3.3. Data Centralization

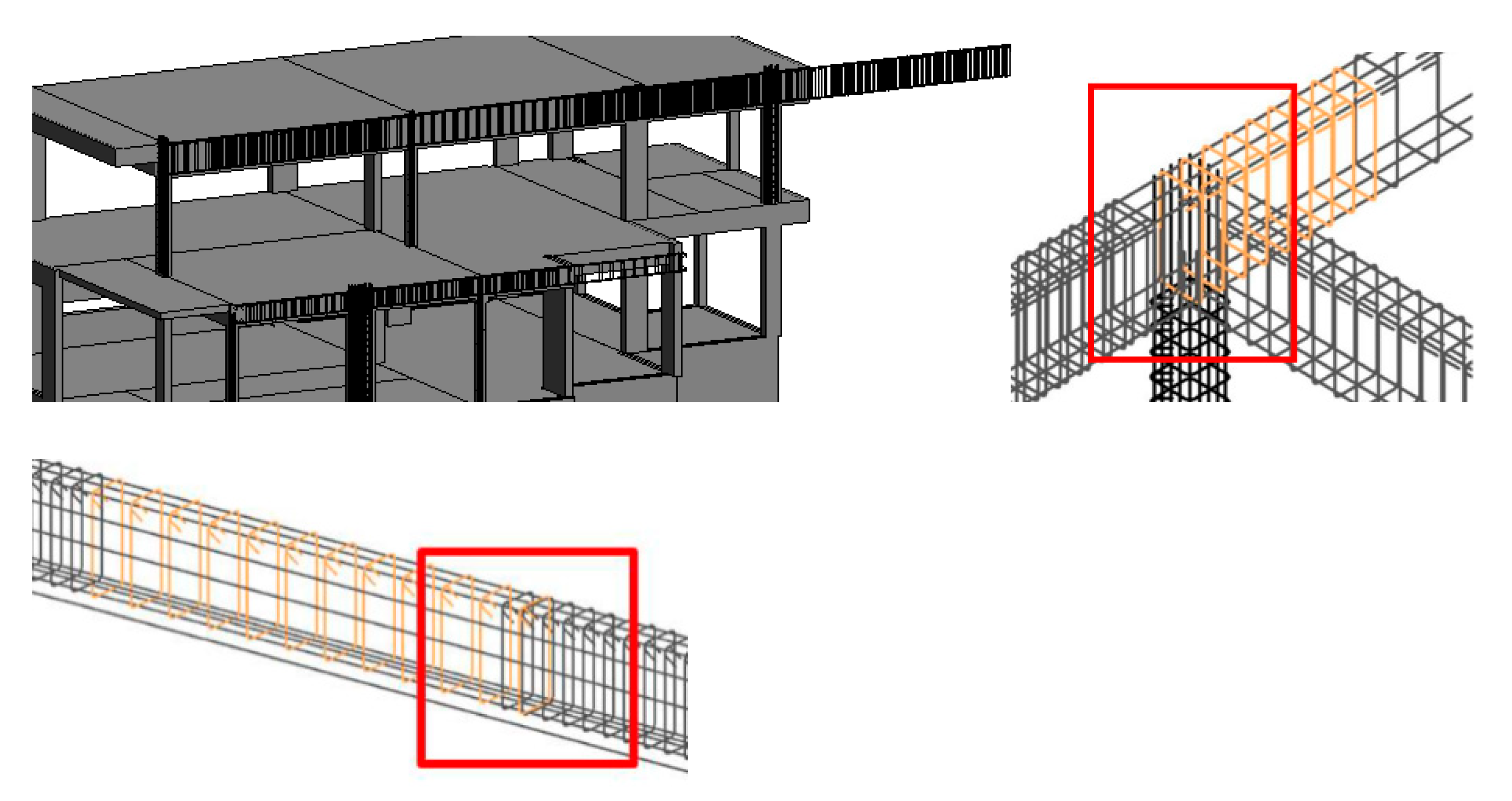

- Robot/Revit export. The reinforcements can be detailed in Robot and then transferred into the Revit model, or only the required areas for each element is transferred, and the bars distribution is thereafter defined in Revit. In relation to slabs, beams, and pillars, Robot perform correctly all bars detailing information but its export into Revit is still limited, denoting a low level of interoperability between the software. Then, the model with the reinforcements included in it, is transferred to the Revit model, several inaccuracies are verified, namely, concerning the multi-span beams the reinforcements frequently exceed their geometric limits, the stirrups included in beams are presented with some overlap, and the reinforcements of slabs and foundations are not recognized (Figure 14). However, it is possible to import the dxf or dwg drawings of the slabs and foundations reinforcement details carried out on Robot, which serve as the basis for the elaboration of the detailing of bars using the reinforcement functionality of Revit (Figure 15) [16].

- SAP/Revit transfer. The distribution of bars within each structure elements made in SAP is not allowed to be transferred to Revit. As so, all structure framework concerning the reinforcement task must be performed in Revit based on the drawings produced in SAP, that must be imported into Revit, in dwg or dxf files format.

- ETABS/ArchiCAD transfer. Although ETABS has a high production capacity of drawn the detailing reinforcements, based on the parameterized detailing process, this information is not eligible to be exported in IFC format, and in consequence the detailing task cannot be transferred to the initial structure model. Thus, the process of detailing the reinforcements was subsequently performed in ArchiCAD, based on the analyses result transferred to it [18].

- SAP/AECOsim transfer. The process of exporting the SAP model, only with the result of the calculation, to the AECOsim is carried out in IFC format. The model is transferred automatically, resulting in the model with the omission of the resistant wall elements and without information related to loads and border conditions [19].

4. Results and Discussion

- Structural model generation: For the development of the BIM model of the structural solution establish for each building case of distinct size and complexity, all software used are adequate, as they present the ability of defining and applying parametric objects, realistic in configuration and in mechanical proprieties. The software used were Revit (Autodesk), AECOsim (Bentley), and ArchiCAD (Graphisoft);

- Checking geometric consistency: All modelling systems allow the visualization of the correspondent analytical model and over it the user can correct any verified inconsistency;

- Transfer of models: The performance of the combination of tools modeling/structure is distinct depending of the software used:

- -

- Revit/Robot presents the most efficient transfer process requiring only a few adjustments, as the stairs and foundations elements were missing;

- -

- In Revit/SAP exchange the main structure elements were identified except the stairs and foundations components, and the axis of linear finite elements and the rigid links were not well recognized;

- -

- The export ArchiCAD/ETABS procedure brings a great number of nodes disconnected between adjacent elements, needing a relevant complementary work before analyses;

- -

- Concerning AECOsim/SAP transfer the process is associated with the lack on the identification of foundations, stairs, and border conditions, however SAP presents the ability to join automatically the nodes that are distant between the axis ends.

- Loads application and reinforcement detailing: Each structural system can easily perform the loads and the mandatory loads combination. Also all structural tools present advanced functionalities allowing the complete definition of the reinforcements in the structural elements.

- Transfer of reinforcements: The exchange data process required after the structural analyses, in order to centralize all the produced information, is the most inefficient task in all the structural BIM design procedure:

- -

- When exporting Robot/Revit reinforcements the accuracy of data is verified. Concerning slabs, beams, columns, and foundations, Revit revels inefficiency as the reinforcements included in those elements were transferred with several inaccuracies. Namely, the bars of multi-span beams exceed their limits, the stirrups of the beams presents duplication, and the reinforcements of slabs and foundations are not recognized. An important additional work is then required;

- -

- The SAP/Revit transfer does not recognize any bar associated to each structural element and the necessary reinforcement detailing must be elaborated in the modelling tool;

- -

- The reinforcements export in ETABS/ArchiCAD transfer was first made using IFC format, but the results were deficient. As so, the detailing work was then totally performed in ArchiCAD, supported on the analyses result.

- -

- The SAP/AECOsim transfer process is effectuated in an automatic mode but the walls elements, the loads, and the border conditions were not recognized.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mehran, D. Exploring the Adoption of BIM in the UE Construction Industry for AEC Firms. Procedia Eng. 2016, 145, 1110–1118. [Google Scholar] [CrossRef]

- Gao, X.; Bozorgi, P.P. BIM-enabled facilities operation and maintenance: A review. Adv. Eng. Inform. 2019, 39, 227–247. [Google Scholar] [CrossRef]

- Sacks, R.; Eastman, C.M.; Teicholz, P.; Lee, G. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; p. 688. ISBN 978-1-119-28755. [Google Scholar]

- Bozorgia, P.P.; Gao, X.; Eastman, C.; Alonzo, P.S. Planning and developing facility management-enabled building information model (FM-enabled BIM). Autom. Constr. 2018, 87, 22–38. [Google Scholar] [CrossRef]

- Migilinskas, D.; Popov, V.; Juocevicius, V.; Ustinovichius, L. The Benefits, Obstacles and Problems of Practical Bim Implementation. Procedia Eng. 2013, 57, 767–774. [Google Scholar] [CrossRef]

- NIBS News & Press. BIM Educational Strategy the Focus of National Institute of Building Sciences Conference. Building Innovation. 2013. Available online: http://www.nibs.org/news/113631/ (accessed on 8 February 2021).

- Mohamed, A.G.; Abdallah, M.R.; Mohamed, M. BIM and semantic web-based maintenance information for existing buildings. Autom. Constr. 2020, 116, 103209. [Google Scholar] [CrossRef]

- Sampaio, A.Z. BIM as a Computer-Aided Design methodology in Civil Engineering. Int. J. Softw. Eng. Appl. 2017, 10, 194–210. [Google Scholar] [CrossRef]

- BuildingSMART, Industry Foundation Classes (IFC)-buildingSMART Technical. 2019. Available online: https://technical.buildingsmart.org/standards/ifc/ (accessed on 8 February 2021).

- Ilter, D.; Ergen, E. BIM for building refurbishment and maintenance: Current status and research directions. Struct. Surv. 2015, 33. [Google Scholar] [CrossRef]

- Vilutiene, T.; Kalibatiene, D.; Hosseini, M.R.; Pellicer, E.; Zavadskas, E.K. Building Information Modelling (BIM) for Structural Engineering: A Bibliometric Analysis of the Literature, Hindawi. Adv. Civ. Eng. 2019, 19. [Google Scholar] [CrossRef]

- Shin, T.S. Building information modeling (BIM) collaboration from the structural engineering perspective. Int. J. Steel Struct. 2017, 17, 205–214. [Google Scholar] [CrossRef]

- Subramani, T.; Ammai, A. Maturing construction management up the BIM model and scheduling using primavera. Int. J. Eng. Technol. 2018, 7. [Google Scholar] [CrossRef]

- Musella, C.; Serra, M.; Salzano, A.; Menna, C.; Asprone, D. Open BIM standards: A review of the processes for managing existing structures in the pre- and post-earthquake phases. Civ. Eng. 2020, 1, 291–309. [Google Scholar] [CrossRef]

- Araszkiewicz, K. Digital technologies in facility management—The state of practice and research challenges. Procedia Eng. 2017, 196, 1034–1042. [Google Scholar] [CrossRef]

- Sampaio, A.Z.; Novais, J.N.; Diniz, J.P. Analysis of BIM implementation in structural projects. In Proceedings of the Congress of Numerical Methods in Engineering; Lourenço, P.B., Flores, P., Clain, S., Eds.; University of Minho: Guimaraes, Portugal, 2019. [Google Scholar]

- Azevedo, V.S. Analysis of the BIM Model from a Design Perspective. Master’s Thesis, Civil Engineering, University of Lisbon, Lisbon, Portugal, 2015. [Google Scholar]

- Farinha, T.S. Analysis of the Transfer Process of Information between Structure Models in a BIM Environment. Master’s Thesis, Civil Engineering, University of Lisbon, Lisbon, Portugal, 2018. [Google Scholar]

- Serra, P.M. Analysis of the Implementation of BIM Processes Applied in Structure Design. Master’s Thesis, Civil Engineering, University of Lisbon, Lisbon, Portugal, 2015. [Google Scholar]

| Walls | ||||

|---|---|---|---|---|

| Type | Volume of Concrete (m3) | Volume of Bars (cm3) | Weight of Steel (kg) | Area (m2) |

| W0_0.20 | 34.48 | 391,841.14 | 3075.95 | 172 |

| W1_0.20 | 8.23 | 167,146.46 | 1312.10 | 41 |

| Total | 42.72 | 558,987.60 | 4388.05 | 214 |

| Columns | ||||

| Type | Volume of Concrete (m3) | Volume of Bars (cm3) | Weight of Steel (kg) | Extension (m) |

| C20x20 | 0.81 | 11,171.50 | 87.70 | 21 |

| C20x40 | 2.09 | 21,969.15 | 172.46 | 27 |

| C20x60 | 2.44 | 23,238.37 | 182.42 | 21 |

| C30x35 | 0.30 | 2909.11 | 22.84 | 3 |

| C35x40 | 0.80 | 5695.71 | 44.71 | 6 |

| Total | 6.43 | 64,983.84 | 510.12 | 78 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sampaio, A.Z.; Gomes, A.M. BIM Interoperability Analyses in Structure Design. CivilEng 2021, 2, 174-192. https://doi.org/10.3390/civileng2010010

Sampaio AZ, Gomes AM. BIM Interoperability Analyses in Structure Design. CivilEng. 2021; 2(1):174-192. https://doi.org/10.3390/civileng2010010

Chicago/Turabian StyleSampaio, Alcinia Zita, and Augusto Martins Gomes. 2021. "BIM Interoperability Analyses in Structure Design" CivilEng 2, no. 1: 174-192. https://doi.org/10.3390/civileng2010010

APA StyleSampaio, A. Z., & Gomes, A. M. (2021). BIM Interoperability Analyses in Structure Design. CivilEng, 2(1), 174-192. https://doi.org/10.3390/civileng2010010