Recovery of Lac Resin from the Aqueous Effluent of Shellac Industry

Abstract

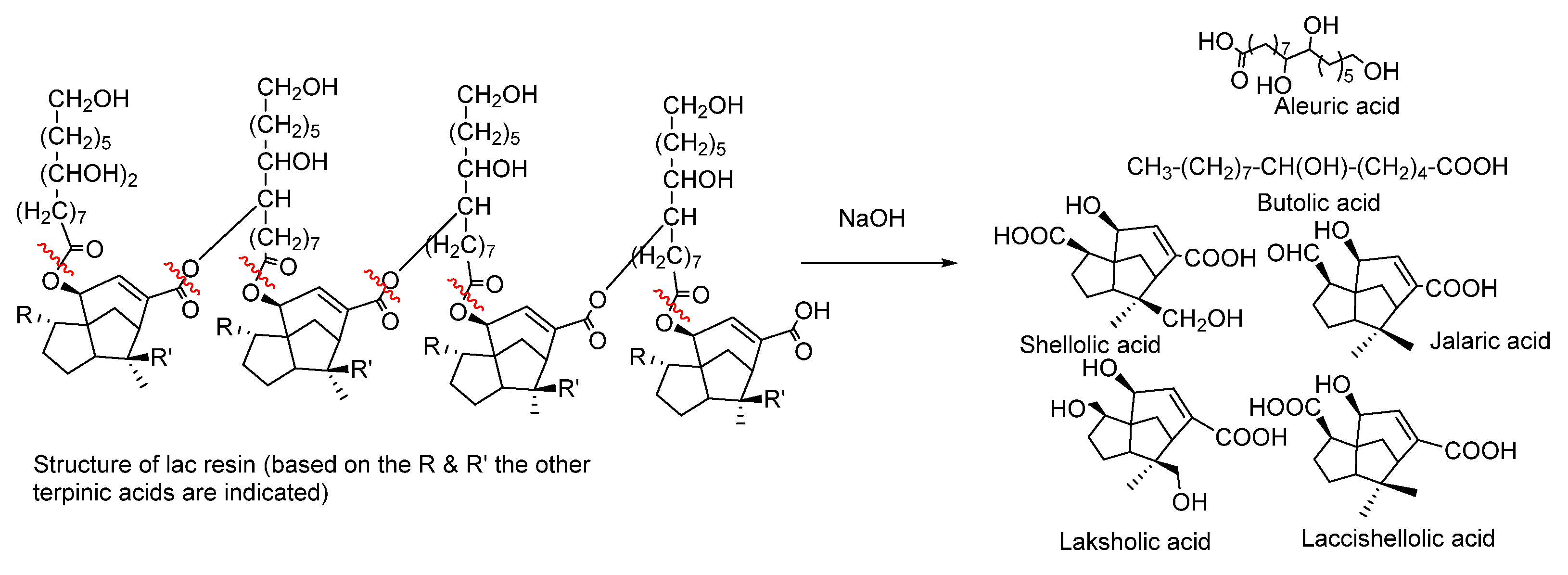

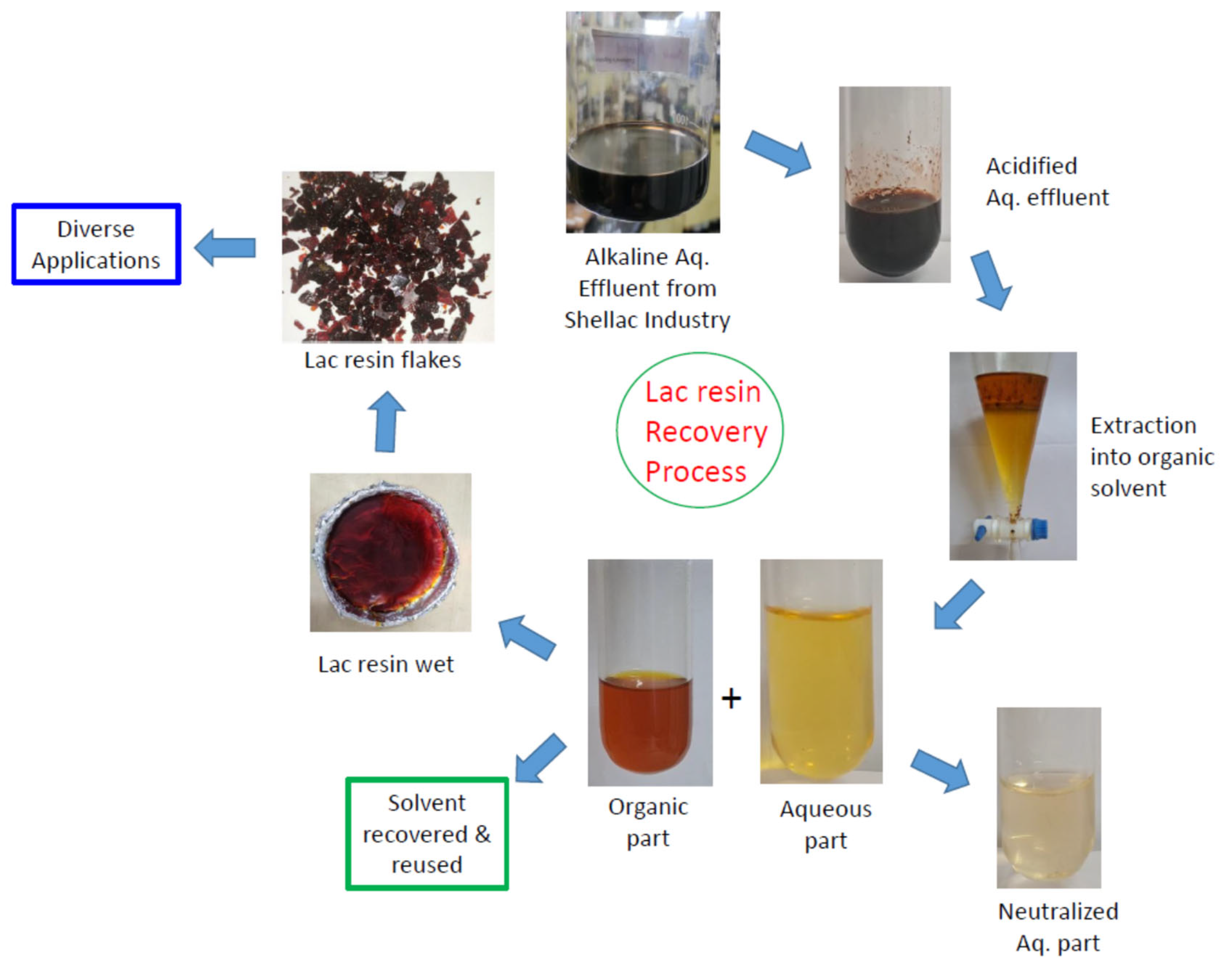

:1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

6. Patents

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goswami, D.N.; Sarkar, P.C. Processing of lac. In Processing, Chemistry and Applications of Lac; Baboo, B., Goswami, D.N., Eds.; Directorate of Information and Publications of Agriculture, Indian Council, Indian Council of Agricultural Research: New Delhi, India, 2010; pp. 12–28. [Google Scholar]

- Goswami, D.N.; Sarkar, P.C. Applications of lac. In Processing, Chemistry and Applications of Lac; Baboo, B., Goswami, D.N., Eds.; Directorate of Information and Publications of Agriculture, Indian Council, Indian Council of Agricultural Research: New Delhi, India, 2010; pp. 118–153. [Google Scholar]

- Bose, P.K.; Sankaranarayanan, Y.; Sen Gupta, S.C. Chemistry of Lac; Indian Lac Research Institute: Ranchi, India, 1963; p. 225. [Google Scholar]

- Sharma, K.K. Lac Crop Harvesting and Processing. In Industrial Entomology; Omkar, Ed.; Springer Nature: Berlin/Heidelberg, Germany, 2017; pp. 181–196. [Google Scholar]

- Zhou, T.; Zhou, L.; Yang, Z. Preparation of Aleuritic Acid. CN 92104516, 9 June 1992. [Google Scholar]

- Chawla, M.H. An Improved Process for Production of Aleuritic Acid from Lac and Its Waste, And Product Thereof. Indian Patent 701/DEL/1999, 27 March 2009. [Google Scholar]

- Nagappayya, S.K.; Gaikar, V.G. Extraction of Aleuritic Acid from Seedlac and Purification by Reactive Adsorption on Functionalized Polymers. Ind. Eng. Chem. Res. 2010, 49, 6547–6553. [Google Scholar] [CrossRef]

- Agarwal, S.C.; Srivastava, B.C.; Majee, R.N. Improved method of isolating aleuritic acid for maximising its recovery from lac. Res. Ind. 1988, 33, 243–248. [Google Scholar]

- Adimurthy, S.; Ghosh, S.; Patoliya, P.U.; Ramachandraiah, G.; Agrawal, M.; Gandhi, M.R.; Upadhyay, S.C.; Ghosh, P.K.; Ranu, B.C. An Alternative Method for the Regio- and Stereoselective Bromination of Alkenes, Alkynes, Toluene Derivatives and Ketones Using a Bromide/Bromate Couple. Green Chem. 2008, 10, 232–237. [Google Scholar] [CrossRef]

- Adimurthy, S.; Ramachandraiah, G.; Bedekar, A.V.; Ghosh, S.; Ranu, B.C.; Ghosh, P.K. Eco-Friendly and Versatile Brominating Reagent Prepared from a Liquid Bromine Precursor. Green Chem. 2006, 8, 916–992. [Google Scholar] [CrossRef]

- Nageswara Rao, S.; Chandra Mohan, D.; Adimurthy, S. Chitosan: An Efficient Recyclable Catalyst for Transamidation of Carboxamides with Amines under Neat Conditions. Green Chem. 2014, 16, 4122–4126. [Google Scholar] [CrossRef]

- Joshi, A.; Kumar, R.; Semwal, R.; Rawat, D.; Adimurthy, S. Ionic Liquid Catalysed Aerobic Oxidative Amidation and Thioamidation of Benzylic Amines under Neat Conditions. Green Chem. 2019, 21, 962–967. [Google Scholar] [CrossRef]

- Rao, S.N.; Mohan, D.C.; Adimurthy, S. L-Proline: An Efficient Catalyst for Transamidation of Carboxamides with Amines. Org. Lett. 2013, 15, 1496–1499. [Google Scholar] [CrossRef] [PubMed]

- Badhani, G.; Joshi, A.; Adimurthy, S. Ionic-Liquid-Catalyzed Synthesis of Imines, Benzimidazoles, Benzothiazoles, Quinoxalines and Quinolines through C−N, C−S, and C−C Bond Formation. Eur. J. Org. Chem. 2021, 2021, 6705–6716. [Google Scholar] [CrossRef]

- Rawat, D.; Kumar, R.; Subbarayappa, A. Visible-Light Induced Phosphonation of Quinoxalines and Quinoxalin-2(1H)-Ones under Aerobic Metal-Free Conditions. Green Chem. 2020, 22, 6170–6175. [Google Scholar] [CrossRef]

- The Alkaline Aqueous Effluent was Provided by the Industry (Jaiswal Shellac Industry, West Bengal-723143 India) to Recover the Lac Resin from the Aqueous Effluent. Available online: https://www.indiamart.com/jaiswalshellac-industry/aboutus.html (accessed on 20 October 2022).

- Adimurthy, S.; Badhani, G. Indian Patent 202111001134 A, 23 September 2022.

- Mishra, Y.D.; Kumar, P. Lac Culture. In Industrial Entomology; Omkar, Ed.; Springer Nature: Berlin/Heidelberg, Germany, 2017; pp. 109–156. [Google Scholar]

- Khurana, R.G.; Singh, A.N.; Upadhye, A.B.; Mhaskar, V.V.; Dev, S. Chemistry of Lac Resin-III. Lac Acids-3: An Integrated Procedure for Their Isolation from Hard Resin; Chromatography Characteristics and Quantitative Determination. Tetrahedron 1970, 26, 4167–4175. [Google Scholar] [CrossRef]

- Singh, A.N.; Upadhye, A.B.; Wadia, M.S.; Mhaskar, V.V.; Dev, S. Chemistry of Lac Resin-II Lac Acids (Part 2): Laccijalaric Acid. Tetrahedron 1969, 25, 3855–3867. [Google Scholar] [CrossRef]

- Upadhye, A.B.; Wadia, M.S.; Mhaskar, V.V.; Dev, S. Chemistry of Lac Resin-IV. Pure Lac Resin-1: Isolation and Quantitative Determination of Constituent Acids. Tetrahedron 1970, 26, 4177–4187. [Google Scholar] [CrossRef]

- Upadhye, A.B.; Wadia, M.S.; Mhaskar, V.V.; Dev, S. Chemistry of Lac Resin-V. Pure Lac Resin-2: Points of Linkage of Constituent Acids. Tetrahedron 1970, 26, 4387–4396. [Google Scholar] [CrossRef]

- Singh, A.N.; Upadhye, A.B.; Mhaskar, V.V.; Dev, S. Chemistry of Lac Resin—VI. Tetrahedron 1974, 30, 867–874. [Google Scholar] [CrossRef]

- Burwood, R.; Read, G.; Schofield, K.; Wright, D.E. 1133. The Pigments of Stick Lac. Part I. Isolation and Preliminary Examination. J. Chem. Soc. 1965, 1, 6067–6073. [Google Scholar] [CrossRef]

| Sl. No. | Solvent | pH | Yield of Lac Resin (% wt/vol) | Nature of Lac Resin |

|---|---|---|---|---|

| 1 | Ethyl acetate | 7 (neutral) | 8 | Sticky dark brown solid |

| 2 | Ethyl acetate | 4.0 | 10 | Sticky brown solid |

| 3 | Ethyl acetate | 1.0 | 12 | Non-sticky light brown solid |

| 4 | Hexane | 4.0 | 1.0 | Brown sticky solid |

| 5 | Hexane | 1.0 | 1.2 | Brown sticky solid |

| 6 | Dichloromethane | 1.0 | 1.5 | Sticky light brown solid |

| 7 | Dichloroethane | 0.5 | 0.5 | Sticky grey solid |

| 8 | Dichloroethane | 1.0 | 2 | Sticky light brown solid |

| 9 | Diethyl ether | 1.0 | 3 | Non-sticky light brown solid |

| 10 | Dimethyl acetamide | 1.0 | 10 | Non-sticky dark brown solid |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Badhani, G.; Yadav, S.; Reji, E.; Adimurthy, S. Recovery of Lac Resin from the Aqueous Effluent of Shellac Industry. Sustain. Chem. 2023, 4, 1-7. https://doi.org/10.3390/suschem4010001

Badhani G, Yadav S, Reji E, Adimurthy S. Recovery of Lac Resin from the Aqueous Effluent of Shellac Industry. Sustainable Chemistry. 2023; 4(1):1-7. https://doi.org/10.3390/suschem4010001

Chicago/Turabian StyleBadhani, Gaurav, Shruti Yadav, Elen Reji, and Subbarayappa Adimurthy. 2023. "Recovery of Lac Resin from the Aqueous Effluent of Shellac Industry" Sustainable Chemistry 4, no. 1: 1-7. https://doi.org/10.3390/suschem4010001

APA StyleBadhani, G., Yadav, S., Reji, E., & Adimurthy, S. (2023). Recovery of Lac Resin from the Aqueous Effluent of Shellac Industry. Sustainable Chemistry, 4(1), 1-7. https://doi.org/10.3390/suschem4010001