Abstract

This study compared the yield of biodiesel produced from tall oil fatty acids (TOFA) via (i) homogeneous catalyst (sulfuric acid) and (ii) a heterogeneous catalyst (Amberlyst® BD20, together with Ambersep BD 19 (Midcontinental Chemical Co., Olathe, KS, USA)® using a batch reactor. The effect of operation conditions including temperature, catalyst concentration, methanol: oil ratio and reaction time on esterification yield were investigated. Gas chromatographic data showed that the major fatty acids present in the TOFA are oleic acid (C18:1n9) and linoleic acid (C18:2n6). Homogenous catalysis yielded 96.76% biodiesel compared to 90.24% for heterogeneous catalysis. Optimized conditions for homogenous catalysis were at a catalyst concentration of 0.5 w/w%, 15:1 methanol: oil mass ratio at 55 °C for 60 min. FTIR results also showed that the homogeneous catalyst yielded a more complete reaction toward biodiesel production in a shorter time (60 min) compared to the heterogeneous catalyst (4.7 h). For heterogeneous catalysis, the highest yield and the lowest acid value were achieved after a second recycling because the reactants were not fully in contact with the catalyst during the first recycling. The catalyst did not show a reduction in catalytic activity even after the fourth recycling. However, the acid value was higher than that for ASTM standards for biodiesel.

1. Introduction

The continuous depletion of fossil fuels coupled with their negative impact on the environment has necessitated the search for alternate energy sources with lower environmental footprint. Biodiesel, mostly the methyl and ethyl esters of fatty acids, is currently the subject of much attention because it is a clean, renewable and biodegradable source of energy [1]. Crude tall oil (CTO), the third largest chemical by-product of the pulp and paper industry, is an ideal feedstock for biodiesel production [2]. CTO can be distilled to make TOFA, a mixture of nearly pure free fatty acids (FFA). The global market for TOFA is expected to reach USD 1 billion in 2020 [3]. As the demand for naturally derived fatty acid-based biofuel increases, there needs to be sustained research focused on newer sources of biodiesel as well as improvements in their conversion processes.

The majority of biodiesel is obtained from transterification of triglycerides from plant oils or animal fats [4,5,6,7]. Methanol or ethanol are commonly used for producing biodiesel in the presence of a base catalyst (e.g., sodium hydroxide), acid catalyst (e.g., sulfuric acid), with glycerol produced as a by-product [8]. The selection of an acid or base catalyst mainly depends on the free fatty acid (FFA) composition of oil. Additionally, FFA present in oils will affect the quality, yield, and fuel properties of biodiesel significantly [9]. For instance, when FFAs are high (typically >1%), heterogeneous catalysis cannot be applied directly due to saponification (soap) problems. An acid–base catalyzed process can be used instead, where firstly FFAs are reduced to <0.5% by acid esterification followed by base-catalyzed conversion to biodiesel.

Tall oil is abundant, readily available and represents a sustainable source of raw material for biodiesel production. Additionally, tall oil is 60% cheaper compared to the traditional vegetable oils used in making biodiesel [10]. The potential for TOFA in biodiesel production has been investigated by few researchers [11,12,13,14]. White et al. [15] used supercritical conditions to convert TOFA to biodiesel in the absence of a catalyst. Yields of 81% and 75% were obtained depending on temperature, time of reaction and molar ratio. However, capital costs for the supercritical method are very high due to the high temperature and pressure reached [16]. When employing a homogenous catalyst (sulfuric acid), TOFA biodiesel yields of 98.45% have been reported [17]. Although homogenous catalysts result in higher (90–99%) biodiesel yields [18,19], factors such as saponification, excess reactant consumption, and additional separation costs present disadvantages. Furthermore, the use of sulfuric acid in esterification purposes cause toxic wastewater. There is therefore a need to search for new, high yield, reusable, non-saponifying catalysts [20].

Recently, heterogeneous solid catalysts have received much attention because of their high activity, high selectivity, and recyclability. Depending on the amount and strengths of their active acid or basic sites, solid catalysts employing tungsten oxides, zirconia, zeolites, heteropolyacids have been used with high FFA conversions [21,22]. Similarly, sulfonic acid-based ion-exchange resins have also been investigated for catalyzing esterification reactions. Dow Chemicals, previously known as Rohm and Haas, commercialized Amberlyst® ion-exchange resin catalysts as solid acid replacements for homogeneous catalysts. FFA conversions of 47.5% with methyl ester yields as high as 78% have been reported for Amberlyst® 15 [23]. Talukder et al. [24] reported maximum biodiesel yields of 97% and 95% using Amberlyst® 15 and Novozym 435, respectively. Both catalyst activities were reduced by the presence of water, but Amberlyst 15 was more negatively influenced. The relatively slower kinetics, incomplete conversion, and limited lifetime of Amberlyst® 15 necessitated an improvement. In subsequent years, DOW Chemicals has replaced Amberlyst® 15 with Amberlyst® BD20 [25]. Park et al. [26] compared the efficiency properties of Amberlyst™ 15 with Amberlyst® BD20 using high FFA oil. Their results showed that Amberlyst® BD20 showed good catalytic efficiency (90%) compared to 50% conversion by Amberlyst® 15. After reuse, the activity of Amberlyst BD20 did not decrease, but that of Amberlyst® 15 decreased with recycling due to water poisoning. Dow also developed Ambersep® BD19 to extend the lifetime of Amberlyst® BD 20. Ambersep® BD19 removes biodiesel pollutants such as phospholipids and proteins, as well as metal ions such as sodium, potassium and magnesium, which age the catalyst [27].

The purpose of this work is to compare activities of sulfuric acid (homogeneous catalyst) and Amberlyst® BD20 (heterogeneous catalyst) for FFA esterification in TOFA and examine the effect of methanol: oil ratio, catalyst concentration, reaction time and temperature on the biodiesel yield. Ambersep® BD19 was used together with Amberlyst® BD20 for purification purposes. The possibility of recycling the heterogeneous phase catalysts was also investigated.

2. Materials and Methods

2.1. Materials

Tall Oil Fatty Acid (TOFA) was provided by Georgia Pacific Company (Atlanta, GA, USA). Methanol (CH3OH), ACS grade (Fisher Scientific, New Brunswick, NJ, USA), Ambersep® BD19 (Midcontinental Chemical Co., Olathe, KS, USA), Amberlyst® BD20 (Midcontinental Chemical Co., Olathe, KS, USA), anhydrous sodium sulfate (Na2SO4), potassium acid phthalate, 0.05 N (Alfa Aesar, Ward Hill, MA, USA), barium hydroxide (Fisher Scientific, Nazareth, PA, USA), phenolphthalein indicator (Allied Chemical Corporation, Morristown, NJ, USA), isopropyl alcohol (Acros Organics, Ferrand, NJ, USA), Specific Gravity Bottles (Kimble Glass Inc., Chicago, IL, USA).

2.2. Synthesis of Biodiesel via Homogeneous Catalysis

Approximately 20 g of TOFA was weighed into 125 mL conical flasks. Based on the methanol: oil ratio, equivalent amounts of methanol and sulfuric acid were measured into a 250 mL conical flask. The catalyst-methanol mixture was added to the TOFA and stirred (100 rpm) at target temperature under reflux. Reaction time was calculated when the mixture attained the target temperature. At the end of the reaction period, the mixture was poured into a separating funnel and kept overnight for the separation of the water and methyl ester phases. The heavier bottom water phase was collected first by gravity, and the upper biodiesel phase (methyl ester or biodiesel) was washed with warm water several times to remove suspended impurities, unreacted methanol, catalyst, and any soap formed. The biodiesel phase was filtered through a bed of anhydrous sodium sulfate to remove all water and then stored in a refrigerator at approximately 6 °C until use.

2.3. Synthesis of Biodiesel via Heterogeneous Catalysis

Prior to esterification, TOFA was purified with Ambersep® BD19. Heterogeneous catalysis was carried out in a water bath at a constant temperature range of 75–80 °C. Briefly, 40 g of TOFA was weighed into a conical flask and dry Amberlyst® BD20 ion-exchange resin catalyst added. Methanol was added to the reaction mixture and then refluxed at 800 rpm for the required reaction time. The catalyst was filtered from the reaction mixture after completion. The mixture was heated in a Buchi Rotavapor R-210 under vacuum to separate unreacted methanol, residual water and any impurities from the biodiesel. The resultant biodiesel solution was poured into a separating funnel and the heavier water portion separated from the biodiesel. Finally, the biodiesel fraction was passed through a bed of anhydrous sodium sulfate (Na2SO4) to remove residual water. The yield of biodiesel was determined gravimetrically.

2.4. TOFA and Biodiesel Characterization

Water content of biodiesel was determined as per ASTM D2709-96 (reapproved 2011). Kinematic viscosity of TOFA and biodiesel were determined according to ASTM D445-12 and ASTM D446-07, respectively. Specific gravity of TOFA and biodiesel were determined at 25/25 and 60/25 °C, respectively, as per ASTM D5355-95 (reapproved 2006).

TOFA samples were analyzed for elemental metal impurities using an inductively coupled plasma optical emission spectroscopy (ICP-OES). Samples were digested with concentrated HNO3 before analysis. Acid value of the biodiesel produced was determined according to the AOCS Official Method Cd 3a-63 (Revised 1987, Reapproved 1989).

Fatty acid methyl ester (FAME) content was determined by capillary gas chromatography (GC) using a Varian CP-3800 GC equipped with a flame ionization detector (FID) and an Agilent Select Biodiesel column (100 m, 0.25 mm, 0.20 μm). GC inlet temperature was set to 250 °C with a 10:1 split, nitrogen carrier gas at 4 mL/min, and the initial oven temperature was set to 140 °C and held for 6 min, ramped up to 225 °C at 4 °C per min, and held for 15 min. Injector temperature was 270 °C and the detector temperature reached 300 °C. Identification of FAME based on comparison with retention times of FAME standards (Supleco quantitative standard FAME 37).

Fourier transform infrared spectroscopy (FTIR) was used to acquire the transmission spectra of the samples in the region between 4000–400 cm−1. FTIR analysis was performed with a PerkinElmer Spectrum 100 FTIR. Analysis was based on the characteristic functional groups in the ester after removal of water and other impurities. Esterification of TOFA at any time under various experimental conditions was defined by the shape of the peaks in the carbonyl region of the spectrum.

2.5. Design of Experiments

In homogenous phase catalysis, a full factorial (24) experimental design—four factors each at two levels (Table 1)—was used to investigate their effect on biodiesel yield (response selected). The factors included methanol: oil molar ratio, reaction temperature, catalyst concentration, and reaction time. Experiments were carried out in triplicates and biodiesel yield was expressed as a regression model.

Table 1.

Experimental design: Factors and levels of treatments.

For heterogeneous catalysis, a central composite design (CCD) with temperature held constant was used. The treatment conditions were methanol: oil ratio, catalyst concentration, and reaction time. Each condition called for a low and a very high point, with intermediate points (Table 1). Each treatment condition generated was duplicated, except one central point for treatment 6, which was triplicated. In the optimization process, the influence of methanol: oil molar ratio, catalyst concentration, and reaction time on yield of TOFA biodiesel was investigated by applying response surface methodology (RSM).

3. Results and Discussion

The present study describes a comparison between two different catalysts used for TOFA esterification. The chosen catalysts for this study were a homogeneous phase catalyst, H2SO4, which is commonly used, and a commercial ion-exchange resin heterogeneous phase catalyst—Amberlyst BD20. FAME products from both catalysts were compared.

3.1. Elemental Analysis of TOFA

The results of the elemental analysis of TOFA are shown in Table 2. The results show that sodium and calcium account for the highest amounts in the oil sample. However, their amounts are lower than the minimum amount of 10 mg/L value for impurities in the oil sample that would cause the catalyst to lose its activity [26].

Table 2.

Elemental Analysis Results.

Impurities such as salts, phosphorus compounds and proteins should be removed from oil by a pretreatment process before biodiesel production because they negatively affect the production process (www.amberlyst.com) (accessed on 25 February 2021). Impurities such as proteins, phospholipids, metal ions (sodium, potassium, etc.) cause the catalyst to lose its activity. If any metal ions are present in the feed at levels greater than 10 ppm, full analysis of the oil feedstock for such impurities must be determined [26]. The oil was, however, purified using Ambersep BD 19 to forestall any deactivation of the catalyst. The purification process ensured the removal of the metal ions and other impurities that may impede the conversion process.

3.1.1. Physicochemical Properties of TOFA

TOFA is a mixture of acidic compounds namely resin acids, fatty acids and unsaponifiables (neutrals). Results from GC characterization of TOFA are shown in Table 3. The major fatty acids present were oleic acid (C18:1 cis-9; 57.72%) and linoleic acid (C18:2 cis-9, 12; 35.41%). Trace amounts of pentadecanoic acid (C15:1 cis-10, 1.4%), palmitoleic acid (C16:1 cis-9, 0.87%) and arachidic acid (C20:0, 2.61%) were also present. Trace amounts of minor fatty acids with a total composition of 1.98% were also recorded. These results are in good agreement with previously reported literature. For instance, Keskin et al. [28] reported TOFA composition of 52.7% oleic acid, 38.3% linoleic acid, and 6.9% linolenic acid. Variations in chemical composition of TOFA is attributed to the age, pine species, geographical location of the coniferous trees and pulping process used [29].

Table 3.

Physicochemical properties of TOFA and biodiesel.

Table 3 also shows the fuel properties of TOFA and their methyl esters (TOME). There was a drop in kinematic viscosity of TOFA from 20.614 cSt to 5.216 cSt for biodiesel. This result is within the ASTM standard level of 1.9–6.0 cSt (ASTM D445).

3.1.2. FTIR Characterization of TOFA and Biodiesel

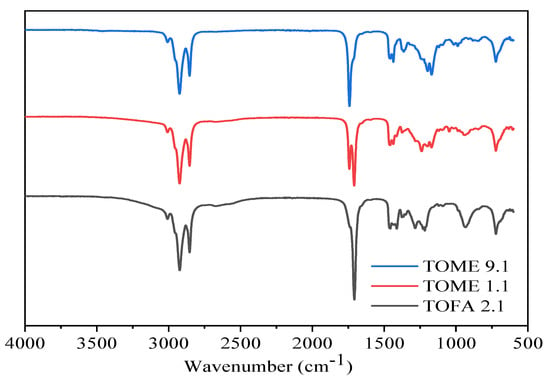

The FTIR spectra of TOFA and the biodiesel (TOME) produced via homogeneous catalysis are shown in Figure 1. The strong, sharp peaks at 2923 cm−1 and 2854 cm−1 are representative of aliphatic anti-symmetric CH2 stretching and aliphatic symmetrical CH2 stretching vibrations, respectively. The high intensity of these peaks is indicative of saturated oil; however, the small peak at the shoulder of the intense antisymmetric CH2 peak at 3007 cm−1 represents unsaturation and is due to olefinic double bond [30]. Oils with a high proportion of linolenic or linoleic acyl groups show a higher frequency than those with oleic acyl groups. The absorption at 1741 cm−1 is due to the ester carbonyl (C=O), because carbonyl absorption of aliphatic esters usually appears in the 1750–1735 cm−1 region [31]. For α, β-unsaturated esters, the peaks appear in the region 1730–1715 cm−1. The absence of a peak in this region indicates the absence of α, β- unsaturated ester, and hence there is no conjugation of cyclic compound present. This observation agrees with the GC data showing that the fatty acids present are long chain carboxylic acids.

Figure 1.

FTIR spectra of TOFA and acid-catalyzed biodiesel. TOME = tall oil methyl ester (biodiesel); TOME 9.1 = biodiesel from treatment 9, replication1; TOME 1.1 = biodiesel from treatment 1, replication1; TOFA 2.1 = tall oil fatty acid.

3.2. Homogeneous Catalysis

3.2.1. Biodiesel Yield

The experimental matrix for the factorial design and the results of biodiesel %yield after homogeneous phase (H2SO4) catalysis of TOFA are shown in Table 4. The reaction parameters were (6:1, 15:1), (55, 75 °C), (0.5, 2% w/w), (30, 60 min) for methanol: oil ratio, temperature, catalyst concentration and time, respectively (Table 1). The mathematical model representing biodiesel %yield as a function of the test variables in the experiment is expressed by the following equations:

%Yield = 104.71 + 0.75 × Ratio − 0.21 × Temperature − 4.59 × Catalyst Conc.

− 0.14 × Time + 0.03 × Ratio × Temperature + 0.81 × Ratio × Catalyst Conc. +

0.05 × Ratio × Time − Temperature × Time − 0.23 × Catalyst Conc. × Time.

− 0.14 × Time + 0.03 × Ratio × Temperature + 0.81 × Ratio × Catalyst Conc. +

0.05 × Ratio × Time − Temperature × Time − 0.23 × Catalyst Conc. × Time.

Table 4.

Experimental matrix and results of biodiesel %yield after homogeneous phase catalysis.

Statistical analysis of biodiesel %yield using JMP statistical software (JMP Pro 11) gave a p-value of 0.0001 at the 5% significance level. To test the fit of the model, the regression equation (Equation (1)) and coefficient of determination (R2) were evaluated. A determination coefficient, R2, of 0.79 indicated that the variation in 79% TOFA biodiesel %yield obtained by homogeneous phase catalysis can be attributed to the independent variables selected (X1, X2, X3 and X4) and 21% of the total variation is not explained by the model. Other variables within the process may have affected biodiesel %yield. Statistical analysis of the experimental variables shows that methanol: oil molar ratio is the most important factor in the response.

For interaction variables, ratio and catalyst concentration had the most positive effect, and a slight influence from ratio and time. Temperature, catalyst concentration and time had a negative influence on the response (biodiesel yield). From Table 4, the optimum biodiesel %yield was determined with a methanol: oil ratio of 15:1, temperature of 55 °C, and catalyst concentration of 0.5% at a reaction time of 60 min. The optimum biodiesel %yield as predicted from the model was 96.76.

The main factor effects, including methanol: oil ratio, temperature, catalyst concentration, time and all two-way interaction terms, were significant at the 5% level except temperature and catalyst concentration (p-value of 0.68). Thus, it was concluded that all five factors investigated had significant effects, either as individual or as two-factor interactions. The R2 value was 0.79, with an adjusted R2 value of 0.73. There is therefore a high correlation between the factors. The regression explained 79% of the model.

3.2.2. Characterization of Homogenous Catalyzed TOFA Biodiesel Quality

FTIR spectroscopy was used to monitor the extent of conversion of TOFA to methyl ester (biodiesel) via the disappearance and appearance of certain absorption peaks. The homogeneous catalyzed conversion of TOFA to their methyl esters is a reversible reaction, and certain peaks or regions in the FTIR spectra can reveal the extent of biodiesel production. The wavenumber 3300–2500 cm−1 region gives a broad spectrum for TOFA, and this is attributed to –OH stretching absorption [31,32]. As the reaction proceeds to the formation of the ester, the broadness of this region begins to flatten and disappear completely when total conversion is achieved. The peaks observed at 3007 cm−1 were attributed to the C–H stretch of Cis-C=C bonds. The peaks at 2923 and 2854 cm−1 are related to the asymmetric and symmetric vibration of the CH2 stretch, respectively [33].

The band at 1741 cm−1 is related to the C=O stretch of triglyceride ester linkage and the peak at 1710 cm−1 is the characteristic carbonyl stretching band of FFAs (C=OH). A single sharp peak at 1741 cm−1 (ester carbonyl C=O peak, Tome 9.1) is observed. This single peak is indicative of the higher purity of this sample compared with the spectra of the sample in Figure 1 (Tome 1.1), which has an acid C=O peak at 1709 cm−1. The bands at 1434 and 1459 cm−1 are related to the C–H absorption of bending vibrations of CH2 and CH3 bands [31].

The bands of CH2 bending vibrations can be observed at 1376 and 1236 cm−1. The bands at 1171, 1197 cm−1 are attributed to C-O-C and O-CH3 stretching vibration of a terminal methoxy group of the ester (biodiesel) respectively [34,35]. The peaks at 1284 cm−1 and 1217 cm−1 observed for TOFA are due to the C-O stretching band (1320–1210 cm−1) of carboxylic acids from the interaction between C-O stretching and in-plane C-O-H bending vibrations. These are absent in the ester spectra of the biodiesel. Additionally, a peak at 1241–1244 cm−1 (in the ester band) occurred, but was absent in the carboxylic acid band of TOFA spectra. For TOFA, a peak at 1412 cm−1 due to the C-O-H bending vibration can be observed.

The band at 968 cm−1 is assigned to isolated trans-double bonds vibrational [30]. Furthermore, a peak around 930–940 cm−1 due to O-H out of plane bending vibration [31] can be observed. For TOFA (Figure 1), peaks due to acid –OH and C=O as well as C-OH bonds are more prominent. The CH2 rocking vibration of long-chain alkanes can be clearly seen at 723 cm−1 [31].

The intensity (I) ratio of the band at 3007 cm−1 and 2854 cm−1 is a measure of the degree of unsaturation [36]. The higher the intensity ratio is, the higher the unsaturation. Acid carbonyl intensity ratios for the various treatment groups decreased, while the ester carbonyl intensity ratios increased. The intensity ratios show that treatments 8 exhibited the highest average intensity ratio of 0.9929, with 84.4% yield (due to the ester carbonyl), followed by treatment 7, with an average intensity ratio of 0.9816 and 85.3% yield (Supplementary Materials). This was followed by treatment 16 (average intensity ratio 0.9185; 93.3% yield), treatment 14 (average intensity ratio 0.9163; 94.7% yield), and treatment 3 (average intensity ratio 0.8929; 91.9% yield).

Although FTIR spectra monitoring demonstrated complete conversion of TOFA to biodiesel, statistical analysis showed that optimum biodiesel yield was achieved with treatment 3 (methanol: oil ratio of 15:1, temperature 55 °C, catalyst concentration 0.5% and reaction time of 60 min). Thus, a biodiesel yield of 96.76% was obtained under these optimum conditions, even though treatment 8 exhibited the highest intensity ratio.

3.3. Heterogeneous Catalysis

3.3.1. Biodiesel Yield

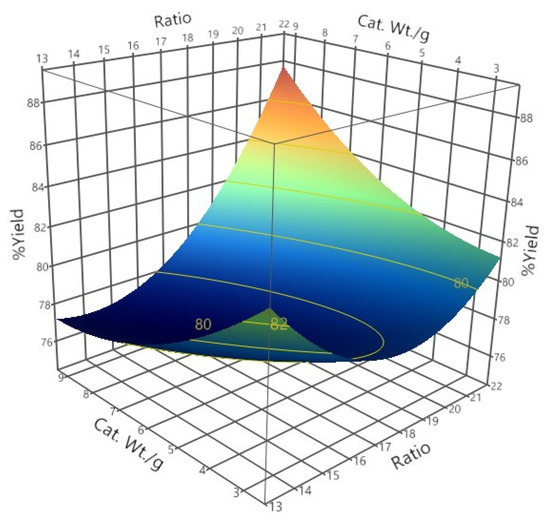

The results of the heterogeneous catalysis of TOFA using the solid catalyst Amberlyst BD 20 are shown in Table 5. Statistical analysis of the heterogeneous catalysis of TOFA to produce biodiesel was done using the central composite design (CCD) and the response surface methodology (RSM). The results of the analysis gave an R2 value of 0.53, with an adjusted R2 value of 0.33. This indicates that there are other factors not in the model that affect the yield. ANOVA yielded a p-value of 0.03, which is significant at p = 0.05. The only factor that was significant at p = 0.01 was methanol: oil ratio. Catalyst concentration and time of reaction were both not significant at the p = 0.05 significance level. Likewise, all the square and interaction terms were insignificant. The regression equation generated for %Yield is given by:

%Yield = 66.16 + 0.5 × Ratio.

Table 5.

Central composite design (CCD) and responses for biodiesel yield after heterogeneous catalysis.

Optimum biodiesel production was obtained with an oil-to-methanol ratio of 15.5:1, a catalyst concentration with 6.4 g of Amberlyst BD20 (representing 16% of oil weight), and a time of 3.4 h. The optimum solution was therefore a Saddle Point with a %yield of 76.79 (Figure 2). The model was maximized to predict a higher %yield of biodiesel of 90.24% using a methanol: oil ratio of 20.8, a catalyst concentration of 9.36 g (representing 23.4% of the oil weight), and a time of 4.7 h.

Figure 2.

Response surface graph showing ratio and catalyst concentration against %yield.

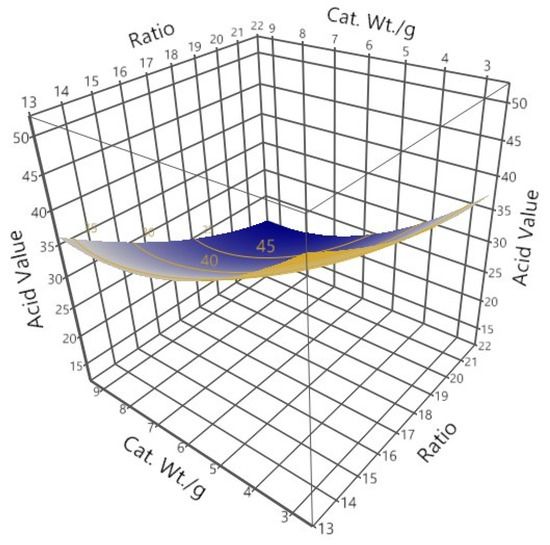

For acid value, R2 and adjusted R2 values of 0.58 and 0.41, respectively, were obtained. ANOVA gave a p-value of 0.01, which was significant at the p = 0.05 significance level. Ratio was significant at a p-value of 0.03 and catalyst concentration was significant at p = 0.01 (p = 0.05 significance level). All the squared terms were insignificant. However, the interaction between catalyst concentration and time gave a p-value of 0.002 (at p = 0.05 significance level). Time was not significant, and hence the interaction term was left out of the model. The acid value regression equation is given by:

Acid Value = 63.28 − 1.48 × Ratio − 2.13 × Catalyst Conc.

The Acid Value at optimum production was predicted with a methanol: oil ratio of 20.2:1, catalyst concentration of 4.89 g (representing 12.23% of the oil weight), and time of reaction of 2.12 h. This optimal solution was a saddle point, with a predicted acid value of 27.21 (Figure 3). Minimizing the model in order to predict the smallest value of acid number gave a methanol: oil ratio of 21.4:1, and a catalyst concentration of 8.22 g (representing 20.6% of oil weight), and a time of 4.7 h. The minimization produced an acid value of 14.1 mg KOH/g oleic acid.

Figure 3.

Response surface graph showing Ratio and Catalyst concentration against Acid Value.

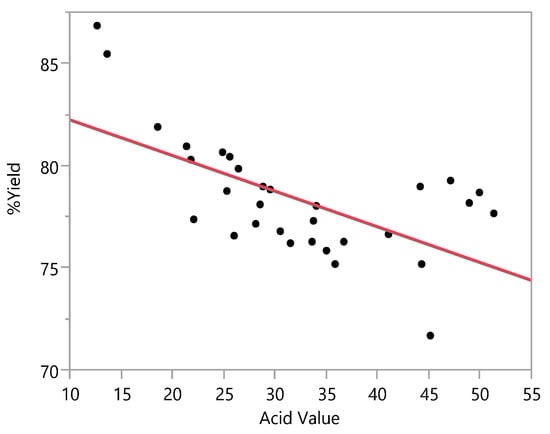

A graph of %yield against the acid value (Figure 4) was linear, with an R2 value of 0.39 and an adjusted R2 value of 0.37. The model was significant, with a p-value of 0.0002. The linear equation is given by:

%Yield = 84.01 − 0.17 × Acid Value

Figure 4.

A graph of %yield against acid value.

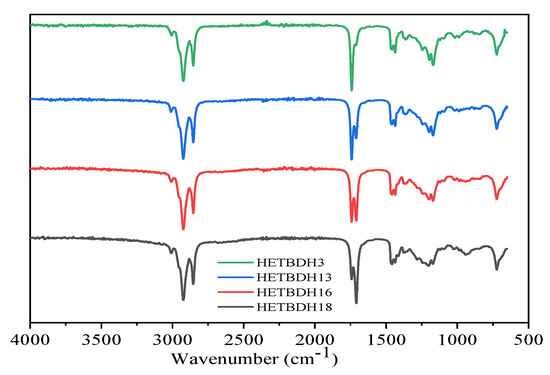

3.3.2. FTIR Characterization of Heterogeneous Catalysis of TOFA

In the heterogeneous synthesis of biodiesel from TOFA (Figure 5), FTIR spectra monitoring showed that there was a gradual shift from acid carbonyl peaks to ester carbonyl peaks. Ester carbonyl peaks formed became prominent attended by decrease in intensity of peaks corresponding to acid carbonyl. The acid carbonyl peak finally disappeared. The elimination of the acid peak is marked by the flatness of the curve beyond the 3000 cm−1 region, an indication that the –OH of the carboxylic acid is completely removed after the reaction.

Figure 5.

FTIR spectra of heterogeneous catalysis for biodiesel treatments. (HETEBDH3 = Heterogeneous catalysis for biodiesel treatment 3; HETEBDH13 = Heterogeneous catalysis for biodiesel treatment 13; HETEBDH16 = Heterogeneous catalysis for biodiesel treatment 16; HETEBDH18 = Heterogeneous catalysis for biodiesel treatment 18).

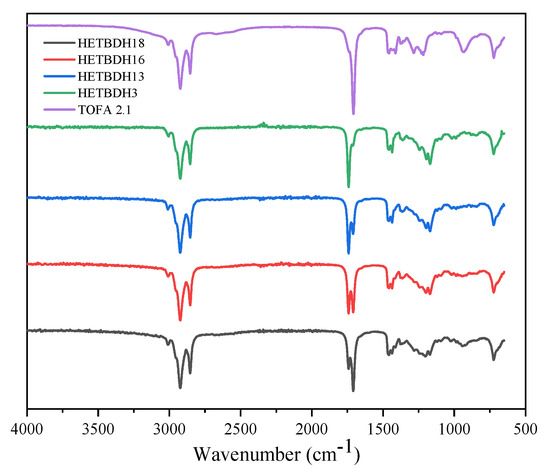

FTIR spectra of the various reaction conditions are shown in Figure 6. There is a gradual elimination of the acid functional groups and replacement by ester functional groups. This demonstrates the reversibility of the reaction process. The FTIR spectra in the 3375 and 2425 cm−1 regions showed a lower intensity due to complete removal of –OH acid bond resulting in flattening of the spectra curve in this region (HETBDH3). FTIR spectra monitoring the heterogeneous catalysis process showed that TOFA exhibited the highest intensity of the acid carbonyl peak (44%T) followed by treatment HetBDH18 (61%T), treatment HetBDH16 (69%T), treatment HetBDH13 (76%T) and treatment HetBDH3 (88%T) in that order. This trend was reversed in the ester carbonyl peak intensities in the 1741–1742 cm−1 region. Here, treatment HetBDH3 exhibited the highest intensity of ester carbonyl peak (61%T) while treatment HetBDH18 gave the lowest peak intensity (75%T).

Figure 6.

Full Range FTIR spectra for TOFA, and four different heterogeneously catalyzed biodiesel treatments. (HETEBDH18 = Heterogeneous catalysis for biodiesel treatment 18; HETEBDH16 = Heterogeneous catalysis for biodiesel treatment 16; HETEBDH13 = Heterogeneous catalysis for biodiesel treatment 13; TOFA 2.1 = Tall oil fatty acid).

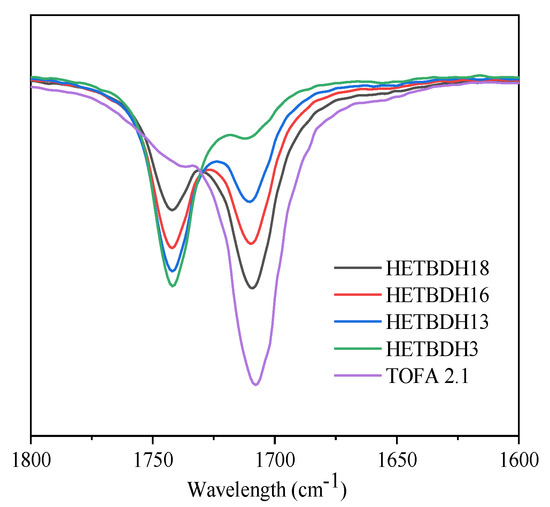

The heterogeneously catalyzed treatments HetBDH3 and HetBDH7 are replicates for reaction conditions of Methanol:Oil mole ratio of 20:1, catalyst concentration of 20%, the time of reaction of 4 h within a temperature range of 75–80 °C (Figure 6 and Figure 7, Supplementary Materials). Treatments HetBDH3 and HetBDH7 exhibited the lowest Acid Value of 12.65 and 13.59 respectively with corresponding percent yields of 86.88% and 85.49% (average, 86.18%). However, statistical optimization of the process gave a molar ratio of Methanol:Oil as 20.8:1, a catalyst concentration of 23.4% (of the weight of oil), and a reaction time of 4.7 h to give a yield of 90.24%. Importantly, the acid value did show that HetBDH3 and HetBDH7 had the lowest values consistent with the carbonyl peaks from the FTIR spectra. FTIR spectra monitoring of the reaction showed that treatments HetBDH3 and HetBDH7 were nearest to the optimum conditions.

Figure 7.

FTIR spectra of TOFA and four heterogeneously catalyzed treatments within the wavenumber range of 1800–1600 cm−1. (HETEBDH18 = Heterogeneous catalysis for biodiesel treatment 18; HETEBDH16 = Heterogeneous catalysis for biodiesel treatment 16; HETEBDH13 = Heterogeneous catalysis for biodiesel treatment 13; HETEBDH3 = Heterogeneous catalysis for biodiesel treatment 3; TOFA2.1 = Tall oil fatty acid).

However, the optimum conditions for the heterogeneous catalyst, Amberlyst BD 20, to produce a 90.24% yield was given by Methanol:Oil Molar ratio of 20.8:1, Catalyst concentration of 23.4% and Time of Reaction of 4.7 h. The acid value attained in this process was too high for use as a biodiesel. There is the need to lower the acid value of the biodiesel produced.

3.4. Recycling of Catalyst

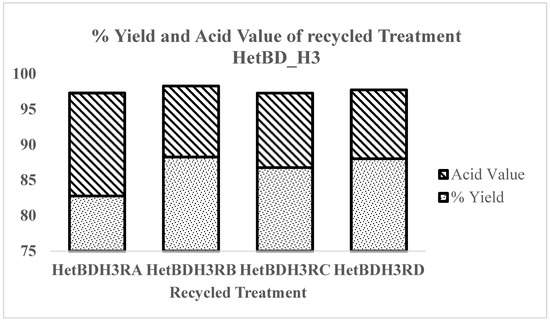

The effect of the recycling of the catalyst on the biodiesel production process is presented in Table 6 and Figure 8 and Figure 9. The catalyst recycling step was evaluated because of its impact on the overall cost of the production process.

Table 6.

Results of recycling of catalyst for treatment HetBDH3.

Figure 8.

Graph showing %yield and acid value vs. recycled treatment. HetBDH3RA = First recycle of heterogeneously catalyzed treatment 3; HetBDH3RB = Second recycle of heterogeneously catalyzed treatment 3; HetBDH3RC = Third recycle of heterogeneously catalyzed treatment 3; HetBDH3RD = Fourth recycle of heterogeneously catalyzed treatment 3.

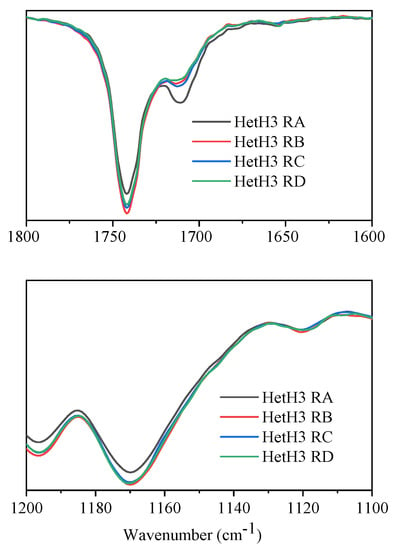

Figure 9.

Overlaid FTIR spectra of the biodiesel from recycled catalyst within the 1800–1600 cm−1 and 1200–1100 cm−1 ranges. HetH3 RA = First recycle of heterogeneously catalyzed treatment 3; HetH3RB = Second recycle of heterogeneously catalyzed treatment 3; HetH3RC = Third recycle of heterogeneously catalyzed treatment 3; HetH3RD = Fourth recycle of heterogeneously catalyzed treatment 3.

The %yield showed an increase after the first reaction, an indication that the catalyst was more potent after the first cycle. Similarly, the acid value gave the highest value of 14.53 after the first cycle, and the value continued to fall to a minimum of 9.72 after the fourth cycle (Figure 8). This phenomenon whereby the catalyst increased the process yield to the maximum before becoming stable may be due to swelling, as reported by Lopez et al. [37]. Park et al. [26] also reported that Amberlyst BD 20 increases its catalytic activity from the second cycle and ascribed it to time required by the catalyst to contact the reactants. Consequently, the catalytic activity of the first cycle is retarded. The results also demonstrated that the catalyst could be recycled even to the fourth cycle without decrease in activity of the catalyst (Figure 8). This is consistent with the work of Telebian-Kiakalaieh et al. [38], Park et al. [26]. The overlaid FTIR spectra of the biodiesel from the recycled catalyst in the wavelength region of 1200–1100 cm−1 (Figure 9) shows that the first cycle had the highest acid carbonyl peak, and that the recycling reduces that peak while increasing the ester carbonyl peak. The highest catalytic activity is shown for the second cycle, and while it gradually decreases towards the fourth cycle, it remains still potent in its activity.

4. Conclusions

FTIR spectroscopy was used to monitor the progress of biodiesel synthesis from tall oil fatty acids using homogeneous catalyst (sulfuric acid), and heterogeneous catalyst (Amberlyst BD 20, from Dow Chemicals). The optimum reaction conditions for the homogeneous catalysis was a methanol: oil molar ratio of 15:1 at a Temperature of 55 °C, catalyst concentration of 0.5%, and a reaction time of 60 min. The yield obtained was 96.76%. The FTIR data and spectra agreed with the optimum treatment conditions showing a total conversion of the fatty acid into biodiesel. The acid value was reduced from 113.18 ± 0.01 mg KOH/g oleic for the TOFA to 4.24 ± 0.12 mg KOH/g oleic acid for the biodiesel. This acid value is too high above the ASTM standard value of 0.8 mg KOH/g oleic acid. Kinematic viscosity was reduced from a value of 20.614 ± 0.059 mm2/s for the TOFA to 5.216 ± 0.016 mm2/s for the biodiesel which is within the ASTM standard value of 1.9–6.0 mm2/s.

For the heterogeneous catalysis process, the optimum conditions used for the biodiesel production were a methanol: oil molar ratio of 20.8:1, a catalyst concentration of 23.4% of the oil, and a reaction time of 4.7 h at a constant temperature range of 75–80 °C. The predicted optimum yield obtained was 90.24%. The acid value for the heterogeneous catalysis was higher, at a value of 14.1 mg KOH/g of oleic acid. There is a need to further reduce the acid value in order to meet the ASTM standards for biodiesel. The major fatty acids present in the TOFA are oleic and linoleic acids. The biodiesel percent yield from the homogeneous catalysis was higher than that of the heterogeneous catalysis. However, the heterogeneous catalyst could be recycled about four times without losing its catalytic activity. The FTIR spectra agree with the yield data, showing a better conversion of biodiesel for the homogeneous catalysis than the heterogeneous catalysis.

Supplementary Materials

The following are available online at https://www.mdpi.com/2673-4079/2/1/12/s1, Table S1: Intensity ratios of the carbonyl peak for TOFA and corresponding biodiesel; Table S2: Results of heterogeneous catalysis to produce biodiesel.

Author Contributions

Conceptualization, B.D.-A. and G.L.-Y.; methodology, G.L.-Y.; software, E.A.-O.; validation, B.D.-A. and G.L.-Y.; formal analysis, E.A.-O.; investigation, G.L.-Y.; resources, B.D.-A.; data curation, E.A.-O.; writing—original draft preparation, G.L.-Y.; writing—review and editing, G.L.-Y. and E.A.-O.; supervision, B.D.-A.; project administration, B.D.-A. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge the financial support of USDA McIntire-Stennis Project # 1002913.

Acknowledgments

The authors would also like to thank the School of Natural Resources, Davis College of Agriculture, Natural Resources and Design, West Virginia University, Morgantown, WV. USA and WVU Division of Diversity, Equity and Inclusion, Chancellor’s Scholars Program for their partial support.

Conflicts of Interest

The authors declare no competing interest from any financial and personal with other people or organizations that could have inappropriately influenced this study.

References

- Kant Bhatia, S.; Kant Bhatia, R.; Jeon, J.-M.; Pugazhendhi, A.; Kumar Awasthi, M.; Kumar, D.; Kumar, G.; Yoon, J.-J.; Yang, Y.-H. An overview on advancements in biobased transesterification methods for biodiesel production: Oil resources, extraction, biocatalysts, and process intensification technologies. Fuel 2021, 285, 119117. [Google Scholar] [CrossRef]

- Aryan, V.; Kraft, A. The crude tall oil value chain: Global availability and the influence of regional energy policies. J. Clean. Prod. 2021, 280, 124616. [Google Scholar] [CrossRef]

- Pulidindi, K.; Prakash, A. Tall Oil Fatty Acid Market Size—Industry Trends Report 2024; Global Market Insights, Inc.: Delaware, DE, USA, 2017; Available online: https://www.gminsights.com/industry-analysis/tall-oil-fatty-acid-market (accessed on 16 June 2020).

- Avagyan, A.B.; Singh, B. Biodiesel from Plant Oil and Waste Cooking Oil. In Biodiesel: Feedstocks, Technologies, Economics and Barriers: Assessment of Environmental Impact in Producing and Using Chains; Avagyan, A.B., Singh, B., Eds.; Springer: Singapore, 2019; pp. 15–75. [Google Scholar] [CrossRef]

- Abomohra, A.E.-F.; Elsayed, M.; Esakkimuthu, S.; El-Sheekh, M.; Hanelt, D. Potential of fat, oil and grease (FOG) for biodiesel production: A critical review on the recent progress and future perspectives. Prog. Energy Combust. Sci. 2020, 81, 100868. [Google Scholar] [CrossRef]

- Pinzi, S.; Garcia, I.L.; Lopez-Gimenez, F.J.; Luque de Castro, M.D.; Dorado, G.; Dorado, M.P. The Ideal Vegetable Oil-based Biodiesel Composition: A Review of Social, Economical and Technical Implications. Energy Fuels 2009, 23, 2325–2341. [Google Scholar] [CrossRef]

- Sander, A.; Antonije Košćak, M.; Kosir, D.; Milosavljević, N.; Parlov Vuković, J.; Magić, L. The influence of animal fat type and purification conditions on biodiesel quality. Renew. Energy 2018, 118, 752–760. [Google Scholar] [CrossRef]

- Nasreen, S.; Nafees, M.; Qureshi, L.A.; Asad, M.S.; Sadiq, A.; Ali, S.D. Review of Catalytic Transesterification Methods for Biodiesel Production. Biofuels State Dev. 2018. [Google Scholar] [CrossRef]

- Bouaid, A.; Vázquez, R.; Martinez, M.; Aracil, J. Effect of free fatty acids contents on biodiesel quality. Pilot plant studies. Fuel 2016, 174, 54–62. [Google Scholar] [CrossRef]

- Brännström, H.; Kumar, H.; Alén, R. Current and Potential Biofuel Production from Plant Oils. Bioenergy Res. 2018, 11, 592–613. [Google Scholar] [CrossRef]

- Islam, M.S.; Christopher, L.P.; Alam, M.N. Separation and Purification of ω-6 Linoleic Acid from Crude Tall Oil. Separations 2020, 7, 9. [Google Scholar] [CrossRef]

- Govorin, A.S.; Gubanov, N.D.; Konovalov, N.P. Esterification of tall oil fatty acids using ion exchange resins in order to produce energy-efficient engine oil. IOP Conf. Ser. Earth Environ. Sci. 2020, 408, 012074. [Google Scholar] [CrossRef]

- Adewale, P.; Christopher, L.P. Thermal and Rheological Properties of Crude Tall Oil for Use in Biodiesel Production. Processes 2017, 5, 59. [Google Scholar] [CrossRef]

- Lawer-Yolar, G.S. Biodiesel from Tall Oil Fatty Acids and Physico Thermal Properties of Tropical Tree Fruit Oils as Thermal Energy Storage Systems. Ph.D. Thesis, West Virginia University, Morgantown, WV, USA, 2015. [Google Scholar] [CrossRef]

- White, K.; Lorenz, N.; Potts, T.; Penney, W.R.; Babcock, R.; Hardison, A.; Canuel, E.A.; Hestekin, J.A. Production of biodiesel fuel from tall oil fatty acids via high temperature methanol reaction. Fuel 2011, 90, 3193–3199. [Google Scholar] [CrossRef]

- Sakdasri, W.; Sawangkeaw, R.; Ngamprasertsith, S. Techno-economic analysis of biodiesel production from palm oil with supercritical methanol at a low molar ratio. Energy 2018, 152, 144–153. [Google Scholar] [CrossRef]

- Abstract: Biodiesel from Tall Oil Fatty Acids Using Homogeneous and Heterogeneous Catalysts (21st National Annual Meeting (7–12 June 2009)). Available online: https://nam.confex.com/nam/2009/webprogram/Paper2285.html (accessed on 28 May 2020).

- Thangaraj, B.; Solomon, P.R.; Muniyandi, B.; Ranganathan, S.; Lin, L. Catalysis in biodiesel production—A review. Clean Energy 2019, 3, 2–23. [Google Scholar] [CrossRef]

- Rizwanul Fattah, I.M.; Ong, H.C.; Mahlia, T.M.I.; Mofijur, M.; Silitonga, A.S.; Rahman, S.M.A.; Ahmad, A. State of the Art of Catalysts for Biodiesel Production. Front. Energy Res. 2020, 8, 8. [Google Scholar] [CrossRef]

- Abdullah, S.H.Y.S.; Hanapi, N.H.M.; Azid, A.; Umar, R.; Juahir, H.; Khatoon, H.; Endut, A. A review of biomass-derived heterogeneous catalyst for a sustainable biodiesel production. Renew. Sustain. Energy Rev. 2017, 70, 1040–1051. [Google Scholar] [CrossRef]

- Islam, A.; Taufiq-Yap, Y.H.; Chu, C.-M.; Chan, E.-S.; Ravindra, P. Studies on design of heterogeneous catalysts for biodiesel production. Process Saf. Environ. Prot. 2013, 91, 131–144. [Google Scholar] [CrossRef]

- Yusuff, A.S.; Adeniyi, O.D.; Olutoye, M.A.; Akpan, U.G. A Review on Application of Heterogeneous Catalyst in the Production of Biodiesel from Vegetable Oils. J. Appl. Sci. Process Eng. 2017, 4, 142–157. [Google Scholar] [CrossRef]

- Boz, N.; Degirmenbasi, N.; Kalyon, D.M. Esterification and transesterification of waste cooking oil over Amberlyst 15 and modified Amberlyst 15 catalysts. Appl. Catal. B Environ. 2015, 165, 723–730. [Google Scholar] [CrossRef]

- Talukder, M.M.R.; Wu, J.C.; Lau, S.K.; Cui, L.C.; Shimin, G.; Lim, A. Comparison of Novozym 435 and Amberlyst 15 as Heterogeneous Catalyst for Production of Biodiesel from Palm Fatty Acid Distillate. Energy Fuels 2009, 23, 1–4. [Google Scholar] [CrossRef]

- Schultz, A.K.; Hanlon, R.T.; Banavali, R. Heterogeneous Catalyst and Process for Production of Biodiesel; Dow Chemical: Spring House, PA, USA, 2011. [Google Scholar]

- Park, J.-Y.; Kim, D.-K.; Lee, J.-S. Esterification of free fatty acids using water-tolerable Amberlyst as a heterogeneous catalyst. Bioresour. Technol. 2010, 101, S62–S65. [Google Scholar] [CrossRef]

- Biodiesel Magazine. The Latest News and Data about Biodiesel Production. Available online: http://www.biodieselmagazine.com/articles/3193/rohm-and-haas-releases-new-technology (accessed on 2 July 2020).

- Keskin, A.; Yaşar, A.; Gürü, M.; Altıparmak, D. Usage of methyl ester of tall oil fatty acids and resinic acids as alternative diesel fuel. Energy Convers. Manag. 2010, 51, 2863–2868. [Google Scholar] [CrossRef]

- Keskin, A.; Gürü, M.; Altıparmak, D. Influence of tall oil biodiesel with Mg and Mo based fuel additives on diesel engine performance and emission. Bioresour. Technol. 2008, 99, 6434–6438. [Google Scholar] [CrossRef] [PubMed]

- Hosseinpourpia, R.; Adamopoulos, S.; Parsland, C. Utilization of different tall oils for improving the water resistance of cellulosic fibers. J. Appl. Polym. Sci. 2019, 136, 47303. [Google Scholar] [CrossRef]

- Silverstein, R.M.; Webster, F.X.; Kiemle, D.; Bryce, D.L. Spectrometric Identification of Organic Compounds, 8th ed.; Wiley: Hoboken, NJ, USA, 2014; Available online: https://www.wiley.com/en-us/Spectrometric+Identification+of+Organic+Compounds%2C+8th+Edition-p-9780470616376 (accessed on 6 January 2021).

- Yadav, L.D.S. Organic Spectroscopy; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

- Zhou, J.; Xiong, Y.; Gong, Y.; Liu, X. Analysis of the oxidative degradation of biodiesel blends using FTIR, UV–Vis, TGA and TD-DES methods. Fuel 2017, 202, 23–28. [Google Scholar] [CrossRef]

- Mahamuni, N.N.; Adewuyi, Y.G. Fourier Transform Infrared Spectroscopy (FTIR) Method to Monitor Soy Biodiesel and Soybean Oil in Transesterification Reactions, Petrodiesel−Biodiesel Blends, and Blend Adulteration with Soy Oil. Energy Fuels 2009, 23, 3773–3782. [Google Scholar] [CrossRef]

- Praptijanto, A.; Sebayang, D.; Agustian, E.; Untoro, P. Rapid monitoring of fatty acid methyl ester in sonochemistry transesterification process using attenuated total reflection. In Proceedings of the International Conference on Environment (ICENV2010), Penang, Malaysia, 13–15 December 2010. [Google Scholar]

- Dymińska, L.; Calik, M.; Albegar, A.M.M.; Zając, A.; Kostyń, K.; Lorenc, J.; Hanuza, J. Quantitative determination of the iodine values of unsaturated plant oils using infrared and Raman spectroscopy methods. Int. J. Food Prop. 2017, 20, 2003–2015. [Google Scholar] [CrossRef]

- López, D.E.; Goodwin, J.G.; Bruce, D.A.; Lotero, E. Transesterification of triacetin with methanol on solid acid and base catalysts. Appl. Catal. A Gen. 2005, 295, 97–105. [Google Scholar] [CrossRef]

- Talebian-Kiakalaieh, A.; Aishah, N.; Saidina Amin, N.A.; Zarei, A.; Noshadi, I. Transesterification of waste cooking oil by heteropoly acid (HPA) catalyst: Optimization and kinetic model. Appl. Energy 2012. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).