New Approach for Detecting Variability in Industrial Assembly Line Balancing Based on Multi-Criteria Analysis

Abstract

1. Introduction

- A generalizable approach for detecting, upstream, the critical parameters with high variability that cause imbalances, regardless of how the problem is formulated (SALBP-1, SALBP-2, SALBP-E, etc.);

- A multi-criteria analysis of appropriate statistical methods, including standard deviation, coefficient of variation, and significance tests, to select the most appropriate method for each parameter; this approach makes it possible to more effectively detect highly variable variables that impact production line balancing;

- A pragmatic illustration using the case study of automotive pre-assembly, demonstrating the measurable impact of the methodology (an average efficiency gain of 12% and a significant reduction in bottlenecks) and highlighting the potential for transferring it to other types of assembly lines under conditions of uncertainty.

2. Related Work

2.1. Variability in Assembly Line Balancing

2.1.1. Simulation Approaches and Industry 4.0

2.1.2. Traditional and Deterministic Approaches

2.1.3. Robust and Stochastic Approaches

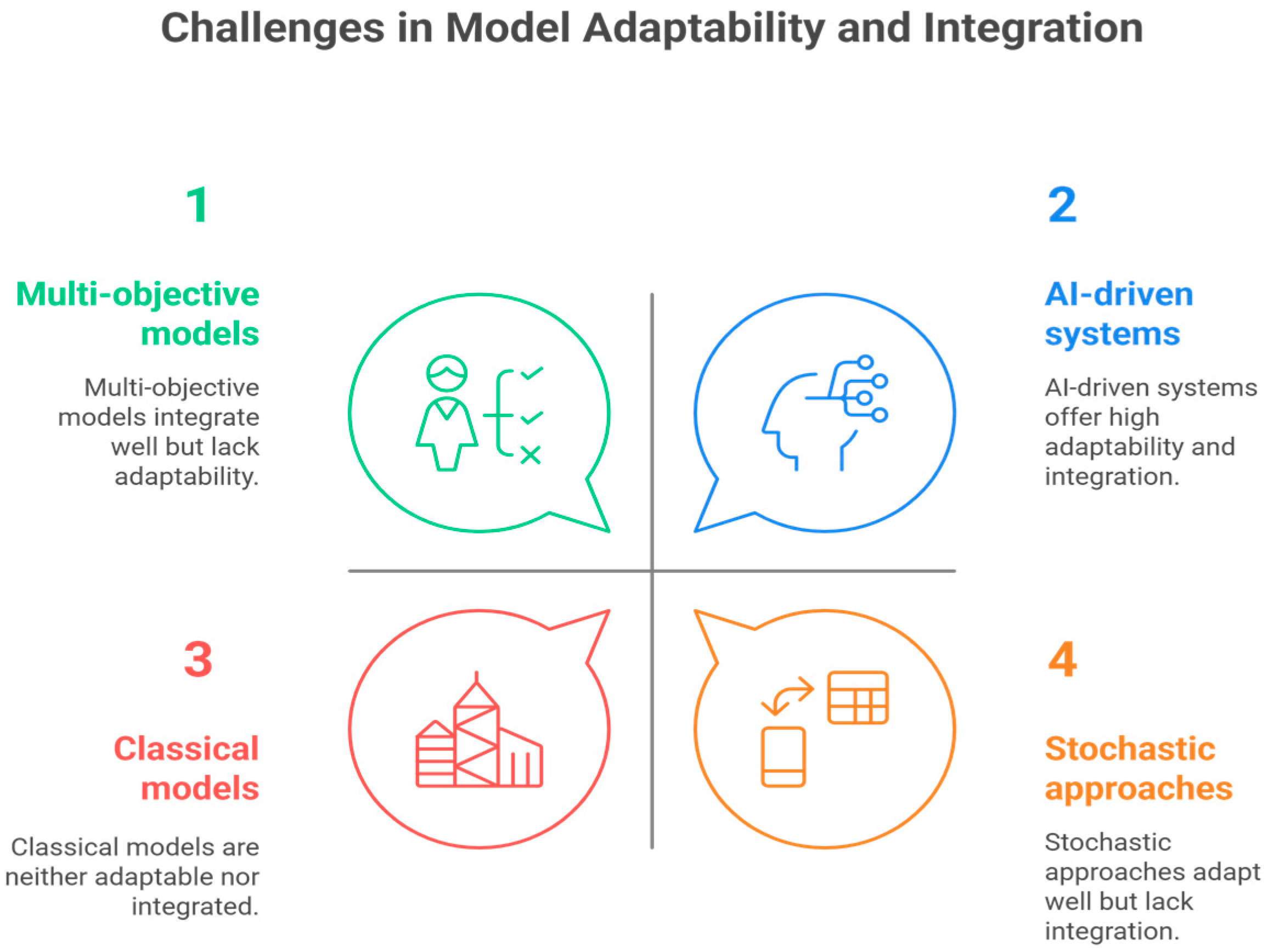

2.1.4. Flexibility, Adaptability, and Artificial Intelligence

2.1.5. Fuzzy Methods Applied to Assembly Line Balancing

2.2. Limitations of Existing Methods

- It uses a 3D structure to pinpoint the sources of variability in industrial process parameters.

- It combines several relevant criteria (noise sensitivity, data requirements, calculation speed, etc.) to select the most effective statistical methods in a given context.

- It provides a systematic process for prioritizing and detecting critical parameters that impact balance, where previous approaches often remained global or empirical.

- Ultimately, it improves the sensitivity of balancing to real variations and facilitates the dynamic adaptation of workstations. In this respect, our method brings real scientific added value by filling the gaps identified in the current literature and paving the way for more robust and flexible industrial applications.

3. Preliminary

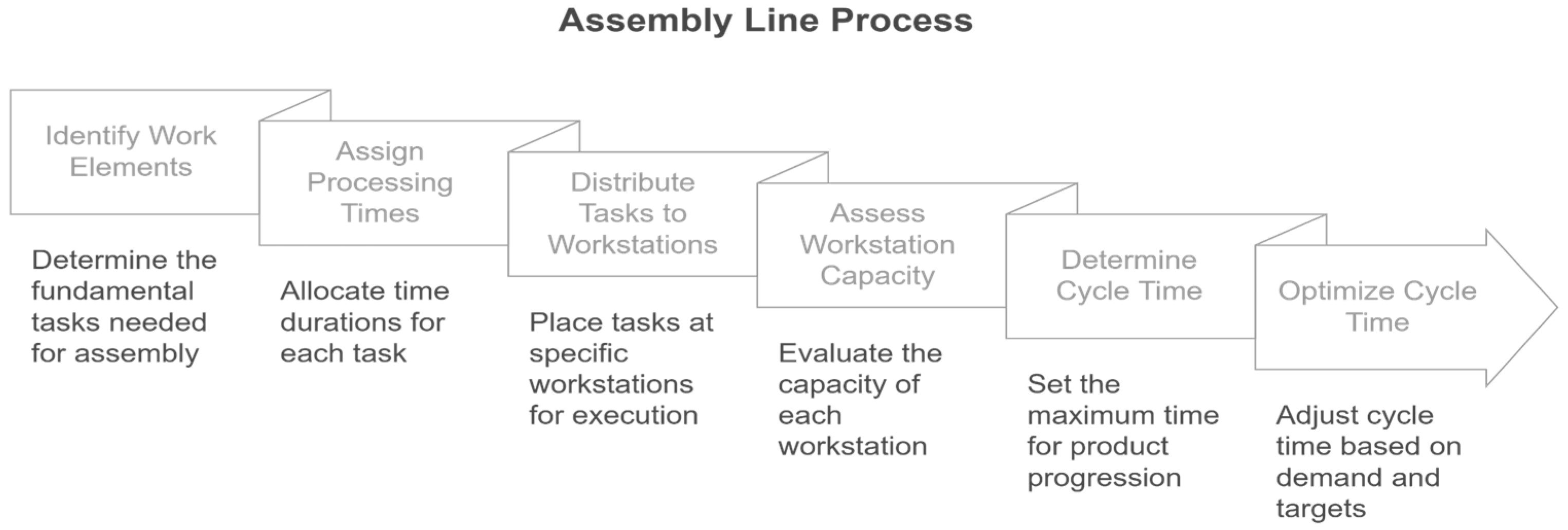

3.1. Assembly Line Balancing Problem

- Minimize the number of workstations required.

- Balance the workload as evenly as possible among the workstations.

- Ensure that the cycle time is not exceeded.

- Minimize production costs while meeting constraints.

3.2. Statistical Methods in Production Line

- Quality improvement: Statistical Process Control (SPC) is one of the statistical methods used to monitor and control product quality. This involves the use of control charts to monitor key quality indicators in real time, enabling any deviation from desired standards to be identified immediately.

- Process optimization: Statistical methods using the Design of Experiments (DOE) approach to help identify key process parameters. Manufacturers can determine optimal settings that lead to higher yields, reduced resource costs, and minimized cycle times by dynamically adjusting and monitoring these parameters.

- Informed decision-making: Statistical data and analysis provides decision-makers with quantitative evidence to support their choices. Managers and engineers can make data-driven decisions to address production challenges, allocate resources effectively, and prioritize improvement projects based on a thorough understanding of the underlying factors.

- Continuous improvement: The concept is central to many production management methodologies, such as Lean and Six Sigma. Statistical methods, including root cause analysis, hypothesis testing, and process capability studies, help to identify the root causes of problems and develop solutions to prevent their recurrence. This results in ongoing enhancements to production processes.

- Compliance with standards: Statistical methods ensure that production processes adhere to quality and safety standards by maintaining meticulous records of processes and product characteristics. Organizations can demonstrate compliance with regulations and industry standards, which is particularly critical in highly regulated industries like pharmaceuticals and aerospace.

- Innovation and product development: Statistical methods are used during the research and development of the specifications of new products. They assist in assessing the performance and characteristics of prototypes and experimental designs. By quantifying the impact of various design variables, companies can develop innovative products that meet or exceed customer expectations.

3.3. Multi-Criteria Analysis of Statistical Methods

4. Methodology

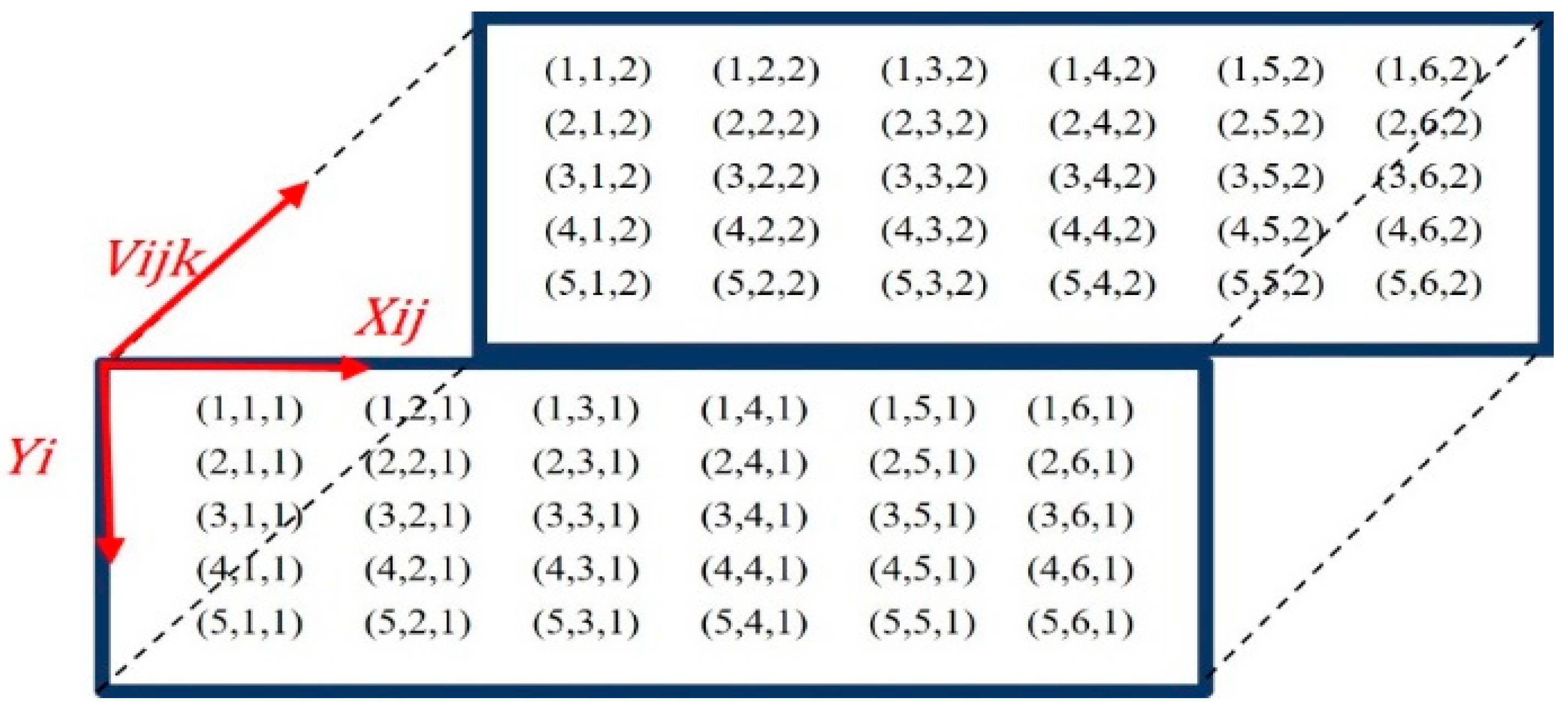

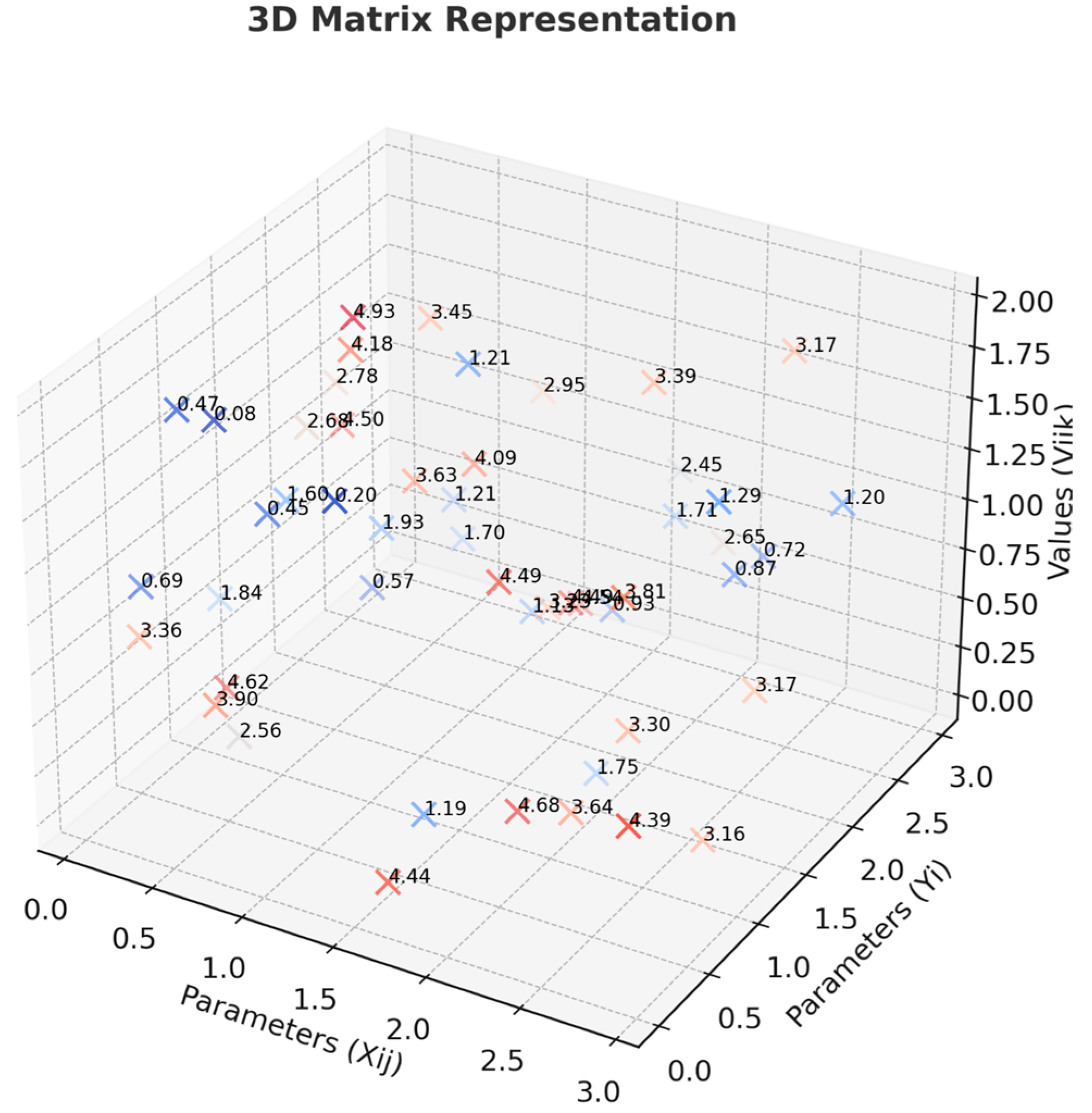

4.1. Matrix Representation

- ❖

- Define the dimensions:

- Let I be the number of root parameters Yi.

- Let Ji be the number of sub-parameters Xij for each Yi.

- Let Kij be the number of possible values Vijk for each sub-parameter Xij.

- ❖

- Parameter descriptions:

- Yi: These are the fundamental elements or factors that influence the overall variability in assembly line balancing, represented by Y.

- Xij: These are sub-parameters or specific aspects that make up each root parameter Yi.

- Vijk: These represent the possible values that can take each sub-parameter Xij.

- ❖

- Matrix representation:

- Root rarameters (Yi):

- Y = {Y1, Y2 …, YI} are the main factors affecting the assembly line balancing.

- Sub-parameters (Xij):

- Each Yi consists of several sub-parameters Xij, where Yi = {Xi1, Xi2 …, XiJi}.

- Possible values (Vijk):

- Each Xij has multiple possible values Vijk, where Xij = {Vij1, Vij2 …, VijKij}.

- ❖

- The 3D matrix A:The 3D matrix A is constructed as follows:

- For each i (corresponding to each Yi);

- For each j (corresponding to each Xij);

- For each k (corresponding to each Vijk);

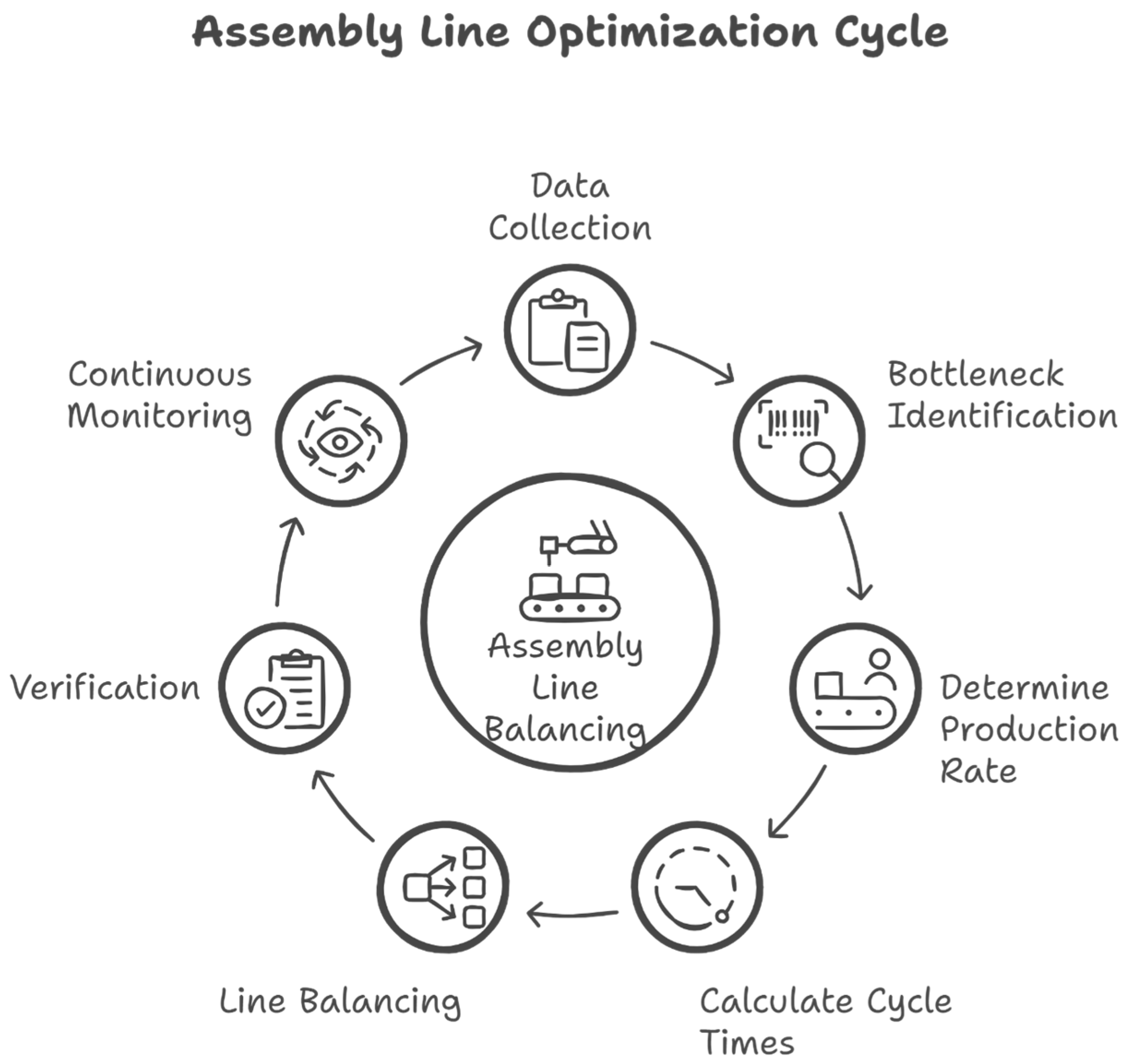

4.2. Procedure for Detecting Highly Variable Parameters Impacting Balancing

5. Case Study

5.1. Balancing the Assembly Line

- Yb: balancing efficiency indicator;

- Twc: work content time;

- m: number of workstations;

- Ts: the duration of the slowest station.

5.2. Matrix Representation

- X11: Cadence: Number of conforming bundles made per time;

- X12: Range time: Fixed index which expresses the duration of a cycle of assembly until the final control;

- X13: Staff: number of staff present;

- X14: Working hours.

- X21: Shift time bottleneck;

- X22: Shift time.

- X31: Production time;

- X32: Daily demand.

- X41: Routing time;

- X42: LAD frequency (product rotation frequency).

5.3. Statistical Methods Application

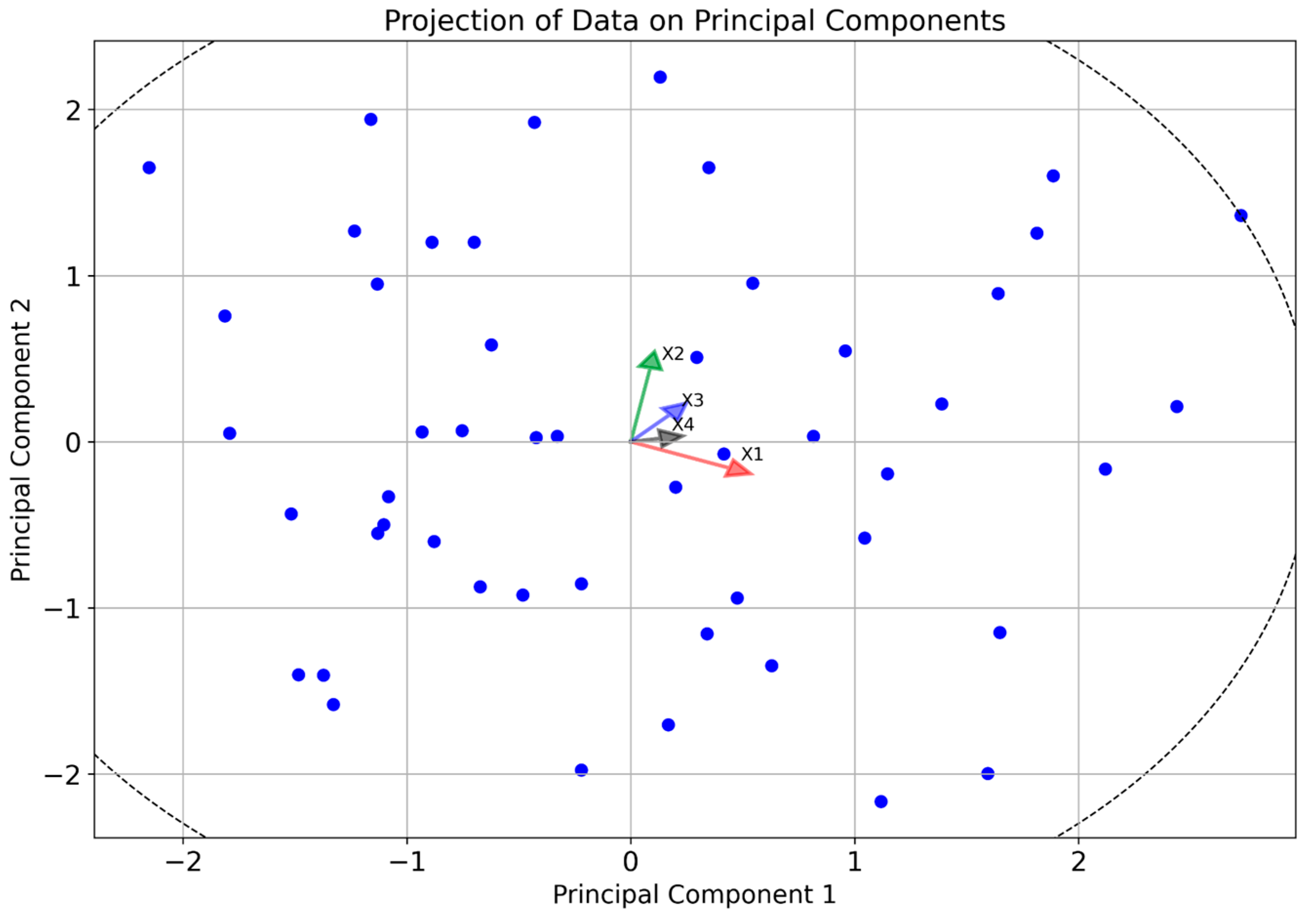

5.3.1. Principal Component Analysis Application

- Mathematical Model of PCA

- ❖

- Standardization:

- ❖

- Covariance matrix computation:

- ❖

- Eigenvalues and eigenvectors:

- ❖

- Principal components:

- ❖

- Projection onto principal components:

- The horizontal axis represents the first principal component (PC1), which explains the maximum variance in the data.

- The vertical axis represents the second principal component (PC2), which explains the second largest amount of variance, independently of PC1.

- The direction and length of each vector indicates how each factor is correlated with the principal components.

- For example, vector Y1 is strongly correlated with PC1, while Y2 has a significant component on PC2.

- Y1: 66.5732%;

- Y2: 32.9541%;

- Y3: 0.47268%;

- Y4: .

- X11: 99.9912%;

- X12: 0.0087739%;

- X13: 0%;

- X14: 0%.

5.3.2. Correlation Study Application

- X = is a parameter that can take many values.

- = is the average of the values of the parameter X.

- Y = is a second parameter that can take many values.

- = is the average of the values of a second parameter Y.

- r = +1 means positive correlation.

- r = 0 means absence of correlation.

- r = −1 means negative correlation.

- The link type between X12 and X11 (−0.59) shows that as task duration (X12) increases, production cadence (X11) decreases.

- The inverse correlation between Y2 and X12 (−0.54) suggests that longer task durations negatively impact efficiency metrics related to the workforce or process speed.

- The parameters X22 and X31 expose a near-perfect correlation (~1.00), meaning that changes in shift-related factors (X22) directly impact production cycle time (X31).

- Similarly, X31 and X32 show a correlation of 1.00, reinforcing the idea that the Takt time and production cycle are intrinsically linked.

- The efficiency-related factor Y4 is strongly correlated with X31 and X32 (0.96 each). This suggests that production time and demand fluctuations directly impact overall efficiency.

- Some variables exhibit weak or negligible correlations (e.g., Y1 and X14 (0.38), or Y1 and X41 (0.10)). This indicates that factors such as material routing or secondary task dependencies have minimal direct influence on overall assembly line efficiency.

- However, their indirect effects should not be overlooked, as they may play a role in localized inefficiencies.

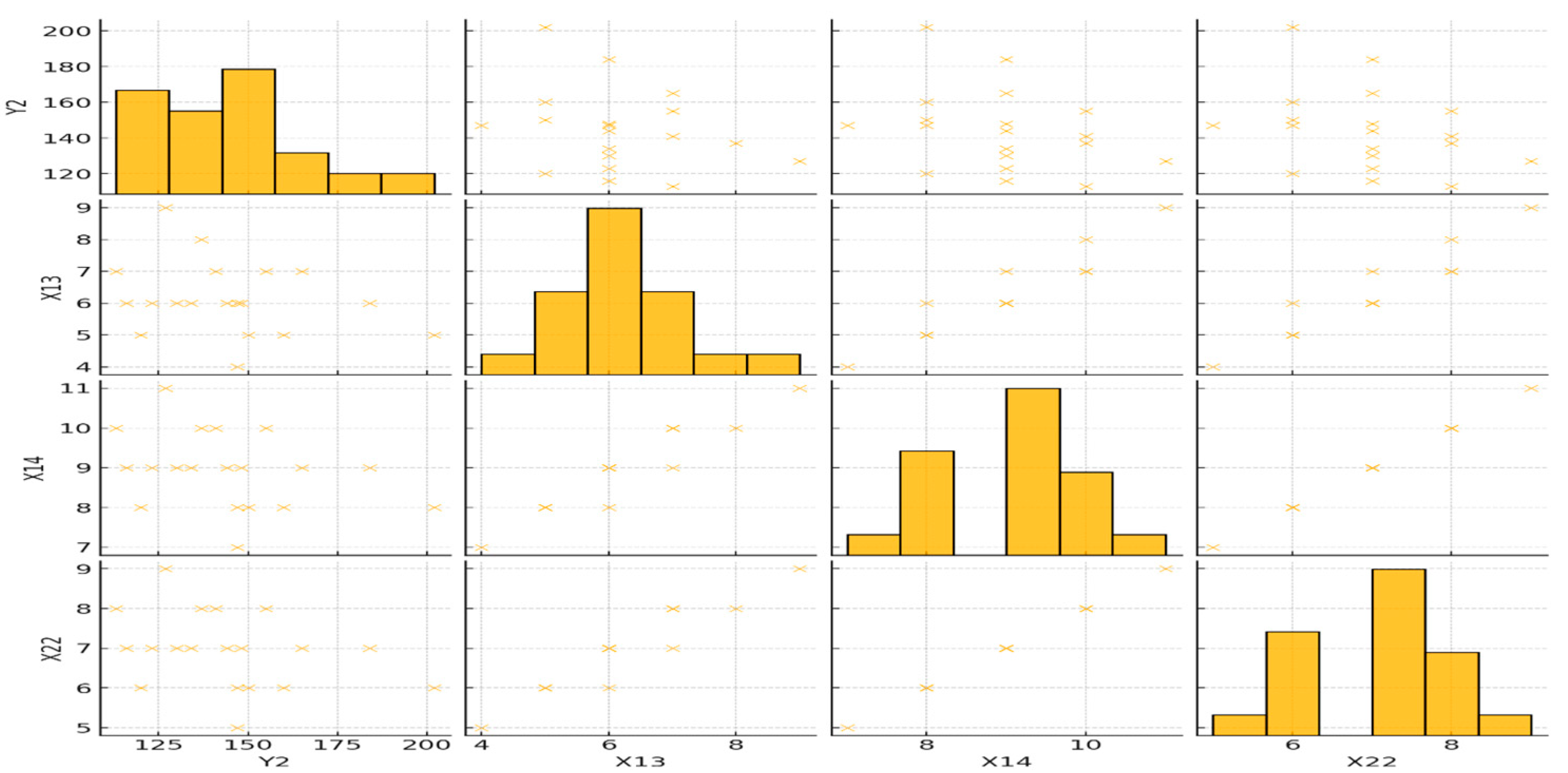

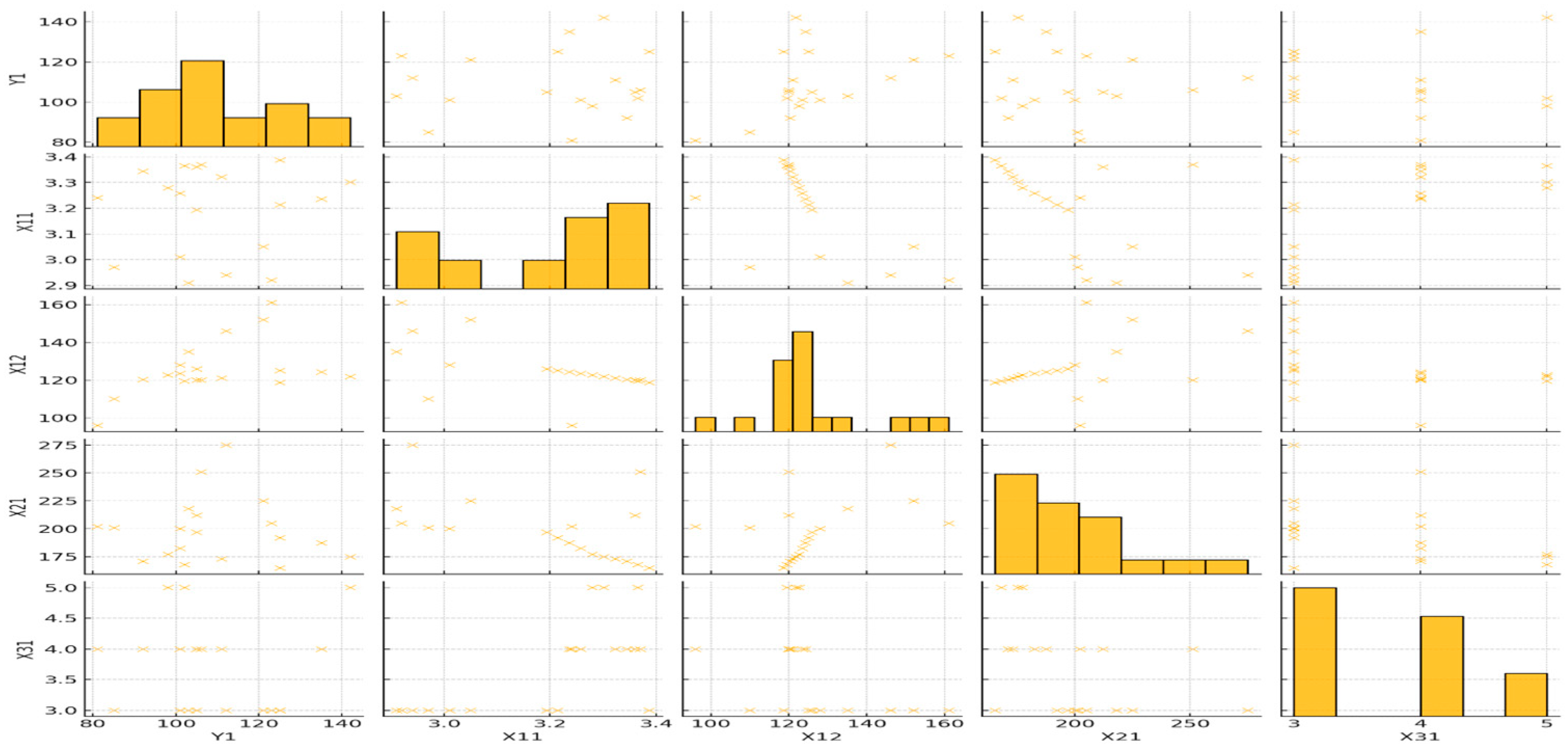

5.3.3. Graphical Representation Application

- Some parameters (X42 and X22) show highly structured distributions, indicating controlled operational constraints.

- Others (X41 and X14) exhibit wider distributions, suggesting greater variability in their impact.

- X31 and Y2 show a strong relationship, meaning that Takt time plays a critical role in production efficiency.

- X13 correlates with Y2, suggesting that operator productivity affects manufacturing time.

- Workforce efficiency and Takt time adjustments should be prioritized for process improvement.

- Product-related parameters (X41) should be further analyzed for potential standardization or optimization.

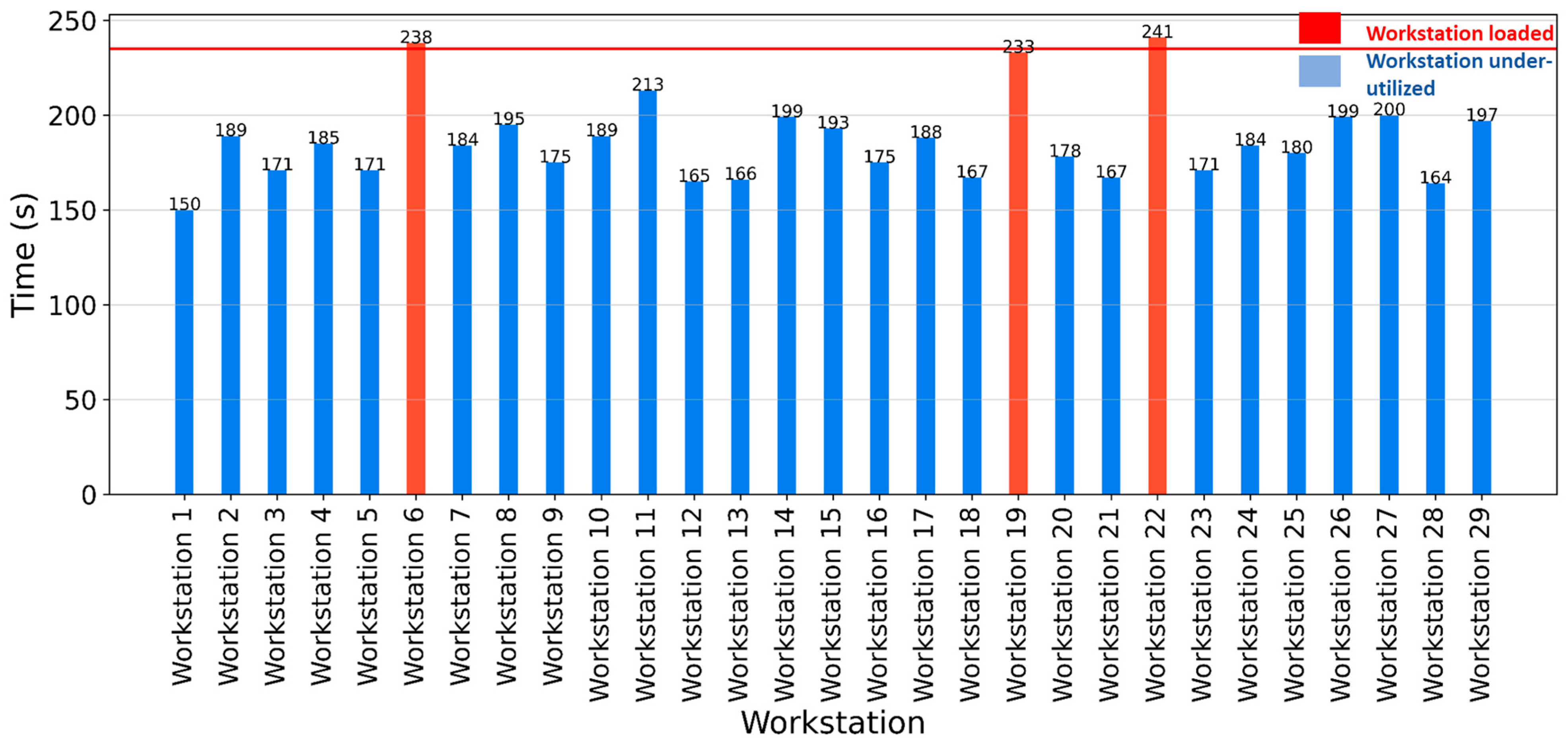

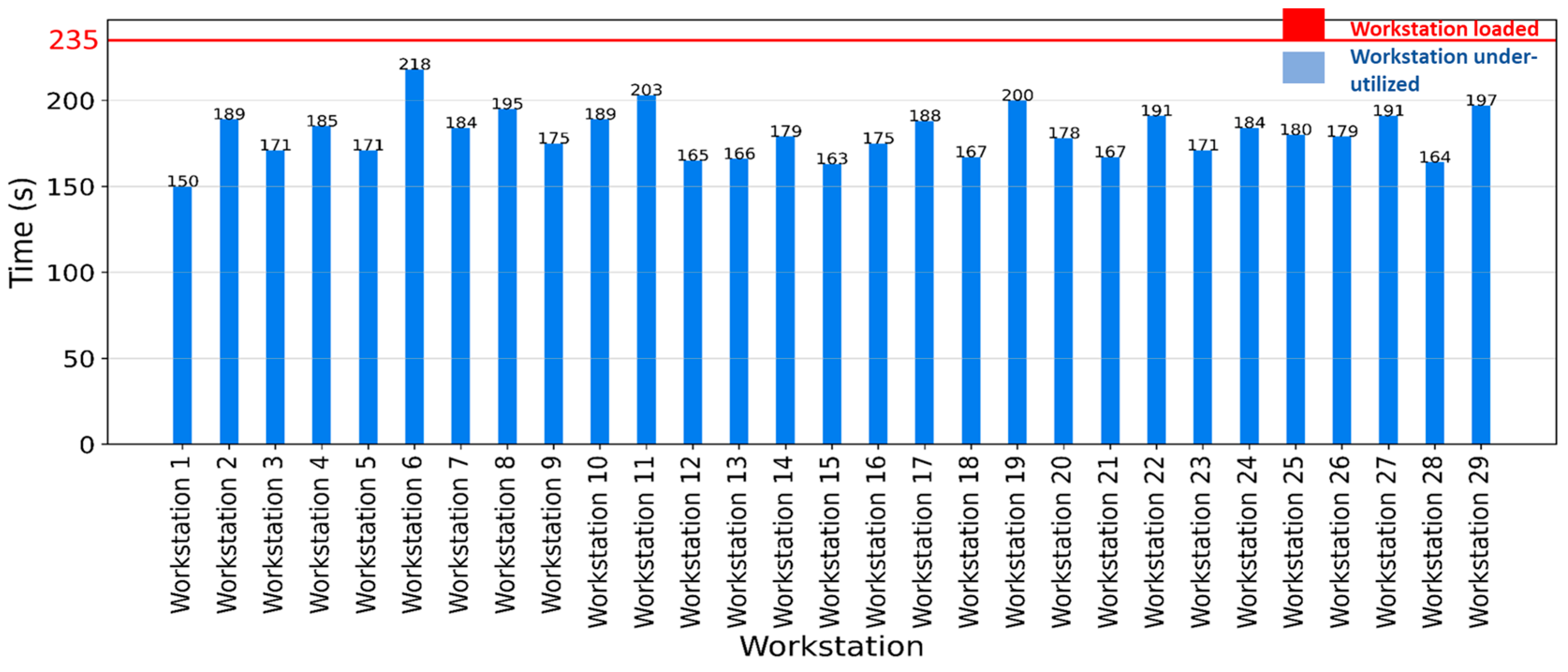

6. Results and Discussion

6.1. Results of Our Approach

6.1.1. Graphical Representation Interpretation

6.1.2. Correlation Study Interpretation

6.1.3. Principal Component Analysis Interpretation

6.2. Discussion

- Method A—reference: balancing based on mean task times alone, without taking into account dispersion or correlations between factors;

- Method B—proposed: multi-criteria variability analysis simultaneously integrating the standard deviation, coefficient of variation, and relative weight of each parameter on the overall balancing indicator Y.

- Identifies all five variables actually responsible for fluctuations, whereas the reference method reveals only two;

- Reduces disturbance-induced efficiency loss by over 12% (84% vs. 75%);

- Almost triples the number of persistent bottlenecks and halves job under-employment, reflecting better load distribution.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviation

| ALB | Assembly line balancing |

| ALBP | Assembly line balancing problem |

| SALBP | Simple assembly line balancing problem |

| GALBP | General assembly line balancing problem |

| PCA | Principal component analysis |

References

- Ren, W.; Wen, J.; Guan, Y.; Hu, Y. Research on Assembly Module Partition for Flexible Production in Mass Customization. Procedia CIRP 2018, 72, 744–749. [Google Scholar] [CrossRef]

- Tsutsui, S.; Kaihara, T.; Kokuryo, D.; Fujii, N.; Harano, K. A Proposal of Production Scheduling Method with Dynamic Parts Allocation for Mass Customization. Procedia CIRP 2022, 107, 882–887. [Google Scholar] [CrossRef]

- Bastos, N.M.; Alves, A.C.; Castro, F.X.; Duarte, J.; Ferreira, L.P.; Silva, F.J.G. Reconfiguration of Assembly Lines Using Lean Thinking in an Electronics Components’ Manufacturer for the Automotive Industry. Procedia Manuf. 2021, 55, 383–392. [Google Scholar] [CrossRef]

- Salveson, M.E. The Assembly-Line Balancing Problem. J. Fluids Eng. 1955, 77, 939–947. [Google Scholar] [CrossRef]

- Espinoza Pérez, A.T.; Rossit, D.A.; Tohmé, F.; Vásquez, Ó.C. Mass Customized/Personalized Manufacturing in Industry 4.0 and Blockchain: Research Challenges, Main Problems, and the Design of an Information Architecture. Inf. Fusion 2022, 79, 44–57. [Google Scholar] [CrossRef]

- Battaïa, O.; Otto, A.; Sgarbossa, F.; Pesch, E. Future Trends in Management and Operation of Assembly Systems: From Customized Assembly Systems to Cyber-Physical Systems. Omega 2018, 78, 1–4. [Google Scholar] [CrossRef]

- Li, Z.; Janardhanan, M.N.; Rahman, H.F. Enhanced Beam Search Heuristic for U-Shaped Assembly Line Balancing Problems. Eng. Optim. 2021, 53, 594–608. [Google Scholar] [CrossRef]

- Troise, C.; Corvello, V.; Ghobadian, A.; O’Regan, N. How Can SMEs Successfully Navigate VUCA Environment: The Role of Agility in the Digital Transformation Era. Technol. Forecast. Soc. Change 2022, 174, 121227. [Google Scholar] [CrossRef]

- Zhang, W.; Hou, L.; Jiao, R.J. Dynamic Takt Time Decisions for Paced Assembly Lines Balancing and Sequencing Considering Highly Mixed-Model Production: An Improved Artificial Bee Colony Optimization Approach. Comput. Ind. Eng. 2021, 161, 107616. [Google Scholar] [CrossRef]

- Gilles, M.A.; Gaudez, C.; Savin, J.; Remy, A.; Remy, O.; Wild, P. Do Age and Work Pace Affect Variability When Performing a Repetitive Light Assembly Task? Appl. Ergon. 2022, 98, 103601. [Google Scholar] [CrossRef]

- Gräßler, I.; Roesmann, D.; Cappello, C.; Steffen, E. Skill-Based Worker Assignment in a Manual Assembly Line. Procedia CIRP 2021, 100, 433–438. [Google Scholar] [CrossRef]

- Karas, A.; Ozcelik, F. Assembly Line Worker Assignment and Rebalancing Problem: A Mathematical Model and an Artificial Bee Colony Algorithm. Comput. Ind. Eng. 2021, 156, 107195. [Google Scholar] [CrossRef]

- Khan, S.H.; Majid, A.; Yasir, M. Strategic Renewal of SMEs: The Impact of Social Capital, Strategic Agility and Absorptive Capacity. Manag. Decis. 2020, 59, 1877–1894. [Google Scholar] [CrossRef]

- Andrés-López, E.; González-Requena, I.; Sanz-Lobera, A. Lean Service: Reassessment of Lean Manufacturing for Service Activities. Procedia Eng. 2015, 132, 23–30. [Google Scholar] [CrossRef]

- Nallusamy, S. Execution of Lean and Industrial Techniques for Productivity Enhancement in a Manufacturing Industry. Mater. Today Proc. 2020, 37, 568–575. [Google Scholar] [CrossRef]

- Çelik, M.T.; Arslankaya, S. Solution of the Assembly Line Balancing Problem Using the Rank Positional Weight Method and Kilbridge and Wester Heuristics Method: An Application in the Cable Industry. J. Eng. Res. 2023, 11, 100082. [Google Scholar] [CrossRef]

- Moncayo-Martínez, L.A.; Arias-Nava, E.H. Assessing by Simulation the Effect of Process Variability in the SALB-1 Problem. AppliedMath 2023, 3, 563–581. [Google Scholar] [CrossRef]

- Ragazzini, L.; Saporiti, N.; Negri, E.; Rossi, T.; Macchi, M.; Pirovano, G. A Digital Twin-Based Approach to the Real-Time Assembly Line Balancing Problem. In Proceedings of the 2nd International Conference on Innovative Intelligent Industrial Production and Logistics, Valletta, Malta, 25–27 October 2021; SCITEPRESS-Science and Technology Publications: Lisbon, Portugal, 2021; pp. 93–99. [Google Scholar]

- Hazır, Ö.; Dolgui, A. (PDF) A Review on Robust Assembly Line Balancing Approaches. IFAC-PapersOnLine 2019, 52, 987–991. [Google Scholar] [CrossRef]

- Nikkerdar, M. Smart Adaptable Assembly Line Rebalancing. Ph.D. Thesis, University of Windsor, Windsor, ON, Canada, 2025. [Google Scholar]

- Fisel, J.; Exner, Y.; Stricker, N.; Lanza, G. Changeability and Flexibility of Assembly Line Balancing as a Multi-Objective Optimization Problem. J. Manuf. Syst. 2019, 53, 150–158. [Google Scholar] [CrossRef]

- Zacharia, P.T.; Nearchou, A.C. The Fuzzy Assembly Line Worker Assignment and Balancing Problem. Cybern. Syst. 2020, 52, 221–243. [Google Scholar] [CrossRef]

- Kumar, N.; Mahto, D. Assembly Line Balancing: A Review of Developments andTrends in Approach to Industrial Application. Glob. J. Res. Eng. Ind. Eng. 2013, 13, 29–50. [Google Scholar]

- Sarwar, F. Multi-Objective Assembly Line Balancing Problem under Uncertainty Using Genetic Algorithm. Int. J. Serv. Oper. Manag. 2019, 34, 33–47. [Google Scholar] [CrossRef]

- Alavidoost, M.H.; Tarimoradi, M.; Zarandi, M.H.F. Fuzzy Adaptive Genetic Algorithm for Multi-Objective Assembly Line Balancing Problems. Appl. Soft Comput. 2015, 34, 655–677. [Google Scholar] [CrossRef]

- Zacharia, P.; Nearchou, A.C. The Robotic Assembly Line Balancing Problem under Task Time Uncertainty. Int. J. Adv. Manuf. Technol. 2025, 137, 2991–3011. [Google Scholar] [CrossRef]

- Kucukkoc, I.; Zhang, D.Z. A Mathematical Model and Genetic Algorithm-Based Approach for Parallel Two-Sided Assembly Line Balancing Problem. Prod. Plan. Control 2015, 26, 874–894. [Google Scholar] [CrossRef]

- Wu, Y. An Automated Method for Assembly Tolerance Analysis. Procedia CIRP 2020, 92, 57–62. [Google Scholar] [CrossRef]

- Boysen, N.; Schulze, P.; Scholl, A. Assembly Line Balancing: What Happened in the Last Fifteen Years? Eur. J. Oper. Res. 2022, 301, 797–814. [Google Scholar] [CrossRef]

- Hahs-Vaughn, D.L. Foundational Methods: Descriptive Statistics: Bivariate and Multivariate Data (Correlations, Associations). In International Encyclopedia of Education, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 734–750. [Google Scholar] [CrossRef]

- Jia, G.; Zhang, Y.; Shen, S.; Liu, B.; Hu, X.; Wu, C. Load Balancing of Two-Sided Assembly Line Based on Deep Reinforcement Learning. Appl. Sci. 2023, 13, 7439. [Google Scholar] [CrossRef]

- Bottani, E.; Montanari, R.; Volpi, A.; Tebaldi, L. Statistical Process Control of Assembly Lines in Manufacturing. J. Ind. Inf. Integr. 2023, 32, 100435. [Google Scholar] [CrossRef]

- Chen, H.; Li, X.; Jin, S. A Statistical Method of Distinguishing and Quantifying Tolerances in Assemblies. Comput. Ind. Eng. 2021, 156, 107259. [Google Scholar] [CrossRef]

- Tian, A.; Shu, X.; Guo, J.; Li, H.; Ye, R.; Ren, P. Statistical Modeling and Dependence Analysis for Tide Level via Multivariate Extreme Value Distribution Method. Ocean Eng. 2023, 286, 115616. [Google Scholar] [CrossRef]

- Bortolini, M.; Ferrari, E.; Gamberi, M.; Pilati, F.; Faccio, M. Assembly System Design in the Industry 4.0 Era: A General Framework. IFAC-PapersOnLine 2017, 50, 5700–5705. [Google Scholar] [CrossRef]

- Li, X.; Athinarayanan, R.; Wang, B.; Yuan, W.; Zhou, Q.; Jun, M.; Bravo, J.; Gao, R.X.; Wang, L.; Koren, Y. Smart Reconfigurable Manufacturing: Literature Analysis. Procedia CIRP 2024, 121, 43–48. [Google Scholar] [CrossRef]

- Keshvarparast, A.; Katiraee, N.; Pirayesh, A.; Battaia, O.; Berti, N. Integrated Resource Optimization in a Multi-Product Separated Line Collaborative Assembly Line Balancing Problem (MPSLC-ALBP). IFAC-PapersOnLine 2023, 56, 713–718. [Google Scholar] [CrossRef]

- Jaskó, S.; Skrop, A.; Holczinger, T.; Chován, T.; Abonyi, J. Development of Manufacturing Execution Systems in Accordance with Industry 4.0 Requirements: A Review of Standard- and Ontology-Based Methodologies and Tools. Comput. Ind. 2020, 123, 103300. [Google Scholar] [CrossRef]

- Pilati, F.; Lelli, G.; Faccio, M.; Gamberi, M.; Regattieri, A. Assembly Line Balancing for Personalized Production. IFAC-PapersOnLine 2020, 53, 10261–10266. [Google Scholar] [CrossRef]

- Hillali, Y.; Chafik, S.; Alfathi, N.; Zegrari, M. Variability and Correlation of Parameters for Dynamic Balancing of an Assembly Line Based on a Statistic Method. In Proceedings of the 2023 14th International Conference on Intelligent Systems: Theories and Applications (SITA), Mohammedia, Morocco, 22–23 November 2023; pp. 1–6. [Google Scholar]

- Hillali, Y.; Zegrari, M.; Alfathi, N.; Chafik, S.; Tabaa, M. Statistical Method Using Principal Component Analysis to Determine High Variability Parameters Affecting the Balancing of an Assembly Line. Math. Model. Comput. 2024, 11, 663–673. [Google Scholar] [CrossRef]

- Li, M.-L. An Algorithm for Arranging Operators to Balance Assembly Lines and Reduce Operator Training Time. Appl. Sci. 2021, 11, 8544. [Google Scholar] [CrossRef]

- GN, M.B. Application of Lean Line Concepts to Improve Efficiency of PE Pump Assembly Lines. Int. J. Eng. Res. 2014, 3, 1–7. [Google Scholar]

- Cuik Chapter 6 Assembly Systems And Line Balancing. Available online: https://rekadayaupaya.wordpress.com/category/computer-integrated-manufacturing/part-ii/chapter-6-assembly-systems-and-line-balancing/ (accessed on 1 July 2025).

- Hillali, Y.; Zegrari, M.; Alfathi, N.; Chafik, S. Balancing Assembly Line Based on Lean Management Tools. In Proceedings of the Smart Applications and Data Analysis, Tangier, Morocco, 18–20 April 2024; Hamlich, M., Dornaika, F., Ordonez, C., Bellatreche, L., Moutachaouik, H., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 131–144. [Google Scholar]

- Buyukozkan, K.; Kucukkoc, I.; Satoglu, S.I.; Zhang, D.Z. Lexicographic Bottleneck Mixed-Model Assembly Line Balancing Problem: Artificial Bee Colony and Tabu Search Approaches with Optimised Parameters. Expert Syst. Appl. 2016, 50, 151–166. [Google Scholar] [CrossRef]

- Zamzam, N.; El-Kharbotly, A.K. Balancing Two-Sided Multi-Manned Assembly Line under Time and Space Constraint. Ain Shams Eng. J. 2023, 15, 102464. [Google Scholar] [CrossRef]

- Fortuny-Santos, J.; Ruiz-de-Arbulo-López, P.; Cuatrecasas-Arbós, L.; Fortuny-Profitós, J. Balancing Workload and Workforce Capacity in Lean Management: Application to Multi-Model Assembly Lines. Appl. Sci. 2020, 10, 8829. [Google Scholar] [CrossRef]

- Özcan, U.; Aydoğan, E.K.; Himmetoğlu, S.; Delice, Y. Parallel Assembly Lines Worker Assignment and Balancing Problem: A Mathematical Model and an Artificial Bee Colony Algorithm. Appl. Soft Comput. 2022, 130, 109727. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, Y.; Wang, X.V.; Zhong, R.Y.; Zhang, Y.; Tao, F. Data-Driven Smart Production Line and Its Common Factors. Int. J. Adv. Manuf. Technol. 2019, 103, 1211–1223. [Google Scholar] [CrossRef]

- Huo, J.; Chan, F.T.S.; Lee, C.K.M.; Strandhagen, J.O.; Niu, B. Smart Control of the Assembly Process with a Fuzzy Control System in the Context of Industry 4.0. Adv. Eng. Inform. 2020, 43, 101031. [Google Scholar] [CrossRef]

- Furugi, A. Sequence-Dependent Time- and Cost-Oriented Assembly Line Balancing Problems: A Combinatorial Benders’ Decomposition Approach. Eng. Optim. 2022, 54, 170–184. [Google Scholar] [CrossRef]

- Kuo, Y.; Chen, S.-H.; Yang, T.; Hsu, W.-C. Optimizing a U-Shaped Conveyor Assembly Line Balancing Problem Considering Walking Times between Assembly Tasks. Appl. Sci. 2023, 13, 3702. [Google Scholar] [CrossRef]

- Álvarez-Miranda, E.; Pereira, J.; Vilà, M. Analysis of the Simple Assembly Line Balancing Problem Complexity. Comput. Oper. Res. 2023, 159, 106323. [Google Scholar] [CrossRef]

- Wang, J.; Swartz, C.L.E.; Corbett, B.; Huang, K. Supply Chain Monitoring Using Principal Component Analysis. Ind. Eng. Chem. Res. 2020, 59, 12487–12503. [Google Scholar] [CrossRef]

- Schlüter, M.J.; Ostermeier, F.F. Dynamic Line Balancing in Unpaced Mixed-Model Assembly Lines: A Problem Classification. CIRP J. Manuf. Sci. Technol. 2022, 37, 134–142. [Google Scholar] [CrossRef]

- Qiang, Y.; Xie, S.; Li, L.; Xia, H.; Chen, Y. Application of Dimension Reduction Methods on Propeller Performance Prediction Model. Ocean Eng. 2024, 291, 116310. [Google Scholar] [CrossRef]

- Yan, R.; Gao, R.X.; Chen, X. Wavelets for Fault Diagnosis of Rotary Machines: A Review with Applications. Signal Process. 2014, 96, 1–15. [Google Scholar] [CrossRef]

- Lai, X.; Qiu, T.; Shui, H.; Ding, D.; Ni, J. Predicting Future Production System Bottlenecks with a Graph Neural Network Approach. J. Manuf. Syst. 2023, 67, 201–212. [Google Scholar] [CrossRef]

| Statistical Method | Description | Applications |

|---|---|---|

| Linear regression | Models the linear relationship between a dependent variable and one or more independent variables. | Predicting production yields, ensuring quality control, and optimizing resource allocation in manufacturing. |

| Logistic regression | Used to predict a binary outcome (yes/no) based on independent variables. | Identifying defective products, ensuring compliance with quality standards, and minimizing defects in production lines. |

| Analysis of variance (ANOVA) | Compares the means of three or more groups to determine if they are statistically different. | Assessing the impact of process parameters on product quality, optimizing production conditions, and enhancing overall process efficiency. |

| Multiple regression analysis | Extends linear regression to analyze the relationship between a dependent variable and multiple independent variables. | Predicting academic performance based on study time, diet, and sleep, etc. |

| Time-series analysis | Analyzes chronological data to identify trends, seasons, and patterns. | Predicting equipment failures, minimizing downtime, and optimizing maintenance schedules in production lines. |

| PCA | Reduces data dimensionality while preserving maximum variance. | Reducing the dimensionality of production data, facilitating data-driven decision-making, and improving overall process efficiency. |

| Cluster analysis | Groups similar observations into clusters based on similar characteristics. | Optimizing sub-processes within production lines, identifying bottlenecks, and enhancing resource allocation. |

| Artificial neural networks | A deep learning model inspired by the human brain’s functioning. | Process control, fault detection, and the optimization of complex production systems. |

| Survival analysis | Studies the time until a specific event, such as lifespan or time to failure. | Estimating equipment lifespans, optimizing maintenance schedules, and minimizing unplanned downtime. |

| Robust regression analysis | Identifies trends and relationships in data while minimizing the impact of outliers. | Modeling in the presence of noisy data, improving the accuracy of production predictions, and enhancing process robustness. |

| Statistical Method | Complexity | Robustness | Modeling | Flexibility | Applications |

|---|---|---|---|---|---|

| Linear regression | Low | Sensitive to outliers | Suitable for simple linear relationships | Limited | Linear prediction |

| Logistic regression | Moderate | Can handle imbalanced data | Binary variable prediction | Non-linear models possible | Binary classification |

| Analysis of variance (ANOVA) | Moderate | Sensitive to violations of assumptions | Comparison of means | Multiple factors and interactions possible | Multiple group comparisons |

| Multiple regression analysis | Moderate | Sensitive to outliers | Multiple linear models | Can include many independent variables | Prediction with multiple predictors |

| Time-series analysis | Moderate to high | Depends on time-series stability | Complex time-based models | Can handle non-linear time series | Time-series forecasting |

| PCA | Low to moderate | Sensitive to outliers | Dimensionality reduction | Used for data visualization and compression | Dimensionality reduction |

| Cluster analysis | Moderate to high | Can handle noisy data | Identification of similar groups | Variable number of clusters | Data segmentation |

| Artificial neural networks | High | Can learn from noisy data | Complex, non-linear modeling | Suitable for various machine learning problems | Machine learning and AI |

| Survival analysis | Moderate | Sensitive to censoring | Survival analysis | Parametric and non-parametric models | Survival studies |

| Robust regression analysis | Moderate | Resistant to outliers | Outlier-resistant linear modeling | Suitable for data with outliers | Robust modeling |

| The Statistical Method Used | Results | Interpretation |

|---|---|---|

| The graphical interpretation |

| Y1 (Efficiency) variability caused by the fluctuation of X11 and X12. Y2 (The time allocated to manufacture a beam) variability caused by the parameter X21. |

| The correlation study |

| Y1 (Efficiency) variability caused by the fluctuation of parameter X11. |

| Principal component analysis study |

| Y1 (Efficiency) variability caused by the fluctuation of X11 and X12. |

| Indicator | Method A (Average Times) | Method B (Our Approach) |

|---|---|---|

| Critical variables correctly detected | 2/5 | 5/5 |

| Balancing efficiency after disturbance | 75 ± 1.8% | 84 ± 1.5% |

| Average number of persistent bottlenecks | 3.4 | 1.2 |

| Average rate of underutilization (%) | 14% | 7% |

| Average cycle time per shift (s) | 54.2 | 48.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hillali, Y.; Zegrari, M.; Alfathi, N.; Chafik, S. New Approach for Detecting Variability in Industrial Assembly Line Balancing Based on Multi-Criteria Analysis. Automation 2025, 6, 33. https://doi.org/10.3390/automation6030033

Hillali Y, Zegrari M, Alfathi N, Chafik S. New Approach for Detecting Variability in Industrial Assembly Line Balancing Based on Multi-Criteria Analysis. Automation. 2025; 6(3):33. https://doi.org/10.3390/automation6030033

Chicago/Turabian StyleHillali, Youness, Mourad Zegrari, Najlae Alfathi, and Samir Chafik. 2025. "New Approach for Detecting Variability in Industrial Assembly Line Balancing Based on Multi-Criteria Analysis" Automation 6, no. 3: 33. https://doi.org/10.3390/automation6030033

APA StyleHillali, Y., Zegrari, M., Alfathi, N., & Chafik, S. (2025). New Approach for Detecting Variability in Industrial Assembly Line Balancing Based on Multi-Criteria Analysis. Automation, 6(3), 33. https://doi.org/10.3390/automation6030033