The Role of 3D Printing in Advancing Automated Manufacturing Systems: Opportunities and Challenges

Abstract

1. Introduction

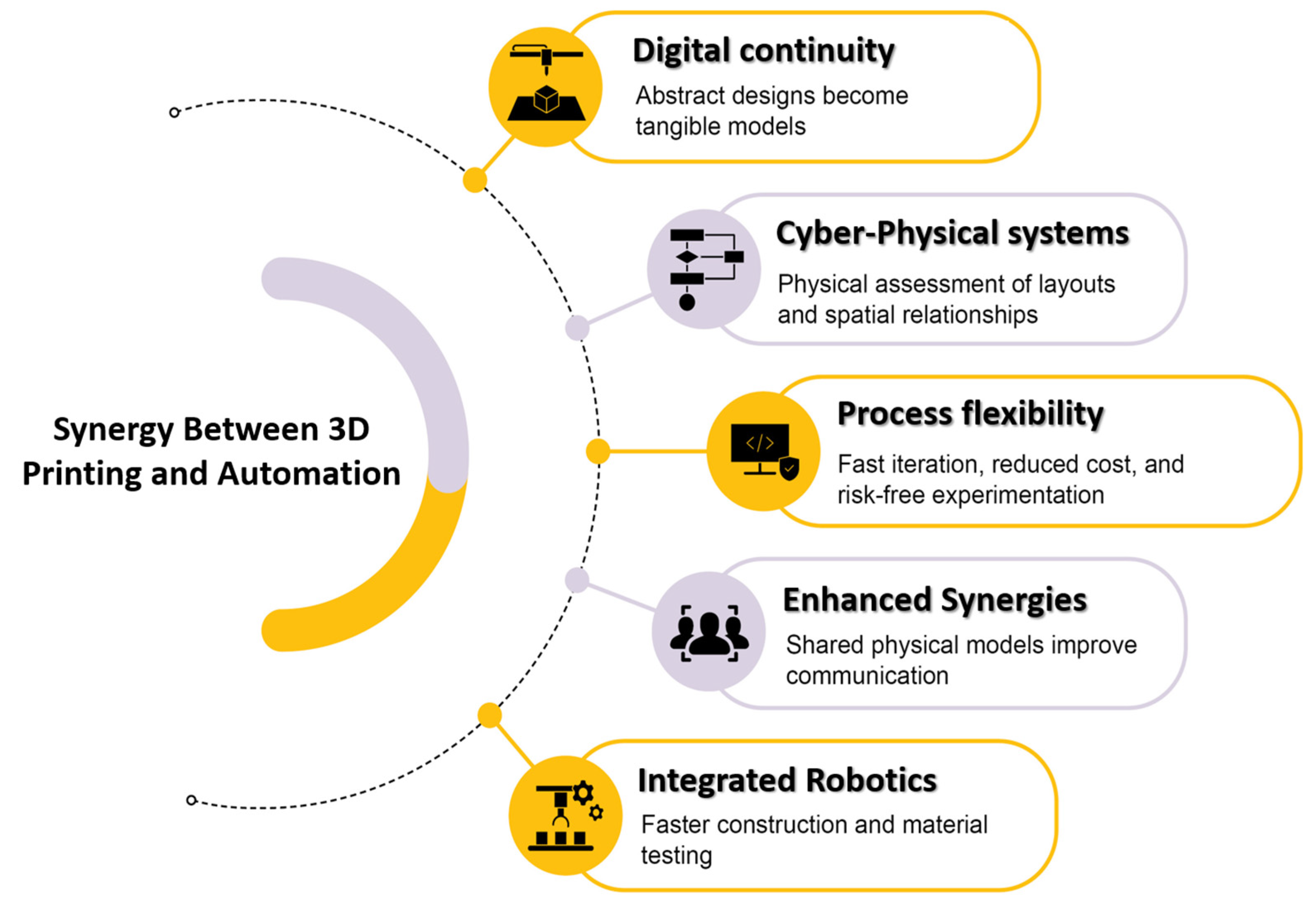

2. Three-Dimensional Printing as a Catalyst in Automated Manufacturing

3. Opportunities in Automated 3D Printing

3.1. Methodological Approach

3.2. Case Studies of 3D Printing and Automation Integration

3.3. Opportunities Identified Across Case Studies

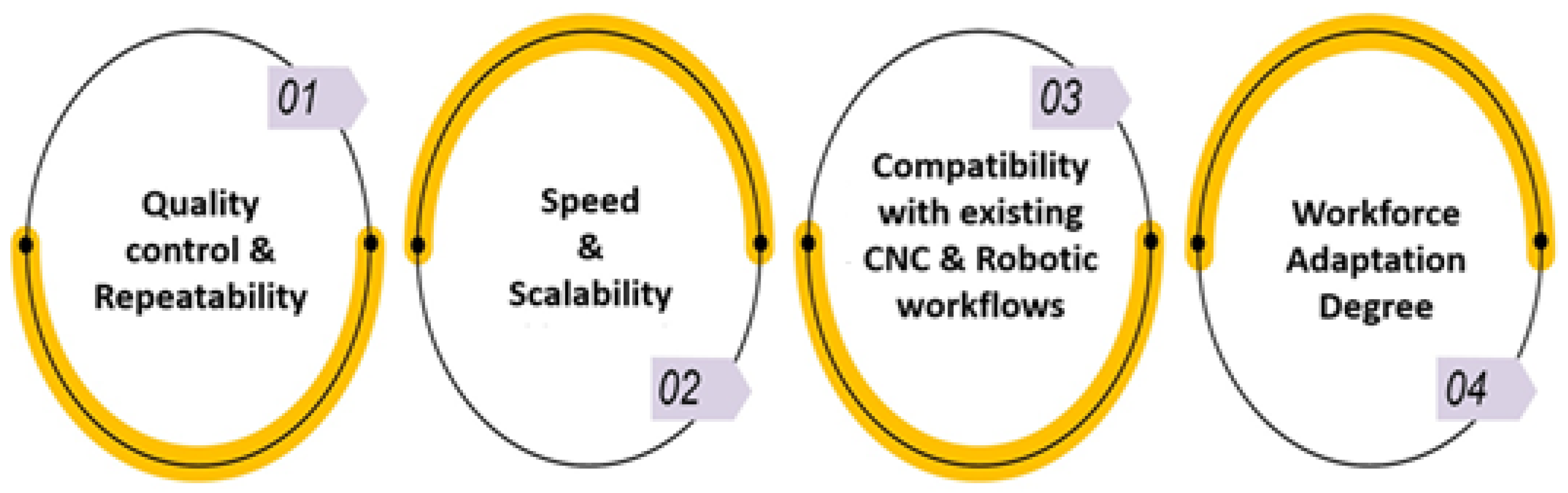

4. Challenges and Limitations

4.1. Quality Control and Repeatability

4.2. Speed and Scalability Constraints

4.3. System Integration Challenges

4.4. Workforce and Skill Adaptation

5. Discussion: Synthesis of Opportunities and Challenges

5.1. Emerging Trends: AI-Driven Self-Optimizing Printers, Multi-Material Printing and Hybrid Manufacturing

5.2. The Role of Machine Learning in Predictive Maintenance and Defect Detection

5.3. Standardization and Regulatory Considerations

6. Conclusions and Future Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbreviation | Full Form |

| 3DP | Three-Dimensional Printing |

| AI | Artificial Intelligence |

| CNC | Computer Numerical Control |

| FDM | Fused Deposition Modeling |

| ML | Machine Learning |

| SLA | Stereolithography |

| SLS | Selective Laser Sintering |

| IP | Intellectual Property |

| JIT | Just-In-Time |

| IoT | Internet of Things |

| AI-Driven | Artificial Intelligence-Driven |

| ISO | International Organization for Standardization |

| ASTM | American Society for Testing and Materials |

| ISO/IEC | International Organization for Standardization/International Electrotechnical Commission |

| AM | Additive Manufacturing |

| DMLS | Direct Metal Laser Sintering |

| R&D | Research and Development |

References

- Ashima, R.; Haleem, A.; Bahl, S.; Javaid, M.; Kumar Mahla, S.; Singh, S. Automation and Manufacturing of Smart Materials in Additive Manufacturing Technologies Using Internet of Things towards the Adoption of Industry 4.0. Mater. Today 2021, 45, 5081–5088. [Google Scholar] [CrossRef]

- Karumban, S.; Sanyal, S.; Laddunuri, M.M.; Dhanasingh Sivalinga, V.; Shanmugam, V.; Bose, V.; Mahesh, B.N.; Narasimhaiah, R.; Thangam, D.; Murugan, S.P. Industrial Automation and Its Impact on Manufacturing Industries. In Advances in Computational Intelligence and Robotics; IGI Global: Hershey, PA, USA, 2022; pp. 24–40. [Google Scholar]

- Lievano-Martínez, F.A.; Fernández-Ledesma, J.D.; Burgos, D.; Branch-Bedoya, J.W.; Jimenez-Builes, J.A. Intelligent Process Automation: An Application in Manufacturing Industry. Sustainability 2022, 14, 8804. [Google Scholar] [CrossRef]

- Dafflon, B.; Moalla, N.; Ouzrout, Y. The Challenges, Approaches, and Used Techniques of CPS for Manufacturing in Industry 4.0: A Literature Review. Int. J. Adv. Manuf. Technol. 2021, 113, 2395–2412. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T. Integration of Cyber-Physical Systems, Digital Twins and 3D Printing in Advanced Manufacturing: A Synergistic Approach. Am. J. Eng. Appl. Sci. 2024, 17, 1–22. [Google Scholar] [CrossRef]

- El-Haouzi, H.B.; Valette, E.; Krings, B.-J.; Moniz, A.B. Social Dimensions in CPS & IoT Based Automated Production Systems. Societies 2021, 11, 98. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Giallanza, A. Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions. Appl. Sci. 2021, 11, 5725. [Google Scholar] [CrossRef]

- Fatima, Z.; Tanveer, M.H.; Waseemullah; Zardari, S.; Naz, L.F.; Khadim, H.; Ahmed, N.; Tahir, M. Production Plant and Warehouse Automation with IoT and Industry 5.0. Appl. Sci. 2022, 12, 2053. [Google Scholar] [CrossRef]

- Vieira, R.; Silva, D.; Ribeiro, E.; Perdigoto, L.; Coelho, P.J. Performance Evaluation of Computer Vision Algorithms in a Programmable Logic Controller: An Industrial Case Study. Sensors 2024, 24, 843. [Google Scholar] [CrossRef]

- Alexandropoulos, E.; Papoutsidakis, M.; Nikitakos, N. SCADA Backup System for the Control of Networked Valves in Modern Ships Facilities. Int. J. Comput. Appl. 2019, 178, 1–3. [Google Scholar] [CrossRef]

- Dzedzickis, A.; Subačiūtė-Žemaitienė, J.; Šutinys, E.; Samukaitė-Bubnienė, U.; Bučinskas, V. Advanced Applications of Industrial Robotics: New Trends and Possibilities. Appl. Sci. 2021, 12, 135. [Google Scholar] [CrossRef]

- Kubasakova, I.; Kubanova, J.; Benco, D.; Kadlecová, D. Implementation of Automated Guided Vehicles for the Automation of Selected Processes and Elimination of Collisions between Handling Equipment and Humans in the Warehouse. Sensors 2024, 24, 1029. [Google Scholar] [CrossRef] [PubMed]

- Pérez Estébanez, R. An Approach to Sustainable Enterprise Resource Planning System Implementation in Small- and Medium-Sized Enterprises. Adm. Sci. 2024, 14, 91. [Google Scholar] [CrossRef]

- Mastrantonas, A.; Kokkas, P.; Chatzopoulos, A.; Papoutsidakis, M.; Stergiou, C.; Vairis, A.; Kanetaki, Z. Identifying the Effects of Industry 4.0 in the Pharmaceutical Sector: Achieving the Sustainable Development Goals. Discov. Sustain. 2024, 5, 460. [Google Scholar] [CrossRef]

- Tsaramirsis, G.; Kantaros, A.; Al-Darraji, I.; Piromalis, D.; Apostolopoulos, C.; Pavlopoulou, A.; Alrammal, M.; Ismail, Z.; Buhari, S.M.; Stojmenovic, M.; et al. A Modern Approach towards an Industry 4.0 Model: From Driving Technologies to Management. J. Sens. 2022, 2022, 1–18. [Google Scholar] [CrossRef]

- Watch, F. Antifragile Manufacturing for People, Planet, and Profit with Passion. Available online: https://www.businessfinland.fi/4a5d8b/globalassets/julkaisut/industry-x-white-paper.pdf (accessed on 7 April 2025).

- Ahmad, I.; Rodriguez, F.; Kumar, T.; Suomalainen, J.; Jagatheesaperumal, S.K.; Walter, S.; Asghar, M.Z.; Li, G.; Papakonstantinou, N.; Ylianttila, M.; et al. Communications Security in Industry X: A Survey. IEEE Open J. Commun. Soc. 2024, 5, 982–1025. [Google Scholar] [CrossRef]

- Zikria, Y.B.; Ali, R.; Afzal, M.K.; Kim, S.W. Next-Generation Internet of Things (IoT): Opportunities, Challenges, and Solutions. Sensors 2021, 21, 1174. [Google Scholar] [CrossRef]

- Bourechak, A.; Zedadra, O.; Kouahla, M.N.; Guerrieri, A.; Seridi, H.; Fortino, G. At the Confluence of Artificial Intelligence and Edge Computing in IoT-Based Applications: A Review and New Perspectives. Sensors 2023, 23, 1639. [Google Scholar] [CrossRef]

- Xidias, E.; Zacharia, P. Balanced Task Allocation and Motion Planning of a Multi-Robot System under Fuzzy Time Windows. Eng. Comput. 2024, 41, 1301–1326. [Google Scholar] [CrossRef]

- Al-Sai, Z.A.; Husin, M.H.; Syed-Mohamad, S.M.; Abdin, R.M.S.; Damer, N.; Abualigah, L.; Gandomi, A.H. Explore Big Data Analytics Applications and Opportunities: A Review. Big Data Cogn. Comput. 2022, 6, 157. [Google Scholar] [CrossRef]

- Thayyib, P.V.; Mamilla, R.; Khan, M.; Fatima, H.; Asim, M.; Anwar, I.; Shamsudheen, M.K.; Khan, M.A. State-of-the-Art of Artificial Intelligence and Big Data Analytics Reviews in Five Different Domains: A Bibliometric Summary. Sustainability 2023, 15, 4026. [Google Scholar] [CrossRef]

- Kitsou, O.; Mavromoustakis, C.X.; Markakis, E.K.; Mastorakis, G.; Pallis, E.; Bourdena, A.; Kourgiantakis, M. Health Data Analytics: Frameworks, Tools, and Impact on the Administration Efficiency and Performance in Healthcare. In Signals and Communication Technology; Springer Nature: Cham, Switzerland, 2024; pp. 173–189. ISBN 9783031585265. [Google Scholar]

- Segovia, M.; Garcia-Alfaro, J. Design, Modeling and Implementation of Digital. Twins Sens. 2022, 22, 5396. [Google Scholar] [CrossRef] [PubMed]

- Piromalis, D.; Kantaros, A. Digital Twins in the Automotive Industry: The Road toward Physical-Digital Convergence. Appl. Syst. Innov. 2022, 5, 65. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D. Setting up a Digital Twin Assisted Greenhouse Architecture. Am. J. Eng. Appl. Sci. 2022, 15, 230–238. [Google Scholar] [CrossRef]

- Kubiak, K.; Dec, G.; Stadnicka, D. Possible Applications of Edge Computing in the Manufacturing Industry-Systematic Literature Review. Sensors 2022, 22, 2445. [Google Scholar] [CrossRef]

- Abreha, H.G.; Hayajneh, M.; Serhani, M.A. Federated Learning in Edge Computing: A Systematic Survey. Sensors 2022, 22, 450. [Google Scholar] [CrossRef]

- Mijailović, Đ.; Đorđević, A.; Stefanovic, M.; Vidojević, D.; Gazizulina, A.; Projović, D. A Cloud-Based with Microcontroller Platforms System Designed to Educate Students within Digitalization and the Industry 4.0 Paradigm. Sustainability 2021, 13, 12396. [Google Scholar] [CrossRef]

- Babbar, H.; Rani, S.; Singh, A.; Abd-Elnaby, M.; Choi, B.J. Cloud Based Smart City Services for Industrial Internet of Things in Software-Defined Networking. Sustainability 2021, 13, 8910. [Google Scholar] [CrossRef]

- Kantaros, A.; Diegel, O.; Piromalis, D.; Tsaramirsis, G.; Khadidos, A.O.; Khadidos, A.O.; Khan, F.Q.; Jan, S. 3D Printing: Making an Innovative Technology Widely Accessible through Makerspaces and Outsourced Services. Mater. Today 2022, 49, 2712–2723. [Google Scholar] [CrossRef]

- Kantaros, A.; Zacharia, P.; Drosos, C.; Papoutsidakis, M.; Pallis, E.; Ganetsos, T. Smart Infrastructure and Additive Manufacturing: Synergies, Advantages, and Limitations. Appl. Sci. 2025, 15, 3719. [Google Scholar] [CrossRef]

- Arefin, A.M.E.; Khatri, N.R.; Kulkarni, N.; Egan, P.F. Polymer 3D Printing Review: Materials, Process, and Design Strategies for Medical Applications. Polymers 2021, 13, 1499. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Evaluating Benchtop Additive Manufacturing Processes Considering Latest Enhancements in Operational Factors. Processes 2024, 12, 2334. [Google Scholar] [CrossRef]

- Kantaros, A.; Soulis, E.; Ganetsos, T.; Petrescu, F.I.T. Applying a Combination of Cutting-Edge Industry 4.0 Processes towards Fabricating a Customized Component. Processes 2023, 11, 1385. [Google Scholar] [CrossRef]

- Kantaros, A.; Katsantoni, M.; Ganetsos, T.; Petrescu, N. The Evolution of Thermoplastic Raw Materials in High-Speed FFF/FDM 3D Printing Era: Challenges and Opportunities. Materials 2025, 18, 1220. [Google Scholar] [CrossRef] [PubMed]

- Pustišek, M.; Chen, M.; Kos, A.; Kos, A. Decentralized Machine Autonomy for Manufacturing Servitization. Sensors 2022, 22, 338. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Leveraging 3D Printing for Resilient Disaster Management in Smart Cities. Smart Cities 2024, 7, 3705–3726. [Google Scholar] [CrossRef]

- Nuñez Rodriguez, J.; Andrade Sosa, H.H.; Villarreal-Archila, S.M.; Ortiz, A. The Impact of Additive Manufacturing on Supply Chain Management from a System Dynamics Model—Scenario: Traditional, Centralized, and Distributed Supply Chain. Processes 2022, 10, 2489. [Google Scholar] [CrossRef]

- Assad, H.; Assad, A.; Kumar, A. Recent Developments in 3D Bio-Printing and Its Biomedical Applications. Pharmaceutics 2023, 15, 255. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Ganetsos, T. From Stents to Smart Implants Employing Biomimetic Materials: The Impact of 4D Printing on Modern Healthcare. Biomimetics 2025, 10, 125. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T. From Static to Dynamic: Smart Materials Pioneering Additive Manufacturing in Regenerative Medicine. Int. J. Mol. Sci. 2023, 24, 15748. [Google Scholar] [CrossRef]

- Kantaros, A. Bio-Inspired Materials: Exhibited Characteristics and Integration Degree in Bio-Printing Operations. Am. J. Eng. Appl. Sci. 2022, 15, 255–263. [Google Scholar] [CrossRef]

- Kantaros, A. 3D Printing in Regenerative Medicine: Technologies and Resources Utilized. Int. J. Mol. Sci. 2022, 23, 14621. [Google Scholar] [CrossRef] [PubMed]

- Žujović, M.; Obradović, R.; Rakonjac, I.; Milošević, J. 3D Printing Technologies in Architectural Design and Construction: A Systematic Literature Review. Buildings 2022, 12, 1319. [Google Scholar] [CrossRef]

- García-Alvarado, R.; Moroni-Orellana, G.; Banda-Pérez, P. Architectural Evaluation of 3D-Printed Buildings. Buildings 2021, 11, 254. [Google Scholar] [CrossRef]

- Živković, M.; Žujović, M.; Milošević, J. Architectural 3D-Printed Structures Created Using Artificial Intelligence: A Review of Techniques and Applications. Appl. Sci. 2023, 13, 10671. [Google Scholar] [CrossRef]

- Volpe, S.; Sangiorgio, V.; Petrella, A.; Coppola, A.; Notarnicola, M.; Fiorito, F. Building Envelope Prefabricated with 3D Printing Technology. Sustainability 2021, 13, 8923. [Google Scholar] [CrossRef]

- Romanczuk-Ruszuk, E.; Sztorch, B.; Pakuła, D.; Gabriel, E.; Nowak, K.; Przekop, R.E. 3D Printing Ceramics—Materials for Direct Extrusion Process. Ceramics 2023, 6, 364–385. [Google Scholar] [CrossRef]

- Kremzer, M.; Tomiczek, B.; Matula, G.; Gocki, M.; Krzemiński, Ł. Aluminium Matrix Composite Materials Reinforced by 3D-Printed Ceramic Preforms. Materials 2023, 16, 5473. [Google Scholar] [CrossRef]

- Mazeeva, A.; Masaylo, D.; Konov, G.; Popovich, A. Multi-Metal Additive Manufacturing by Extrusion-Based 3D Printing for Structural Applications: A Review. Metals 2024, 14, 1296. [Google Scholar] [CrossRef]

- Hartung, D.; Seidlitz, H.; Osiecki, T.; Sztorch, B.; Przekop, R.E.; Kazimierczuk, M. Flax Fiber Reinforced PET-G Composites with Improved Interfacial Adhesion. Polimery 2025, 70, 113–123. [Google Scholar] [CrossRef]

- Sztorch, B.; Romanczuk-Ruszuk, E.; Głowacka, J.; Kustosz, M.; Osiecki, T.; Jakubowska, P.; Seidlitz, H.; Przekop, R.E. Improving the Processing and Mechanical Properties of 3D Printable Biocomposite Based on Polylactide, Sediment Rock, and Natural Beeswax. Polym. Bull. 2024, 82, 2523–2553. [Google Scholar] [CrossRef]

- Konieczna, R.; Przekop, R.E.; Pakuła, D.; Głowacka, J.; Ziętkowska, K.; Kozera, R.; Sztorch, B. Functional Silsesquioxanes-Tailoring Hydrophobicity and Anti-Ice Properties of Polylactide in 3D Printing Applications. Materials 2024, 17, 4850. [Google Scholar] [CrossRef]

- Łapińska, A.; Grochowska, N.; Cieplak, K.; Płatek, P.; Wood, P.; Deuszkiewicz, P.; Dużyńska, A.; Sztorch, B.; Głowcka, J.; Przekop, R.; et al. Architecture Influence on Acoustic Performance, EMI Shielding, Electrical and Thermal, Properties of 3D Printed PLA/Graphite/Molybdenum Disulfide Composites. Mater. Des. 2024, 245, 113241. [Google Scholar] [CrossRef]

- Dabbagh, S.R.; Ozcan, O.; Tasoglu, S. Machine Learning-Enabled Optimization of Extrusion-Based 3D Printing. Methods 2022, 206, 27–40. [Google Scholar] [CrossRef] [PubMed]

- Ngoh, S. Case Study: An Industrial Automation Company Rethinks Fixturing with 3D Printing. Available online: https://www.xometry.com/resources/case-studies/case-study-industrial-automation-company-rethinks-fixturing-3d-printing/ (accessed on 11 April 2025).

- Kantaros, A. Intellectual Property Challenges in the Age of 3D Printing: Navigating the Digital Copycat Dilemma. Appl. Sci. 2024, 14, 11448. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The Potential of Additive Manufacturing in the Smart Factory Industrial 4.0: A Review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- Chen, T.; Lin, Y.-C. Feasibility Evaluation and Optimization of a Smart Manufacturing System Based on 3D Printing: A Review: Smart Manufacturing System Based on 3d Printing. Int. J. Intell. Syst. 2017, 32, 394–413. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Internet of Things for Smart Factories in Industry 4.0, a Review. Internet Things Cyber-Phys. Syst. 2023, 3, 192–204. [Google Scholar] [CrossRef]

- Jin, Y.; Gao, C. Hybrid Optimization of Green Supply Chain Network and Scheduling in Distributed 3D Printing Intelligent Factory. Sustainability 2023, 15, 5948. [Google Scholar] [CrossRef]

- De Antón, J.; Senovilla, J.; González, J.M.; Acebes, F. Production Planning in 3D Printing Factories. Int. J. Prod. Manag. Eng. 2020, 8, 75. [Google Scholar] [CrossRef]

- Meng, Y.; Yang, Y.; Chung, H.; Lee, P.-H.; Shao, C. Enhancing Sustainability and Energy Efficiency in Smart Factories: A Review. Sustainability 2018, 10, 4779. [Google Scholar] [CrossRef]

- Sajadieh, S.M.M.; Son, Y.H.; Noh, S.D. A Conceptual Definition and Future Directions of Urban Smart Factory for Sustainable Manufacturing. Sustainability 2022, 14, 1221. [Google Scholar] [CrossRef]

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and Limitations in 3D Printing Materials and Technologies: A Critical Review. Polymers 2023, 15, 2519. [Google Scholar] [CrossRef] [PubMed]

- Dahmani, A.; Benyoucef, L.; Mercantini, J.-M. Toward Sustainable Reconfigurable Manufacturing Systems (SRMS): Past, Present, and Future. Procedia Comput. Sci 2022, 200, 1605–1614. [Google Scholar] [CrossRef]

- Wang, R.; Tong, Y.; Zhuang, C. Lights-out Factories: Review and Prospect. Proc. Inst. Mech. Eng. Pt. B J. Eng. Manuf. 2024. [Google Scholar] [CrossRef]

- Nadimpalli, C.S.C.; Muttamsetty, L.S.; Pamu, R.N. Dark Factories and Lights-out Manufacturing: The Future of Production. In Advances in Finance, Accounting, and Economics; IGI Global: Hershey, PA, USA, 2025; pp. 233–266. ISBN 9798369370360. [Google Scholar]

- Jia, F.; Jebelli, A.; Ma, Y.; Ahmad, R. An Intelligent Manufacturing Approach Based on a Novel Deep Learning Method for Automatic Machine and Working Status Recognition. Appl. Sci. 2022, 12, 5697. [Google Scholar] [CrossRef]

- Popela, M.; Olivová, J.; Plíva, Z.; Petržílka, L.; Krchová, M.; Joska, Z.; Janů, P. A Novel Approach to the Production of Printed Patch Antennas. Appl. Sci. 2024, 14, 1556. [Google Scholar] [CrossRef]

- Zoubek, M.; Simon, M.; Poor, P. Overall Readiness of Logistics 4.0: A Comparative Study of Automotive, Manufacturing, and Electronics Industries in the West Bohemian Region (Czech Republic). Appl. Sci. 2022, 12, 7789. [Google Scholar] [CrossRef]

- Rahman, M.A.; Shakur, M.S.; Ahamed, M.S.; Hasan, S.; Rashid, A.A.; Islam, M.A.; Haque, M.S.S.; Ahmed, A. A Cloud-Based Cyber-Physical System with Industry 4.0: Remote and Digitized Additive Manufacturing. Automation 2022, 3, 400–425. [Google Scholar] [CrossRef]

- Ullrich, M.; Thalappully, R.; Heieck, F.; Lüdemann-Ravit, B. Virtual Commissioning of Linked Cells Using Digital Models in an Industrial Metaverse. Automation 2024, 5, 1–12. [Google Scholar] [CrossRef]

- Christ, L.; Milloch, E.; Boshoff, M.; Hypki, A.; Kuhlenkötter, B. Implementation of Digital Twin and Real Production System to Address Actual and Future Challenges in Assembly Technology. Automation 2023, 4, 345–358. [Google Scholar] [CrossRef]

- Zani, C.M.; Rocha, C.G. da Product and Process Complexity in Construction: An Exploratory Study Using Bill-of-Materials (Bom). In Proceedings of the Annual Conference of the International Group for Lean Construction, Lisbon, Portugal, 3–7 July 2023; pp. 711–722. [Google Scholar]

- Sánchez Ros, E. A Cost Comparison of Outsourcing Amb Insourcing in 3D Printer Manufacturing. Bachelor’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2024. [Google Scholar]

- Al Rashid, A.; Koç, M. Additive Manufacturing for Sustainability and Circular Economy: Needs, Challenges, and Opportunities for 3D Printing of Recycled Polymeric Waste. Materials Today Sustainability 2023, 24, 100529. [Google Scholar] [CrossRef]

- Samad, A. International Journal of Multidisciplinary Sciences and Arts. Inf. Technol. Sci. 2024, 4, 2. [Google Scholar]

- Zgodavová, K.; Lengyelová, K.; Bober, P.; Eguren, J.A.; Moreno, A. 3D Printing Optimization for Environmental Sustainability: Experimenting with Materials of Protective Face Shield Frames. Materials 2021, 14, 6595. [Google Scholar] [CrossRef]

- Tabassum, T.; Ahmad Mir, A. A Review of 3d Printing Technology-the Future of Sustainable Construction. Mater. Today 2023, 93, 408–414. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H.; Bhuddhi, D. Additive Manufacturing: Expanding 3D Printing Horizon in Industry 4.0. Int. J. Interact. Des. Manuf. 2023, 17, 2221–2235. [Google Scholar] [CrossRef]

- Elbadawi, M.; Li, H.; Sun, S.; Alkahtani, M.E.; Basit, A.W.; Gaisford, S. Artificial Intelligence Generates Novel 3D Printing Formulations. Appl. Mater. Today 2024, 36, 102061. [Google Scholar] [CrossRef]

- Yang, C.-J. Accelerated Quality Improvement of 3D Printed Objects Based on a Case-Based Reasoning System. Int. J. Adv. Manuf. Technol. 2022, 119, 4599–4612. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Tseles, D. 3D Printing and 3D Scanning: Applications in the Cultural Heritage Field. In Proceedings of the International Scientific Conference Modern Research Methods of Bio-Nano-Agents, Batumi, Georgia, 24–26 November 2021. [Google Scholar] [CrossRef]

- Lengyel, F. Generative AI in the Printing Industry: Revolutionizing Workflow, Design, and Efficiency. Preprint 2024. [Google Scholar]

- Nguyen, H.; Adrian, N.; Yan, J.L.X.; Salfity, J.M.; Allen, W.; Pham, Q.-C. Development of a Robotic System for Automated Decaking of 3D-Printed Parts. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 1 January 2020. [Google Scholar]

- Bouchard, S.; Gamache, S.; Abdulnour, G. Operationalizing Mass Customization in Manufacturing SMEs—A Systematic Literature Review. Sustainability 2023, 15, 3028. [Google Scholar] [CrossRef]

- Pech, M.; Vrchota, J. The Product Customization Process in Relation to Industry 4.0 and Digitalization. Processes 2022, 10, 539. [Google Scholar] [CrossRef]

- Martínez-Olvera, C. Towards the Development of a Digital Twin for a Sustainable Mass Customization 4.0 Environment: A Literature Review of Relevant Concepts. Automation 2022, 3, 197–222. [Google Scholar] [CrossRef]

- Qin, Z.; Lu, Y. Self-Organizing Manufacturing Network: A Paradigm towards Smart Manufacturing in Mass Personalization. J. Manuf. Syst. 2021, 60, 35–47. [Google Scholar] [CrossRef]

- Bortolini, M.; Faccio, M.; Galizia, F.G.; Gamberi, M.; Pilati, F. Adaptive Automation Assembly Systems in the Industry 4.0 Era: A Reference Framework and Full–Scale Prototype. Appl. Sci. 2021, 11, 1256. [Google Scholar] [CrossRef]

- Eid Mohamed, B.; Carbone, C. Mass Customization of Housing: A Framework for Harmonizing Individual Needs with Factory Produced Housing. Buildings 2022, 12, 955. [Google Scholar] [CrossRef]

- Carqueijó, S.; Ramos, D.; Gonçalves, J.; Carvalho, S.; Murmura, F.; Bravi, L.; Doiro, M.; Santos, G.; Zgodavová, K. The Importance of Fab Labs in the Development of New Products toward Mass Customization. Sustainability 2022, 14, 8671. [Google Scholar] [CrossRef]

- Guo, S.; Choi, T.-M.; Chung, S.-H. Self-Design Fun: Should 3D Printing Be Employed in Mass Customization Operations? Eur. J. Oper. Res. 2022, 299, 883–897. [Google Scholar] [CrossRef]

- Jin, Y.; Campbell, R.; Tang, J.; Ji, H.; Song, D.; Liu, X. Designing and Simulating a “Mass Selective Customization-Centralized Manufacturing” Business Model for Clothing Enterprises Using 3D Printing. Rapid Prototyp. J. 2021, 27, 1664–1680. [Google Scholar] [CrossRef]

- Dong, L.; Shi, D.; Zhang, F. 3D Printing and Product Assortment Strategy. Manag. Sci. 2022, 68, 5724–5744. [Google Scholar] [CrossRef]

- Habib, T.; Omair, M.; Habib, M.S.; Zahir, M.Z.; Khattak, S.B.; Yook, S.-J.; Aamir, M.; Akhtar, R. Modular Product Architecture for Sustainable Flexible Manufacturing in Industry 4.0: The Case of 3D Printer and Electric Toothbrush. Sustainability 2023, 15, 910. [Google Scholar] [CrossRef]

- Cui, T.Z.; Raji, R.K.; Han, J.L.; Chen, Y. Application of 3D Printing Technology in Footwear Design and Manufacture–A Review of Developing Trends. Text. Leather Rev. 2024, 7, 1304–1321. [Google Scholar] [CrossRef]

- Zavodna, L.; Trejtnarová, L. Additive Manufacturing in the Footwear Industry. Available online: https://www.researchgate.net/publication/370952638_ADDITIVE_MANUFACTURING_IN_THE_FOOTWEAR_INDUSTRY (accessed on 11 April 2025).

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T.; Alysandratou, E. Bioprinting and Intellectual Property: Challenges, Opportunities, and the Road Ahead. Bioengineering 2025, 12, 76. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.; Abdoli, H.; Diegel, O.; Chan, S.; Iliescu, M.; Ganetsos, T.; Munteanu, I.; Ungureanu, L. Additive Manufacturing for Surgical Planning and Education: A Review. Appl. Sci. 2024, 14, 2550. [Google Scholar] [CrossRef]

- Pérez-Davila, S.; González-Rodríguez, L.; Lama, R.; López-Álvarez, M.; Oliveira, A.L.; Serra, J.; Novoa, B.; Figueras, A.; González, P. 3D-Printed PLA Medical Devices: Physicochemical Changes and Biological Response after Sterilisation Treatments. Polymers 2022, 14, 4117. [Google Scholar] [CrossRef]

- M’Bengue, M.-S.; Mesnard, T.; Chai, F.; Maton, M.; Gaucher, V.; Tabary, N.; García-Fernandez, M.-J.; Sobocinski, J.; Martel, B.; Blanchemain, N. Evaluation of a Medical Grade Thermoplastic Polyurethane for the Manufacture of an Implantable Medical Device: The Impact of FDM 3D-Printing and Gamma Sterilization. Pharmaceutics 2023, 15, 456. [Google Scholar] [CrossRef]

- Jayawardane, H.; Davies, I.J.; Gamage, J.R.; John, M.; Biswas, W.K. Investigating the ‘Techno-Eco-Efficiency’ Performance of Pump Impellers: Metal 3D Printing vs. CNC Machining. Int. J. Adv. Manuf. Technol. 2022, 121, 6811–6836. [Google Scholar] [CrossRef]

- Alves, A.S.F.; Kokare, S.; Oliveira, J.P.; Godina, R. Environmental Comparison of Wire and Arc Additive Manufacturing and CNC Milling on Steel Produced Parts. Procedia Comput. Sci. 2025, 253, 3025–3036. [Google Scholar] [CrossRef]

- Brion, D.A.J.; Pattinson, S.W. Quantitative and Real-time Control of 3D Printing Material Flow through Deep Learning. Adv. Intell. Syst. 2022, 4, 2200153. [Google Scholar] [CrossRef]

- Xie, J.; Saluja, A.; Rahimizadeh, A.; Fayazbakhsh, K. Development of Automated Feature Extraction and Convolutional Neural Network Optimization for Real-Time Warping Monitoring in 3D Printing. Int. J. Comput. Integr. Manuf. 2022, 35, 813–830. [Google Scholar] [CrossRef]

- Mantalas, E.-M.; Sagias, V.D.; Zacharia, P.; Stergiou, C.I. Neuro-Fuzzy Model Evaluation for Enhanced Prediction of Mechanical Properties in AM Specimens. Appl. Sci. 2024, 15, 7. [Google Scholar] [CrossRef]

- Sagias, V.D.; Zacharia, P.; Tempeloudis, A.; Stergiou, C. Adaptive Neuro-Fuzzy Inference System-Based Predictive Modeling of Mechanical Properties in Additive Manufacturing. Machines 2024, 12, 523. [Google Scholar] [CrossRef]

- Siddiqui, M.M.U.Z.; Tabassum, A. Condition-Based Monitoring Techniques and Algorithms in 3d Printing and Additive Manufacturing: A State-of-the-Art Review. Prog. Addit. Manuf. 2024. [Google Scholar] [CrossRef]

- Jandyal, A.; Chaturvedi, I.; Wazir, I.; Raina, A.; Ul Haq, M.I. 3D Printing–A Review of Processes, Materials and Applications in Industry 4.0. Sustain. Oper. Comput. 2022, 3, 33–42. [Google Scholar] [CrossRef]

- Samal, S.K.; Vishwanatha, H.M.; Saxena, K.K.; Behera, A.; Nguyen, T.A.; Behera, A.; Prakash, C.; Dixit, S.; Mohammed, K.A. 3D-Printed Satellite Brackets: Materials, Manufacturing and Applications. Crystals 2022, 12, 1148. [Google Scholar] [CrossRef]

- Hedayati, R.; Stulova, V. 3D Printing for Space Habitats: Requirements, Challenges, and Recent Advances. Aerospace 2023, 10, 653. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Piromalis, D. 4D Printing: Technology Overview and Smart Materials Utilized. J. Mechatron. Robot. 2023, 7, 1–14. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D. Fabricating Lattice Structures via 3D Printing: The Case of Porous Bio-Engineered Scaffolds. Appl. Mech. 2021, 2, 289–302. [Google Scholar] [CrossRef]

- Serrano, D.R.; Kara, A.; Yuste, I.; Luciano, F.C.; Ongoren, B.; Anaya, B.J.; Molina, G.; Diez, L.; Ramirez, B.I.; Ramirez, I.O.; et al. 3D Printing Technologies in Personalized Medicine, Nanomedicines, and Biopharmaceuticals. Pharmaceutics 2023, 15, 313. [Google Scholar] [CrossRef]

- Zakaria, S.; Mativenga, P. A Scientific Base for Optimising Energy Consumption and Performance in 3D Printing. J. Clean. Prod. 2024, 482, 144227. [Google Scholar] [CrossRef]

- Mohamed, R.A.; Mohamed, A.F.A. Exploring the Environmental Benefits of 3D Printing Technology in Concrete Construction; a Review. Prog. Addit. Manuf. 2025, 10, 279–289. [Google Scholar] [CrossRef]

- Ulkir, O. Energy-Consumption-Based Life Cycle Assessment of Additive-Manufactured Product with Different Types of Materials. Polymers 2023, 15, 1466. [Google Scholar] [CrossRef]

- Lara, A.C.; Menegon, E.M.P.; Sehnem, S.; Kuzma, E. Relationship between Just in Time, Lean Manufacturing, and Performance Practices: A Meta-Analysis. Gest. Prod. 2022, 29, e9021. [Google Scholar] [CrossRef]

- Görmen, M. Statistical Process Control (SPC) under the Quality Approach of Just in Time (JIT) Manufacturing Philosophie and an Application. J. Bus. Res.-Turk. 2022, 14, 646–670. [Google Scholar] [CrossRef]

- Singhal, V.; Maiyar, L.M.; Roy, I. Environmental Sustainability Consideration with Just-in-Time Practices in Industry 4.0 Era—A State of the Art. Oper. Manag. Res. 2024. [Google Scholar] [CrossRef]

- Pillai, A.S.; Thonakkot, L.S. Just in Time (Jit): A Literature Review. NIJASET 2023, 2, 6–14. [Google Scholar]

- García-Cutrín, J.; Rodríguez-García, C. Enhancing Corporate Sustainability through Just-in-Time (JIT) Practices: A Meta-Analytic Examination of Financial Performance Outcomes. Sustainability 2024, 16, 4025. [Google Scholar] [CrossRef]

- Chen, L.; Cui, Y.; Lee, H.L. Retailing with 3D Printing. Prod. Oper. Manag. 2021, 30, 1986–2007. [Google Scholar] [CrossRef]

- Westerweel, B.; Basten, R.; den Boer, J.; van Houtum, G.-J. Printing Spare Parts at Remote Locations: Fulfilling the Promise of Additive Manufacturing. Prod. Oper. Manag. 2021, 30, 1615–1632. [Google Scholar] [CrossRef]

- Katsaliaki, K.; Galetsi, P.; Kumar, S. Supply Chain Disruptions and Resilience: A Major Review and Future Research Agenda. Ann. Oper. Res. 2022, 319, 965–1002. [Google Scholar] [CrossRef]

- Serohi, A. Impact of 3-D Printing Technology in Manufacturing Supply Lines to Improve Resilience during Black Swan Events. Int.J Sup. Chain. Mgt. 2021, 10, 3, 8–103. [Google Scholar] [CrossRef]

- Ali, A.A.A.; Fayad, A.A.S.; Alomair, A.; Al Naim, A.S. The Role of Digital Supply Chain on Inventory Management Effectiveness within Engineering Companies in Jordan. Sustainability 2024, 16, 8031. [Google Scholar] [CrossRef]

- Montes, J.O.; Olleros, F.X. Local On-Demand Fabrication: Microfactories and Online Manufacturing Platforms. J. Manuf. Technol. Manag. 2020, 32, 20–41. [Google Scholar] [CrossRef]

- Capellades, G.; Neurohr, C.; Briggs, N.; Rapp, K.; Hammersmith, G.; Brancazio, D.; Derksen, B.; Myerson, A.S. On-Demand Continuous Manufacturing of Ciprofloxacin in Portable Plug-and-Play Factories: Implementation and in Situ Control of Downstream Production. Org. Process Res. Dev. 2021, 25, 1534–1546. [Google Scholar] [CrossRef]

- Pennekamp, J.; Matzutt, R.; Kanhere, S.S.; Hiller, J.; Wehrle, K. The Road to Accountable and Dependable Manufacturing. Automation 2021, 2, 202–219. [Google Scholar] [CrossRef]

- McDougall, N.; Wagner, B.; MacBryde, J. Leveraging Competitiveness from Sustainable Operations: Frameworks to Understand the Dynamic Capabilities Needed to Realise NRBV Supply Chain Strategies. Supply Chain. Manag. Int. J. 2022, 27, 12–29. [Google Scholar] [CrossRef]

- Ventura, J.A.; Golany, B.; Mendoza, A.; Li, C. A Multi-Product Dynamic Supply Chain Inventory Model with Supplier Selection, Joint Replenishment, and Transportation Cost. Ann. Oper. Res. 2022, 316, 729–762. [Google Scholar] [CrossRef]

- Moosavi, J.; Fathollahi-Fard, A.M.; Dulebenets, M.A. Supply Chain Disruption during the COVID-19 Pandemic: Recognizing Potential Disruption Management Strategies. Int. J. Disaster Risk Reduct. 2022, 75, 102983. [Google Scholar] [CrossRef]

- Sudan, T.; Taggar, R.; Jena, P.K.; Sharma, D. Supply Chain Disruption Mitigation Strategies to Advance Future Research Agenda: A Systematic Literature Review. J. Clean. Prod. 2023, 425, 138643. [Google Scholar] [CrossRef]

- Katsigiannis, M.; Evans, M.; Osho, J.; Pantelidakis, M.; Bitencourt, J.; Mykoniatis, K. Empowering Decentralized Production: A Distributed Manufacturing System for Additive Manufacturing Processes. Manuf. Lett. 2024, 41, 1507–1514. [Google Scholar] [CrossRef]

- Poudel, L.; Elagandula, S.; Zhou, W.; Sha, Z. Decentralized and Centralized Planning for Multi-Robot Additive Manufacturing. J. Mech. Des. 2023, 145, 10. [Google Scholar] [CrossRef]

- Makanda, I.L.D.; Yang, M.; Shi, H.; Guo, W.; Jiang, P. A Multi-Part Production Planning System for a Distributed Network of 3D Printers under the Context of Social Manufacturing. Machines 2022, 10, 605. [Google Scholar] [CrossRef]

- Chadha, U.; Abrol, A.; Vora, N.P.; Tiwari, A.; Shanker, S.K.; Selvaraj, S.K. Performance Evaluation of 3D Printing Technologies: A Review, Recent Advances, Current Challenges, and Future Directions. Prog. Addit. Manuf. 2022, 7, 853–886. [Google Scholar] [CrossRef]

- Malik, A.; Ul Haq, M.I.; Raina, A.; Gupta, K. 3D Printing towards Implementing Industry 4.0: Sustainability Aspects, Barriers and Challenges. Ind. Rob. 2022, 49, 491–511. [Google Scholar] [CrossRef]

- Bănică, C.-F.; Sover, A.; Anghel, D.-C. Printing the Future Layer by Layer: A Comprehensive Exploration of Additive Manufacturing in the Era of Industry 4.0. Appl. Sci. 2024, 14, 9919. [Google Scholar] [CrossRef]

- Kannaki, S.; Sooraj, S.; Vijeth, R.; Selvalakshmi, S.U.; Sharmietha, S.P.; Sruthi, S. Fabrication of Multi-Purpose 3D Printer (3D Printer, CNC & Laser Engraving). In Proceedings of the AIP Conference Proceedings, Melville, NY, USA, 5 February 2025; Volume 3262, p. 030013. [Google Scholar]

- Xu, Z.; Song, T.; Guo, S.; Peng, J.; Zeng, L.; Zhu, M. Robotics Technologies Aided for 3D Printing in Construction: A Review. Int. J. Adv. Manuf. Technol. 2022, 118, 3559–3574. [Google Scholar] [CrossRef]

- Lishchenko, N.; Piteľ, J.; Larshin, V. Online Monitoring of Surface Quality for Diagnostic Features in 3D Printing. Machines 2022, 10, 541. [Google Scholar] [CrossRef]

- Portoacă, A.I.; Ripeanu, R.G.; Diniță, A.; Tănase, M. Optimization of 3D Printing Parameters for Enhanced Surface Quality and Wear Resistance. Polymers 2023, 15, 3410. [Google Scholar] [CrossRef]

- Kantaros, A.; Karalekas, D. In-Situ Monitoring of Strain Build up and Temperature in a 3D Polymer Printing Process. In Proceedings of the 16th International Conference on Experimental Mechanics (ICEM16), Cambridge, UK, 7–11 July 2022. [Google Scholar]

- Kantaros, A.; Bimis, A.; Karalekas, D. In Situ Characterization of Residual Strains in Layered Manufacturing. In Proceedings of the 5th International Conference on Materials Integrated Non Destructive Testing (IC-MINDT-2013), Athens, Greece, 20–22 May 2025. [Google Scholar]

- Phillips, C.; Kortschot, M.; Azhari, F. Towards Standardizing the Preparation of Test Specimens Made with Material Extrusion: Review of Current Techniques for Tensile Testing. Addit. Manuf. 2022, 58, 103050. [Google Scholar] [CrossRef]

- Alexander, A.E.; Wake, N.; Chepelev, L.; Brantner, P.; Ryan, J.; Wang, K.C. A Guideline for 3D Printing Terminology in Biomedical Research Utilizing ISO/ASTM Standards. 3D Print. Med. 2021, 7, 8. [Google Scholar] [CrossRef]

- Głowacki, M.; Mazurkiewicz, A.; Słomion, M.; Skórczewska, K. Resistance of 3D-Printed Components, Test Specimens and Products to Work under Environmental Conditions-Review. Materials 2022, 15, 6162. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Macko, M.; Szczepański, Z.; Dostatni, E. Optimization of Extrusion-Based 3D Printing Process Using Neural Networks for Sustainable Development. Materials 2021, 14, 2737. [Google Scholar] [CrossRef]

- Ferretti, P.; Leon-Cardenas, C.; Santi, G.M.; Sali, M.; Ciotti, E.; Frizziero, L.; Donnici, G.; Liverani, A. Relationship between FDM 3D Printing Parameters Study: Parameter Optimization for Lower Defects. Polymers 2021, 13, 2190. [Google Scholar] [CrossRef]

- Rojek, I.; Mikołajewski, D.; Kotlarz, P.; Tyburek, K.; Kopowski, J.; Dostatni, E. Traditional Artificial Neural Networks versus Deep Learning in Optimization of Material Aspects of 3D Printing. Materials 2021, 14, 7625. [Google Scholar] [CrossRef]

- Jackson, B.; Fouladi, K.; Eslami, B. Multi-Parameter Optimization of 3D Printing Condition for Enhanced Quality and Strength. Polymers 2022, 14, 1586. [Google Scholar] [CrossRef]

- Yang, C.-J.; Wu, S.-S. Sustainable Manufacturing Decisions through the Optimization of Printing Parameters in 3D Printing. Appl. Sci. 2022, 12, 10060. [Google Scholar] [CrossRef]

- Antreas, K.; Piromalis, D. Employing a Low-Cost Desktop 3D Printer: Challenges, and How to Overcome Them by Tuning Key Process Parameters. Int. J. Mech. Appl. 2021, 10, 11–19. [Google Scholar] [CrossRef]

- Kim, M.; Yoo, G.; Kim, B.; Song, Y.; Lee, B.J. Scalability Enhancement in Projection-Based 3D Printing through Optical Expansion. Addit. Manuf. 2024, 95, 104511. [Google Scholar] [CrossRef]

- Aizawa, T.; Yoshino, T.; Suzuki, Y.; Inohara, T. Micro-/Nano-Texturing onto Plasma-Nitrided Tool Surface by Laser Printing for CNC Imprinting and Piercing. Micromachines 2022, 13, 265. [Google Scholar] [CrossRef]

- Herpel, C.; Tasaka, A.; Higuchi, S.; Finke, D.; Kühle, R.; Odaka, K.; Rues, S.; Lux, C.J.; Yamashita, S.; Rammelsberg, P.; et al. Accuracy of 3D Printing Compared with Milling—A Multi-Center Analysis of Try-in Dentures. J. Dent. 2021, 110, 103681. [Google Scholar] [CrossRef]

- Popescu, D.; Gheorghe Amza, C.; Marinescu, R.; Cristiana Iacob, M.; Luminiţa Căruţaşu, N. Investigations on Factors Affecting 3D-Printed Holes Dimensional Accuracy and Repeatability. Appl. Sci. 2022, 13, 41. [Google Scholar] [CrossRef]

- Kantaros, A.; Karalekas, D. FBG Based in Situ Characterization of Residual Strains in FDM Process. In Residual Stress, Thermomechanics & Infrared Imaging, Hybrid Techniques and Inverse Problems; Springer International Publishing: Cham, Switzerland, 2014; Volume 8, pp. 333–337. ISBN 9783319008752. [Google Scholar]

- Lorkowski, L.; Wybrzak, K.; Brancewicz-Steinmetz, E.; Świniarski, J.; Sawicki, J. Influence of Print Speed on the Mechanical Performance of 3D-Printed Bio-Polymer Polylactic Acid. Materials 2025, 18, 1765. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.; Ungureanu, L.; Munteanu, I. Post-Production Finishing Processes Utilized in 3D Printing Technologies. Processes 2024, 12, 595. [Google Scholar] [CrossRef]

- Amirpour, M.; Cracknell, D.; Amirian, A.; Alipour, A.N. Hybrid 3D Printing of Fluid-Filled Lattices for Biomedical Applications: A Review. Int. J. Adv. Manuf. Technol. 2025, 136, 4083–4105. [Google Scholar] [CrossRef]

- Dai, Y.; Lu, Y. 3D Printing Driven Business Model Innovation and Supply Chain Operations: A Perspective of Strategic Alignment. J. Manuf. Technol. Manag. 2025, 36, 820–839. [Google Scholar] [CrossRef]

- Miri, Z.S.; Baaj, H.; Polak, M.A. 3D-Printed Concrete Bridges: Material, Design, Construction, and Reinforcement. Appl. Sci. 2025, 15, 3054. [Google Scholar] [CrossRef]

- Zuo, Z.; Zhang, Y.; Li, J.; Huang, Y.; Zhang, L.; Wang, X.; Tao, Y.; De Corte, W. Systematic Workflow for Digital Design and On-Site 3D Printing of Large Concrete Structures: A Case Study of a Full-Size Two-Story Building. J. Build. Eng. 2025, 104, 112370. [Google Scholar] [CrossRef]

- Saif, H.M.; Crespo, J.G.; Pawlowski, S. Can 3D-Printed Flow Electrode Gaskets Replace CNC-Milled Graphite Current Collectors in Flow Capacitive Deionization? Desalination 2025, 597, 118362. [Google Scholar] [CrossRef]

- Alghamdi, A. Enhancing 3D Printing Workflows through Multi-Objective Optimization and Reinforcement Learning Techniques. Eng. Technol. Appl. Sci. Res. 2025, 15, 21300–21305. [Google Scholar] [CrossRef]

- İnal, C.B.; Ayten, U.B.C.; Nemli, S.K. Replacement Implant-Retained Ear Prosthesis Using a Semidigital Workflow: A Case Report. Int. J. Prosthodont. 2025, 25, 268–270. [Google Scholar] [CrossRef]

- Jiménez-Sarda, J.; Silva, D.F.; Smith, A.E. Drone-enabled Material Handling in Smart Manufacturing. Int. Trans. Oper. Res. 2025. [Google Scholar] [CrossRef]

- Naranbat, D.; Phelps, B.; Murphy, J.; Tripathi, A. How to Convert a 3D Printer to a Personal Automated Liquid Handler for Life Science Workflows. SLAS Technol. 2025, 30, 100239. [Google Scholar] [CrossRef]

- Kantaros, A.; Soulis, E.; Petrescu, F.I.T.; Ganetsos, T. Advanced Composite Materials Utilized in FDM/FFF 3D Printing Manufacturing Processes: The Case of Filled Filaments. Materials 2023, 16, 6210. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, N.; Puttapati, S.K. Advancing Optical Transparency in 3D-printed PLA Parts Using Chemical Post-processing. Polym. Eng. Sci. 2025, 65, 299–314. [Google Scholar] [CrossRef]

- Regassa Hunde, B.; Debebe Woldeyohannes, A. Future Prospects of Computer-Aided Design (CAD)–A Review from the Perspective of Artificial Intelligence (AI), Extended Reality, and 3D Printing. Results Eng. 2022, 14, 100478. [Google Scholar] [CrossRef]

- Talaat, F.M.; Hassan, E. Artificial Intelligence in 3D Printing. In Enabling Machine Learning Applications in Data Science; Springer: Singapore, 2021; pp. 77–88. ISBN 9789813361287. [Google Scholar]

- Soori, M.; Jough, F.K.G.; Dastres, R.; Arezoo, B. Additive Manufacturing Modification by Artificial Intelligence, Machine Learning, and Deep Learning: A Review. Addit. Manuf. Front. 2025, 4, 200198. [Google Scholar] [CrossRef]

- Chi, X.; Xue, J.; Jia, L.; Yao, J.; Miao, H.; Wu, L.; Liu, T.; Tian, X.; Li, D. Machine Learning-Based Online Monitoring and Closed-Loop Controlling for 3D Printing of Continuous Fiber-Reinforced Composites. Addit. Manuf. Front. 2025, 4, 200196. [Google Scholar] [CrossRef]

- Belmouadden, M.; Dadouchi, C.; Pellerin, R. Artificial Intelligence Applied in Adaptive Manufacturing Process Monitoring: A State-of-the-Art in the Era of Automation. Procedia Comput. Sci. 2025, 256, 47–54. [Google Scholar] [CrossRef]

- Taheri, H.; Salimi Beni, A. Artificial Intelligence, Machine Learning, and Smart Technologies for Nondestructive Evaluation. In Handbook of Nondestructive Evaluation 4.0; Springer Nature: Cham, Switzerland, 2025; pp. 1–29. ISBN 9783030482008. [Google Scholar]

- Bustillo, A.; Karlis, A. Artificial Intelligence in Fault Diagnosis and Signal Processing. Appl. Sci. 2025, 15, 3922. [Google Scholar] [CrossRef]

- Islam, M.M.M.; Emon, J.I.; Ng, K.Y.; Asadpour, A.; Aziz, M.M.R.A.; Baptista, M.L.; Kim, J.-M. Artificial Intelligence in Smart Manufacturing: Emerging Opportunities and Prospects. In Springer Series in Advanced Manufacturing; Springer Nature: Cham, Switzerland, 2025; pp. 9–36. ISBN 9783031801532. [Google Scholar]

- Babashahi, L.; Barbosa, C.E.; Lima, Y.; Lyra, A.; Salazar, H.; Argôlo, M.; Almeida, M.A.d.; Souza, J.M.d. AI in the Workplace: A Systematic Review of Skill Transformation in the Industry. Adm. Sci. 2024, 14, 127. [Google Scholar] [CrossRef]

- Martini, B.; Bellisario, D.; Coletti, P. Human-Centered and Sustainable Artificial Intelligence in Industry 5.0: Challenges and Perspectives. Sustainability 2024, 16, 5448. [Google Scholar] [CrossRef]

- Banerjee, A.; Haridas, H.K.; SenGupta, A.; Jabalia, N. Artificial Intelligence in 3D Printing: A Revolution in Health Care. In Lecture Notes in Bioengineering; Springer: Singapore, 2022; pp. 57–79. ISBN 9789813367029. [Google Scholar]

- Kanthimathi, T.; Rathika, N.; Fathima, A.J.; Rajesh; Srinivasan, S.; Thamizhamuthu, R. Robotic 3D Printing for Customized Industrial Components: IoT and AI-Enabled Innovation. In Proceedings of the 2024 14th International Conference on Cloud Computing, Noida, India, 18–19 January 2024; pp. 509–513. [Google Scholar]

- Johnson, M.; Jain, R.; Brennan-Tonetta, P.; Swartz, E.; Silver, D.; Paolini, J.; Mamonov, S.; Hill, C. Impact of Big Data and Artificial Intelligence on Industry: Developing a Workforce Roadmap for a Data Driven Economy. Glob. J. Flex. Syst. Manag. 2021, 22, 197–217. [Google Scholar] [CrossRef]

- Tyagi, A.K.; Bhatt, P.; Chidambaram, N.; Kumari, S. Artificial Intelligence Empowered Smart Manufacturing for Modern Society: A Review. In Artificial Intelligence-Enabled Digital Twin for Smart Manufacturing; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2024; pp. 55–83. [Google Scholar]

- Shaji George, A.; Hovan George, A.S.; Baskar, T. The Evolution of Smart Factories: How Industry 5.0 Is Revolutionizing Manufacturing. Zenodo 2023, 1, 33–53. [Google Scholar] [CrossRef]

- Sadeghi, S.; Canty, R.B.; Mukhin, N.; Xu, J.; Delgado-Licona, F.; Abolhasani, M. Engineering a Sustainable Future: Harnessing Automation, Robotics, and Artificial Intelligence with Self-Driving Laboratories. ACS Sustain. Chem. Eng. 2024, 12, 12695–12707. [Google Scholar] [CrossRef]

- Goh, G.D.; Sing, S.L.; Yeong, W.Y. A Review on Machine Learning in 3D Printing: Applications, Potential, and Challenges. Artif. Intell. Rev. 2021, 54, 63–94. [Google Scholar] [CrossRef]

- Zhang, X.; Chu, D.; Zhao, X.; Gao, C.; Lu, L.; He, Y.; Bai, W. Machine Learning-Driven 3D Printing: A Review. Appl. Mater. Today 2024, 39, 102306. [Google Scholar] [CrossRef]

- Farhan Khan, M.; Alam, A.; Ateeb Siddiqui, M.; Saad Alam, M.; Rafat, Y.; Salik, N.; Al-Saidan, I. Real-Time Defect Detection in 3D Printing Using Machine Learning. Mater. Today 2021, 42, 521–528. [Google Scholar] [CrossRef]

- Ali, A.; Riaz, R.D.; Malik, U.J.; Abbas, S.B.; Usman, M.; Shah, M.U.; Kim, I.-H.; Hanif, A.; Faizan, M. Machine Learning-Based Predictive Model for Tensile and Flexural Strength of 3D-Printed Concrete. Materials 2023, 16, 4149. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Farina, I.; Colangelo, F.; Feo, L.; Fraternali, F. Multi-Material Additive Manufacturing of Sustainable Innovative Materials and Structures. Polymers 2019, 11, 62. [Google Scholar] [CrossRef]

- Khatri, B.; Frey, M.; Raouf-Fahmy, A.; Scharla, M.-V.; Hanemann, T. Development of a Multi-Material Stereolithography 3D Printing Device. Micromachines 2020, 11, 532. [Google Scholar] [CrossRef]

- Afshar, A.; Wood, R. Development of Weather-Resistant 3D Printed Structures by Multi-Material Additive Manufacturing. J. Compos. Sci. 2020, 4, 94. [Google Scholar] [CrossRef]

- Valentine, A.D.; Busbee, T.A.; Boley, J.W.; Raney, J.R.; Chortos, A.; Kotikian, A.; Berrigan, J.D.; Durstock, M.F.; Lewis, J.A. Hybrid 3D Printing of Soft Electronics. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef]

- Mikolajczyk, T.; Malinowski, T.; Moldovan, L.; Fuwen, H.; Paczkowski, T.; Ciobanu, I. CAD CAM System for Manufacturing Innovative Hybrid Design Using 3D Printing. Procedia Manuf. 2019, 32, 22–28. [Google Scholar] [CrossRef]

- Apeiranthitis, S.; Zacharia, P.; Chatzopoulos, A.; Papoutsidakis, M. Predictive Maintenance of Machinery with Rotating Parts Using Convolutional Neural Networks. Electronics 2024, 13, 460. [Google Scholar] [CrossRef]

- Omairi, A.; Ismail, Z.H. Towards Machine Learning for Error Compensation in Additive Manufacturing. Appl. Sci. 2021, 11, 2375. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Abdussalam Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Sampedro, G.A.R.; Rachmawati, S.M.; Kim, D.-S.; Lee, J.-M. Exploring Machine Learning-Based Fault Monitoring for Polymer-Based Additive Manufacturing: Challenges and Opportunities. Sensors 2022, 22, 9446. [Google Scholar] [CrossRef]

- Kadam, V.; Kumar, S.; Bongale, A.; Wazarkar, S.; Kamat, P.; Patil, S. Enhancing Surface Fault Detection Using Machine Learning for 3D Printed Products. Appl. Syst. Innov. 2021, 4, 34. [Google Scholar] [CrossRef]

- Heymann, H.; Schmitt, R.H. Machine Learning Pipeline for Predictive Maintenance in Polymer 3D Printing. Procedia CIRP 2023, 117, 341–346. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D.; Tsaramirsis, G.; Papageorgas, P.; Tamimi, H. 3D Printing and Implementation of Digital Twins: Current Trends and Limitations. Appl. Syst. Innov. 2021, 5, 7. [Google Scholar] [CrossRef]

- Herzog, T.; Brandt, M.; Trinchi, A.; Sola, A.; Molotnikov, A. Process Monitoring and Machine Learning for Defect Detection in Laser-Based Metal Additive Manufacturing. J. Intell. Manuf. 2024, 35, 1407–1437. [Google Scholar] [CrossRef]

- Rojek, I.; Kopowski, J.; Lewandowski, J.; Mikołajewski, D. Use of Machine Learning to Improve Additive Manufacturing Processes. Appl. Sci. 2024, 14, 6730. [Google Scholar] [CrossRef]

- Dostatni, E.; Osiński, F.; Mikołajewski, D.; Sapietová, A.; Rojek, I. Neural Networks for Prediction of 3D Printing Parameters for Reducing Particulate Matter Emissions and Enhancing Sustainability. Sustainability 2024, 16, 8616. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef] [PubMed]

- Madla, C.M.; Trenfield, S.J.; Goyanes, A.; Gaisford, S.; Basit, A.W. 3D Printing Technologies, Implementation and Regulation: An Overview. In AAPS Advances in the Pharmaceutical Sciences Series; Springer International Publishing: Cham, Switzerland, 2018; pp. 21–40. ISBN 9783319907543. [Google Scholar]

- Taylor, A.A.; Freeman, E.L.; van der Ploeg, M.J.C. Regulatory Developments and Their Impacts to the Nano-Industry: A Case Study for Nano-Additives in 3D Printing. Ecotoxicol. Environ. Saf. 2021, 207, 111458. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Dong, Z. Interfacial Regulation for 3D Printing Based on Slice-Based Photopolymerization. Adv. Mater. 2023, 35, e2300903. [Google Scholar] [CrossRef] [PubMed]

- Paxton, N.C. Navigating the Intersection of 3D Printing, Software Regulation and Quality Control for Point-of-Care Manufacturing of Personalized Anatomical Models. 3D Print. Med. 2023, 9, 9. [Google Scholar] [CrossRef]

- Montes, J. Risks and Regulation of Emerging Technologies in Chaotic and Uncertain Times the Case of 3D Printing. In Proceedings of the 2017 International Conference on Infocom Technologies and Unmanned Systems (Trends and Future Directions) (ICTUS), Dubai, United Arab Emirates, 18–20 December 2017. [Google Scholar]

- Daly, A. Medical 3D Printing, Intellectual Property, and Regulation. In 3D Printing in Medicine; Elsevier: Amsterdam, The Netherlands, 2023; pp. 385–398. ISBN 9780323898317. [Google Scholar]

- Osborn, L. 3D Printing and Intellectual Property. In Research Handbook on Digital Transformations; Cambridge University Press: Cambridge, UK, 2016; pp. 254–271. [Google Scholar]

- OECD 2017—The next Production Revolution- Implications for Governments and Business—Ch.5 Only.Pdf. Available online: https://drive.google.com/file/d/1H--DA7R97HWhmeXeGXEZyvfWQFLOLLuh/view (accessed on 16 April 2025).

- Khosravani, M.R.; Reinicke, T. On the Environmental Impacts of 3D Printing Technology. Appl. Mater. Today 2020, 20, 100689. [Google Scholar] [CrossRef]

- Jovanović, M.; Sanguino, T.d.J.M.; Damjanović, M.; Đukanović, M.; Thomopoulos, N. Driving Sustainability: Carbon Footprint, 3D Printing, and Legislation Concerning Electric and Autonomous Vehicles. Sensors 2023, 23, 9104. [Google Scholar] [CrossRef]

| Case Study/Reference | Technology Employed | Application Area | Key Benefits |

|---|---|---|---|

| Dabbagh et al. [82] | Machine Learning in Extrusion-based 3D Printing | Process Optimization | Real-time parameter adjustment, improved print quality, reduced waste |

| Elbadawi et al. [83] | Conditional Generative Adversarial Networks (cGANs) | Material Formulation | Novel FDM material development, reduced trial-and-error, accelerated innovation |

| Yang [84] | Case-Based Reasoning Systems | Print Quality Enhancement | Knowledge reuse, optimized printing parameters, reduced manual adjustments |

| Melton Machine & Control Co. [85] | SLS 3D Printing | Welding Fixture Components | Custom switch housings with enhanced durability and thermal resistance |

| Lengyel (PrintMax Solutions) [86] | AI-Driven Workflow Automation | End-to-End Print Services | 40% reduction in production time, 30% fewer errors, improved customer satisfaction |

| Nguyen et al. [87] | Robotics with Deep Learning | Post-Processing (Decaking) | Automated powder removal, enhanced scalability, reduced manual labor |

| Key Benefit | Description | Impact on Manufacturing | Examples/Applications |

|---|---|---|---|

| Customization at Scale | Ability to produce personalized products without increasing cost or production time. | Enables personalized products in high volumes, meeting specific consumer needs while maintaining production efficiency. | Customized footwear (e.g., Adidas and Nike), custom medical devices, personalized consumer goods. |

| Reduced Material Waste | Three-dimensional printing’s additive process uses only the required material, minimizing waste. | Reduces material consumption and environmental footprint, while optimizing production processes. | Aerospace parts, custom automotive components, 3D-printed prosthetics. |

| Sustainability through Efficient Resource Use | Real-time optimization of material and energy usage via automation. | Improves sustainability by reducing material waste, energy consumption, and excess inventory. | Energy-efficient manufacturing in automotive and healthcare sectors, local production of goods. |

| Enhanced Just-in-Time (JIT) Manufacturing | On-demand production using digital inventory and automated systems. | Reduces inventory costs, enables quick responses to market demand, and decreases overproduction. | Automotive parts, consumer electronics, on-demand production of complex parts. |

| Improved Digital Inventory Management | Digital designs are stored and produced on-demand, reducing reliance on physical stock. | Reduces the need for extensive physical inventories and logistics, lowering costs. | Spare parts for machinery, customized products (e.g., shoes, medical implants). |

| Decentralized Manufacturing and Local Production | Production can be moved closer to the point of use, enhancing supply chain resilience. | Shortens lead times, reduces transportation costs, and mitigates the risks associated with global supply chains. | Localized manufacturing in industries like healthcare, automotive, and consumer goods. |

| Challenge | Description | Impact on Manufacturing | Potential Solutions |

|---|---|---|---|

| Quality Control and Repeatability | Variability in material properties, print layer adhesion, and machine calibration can lead to inconsistent part quality. | Inconsistent quality across large production runs, affecting product reliability. | Advanced sensor integration, AI-driven real-time monitoring, and process optimization. |

| Scalability | Three-dimensional printing is typically slower than traditional manufacturing methods, limiting its ability to scale in high-volume production. | Slower production rates compared to conventional methods, hindering large-scale applications. | Hybrid manufacturing systems, multi-printer configurations, and optimized post-processing workflows. |

| Compatibility with Existing Systems | Integration of 3D printing with traditional automated systems (e.g., robotic arms, CNC machines) requires significant modification. | Disruption to existing workflows and difficulty in synchronizing additive and subtractive processes. | Development of standardized software and hardware interfaces for seamless integration. |

| Workforce Adaptation | AI and machine learning technologies in 3D printing systems require workers to adapt to new roles and skill sets. | Potential job displacement and need for reskilling in high-tech areas such as AI and robotics. | Investment in workforce training programs and skill development in emerging technologies. |

| Trend/Consideration | Description | Impact on Automated 3D Printing |

|---|---|---|

| AI-Driven Self-Optimizing Printers | Integration of AI to optimize print parameters in real-time based on environmental and process data. | Enhanced print quality, reduced waste, and increased production efficiency. |

| Predictive Maintenance | Use of machine learning algorithms to predict printer failures and schedule maintenance. | Minimizes downtime and reduces operational costs by preventing unexpected machine failures. |

| Multi-Material Printing | Ability to print using multiple materials within a single part, optimizing material distribution based on part function. | Increases versatility and functionality of printed parts, especially for complex geometries requiring varied material properties. |

| Hybrid Manufacturing Systems | Combining additive (3D printing) and subtractive processes (e.g., CNC machining) in a single system. | Enables high precision and complex part fabrication, balancing the strengths of both 3D printing and traditional manufacturing. |

| Standardization and Regulatory Frameworks | Development of international standards for 3D printing materials, processes, and quality assurance. | Ensures part quality, consistency, and safety, enabling broader adoption across industries with confidence in product reliability. |

| Intellectual Property (IP) Regulations | Regulatory frameworks addressing the protection of digital designs and ensuring secure sharing of 3D printing files. | Addresses IP challenges raised by digital fabrication and ensures secure and legal reproduction of designs. |

| Environmental Regulations | Guidelines to minimize the environmental impact of 3D printing, including sustainable material use and recycling practices. | Promotes eco-friendly practices in 3D printing, reducing waste and encouraging the use of biodegradable or recyclable materials. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kantaros, A.; Drosos, C.; Papoutsidakis, M.; Pallis, E.; Ganetsos, T. The Role of 3D Printing in Advancing Automated Manufacturing Systems: Opportunities and Challenges. Automation 2025, 6, 21. https://doi.org/10.3390/automation6020021

Kantaros A, Drosos C, Papoutsidakis M, Pallis E, Ganetsos T. The Role of 3D Printing in Advancing Automated Manufacturing Systems: Opportunities and Challenges. Automation. 2025; 6(2):21. https://doi.org/10.3390/automation6020021

Chicago/Turabian StyleKantaros, Antreas, Christos Drosos, Michail Papoutsidakis, Evangelos Pallis, and Theodore Ganetsos. 2025. "The Role of 3D Printing in Advancing Automated Manufacturing Systems: Opportunities and Challenges" Automation 6, no. 2: 21. https://doi.org/10.3390/automation6020021

APA StyleKantaros, A., Drosos, C., Papoutsidakis, M., Pallis, E., & Ganetsos, T. (2025). The Role of 3D Printing in Advancing Automated Manufacturing Systems: Opportunities and Challenges. Automation, 6(2), 21. https://doi.org/10.3390/automation6020021