1. Introduction

One way of understanding the mechanics of locomotion is by recreating it. Legged systems with one-, two-, and four-legs have been built, modeled, and controlled. In such systems, stability is a key issue that needs to be accounted for during control synthesis and to an extent, interferes in developing an understanding of the effect of morphology (e.g., the mass, the moment of inertia, the springiness of legs) on the gait. A rimless wheel robot when constructed properly does not have any issues of stability (i.e., falling) and provides an appropriate system for studying the effect of morphology on gait mechanics. The paper presents the design of a relatively simple rimless wheel that can move and turn. We follow this by detailed modeling, simulation, and parameter studies.

The rimless wheel, as the name suggests, is a wheel without the rim and was first mentioned as a model of walking by Margaria [

1]. When one launches the rimless wheel with momentum on level ground, the legs of the wheel collide with the ground, losing energy at every step, and eventually coming to a complete stop.

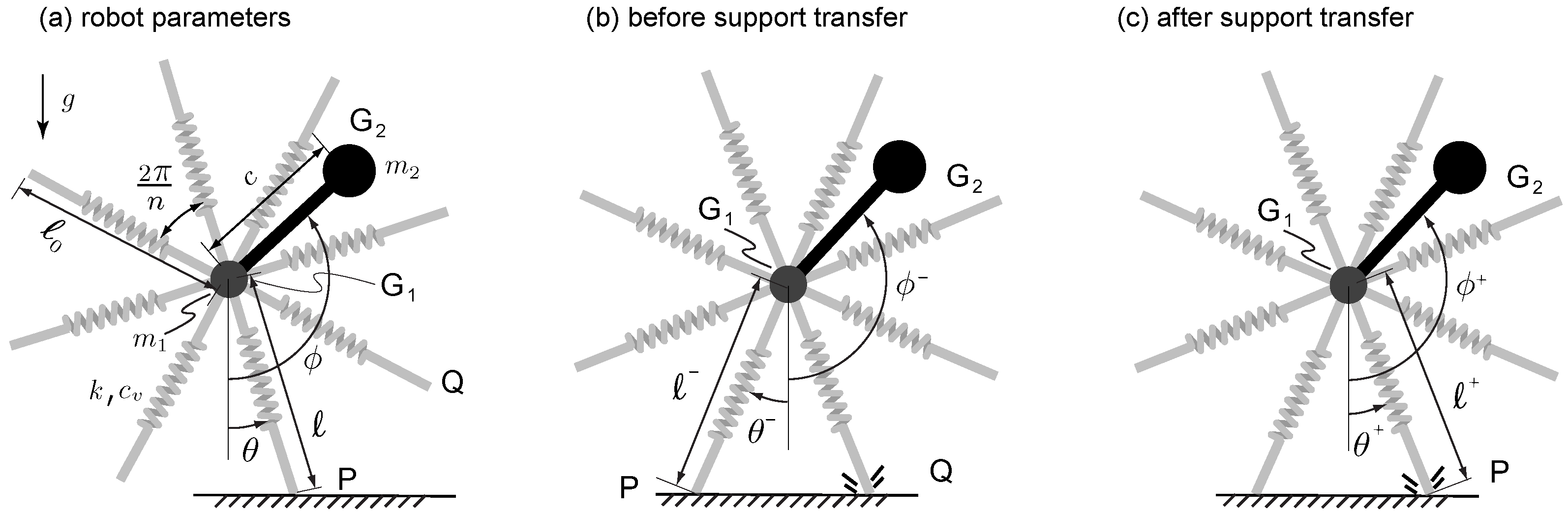

The simplest method of sustaining walking with the rimless wheel is to launch it down a slope. Depending on the mass, inertia, leg length, and the number of spokes, there is a certain slope that ensures steady walking speed. This notion of steady speed walking was first analyzed using tools in dynamical systems by McGeer [

2] using Poincaré section and limit cycle. The analysis comprises first finding an initial condition at a Poincaré section (a chosen instant in the locomotion cycle such as foot-strike), that repeats at the Poincaré section at the subsequent step, resulting in a limit cycle or periodic motion. Then, using a linearization of the step-to-step dynamics, one can determine if small perturbations would grow or diminish every step. It is relatively easy to find stable limit cycle for the 2D rimless wheel [

3]. However, in 3D, the rimless wheel is stable in the sagittal fore-aft plane but not stable in the yaw (heading) direction [

4]. One can achieve stable motion by adding a finite width to the rimless wheel, i.e., two rimless wheels connected via a finite width bar [

5].

An unpowered rimless wheel can sustain periodic walking on level ground if it reduces impact losses to zero. Gomes and Ahlin [

6] created an ingenious design that involved connecting a torsional spring between the legs and the robot frame in such a way that the spring winds-up from mid-stance to support exchange, extracting the energy from the robot to ensure a nearly impact-less collision. Thereafter, the spring restores the energy to the robot by unwinding itself from support exchange to the next mid-stance.

Powering the rimless wheel enables locomotion on flat terrain. Agrawal and Yin [

7] created a vehicle with a castor wheel in front and two rimless wheels at the rear. These two rear rimless wheels have one motor to power both the wheels in tandem and another one to expand/contract the leg length relative to each other. The rimless wheel moves straight by rotating both wheels at the same speed but can turn by contracting or expanding the spokes on one wheel relative to the other. Laney and Hong [

8] created a robot with two pairs of rimless wheels, each with six telescopic legs. There is a single motor on a diagonal pair of legs that can expand/contract the pair. Thus, there are three motors per rimless wheel. The robot moved straight and turned by retracting/protracting the telescopic legs in a suitable pattern. Most recently, Cotton et al. [

9] built a series of rimless wheel robots with two pairs of wheels arranged side by side with fixed-length legs. The rimless wheel moved straight using a single motor on its central axle and turned using another motor that rocks a wobbling mass in the lateral plane. One robot they built called the Outrunner was 0.6 m tall (2 feet) and achieved a top speed of 8.9 m/s (20 mph) and another called HexRunner [

10] was 1.83 m tall (6 feet) and achieved a top speed of 14.4 m/s (32.2 mph).

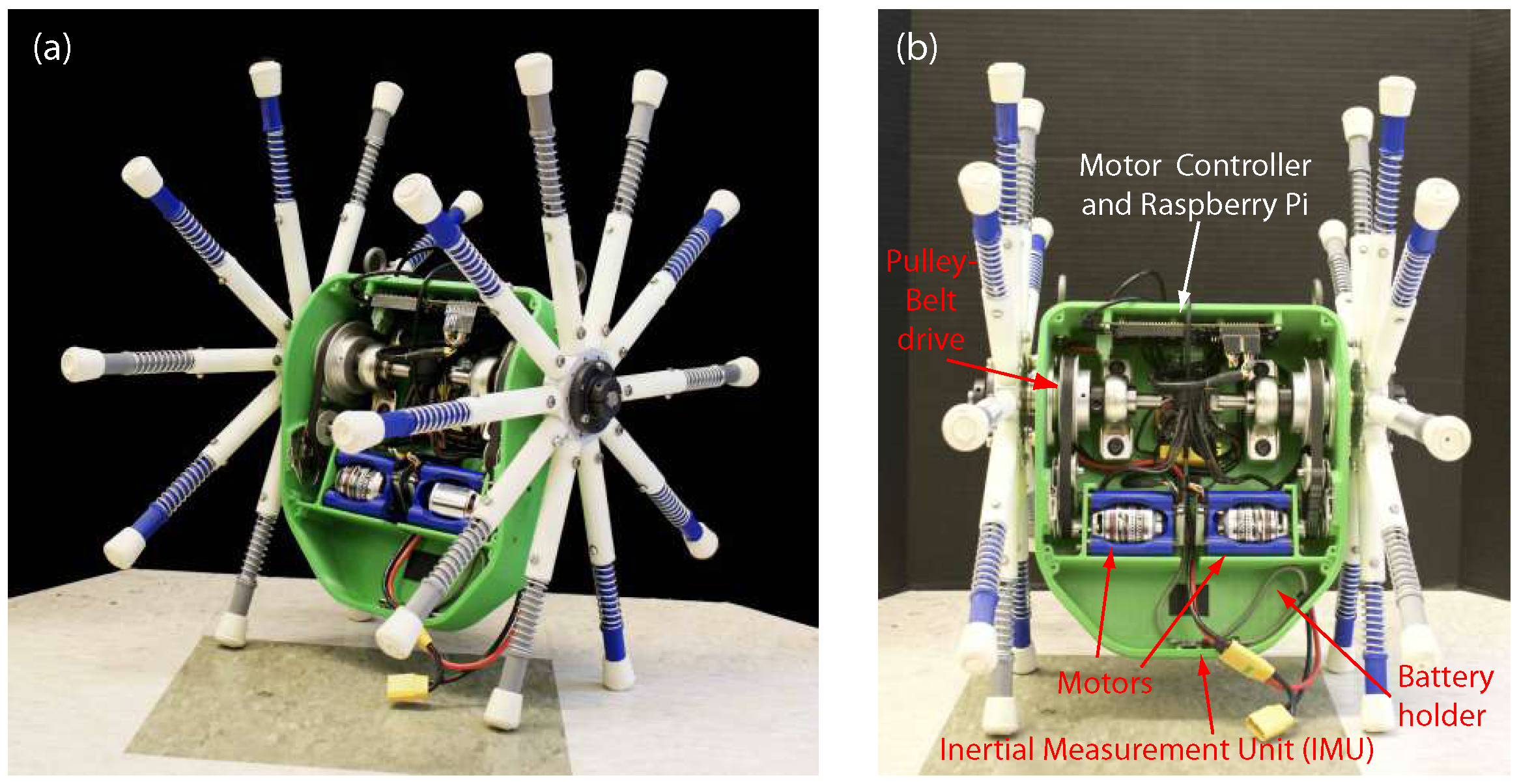

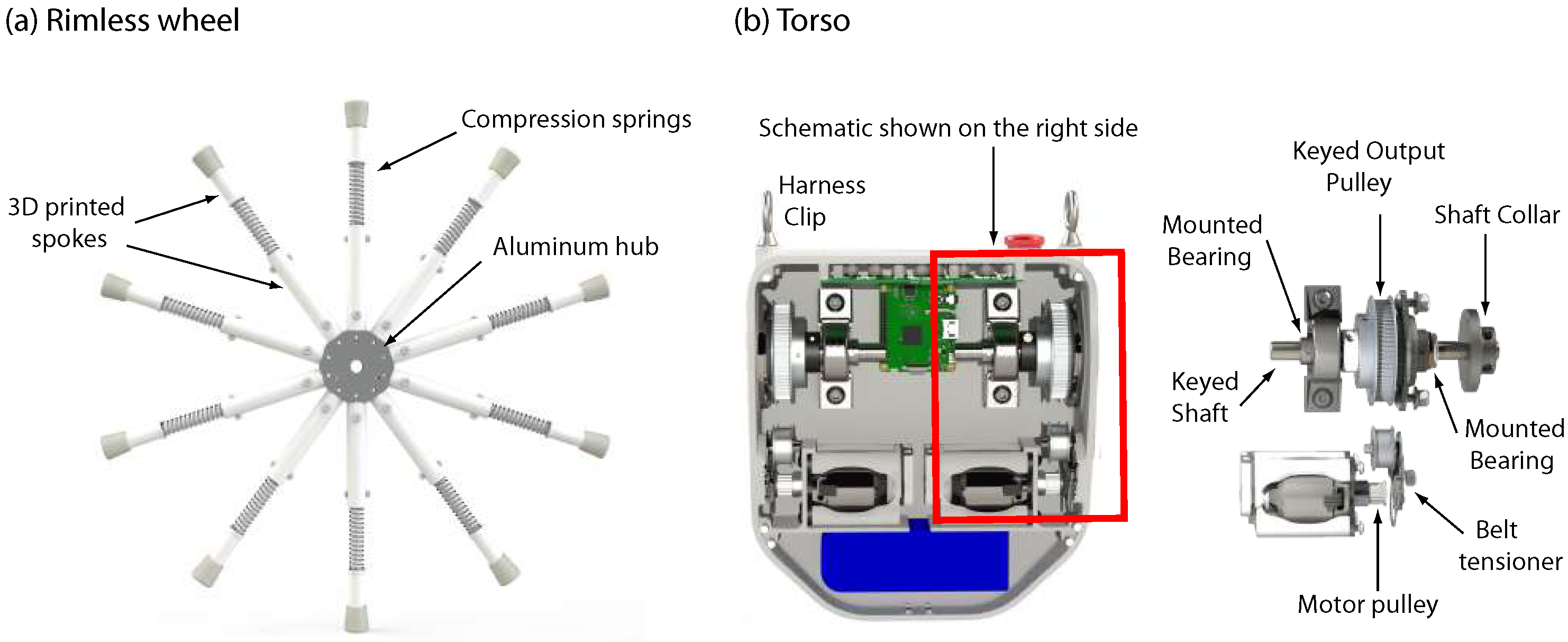

Our work builds upon an earlier rimless wheel robot [

11], which had two sets of rimless wheels with eight legs each. A single motor fixed to the axle connecting the two rimless wheels propelled the robot forward. That robot could not turn. Here we have modified the design to include two motors, one for each rimless wheel, to enable turning by spinning them at different speeds. This work details the mechanical and electrical design, the controller design, the modeling and simulation, and finally parameter studies. This work is novel in a few ways. (1) Though there only a few rimless wheels that can turn, ours is the first one to use a differential drive mechanism for turning. The mechanism allows for relatively sharp turns and decouples the sagittal fore-aft plane motion to lateral or turning motion. (2) The demonstration of versatile metrics, energy-efficient locomotion, high-speed locomotion, and turning. The robot had a best-case energy-efficiency (Total Cost of Transport (TCOT), which is total input power per unit weight per unit speed) of 0.13, which is close to that of the most energy efficient legged robot so far, Cargo [

12] at 0.11. The top speed achieved was 4.3 m/s (9.66 mph). The smallest turning radius achieved was 0.5 m. However, note that these metrics were achieved in separate trials. This work does not cover feedback control against external perturbations, which we report elsewhere [

13]. An earlier conference paper [

14] described construction details and limited results, but this paper has more extensive results including modeling and parameter studies.

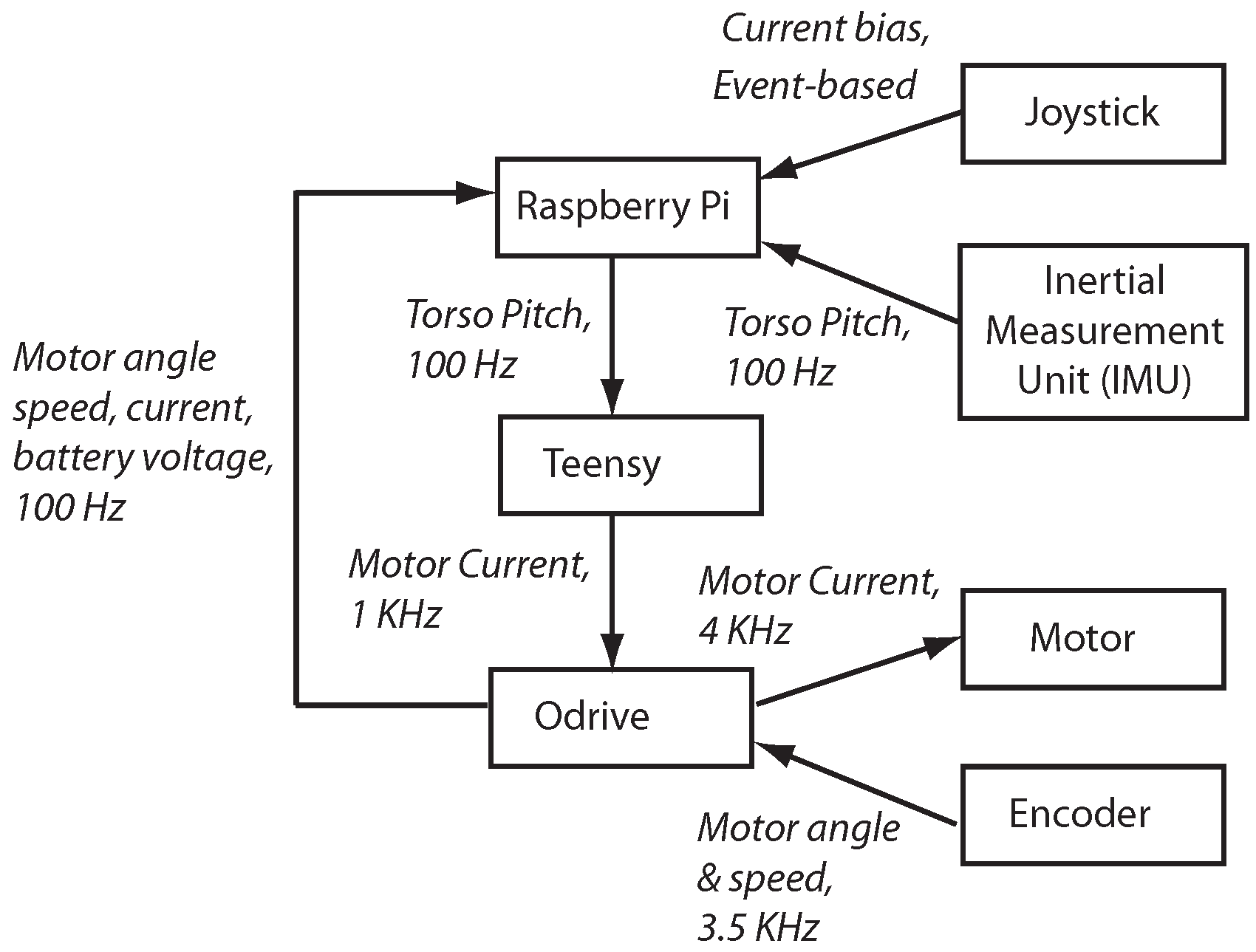

The flow of the paper is as follows. The hardware section presents the mechanical and electrical design is in

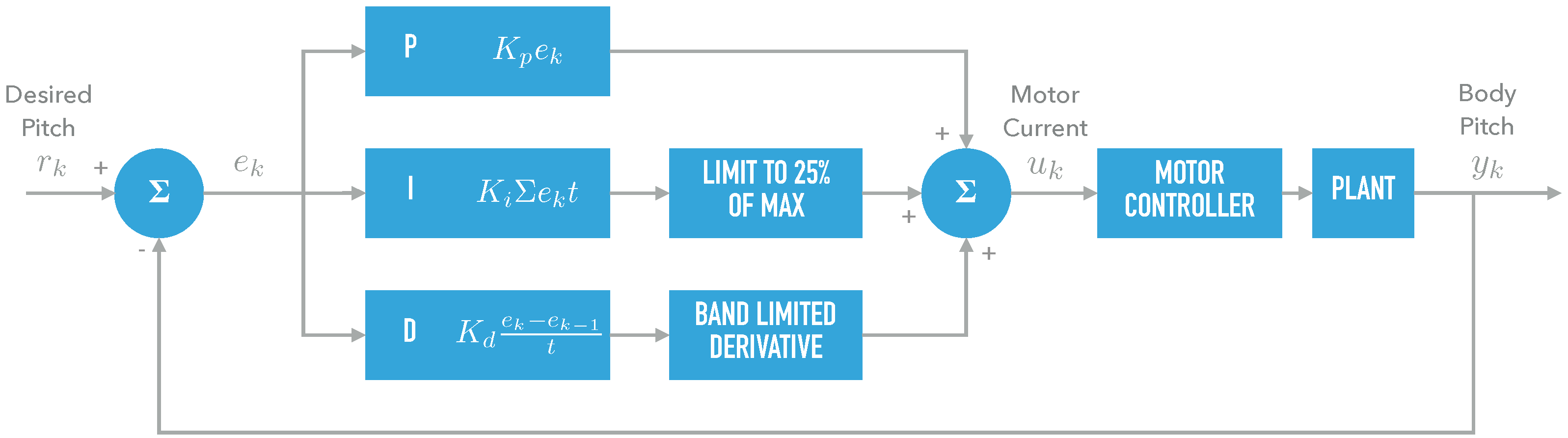

Section 2, the controller is in

Section 3, the modeling and simulation is in

Section 4, the results are in

Section 5, and discussion in

Section 6.

5. Results

This section presents the experimental and simulation results. To initialize the robot, we held the robot in a stationary position on two spokes, one on each side. We turn ON the torso pitch controller and allowed to stabilize. Once stabilized, we gently push the robot to impart slight momentum that helps it move forward. For a steady torso pitch angle, the robot achieves a set steady-state speed when initialized in this fashion. To turn the robot, we use a wireless joystick that sets a differential current to each motor as described in

Section 5.2.

Our metrics for the robot performance are the overall robot speed, the mean torque on the motors, the power drawn by the motors, the Actuator Cost Of Transport (ACOT) and the Total Cost Of Transport (TCOT). We define the latter two quantities

The difference in ACOT and TCOT is in the power term used in the numerator. The ACOT uses the power of the two motors while TCOT uses the power of the motors and power of the electronics and computers. Thus, TCOT has a greater value than ACOT. A low Cost of Transport (Total or Actuator) demonstrates a more energy-efficient motion.

5.1. Straight-Line Motion

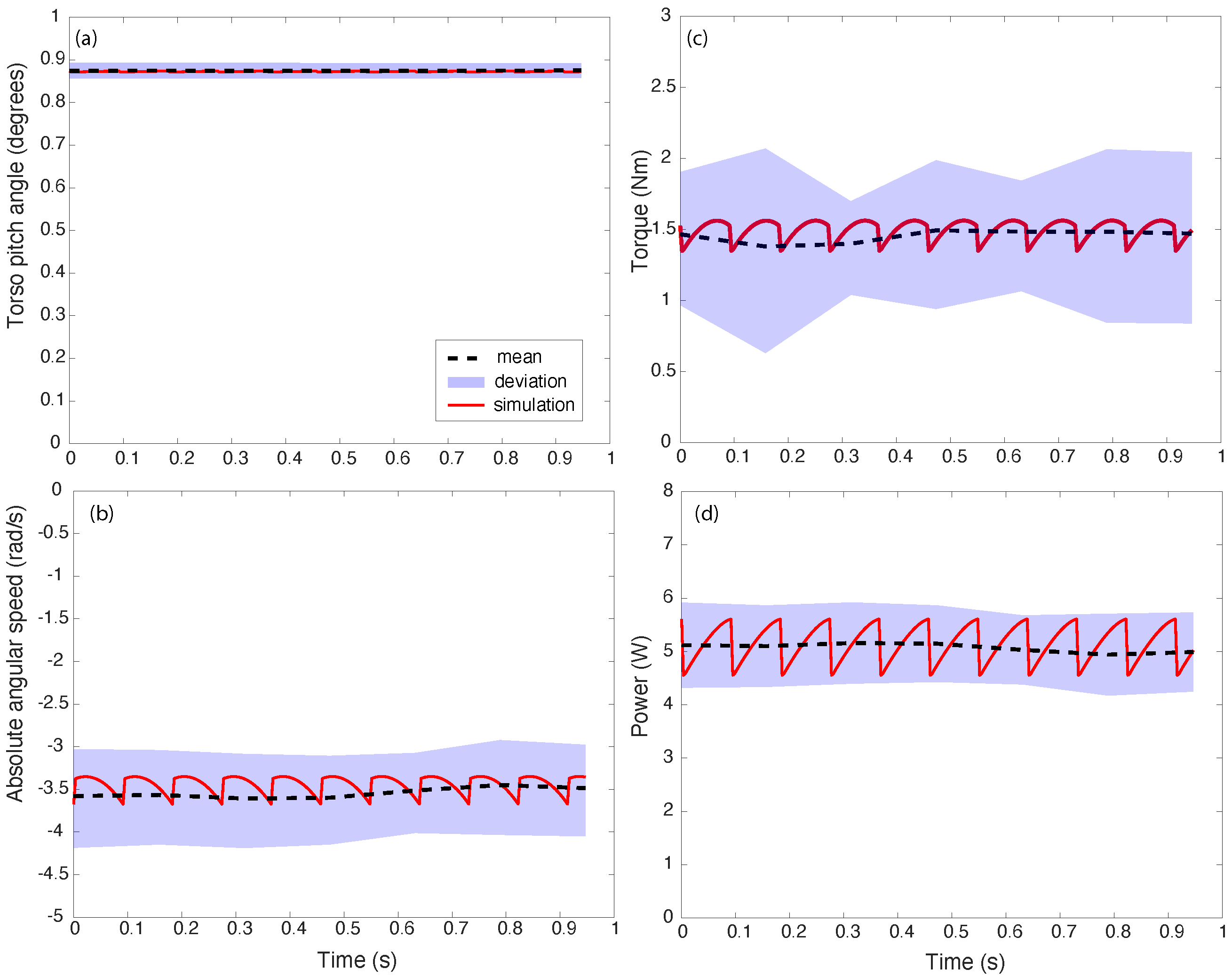

Figure 7 compares the trajectory data between simulation and experiments for a test run on concrete with a torso pitch setpoint of

. The data is for 5 seconds after the robot reaches a steady-state speed. The thick red lines are the simulation data, the black dashed lines and blue bands are the mean values and one standard deviation respectively for the experimental data. Although the setpoint tracking is achieved with high accuracy as shown by (a), the speed is within

rad/s and the torque is within

Nm. The power which is the product of the torque and speed is

W. The experimental data is considerably noisy hence the relatively large standard deviation, but the average values between simulation and experiments agree reasonably well as indicted by

Table 1. There are two reasons for the spiky data: (1) the collisions during support transfer, and (2) the cogging torque in the motor. The cogging torque is more pronounced when doing a current control as done here. Cogging torque is when there is zero output torque that occurs when the rotor lines onto the dead-band (no magnetic field) of the stator.

We tested the rimless wheel on different surfaces to study the effect of floor compliance on the TCOT and speed.

Table 2 shows the results of testing on 5 different surfaces. All these results were for a torso setpoint of

and after achieving steady-state motion. As seen from the table, polished concrete has the lowest speed and highest TCOT while asphalt has the highest speed and lowest TCOT.

We also tested the rimless wheel for different torso pitch angle. Theoretically, a torso pitch angle of should give the fastest speed. However, because the torso pitch set-point control is not perfect, the torso would overshoot beyond driving the system unstable. To offset the issue, we limit the torso pitch to a maximum of to the vertically downward direction. The maximum speed achieved with this torso pitch angle is m/s ( mph) on polished wood (i.e., an indoor basketball court).

5.2. Turning Motion

To induce turning, we command the robot torso pitch to

and launched to move in a straight line. After the robot reaches a steady-state speed, it turns when commanding different currents in the motors using a hobby remote control.

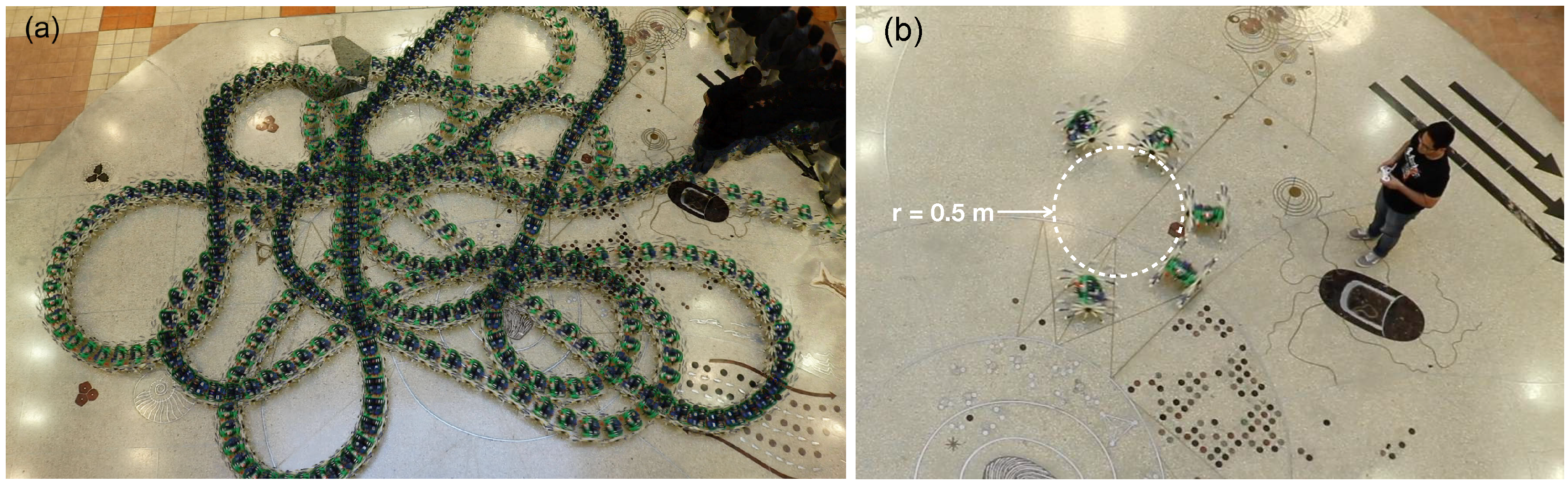

Figure 8a show the path taken by the robot. The robot can turn within the indoor facility without bumping into obstacles. We show the smallest turn radius during our trials in

Figure 8b. We obtain the figure by super-posing five video frames and using a calibration scale to measure the radius. The smallest turn radius achieved is

m. The turn radius is measured using the inner side of the rimless wheel when it turns. Theoretically the smallest turn radius is zero corresponding to the one wheel stationary and other moving a non-zero speed. The issue is that the torque requirement for this is too low for the robot to hold a constant pitch angle of

leading to a loss of forward momentum, consequently coming to a halt. From multiple runs, we found that the robot turns more easily on hard floors at slow speeds most likely because of the better traction between the legs and the floor at slow speeds.

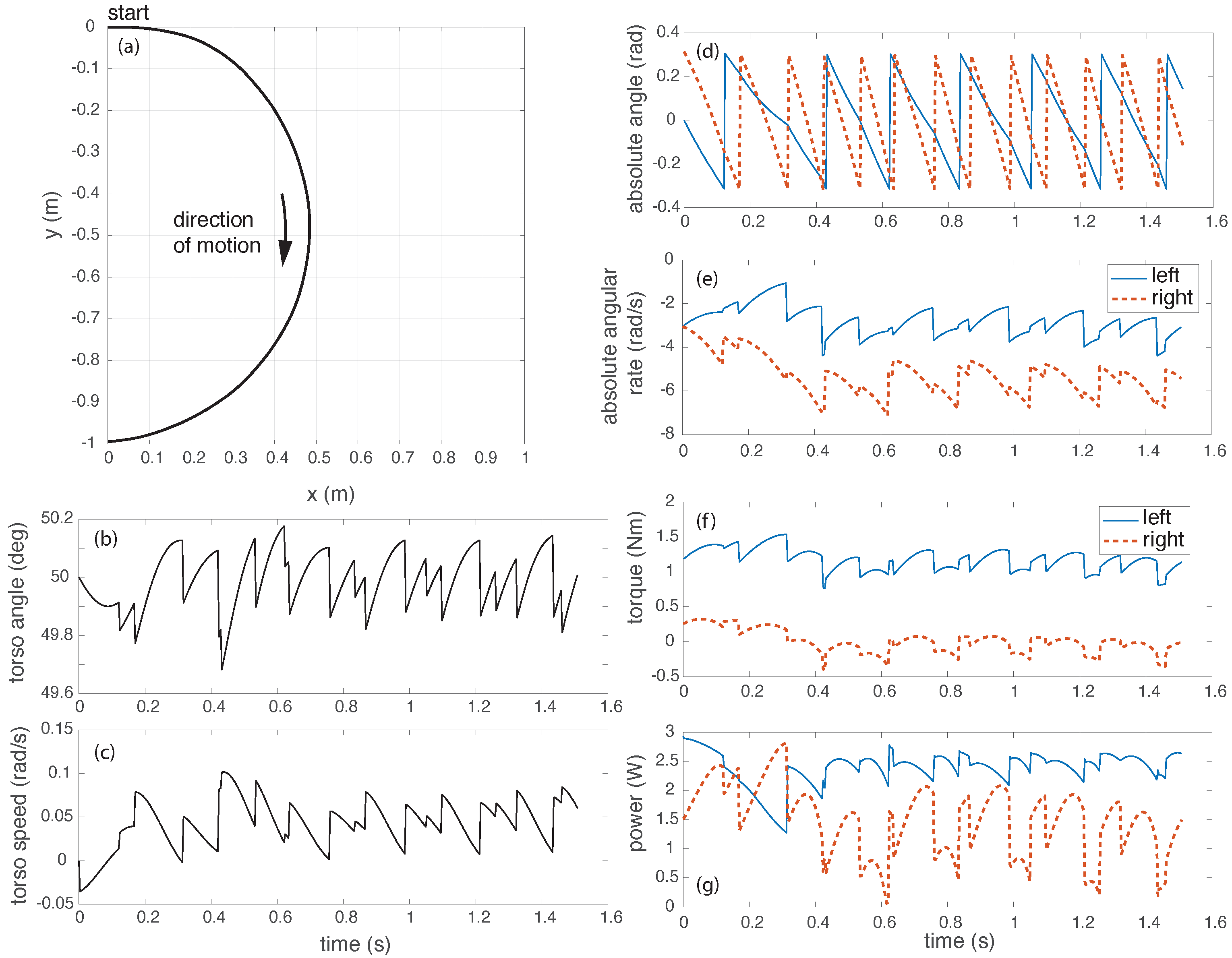

Figure 9 shows the simulation data for turning with a radius of

m. Here, the relative difference between the left and right motor current is

A.

Figure 9a shows the spatial position of the center of the torso as viewed from top. The rimless wheel starts at

and turns clockwise. As shown in subsequent figures, the robot takes about

s to complete half-turn. The

Figure 9b,c shows the torso pitch angle and torso speed. It can be seen that the torso pitch stays around

while there is mild fluctuation in the speed. Note that we used a simple position servo without considering the model compensation (e.g., gravity compensation).

Figure 9d,e shows the position and speed of the spoke in contact with the ground. It can be seen that the left wheel is traveling faster than the right one. Finally,

Figure 9f,g shows the motor torques and motor powers respectively. It can be seen that the differential torque is about 1 Nm and the total motor powers is about

W consistent with straight line movement. These results demonstrates that (1) our control algorithm of introducing a small differential current in the two motors is sufficient to get the rimless wheel to turn without losing momentum and (2) validates the kinematics-based steering model.

5.3. Parameter Studies

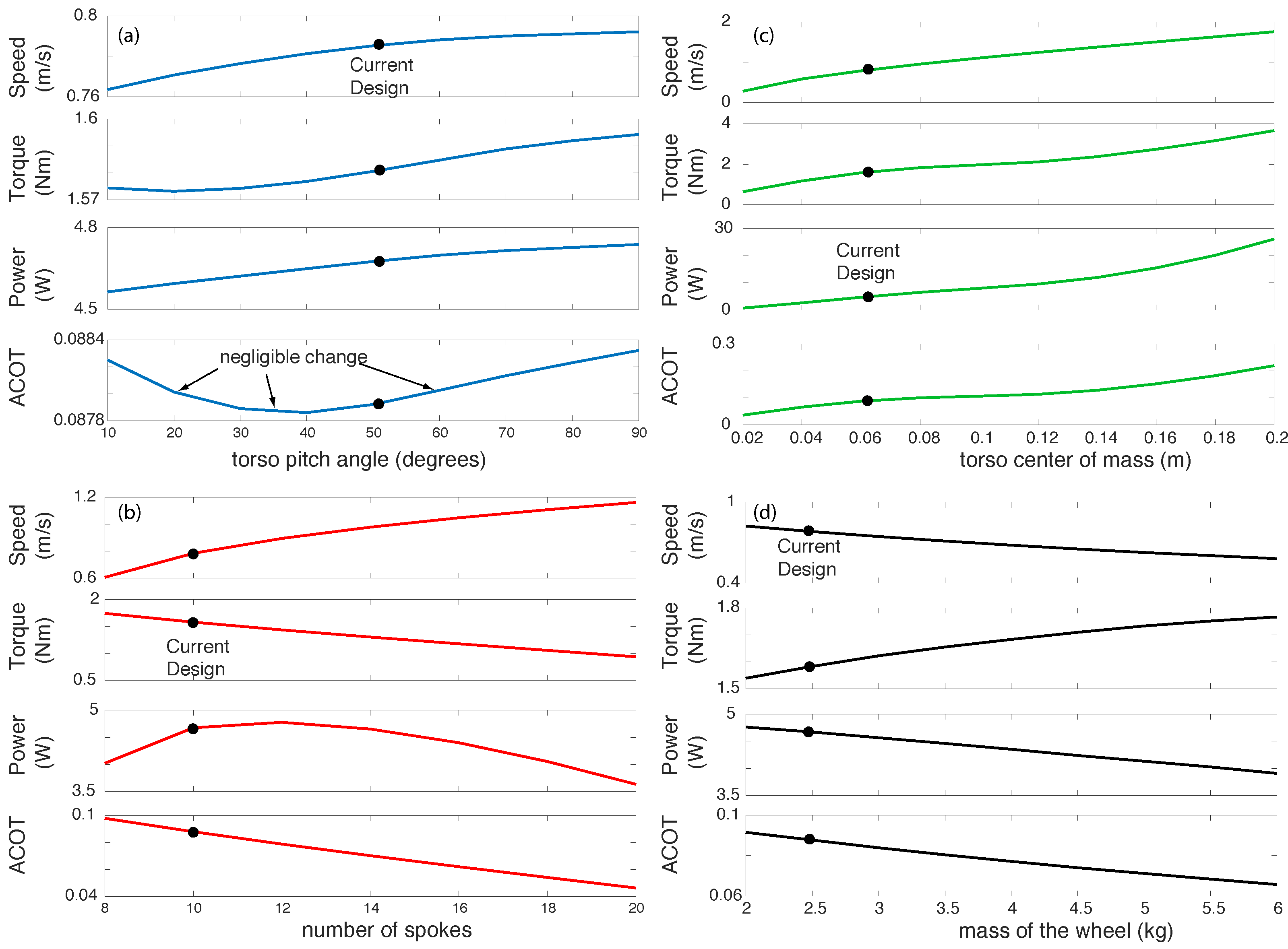

To do parameter studies, we vary one parameter at a time keeping the other parameters the same as the one for straight-line motion. For each simulation, we start the rimless wheel in the upright position and angular speed rad/s and simulation time is 5 s. The time is sufficiently long for the rimless wheel to achieve steady-state speed. The parameters we vary are the torso pitch angle, location of the center of mass of the torso, the number of spokes, the mass of the wheel, and the stiffness of the springs in the leg.

Figure 10 shows plots of the output parameters: average speed, average torque on the torso, average motor power, and average motor cost of transport for all the above parameters except the leg stiffness. We have not shown the leg stiffness data because we found that there are no significant changes in the output parameters when we vary spring stiffness from 500 to 4000 N/m. The black dot in the plot shows the value for the current robot design and the straight-line movement experiment reported earlier. From these plots, we can draw the following conclusions: (1) to increase the speed, the torso pitch angle, the distance of the center of mass from the center of the wheel, and the number of spokes should all increase but the mass of the wheel should decrease; (2) to decrease the torque on the torso, the pitch angle, the torso center of mass, and the mass of the wheel should all decrease but the number of spokes should increase; (3) to decrease power consumption the torso pitch angle, the center of mass location should decrease but the mass of the wheel should increase, but there is a range of spokes between 10 and 12 where the power achieves a maximum; and (4) to decrease the cost of transport, the location of the center of mass from the center of the wheel should decrease but the number of spokes and mass of the wheel should increase, but there is a negligible change as the torso pitch angle changes.

One can use these plots or computer simulations as a starting point to achieve specific performance metrics for the rimless wheel robot.

6. Discussion

This paper presented the design, modeling, and control of a differential drive rimless wheel robot that achieved a maximum speed of m/s ( mph) and a minimum turn radius of m. The kg robot achieved a Total Cost of Transport (power per unit weight per unit speed) between to for different surfaces with speed ranging from to in m/s ( to in mph). The model of the rimless wheel robot comprises a kinematics-based model for steering motion and dynamics-based for sagittal or fore-aft plane for forward movement. The model can explain the energetics, speed, and turning characteristics of the robot. Finally, parameters studies show key parameters that affect the speed and energetics.

The Total Cost Of Transport (TCOT) defined as the power used per unit weight per unit velocity is the most widely accepted measure of energy usage of locomotion [

22]. Humans have a TCOT of

while walking at a self-selected speed [

23]. However, among ‘true’ bipedal robots, the most energy-efficient robots are Cornell biped with TCOT of 0.2 [

24] and Cornell Ranger with a TCOT of 0.19 [

25,

26]. The most energy-efficient legged robot is by ETH Zurich, Cargo at a TCOT of 0.1 [

12] while RR 2 at TCOT of 0.13. However, Cargo has large feet and RR2 has multiple spokes. These features afford these robots enhanced stability with no additional controller considerations. The parameter studies the following measures to further decrease the TCOT: (1) moving the center of mass closer to the center of the wheel, thus reducing the motor torque; (2) increasing the number of spokes which leads to lowering the collisional losses; and (3) increasing the total mass presumably because the power increase in the numerator of TCOT is proportionately less than the decrease of TCOT because of the increased mass in the denominator.

The RR2 with 20 total legs reached a maximum speed of 4.3 m/s (9.66 mph). The robot has legs with a length of 0.26 m, which gives it a Froude number of 2.71 (Froude number is where v is speed, g is gravity 9.8 m/s2, and ℓ is leg length). Outrunner, the 0.6 m tall, 6 legged rimless wheel had a Froude number of 5.14 and HexRunner, the 1.83 m tall, 6 legged rimless wheel had a Froude number of 4.82. Thus, RR2 is twice as slow as these other rimless wheels. To increase the speed of the rimless wheel we need to reduce the collisional losses. We can do this either by decreasing its mass or increasing the number of spokes. Alternately one can add more energy to the system during the single stance phase by increasing the pitch angle or increasing the distance of the center of mass from the center of the wheel.

A differential drive-based turning is simple (only two motors needed) and enables a short turn radius. The minimum turning radius achieved by RR2 is 0.5 m (see

Figure 8). The low net torque prevents us from achieving the shortest turn radius of 0 m (turning in place) as discussed in

Section 5.2. The Outrunner and HexRunner use an oscillating pendulum-like mechanism in the lateral (side-ways) plane for turning, but the minimum turn radius has not been made publicly available. The main difference between RR2 and these runners is that RR2 relies on kinematics to turn (speed of one wheel relative to the other) while the runners rely on the dynamics of the oscillating mass, the location of its center of mass, and oscillating frequency. We need to control the oscillation to ensure that the turning motion does not destabilize the robot in the sideways direction. Although the differential drive rimless wheel and the differential drive wheel have the same turning kinematics, the rimless wheel has hybrid dynamics in the sagittal plane with energy losses during collision, while the wheel has purely kinematic movement without energy losses assuming that it rolls without slipping.

Direct drive motors are attractive because they provide low backlash, low friction, low reflected inertia, mechanical robustness/efficiency, high-actuation bandwidth, and high efficiency [

27]. The direct-drive brushless motor used in the robot has a KV rating of 280. This means that for a 1 V voltage output across the motor terminals, the input motor speed is 280 rpm. A high KV ensures high speed but a low KV ensures a high torque. This KV rating did not provide enough torque to support the weight of the torso. Thus we add a pulley transmission to increase the gearing by a factor of

, thus increasing the torque without reducing the advantages of the direct drive motors appreciably.

A significant issue with the hobby-grade motors such as the ones used here is the torque ripple or the periodic fluctuation of the output torque for constant input current and load. This is because of the low number of magnetic cores in hobby-grade motors that lead to a lower magnetic strength as the rotor moves from one core to the next. The torque ripple causes controllability issues leading to a poor torque and/or position control (see

Figure 7c). The torque ripple made it difficult to achieve rapid modification in the speed and turning.

The rimless wheel had some failure modes. A successful launch was sensitive to the push. Too hard or too slow a push or asymmetrical push leads the rimless wheel to not launch properly causing a failed trial. A fixture for standardizing the launch can solve this issue. On numerous occasions, the rimless wheel ran into walls and broke one or more legs. However, because the legs were modular and 3D printed, it is relatively easy to fix the broken legs.

Rimless wheels are traditionally been argued to be useful in uneven terrain (e.g., sand, rock). However, if rimless wheel can easily move straight and turn, it can be useful in navigating in tight spaces (e.g., warehouses, buildings) such as the case here. In the rimless wheel presented here, we control the speed by maintaining a constant pitch on the torso. Thus, the torso is always at a fixed angle with respect to the world frame. In such settings, one can mount a stereo camera on the torso to enable vision-based movement control.

There are several limitations of the robot that could be addressed in future iterations. The robot cannot self-start and needs to be manually launched. If the robot goes too slow, it comes to a complete stop. This is because there is an energy barrier to cross from the standing position with four spokes (two on each side) touching the ground to the vertical upright position with two spokes touching the ground (one on each side). One way of crossing the energy barrier is by pitching the torso appropriately to pump energy into the wheel. It is challenging to control the pumping with noisy sensors without leading to instability. One option to self-start is to additional means of actuation such as an actuated tail or actuated spokes. The torque ripple prevents high fidelity motion control such as stabilizing against disturbance and quick turning. This issue may be addressed by upgrading to motors with a higher number of magnetic cores [

28] or by position or force-based feedback compensation [

29]. The robot cannot work on rough terrain such as sandy and muddy terrain and is probably because of its relatively low speed for its size.