Enhancing Oil Recovery Through Vibration-Stimulated Waterflooding: Experimental Insights and Mechanisms

Abstract

1. Introduction

2. Experiment

2.1. Materials

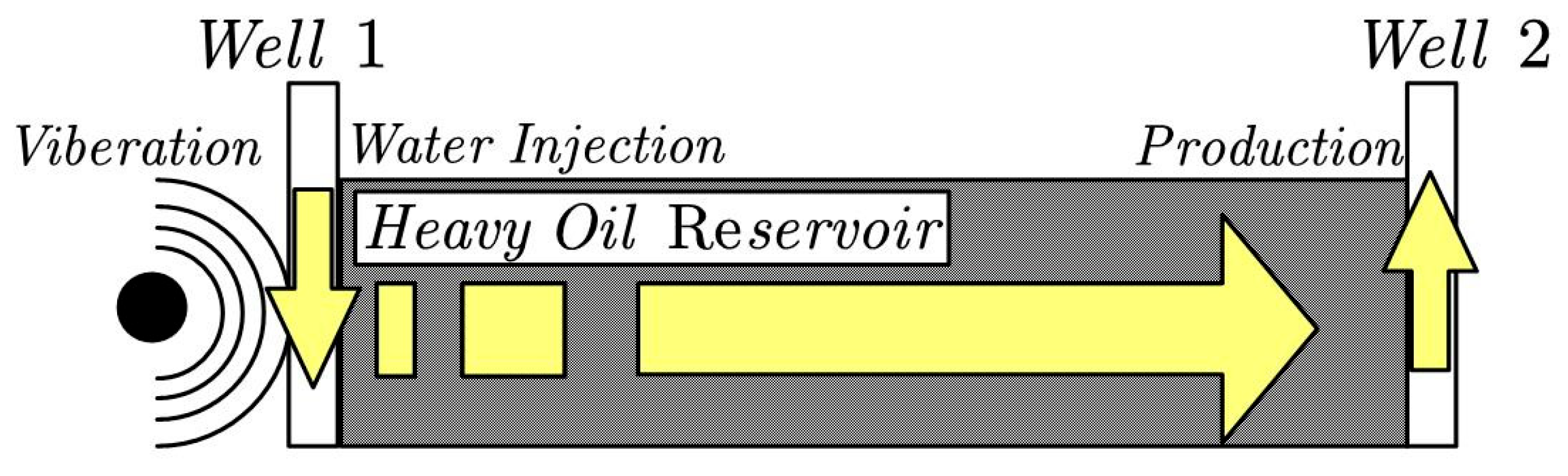

2.2. Experiment Setup

2.3. Experimental Preparation

2.4. Experimental Procedure

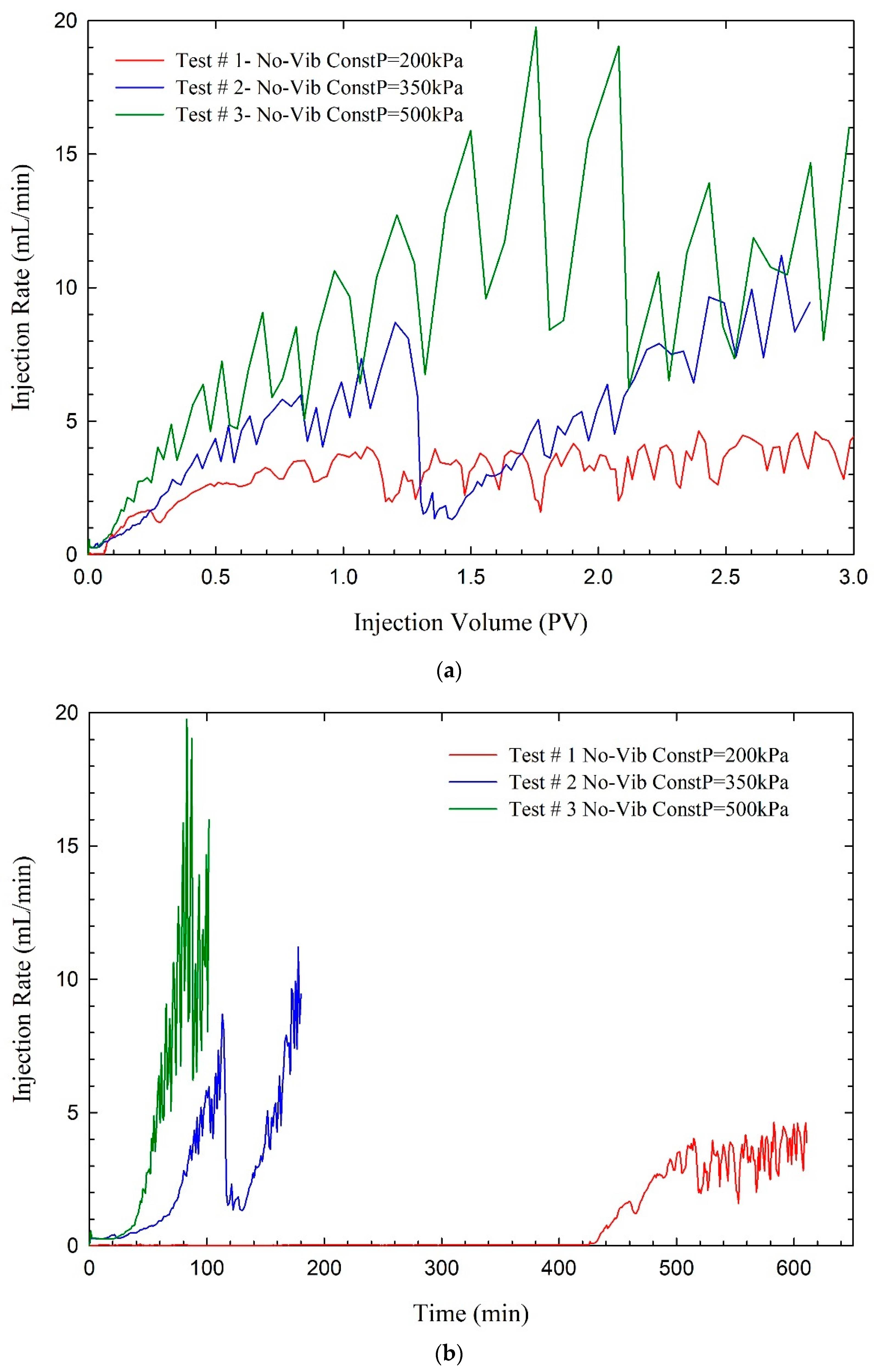

- Constant-pressure WF tests (Tests 1–3): No vibration; injection pressures of 200, 350, and 500 kPa.

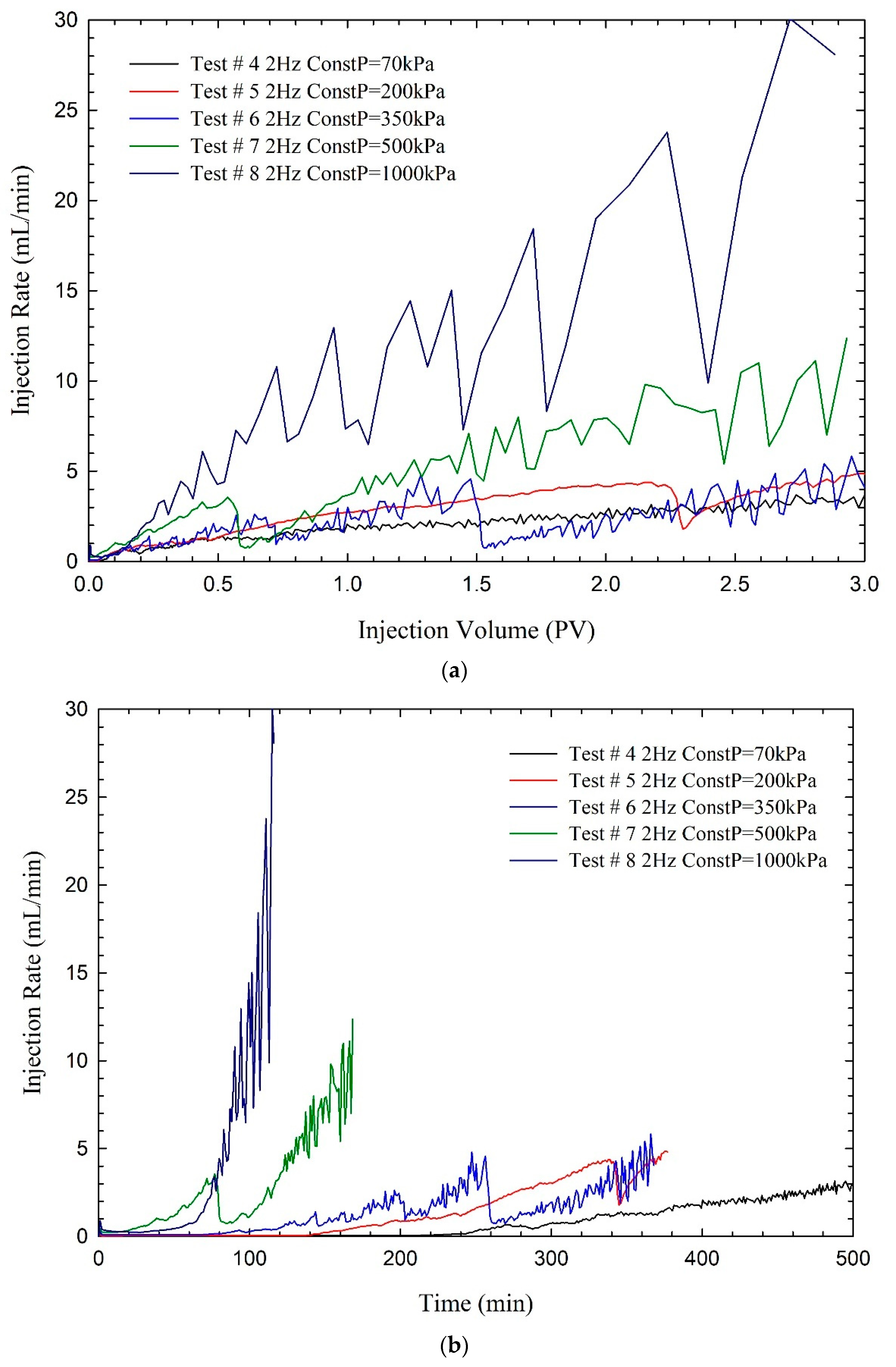

- Constant-pressure VS-WF tests (Tests 4–8): 2 Hz vibration applied at pressures of 70, 200, 350, 500, and 1000 kPa.

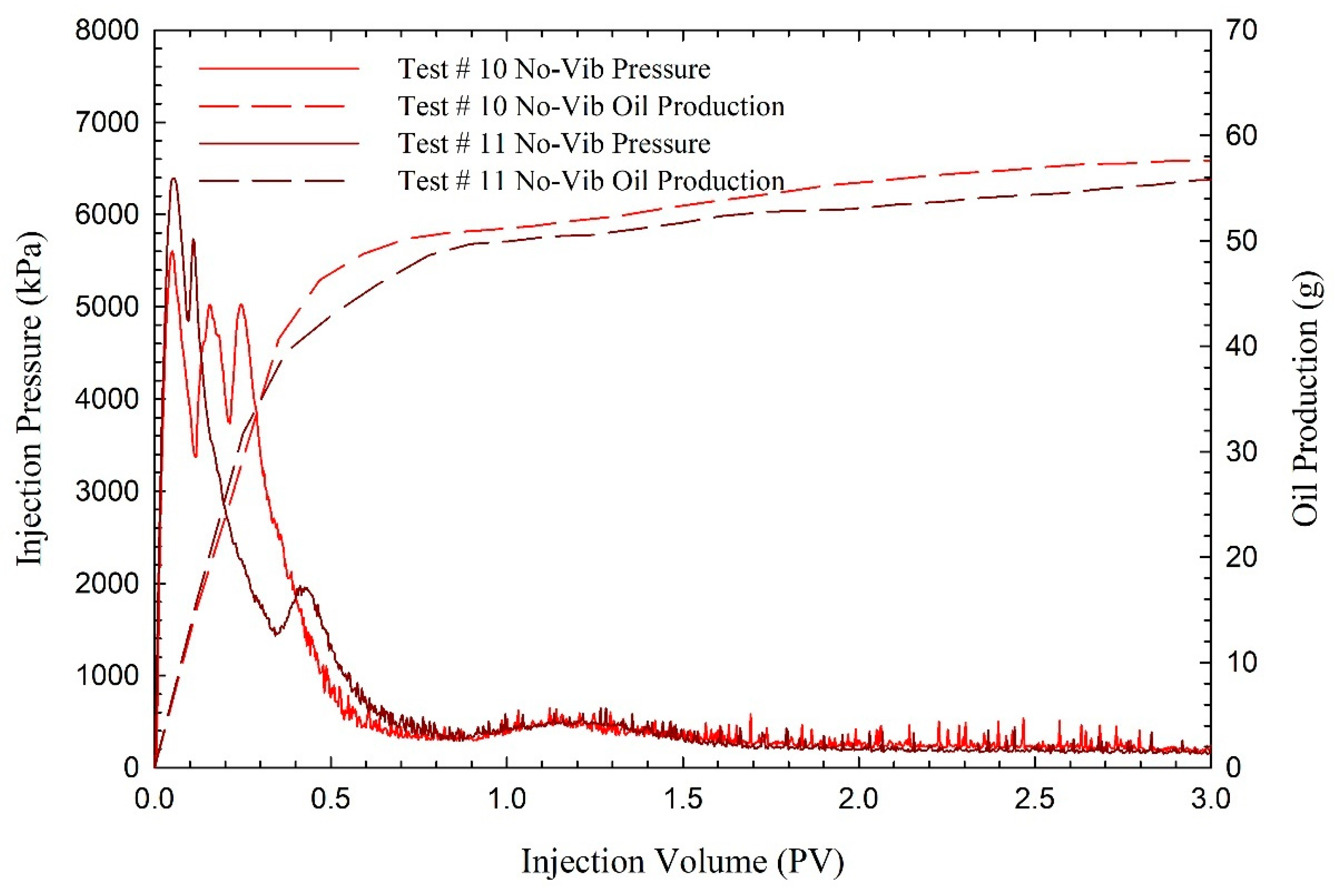

- Constant-flow-rate WF tests (Tests 10–11, 16): No vibration; constant flow rate of 3 mL/min.

- Constant-flow-rate VS-WF tests (Tests 12–15, 17–18): 2 Hz or 5 Hz vibration at 3 mL/min flow rate.

- Intermittent VS-WF tests (Tests 9, 19–22):

- Test 9 alternates 2 Hz vibration and rest (20 min each) at 500 kPa.

- Tests 19–22 combine injection mode switching (from 350 kPa constant pressure to 3 mL/min flow) with intermittent 5 Hz vibration during the first stage.

3. Results and Discussion

3.1. Stick-Slip Motion of Water-Heavy Oil Under Constant Pressure WF

3.2. Vibration Effects on Stick-Slip Dynamics

3.3. Intermittent Vibration Under Constant Pressure VS-WF Test

3.4. Constant Flow Rate Analysis

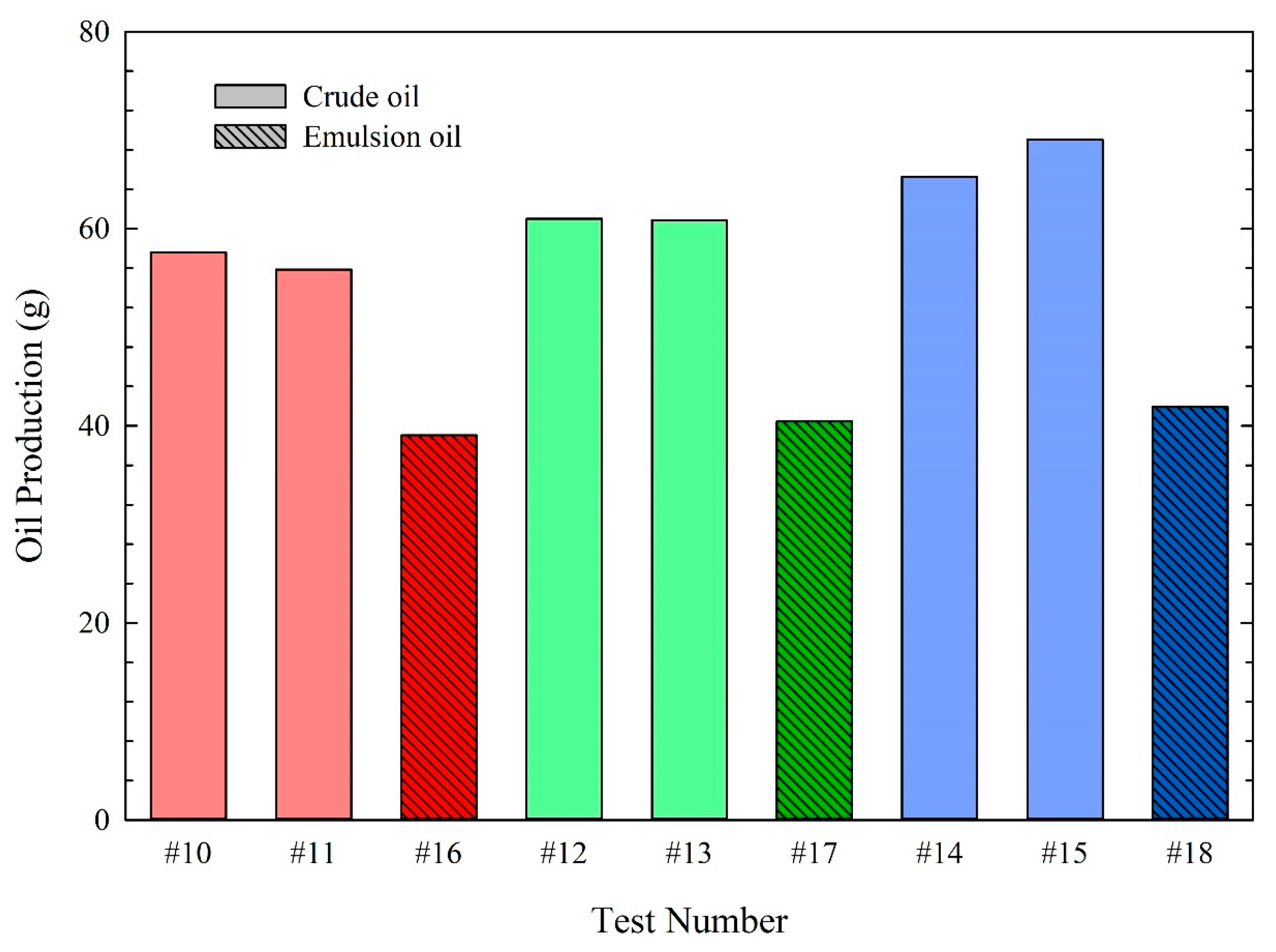

3.4.1. Non-Vibration Baseline Performance

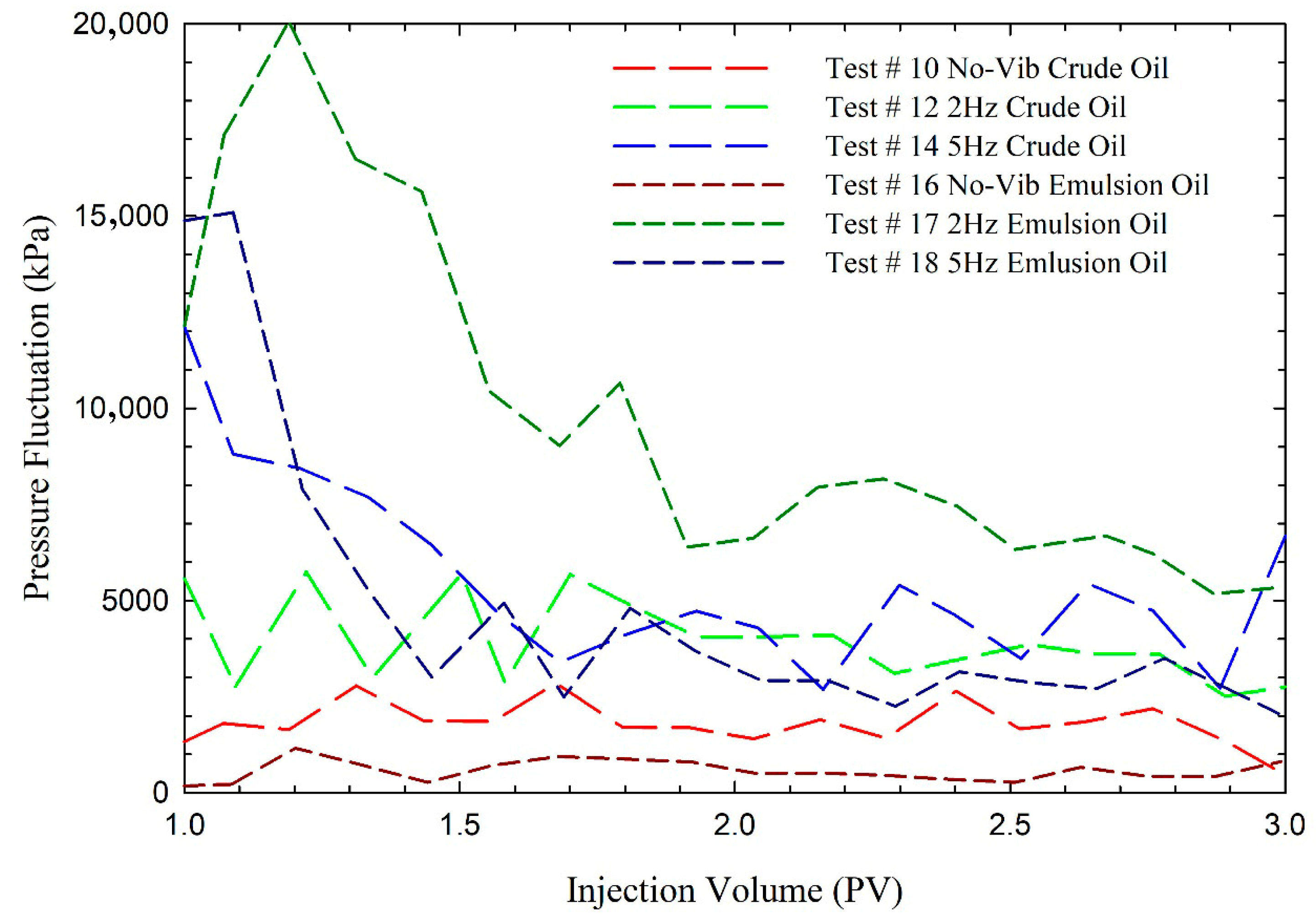

3.4.2. Low-Frequency Vibration Effects (2 Hz)

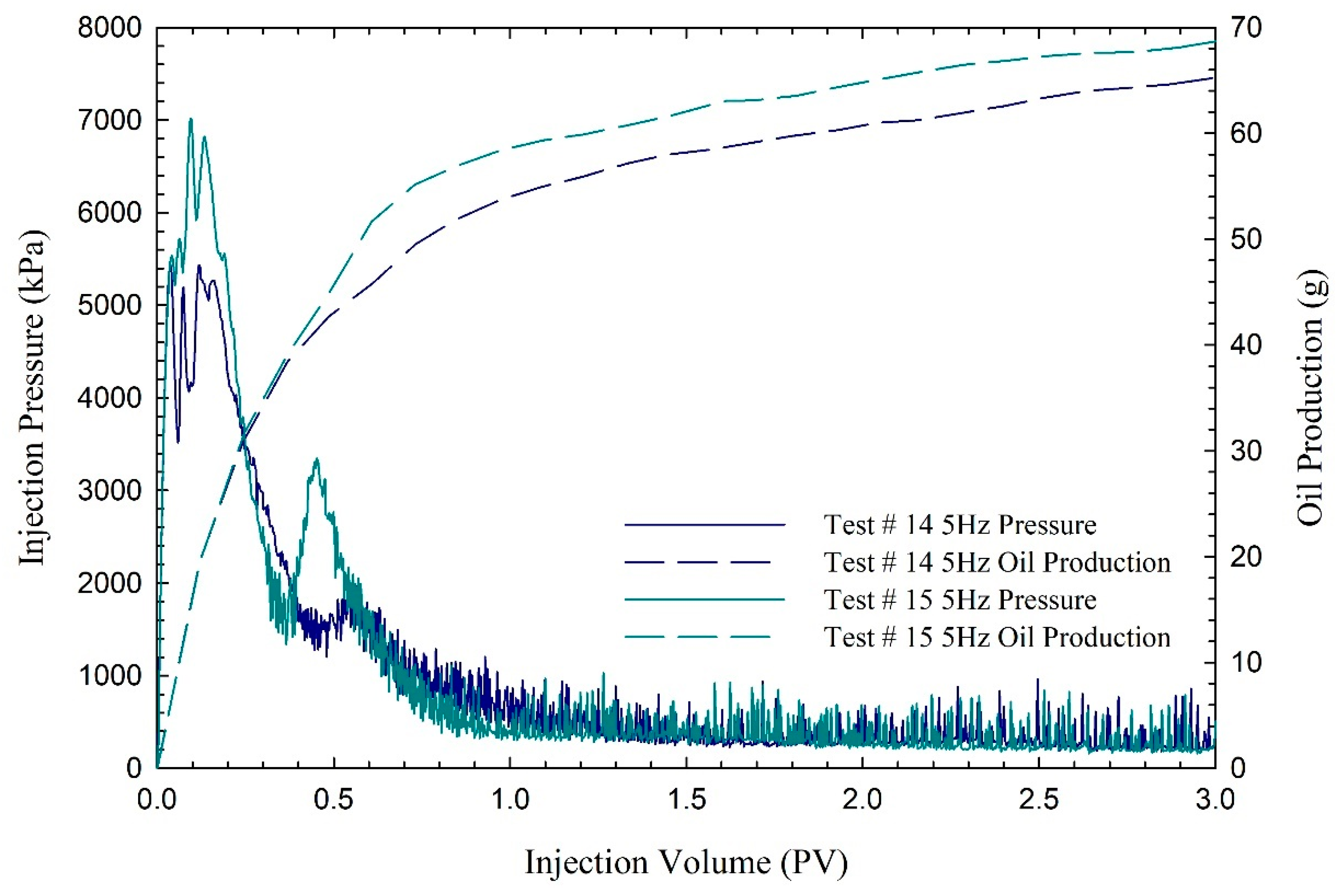

3.4.3. Higher-Frequency Vibration Effects (5 Hz)

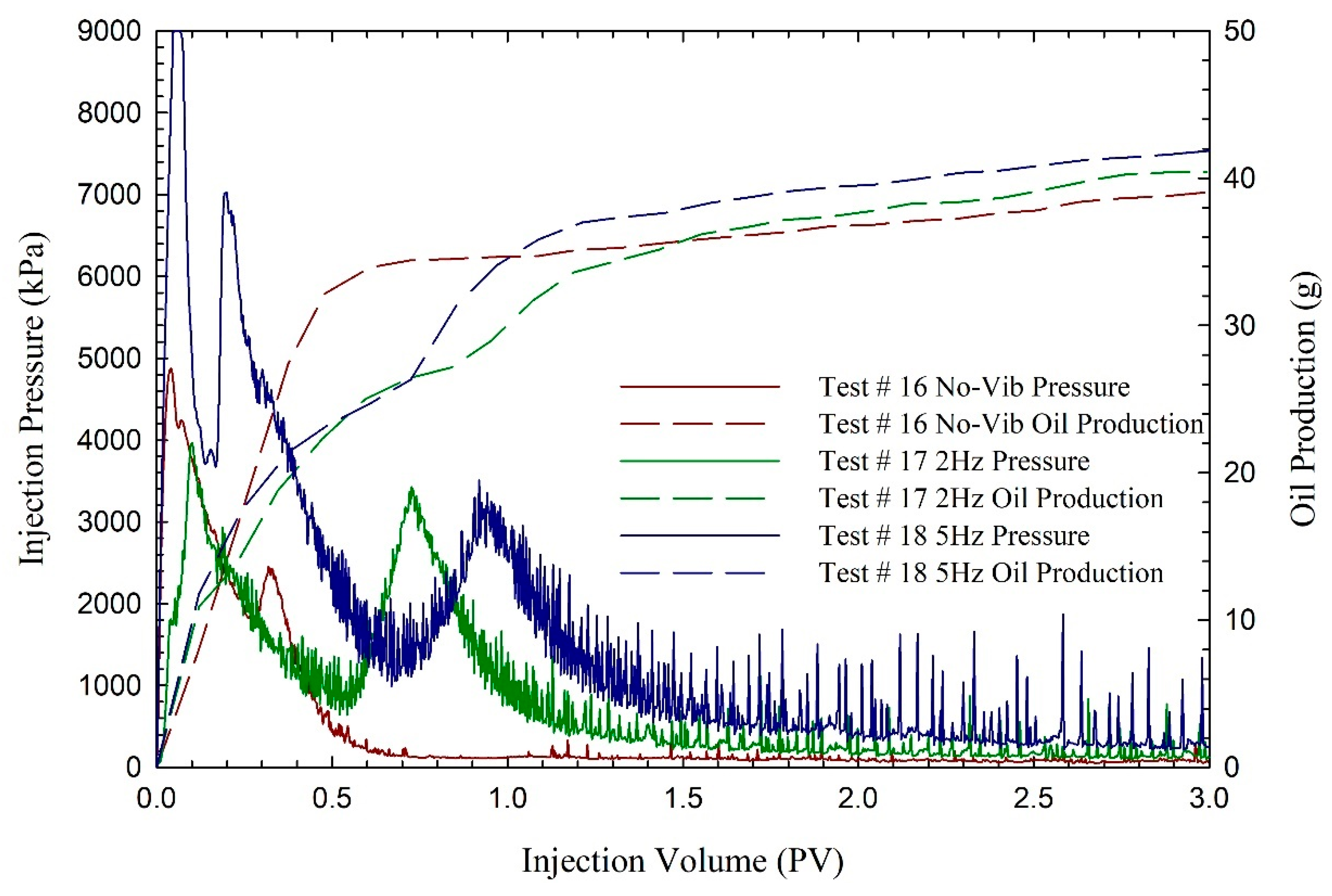

3.5. Emulsified Oil Recovery Analysis

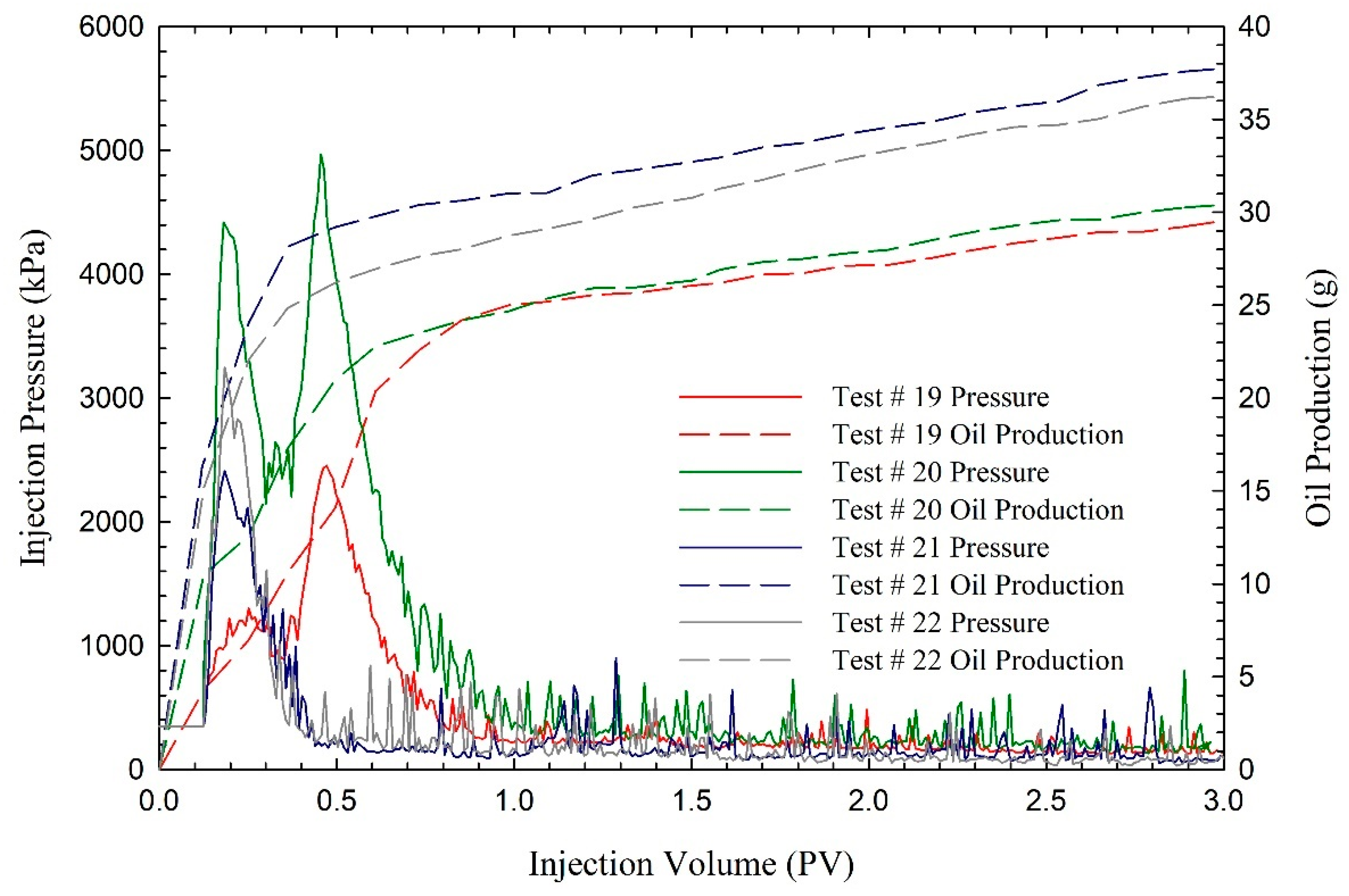

3.6. Intermittent Mode of WF and VS-WF Tests

4. Mechanistic Discussion

4.1. Vibration-Induced Flow Enhancement Mechanisms

4.2. Frequency-Dependent Performance

4.3. Comparison with Existing Literature

5. Conclusions

- Vibration alters flow behavior by inducing stick-slip dynamics, reducing flow resistance, and facilitating trapped oil mobilization.

- Higher frequencies and pressures more easily overcome critical thresholds for slip event initiation.

- Intermittent vibration provides energy-efficient alternatives to continuous stimulation, achieving comparable recovery with approximately 50% reduced energy input.

- Strong correlations exist between pressure fluctuations and oil production in vibration-assisted tests, contrasting with smooth pressure profiles and lower recovery in non-vibration cases.

- Emulsified oil recovery demonstrates reduced sensitivity to vibration due to elevated viscosity, but clear benefits remain evident.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, Q.; Retnanto, A.; Amani, M. Seismic Vibration for Improved Oil Recovery: A Comprehensive Review of Literature. Int. J. Hydrogen Energy 2020, 45, 14756–14778. [Google Scholar] [CrossRef]

- Yang, H.; Lao, J.; Tong, D.; Song, H. Numerical Investigation on EOR in Porous Media by Cyclic Water Injection with Vibration Frequency. Water 2022, 14, 3961. [Google Scholar] [CrossRef]

- Pham, T.; Bui-Thanh, T.; Nguyen, Q. Microseismicity-Based Modelling of Induced Fracture Networks in Unconventional Reservoirs. Fuels 2024, 5, 839–856. [Google Scholar] [CrossRef]

- Westermark, R.V.; Brett, J.F.; Maloney, D.R. Enhanced Oil Recovery with Downhole Vibration Stimulation. In Proceedings of the SPE Production and Operations Symposium, Oklahoma City, OK, USA, 24–27 March 2001. [Google Scholar] [CrossRef]

- Kouznetsov, O.L.; Simkin, E.M.; Chilingar, G.V.; Katz, S.A. Improved Oil Recovery by Application of Vibro-Energy to Waterflooded Sandstones. J. Pet. Sci. Eng. 1998, 19, 191–200. [Google Scholar] [CrossRef]

- Li, W.; Vigil, R.D.; Beresnev, I.A.; Iassonov, P.; Ewing, R. Vibration-Induced Mobilization of Trapped Oil Ganglia in Porous Media: Experimental Validation of a Capillary-Physics Mechanism. J. Colloid. Interface Sci. 2005, 289, 193–199. [Google Scholar] [CrossRef]

- Oraby, M.; Abdalla, M.; Aal, T.A.; Mousa, M.; El-Banbi, A. Optimization of the Vibration Parameters in the Vibro-Seismic Applications. J. Pet. Sci. Eng. 2022, 219, 111029. [Google Scholar] [CrossRef]

- Dong, M.; Fan, Q.; Dai, L. An Experimental Study of Mobilization and Creeping Flow of Oil Slugs in a Water-Filled Capillary. Transp. Porous Med. 2009, 80, 455–467. [Google Scholar] [CrossRef]

- Dai, L.; Zhang, Y. Effects of Low Frequency External Excitation on Oil Slug Mobilization and Flow in a Water Saturated Capillary Model. Petroleum 2019, 5, 375–381. [Google Scholar] [CrossRef]

- Riabokon, E.; Turbakov, M.; Kozhevnikov, E.; Aglan, M.; Startsev, D.; Yin, Q.; Wu, J. The Influence of Acoustic Vibrations Parameters on Permeability of Rocks. In Proceedings of the International Field Exploration and Development Conference, Xi’an, China, 12–14 September 2024; Lin, J., Ed.; Springer Nature: Singapore, 2025; pp. 1381–1392. [Google Scholar]

- Riabokon, E.; Yin, Q.; Guzev, M.; Turbakov, M.; Kozhevnikov, E.; Riabokon, N.; Panteleev, I. Resonance-Induced Restoration of Rock Permeability Degraded by Heavy Components of Crude Oil. Deep Undergr. Sci. Eng. 2025; early view. [Google Scholar] [CrossRef]

- Zheng, L.; Cui, W.; Liu, J.; Zhang, L. Influence of Low-Frequency Vibration Acceleration on the Permeability of Low Permeable Porous Media During Water Flooding. In Proceedings of the International Field Exploration and Development Conference, Xi’an, China, 18–20 September 2018; Lin, J., Ed.; Springer: Singapore, 2020; pp. 74–86. [Google Scholar]

- Pinilla, A.; Asuaje, M.; Ratkovich, N. Experimental and Computational Advances on the Study of Viscous Fingering: An Umbrella Review. Heliyon 2021, 7, e07614. [Google Scholar] [CrossRef] [PubMed]

- Song, R.; Tang, Y.; Wang, Y.; Xie, R.; Liu, J. Pore-Scale Numerical Simulation of CO2–Oil Two-Phase Flow: A Multiple-Parameter Analysis Based on Phase-Field Method. Energies 2023, 16, 82. [Google Scholar] [CrossRef]

- Kozlov, V.; Subbotin, S.; Karpunin, I. Supercritical Dynamics of an Oscillating Interface of Immiscible Liquids in Axisymmetric Hele-Shaw Cells. Fluids 2023, 8, 204. [Google Scholar] [CrossRef]

- Lyubimova, T.; Ivantsov, A.; Lyubimov, D. Control of Fingering Instability by Vibrations. Math. Model. Nat. Phenom. 2021, 16, 40. [Google Scholar] [CrossRef]

- Marfin, E.A.; Garaeva, S.V.; Abdrashitov, A.A. Experimental Study on Viscous Fingering in Hele-Shaw Cell under Acoustic Impact. IOP Conf. Ser. Mater. Sci. Eng. 2020, 927, 012027. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, F.; Wang, J.; Li, Z.; Zhang, S. Investigation on Energy Enhancement of Shale Oil Imbibition Under Different Fracture Fluid Injection Methods—A Case Investigation of Jimsar Lucaogou Formation. Energies 2025, 18, 1412. [Google Scholar] [CrossRef]

- Bui, D.; Pham, D.; Nguyen, S.; Nguyen, K. Simulation-Based Optimization Workflow of CO2-EOR for Hydraulic Fractured Wells in Wolfcamp A Formation. Fuels 2024, 5, 673–697. [Google Scholar] [CrossRef]

- Guo, J.; Yang, E.; Zhao, Y.; Fu, H.; Dong, C.; Du, Q.; Zheng, X.; Wang, Z.; Yang, B.; Zhu, J. A New Method for Optimizing Water-Flooding Strategies in Multi-Layer Sandstone Reservoirs. Energies 2024, 17, 1828. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, L.; Wu, Q.; Xu, A.; Yue, D.; Zhang, Y.; Gao, L. Influence of Sandstone Architecture on Waterflooding Characteristics in Common Heavy Oil Reservoir. In Proceedings of the International Field Exploration and Development Conference, Chengdu, China, 21–22 September 2017; Qu, Z., Lin, J., Eds.; Springer: Singapore, 2019; pp. 265–280. [Google Scholar]

- Lee, P.; Tang, H.; Yan, X.; Zhang, S.; Zhang, Z.; Liu, H. Laboratory Evaluation on the Water Flooding Characteristics in Bottom Water Reservoir Containing Interbeds. ACS Omega 2023, 8, 42409–42416. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Liu, Y.; Xue, L.; Yang, L.; Yuan, Z. Experimental Investigation on the Pore-Scale Mechanism of Improved Sweep Efficiency by Low-Salinity Water Flooding Using a Reservoir-on-a-Chip. ACS Omega 2021, 6, 20984–20991. [Google Scholar] [CrossRef]

- Mai, A.; Kantzas, A. Mechanisms of Heavy Oil Recovery by Low Rate Waterflooding. J. Can. Pet. Technol. 2010, 49, 44–50. [Google Scholar] [CrossRef]

- Hageman, T.; de Borst, R. Stick-Slip like Behavior in Shear Fracture Propagation Including the Effect of Fluid Flow. Int. J. Numer. Anal. Methods Geomech. 2021, 45, 965–989. [Google Scholar] [CrossRef]

- Zhao, F.; Sun, M.; Liu, Y.; Sun, W.; Guo, Q.; Yang, Z.; Zhang, C.; Li, M. Review of Foam with Novel CO2-Soluble Surfactants for Improved Mobility Control in Tight Oil Reservoirs. Molecules 2024, 29, 5411. [Google Scholar] [CrossRef]

- Turbakov, M.; Shcherbakov, A. Determination of Enhanced Oil Recovery Candidate Fields in the Volga-Ural Oil and Gas Region Territory. Energies 2015, 8, 11153–11166. [Google Scholar] [CrossRef]

- Gao, C.; Kuhlmann-Wilsdorf, D. On Stick-Slip and the Velocity Dependence of Friction at Low Speeds. J. Tribol. 1990, 112, 354–360. [Google Scholar] [CrossRef]

- Sochi, T. Slip at Fluid-Solid Interface. Polym. Rev. 2011, 51, 309–340. [Google Scholar] [CrossRef]

- Agi, A.; Junin, R.; Chong, A.S. Intermittent Ultrasonic Wave to Improve Oil Recovery. J. Pet. Sci. Eng. 2018, 166, 577–591. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, Z.; Dai, L.; Jia, N. Vibration-Stimulated Gas Pressure Cycling Process for Enhanced Heavy Oil Recovery. Energy Fuels 2022, 36, 13007–13013. [Google Scholar] [CrossRef]

| Test No. | Method | Frequency (Hz) | Inject Volume | Pressure (kPa) | Flow Rate (mL/min) | Inject Time (min) | Oil |

|---|---|---|---|---|---|---|---|

| 1 | Constant Pressure | - | 3 PV | 200 | - | 611 | Crude Oil |

| 2 | - | 500 | 180 | ||||

| 3 | - | 1000 | 102 | ||||

| 4 | 2 | 70 | 533 | ||||

| 5 | 2 | 200 | 377 | ||||

| 6 | 2 | 350 | 368 | ||||

| 7 | 2 | 500 | 168 | ||||

| 8 | 2 | 1000 | 116 | ||||

| 9 | Intermittent 2 Hz | 500 | 181 | ||||

| 10 | Constant Flow Rate | - | - | 3 | 167 | ||

| 11 | - | 167 | |||||

| 12 | 2 | 167 | |||||

| 13 | 2 | 167 | |||||

| 14 | 5 | 167 | |||||

| 15 | 5 | 167 | |||||

| 16 | - | 167 | Emulsion Oil | ||||

| 17 | 2 | 167 | |||||

| 18 | 5 | 167 | |||||

| 19 | Intermittent Injection | - | 350 | 225 | |||

| 20 | 5 | 228 | |||||

| 21 | 5 | 248 | |||||

| 22 | 5 | 250 |

| Constant Pressure | Constant Flow Rate | |||||||

|---|---|---|---|---|---|---|---|---|

| Test No. | Frequency (Hz) | Pressure (kPa) | Time (min) | Inject Volume | Frequency (Hz) | Flow Rate (mL/min) | Time (min) | Inject Volume |

| 19 | - | 350 | 66 | 0.125 PV | - | 3 | 159 | 2.875 PV |

| 20 | - | 70 | 5 | 158 | ||||

| 21 | 5 | 89 | - | 159 | ||||

| 22 | 5 | 90 | 5 | 160 | ||||

| Constant Pressure | Constant Flow Rate | Total Oil Production (g) | |||||

|---|---|---|---|---|---|---|---|

| Test No. | Frequency (Hz) | Pressure (kPa) | Oil Production (g) | Frequency (Hz) | Flow Rate (mL/min) | Oil Production (g) | |

| 19 | - | 350 | 4.3 | - | 3 | 25.31 | 29.61 |

| 20 | - | 10.48 | 5 | 19.96 | 30.44 | ||

| 21 | 5 | 16.3 | - | 21.49 | 37.79 | ||

| 22 | 5 | 15.18 | 5 | 21.08 | 36.26 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, S.; Zhang, Z.; Dai, L.; Jia, N. Enhancing Oil Recovery Through Vibration-Stimulated Waterflooding: Experimental Insights and Mechanisms. Fuels 2025, 6, 56. https://doi.org/10.3390/fuels6030056

Lu S, Zhang Z, Dai L, Jia N. Enhancing Oil Recovery Through Vibration-Stimulated Waterflooding: Experimental Insights and Mechanisms. Fuels. 2025; 6(3):56. https://doi.org/10.3390/fuels6030056

Chicago/Turabian StyleLu, Shixuan, Zhengyuan Zhang, Liming Dai, and Na Jia. 2025. "Enhancing Oil Recovery Through Vibration-Stimulated Waterflooding: Experimental Insights and Mechanisms" Fuels 6, no. 3: 56. https://doi.org/10.3390/fuels6030056

APA StyleLu, S., Zhang, Z., Dai, L., & Jia, N. (2025). Enhancing Oil Recovery Through Vibration-Stimulated Waterflooding: Experimental Insights and Mechanisms. Fuels, 6(3), 56. https://doi.org/10.3390/fuels6030056