1. Introduction

The increasing demand for energy and the environmental impact of fossil fuels have driven the search for alternative and sustainable energy sources. Among these, synthetic fuels have emerged as promising candidates due to their potential to reduce greenhouse gas emissions and reliance on non-renewable resources. Dimethyl carbonate (DMC) and polyoxymethylene dimethyl ethers (PODE) are two such synthetic fuels that have garnered significant attention as diesel additives. This paper explores the advantages of blending DMC and PODE with diesel fuel, focusing on their impact on diesel engine performance and emissions, as well as their material compatibility and hydraulic injection behavior.

DMC, a carbonate ester with the formula OC(OCH

3)

2, offers several benefits as a diesel additive. DMC is known for its high oxygen content, which enhances oxidation of the fuel and reduces the formation of soot and other harmful emissions. [

1] Compared to conventional diesel fuel, however, DMC has a lower cetane number. This means that DMC exhibits a longer ignition delay than diesel, which can lead to a reduced engine efficiency [

2]. DMC has therefore mostly been used only as a diesel additive instead of neat fuel to minimize the disadvantages of the low cetane number.

Ruijin Zhu et al. [

3] tested diesel fuel blended with DMC in a 4-cylinder direct-injection diesel engine. They found that blending diesel with DMC reduces particulate emissions. When analyzing the combustion characteristics, it was found that the ignition delay increased with the addition of DMC, but both the diffusive burning duration and the total combustion duration decreased. G. D. Zhang et al. [

4] achieved similar results when investigating DMC blends. They found that by adding DMC the particulate matter (PM) emissions could be reduced, while the ignition delay was increased, and the combustion duration was shortened.

Aguado-Deblas et al. [

5] used DMC as a solvent for sunflower oil and castor oil to create biofuels that can replace fossil diesel. They found that DMC is an effective blending component, improving engine efficiency and reducing soot emissions while allowing the significant replacement of fossil diesel.

Maier et al. [

6] investigated the emissions and performance of DMC and methyl formate as oxygenate fuels in a single-cylinder, direct-injection SI-engine. The results show that both fuels significantly reduce particulate number emissions compared to conventional gasoline, with emissions dropping below ambient levels. However, a higher proportion of sub-23 nm particles was observed.

PODE, a series of compounds with the general formula CH

3O(CH

2O)

nCH

3, where

n represents the number of oxymethylene units, has been identified as a potential diesel additive due to its high oxygen content and favorable combustion properties [

7]. Studies have shown that PODE can enhance the efficiency of diesel engines [

8,

9], while also reducing particulate matter (PM) emissions [

8,

9,

10].

Haoye Liu et al. [

8] investigated the potential of using PODE 3–4 as an additive in diesel fuel to improve the combustion efficiency and reduce emissions. The study finds that PODE improved the engine efficiency and significantly reduced particulate matter and CO emissions without a significant impact on nitrogen oxide (NO

X) emissions. Jing Tian et al. [

11] blended diesel with PODE at 10%, 20%, and 30% in an unmodified diesel engine and compared the results to pure diesel. An engine exhaust particle sizer was used to measure the PM concentration and particle size distribution, finding that PODE reduced PM emissions significantly.

Gelner et al. [

12] examined the particle size distribution of a heavy-duty engine operating with fossil diesel and PODE. The solid particle number emissions in the PODE operation were found to be lower than those in the Euro VI diesel operation. In another study, Gelner et al. [

13] investigated the hydraulic injection behavior of two solenoid injectors using PODE and diesel fuel. They showed that PODE exhibits longer injection delays, especially at higher rail pressures, while the slower motion of the needle results in a prolonged closing time. Additionally, the maximum flow rate was shown to be higher with PODE than with diesel.

Recently, significant advances continue to be made in all fields regarding PODE. Wiesmann et al. [

14] developed an oxidation mechanism for PODE 1–6 and integrated it into a validated spray combustion CFD model. Simulations for various injection patterns, temperatures, and oxygen levels were validated against chamber experiments. Improvements in predicting the ignition delay and flame lift-off length were achieved, with enhanced OH* radical formation in high-temperature reaction zones.

Wanchen Sun et al. [

15] investigated the potential of oxygenated fuels (including both DMC and PODE) blended with Fischer–Tropsch synthetic diesel and combined with different exhaust gas recirculation (EGR) schemes to achieve efficient and clean combustion. All tested oxygenated fuels (including DMC and PODE) reduced soot emissions. They also tested different methods of exhaust gas recirculation, finding that increasing the EGR rate of an external EGR had a stronger inhibiting effect on heat release and soot formation compared to an internal EGR. Combining oxygenated fuels with controlled EGR rates can optimize combustion and reduce soot emissions effectively.

The production of DMC and PODE from renewable sources is a critical aspect of their sustainability. DMC can be produced via transesterification of methanol and carbon dioxide, with the methanol being sourced from renewable feedstocks. Traditionally, synthesis routes such as methanol phosgenation, transesterification, and oxidative carbonylation of methanol have been used. Currently the most promising method is synthesizing DMC from carbon dioxide (CO

2) and methanol, which is more eco-friendly. These production methods align with the principles of green chemistry and support the transition to a circular economy [

16].

Similarly, PODE can be synthesized from methanol, which can be derived from biomass or CO

2 through catalytic processes [

7,

17]. This not only provides a renewable pathway for PODE production but also contributes to carbon recycling and the reduction of CO

2 emissions.

Jianqiang Zhang et al. [

18] studied the synthesis of PODE from methanol and formaldehyde using a fixed bed reactor with a strong acid cation exchange resin catalyst. The researchers successfully developed a kinetic model and mechanism for the synthesis of PODE, demonstrating the influence of temperature on conversion rates and providing predictive rate equations.

According to the literature, the integration of DMC and PODE as diesel additives offers significant advantages in terms of engine performance and emission reduction. Their production from renewable sources further enhances their appeal as sustainable alternatives to conventional diesel fuel.

However, there is still a lack of comprehensive studies with a focus on the practical application of these fuels covering the whole chain from material compatibility to injection, combustion, and emissions. In particular, the following questions remain largely unaddressed:

Material compatibility. Both DMC and PODE are known to be solvents with a possibly negative impact on the sealing materials used in diesel engine injection systems. Which sealing materials are suitable?

Direct comparison of DMC and PODE as diesel additives in standard series engines under comparable conditions. How do these fuels differ in injection behavior, combustion parameters, and emissions in the same engine at the same settings and could blends with diesel and DMC or PODE be used interchangeably?

Which fractions of DMC or PODE are necessary to achieve significant effects and are there differences between DMC and PODE regarding the required blending levels?

Our paper addresses a significant research gap by comprehensively exploring the effects of admixing DMC and PODE with diesel fuel, focusing on material compatibility, hydraulic injection behavior, and exhaust and particle emissions. To our knowledge, this study is the first to investigate the material compatibility of DMC and PODE blends with diesel, and to examine the complete chain from material compatibility to injection behavior and emissions. Specifically, we aim to identify suitable sealing materials, directly compare DMC and PODE as diesel additives under standard series engine conditions, and determine the necessary fractions of DMC or PODE required to achieve significant effects in diesel engines. Our research confirms and builds upon previous studies, while focusing on industrial diesel engines that can utilize DMC and PODE as drop-in fuels without modifications. We therefore only use blends of DMC and PODE with diesel instead of neat fuels and keep all components and settings of the test engine at the manufacturer’s series standards.

2. Materials and Methods

In this study, DMC and PODE were analyzed as additives to B0 diesel, a pure diesel fuel with no bio-components, which was used as the reference fuel.

Table 1 lists some of the most important fuel parameters of diesel, DMC, and PODE in comparison to the diesel standard DIN EN 590 [

19]. Commercially available PODE 3–5 mix and the B0 test diesel were acquired from ASG Analytik GmbH, Neusäß, Germany, for the study, while the DMC was acquired from CSC JÄKLECHEMIE GmbH & Co. KG, Nürnberg, Germany. The properties of the B0 diesel, DMC, and PODE were all measured by an independent laboratory (flucon fluid control GmbH, Bad Lauterberg, Germany). The densities of DMC and PODE are significantly higher than for diesel, and outside the limit values of the diesel standard DIN EN 590 [

19]. In addition, the kinematic viscosity of both test fuels is significantly lower than for B0 diesel. The density and kinematic viscosity of the fuels will have a significant effect on the hydraulic injection behavior. Furthermore, the lubricity of PODE is just within the tolerance whereas for DMC it is just outside the tolerance, and in both cases it is significantly inferior compared to conventional diesel. This can have an impact on the durability of many engine components, especially the fuel pump and injectors. Due to their low lubricity, the two fuels DMC and PODE should only be used as a blend with diesel or similar fuels when used in state-of-the-art series engines. Another important property of the fuels is the calorific value, which is significantly lower for DMC and PODE compared to B0 diesel. This means that a larger quantity must be injected to operate the engine with the same power output compared to conventional diesel.

It is also important to consider the solubility of both DMC and PODE for practical applications. Xiaoming Zhao et al. [

20] have investigated the critical solubility of DME and DMC in diesel. The results show that the two fuels can be mixed at approx. 273 K up to 5% DMC content. The critical solubility temperature then also increases as the mass fraction of DMC increases. For a mass fraction of 50%, over 295 K is required to ensure a homogeneous mixture. According to Xiaoming Zhao et al., DMC can realistically be used as an additive in warm regions and with a low DMC content.

According to Zhenbin Yang et al. [

21], the solubility of neat PODE 1−8 in diesel hydrocarbons and model diesel fuels decreases with an increasing oxygen content and chain length. The miscibility of PODE mixtures with diesel also decreases with longer-chain PODE. Additives like anti-wear agents, CN improvers, stabilizers, and emulsifiers enhance miscibility, while pour point depressants reduce it.

Based on the properties of the DMC and PODE, especially the low lubricity and the low calorific value, a maximum blend ratio of 20 vol-% was chosen for the experiments. The lower limit of 5% was chosen as these blends would be in line with the limits of DIN EN 590. However, a blend of 5% would only show small effects on the experimental results. Therefore, a blend of 10% was also included to analyze the effects of different mixing ratios. These blend ratios were used for all experiments, including the investigation into hydraulic injection behavior, exhaust and particle emissions, as well as material compatibility.

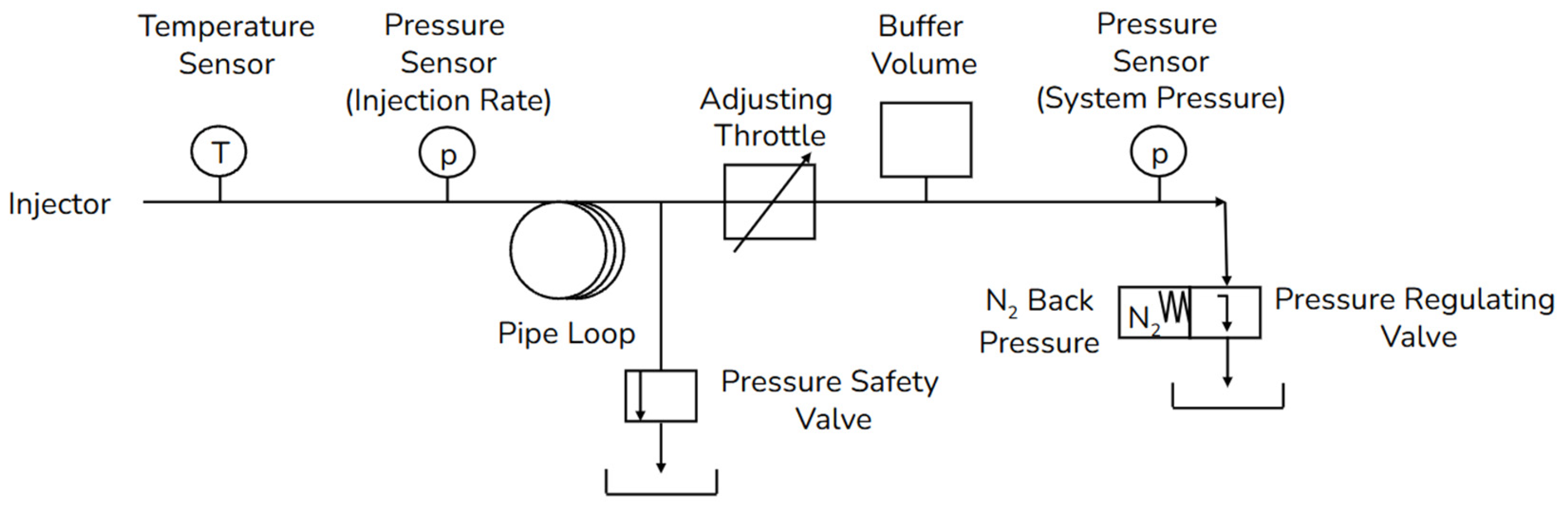

The hydraulic injection behavior was investigated using the injection system test bench at OTH Amberg-Weiden. A solenoid valve common-rail injection system for diesel engines is set up on the test bench. The high-pressure pump is supplied with fuel via a pre-feed pump. A metering unit is installed on the high-pressure pump to regulate the pressure in the injection system. A solenoid valve injector is supplied from the common rail, which injects into the measuring device for determining the injection rate, the ‘Injection Analyzer’ by IAV GmbH.

In the Injection Analyzer, the injection rate and injection quantity are determined by measuring the increase in pressure due to the propagation of a dynamic pressure wave in a tube loop filled with fuel (see

Figure 1). Nitrogen (N

2) is used to create a back pressure, which in our experiments was set to 4 MPa. The measured pressure wave is proportional to the injection rate

[

22] as follows:

where

= pipe cross-sectional area

= sound velocity1

= dynamic pressure increase

The exact quantity of fuel injected

m is determined from the measured pressure wave and the temperature- and pressure-dependent speed of sound of the fuel based on the following equation: [

22]

The tests were carried out with a common-rail injection system for light-duty engines. Diesel–DMC fuel mixtures with proportions of 5, 10, and 20% were analyzed. In addition, tests were carried out on Diesel–PODE fuel mixtures with the same volume proportions.

Figure 1.

Schematic diagram of the ‘Injection Analyzer’ based on [

22].

Figure 1.

Schematic diagram of the ‘Injection Analyzer’ based on [

22].

In the next step, the test fuels were analyzed on the engine test bench in the combustion engine laboratory at OTH Amberg-Weiden. The test engine was a 4-stroke diesel engine from Motorenfabrik Hatz GmbH & Co. KG, Ruhstorf an der Rott, Germany (see

Table 2). The engine represents the current state-of-the-art in the field of small stationary engines and is equipped with a common-rail injection system, a turbocharger, and an intercooler, as well as exhaust gas recirculation (EGR) to reduce nitrogen oxide emissions. At rated power, the engine consumes approx. 15 L of diesel fuel per hour and delivers a mechanical output of 55.4 kW. The aim of the investigation was to analyze the effect of the diesel additives during realistic full load operation of the engine using the manufacturer’s standard ECU presets. These parameters included a small post injection for reducing the particulate emissions during standard diesel operation. Running the engine with both EGR and a post injection represents the optimal setting regarding particle and NO

X emissions during diesel operation. For this reason, the post injection was retained in the experiments to compare the effect of the diesel additives with the standard operation of the engine.

A piezoelectric pressure sensor of type 6056BS7-2 (from Kistler Group, Winterthur, Switzerland) installed in a glow plug adapter was used to measure the pressure in the combustion chamber. An Indimicro indicating system from AVL was used to evaluate the signals. In addition to the pressure signal, a crank angle sensor was connected to determine the piston position. The current signal from the injector was recorded via a current probe.

A gas analysis system from Ansyco/Gasmet was used for the exhaust gas measurements. The centerpiece of the system is a Fourier transform infrared spectrometer (FT-IR) of type Gasmet CX4000 (Gasmet, Vantaa, Finland), which can be used to measure a wide range of organic and inorganic components. Additionally, a paramagnetic oxygen analyzer is also installed. Carbon monoxide and nitrogen oxide emissions were of particular interest in the exhaust gas measurement.

A Scanning Mobility Particle Sizer (SMPS, from TSI, Shoreview, MN, USA), comprised of an electrostatic classifier 3080 and condensation particle counter 3772, was used to determine the particle size distribution and number of particles in the exhaust gas, such as soot. Particles with a diameter from 7 to 300 nm can be measured with the SMPS.

All tests were carried out at the nominal load point (55.4 kW) of the engine. B0 diesel was used as the reference fuel. In addition to the reference measuring point, a measurement with B0 was carried out with the EGR valve closed to visualize the effect of exhaust gas recirculation. Three blends with different proportions of DMC and PODE (DMC5, PODE5, DMC10, PODE10, DMC20, PODE20) were tested, each at standard setting, i.e., with EGR applied.

3. Results

3.1. Material Compatibility

A series of tests was carried out to identify the sealing materials that are suitable for use with the investigated fuel blends. Various materials available on the market were selected for the tests, including perfluoro rubber (FFKM), polytetrafluoroethylene (PTFE), and fluorocarbon rubber (FKM), which is commonly used in diesel fuel systems. Material samples were placed in B0 diesel and pure DMC as well as PODE, as seen in

Figure 2. In addition, both diesel–DMC mixtures and diesel–PODE mixtures with 5% (DMC5, PODE5), 10% (DMC10, PODE10), and 20% (DMC20, PODE20) DMC or PODE by volume were analyzed. The samples were stored at 60 °C to obtain results comparable to a realistic engine operation. The mass of the samples was measured after a period of 500 h as an indicator of the swelling of the sealing materials. A mass change of less than 10% after approx. 500 h was specified as criterion for the suitability of the materials for the respective fuel.

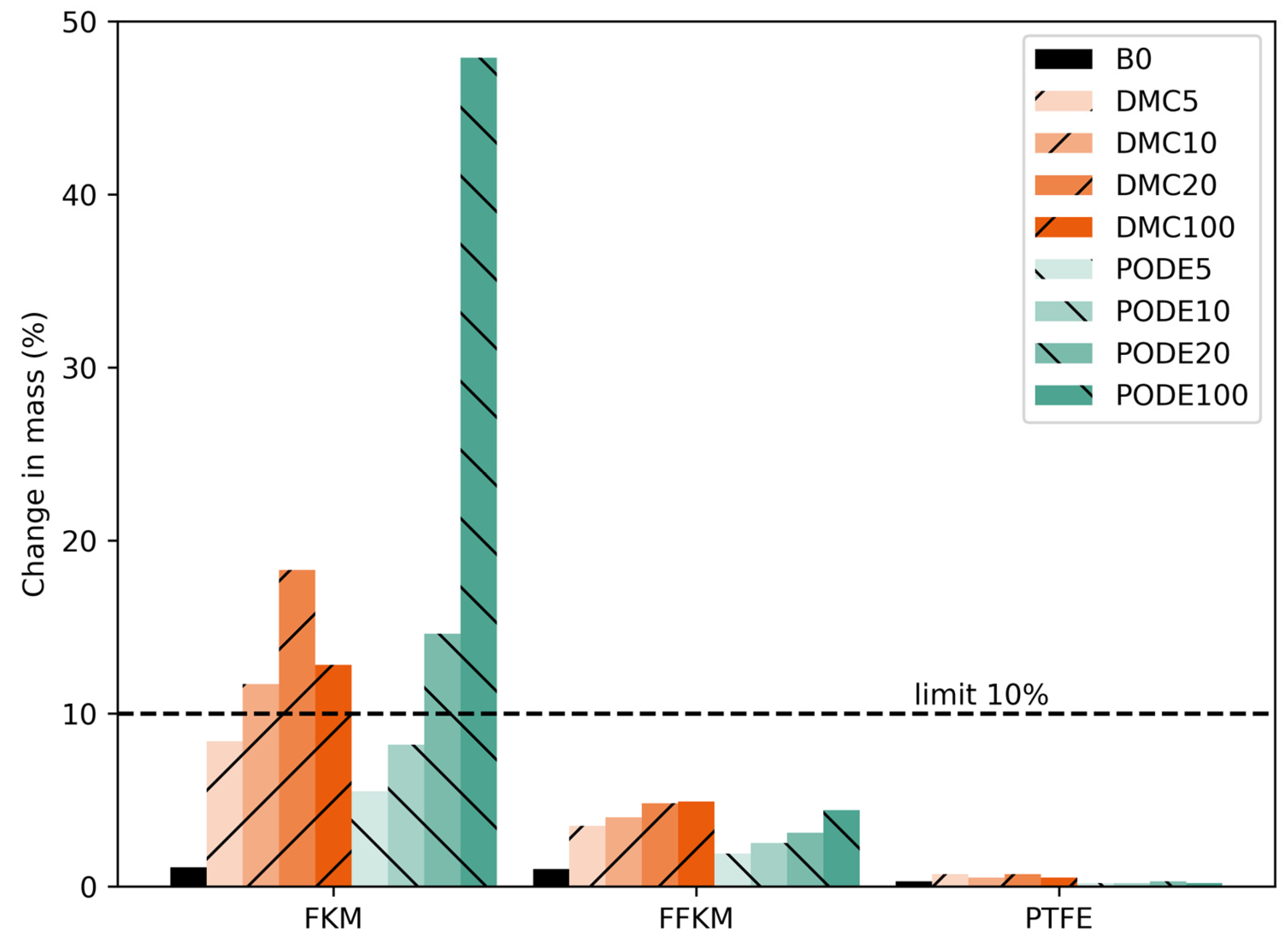

Figure 3 shows the change in mass for the tested samples with different materials after 500 h.

The standard FKM seals were compatible with B0 diesel, with a change in mass of around 1%. The higher the DMC content of the blends, the greater the change in mass, whereby DMC20 and pure DMC behaved very similarly. The mass of the FKM samples increased by around 20% with DMC20. The mass increase with pure PODE (>45%) was significantly higher than with DMC. The PODE blends behaved similarly to the DMC blends.

The FFKM showed good results with a maximum change in mass of 5% for all the fuels tested. Generally, the higher the DMC content, the higher the change in mass, apart from DMC20 which showed virtually no difference in the mass increase compared to pure DMC. Pure PODE and the PODE blends behaved similarly to DMC.

Hardly any change in mass was recognizable in the PTFE samples; the change in mass was less than 1% for all samples. The different fuels and mixtures had no noticeable influence on the results.

According to the defined threshold of a 10% mass change after 500 h, only FFKM and PTFE are suitable for use with neat DMC and DMC–diesel blends as well as neat PODE and PODE–diesel blends.

It should be noted here that FFKM gaskets are the most suitable due to their good material compatibility and similar degree of hardness to commercially available FKM gaskets. However, gaskets made from this material are the most expensive due to the complex manufacturing process. PTFE gaskets have the best chemical resistance and are significantly cheaper, but they are considered mechanically unstable and exhibit so-called flow or creep after some time.

As a recommendation for the use of DMC and PODE diesel blends in the fuel system, it was concluded from the investigations that PTFE gaskets can be used wherever low mechanical loads are expected. FFKM seals should be used for all critical components.

3.2. Injection Behavior

The focus of the injection tests was to map the entire application range of an injector. In other words, both the ballistic and non-ballistic operating range of the injector were investigated. The ballistic range refers to the operating mode for small injections in which the injector needle does not reach its maximum lift before it closes again. In this case, the injection rate has a triangular shape. In the non-ballistic range, on the other hand, the injector needle reaches its maximum lift and remains fully open for some time. This applies to large injections and leads to a clearly pronounced plateau in the injection rate curve. The differences between the injection curves in the ballistic and non-ballistic range of an injector are shown in

Figure 4. During the opening of the injector needle hardly any differences in the injection rate can be detected between the investigated fuels. Once the needle is fully open the injection rate of DMC20 is constantly higher than B0. This is due to the higher density of DMC compared to B0. Only small differences between PODE20 and B0 can be observed.

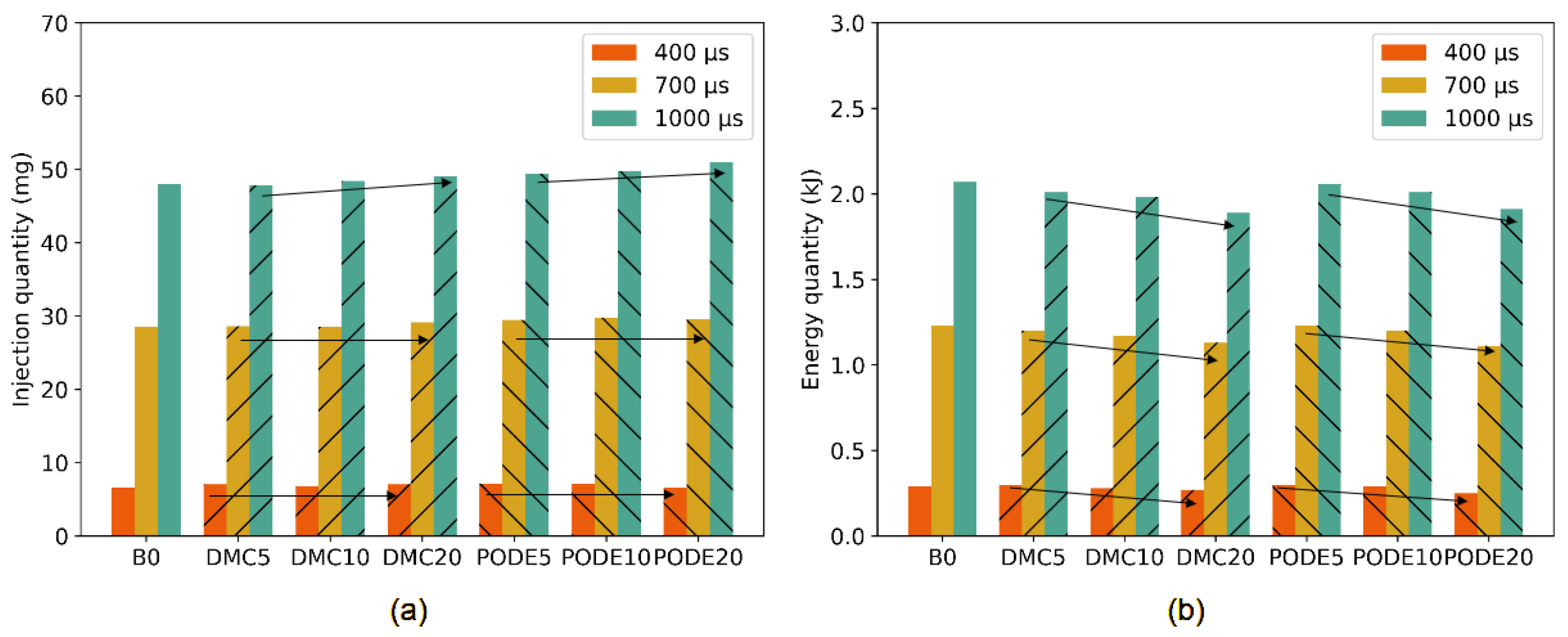

Figure 5 shows the injection quantity and energy quantity for three different activation times (400, 700, and 1000 µs) for B0 and all fuel mixtures analyzed at a constant common rail pressure of 100 MPa. The three activation times were selected to illustrate the different behavior of the injector in the ballistic and non-ballistic ranges. The activation times of 400 µs and 700 µs represent a small and a large injection, respectively, in the ballistic area of the injector. Here, no obvious trend can be seen. However, there are noticeable deviations in the measured injection quantity, regardless of the blend. For small injection quantities the absolute deviation is small. Therefore, the injection quantity remains relatively constant regardless of the fuel mixture. In contrast, at the activation time of 1000 µs, which represents non-ballistic operation, the injection volume increased slightly when the amount of DMC or PODE in the mixture was increased, which can be explained by the higher density and lower kinematic viscosity of DMC and PODE.

At the 400 µs and 700 µs activation times, the energy content of the DMC and PODE blend injections dropped significantly due to the lower calorific value of the mixture. This was to be expected, as the injection quantity of the blends was similar compared to B0. However, at the activation time of 1000 µs, the energy content also fell despite a higher injection quantity of the DMC or PODE blend (

Figure 5). This means that the increased injection quantity in the non-ballistic range cannot compensate for the low calorific value. An increase in the injection quantity of 11.1% was recognizable in the case of DMC20 compared to B0. Despite this increase, the energy content of the injection fell by 3.8%. With PODE20, the injection quantity was 2.1% higher than with B0 and the energy content of the injection was 8.8% lower.

As a conclusion we can state that with both additives, DMC and PODE, the injection quantity must be increased to compensate for the lower calorific value, e.g., by increasing the injection pressure or injection duration. However, this not only influences the injected mass, but also the volume of fuel injected. This in turn affects the penetration depth of the spray for example [

23], which may affect the combustion efficiency. The influence of the compensated injection quantities on the combustion efficiency was, however, not investigated in this study, and must be the subject of further studies.

3.3. Engine Experiments

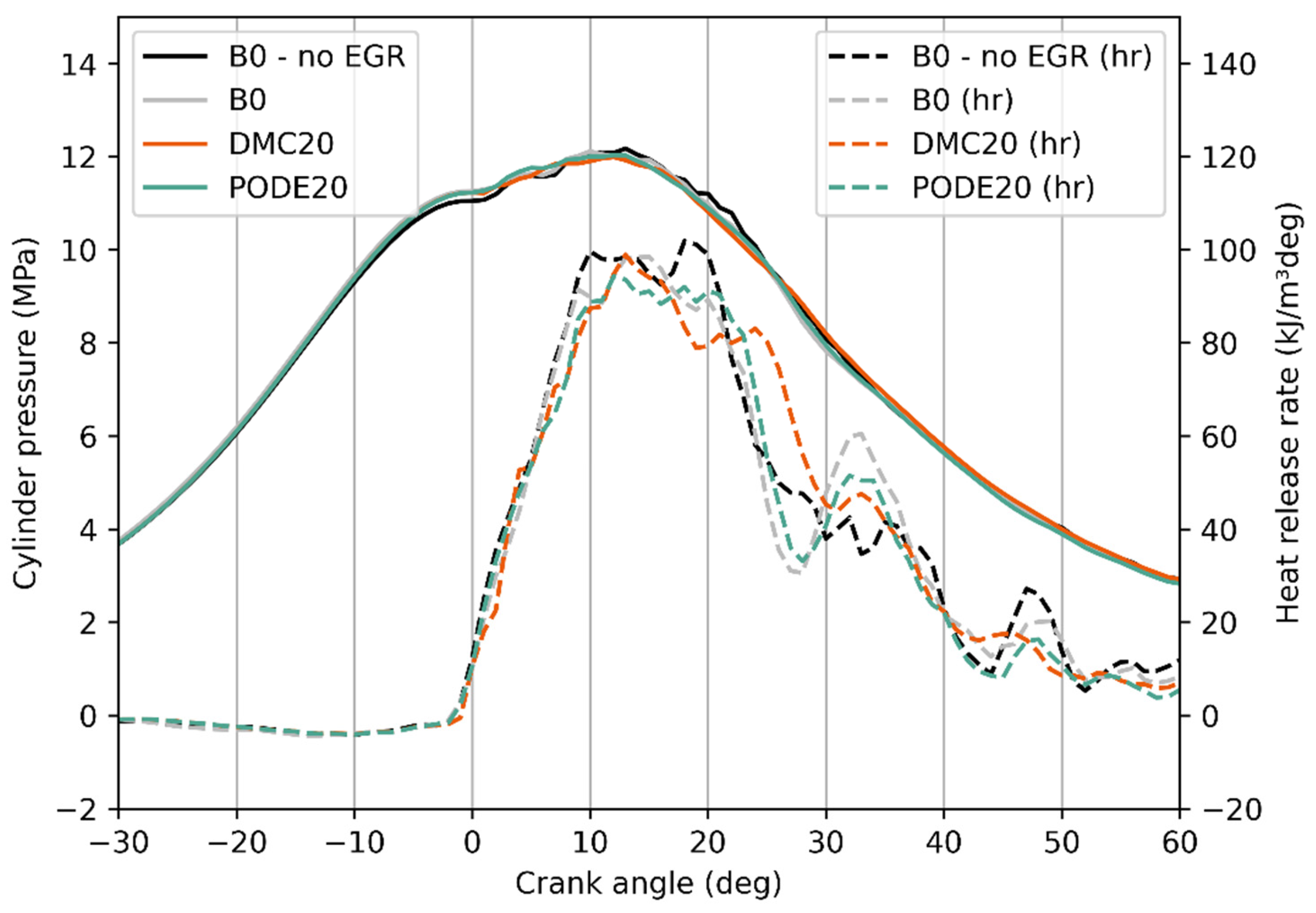

The cylinder pressure traces obtained from the engine tests are shown exemplarily in

Figure 6 for B0 (with and without EGR) and for DMC20 and PODE20. Only very small differences can be observed when comparing the cylinder pressure curves. A slight difference in the compression phase can be observed when comparing B0 with EGR to B0 without EGR. This is partly due to the reduced mass flow over the turbocharger’s turbine and partly due to a slight pressure drop before the turbocharger’s turbine caused by the open EGR valve. However, the slightly lower compression pressure has hardly any influence on the combustion. This is confirmed when analyzing the heat release rates in

Figure 6. Only small differences can be seen when comparing operation with B0 with and without EGR. The contribution of the post injection to the overall combustion profile can be clearly seen with all the investigated fuels.

The most obvious observation is that the main combustion with DMC20 is significantly longer than with any of the other fuels. This is due to the lower calorific value of DMC. To operate the engine with a consistent power, a significantly larger gravimetric injection quantity is needed with DMC20. Due to the injection pressure being regulated at a constant 180 MPa the activation time of the injector had to be increased, which resulted in a significantly longer injection with the beginning of the injection staying constant. The longer injection eventually leads to a longer combustion duration which can be recognized in the heat release curve.

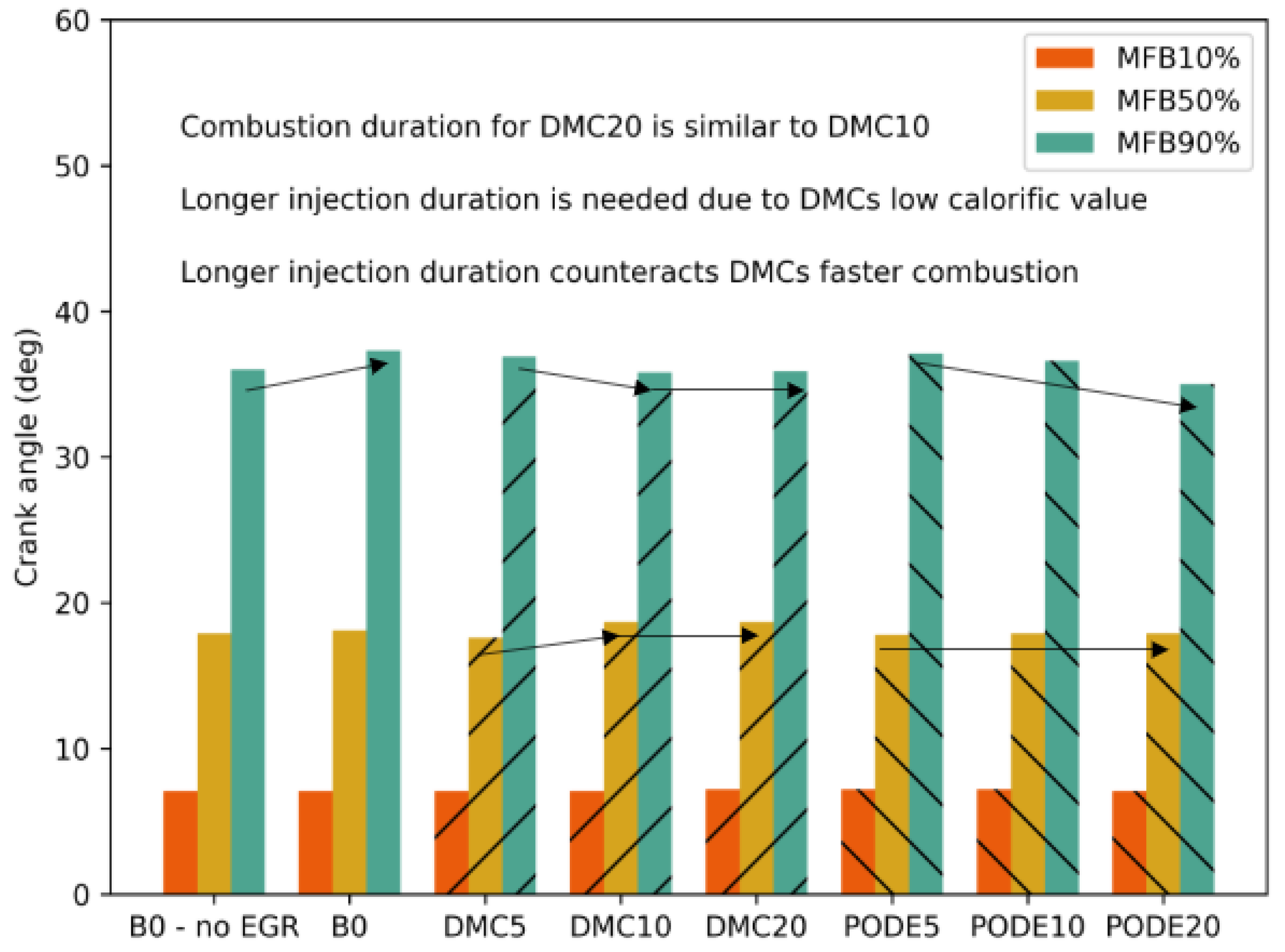

This effect can also be seen in the mass fraction burnt (MFB) rates shown in

Figure 7, which were all recorded at standard ECU settings. In this figure, the MFB or fuel conversion for the beginning of combustion (MFB 10%), the center of combustion (MFB 50%), and the end of combustion (MFB 90%) are displayed. The beginning of combustion, indicated by MFB 10%, is stable at a crank angle of approximately 7 degrees after top dead center (TDC) and is not influenced by the different fuels. It should be noted that 7 degrees after TDC is regarded as rather late for the beginning of combustion, and the overall combustion process is retarded as can be seen from MFB 50% which is at a crank angle of around 18 degrees (cf.

Figure 6). The pressure rise from the combustion only occurs after TDC and the pressure increase rate is quite small. A general trend towards shorter combustion durations can be observed when admixing DMC or PODE, as can be seen from MFB 90% in

Figure 7. There is one outlier though; with DMC20 the combustion duration stays almost the same as with DMC10, although a further reduction could be expected. This is most likely due to the longer injection duration needed to compensate for the lower calorific value of DMC while maintaining the nominal load. The longer injection duration leads to a longer combustion duration and counteracts the faster combustion of DMC.

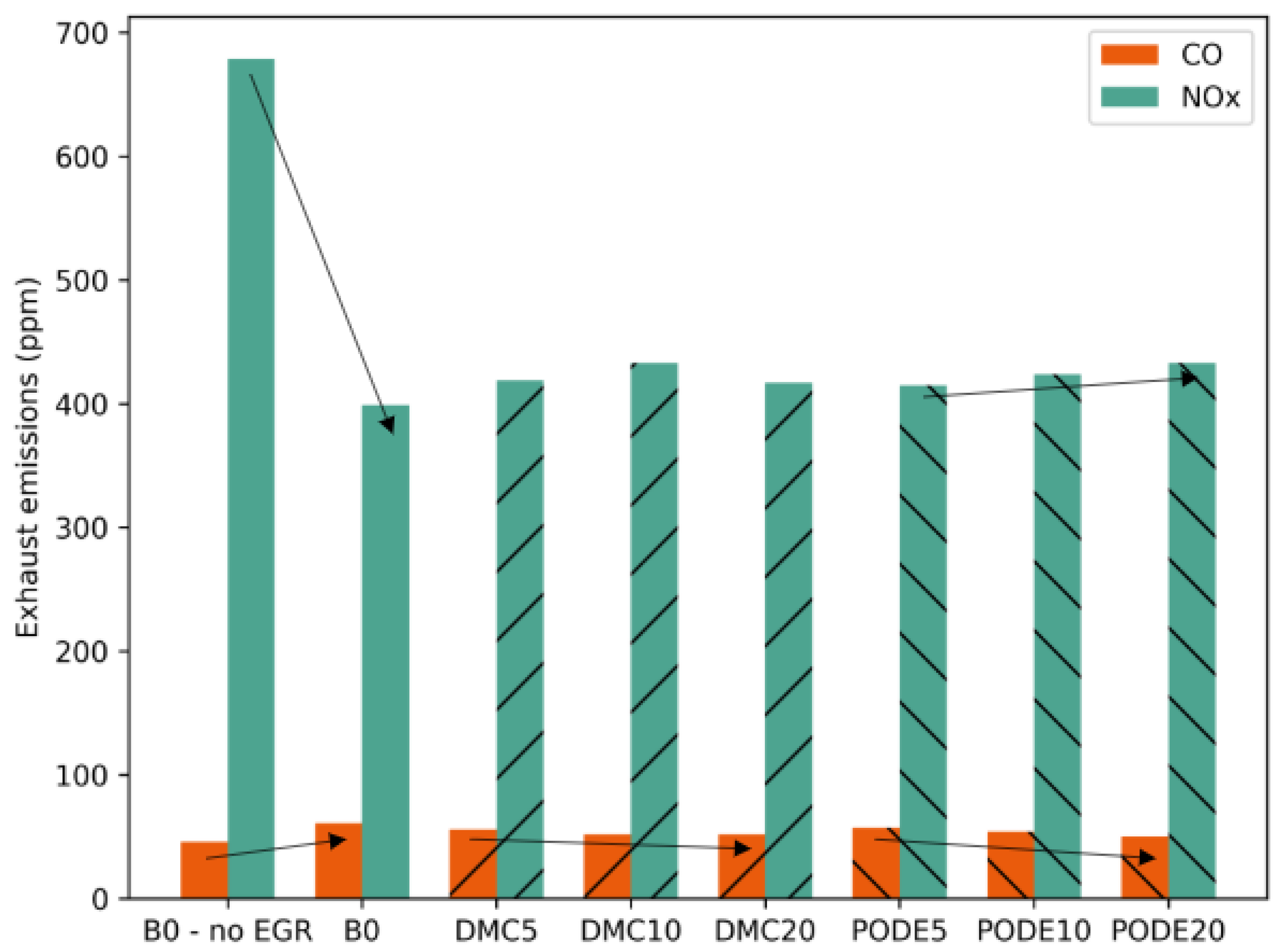

For the exhaust emissions measurement, the focus was placed on the pollutants carbon monoxide and nitrogen oxides. CO is an exhaust gas component that is produced due to incomplete oxidation. The term “nitrogen oxides” refers to various compounds of nitrogen and oxygen that are mainly produced because of side reactions involving atmospheric nitrogen during combustion. These are primarily nitrogen oxide (NO) and nitrogen dioxide (NO2).

Figure 8 shows the CO and NO

X emissions of the investigated fuels. The influence of exhaust gas recirculation can be clearly seen here. Operating the engine with B0 and the EGR valve open, thus supplying exhaust gas to the combustion air, increases the proportion of inert gas, which lowers the combustion speed and the local peak temperatures during combustion. Since NO

X are formed primarily due to high local temperatures in the combustion chamber (thermal NO), this leads to a significant reduction. On the contrary, CO emissions increase due to localized rich areas in the combustion chamber where combustion is incomplete. Admixing of DMC or PODE led to faster combustion (see

Figure 7) with higher peak temperatures, resulting in more complete combustion and reduced CO emissions at the expense of slightly higher NO

X emissions. Even though a trend was recognizable here, the differences between the various fuels can be considered small.

Figure 9 shows the measured particle size distributions for the various test fuels. Two main effects can be observed. Firstly, the diagram clearly shows the influence of exhaust gas recirculation, which for B0 leads to a substantial increase in particulate emissions (cf. curves for B0 and B0—no EGR). Secondly,

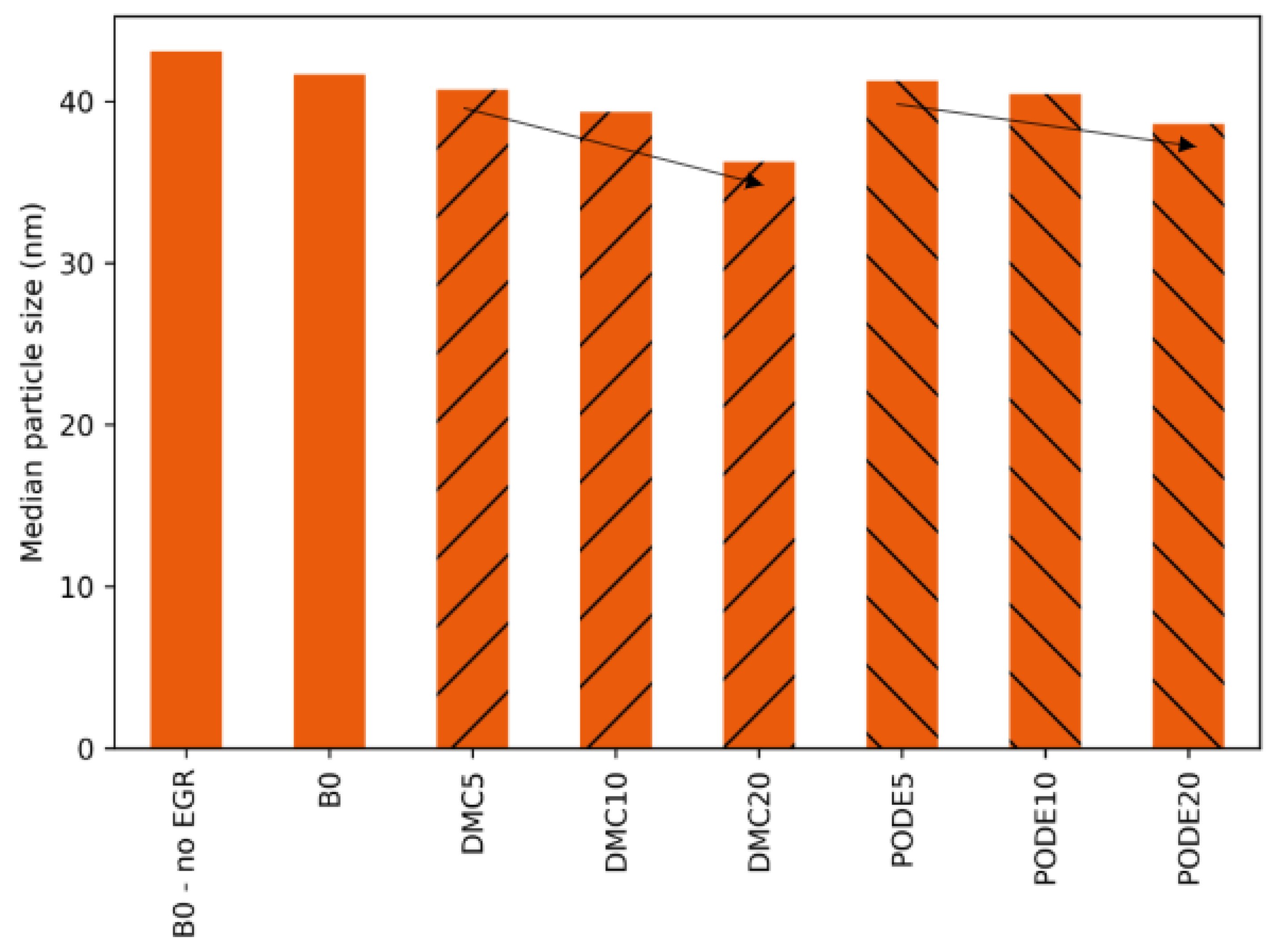

Figure 9 shows the striking particle-reducing effects of DMC and PODE. The higher the proportion of DMC or PODE in the fuel mixture, the lower the particulate emissions in the exhaust gas. Another important observation is that the particle reducing effects of both DMC and PODE seems to be similar, suggesting that both could be used interchangeably as additives with similar effects on particulate emissions.

In addition to the overall particle-reducing effects, the admixing of DMC or PODE also affects the particle size. A shift towards smaller median particle sizes can be observed with an increasing ratio of DMC or PODE. In the case of PODE, the median particle size shifts from 43.1 nm (B0) to 38.6 nm (PODE20), while the median particle size for DMC20 was even smaller at 36.3 nm (cf.

Figure 10). In comparison, EGR had a relatively small effect on particle size. When EGR was applied with B0, the median particle size increased from 41.7 nm to 43.1 nm which is less than the effect of admixing DMC or PODE. These results show that not only is the particle concentration affected by admixing DMC or PODE, but also the size of the particles. This can possibly be attributed due to less agglomeration of soot particles due to a lesser number of C-C bonds in the fuel blend [

24].

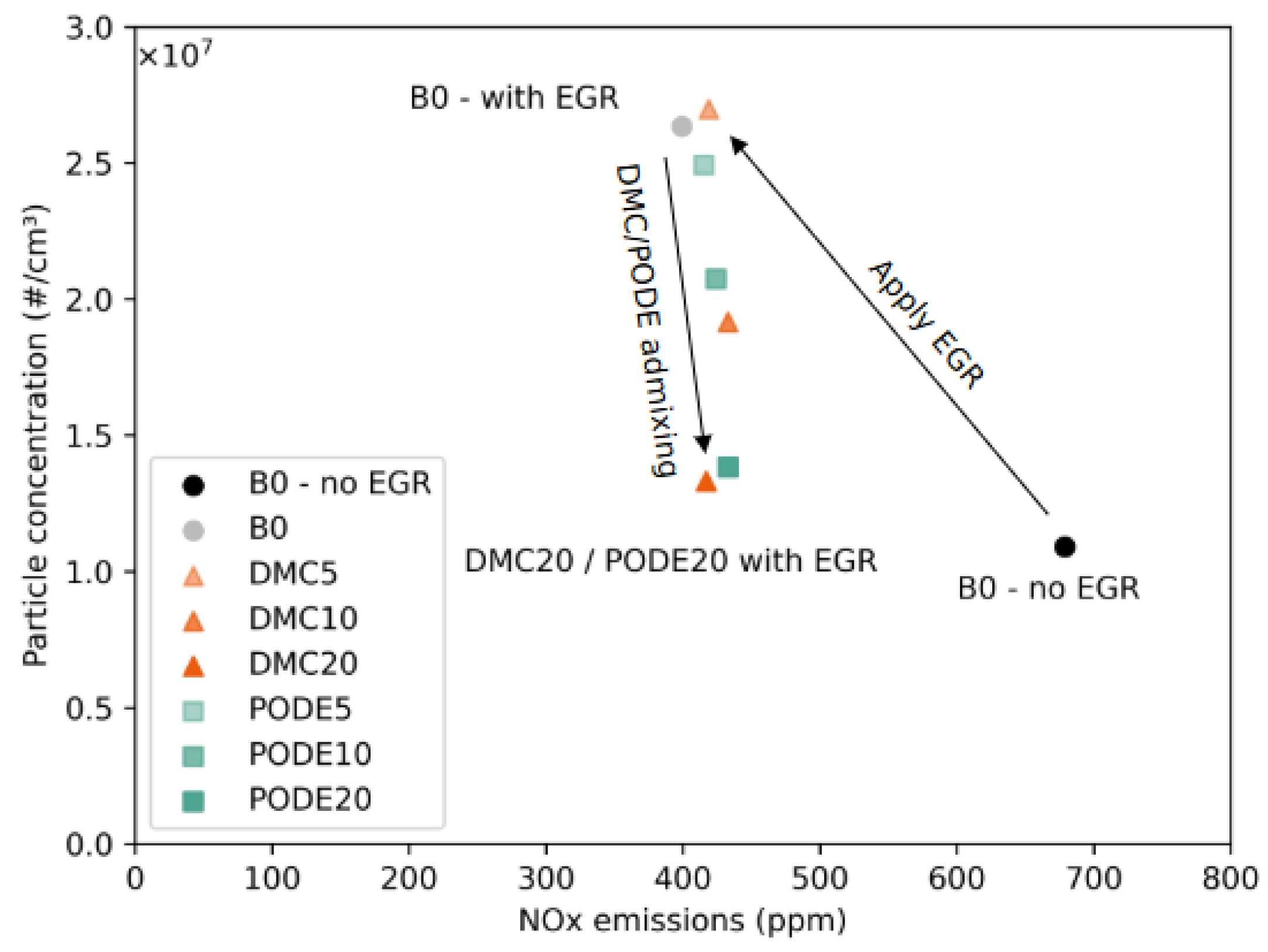

The positive effects of the DMC and PODE blends can be seen particularly clearly when the particulate emissions are plotted against the NO

X emissions (

Figure 11). When operating the engine with neat B0 and no EGR, NO

X emissions where high at up to 700 ppm. By applying EGR, NO

X emissions were significantly reduced to approximately 400 ppm. However, this initially led to a sharp increase in particulate emissions, which could then be reduced again by adding DMC or PODE to the fuel. By adding 20% DMC or PODE to B0, it was possible to achieve particulate emissions similar to neat B0 without EGR, while maintaining the low NO

X level of neat B0 with EGR. Generally, the use of exhaust gas recirculation always presents a trade-off between NO

X and particulate emissions. However, admixing DMC or PODE as a diesel additive can mitigate this trade-off, whereby low NO

X and particulate emissions can be achieved at the same time.

4. Conclusions

This study examines the benefits of blending DMC and PODE with diesel fuel, highlighting their effects on engine performance and emissions, material compatibility, and hydraulic injection behavior.

The material compatibility tests aimed to find suitable materials for use with neat DMC and PODE as well as blends of these fuels with B0. A criterion of less than 10% mass change after 500 h was defined as an acceptable limit value for material compatibility. Of the materials analyzed, only FFKM and PTFE met this criterion. FFKM gaskets are ideal due to their compatibility and hardness but are expensive. PTFE gaskets are cheaper with excellent chemical resistance but are mechanically unstable. For DMC–and PODE–diesel blends, PTFE gaskets are recommended for components with low mechanical stress, while FFKM gaskets should be used for critical components.

The tests of the hydraulic injection behavior aimed to map the injector’s full application range, covering both ballistic and non-ballistic modes. At the activation times 400 µs and 700 µs, representing small and large injections in the ballistic area, the injection quantity shows no obvious trend. However, at 1000 µs, representing non-ballistic operation, the injection volume increases slightly with higher amounts of DMC or PODE due to their higher density and lower kinematic viscosity. Since the calorific values of DMC and PODE are lower than those of diesel, this results in a lower injected energy content. With longer activation times for the injector (non-ballistic operation) the injection quantities increased for both DMC and PODE, albeit not totally compensating for the loss in injected energy. To match B0 diesel power output, injection quantities must therefore be increased for both DMC and PODE blends. This can be achieved through higher injection pressures or longer injection durations.

For the engine tests the focus was on the gaseous and particle emissions. It was found that blending diesel fuel with DMC or PODE reduces particulate emissions and decreases the median particle size, with both additives showing similar particle-reducing effects. While pure B0 EGR will reduce NOX emissions but increase particulate emissions, it has been found that a 20% blend of DMC or PODE will achieve both low NOX and low particulate emissions, effectively balancing the trade-off.

The choice between DMC and PODE as a preferred additive in the future will depend on several factors, including production efficiency, environmental impact, and cost-effectiveness. The ability to produce these additives more efficiently, with lower emissions and at a lower cost, will be crucial in determining their widespread adoption. Further research and development are needed to optimize the production processes and to fully understand the long-term effects of these additives on engine performance and durability.

Overall, the findings of this study highlight the potential of DMC and PODE as viable diesel additives that can help reduce particulate emissions and promote the use of renewable energy sources in the fuel sector. Additionally, our results suggest that both additives could be used interchangeably in the same engine at the same settings with similar effects on injection and combustion behavior as well as exhaust and particle emissions.