1. Introduction

As countries seek sustainable ways to reduce greenhouse gas emissions, CCS has become one of the demanding strategies in the changing global energy sector [

1]. The increasing concentrations of anthropogenic CO

2 in the atmosphere pose a threat to global efforts to prevent climate change. Recent studies investigate the full spectrum of CCS, reviewing capture technologies alignment with net-zero goals [

2], deployment challenges [

3], global innovation trends and advances in CCS techniques [

4,

5], concise policy and economic roadmaps for future implementation [

6], as well as operational insights and lessons from reservoir management and monitoring [

7], which collectively underscore the multidimensional progress and importance of CCS development.

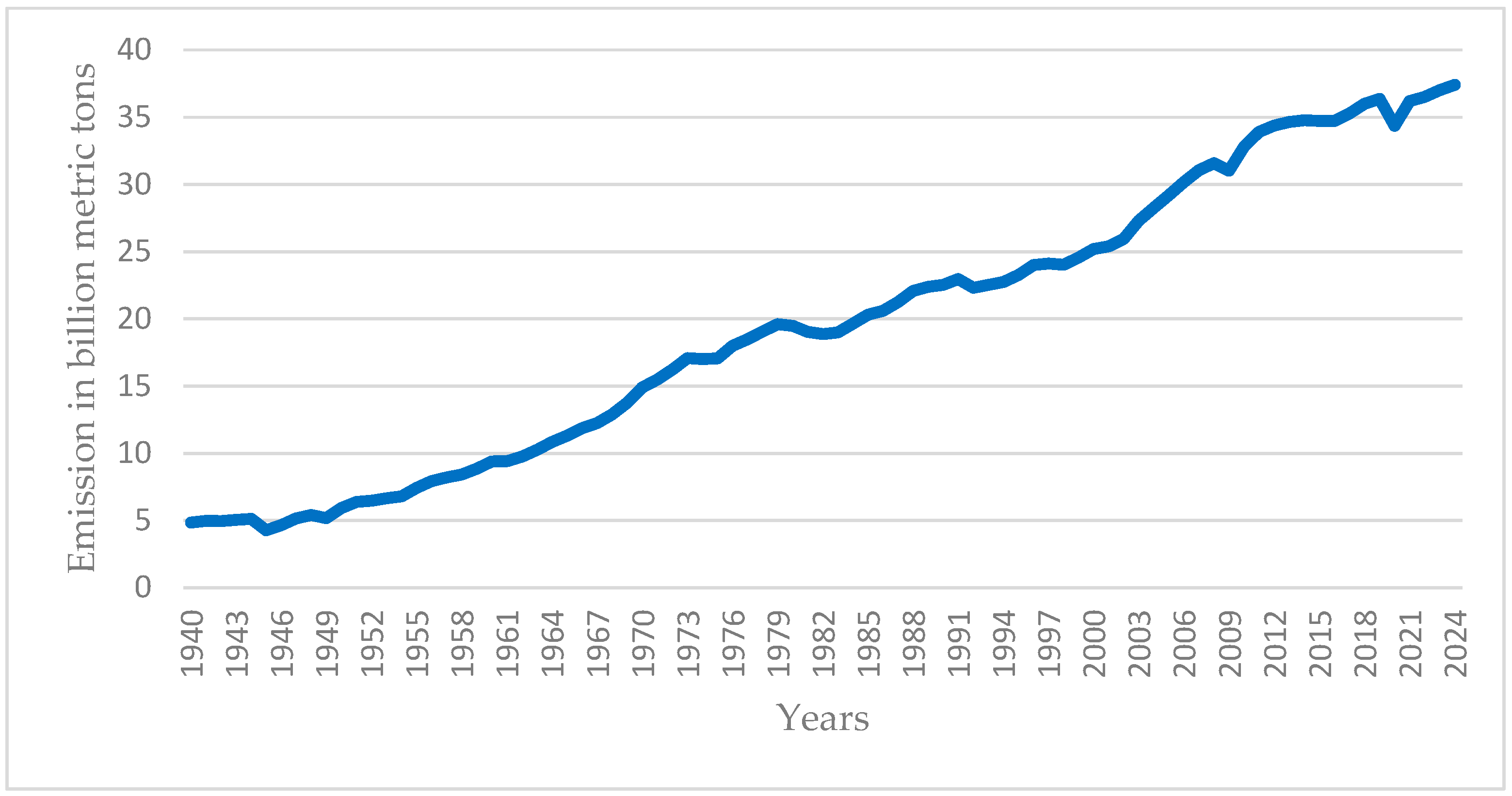

The Earth’s atmosphere now has the highest recorded CO

2 levels, which reached 424.61 parts per million (ppm) as the annual average and 427.09 ppm during February 2025 [

8]. The increase in global CO

2 emissions since 1990 resulted in more than a 60% surge, reaching 37.41 billion metric tons (BMt) CO

2 in 2024 (

Figure 1). Operational CCS facilities worldwide have increased their capture capacity from 28 MtCO

2 per year in 2014 to approximately 50 MtCO

2 per year in 2024. While net-zero emission targets demand approximately 1000 MMtCO

2 capture capacity, the predicted increase in CO

2 capture capacity for 2030 stands at 435 MMtCO

2. Global CCS investment needs to grow its current value by 45 times through yearly expenditures averaging USD 500 billion during the 2024–2030 period to meet the emissions targets [

9,

10].

CCS has proven itself a vital industrial technology by securely storing CO

2 within geological formations for emission reduction. Under U.S. leadership, 231 CCS projects exist at different development levels, and 17 current operational facilities benefit from policy support through the Inflation Reduction Act (IRA) (

Table 1) [

11,

12]. Expanding CCS operations still faces multiple obstacles based on long-term storage security, economic viability, and public perception. The success of CCS heavily relies on site selection, regulatory compliance, financial and political stability, technological capability of monitoring, and storage integrity of CO

2 [

11].

Figure 1.

Annual CO

2 emissions worldwide from 1940 to 2024 in billion metric tons (BMT/y) [

13].

Figure 1.

Annual CO

2 emissions worldwide from 1940 to 2024 in billion metric tons (BMT/y) [

13].

Another crucial component of the CCS project’s success is risk assessment (RA), which guarantees the safe storage of CO

2 for millennia. RA frameworks help us to evaluate potential technical hazards such as CO

2 leakage through legacy wells, geologic faults, cement integrity issues, casing corrosion, leakage from plugs, brine migration, induced seismicity, etc., and non-technical challenges such as public perception, financial security, regulatory compliance, etc. [

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25]. However, uncertainty and limited data surrounding the GCS system trigger constant updates and refinement of existing RA frameworks. For example, the well integrity of legacy wells is a significant threat, as unplugged abandoned wells or poorly sealed plugs have potential leakage pathways for CO

2 in depleted oil and gas reservoirs [

26]. Recently, the State of Texas introduced a bill to plug more than 150,000 inactive legacy wells in the next 15 years across the state that pose a risk of leakage, highlighting the importance of RA [

27,

28].

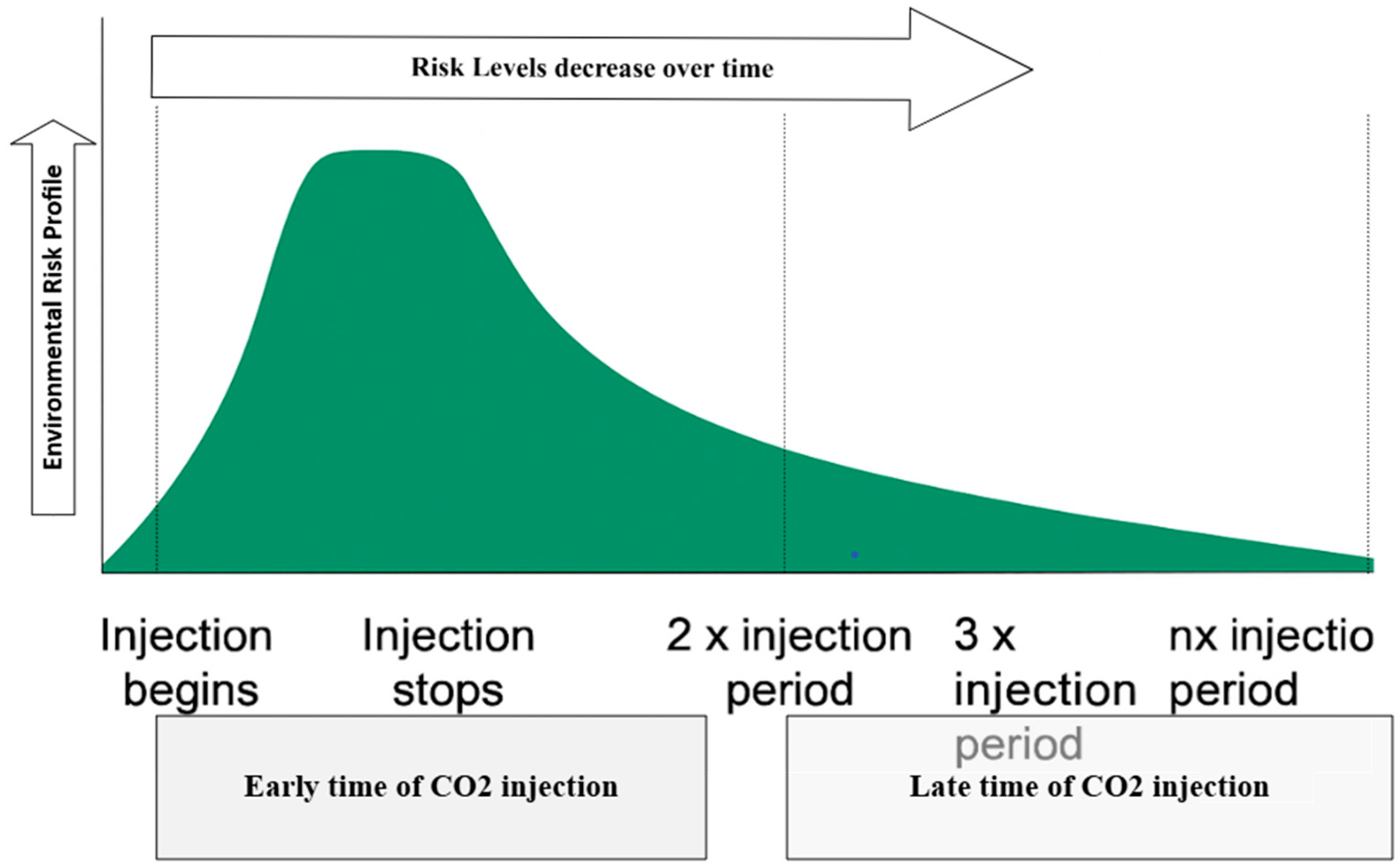

The research examines more than 20 RA tools used in GCS operations, including all four RA methodological scales: qualitative, semi-quantitative, quantitative, and integrated.

Figure 2 depicts the risk levels of CCS projects, with the early time being the highest risk level [

29]. The study shows that early-time RA can be accomplished through qualitative methods, which is helpful regarding limited data. However, these techniques may not identify high-risk formations and require much data, making them open to human errors. Conversely, quantitative frameworks afford more accurate assessments at the expense of requiring large datasets to gauge CO

2 leakage rates accurately. Recently, integrated models have incorporated qualitative and quantitative methods, gaining popularity due to enhanced decision-making. For the first time, this review provides a comparative analysis of two such integrated models to help stakeholders determine tools appropriate for particular CCS projects’ needs.

This review demonstrates the necessity for additional studies regarding integrated (hybrid) RA frameworks, combining qualitative and quantitative approaches for optimizing CCS deployment at a large scale. Through advancements in risk analysis models, improved uncertainty management, and more effective risk prevention protocols, stakeholders can enhance the security of CCS projects alongside operational performance while gaining public acceptance. The evolution of risk analysis methodologies is crucial to successful CCS implementation because it is a key strategy for mitigating climate change.

The paper is divided into three main sections. First, it explains the basic elements of RA for GCS, detailing its crucial components and technical and non-technical challenges. The following section depicts an extensive critical review of more than 20 RA methodologies, including two integrated frameworks. Finally, the paper discusses the results based on the analysis conducted in each section.

The novelty of critical review lies in its comprehensive evaluation of all four primary RA tools currently available, highlighting their strengths and limitations and addressing both technical and non-technical risks within a single study. Previous reviews, including those by Condor et al. [

30], Li et al. [

31], and others did not include all existing RA methods, particularly the recent integrated framework. Other studies, such as those by Damen et al. [

32], focused solely on technical risks, while Sneddon et al. [

33] only performed categorical overviews without a critical evaluation of practical tools. This review provides a more holistic understanding of RA methodologies within GCS by addressing these gaps.

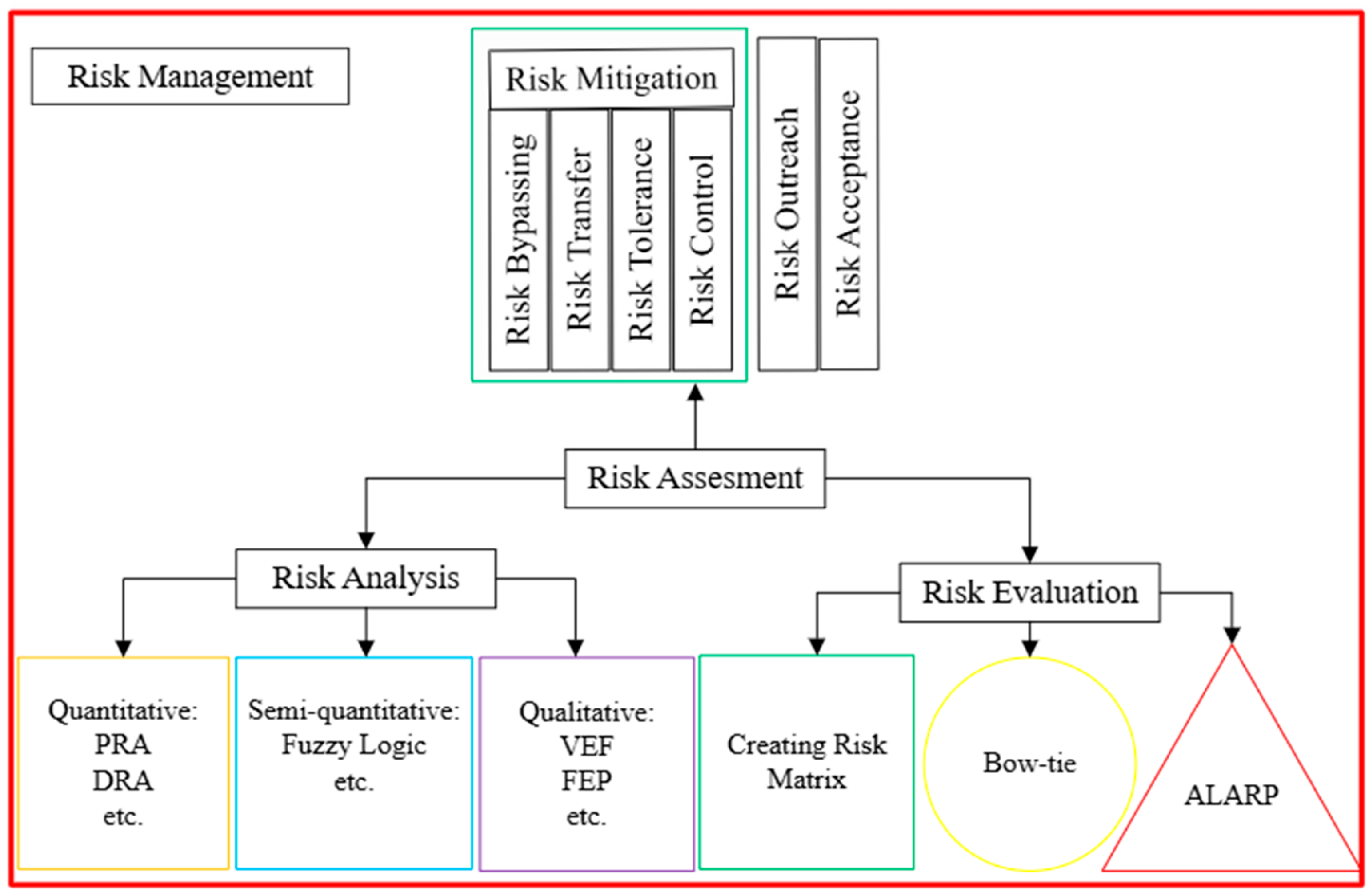

3. Overview of over 20 RA Methods

Risk assessment (RA) methodologies are typically divided into two primary categories: qualitative and quantitative. Since the field of RA and CCS is developing semi-quantitative and integrated (hybrid) methods available on the market. This chapter will discuss over 20 RA methods available on the market and give a comparative analysis of qualitative, semi-quantitative, and quantitative models separately.

3.1. Qualitative Methods

Qualitative risk analysis aims to determine possible hazards/risks and develop mitigation solutions without giving numerical estimates of the potential or effect of specific risks or scenarios on the project. Instead, it uses expert judgment and historical data to determine which risk variables pose the biggest threat to a project, in terms of compatibility with health, safety, and environmental (HSE) regulations [

78]. Qualitative risk assessment methods are extremely easy to apply in the early stages of a CCS project when the numerical data are limited or absent. As CCS projects require assessment of technical (CO

2 leakage, induced seismicity, etc.) and non-technical (public perception, regulatory, political, etc.) challenges, the qualitative RA permits quick and structured decision-making under the degree of uncertainty. Qualitative RA is considered more effective and sufficient when there is a lack of numerical data, time, knowledge, and experience [

30].

Table 5 illustrates several useful qualitative RA tools examined and compared in this chapter.

3.1.1. Features, Events, Processes (FEP) Method

The Features, Events, and Processes (FEPs) method provides a highly systematic and transparent structure to distinguish and explain the characteristics of the several systems specifically under study. In the context of CO

2 storage, the system may include the overall storage framework together with the reservoir, caprock, overburden, side burden, underburned, and wells, or it may consist of only a selected part of that framework, for example, the well and its immediate surroundings [

79,

80,

81]. Features are site-specific qualities such as faults, reservoir permeability, porosity, etc. In the context of CO

2 storage, events that could be considered are earthquakes, induced seismicity, well blow-out, etc. Processes are physical interactions with features such as geochemical or geomechanical processes [

42]. The Quintessa database presents more than 200 FEPs that are divided into eight categories and subcategories [

79,

82]

There are two main approaches to analyzing the FEP method: the bottom-up and top-down. The ‘top-down’ methodology first defines major high-level FEPs and classifies the identified FEPs into scenarios, further developing the scenarios into detailed conceptual models for modeling. A ‘bottom-up’ approach starts with a detailed description of the site where hazards could occur and has a lot of FEPs involved, and these are integrated to come up with conceptual models and scenarios [

83,

84,

85,

86,

87]

Abid et al. utilized the FEP method, integrated it with the interaction matrix IPM (Integrated Potential Matrix), and converted qualitative risk assessment into a semi-quantitative one using cause-effect plot diagrams. The study of two fictitious wells was used to identify key “features”, “events”, and “processes” in terms of CO

2 storage safety. As per the authors, the primary safety concerns were the chemical reaction of water and subsidence with the cement and casing. The risk assessment tool aided in identifying the actions required to remediate the identified risk through multiple barriers (primary and secondary) within the wells. However, there is a need for expert judgment and testing for accuracy [

88].

The FEP qualitative risk assessment method considers various factors and aids in stakeholder communication and traceability. However, the technique is time-consuming and complex for the initial stage of a CCS project, where quick decision-making is preferred.

3.1.2. Vulnerability Evaluation Framework (VEF) Method

VEF is a qualitative risk assessment method developed by the EPA. The technique identifies attributes (permeability, wells, faults, etc.) of the CCS system that can make them vulnerable to adverse effects, outlines impact categories, and offers systematic assessment by decision-making flowcharts

Figure 5 [

71]. Firstly, injection and confining zone-related attributes that could influence the Geological Storage System (GSS) were identified. Furthermore, the spatial area for assessing the adverse effects of migration, leakage, or unexpected pressure change is defined using the presented method. Lastly, the potential effect categories and important receptors identified include human health and welfare, the atmosphere, groundwater, surface water, and the geosphere. The final report of VEF qualitatively defines whether the project has Low or Elevated vulnerability. Low vulnerability means that adverse effects are unlikely to occur on assessed attributes of the system, while elevated vulnerability means that attributes assessed require special attention [

89]. The VEF is not meant to choose sites, set performance standards, or specify data requirements. Instead, it is a helpful guide for regulators and technical experts to pinpoint areas that need design evaluation, specific risk assessment, monitoring, and management [

71,

90].

Although the method provides systematic, holistic decision-making tools, its complexity and data requirements make it time-consuming, and it lacks uncertainty management for elevating vulnerable projects. Also, the method does not consider operational and CO2 transportation-related risks (attributes), which makes it more specific. Existing gaps could be addressed by integrating with other models to provide a quicker and more comprehensive risk assessment.

3.1.3. Screening and Ranking Framework (SRF) Method

The Screening and Ranking Framework (SRF), presented by Oldenburg et al. [

91], aims to estimate potential geologic CO

2 storage sites utilizing the rating of health, safety, and environment (HSE) risks associated with CO

2 leakage. This framework describes risks of CO

2 leakage based on three fundamental characteristics of a geologic CO

2 storage site: (1) the capability of the target formation to provide primary containment, (2) the ability of secondary containment to mitigate leakage if the primary formation fails, and (3) the potential for the attenuation and dispersion of CO

2 if both primary and secondary containment measures fail. SRF requires general input, often relying on expert opinion based on the level of site characterization and available published information. The framework’s assessment is structured around four information classes (

Table 6): (1) site characteristics, (2) attributes defining these characteristics, (3) properties defining the attributes, and (4) user-input values defining the properties [

91]. The SRF is represented with a spreadsheet where the user can input available limited data and plot the numerical points with automatically generated lines where the sealing formation’s poor, fair, or good confinement is defined. Oldenburg et al. [

91] applied the method in three case studies for potential CO

2 storage. The formations were evaluated with limited data and in a short period. The author emphasizes that the presented method is valid only for qualitatively screening the storage sites; further steps require more in-depth quantitative and simulation models for the final decision.

The presented methods allow users to make rapid decisions with relatively limited data from open sources and publications, which is vital at the initial stage of any CCS project. This method is also advantageous in terms of transparency and ease of use. However, there is still a need for more in-depth evaluation of the storage site, testing on the actual storage site, and uncertainty in predictions.

3.1.4. SWIFT (Structured What-If Technique) Method

SWIFT is a group-based technique used by DNV in consultation with GE Plastics to identify risk and uncertainty within commercial operations and industrial sectors, particularly in CO2 storage. Originally used in engineering and heavy lifting, it was transposed to CO2 storage when DNV was helping Norway identify locations for offshore storage. The SWIFT method is advantageous in comprehensive, efficient, and proactive hazard identification.

Some aspects of applying the SWIFT method include the ability to identify risks qualitatively, generate suggestions of risk control measures, and take advantage of expert opinion. It includes brainstorming techniques, discussions, and checklists that systematically discuss hazards from a global perspective, shifting the focus from objects to systems or operations [

92].

Discussions and different segments on the CO

2 storage site are available in the following categories: reservoirs, seals and overburden, wells, and atmosphere. The workshops follow checklists based on the Quintessa database of the Features, Events, and Processes developed with the IEA Greenhouse Gas R&D Program (IEAGHG). These ensure intensive identification of the risks involved, forming the root for future risk assessment. Experts participating in the discussions must be selected based on their outstanding field knowledge. Discussions focus on the causes, potential repercussions, and safeguards for each hazard, emphasizing the need to examine all possible risks, regardless of perceived likelihood [

93].

This approach is constructed with a series of questions (What If?; How could?; etc.) to identify the risks or potential dangers to the project’s safety. SWIFT is considered an easy qualitative estimation method of hazards, where other complex hazard identification techniques do not work or are too complex. The process is also advantageous due to its adaptability, time-saving, clear documentation, and top-down approach (see FEP method above). However, the qualitative nature and limited details make it less reliable, and the technique highly relies on the experts participating. Here, biases based on participants’ opinions might result in subjective results. The method qualitatively identifies the hazards without giving any probabilities or likelihood of events, which is needed for advanced decision-making.

3.1.5. CASSIF (Carbon Sequestration Scenario Identification Framework) Method

CASSIF is a scenario-based analysis framework developed based on the FEP scenario analysis database. The framework assesses containment ability regarding fault and seal integrity [

89]. It consists of four modules, as described in

Table 7.

This module requires less time to analyze risks than the FEP model from which CASSIF was derived. This efficiency is achieved because the online database is implemented in software. The method is considered comprehensive and transparent for detecting, interpreting, and mitigating leakage from storage formations. However, its application has been limited to a specific field. The tool needs to be made available as open-source software for broader adoption.

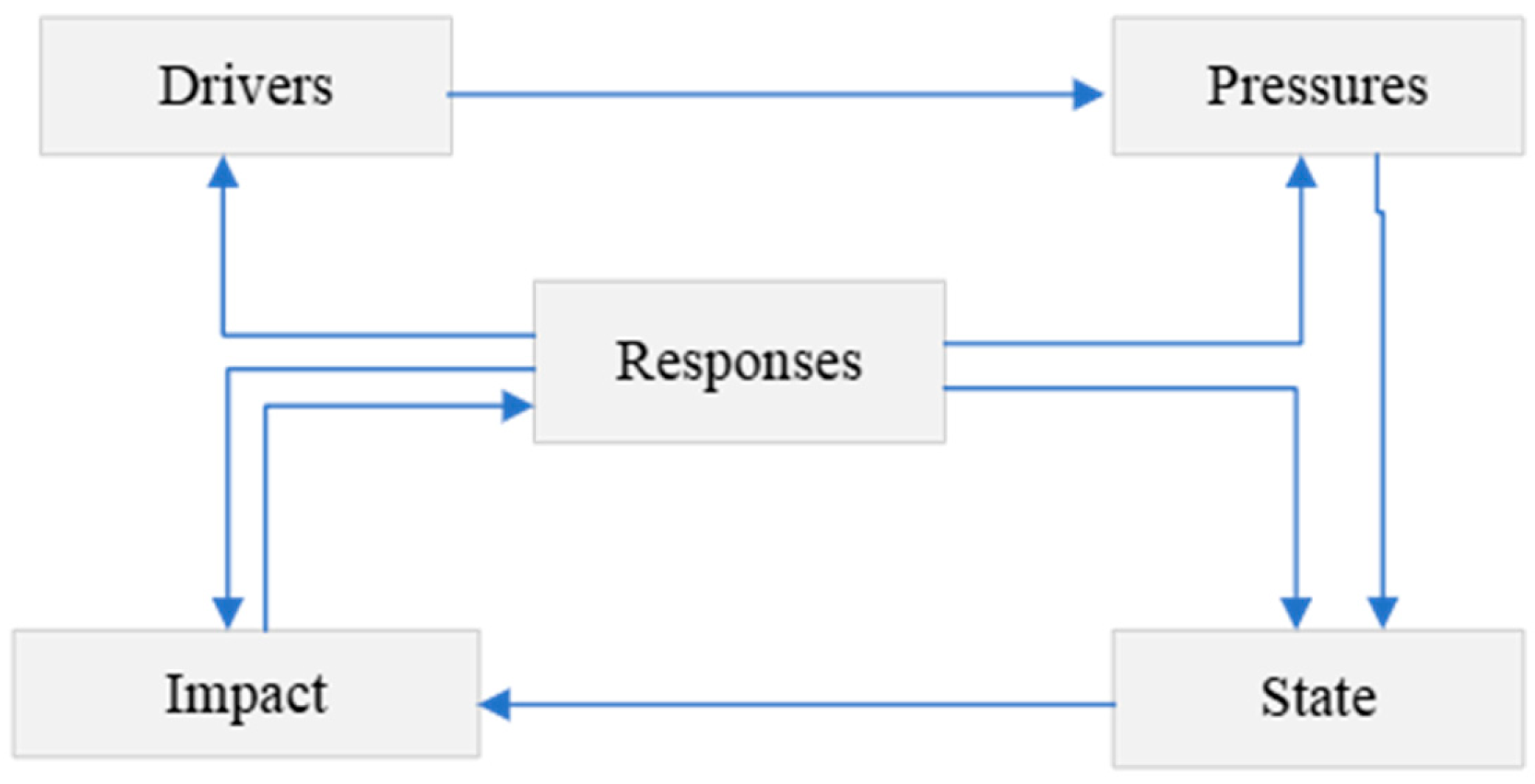

3.1.6. DPSIR (Drivers, Pressures, State, Impact, and Responses) Framework

Within the DPSIR framework, the influence of the components is assessed and defines the state of knowledge on environmental impacts that might hinder the deployment of the CCS project [

94]. The methodology behind this framework contains the following definitions of each component. Drivers or driving forces are environmental forces that lead to CO

2 and highlight the importance of storing CO

2 underground. Pressures refer to CO

2 emissions due to human activities. The state describes the condition of the environment as a result of CO

2 emissions and human activities. Impact refers to the results of environmental changes on human beings and the ecosystem. Responses are actions taken to reduce the effects of the factors mentioned above [

95].

The DPSIR framework evaluates every component meticulously through a pictorial representation found in

Figure 6. Panels within this framework detect and resolve the potential risks involved in CCS projects. This method helps policymakers better understand environmental challenges and possible risks. However, complex data computational needs to prevent the DPSIR framework from performing effectively in analytic tasks. Despite recognizing uncertainties, the framework does not provide any resolution for them.

3.1.7. MCA (Multicriteria Assessment)

The MCA method estimates the suitability of CCS reservoirs and scenarios through weighted analysis, which matches these elements to established performance standards. Through MCA, participants conduct assessments by choosing their preferred assessment factors and ratings to create a structured framework that gathers stakeholder opinions. Participants employing the method gain full accessibility because it works for everyone, no matter their technical level, and maintains straightforward assessments that are easy to comprehend. Using this method, providers have complete flexibility for transparent evaluation procedures [

97].

The Multicriteria Analysis (MCA) was carried out in two stages: first, evaluating carbon storage reservoirs, and second, assessing various scenarios, which leveraged detailed geological expertise. In the first stage, a set of criteria is defined against which the CCS reservoir will be evaluated. In the second stage, various criteria are proposed to assess scenarios. The two-stage MCA procedure enabled comprehensive reservoir assessments and quick implementation of broad scenario trade-off assessments. The process adopted two stages, which integrated specialized carbon storage criteria for expert geological analysis, combined with a general understanding for non-expert participants [

98]. Based on a study conducted by Gough and Shackley [

98], the criteria of CCS reservoir assessment and scenarios could be categorized as in

Table 8. The evaluation has proven instrumental in discovering vital ambiguities and threshold issues affecting storage technologies, while the subsequent phase investigated carbon storage across various CO

2 reduction scenarios.

However, MCA requires intensive resources and extensive stakeholder consultations and data collection, which makes it time-consuming, costly, and site-specific. As the results depend on ratings from respondents, assigning weights to different criteria has the potential for biases in the evaluation process. Although the presenters declare that people with limited geological (technical) knowledge could participate in the evaluation, a certain level of expertise in technical fields like geology is essential, which can limit the participation of non-experts.

3.1.8. ESL (Evidence Support Logic)

The main idea of an evidence-based logical hypothesis is to identify risks and challenges that have the most significant impact on the confidence of the system [

99]. ESL helps identify if deeper research and evidence of the risk and uncertainty would improve confidence in the problem that lacks information. Sensitivity analysis using an ESL model assists in determining the areas where further research and evidence collection are most likely to have the most significant influence on lowering uncertainty brought on by ignorance. ESL tools and other decision-support platforms deliver systematic ways to assess data while maintaining independent human analysis and avoiding objectification of procedures. Using logical models to decompose problems promotes full coverage of essential elements and uncertainties and allows documentation of decision processes. A standard assessment helps discover biases while showing their impact on the process.

Metcalfe et al. [

99] developed a software tool, TESLA, based on the ESL approach and applied it to the Salah CCS project in Algeria. TESLA is a tool that helps users with decision-making when such issues arise. The tool divides the decision into a structure with a hierarchy, simplifies the problem, and allows users to collect and categorize the required information. Although the process does not automate the decision-making process, it provides helpful assistance [

100,

101]. When used in the Salah storage system, the tool revealed high confidence in complete and permanent CO

2 confinement, with limited danger of substantial release due to effective management and the absence of transmissive defects or fractures.

The proposed TESLA tool (based on ESL) allows integration of various data types like seismic surveys, reservoir models, and collective assessment. The processes are transparent and boost the confidence of stakeholders while making decisions. The tool enables us to highlight uncertainties that need to be targeted first and allows authors to apply it in practical applications in long-term storage stability assessment. However, the complexity in constructing decision trees and analyzing them, extensive data requirements, and reliance on spreadsheets that the tool is based on limit its application in initial scanning of storage sites where data, time, and knowledge are limited.

3.1.9. RA-CO2 Method

Paraguassú et al. [

102] proposed this qualitative approach of RA for CCS projects in Brazil. The authors analyzed previously described qualitative methods like VEF, SWIFT, MOSAR, FEP, MCA, and CASSIF and adopted different terms from each method (

Table 9). RA-CO

2 qualitatively assesses the risks and categorizes them, evaluating the level of damage to the environment, the reputation of the operating company, public perception, and the confinement integrity of the storage reservoir [

102,

103].

RA-CO

2 is considered a beneficial qualitative RA tool due to its advantages: low cost, ease of use, transparency, comprehensiveness, systematicity, and flexibility. The authors proposed a worksheet that consists of nine columns where participants can indicate a range of aspects like a migration of CO

2, things that trigger CO

2 leakage, consequences, mitigation actions, frequency, the impact if leakage occurs, risk, monitoring measures, and a column for an identical number for each scenario of an accident. The column “risk” classifies the risks as low, medium, or high using a risk matrix (

Figure 7).

Paraguassú et al. [

102] developed this tool because the methods listed in

Table 8 could not address such gaps as frequency and uncertainty in the sense of limited data and experience. However, the authors consider the SWIFT tool to be more fit for these purposes, but the tool is not user-friendly. It does not systematically tackle the challenges defined during the assessment. The RA-CO

2 method is capable of identifying risks earlier, which might aid the operating company in cost-saving and resource distribution based on the level of risk and uncertainty [

102].

Despite the advantages mentioned in the method, there is no evidence of economic feasibility as the technique was not applied in real-world applications. The authors state that the process is cost-effective compared to other qualitative tools. Still, it is not proven, and success heavily depends on expertise, data availability, and organizational resources. If successfully proved in practice, the method’s qualitative nature limits its application only to the initial stage of the project.

3.1.10. Bow-Tie Diagram (GERICO Database)

Guénan et al. [

104] concluded that the main gaps in RAs are due to a lack of an exact mitigation structure for identified potential risk scenarios and the actual data the operating company needs in the decision-making process. To address these gaps, authors came up with the GERICO database. GERICO database addresses the first gap by developing bow-tie diagrams with safety barriers, and the second gap was filled by constructing sheets with descriptions and pertinent metrics of each measure studied [

104].

The authors used expert judgment to define eleven possible risk events from workshops and developed bow-tie diagrams based on them. Each of these defined risk events was further evaluated at three stages of project development: the planning phase, operational phase, and long-term storage phase. Later, one bow-tie diagram was developed per risk event for each stage (

Figure 8).

The proposed method is beneficial in identifying mitigation measures specific to risk scenarios and developing bow-tie diagrams for each phase. The tool is specifically helpful in preparing preventive measures to ensure they comply with regulatory requirements. The bow-tie diagrams enable stakeholders to enhance decision-making by ranking measures based on relevance to a particular scenario. However, the tool lacks clarity of preventive and corrective measures while classification of measures. Some risk scenarios do not present clear and time frame management measures, such as “ignorance of legacy wells” (abandoned wells), making it challenging to relate to one of the three phases. The diagrams cannot address post-closure risk management because the well becomes inaccessible. It is doubtful that the tool might be immediately practical, as the authors point out that it is still under development. There are plans to transfer to another online web database that will require additional expenses.

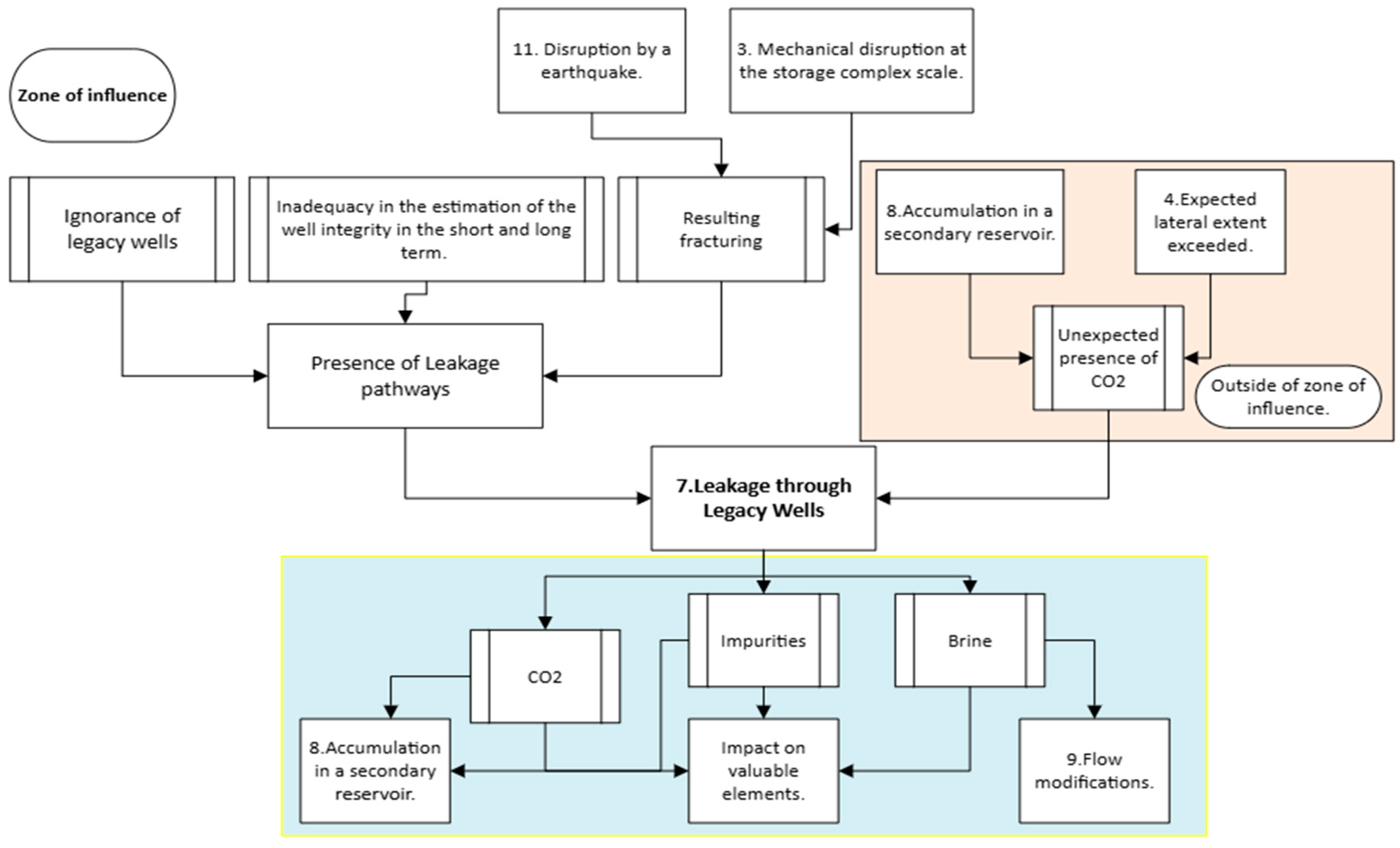

3.1.11. Risk Matrix for RA of Legacy Wells

Arbad et al. [

105] developed a Risk Matrix to qualitatively assess risks from legacy wells within the Area of Review (AoR), penetrating sealing rocks, and storage formations. The method allows the development of datasets for wells that need remediation. The proposed methodology categorizes legacy wells, facilitating a fast and more straightforward comparison of various CCS projects based on AoR. This method benefits operators in obtaining permits for Class VI CO

2 injection wells, as they must present corrective and monitoring actions for poorly plugged or abandoned wells. Although most papers consider wells with sustained casing pressure (SCP) and cement bond logs (CBL) in RA, this methodology aims to focus on different well types, from producers and injectors to orphaned, abandoned, and plugged wells, etc., which are categorized in the “Well Type” column of the risk matrix (

Figure 9). The classification of wells ranges from Type 1, which lacks documentation, to Type 9, which does not penetrate the primary geologic seal or storage reservoir, with varying levels of protection for USDWs, the primary geologic seal, and the storage reservoir, depending on the type [

40,

41,

105].

The proposed method is practical in the early stages of storage site screening and selection, aiding operating companies in identifying faulty wells and those requiring immediate remediation actions. The tool was applied in a real-world experience in an Illinois basin case study, which proves its applicability. However, the tool is limited to the legacy wells RA and an early-stage application of the CCS project. More comprehensive and integrated models must be applied for a more detailed scenario-based and numerical estimation of all leakage pathways to give a numerical analysis of leakage amounts.

3.2. Comparative Analysis of Qualitative RA Methods

The 10 qualitative RA methods undergo comparative analysis, which is displayed in

Table 10 in a tabular presentation. The comparison uses key factors such as user friendliness, time usage requirements, data collection needs, expert assistance needs, CCS project suitability, and strengths and limitations.

Table 11 compares eleven qualitative RA methods based on their top strengths and weaknesses. SWIFT, SRF, and RA-CO

2 serve as cost-efficient tools during the CCS project’s beginning, but the detailed risk analysis benefits from FEP, CASSIF, or ESL. DPSIR and MCA evaluate policies and environments, and the Risk Matrix developed by Arbad et al. [

105] functions for quick qualitative evaluations on legacy wells and speeds up permit obtaining for Class VI CO

2 injection wells.

This analysis allows stakeholders to select their preferred RA tool. It shows the advantages and limitations of each method regarding project demands and resource availability.

3.3. Semi-Quantitative Methods

Semi-quantitative tools utilize both qualitative and quantitative RA methods: qualitative methods to estimate likelihood and impact levels, and quantitative techniques to prioritize and analyze the results for detailed risk identification and assessment. Plenty of semi-quantitative tools have been developed over the years for CO

2 leakage RA. In this chapter, semi-quantitative methods that have been applied in industry were introduced and compared (

Table 12).

3.3.1. CarbonWorkflow™ Tool. (Schlumberger)

The CarbonWorkflow™ Process from Schlumberger delivers a structured semi-quantitative RA method for resource allocation in risk reduction and documentation alongside tracking how risks are mitigated. Coherent project criteria help experts evaluate potential FEPs in a risk matrix with five severity and likelihood assessment category scales. The evaluation tracks health, safety, financial, environmental, research, and industry viability effects.

Expert panels work in two cohorts, which comprise six groups dedicated to examining different project aspects, like air, surface, near surface, and subsurface, to review pre-screened FEPs. Trained experts learn about the project-specific data and RA protocols as a prerequisite to performing the ranking process. The experts supply three quantitative measurements of lower, best, and upper bounds for negative impact estimation as well as likelihood probabilities that relate to the baseline standard of “100 similar projects over 100 years” to establish approximate confidence ranges. The RA for each FEP is derived from producing severity scores with likelihood ratings. The assessment results enable managers to develop key risk scenarios that lead to the creation of risk response actions (RRAs), which form part of risk response action groups (RRAGs) that receive implementation assignments and documentation alongside periodic review processes [

106].

The presented methodology was applied to RA in the Illinois Basin–Decatur Project (IBDP), where evaluation was conducted on five parameters: financial stability, impact on the environment, industry responsibility, and research activity on the project. IBDP experts addressed questions by utilizing technical and non-technical FEPs on the severity vs. likelihood (S × L) scale of the risk matrix [

106,

107,

108]. The Kimberlina site CCS project also utilized the CarbonWorkflow™ tool for RA, which depicted risk scenarios and ranked them utilizing the risk matrix on

Figure 10.

While the CarbonWorkflow™ tool is comprehensive, involves cross-disciplinary collaboration during workshops, and has proven its practical implementation on real-world challenges, the significance of time and resources and data extensiveness might limit the application of the methodology. The S × L matrix approach used semi-quantitative methodology despite potential subjectivity from absent probabilistic risk modeling, which future CCS projects should consider implementing quantitative or hybrid methods for better accuracy.

3.3.2. CO2QUALSTORE Guideline

The CO2QUALSTORE guideline serves as a tool to help operators, authorities, verifiers, and other stakeholders through its development by DNV and its industrial partners with support from national regulators. The main function of the CO2QUALSTORE guideline focuses on establishing a transparent and uniformly applied method to qualify storage sites at reasonable costs. The workflow of the evaluation is as follows: screening stage (site screening, shortlisting), assessing and selecting stage (selection of the best sites and permit application), operation and review of permit stage (commence CO

2 injection, site closure), and lastly, transfer of responsibility stage (final milestone decommissioning) [

109]. The proposed guidelines emphasize the importance of early communication between project operating teams and regulators to speed up permit application [

110].

The guideline is capable of risk management of major steps within the CCS project. The tool is comprehensive and allows stakeholders to assess risks from the screening to the closure phase. The method boosts stakeholder confidence and transparency and aids in harmonizing engineering practices with regulations. However, the framework heavily relies on extensive data collection, and risk documentation may pose a challenge, particularly in the initial stages of the project.

3.3.3. RISQUE Method

Bowden et al. developed this method that is based on the judgment of experts providing stakeholders transparency in understanding the leakage risks throughout the CCS project. The method was successfully applied in the major CCS projects including GCS site in Salah (Algeria), the CO2CRC Otway Stage 1, various sites in Australia and Weyburn–Midale Project [

111,

112,

113,

114]. RISQUE identified leakage pathways like faults, legacy wellbores etc., and uncertainties linked to them, and later they were compared to the dynamic changes at various leakage scenarios. The quantitative part of RA pertains to the leakage rate to be less than 1 percent over 1000 years. The analysis was conducted on such variables as; the potential for leakage on log scale from 0 to 1, amount of CO

2 leak in tons, and the likely time when the scenario would happen [

112]

Although the tool has been used in non-technical spheres for a long time, it has also proven its applicability and effectiveness in a real-world CCS project. RISQUE allows diverse technical data to be integrated into the site characterization process, helps regulators gain confidence through an evaluation structure, and smooths the public perception process with transparency. However, in terms of leakage quantification, the tool is only able to estimate the amount of leakage through a particular containment lease, while the tool is not capable to estimate the leakage and impact on other leases around the geological trap—which limits the tool only in short- to mid-term risk evaluation. Furthermore, the method is limited in consideration of emerging risks like induced seismicity, fault reactivation, and geomechanical risks that may cause well integrity issues.

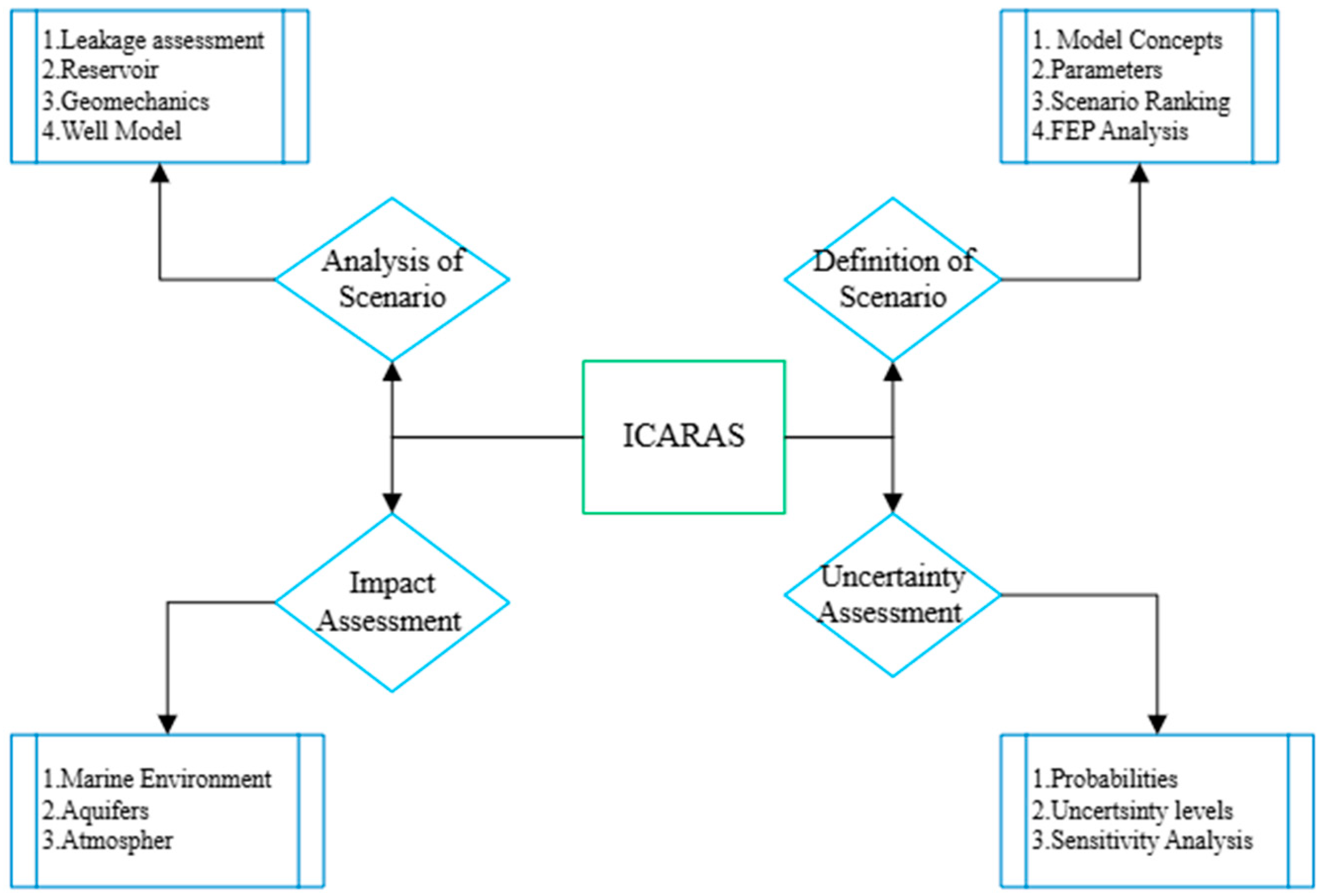

3.3.4. ICARAS Method

According to Wollenweber et al. [

114], the ICARAS framework is a holistic modular approach to monitoring geological CO

2 storage-related risks (

Figure 11).

The methodology connects pre-existing qualitative and quantitative tools, starting from CASSIF scenario definition through detailed models of reservoirs and geomechanics to migration analysis, thus providing step-by-step procedures for the complete storage period. The integration of preliminary screening systems that employ fast models like COSE enables efficient operations through a speed and accuracy balance [

115]. Integrating response surface methods through Cougar™ strengthens risk quantification by improving its robustness.

The framework complexity creates two main practical difficulties: it requires the integration of diverse software programs, and it is essential to confirm that easy-to-use models still accurately represent natural geological systems. Well integrity assessment aspects remain in development, which may impact the reliability of final RA results. ICARAS enables substantial progress toward methodical system-wide RA for GCS; however, the system requires advanced improvements in tool matching along with model testing for comprehensive regulatory backing.

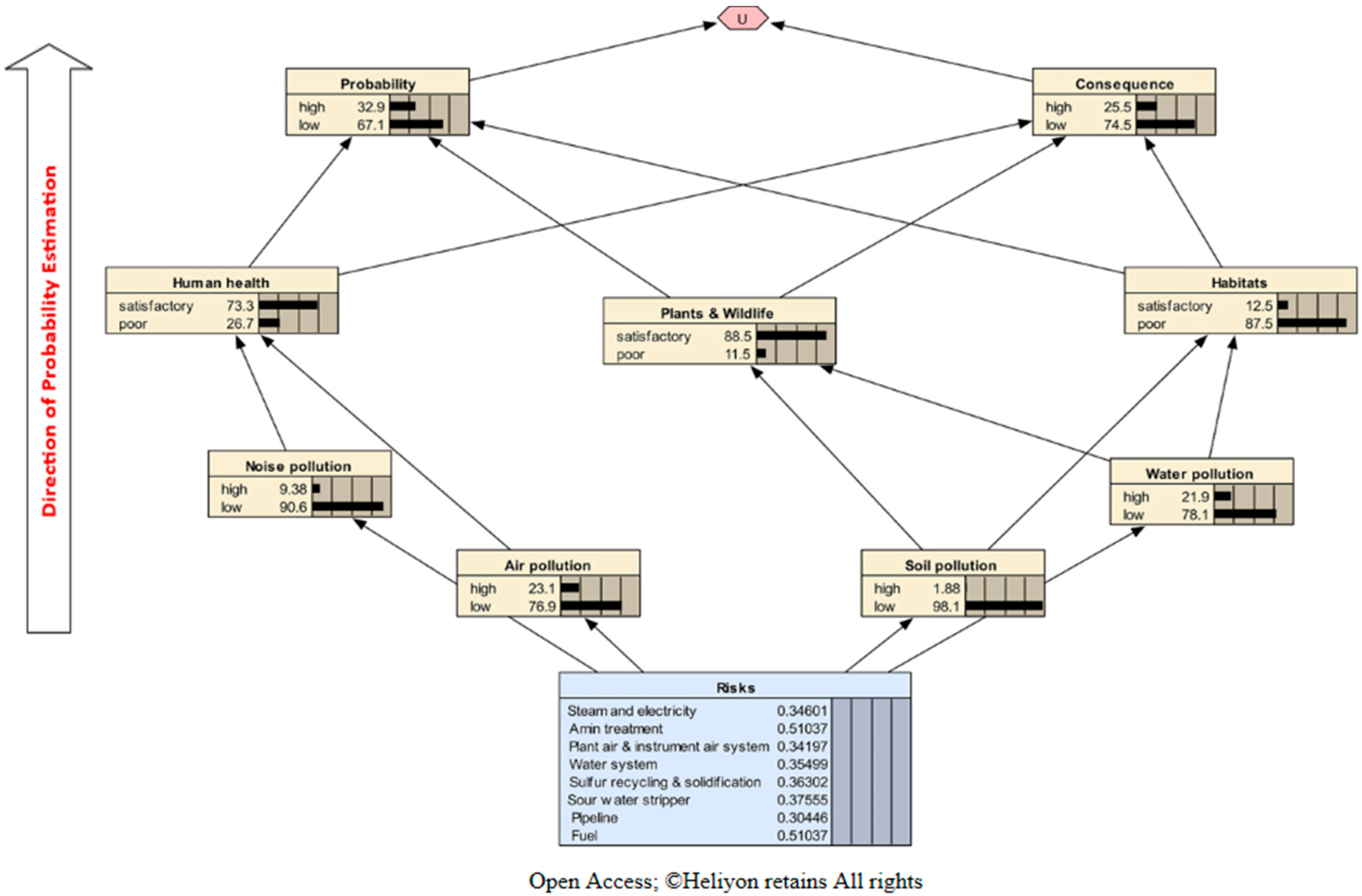

3.3.5. Bayesian Network (BN) in the Bi-Directional Approach of RA

BN was applied as an RA tool in CCS projects with a focus on bi-directionality (predictive and diagnostic reasoning) [

116,

117,

118]. The method is extensively used in diverse technical and non-technical industries because it is a flexible and probabilistic graphical modeling tool where variables are depicted by nodes and arrows connecting nodes. The whole idea of the mechanism and spread of influence due to a change in the state of a node in BN comes from Bayes’ theorem [

116].

Creating a BN model can be complex and time-intensive, particularly if the system that has to be modeled has not yet been defined through variables that constitute the nodes. There are two main components to the process: first, the design of the BN structure, and second, the population of the Conditional Probability Tables (CPTs) for each node within the BN (

Figure 12). As the RA process depends on time, the framework needs to be flexible. BN incorporates RA in the initial site screening process with limited data available (corresponds to the initial time) and the time frame that covers later RA, such as injection and post closure, making it a flexible model in terms of time of RA and amount of input data [

116].

The BN method enables us to conduct predictive analysis of adverse outcome risk and diagnostic analysis of possible cause identification through its inherent bidirectional capabilities. The BN framework establishes an explicit graphical structure that displays relationships among system elements (such as CO

2 input, pore space, injectivity, and migration). This approach allows stakeholders, particularly regulators and the public, to better understand the RA process since it lacks closed “black box” behavior. Expert-elaborated risk assessment processes occur during network model development and CPT population activities. The model relies heavily on expert judgment for its development because CCS data remains insufficient; thus, integrating multiple professional insights helps improve its accuracy [

116].

However, the expert-based extraction of thousands of probabilities requires extensive time and introduces inconsistent results, particularly involving multiple disciplinary backgrounds. Additionally, the model operates statically for one time period, while the CCS system shows dynamic patterns extending throughout its entire lifecycle (e.g., during injection, post-injection, and thousands of years post-closure). This simplified model might restrict the model’s predictive power for long-term RA. Expert elicitation represents a strength, yet it brings subjectivity and potential bias. Implementing this approach requires turning continuous parameters into discretized versions through a process that may reduce precise detail recovery.

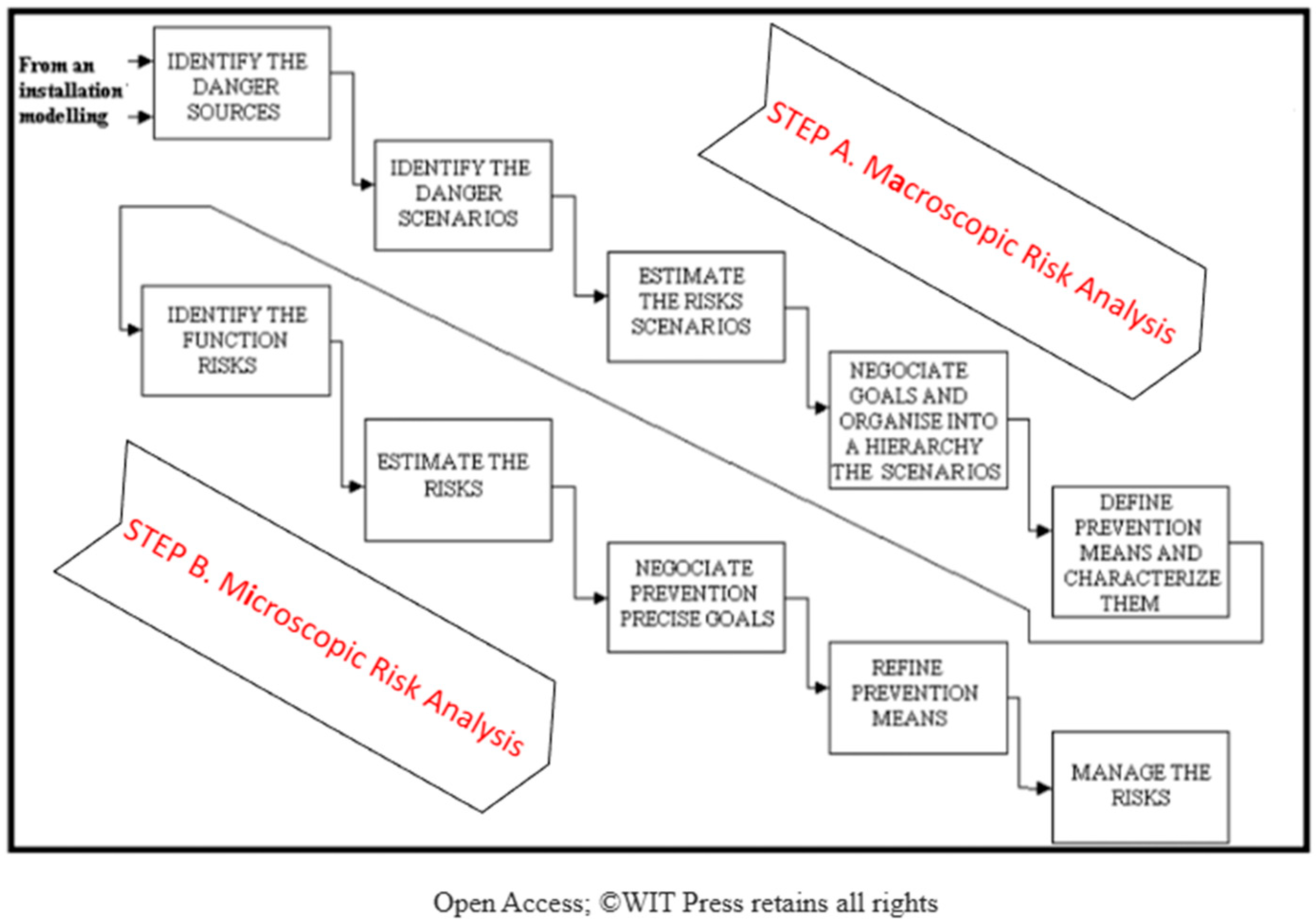

3.3.6. MOSAR Framework

MOSAR provides an organized solution for technical risk analysis of human installation infrastructure and existing facilities that help detect and eliminate risky conditions through preventive actions [

119]. The method consists of two stages. In stage A, the significant risks, sources of risks, and consequences are identified. In stage B, a detailed evaluation of identified risks is conducted (

Figure 13). The whole process of RA with MOSAR takes 10 subcomponents. This method is solely based on site observations. Although all the subcomponents interact with each other and no step can be neglected, the system still provides a means of flexibility by the ability to include new risks into the subsystems without changing the RA results obtained initially [

120].

Through its RA methodology, MOSAR structures, the evaluation process divides storage systems into key parts like injection wells and aquifers. Any risk falls under the classification of mechanical, chemical, or biological aspects in the typology grid, which delivers comprehensive coverage across different RA factors. This method enables teamwork between operators, policymakers, and community members, enhancing RA transparency and shared responsibility. Through its interconnected subsystems approach, MOSAR enables risk detection of sophisticated leakages when fluid faults intersect with aquifers.

However, the authors state that this method requires large amounts of time and resource expenditure. Even though MOSAR needs extensive time to design hazard grids and scenarios, its reliability becomes unstable when used for storage site RA during initial development phases. The authors claim the superiority of MOSAR over complex FEP. Still, its application at the Ketzin site fails to prove practical worth since it lacks quantitative evidence to support the system. Since it lacks time-dependent probability data for these elements, the method experiences substantial limitations when assessing long-term slow risks linked to geological shifts, legacy wells problems, and induced seismicity.

3.4. Comparative Analysis of Semi-Quantitative Methods

Table 13 represents ranked and assessed standard parameters and features across the six semi-quantitative RA tools for CO

2 storage. This enables users to compare their capabilities, practicality, and suitability directly.

Each RA technique provides exclusive coverage for different CCS risk factors. The selection of RA tools should match project phase requirements while using existing data sources to fulfill stakeholder needs through multiple methods.

Table 14 summarizes a comparative analysis of the semi-quantitative RA frameworks.

The critical review indicates that CarbonWorkflow™ facilitates cross-disciplinary collaboration but is limited by a subjective SxL matrix and short-term focus. CO2QUALSTORE supports regulatory compliance, although it imposes a high documentation burden. RISQUE is effective for leakage pathway analysis but does not account for cross-lease impacts. ICARAS enables holistic system-wide modeling, though it is hindered by software complexity. Bayesian Networks provide predictive and diagnostic analysis but are constrained by static timeframes and potential expert bias. Lastly, MOSAR is suitable for infrastructure risk detection but performs poorly in managing long-term risks.

In conclusion, the comparative analysis notes that none of the tools can assess long-term geomechanical risks (e.g., induced seismicity risk), which is a key critical gap among them.

3.5. Quantitative Methods

Various RA methods have been introduced over the past few decades to assess leakage of GCS; however, a significant shift towards quantitative tools is very noticeable. Quantitative models can predict and quantify leakage through wells, faults, and other mechanisms by relying on physics-based models to forecast long-term CO

2 plume behavior [

72,

121,

122,

123]. Quantitative tools are considered accurate RA methods; however, the accuracy highly relies on data quality, in the sense of higher uncertainty, requiring running sensitivity analysis and stochastic models, the computation is costly, time-consuming, and unreliable [

122,

123,

124,

125,

126,

127,

128]. Among quantitative tools, Reduced Order Models (ROM) were used to reduce the time of computation by incorporating factors that affect well leakage and reservoir parameters [

129,

130,

131,

132]. ROM could be developed from surrogate, proxy, meta, and surface response models. Among these subtypes, surrogate models are found helpful in conjunction with numerical models, as surrogate models handle complex computations, keeping accuracy high [

133,

134]. Moreover, surrogate models with emerging deep-learning techniques were used to predict CO

2 flow and the long-term geomechanical response of the formation, which semi-quantitative models were not able to predict [

135,

136]. Southwest Regional Partnership on Carbon Sequestration (SWP) developed ROM with Monte-Carlo simulation for RA and uncertainty quantification in the late Pennsylvanian classis reservoir, Morrow B sandstone formation (initially under CO

2 EOR) at the Farnsworth Unit (FWU) [

137,

138,

139]. ROMs assessed relationship between uncertain input values (porosity, permeability, anisotropy, initial oil saturation, cation exchange capacity (CEC), absorbent specific surface area (SSA), CO

2 leakage rate), and dependent model outputs (cumulative oil production, total dissolved solids (TDS), volume storable CO

2 in different trapping mechanisms, pH of water, etc.) [

140,

141,

142].

Table 15 demonstrates the Quantitative RA methods studied in this paper.

3.5.1. Performance Assessment (PA) Framework

Metcalfe et al. [

143] from Quintessa introduced an integrated framework to perform PA of GCS by connecting qualitative data with quantitative models and expert knowledge. The methodology implements three essential instruments: (1) TESLA, which utilizes Evidence Support Logic (ESL) on its decision-support system to build hypothesis-based decision trees, (2) a generic FEP database that functions as a system model audit scenarios, and (3) QPAC-CO

2, which works as a numerical modeling code for physical-chemical process simulation (

Figure 14). The methodology addresses epistemic and aleatory uncertainties as well as system couplings, to support stakeholder decisions through all project steps [

142,

143,

144].

The framework creates a synergistic evaluation method that utilizes computer output, expert input, and observed data to understand the system’s functioning as a whole. The interval probability approach of TESLA defines separate categories of evidence for hypothesis testing and remaining unawareness while offering improved alternatives to standard probability statistics. The FEP database facilitates thorough scenario development through systematic system components and process cataloging, which helps prevent missed RA areas. QPAC-CO

2 demonstrates the flexibility that lets researchers join different processes at different measurement scales to conduct comprehensive system-level and detailed process analyses simultaneously. The complete audit trail between hypotheses and decision points and their models helps build trust among stakeholders while ensuring regulatory compliance [

142,

143].

However, among the advantages mentioned, the method has several drawbacks. Numerical evidence derived from qualitative data (for example, TESLA’s 0–1 scale) becomes susceptible to biased interpretation because expert opinions may differ without sufficient empirical evidence. The probabilistic capabilities of QPAC-CO2 face difficulties when integrating detailed and system-level models because it requires substantial computational resources. The restricted example of caprock leakage demonstrates the system but fails to provide experimental proof. The predictions spanning 103 years exist in a speculative state because geological and chemical processes produce significant uncertainties. The adoption of TESLA and QPAC-CO2 depends on developing user-friendly interfaces and training users since their usability and learning preferences remain unexplored.

3.5.2. Performance and Risk (P&R™) Methodology

Oxand S.A. developed a quantitative RA framework, known as the Performance and Risk (P&R™), for RA of leakage in CO

2 geological storage systems [

145]. The approach integrates:

The system storage is described as a network of components (i.e., casings, cement sheaths, geological layers) and processes (i.e., CO2 flow, cement degradation, casing corrosion).

Kinetic models are used to simulate key aging mechanisms such as cement leaching/carbonation and casing corrosion, while the development of future technologies related to abdication is investigated. These processes cause impedance changes over time, altering material properties (e.g., permeability-thickness).

Scenarios are generated probabilistically for uncertainties in parameters such as cement permeability and corrosion rates. For instance, the synthetic case was run with 243 scenarios, and random vertical cement permeability values were tested.

Risk expressed as: Risk = Probability (P) × Severity (S). Failure likelihood (e.g., degraded cement pathways) is used to derive probability, and severity impacts on stakes like economic health and the environment. The result is mapped onto critical grids (e.g., F-G matrices) to rank the risks.

In the end, a risk remediation strategy is recommended based on cost–benefit (C/B) ratios and risk reduction potential.

This methodology is operationalized in the simulation platform SIMEO™-STOR, which couples two-phase flow models (Darcy’s law) with degradation kinetics. It predicts CO

2 leakage pathways and rates, as well as cumulative leakages on millennial timescales (i.e., 1000 yrs) [

145,

146,

147].

The P&R™ methodology delivers an effective method to evaluate CO2 storage risks that combines detailed engineering analysis with outcomes that satisfy stakeholders. The methodology incorporates dynamic degradation modeling and scenario analysis to handle key uncertainties within long-term well integrity assessments. However, additional improvements should be made because the method depends on ideal input assumptions, high computational requirements, and insufficient testing of forecasts beyond short periods. The predictive accuracy and adoption rate of the tool will increase when field monitoring programs (such as Sleipner and Weyburn) develop open-source tools alongside it. Regardless of its restrictions, the method is a notable progress in performance-based safety evidence development for CCS projects.

3.5.3. Certification Framework (CF)

Proposed by Oldenburg et al. [

148], the CF is an RA method to evaluate GCS site safety and effectiveness through analysis of potential CO

2 and brine leakages. Effective trapping refers to CO

2 trapping within specific storage areas according to a framework that determines leakage risk factors via probabilistic pathways (wells and faults) and environmental compartments (e.g., USDW and atmosphere) analysis. The CF incorporates reservoir simulation models with probabilistic RA and simplified leakage models to predict impacts using proxy indicators like fluxes and concentrations (

Table 16). A theoretical Texas Gulf Coast model shows the framework for application [

148,

149,

150].

The methodology offers simplicity and transparency in RA by dividing complex systems into components that benefit stakeholders and regulators. The framework incorporates regulatory flexibility, thus accommodating various national standards with those from the framework itself. Also, CF prioritizes leakage pathways by focusing on legacy wells and faults, which are the main pathways in sedimentary basins, reducing unwanted complexity. However, reliance on simplified models (e.g., one-dimensional, homogeneous reservoir assumption) limits their accuracy. CF is impractical for early-stage RA as probabilistic inputs (e.g., well integrity) require extensive site-specific data, which accounts for data gaps. Addressing these gaps is critical for future models for risk and leakage quantification.

3.5.4. GERAS-CO2GS Framework

Tanaka et al. [

151] created GERAS-CO

2GS as an RA platform to determine safety risks from CCS operations. The framework combines CO

2 migration simulation models with atmospheric dispersion computation and industrial accident frequency calculations to predict risks in geological formations, marine settings, soil surfaces, and air environments. Visualization tools, modular risk scenarios, and probabilistic hazard assessment (PHA) are used to ensure stakeholder engagement. The software tool meets criteria from both ISO/TC 265 and CDM requirements to improve operational safety while increasing public acceptance [

151,

152,

153].

It includes the following essential characteristics that GERAS-CO

2GS contains (

Figure 15):

GERAS-CO2GS offers RA for underground reservoirs, marine facilities, surface equipment, and atmospheric emission monitoring.

Combines numerical models (e.g., CO2 migration via CO2/PENS and atmospheric dispersion via ADMER 2.5) with empirical accident data (e.g., high-pressure gas leaks).

The system allows risk scenarios with diverse events, such as well blowouts and caprock failures, by storing categorized data about endpoints (human health and ecosystems).

The system integrates Google Earth functionality, which creates transparent spatial risk maps for public perception.

GERAS-CO2GS provides a novel and original approach to CCS RA on the multiscale, merging simulation rigor and empirical data. The methodology leverages assumptions on industrial accident statistics (e.g., Japanese high-pressure gas incidents) to estimate surface facility risks. It supports compliance with international standards and allows project approvals by schemes such as CDM.

However, its prototype status and reliance on analog data limit its applicability to novel CCS contexts. A limited scope and partial application exist for marine impact analysis and acute event modeling (e.g., blowouts). CO2 production facility surface risk estimates could cause CCS-specific situations (e.g., offshore storage) to be misrepresented. The model relies on steady-state leakage models, which might limit transient ones when sudden well failures due to wellbore integrity issues or Blow Out Prevention (BOP) equipment failures occur.

Figure 15.

The workflow of GERAS-CO

2GS methodology (adjusted from [

150]).

Figure 15.

The workflow of GERAS-CO

2GS methodology (adjusted from [

150]).

3.5.5. CO2-PENS (Predicting Engineered Natural Systems)

The CO

2-PENS model functions as an RA system for GCS that combines system-level and process-level assessment components for CO

2 capture, transport, as well as storage and leakage potential evaluation [

154]. CO

2-PENS utilizes the GoldSim

® platform to build its RA model through probabilistic modules that handle uncertainty in GCS [

155,

156,

157]. The methodology utilizes physical models that analyze CO

2 plume migration, wellbore leakage patterns, and economic RA elements. Latin Hypercube sampling generates probabilistic results for uncertainty propagation for reservoir permeability, wellbore integrity, and energy costs. The methodology uses 3D geologic information about reservoir topography and fault patterns to evaluate spatially based leakage risks from abandoned wells and faults [

158]. The approach also analyzes the production expenses for treating extracted saline water (e.g., reverse osmosis vs. thermal desalination) and estimates their relationship to the sequestration advantages.

The CO

2-PENS model was used to assess storage capacity and leakage risk potential (through faults and wells) and estimate brine disposal expenses at the Rock Springs Uplift in Wyoming [

159,

160]. The framework was also used to evaluate the brine extraction process and select optimal water treatment options under different water salinity and temperature parameters [

156]. Beyond these, CO

2-PENS helps conduct initial site screening through CO

2 plume migration simulation, and pressure management optimization, which aids in selecting the safest sequestration formation [

158]. The method proves suitable for various CCS projects based on these applications.

CO2-PENS establishes itself as an effective method for initial site screening RA and functions across multiple geological environments. However, it requires excellent input data and suitable computational facilities. High-resolution 3D simulations such as FEHM for multiphase flow demand substantial computational resources, making them impractical for storage sites lacking such data. Moreover, using literature-derived data for cost and permeability assessment produces potential biases or insufficient simplifications within the system.

3.6. Comparative Analysis of Quantitative RA Methods Studied

The critical review shows specific strengths and weaknesses that match different phases and goals within CCS projects. The PA Framework successfully merges expertise-generated information with modeling initiatives to build organized scenarios that address various uncertainties effectively. The method’s performance suffers from qualitative data requiring expert interpretation, high computational needs, and minimal experimental evidence. The P&R™ Methodology performs dynamic model estimations for degradation alongside probabilistic modeling and offers cost–benefit analysis to evaluate remediation plans. This approach contains substantial advantages, yet it depends on simplified assumptions, needs complex calculations, and shows constrained proof during long monitoring periods. The CF method receives strong regulatory approval due to its clear compliance standards, which also allow proper adjustments to changes in governing laws. This method lets users focus on key leakage pathways, making it more suitable for regulatory compliance needs. The simplified model approach in this method compromises accuracy while needing plenty of site-specific data and limitations during early-stage evaluation. The GERAS-CO2GS framework offers broad RA capability, incorporating experimental data and visualization elements designed for stakeholder involvement. This technology falls short because it only works with prototype versions, needs analog data, and has limited skills for handling transient occurrences. The mixed set of strengths and weaknesses across models allows stakeholders to pick particular modeling systems based on individual project requirements or create multi-model systems that address all CCS project stages.

Table 17 shows a comparative study of five quantitative methods. As can be seen, CO

2-PENS is the most versatile method among all in terms of technical data handling and initial and long-term RA, while CF is the best fit for regulatory compliance. PA Framework and GERAS-CO

2GS show excellent results in stakeholder communication.

3.7. Emerging Integrated or Hybrid Methods

Among emerging methods, integrated ones, which combine features of qualitative and quantitative methods in one model, have shown great applicability in real-world applications. NRAP-Open-IAM and REX-CO2 are the most well-known integrated models, and this chapter will describe and compare them.

3.7.1. NRAP-Open-IAM

In 2016, NRAP released its first leakage risk forecasting tool for GCS site operators, the NRAP Integrated Assessment Model for Carbon Storage (NRAP-IAM-CS) [

159]. The model framework divides the GCS systems into four components. Each component simulates physical processes in GCS (

Table 18).

The Geologic Stratigraphy component aims to provide foundational data for other models and integrate all components through defined stratigraphic data [

123]. A simple reservoir model (with homogeneous permeability and constant thickness) is used to quickly estimate the storage site screening scenario. Lookup Table models are employed for detailed, complex, and site-specific reservoir simulations. Lookup Table reservoir models are created in CMG, ECLIPSE, or TAUGH2 simulators. The Leakage Pathways model utilizes a completely uncemented legacy wells scenario [

124,

125,

161], a cemented legacy wellbore model [

130], and a multisegmented wellbore model where the leakage is modeled along the wellbore with varying properties and multiple segments [

123,

162,

163]. The main goal of the Aquifer Receptor model is to simulate the geochemical reactions caused by CO

2 and/or brine leakage into the aquifer and evaluate the change in groundwater quality, such as pH and TDS. [

134,

164]. The atmospheric Receptor model is the leakage into the atmosphere and dispersion of CO

2 in the atmosphere, depending on the leakage location, wind speed, and leakage magnitude [

165,

166].

However, NRAP-Open-IAM does not directly address essential parameters such as casing corrosion rates, the number and location of plugs, elastomer/seal mechanical properties, and the operational effects on in situ stress levels. The latter can significantly influence well integrity by inducing fractures and altering the stress distribution around the wellbore. Incorporating these elements into the assessment tool is crucial to achieving a more accurate risk assessment of wellbores.

3.7.2. REX-CO2 (Re-Using EXisting Wells for CO2 Storage Operations)

The REX-CO

2 method is structured to assess risks associated with storing CO

2 in underground reservoirs. It evaluates well design, material compatibility, and potential leakage pathways to ensure safe and long-term CO

2 containment. The tool is designed to evolve based on feedback from industry partners and real-world case studies [

76,

167,

168]. Below is a breakdown of its key components:

The process starts by gathering basic data about the storage site and wells:

- ⚬

Field Information: Location of the oil/gas field, type of storage reservoir (e.g., depleted oil field, saline aquifer).

- ⚬

Well Data: Details like well purpose (injection/monitoring), operational history, and current status.

- ⚬

Storage Parameters: Reservoir depth, pressure, temperature, and injection rates.

The next step will be the Well Design Assessment. This step checks if the well can safely contain CO2 under operational conditions. It includes four assessments:

- A.

Well Integrity Assessment.

Evaluates barriers that prevent CO

2 from leaking out of the well.

Table 19 depicts the types of obstacles that are assessed.

These checks include corrosion, cement bond quality, pressure testing details, and Primary and Secondary well barriers.

- B.

Risk of Out-of-Zone Injection.

This section assesses whether CO

2 might leak outside the intended storage zone. Checks include cement integrity around the casing, integrity of the casing shoe, and proper sealing of overlaps between casings. Also, it ensures corrosion resistance (material compatibility assessment) of the well (e.g., to CO

2 or hydrogen sulfide) and compatibility of elastomer/seals to the change in temperature and pressure within the wellbore (Structural Integrity Assessment) [

76,

166,

167,

168,

169].

Moreover, the assessment tool includes cement integrity prediction. This predicts risks of cement failure and CO2 leakage using two simplified models. The first model, ROM 1 (Geomechanical), is employed by industrial designers to forecast the likelihood of cement failure and the formation of fractures. This model’s predictions hinge on three crucial parameters: Young’s Modulus of the cement’s stiffness, the bond strength between the cement and rock, and the temperature at which the cement is injected.

The second model, ROM 2, assesses leakage and calculates potential CO2 escape rates. This model requires data on three key factors: cement permeability, reservoir depth and pressure, and CO2 concentration values. The REX-CO2 tool includes essential features for comprehensive risk assessment. It collects vital site and well information during the initialization phase. The Well Design Assessment module evaluates barrier integrity and material suitability while identifying potential leakage sources. Cement Integrity Models analyze failures, predicting leaks, and determining failure rates. A Programming Framework ensures a user-friendly experience and efficient risk calculations, while a Feedback Loop mechanism continuously updates predictive models based on real-world data.

The REX-CO

2 assessment tool utilized ISO 27914 [

74] and US EPA Class VI [

45] standards for CO

2 storage and injection, as well as ISO 16530 [

170] and NORSOK D-010 [

171] standards for injection well design and the development of a decision tree, which emphasizes strong regulatory compliance. The tool successfully leverages ROM-based geomechanical cement debonding and well leakage models, which are lacking in most quantitative tools. Moreover, the tool demonstrates flexibility in adapting to changing regulatory requirements across different states and countries. However, the assessment tool does not consider complications like junction integrity of lateral wells and plugs, durability of elastomers, and limited data scenarios.

3.8. Comparative Analysis of Integrated Assessment Tools (NRAP-Open-IAM and REX-CO2)

Table 20 depicts a comparative analysis and summary of each assessment tool’s capabilities. This comparison could be a good starting point for stakeholders in choosing the right integrated assessment tool based on project needs.

The comparison shows that NRAP-Open-IAM is best suited for in-depth leakage analysis, regulatory compliance, AoR delineation, and long-term storage site monitoring. At the same time, it lacks some detailed well integrity assessments. On the other hand, REX-CO2 is most effective for evaluating injection well design, cement debonding analysis, and mitigating certain operational risks; however, the assessment tool has a narrow scope, primarily focused on wells, and has gaps in plug modeling (e.g., cement plug failure). NRAP-Open-IAM provides a macroscopic assessment of the field (from the reservoir to receptors), while REX-CO2 offers a microscopic evaluation of the well. By coupling both assessment tools, stakeholders could significantly enhance the quality of RA in GCS systems.

4. Cross-Category Comparison of RA Frameworks and Discussions

Our evaluation integrated the relevant criteria from four primary RA frameworks: Qualitative, Semi-Quantitative, Quantitative, and Integrated. This would help projects select a suitable RA framework based on their needs. Each category was assessed against seven standardized criteria using a normalized 1–5 scoring scale (5 = excellent, 1 = poor), based on usability, technical demands, and applicability across CCS project phases (

Figure 16).

The qualitative approaches obtained the top scores in Ease of Use (5) and Time Requirements (5) because they maintain a simple structure requiring expert assessment. However, this method is limited in handling uncertainty and needs better data acquisition methods. The evaluation tools work well for early-stage screening but demonstrate restricted capability for leakage quantification and RA in advanced phases.

The semi-quantitative techniques performed strongly overall, earning 4 points in both Ease of Use and Flexibility categories. The approach quantifies risk to a certain extent but remains easy to handle with limited data and expert resources. These models demonstrate excellent suitability for the period, which bridges site selection with operational monitoring phases.

Quantitative methods achieved strong performance in Data Requirements (5) and Uncertainty Handling (5) since they excel at providing measurable risk predictions through scenario-based modeling. These methods failed to perform well in terms of Ease of Use (2) alongside Time Requirements (2) because they required complicated setup periods and extensive computational resources. These methods are best reserved for mature project stages where comprehensive data are available.

The integrated frameworks NRAP-Open-IAM and REX-CO2 demonstrated a steady performance pattern in key operational areas. The system displayed high scores of 5 in all categories of Uncertainty Handling, Real-World Application, and Project Phase Flexibility, showing its ability to maintain precision and adaptability. The hybrid characteristics of these assessment methods make them the optimal selection for complete CCS risk management despite their moderate requirements regarding data and time usage.

5. Conclusions and Recommendations

Comparative studies for CCS RA show distinct benefits and drawbacks between qualitative, semi-quantitative, quantitative, and integrated assessment approaches. Qualitative RA methods like Risk Matrices by Arbad et al. [

104] and SRF deliver superior site screening results in the early stages through expert hazard identification despite the limited data availability. However, these tools struggle to provide accurate assessments because they use subjective assessments instead of probabilistic models when used in later phases of the CCS project. The RISQUE and Bayesian Networks semi-quantitative tools merge engineering data and scenario RA but fail to detect long-term geomechanical hazards, including fault reactivation. Although some quantitative tools and integrated tools (CO

2-PENS and NRAP-Open-IAM) offer high accuracy in leakage quantification, these tools require extensive datasets and computational power, making their initial application impractical.

NRAP-Open-IAM and REX-CO2 show effective results through their fusion of reservoir-scale geologic models with wellbore integrity assessment. For instance, NRAP-Open-IAM’s modular design allows for dynamic risk simulations across reservoir, leakage pathway, and receptor components, while REX-CO2 focuses on cement degradation and material compatibility in legacy wells. The open-source design of NRAP-Open-IAM enables users to conduct dynamic risk analysis across reservoirs, leakage pathways, and receptors, but REX-CO2 specifically analyzes cement degradation in legacy wells. However, current frameworks still exhibit gaps in addressing uncertainties regarding the induced seismicity in the storage sites and the integrity of legacy wells (existence of plugs, integrity of junctions in the lateral section).

Based on the comparative analysis of this review paper, the following points are recommended during RA in GCS projects:

For comprehensive RA, utilize qualitative tools in the beginning and quantitative tools at later stages.

For site-specific RA, employ an integrated RA tool to ensure wellbore integrity assessment and reservoir modeling.

Improve current RA tools (specifically quantitative and integrated) to capture uncertainties related to induced seismicity and legacy wells configurations, especially the integrity of plugs and lateral well junctions.

Promote open-source risk modeling platforms to increase transparency and reproducibility in the RA process.

Strengthen regulatory frameworks and protocols to improve public trust and investor confidence in CCS.

Encourage interdisciplinary collaboration between geoscientists, engineers, and policymakers to bridge technical assessment with non-technical considerations.

In conclusion, this review demonstrates that employing various RA techniques—qualitative, semi-quantitative, quantitative, and integrated—throughout the lifespan of a CCS project is essential for developing a comprehensive risk management strategy. Future research should focus on creating dynamic hybrid RA models that integrate both technical and non-technical aspects to improve stakeholder confidence and compliance while ensuring the long-term reliability of CO2 storage systems.