Flexible Green Ammonia Production: Impact of Process Design on the Levelized Cost of Ammonia

Abstract

1. Introduction

2. Methods

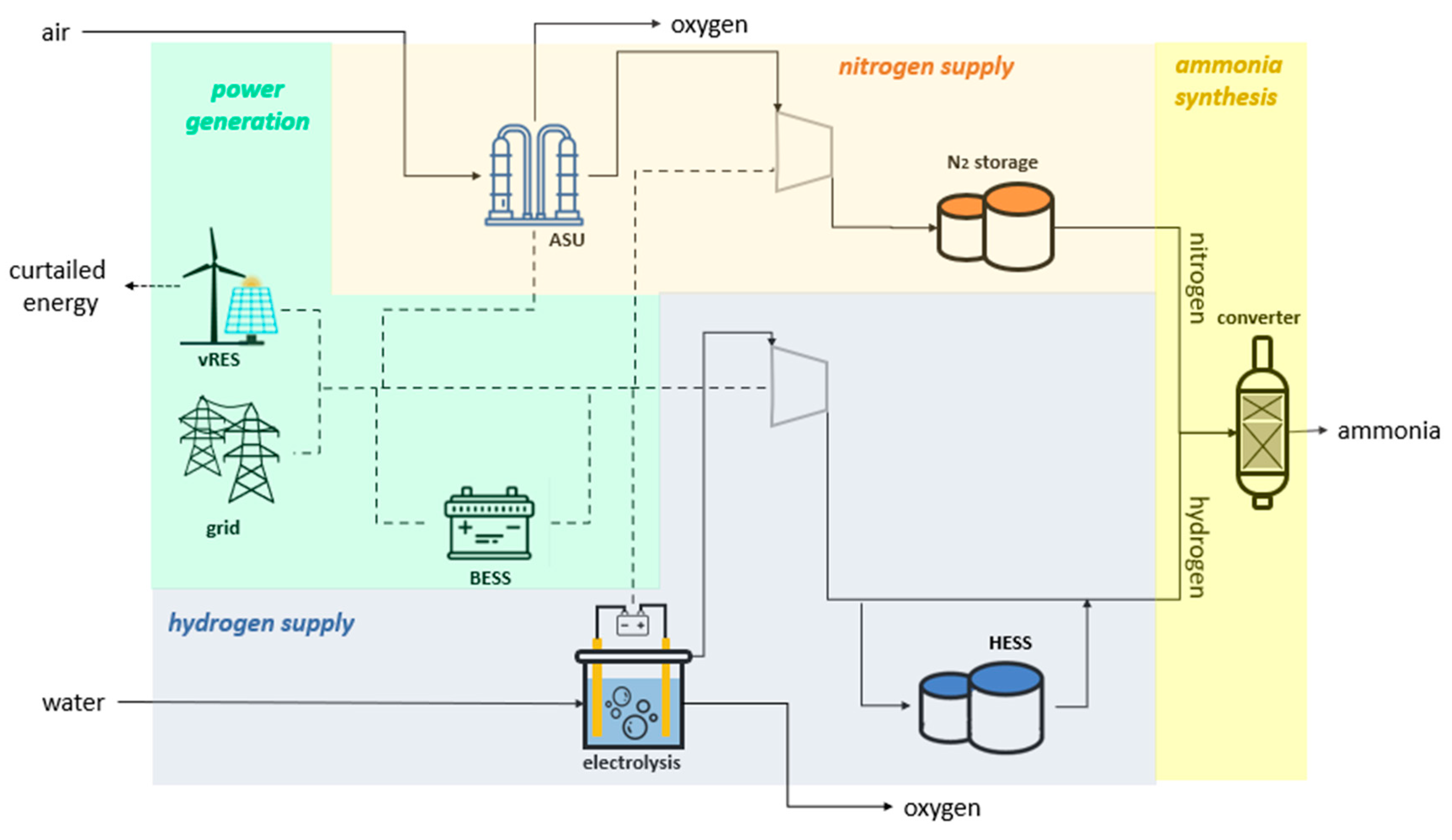

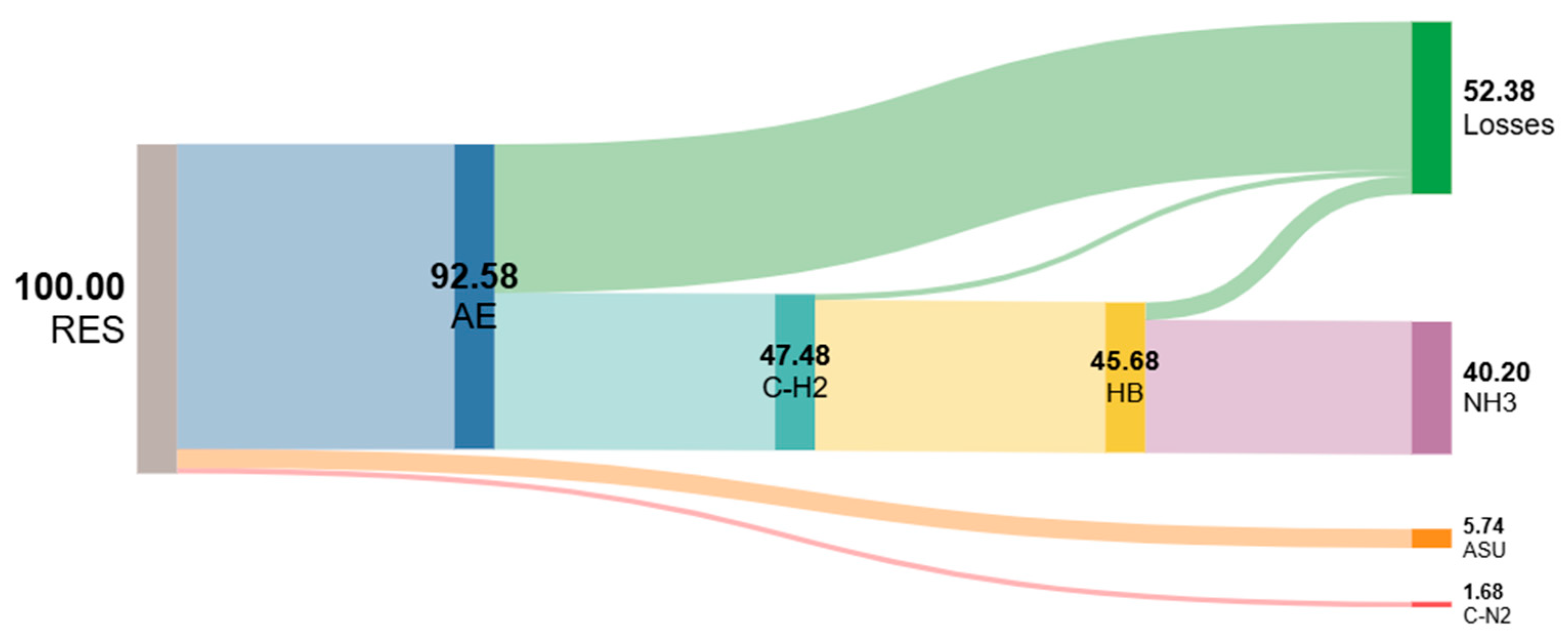

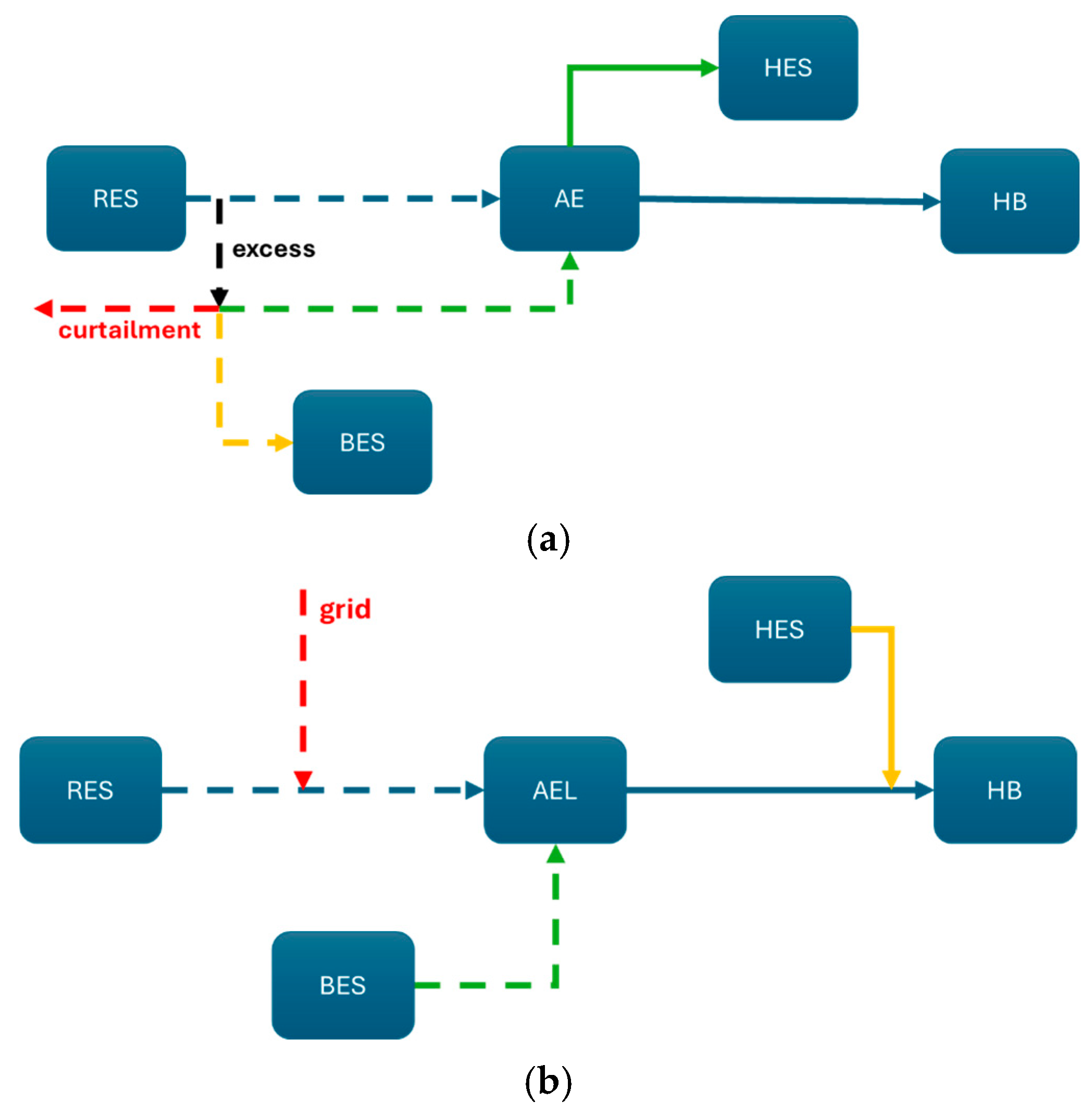

2.1. Plant Description: Efficiency and Cost Assumptions

2.2. Implementation in the MATLAB Environment

- Flexibility (f = 20–100%), representing the minimum operational capacity of the plant as a fraction of its maximum capacity.

- Energy mix (m = 0–100%), defining the share of photovoltaic (PV) power relative to the total power (PV + wind).

- 3.

- The percentile p = 60%, 80%, 100% defines the yearly S and, consequently, assesses the impact of the down-sized renewable energy input and production (i.e., when p = 80%, the plant is sized such that the peak power that is greater than the 80% of the 365 samples of S).

- 4.

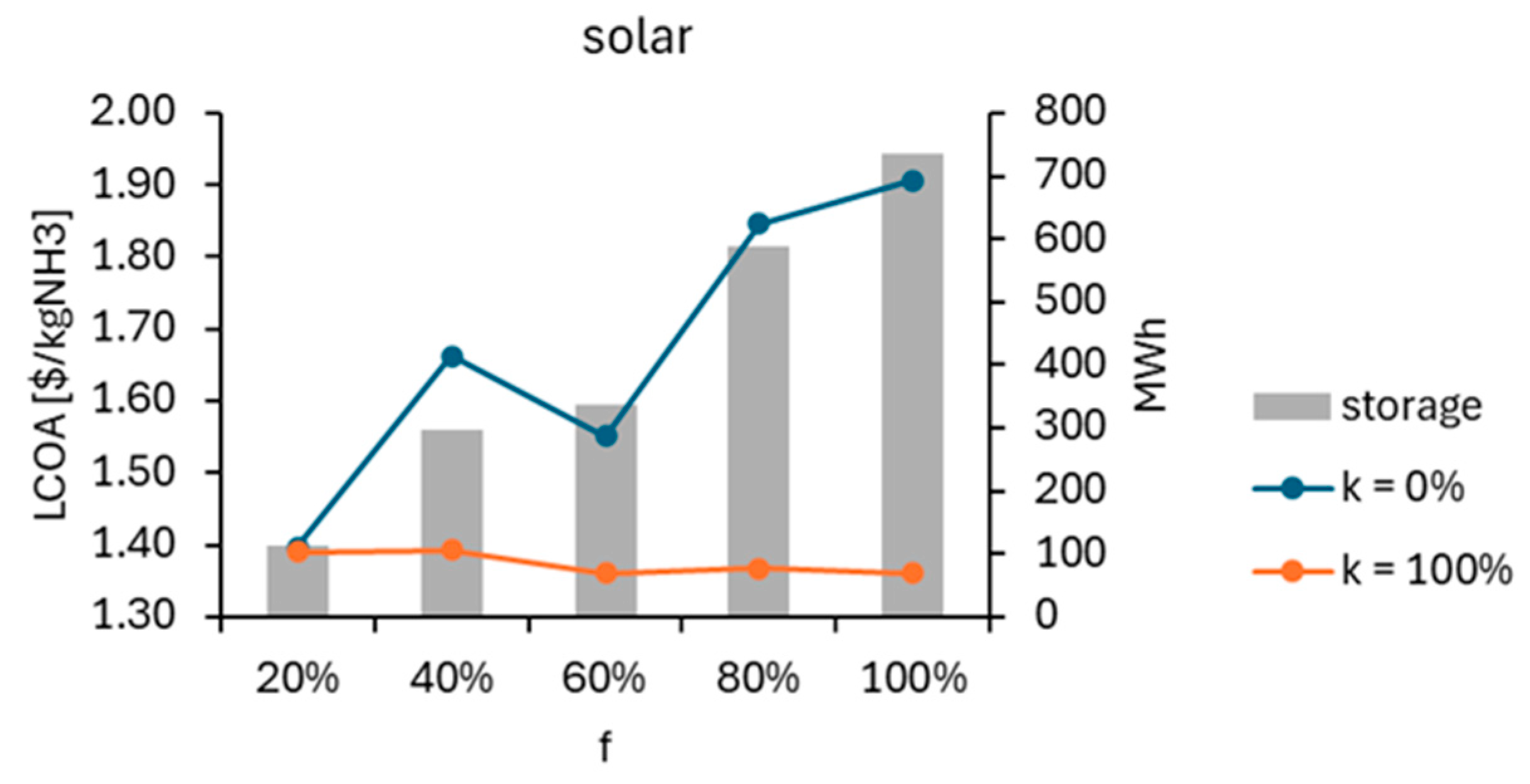

- The allocation parameter k = 0%, 50%, 100%, which regulates the distribution of surplus energy of HES over BES.

2.3. Allowable Grid Share for Green Hydrogen Production

3. Results and Discussion

3.1. Sensitivity Analysis on 2030 Cost Assumptions

3.2. 2050 Cost Scenario

4. Conclusions

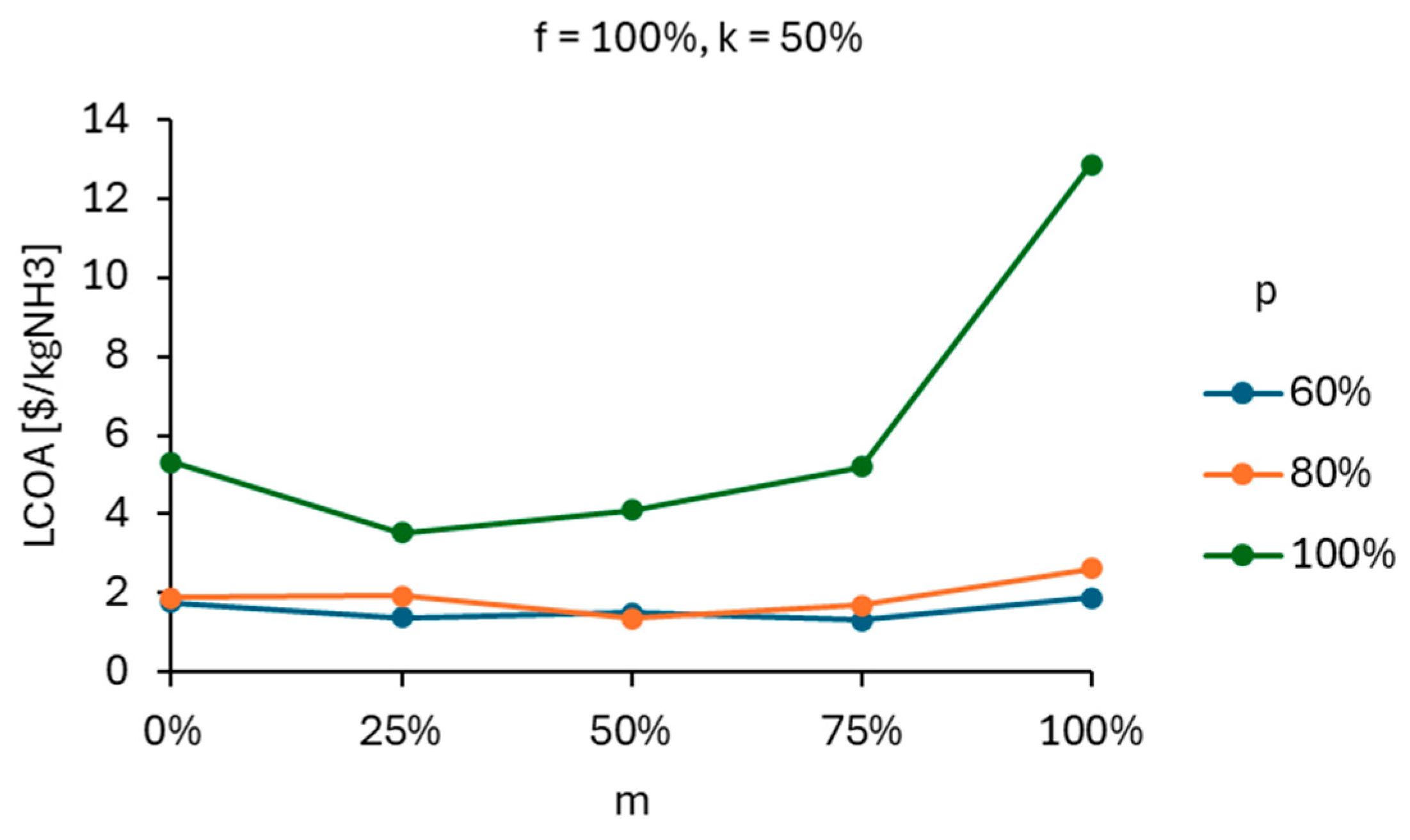

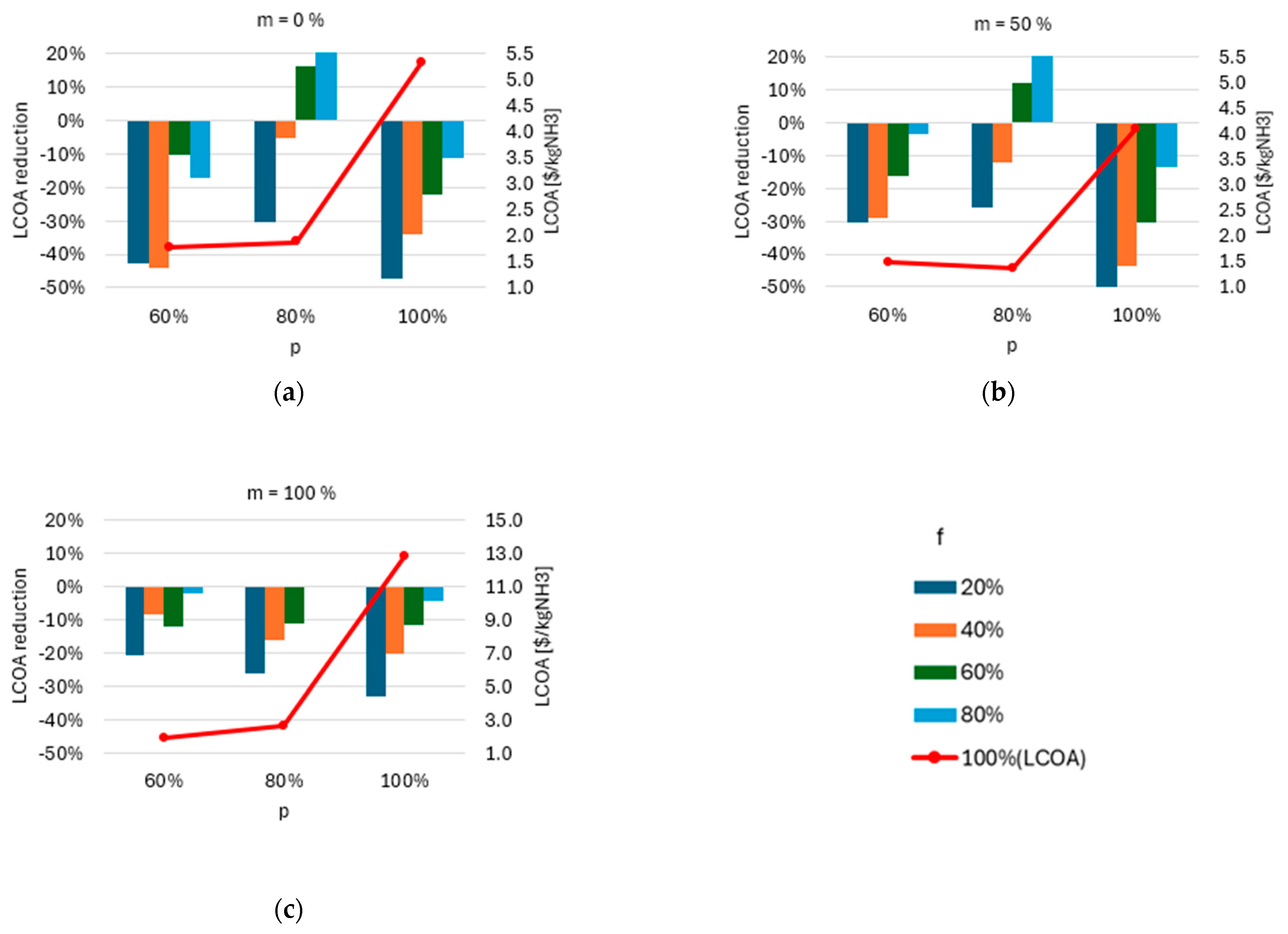

- Conservative choices for the renewable peak power drastically increase LCOA, especially for solar power and subsizing of the renewable park is necessary to obtain significant reductions: operating with p = 80% we obtain a decrease in the LCOA of −80% and −65% for 100% solar and 100% wind plants, respectively. Further downscaling (p = 60%) is definitely less impacting, because of the decrease in yearly ammonia production.

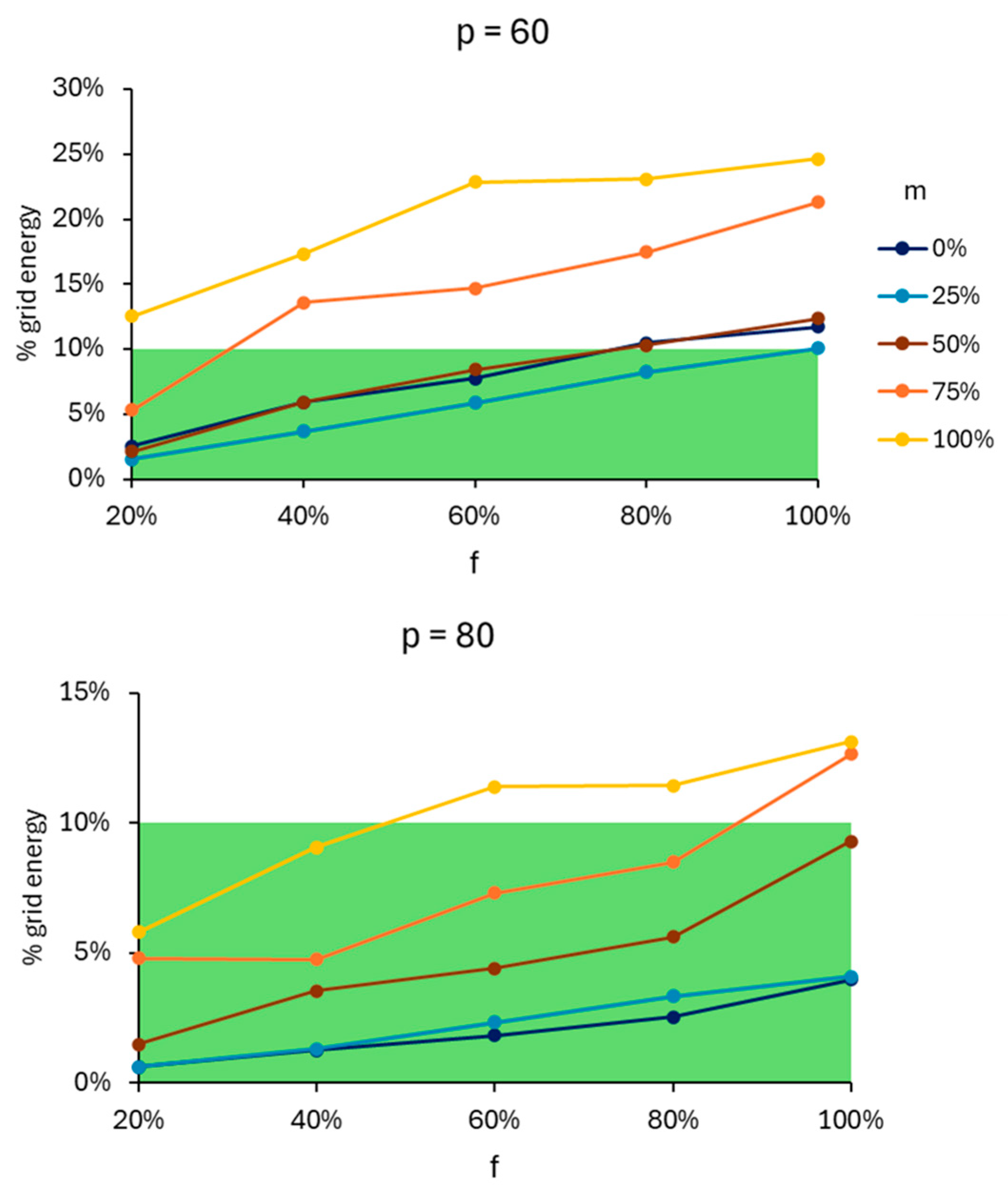

- Flexibility is necessary to reduce the need for grid energy under 10% of the total energy input and therefore make ammonia production actually green. However, when flexibility is applied to a sub-scaled wind powered system, the high decrease in production could lead to the opposite effect and increase the final cost of production.

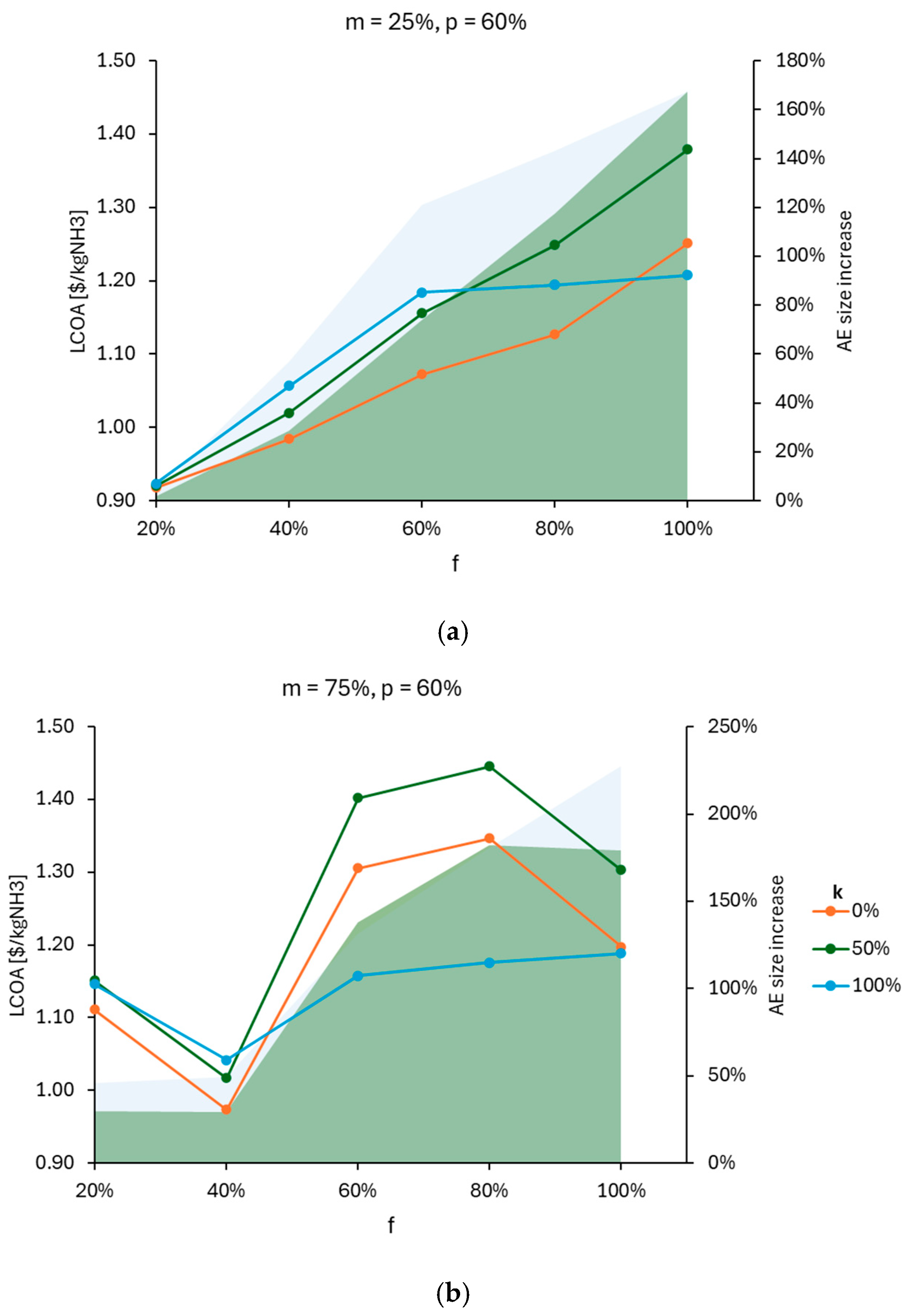

- Hydrogen storage requires notable increase in AE size, reaching approximately +160% and +230% at f = 100% when wind or solar is the relevant renewable source in the mix, respectively. Introducing flexibility, battery storage is preferred for wind-based systems. On the other hand, even under flexible conditions, HES is the preferred option for solar-based systems, where energy storage on average 2.5 times that required when using wind power, since it is cheaper than BES and therefore compensates the increase in the AE size.

- The most cost-effective solution in 2030 is 0.92 USD/kgNH3 with 111 MW of wind power and 37 MW of solar power and a 20–100% range of flexibility to minimize BES. However, in 2050, assuming that water electrolysis and PV costs decrease as projected, solar power combined with hydrogen storage could become a viable solution, showing small deviations from the 2050 optimal LCOA value obtained for wind-driven systems. With an energy mix of 75% PV, 25% wind, hydrogen storage and sub-sized renewable park (p = 60%), an LCOA of 0.593 USD/kgNH3 is targeted. In addition, this competitive LCOA is met for a more narrow range of flexibility (60–100%), which ease the technical feasibility the synthesis unit.

- In conclusion, for different combinations of process design choices and flexibility, the optimal LCOA is approximately 0.59 USD/kgNH3 in 2050. Provided that a carbon rate of 0.12 USD/kgCO2eq is applied, green ammonia could be a cost-competitive alternative to traditional ammonia production.

- Further extension of this study will involve the application of the methodology and the plant layouts in different geographical areas, both in Italy and other countries worldwide.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AE | Alkaline electrolyzer |

| At | Ammonia production in year t [kg] |

| BES | Battery energy storage |

| Egrid | Energy from local grid [MWh] |

| EU | European Union |

| G | Price of grid electricity [USD/MWh] |

| HES | Hydrogen Energy Storage |

| J | Total units of the plant |

| LCOA | Levelized cost of ammonia |

| Pmax | Power requirement for nominal capacity production [MW] |

| Pplant | Hourly power requirement from plant production [MW] |

| PRE | Hourly power input from RE [MW] |

| RE | Renewable energy |

| RED | Renewable Energy Directive |

| S | Total renewable peak power [MW] |

| T | The plant’s lifetime [years] |

| Uj | Size of the j-th unit of the plant, in mass flowrate [kg/hr] or power [MW] |

| f | Ratio between maximum and minimum ammonia production capacity [%] |

| k | Ratio between HES and BES [%] |

| m | Ratio between solar and wind power [%] |

| p | Percentile for peak power definition [%] |

| r | Weighted Average Cost of Capital (WACC) [%] |

Appendix A

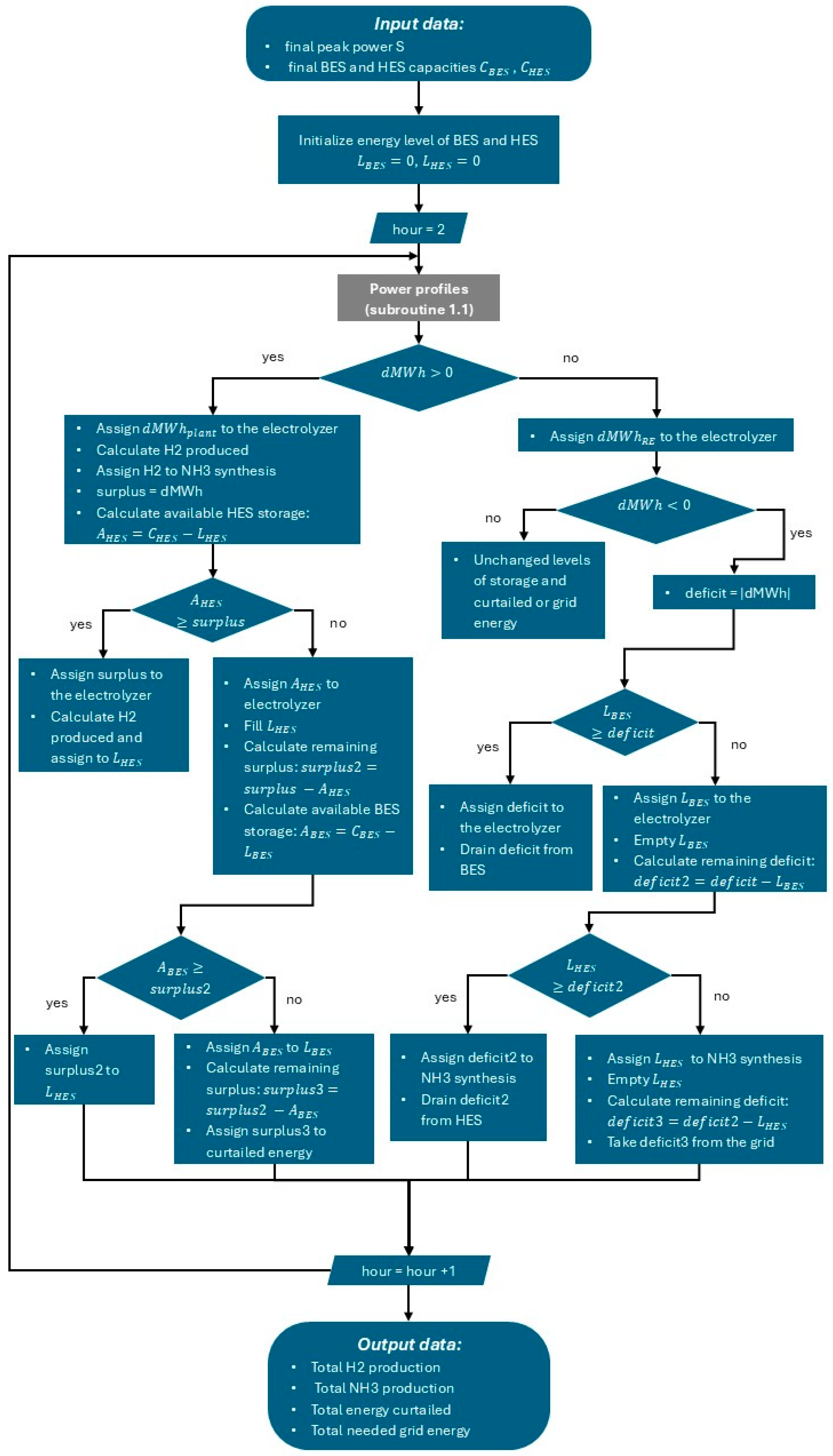

- Renewable power and energy storage sizing (subroutine 1),

- Productivity of hydrogen and ammonia (subroutine 2), and

- Economic evaluation of the LCOA.

References

- CO2 Emissions in 2022; International Energy Agency: Paris, France, 2022.

- Net Zero by 2050—A Roadmap for the Global Energy Sector; International Energy Agency: Paris, France, 2021.

- Rouwenhorst, K.; Castellanos, G. Innovation Outlook: Renewable Ammonia; Abu Dhabi; International Renewable Energy Agency: Brooklyn, NY, USA; Ammonia Energy Association: Ashburn, VA, USA, 2022. [Google Scholar]

- Ghavam, S.; Vahdati, M.; Wilson, I.A.G.; Styring, P. Sustainable Ammonia Production Processes. Front. Energy Res. 2021, 9, 580808. [Google Scholar] [CrossRef]

- Kojima, Y.; Yamaguchi, M. Ammonia as a hydrogen energy carrier. Int. J. Hydrogen Energy 2022, 47, 22832–22839. [Google Scholar] [CrossRef]

- Palone, O.; Cedola, L.; Borello, D.; Markides, C.N. Decarbonizing power and fuels production by chemical looping processes: Systematic review and future perspectives. Appl. Therm. Eng. 2024, 254, 123844. [Google Scholar] [CrossRef]

- Juangsa, F.B.; Irhamna, A.R.; Aziz, M. Production of ammonia as potential hydrogen carrier: Review on thermochemical and electrochemical processes. Int. J. Hydrogen Energy 2021, 46, 14455–14477. [Google Scholar] [CrossRef]

- Rouwenhorst, K.H.R.; Krzywda, P.M.; Benes, N.E.; Mul, G.; Lefferts, L. Ammonia Production Technologies. In Techno-Economic Challenges of Green Ammonia as an Energy Vector; Elsevier: Amsterdam, The Netherlands, 2021; pp. 41–83. [Google Scholar] [CrossRef]

- Ikäheimo, J.; Kiviluoma, J.; Weiss, R.; Holttinen, H. Power-to-ammonia in future North European 100% renewable power and heat system. Int. J. Hydrogen Energy 2018, 43, 17295–17308. [Google Scholar] [CrossRef]

- Nayak-Luke, R.; Bañares-Alcántara, R.; Wilkinson, I. “Green” Ammonia: Impact of Renewable Energy Intermittency on Plant Sizing and Levelized Cost of Ammonia. Ind. Eng. Chem. Res. 2018, 57, 14607–14616. [Google Scholar] [CrossRef]

- Smith, C.; Hill, A.; Torrente-Murciano, L. Current and future role of Haber–Bosch ammonia in a carbon-free energy landscape. Energy Environ. Sci. R. Soc. Chem. 2020, 13, 331–344. [Google Scholar] [CrossRef]

- Global Critical Minerals Outlook 2024; International Energy Agency: Paris, France, 2024.

- Electricity Storage and Renewables: Costs and Markets to 2030; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2017.

- Marashli, A.; Al-Kassab, A.I.; Gab-Allah, D.M.; Shalby, M.; Salah, A. Numerical life cycle assessment of lithium ion battery, Li-NMC type, integrated with PV system. Results Eng. 2024, 23, 102489. [Google Scholar] [CrossRef]

- Ren, Z.; Li, H.; Yan, W.; Lv, W.; Zhang, G.; Lv, L.; Sun, L.; Sun, Z.; Gao, W. Comprehensive evaluation on production and recycling of lithium-ion batteries: A critical review. Renew. Sustain. Energy Rev. 2023, 185, 113585. [Google Scholar] [CrossRef]

- Fahr, S.; Schiedeck, M.; Schwarzhuber, J.; Rehfeldt, S.; Peschel, A.; Klein, H. Design and thermodynamic analysis of a large-scale ammonia reactor for increased load flexibility. Chem. Eng. J. 2023, 471, 144612. [Google Scholar] [CrossRef]

- Kong, B.; Zhang, Q.; Daoutidis, P. Nonlinear model predictive control of flexible ammonia production. Control. Eng. Pract. 2024, 148, 105946. [Google Scholar] [CrossRef]

- Rosbo, J.W.; Ritschel, T.K.S.; Hørsholt, S.; Huusom, J.K.; Jørgensen, J.B. Flexible operation, optimisation and stabilising control of a quench cooled ammonia reactor for power-to-ammonia. Comput. Chem. Eng. 2023, 176, 108316. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, Y.; Huang, H.; Luo, Y.; Lin, L.; Jiang, L. Modeling and simulation of dynamic characteristics of a green ammonia synthesis system. Energy Convers. Manag. 2024, 300, 117893. [Google Scholar] [CrossRef]

- Verleysen, K.; Parente, A.; Contino, F. How does a resilient, flexible ammonia process look? Robust design optimization of a Haber-Bosch process with optimal dynamic control powered by wind. Proc. Combust. Inst. 2023, 39, 5511–5520. [Google Scholar] [CrossRef]

- Armijo, J.; Philibert, C. Flexible production of green hydrogen and ammonia from variable solar and wind energy: Case study of Chile and Argentina. Int. J. Hydrogen Energy 2020, 45, 1541–1558. [Google Scholar] [CrossRef]

- Campion, N.; Nami, H.; Swisher, P.R.; Hendriksen, P.V.; Münster, M. Techno-economic assessment of green ammonia production with different wind and solar potentials. Renew. Sustain. Energy Rev. 2023, 173, 113057. [Google Scholar] [CrossRef]

- Nayak-Luke, R.M.; Bañares-Alcántara, R. Techno-economic viability of islanded green ammonia as a carbon-free energy vector and as a substitute for conventional production. Energy Environ. Sci. 2020, 13, 2957–2966. [Google Scholar] [CrossRef]

- Salmon, N.; Bañares-Alcántara, R. Impact of process flexibility and imperfect forecasting on the operation and design of Haber–Bosch green ammonia. RSC Sustain. 2023, 1, 923–937. [Google Scholar] [CrossRef]

- Smith, C.; Torrente-Murciano, L. The importance of dynamic operation and renewable energy source on the economic feasibility of green ammonia. Joule 2024, 8, 157–174. [Google Scholar] [CrossRef]

- Wang, C.; Walsh, S.D.C.; Longden, T.; Palmer, G.; Lutalo, I.; Dargaville, R. Optimising renewable generation configurations of off-grid green ammonia production systems considering Haber-Bosch flexibility. Energy Convers. Manag. 2023, 280, 116790. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, T.; Tang, S.; Wang, Y.; Ma, M. Research on design and multi-frequency scheduling optimization method for flexible green ammonia system. Energy Convers. Manag. 2024, 300, 117976. [Google Scholar] [CrossRef]

- EU Requirements for Renewable Hydrogen and Its Derivatives; International PtX Hub: Berlin, Germany, 2023.

- Ammonia Synthesis Plant from Intermittent Renewable Energy (ASPIRE), Science and Technology Facilities Council (STFC), Feasibility Study. 2022. Available online: https://assets.publishing.service.gov.uk/media/6467910a628371000c3a8921/HYS2169_STFC_Final_Feasibility_Report__Confidential___Public_.pdf (accessed on 20 February 2025).

- Potenziamento del Parco Eolico di Troia San Vincenzo; ERG Eolica San Vincenzo: Genova, Italy, 2023.

- Progetto di Ammodernamento Complessivo (“Repowering”), Relativo All’impianto Eolico Esistente Denominato “San Vincenzo”, con Dismissione Degli Attuali 21 Aerogeneratori e Sostituzione in Riduzione Degli Stessi con L’installazione di 10 Nuovi Aerogeneratori, Della Potenza Unitaria di 7,2 MW, per Una Potenza Totale D’impianto Pari a 72 MW, Ubicato nel Comune di Troia (FG), con Opere di Connessione Alla RTN Ricadenti Anche nel Comune di Lucera (FG) (cod. MYTERNA 202303531)—Info—Valutazioni e Autorizzazioni Ambientali—VAS—VIA—AIA. Consultato: 15 Novembre 2024. Available online: https://va.mite.gov.it/it-IT/Oggetti/Info/10374 (accessed on 20 February 2025).

- Pfenninger, S.; Staffel, I. Long-term patterns of European PV output using 30 years of validated hourly reanalysis and satellite data. Energy 2016, 114, 1251–1265. [Google Scholar] [CrossRef]

- Staffel, I.; Pfenninger, S. Using Bias-Corrected Reanalysis to Simulate Current and Future Wind Power Output. Energy 2016, 114, 1224–1239. [Google Scholar] [CrossRef]

- Rouholamini, M.; Wang, C.; Nehrir, H.; Hu, X.; Hu, Z.; Aki, H.; Zhao, B.; Miao, Z.; Strunz, K. A Review of Modeling, Management, and Applications of Grid-Connected Li-Ion Battery Storage Systems. IEEE Trans. Smart Grid 2022, 13, 4505–4524. [Google Scholar] [CrossRef]

- Kebede, A.A.; Kalogiannis, T.; Van Mierlo, J.; Berecibar, M. A comprehensive review of stationary energy storage devices for large scale renewable energy sources grid integration. Renew. Sustain. Energy Rev. 2022, 159, 112213. [Google Scholar] [CrossRef]

- Technologies | Electricity | 2023 | ATB | NREL. Consultato: 11 Ottobre 2024. Available online: https://atb.nrel.gov/electricity/2023/technologies (accessed on 20 February 2025).

- Lechner, M.; Kollenda, A.; Bendzuck, K.; Burmeister, J.K.; Mahin, K.; Keilhofer, J.; Kemmer, L.; Blaschke, M.J.; Friedl, G.; Daub, R. Cost modeling for the GWh-scale production of modern lithium-ion battery cells. Commun. Eng. 2024, 3, 155. [Google Scholar] [CrossRef] [PubMed]

- Lazard’s Levelized Cost of Storage Analysis—Version 7.0; Lazard: Hamilton, Bermuda, 2021.

- Green Hydrogen Cost Reduction: Scaling Up Electrolysers to Meet the 1.5 °C Climate Goal; Irena: Abu Dhabi, United Arab Emirates, 2020.

- Lee, B.; Lim, D.; Lee, H.; Lim, H. Which water electrolysis technology is appropriate?: Critical insights of potential water electrolysis for green ammonia production. Renew. Sustain. Energy Rev. 2021, 143, 110963. [Google Scholar] [CrossRef]

- Large | McPhy. Consultato: 18 Novembre 2024. Available online: https://mcphy.com/en/equipment-services/electrolyzers/large/?cn-reloaded=1 (accessed on 20 February 2025).

- Andersson, J.; Grönkvist, S. Large-scale storage of hydrogen. Int. J. Hydrogen Energy 2019, 44, 11901–11919. [Google Scholar] [CrossRef]

- Elberry, A.M.; Thakur, J.; Santasalo-Aarnio, A.; Larmi, M. Large-scale compressed hydrogen storage as part of renewable electricity storage systems. Int. J. Hydrogen Energy 2021, 46, 15671–15690. [Google Scholar] [CrossRef]

- Demesa, N.; Bruno, J.C.; Coronas, A.; Huicochea, A. Efficient waste heat recovery in a cryogenic distillation air separation plant using heat pumps. In Proceedings of the ECOS 2016—The 29th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Portorož, Slovenia, 19–23 June 2016. [Google Scholar]

- GME—Gestore Mercati Energetici. Available online: https://www.mercatoelettrico.org/it/ (accessed on 20 February 2025).

- European Commission. Comm. Deleg. Regul. (EU) 2021/2139 2021, L 442/1, 349. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32021R2139&from=EN (accessed on 20 February 2025).

- European Parliament e European Council. Supplementing Directive (EU) 2018/2001 of the European Parliament and of the Council by establishing a Union methodology setting out detailed rules for the production of renewable liquid and gaseous transport fuels of non-biological origin. Off. J. Eur. Union 2023, L 328/82, 9. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32023R1184 (accessed on 20 February 2025).

- Italy, 2024, Total Electricity Mix. Available online: https://app.electricitymaps.com/zone/IT-SO/all/yearly (accessed on 20 February 2025).

- “Italy, 2025, 01/01-31/01, Carbon Intensity Data”, Electricity Maps, ver. January 27, 2025. Available online: https://www.electricitymaps.com (accessed on 20 February 2025).

- Tjahjono, M.; Stevani, I.; Siswanto, G.A.; Adhitya, A.; Halim, I. Assessing the feasibility of gray, blue, and green ammonia productions in Indonesia: A techno-economic and environmental perspective. Int. J. Renew. Energy Dev. 2023, 12, 1030–1040. [Google Scholar] [CrossRef]

- Italy 2023 Energy Policy Review; International Energy Agency: Paris, France, 2023.

| Site | |

|---|---|

| Country | Italy |

| Latitude | 41.339° |

| Longitude | 15.263° |

| Solar Photovoltaic 1 | |

| Capacity factor (High) | 21.61% |

| Capacity factor (Low) | 9.17% |

| System loss | 10% |

| Tracking | None |

| Tilt | 35° |

| Azimuth | 180° |

| Onshore Wind 1 | |

| Capacity factor (High) | 46.48% |

| Capacity factor (Low) | 12.51% |

| Hub height | 80 m |

| Turbine model | Vestas V90 2000 |

| Unit | CAPEX 2030 | CAPEX 2050 | Reference |

|---|---|---|---|

| PV | 1193 USD/kW | 683 USD/kW | [36] |

| WIND | 1408 USD/kW | 1115 USD/kW | [36] |

| BES | 363 USD/kWh | 260 USD/kWh | [36] |

| AE | 860 USD/kW | 300 USD/kW | [39] |

| HES | 5223 USD/MWh * | [43] | |

| ASU | 1600 USD/kgN2/hr | [9] | |

| HB | 3300 USD/kgNH3/hr | [9] | |

| Inputs | LCOA [USD/kgNH3] | Peak Power [MW] | Storage [MWh] | Average NH3 [tpd] | Grid [%] | Curtailment [%] |

|---|---|---|---|---|---|---|

| p = 60%, k = 0%, m = 25%, f = 20% | 0.585 | 148 | 2 | 61 | 1.53 | 13.36 |

| p = 60%, k = 100%, m = 25%, f = 20% | 0.585 | 148 | 2 | 61 | 1.53 | 13.36 |

| p = 60%, k = 100%, m = 50%, f = 20% | 0.590 | 145 | 40 | 62 | 1.73 | 8.90 |

| p = 80%, k = 100%, m = 75%, f = 20% | 0.592 | 140 | 11 | 53 | 4.43 | 14.95 |

| p = 60%, k = 100%, m = 75%, f = 60% | 0.593 | 178 | 232 | 76 | 9.40 | 12.30 |

| Reference | Optimal LCOA [USD/tonNH3] | Site | RES (Capacity Factor) | Nominal Capacity [t/day] | Minimum Load | Grid Share | Cost Scenario |

|---|---|---|---|---|---|---|---|

| [21] | 462 | Patagonia, Chile | Wind (63.3%) | 96 | 80% (+ stops) | 2.3% | 2020 |

| [21] | 571 | Patagonia, Argentina | Wind (63.9%) | 96 | 80% (+ stops) | 5.1% | 2020 |

| [22] | 832 (760 EUR/ton) | Northern Chile | Solar PV (30.3%) | 1178 | 40–100% | >50% | 2019 |

| [22] | 902 (824 EUR/ton) | Denmark | None | 1178 | 40–100% | 100% | 2019 |

| [22] | 890 (811 EUR/ton) | South Australia | Solar PV (24.6%) + Wind (40.4%) | 1178 | 40–100% | 41% | 2019 |

| [24] | 650–700 | Algeria | Solar PV(N/A) | 2270 (0.83 mmtpa) | 20% | N/A | 2022 |

| [24] | 450–500 | UK | Wind (N/A) | 2460 (0.90 mmtpa) | 20% | N/A | 2022 |

| [24] | 550–600 | Morocco | Solar PV (N/A) + Wind (N/A) | 2680 (0.98 mmtpa) | 20% | N/A | 2022 |

| [26] | 395 (659 AUUSD/ton) | Pilbara, Australia | Solar PV (27%) + Wind (30%) | 100 | 40% | 0% | 2030 |

| present study | 585 | Apulia, South Italy | Solar PV (16.2%) + Wind (29.8%) | 100 | 20% | 1.5% | 2050 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pistolesi, C.; Giaconia, A.; Bassano, C.; De Falco, M. Flexible Green Ammonia Production: Impact of Process Design on the Levelized Cost of Ammonia. Fuels 2025, 6, 39. https://doi.org/10.3390/fuels6020039

Pistolesi C, Giaconia A, Bassano C, De Falco M. Flexible Green Ammonia Production: Impact of Process Design on the Levelized Cost of Ammonia. Fuels. 2025; 6(2):39. https://doi.org/10.3390/fuels6020039

Chicago/Turabian StylePistolesi, Cecilia, Alberto Giaconia, Claudia Bassano, and Marcello De Falco. 2025. "Flexible Green Ammonia Production: Impact of Process Design on the Levelized Cost of Ammonia" Fuels 6, no. 2: 39. https://doi.org/10.3390/fuels6020039

APA StylePistolesi, C., Giaconia, A., Bassano, C., & De Falco, M. (2025). Flexible Green Ammonia Production: Impact of Process Design on the Levelized Cost of Ammonia. Fuels, 6(2), 39. https://doi.org/10.3390/fuels6020039