Evaluation of Advanced Biofuels in Internal Combustion Engines: Diesel/Fusel Oil/Vegetable Oil Triple Blends

Abstract

1. Introduction

2. Materials and Methods

2.1. Fusel Oil (FO) as an LVLC Solvent in Double Blends (FO/SVOs) and Triple Blends (Diesel/FO/SVOs)

2.2. Characterization of the Physical–Chemical Properties of the Biofuel Blends

2.3. Performance and Exhaust Emissions of a Diesel Engine Electric Generator Fueled with FO/SVO Double Blends and Diesel/FO/SVO Triple Blends

3. Results and Discussion

3.1. Physicochemical Properties of FO/SVO Double Blends and D/FO/SVO Triple Blends

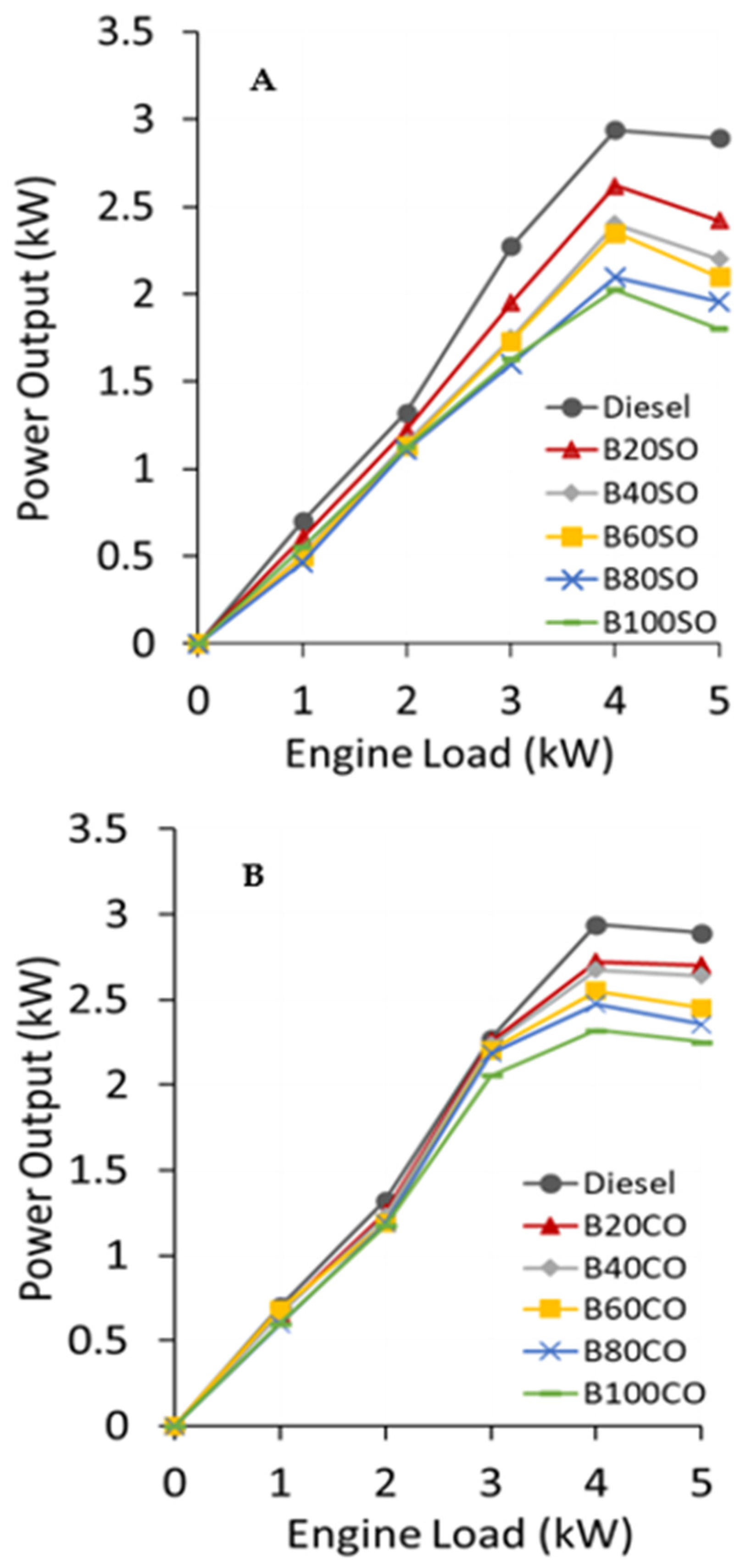

3.2. Mechanical Performance of Diesel/Fusel Oil/Straight Vegetable Oil Triple Blends

3.3. Brake-Specific Fuel Consumption (BSFC)

3.4. Exhaust Emissions from Diesel Engine

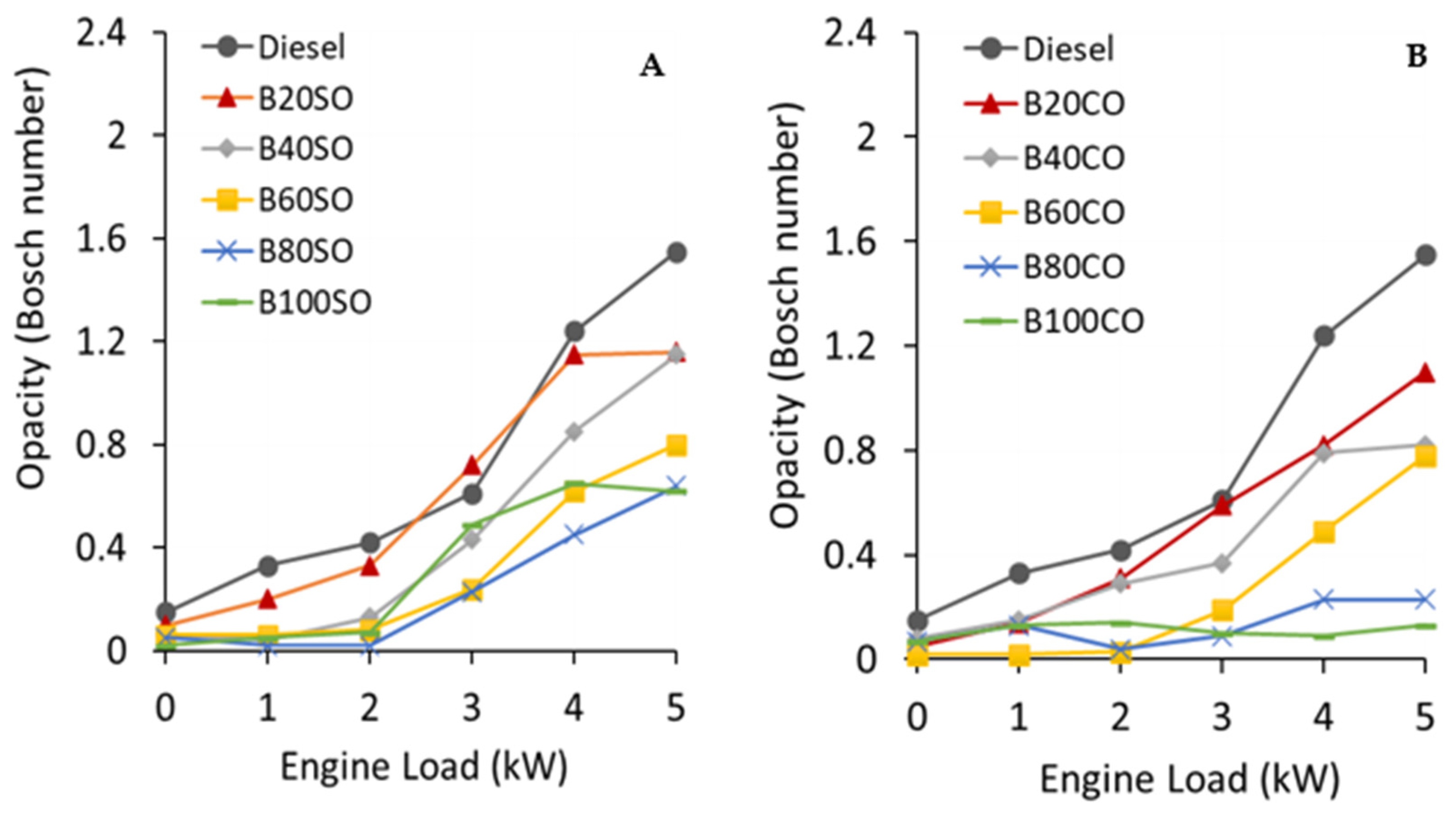

3.4.1. Opacity of Smoke Emissions

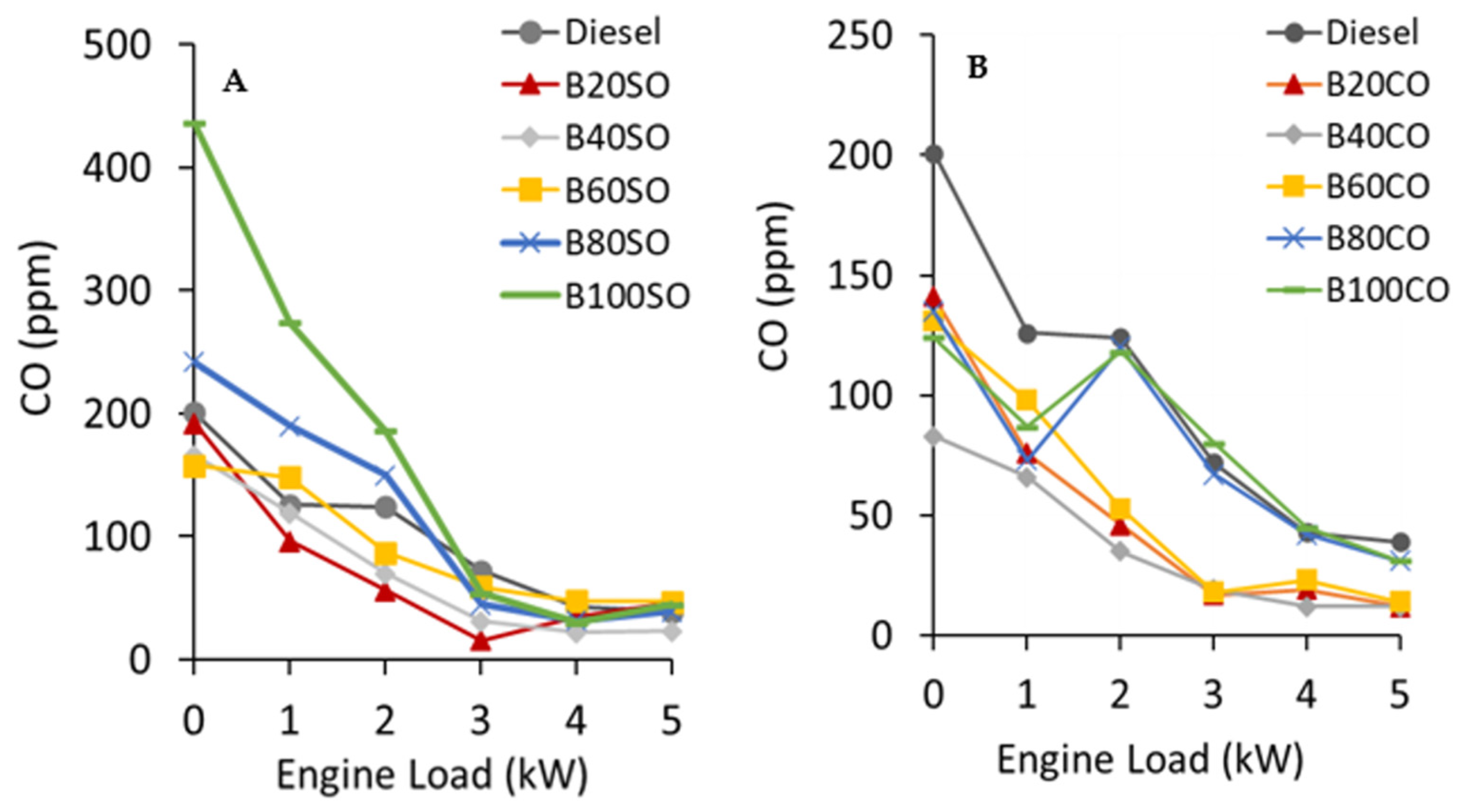

3.4.2. Smoke Carbon Monoxide (CO) Emissions

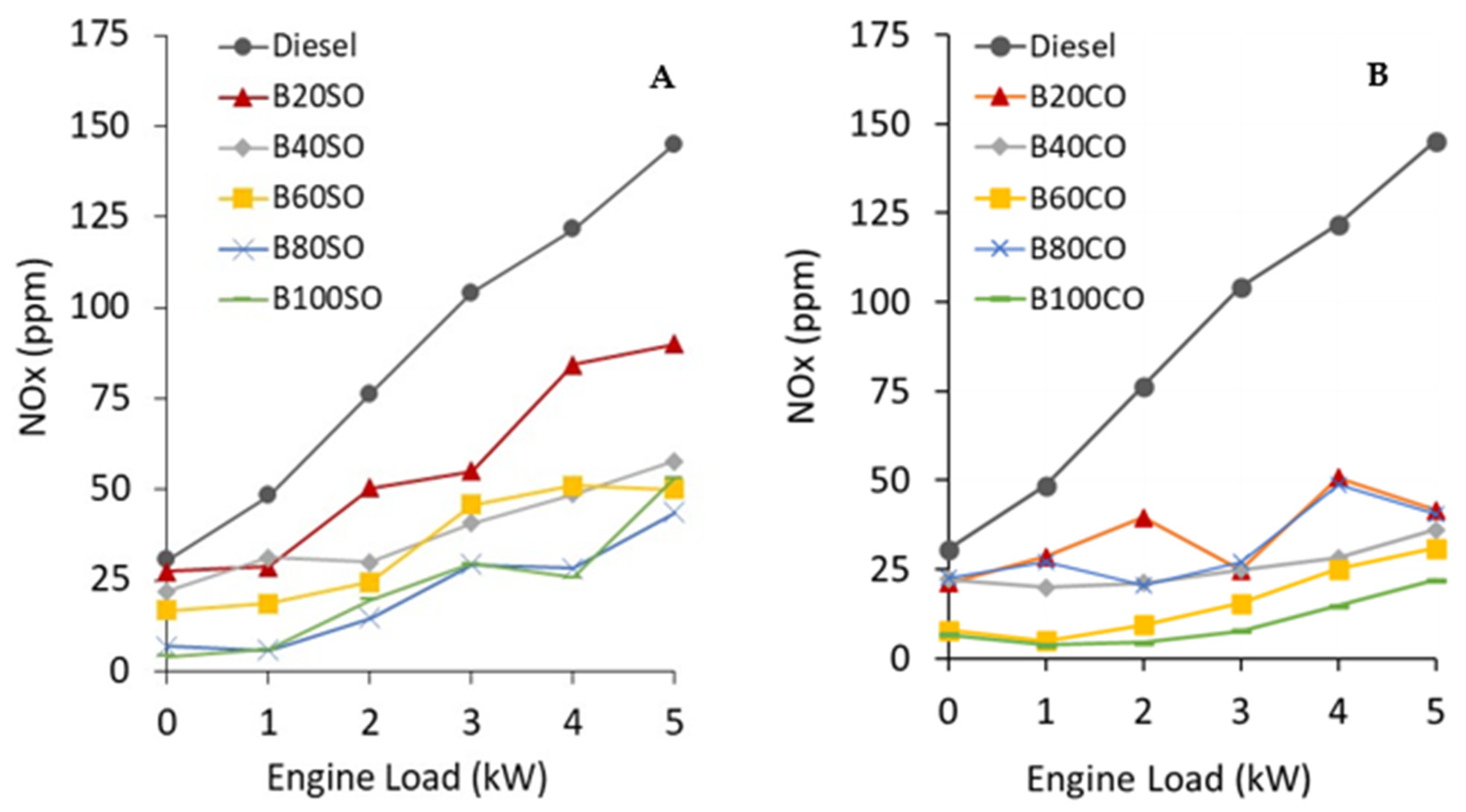

3.4.3. Nitrogen Oxide (NOx) Emissions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Castle, J.L.; Hendry, D.F. Five Sensitive Intervention Points to Achieve Climate Neutrality by 2050, Illustrated by the UK. Renew. Energy 2024, 226, 120445. [Google Scholar] [CrossRef]

- Estevez, R.; Aguado-Deblas, L.; López-Tenllado, F.J.; Bautista, F.M.; Romero, A.A.; Luna, D. Internal Combustion Engines and Carbon-Neutral Fuels: A Perspective on Emission Neutrality in the European Union. Energies 2024, 17, 1172. [Google Scholar] [CrossRef]

- Senecal, P.K.; Leach, F. Diversity in Transportation: Why a Mix of Propulsion Technologies Is the Way Forward for the Future Fleet. Results Eng. 2019, 4, 100060. [Google Scholar] [CrossRef]

- Cichowicz, R.; Bochenek, A.D. Assessing the Effects of Urban Heat Islands and Air Pollution on Human Quality of Life. Anthropocene 2024, 46, 100433. [Google Scholar] [CrossRef]

- Yu, X.; LeBlanc, S.; Sandhu, N.; Wang, L.; Wang, M.; Zheng, M. Decarbonization Potential of Future Sustainable Propulsion—A Review of Road Transportation. Energy Sci. Eng. 2024, 12, 438–455. [Google Scholar] [CrossRef]

- Scholz, V.; da Silva, J.N. Prospects and Risks of the Use of Castor Oil as a Fuel. Biomass Bioenergy 2008, 32, 95–100. [Google Scholar] [CrossRef]

- Nikolopoulos, I.; Kordouli, E.; Mourgkogiannis, N.; Karapanagioti, H.K.; Lycourghiotis, A.; Kordulis, C. Valorization of Pyrolyzed Biomass Residues for the Transformation of Waste Cooking Oil into Green Diesel. Catalysts 2023, 13, 1004. [Google Scholar] [CrossRef]

- da Costa, A.A.F.; de Oliveira Pires, L.H.; Padrón, D.R.; Balu, A.M.; da Rocha Filho, G.N.; Luque, R.; do Nascimento, L.A.S. Recent Advances on Catalytic Deoxygenation of Residues for Bio-Oil Production: An Overview. Mol. Catal. 2022, 518, 112052. [Google Scholar] [CrossRef]

- del Río, J.I.; Pérez, W.; Cardeño, F.; Marín, J.; Rios, L.A. Pre-Hydrogenation Stage as a Strategy to Improve the Continuous Production of a Diesel-like Biofuel from Palm Oil. Renew. Energy 2021, 168, 505–515. [Google Scholar] [CrossRef]

- d’Ambrosio, S.; Mancarella, A.; Manelli, A. Utilization of Hydrotreated Vegetable Oil (HVO) in a Euro 6 Dual-Loop EGR Diesel Engine: Behavior as a Drop-In Fuel and Potentialities along Calibration Parameter Sweeps. Energies 2022, 15, 7202. [Google Scholar] [CrossRef]

- Goeb, D.; Davidovic, M.; Cai, L.; Pancharia, P.; Bode, M.; Jacobs, S.; Beeckmann, J.; Willems, W.; Heufer, K.A.; Pitsch, H. Oxymethylene Ether—N-Dodecane Blend Spray Combustion: Experimental Study and Large-Eddy Simulations. Proc. Combust. Inst. 2021, 38, 3417–3425. [Google Scholar] [CrossRef]

- Pfleger, B.F.; Takors, R. Recent Progress in the Synthesis of Advanced Biofuel and Bioproducts. Curr. Opin. Biotechnol. 2023, 80, 102913. [Google Scholar] [CrossRef]

- Abdulkareem-Alsultan, G.; Asikin-Mijan, N.; Lee, H.V.; Rashid, U.; Islam, A.; Taufiq-Yap, Y.H. A Review on Thermal Conversion of Plant Oil (Edible and Inedible) into Green Fuel Using Carbon-Based Nanocatalyst. Catalysts 2019, 9, 350. [Google Scholar] [CrossRef]

- Hongloi, N.; Prapainainar, P.; Prapainainar, C. Review of Green Diesel Production from Fatty Acid Deoxygenation over Ni-Based Catalysts. Mol. Catal. 2022, 523, 111696. [Google Scholar] [CrossRef]

- Lindfors, C.; Elliott, D.C.; Prins, W.; Oasmaa, A.; Lehtonen, J. Co-Processing of Biocrudes in Oil Refineries. Energy Fuels 2023, 37, 799–804. [Google Scholar] [CrossRef]

- Su, J.; van Dyk, S.; Saddler, J. Repurposing Oil Refineries to “Stand-Alone Units” That Refine Lipids/Oleochemicals to Produce Low-Carbon Intensive, Drop-in Biofuels. J. Clean. Prod. 2022, 376, 134335. [Google Scholar] [CrossRef]

- Che Mat, S.; Idroas, M.Y.; Hamid, M.F.; Zainal, Z.A. Performance and Emissions of Straight Vegetable Oils and Its Blends as a Fuel in Diesel Engine: A Review. Renew. Sustain. Energy Rev. 2018, 82, 808–823. [Google Scholar] [CrossRef]

- Vallinayagam, R.; Vedharaj, S.; Yang, W.M.; Roberts, W.L.; Dibble, R.W. Feasibility of Using Less Viscous and Lower Cetane (LVLC) Fuels in a Diesel Engine: A Review. Renew. Sustain. Energy Rev. 2015, 51, 1166–1190. [Google Scholar] [CrossRef]

- Estevez, R.; Aguado-Deblas, L.; Posadillo, A.; Hurtado, B.; Bautista, F.M.; Hidalgo, J.M.; Luna, C.; Calero, J.; Romero, A.A.; Luna, D. Performance and Emission Quality Assessment in a Diesel Engine of Straight Castor and Sunflower Vegetable Oils, in Diesel/Gasoline/Oil Triple Blends. Energies 2019, 12, 2181. [Google Scholar] [CrossRef]

- Afzal, A.; Roy, R.G.; Koshy, C.P.; Alex, Y.; Abbas, M.; Cuce, E.; Razak, R.K.A.; Shaik, S.; Saleel, C.A. Characterization of Biodiesel Based on Plastic Pyrolysis Oil (PPO) and Coconut Oil: Performance and Emission Analysis Using RSM-ANN Approach. Sustain. Energy Technol. Assess. 2023, 56, 103046. [Google Scholar] [CrossRef]

- Coughlin, B.; Hoxie, A. Combustion Characteristics of Ternary Fuel Blends: Pentanol, Butanol and Vegetable Oil. Fuel 2017, 196, 488–496. [Google Scholar] [CrossRef]

- Atmanli, A.; Ileri, E.; Yilmaz, N. Optimization of Diesel–Butanol–Vegetable Oil Blend Ratios Based on Engine Operating Parameters. Energy 2016, 96, 569–580. [Google Scholar] [CrossRef]

- Eiadtrong, S.; Maliwan, K.; Theppaya, T.; Kattiyawan, T.; Prateepchaikul, G.; Leevijit, T. An Investigation to Utilize Ternary Diesel-Palm Fatty Acid Distillate-10 Wt% n-Butanol Blends as Simply Novel Diesel Substitutes. Fuel 2021, 289, 119965. [Google Scholar] [CrossRef]

- Jin, C.; Liu, X.; Sun, T.; Ampah, J.D.; Geng, Z.; Ji, J.; Wang, G.; Liu, H. Preparation and Performance Improvement of Methanol and Palm Oil/Palm Kernel Oil Blended Fuel. Fuel Process. Technol. 2021, 223, 106996. [Google Scholar] [CrossRef]

- Che Mat, S.; Idroas, M.Y.; Teoh, Y.H.; Hamid, M.F. Optimisation of Viscosity and Density of Refined Palm Oil-Melaleuca Cajuputi Oil Binary Blends Using Mixture Design Method. Renew. Energy 2019, 133, 393–400. [Google Scholar] [CrossRef]

- Prakash, T.; Geo, V.E.; Martin, L.J.; Nagalingam, B. Evaluation of Pine Oil Blending to Improve the Combustion of High Viscous (Castor Oil) Biofuel Compared to Castor Oil Biodiesel in a CI Engine. Heat. Mass. Transf. 2019, 55, 1491–1501. [Google Scholar] [CrossRef]

- No, S.-Y. Application of Straight Vegetable Oil from Triglyceride Based Biomass to IC Engines—A Review. Renew. Sustain. Energy Rev. 2017, 69, 80–97. [Google Scholar] [CrossRef]

- Gurusamy, M.; Ponnusamy, C. The Influence of Hydrogen Induction on The Characteristics of a CI Engine Fueled with Blend of Camphor Oil and Diesel with Diethyl Ether Additive. Int. J. Hydrogen Energy 2023, 48, 24054–24073. [Google Scholar] [CrossRef]

- Schubert, T. Production Routes of Advanced Renewable C1 to C4 Alcohols as Biofuel Components—A Review. Biofuels Bioprod. Biorefining 2020, 14, 845–878. [Google Scholar] [CrossRef]

- Veza, I.; Muhamad Said, M.F.; Latiff, Z.A. Recent Advances in Butanol Production by Acetone-Butanol-Ethanol (ABE) Fermentation. Biomass Bioenergy 2021, 144, 105919. [Google Scholar] [CrossRef]

- Aguado-Deblas, L.; López-Tenllado, F.J.; Luna, D.; Bautista, F.M.; Romero, A.A.; Estevez, R. Advanced Biofuels from ABE (Acetone/Butanol/Ethanol) and Vegetable Oils (Castor or Sunflower Oil) for Using in Triple Blends with Diesel: Evaluation on a Diesel Engine. Materials 2022, 15, 6493. [Google Scholar] [CrossRef] [PubMed]

- Žaglinskis, J.; Rimkus, A. Research on the Performance Parameters of a Compression-Ignition Engine Fueled by Blends of Diesel Fuel, Rapeseed Methyl Ester and Hydrotreated Vegetable Oil. Sustainability 2023, 15, 14690. [Google Scholar] [CrossRef]

- Massa, T.B.; Raspe, D.T.; Feiten, M.C.; Cardozo-Filho, L.; da Silva, C. Fusel Oil: Chemical Composition and an Overview of Its Potential Application. J. Braz. Chem. Soc. 2023, 34, 153–166. [Google Scholar] [CrossRef]

- Süleyman Üstün, B.D.; Erol, D. Exergy Analysis of Fusel Oil as an Alternative Fuel Additive for Spark Ignition Engines. Biofuels 2023, 14, 445–460. [Google Scholar] [CrossRef]

- Doğan, B.; Özer, S.; Erol, D. Exergy, Exergoeconomic, and Exergoenviroeconomic Evaluations of the Use of Diesel/Fusel Oil Blends in Compression Ignition Engines. Sustain. Energy Technol. Assess. 2022, 53, 102475. [Google Scholar] [CrossRef]

- Yılmaz, E. Investigation of the Effects of Diesel-Fusel Oil Fuel Blends on Combustion, Engine Performance and Exhaust Emissions in a Single Cylinder Compression Ignition Engine. Fuel 2019, 255, 115741. [Google Scholar] [CrossRef]

- Mannu, A.; Garroni, S.; Ibanez Porras, J.; Mele, A. Available Technologies and Materials for Waste Cooking Oil Recycling. Processes 2020, 8, 366. [Google Scholar] [CrossRef]

- Aguado-Deblas, L.; Hidalgo-Carrillo, J.; Bautista, F.M.; Luna, C.; Calero, J.; Posadillo, A.; Romero, A.A.; Luna, D.; Estévez, R. Evaluation of Dimethyl Carbonate as Alternative Biofuel. Performance and Smoke Emissions of a Diesel Engine Fueled with Diesel/Dimethyl Carbonate/Straight Vegetable Oil Triple Blends. Sustainability 2021, 13, 1749. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Sarıdemir, S.; Karagöz, M. Experimental Investigation of Fusel Oil (Isoamyl Alcohol) and Diesel Blends in a CI Engine. Fuel 2020, 267, 117042. [Google Scholar] [CrossRef]

- Baldwin, L.C.; Davis, M.C.; Woodroffe, J. Potential Oxygenated Biofuels Synthesized from Fusel Pentanols. Fuel 2020, 270, 117505. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Wandel, A.P. Performance and Emission Levels of Butanol, Acetone-Butanol-Ethanol, Butanol-Acetone/Diesel Blends in a Diesel Engine. Biofuels 2022, 13, 449–459. [Google Scholar] [CrossRef]

- Chang, Y.-C.; Lee, W.-J.; Wu, T.S.; Wu, C.-Y.; Chen, S.-J. Use of Water Containing Acetone–Butanol–Ethanol for NOx-PM (Nitrogen Oxide-Particulate Matter) Trade-off in the Diesel Engine Fueled with Biodiesel. Energy 2014, 64, 678–687. [Google Scholar] [CrossRef]

- Aguado-Deblas, L.; Hidalgo-Carrillo, J.; Bautista, F.M.; Luna, D.; Luna, C.; Calero, J.; Posadillo, A.; Romero, A.A.; Estevez, R. Acetone Prospect as an Additive to Allow the Use of Castor and Sunflower Oils as Drop-In Biofuels in Diesel/Acetone/Vegetable Oil Triple Blends for Application in Diesel Engines. Molecules 2020, 25, 2935. [Google Scholar] [CrossRef] [PubMed]

- Salamanca, M.; Mondragón, F.; Agudelo, J.R.; Benjumea, P.; Santamaría, A. Variations in the Chemical Composition and Morphology of Soot Induced by the Unsaturation Degree of Biodiesel and a Biodiesel Blend. Combust. Flame 2012, 159, 1100–1108. [Google Scholar] [CrossRef]

- Çakmak, A.; Özcan, H. Analysis of Combustion and Emissions Characteristics of a DI Diesel Engine Fuelled with Diesel/Biodiesel/Glycerol Tert-Butyl Ethers Mixture by Altering Compression Ratio and Injection Timing. Fuel 2022, 315, 123200. [Google Scholar] [CrossRef]

| Property | Diesel | Sunflower Oil | Castor Oil | Fusel Oil Blend |

|---|---|---|---|---|

| Density at 15 °C (kg/m3) | 830 | 920 | 962 | 800.3 |

| Kinematic viscosity at 40 °C (cSt) 1 | 3.20 ± 0.01 | 37.80 ± 0.05 | 226.20 ± 0.05 | 4.16 ± 0.01 |

| Calorific value (MJ/kg) | 42.8 | 39.5 | 37.2 | 28.3 |

| Flash point (°C) | 66 | 220 | 228 | -- |

| Auto-ignition temperature (°C) | 250 | 316 | 448 | 465 |

| Cetane number | 51 | 37 | 40 | 42 |

| Property | Blend | FO (% by Volume) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 10 | 30 | 50 | 60 | 70 | 80 | 100 | ||

| Kinematic viscosity (cSt) | FO/SO | 37.80 ± 0.46 | 32.12 ± 0.26 | 17.74 ± 0.06 | 9.88 ± 0.10 | 7.00 ± 0.03 | 5.59 ± 0.06 | 5.09 ± 0.04 | 3.06 ± 0.01 |

| FO/CO | 226.20 ± 0.55 | 211.10 ± 0.31 | 129.20 ± 0.09 | 26.93 ± 0.12 | 14.08 ± 0.05 | 10.91 ± 0.1 | 4.90 ± 0.09 | 3.06 ± 0.02 | |

| Nomenclature (% Renewable) | D/FO/SVO | Density (kg/m3) | Kinematic Viscosity (cSt) | Cloud Point (°C) | Pour Point (°C) | Calorific Value (MJ/kg) 1 | Cetane Number 1 |

|---|---|---|---|---|---|---|---|

| B0 | 100/0/0 | 820 ± 4 | 3.20 ± 0.04 | −6.0 ± 0.4 | −16.0 ± 0.8 | 35.10 | 51.00 |

| B20SO | 80/16/4 | 815 ± 3 | 3.52 ± 0.04 | −7.8 ± 0.8 | −16.5 ± 0.7 | 34.04 | 48.95 |

| B20CO | 80/16/4 | 818 ± 5 | 3.60 ± 0.04 | −9.0 ± 0.8 | −19.3 ± 0.6 | 34.02 | 49.12 |

| B40SO | 60/32/8 | 805 ± 5 | 4.06 ± 0.04 | −8.3 ± 0.6 | −19.7 ± 0.5 | 32.97 | 46.80 |

| B40CO | 60/32/8 | 815 ± 6 | 3.81 ± 0.04 | −11.0 ± 0.4 | −21.4 ± 0.6 | 32.95 | 47.24 |

| B60SO | 40/48/12 | 798 ± 4 | 4.20 ± 0.04 | −9.0 ± 0.8 | −20.0 ± 0.9 | 31.91 | 44.85 |

| B60CO | 40/48/12 | 810 ± 4 | 3.92 ± 0.09 | −12.0 ± 0.8 | −22.5 ± 0.4 | 31.87 | 45.36 |

| B80SO | 20/64/16 | 782 ± 5 | 4.42 ± 0.07 | −10.8 ± 0.3 | −20.3 ± 0.7 | 30.84 | 42.80 |

| B80CO | 20/64/16 | 808 ± 7 | 4.70 ± 0.02 | −13.0 ± 0.7 | −23.0 ± 0.7 | 30.79 | 43.48 |

| B100SO | 0/80/20 | 742 ± 1 | 5.09 ± 0.04 | −11.5 ± 0.7 | −23.7 ± 0.5 | 26.95 | 36.55 |

| B100CO | 0/80/20 | 806 ± 6 | 4.90 ± 0.09 | −14.0 ± 0.5 | −24.0 ± 0.3 | 29.72 | 42.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Estevez, R.; López-Tenllado, F.J.; Aguado-Deblas, L.; Bautista, F.M.; Romero, A.A.; Luna, D. Evaluation of Advanced Biofuels in Internal Combustion Engines: Diesel/Fusel Oil/Vegetable Oil Triple Blends. Fuels 2024, 5, 660-672. https://doi.org/10.3390/fuels5040036

Estevez R, López-Tenllado FJ, Aguado-Deblas L, Bautista FM, Romero AA, Luna D. Evaluation of Advanced Biofuels in Internal Combustion Engines: Diesel/Fusel Oil/Vegetable Oil Triple Blends. Fuels. 2024; 5(4):660-672. https://doi.org/10.3390/fuels5040036

Chicago/Turabian StyleEstevez, Rafael, Francisco J. López-Tenllado, Laura Aguado-Deblas, Felipa M. Bautista, Antonio A. Romero, and Diego Luna. 2024. "Evaluation of Advanced Biofuels in Internal Combustion Engines: Diesel/Fusel Oil/Vegetable Oil Triple Blends" Fuels 5, no. 4: 660-672. https://doi.org/10.3390/fuels5040036

APA StyleEstevez, R., López-Tenllado, F. J., Aguado-Deblas, L., Bautista, F. M., Romero, A. A., & Luna, D. (2024). Evaluation of Advanced Biofuels in Internal Combustion Engines: Diesel/Fusel Oil/Vegetable Oil Triple Blends. Fuels, 5(4), 660-672. https://doi.org/10.3390/fuels5040036