Abstract

Today, reducing GHG emissions is an important goal worldwide. Initially, first-generation biofuels were considered as a solution; however, they created a conflict between food and fuel. Advanced biofuels, which use non-edible materials, have emerged and are becoming more widespread, thus resolving this conflict. The paper aimed to investigate the three pillars of advanced biofuels’ sustainability (economic, environmental, and social). In the frame of a systematic literature review, 41 out of the initially screened 3407 articles were analyzed in depth. The economic aspect of sustainability was the most frequently occurring topic, followed by the environmental aspect, while the number of articles related to the social aspect was limited. From the economic point of view, all the analyzed articles agreed that advanced biofuels are far from commercialization at this stage; however, there are promising options related to different feedstocks or production technologies. Advanced biofuels perform unequivocally better environmentally than even conventional biofuels. For third-generation biofuels, negative net GHG emissions can even be possible, while fourth-generation biofuels can theoretically be produced from CO2. With respect to the social pillar, job creation was the core element of the articles analyzed. This can be experienced at the farm, production, and research levels. Although the commercialization of advanced biofuel production will take time, humanity must turn to them in order to avoid the food versus fuel problem, as well as to successfully fight against climate change and global warming.

1. Introduction

The fossil energy resources of the Earth are finite, as their extraction rate significantly outstrips their reproduction. Furthermore, population growth and rising living standards will further increase the demand for energy. The transport sector faces a major challenge in replacing fossil fuels. Renewable energy sources can provide a long-term solution to energy supply. However, there are many questions that need to be answered before they can be more widely deployed, namely, technological issues, economics, and managing production fluctuations. Biofuels are one of the most promising alternatives for reducing CO2 emissions in the transport sector. In addition to their renewable nature, they can be considered greenhouse gas (GHG) neutral, as their combustion releases previously absorbed carbon dioxide [1]. Nevertheless, their GHG emissions can be momentous at all stages of cultivation, from planting to processing [2]. The problem is not with the engines or combustion, but rather with the expansion of greenhouse gases (GHG), especially CO2 emitted into the atmosphere. However, it is common not to distinguish between fossil CO2 and renewable CO2 production, or even between CO2 emissions and pollutant emissions [3].

Carbon savings are also notable for 1G biofuels but can be sustained and even higher for the second, third, and fourth generations, mainly due to the negative CO2 balance of the production process.

According to Oh et al. [1], the share of conventional plant-based biofuels (e.g., ethanol and biodiesel) in total transport fuel consumption was very low, around 4% in 2016. This is due to several main constraints, including feedstock scarcity, low CO2 abatement, blending limit, and low cost-competitiveness. Advanced biofuels, such as liquid biofuels from inedible biomass, could be a promising solution to meet the growing demand for biofuels [1]. Their impact on food security and production depends primarily on the raw material used for the production of biofuels [4].

First-generation biofuels (materials produced from edible foodstuffs) are mainly ethanol and biodiesel, and other biofuels (e.g., biogas, biobutanol) or other types of fuels (e.g., hydrogen or ammonia) are not analyzed in this study. Advanced biofuels are second-generation (from non-consumable materials), third-generation (from algae), and fourth-generation (from genetically modified organisms) fuels. It should be noted that new methods are developed, e.g., superstructure optimization [5], and new raw materials are used, e.g., Wodyetia bifurcata [6], as technology evolves. The analysis focuses on advanced biofuels from ethanol and biodiesel.

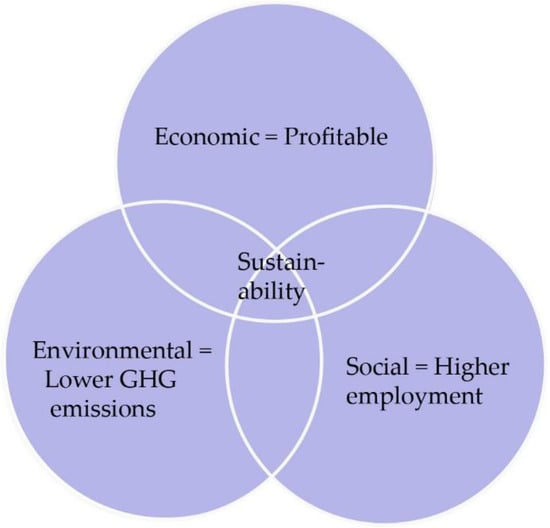

The United Nations defines sustainability [7] as meeting the needs of future generations in the present taking into account similar needs of future generations. According to this document, environmental protection, economic, and social are the three pillars of sustainability. Economic and environmental sustainability have been widely studied. A significant number of sources have addressed and continue to address this issue. The social dimension of sustainability addresses four main areas. The first factor is the cultural dimension (culture and education). The second factor is human capital, which includes the economy, workforce, individual health, and community health. The third factor is the political, which includes civic engagement and civil trust. The fourth is the social, within which are the community and non-profit organizations. Despite this, social science research in this area remains under-researched and sometimes overlooked in the literature, especially in empirical studies [8].

The aim of this study was to analyze the sustainability issues of advanced biofuels on the basis of a systematic literature review. The term sustainability covers three pillars: the economic, the social, and the environmental. This research is particularly important because most of the current biofuel production is based on edible feedstocks; therefore, their long-term sustainability is questionable. The structure of this article is as follows: First, we present the main characteristics of the advanced biofuels sector (both ethanol and biodiesel). We touch upon the typical feedstocks, the magnitude and characteristics of production costs, the generations of ethanol and biodiesel, the major producer countries, and their blending mandates. The third section describes the methodology used to select the articles. Articles analyzed in depth were grouped into three different categories: economic, social, and environmental sustainability. The last section summarizes the main results and conclusions.

2. State of Advanced Biofuels

In the case of ethanol as the final product, the high sugar or starch content gives it the potential to be used in engines. To use biodiesel as a fuel, a high oil content is required. The feedstocks for first-generation biofuels are also used for food, and therefore there is a conflict of interest between food and energy. The most typical feedstock is cereals, which are also the main source of food. For fuels other than the first generation, feedstock is no longer a competitor for nutrition. Other biofuel generations do not cause food conflicts, but their production is not yet stable, their technology is still immature, and the final product can be produced at higher costs. Li and Guo [9] group biofuels by generations. First-generation biofuels are produced from edible raw materials. Feedstocks such as wheat, rapeseed, soybean, animal fat, and corn are considered. Their carbon emissions are positive for both ethanol and biodiesel. Feedstock for further generations is no longer edible. For the second generation, lignocellulosic materials and Jatropha are the most typical raw materials. Carbon emissions are also positive here. However, this becomes negative for the third and fourth generations. In these cases, feedstocks are algae and genetically modified algae.

2.1. Biofuel Productions

Production prices for the main ethanol and biodiesel producers are shown in Table 1. Taking into account the currently high oil price, the producer price of alternative biofuels is competitive.

According to a World Bank report on the energy and food market [8], the increase in the prices of energy resources in 2020 and 2021 was the highest since the oil crisis in 1973. Food and artificial fertilizers, which are highly dependent on natural gas to produce, have seen the largest price increase since 2008. Energy resource prices are projected to grow by an additional 50% this year (2022) before they start to fall in the following two years Prices of non-energy commodities, such as metals, food, and agricultural commodities, are expected to grow by almost 20%. Commodity prices will exceed the average of 2017–2021. Depending on the length of sanctions against Russia, prices could be even higher. Brent crude oil prices are predicted to be higher than USD 100/barrel in 2022 (currently USD 95/barrel) due to trade and production disruptions. This price is at least 40% above the average price of the previous year. Oil prices are predicted to decrease to USD 92/barrel in 2023, which is much higher than that of the USD 60/barrel average of 2017–2021. The price of natural gas is expected to double in Europe due to the supply shortages, similar to that of coal, where an increase of 80% is expected [10]. Table 1 shows ethanol and biodiesel producer prices of the major producers in 2020.

Table 1.

Ethanol and biodiesel producer prices of the main producers in 2020.

Table 1.

Ethanol and biodiesel producer prices of the main producers in 2020.

| Countries | Ethanol | Biodiesel | ||

|---|---|---|---|---|

| USD/L | Weighted USD/L * | USD/L | Weighted USD/L * | |

| Argentina | not in TOP 5 | 0.33 | 0.36 | |

| Brazil | 0.35 | 0.53 | 0.37 | 0.41 |

| China | 0.56 | 0.84 | not in TOP 5 | |

| The EU | 0.54 | 0.81 | 0.74 | 0.81 |

| India | 0.42 | 0.63 | not in TOP 5 | |

| Indonesia | not in TOP 5 | 0.80 | 0.88 | |

| USA | 0.38 | 0.57 | 0.48 | 0.53 |

* Weighting takes into account the one-third lower energy content of ethanol [11] and 10% lower energy content of biodiesel [12]. Source: authors’ calculation based on [13,14].

If the cost without capital is considered, advanced biofuels are competitive with fossil oil. Calculating EUR/USD at a rate of 1.01, most ethanol and biodiesel products cost less than this.

On the basis of the work of Brown et al. [15], the different type of costs of other biofuels can be compared. Capital costs are between EUR 3 and 74/MWh. Cellulosic ethanol and Fischer–Tropsch (FT) liquids have the largest capital cost, and HVO has the smallest cost. Bio-oil plus co-processing and hydrotreated vegetable oils (HVO) have the highest feedstock cost (EUR 68 and EUR 60/MWh, respectively), while cellulosic ethanol “1/2 gen” has no feedstock cost at all. Cellulosic ethanol (48 EUR/MWh) and bio-oil standalone (EUR 59/MWh) have the highest operating cost, whereas bio-oil plus co-processing has the lowest operating cost equal to EUR 5/MWh. These facts mean that cellulosic ethanol, FT liquids–biomass, and bio-oil plus co-processing have the highest total cost, while methanol and methane wastes, cellulosic ethanol “1/2 gen”, HVO, and FT liquids/wastes have the lowest costs. Therefore, most ethanol and biodiesel products are price competitive with oil.

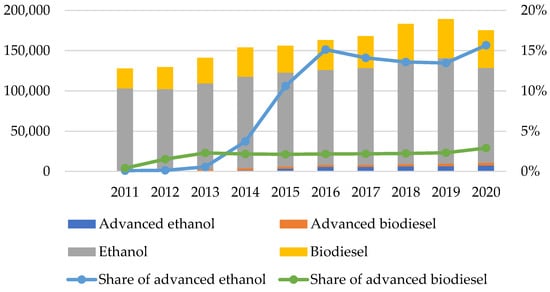

Among the types of advanced biofuels, the largest volume produced was ethanol (5597 million liters in 2015). This was followed by biofuels sold under the RDIF scheme (4200 million liters in 2015), renewable diesel (2593 million liters), and biobutanol (2129 million liters), and then followed by renewable oils (for upgrading). Advanced biofuels have achieved a share of 2–12% of all alternative fuels in recent years. Their share has risen spectacularly since 2013, when the problem of shrinking food crop area began to be considered. The increase in the share of advanced ethanol is more striking. This may have been due to the increased production of lignocellulosic materials (Figure 1).

Figure 1.

World ethanol, biodiesel, and advanced biofuel production in million liters, 2011–2020. Source: authors’ composition based on [16].

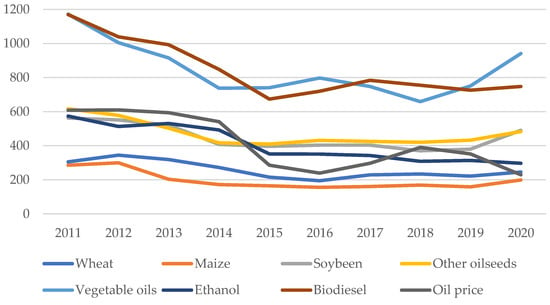

We can see in Figure 2. that the prices of different commodities and energy sources varied between 2011 and 2020. Between 2011 and 2015, the average world market prices typically decreased, while they stagnated between 2015 and 2020. Biofuel prices followed the same path. The correlations calculated for the period 2011–2020 showed a strong relationship between wheat and oil prices, as well as between wheat and ethanol prices. Similarly, there was a strong relationship between soybean and oilseeds (rapeseed, palm oil) and biodiesel prices, as well as between biodiesel and vegetable oil prices. Unsurprisingly, there was also a strong correlation between the prices of biodiesel, ethanol, and oil over the period studied. In the other cases, average correlation was typical.

Figure 2.

World market prices for ethanol, biodiesel, crude oil, and different feedstocks in USD/t2011–2020. Note: ethanol 1 liter = 0.783 kg, biodiesel 1 liter = 0.88 kg, 1 barrel is 0.138 metric tonnes and 158.98 liters. Source: authors’ composition based on [13,17].

Among the largest ethanol-producing countries, both the USA and Brazil utilize a significant share of their production and export only 7–8% of it (Table 2.). The EU exports 10% of its production. Indonesia is the largest exporter in relative terms, exporting 38% of its production. In terms of quantities used, the import activity of the EU, India, and Indonesia is significant, ranging from 8 to 14%. Looking at the area under cultivation, it can be seen that in many countries, for example, Brazil and Argentina, 100% of the sugar cane area can be used for the production of ethanol, while 5–8% of the maize area is used for this purpose. The USA stands out in this regard, with 46% of its land devoted to biofuel production. In the case of biodiesel, export activity is more significant in the largest producer countries. On average, Argentina exported 58%; China, 22%; Indonesia, 28%; the EU, 8%; and the USA, 6% of their production. Imports were significant for China, the EU, and the USA, at 34%, 17%, and 21%, respectively. The leading countries were characterized by high consumption and significant trade.

Table 2.

Largest biofuel-producing countries in aspects of harvested area, production, and export-import activity between 2011 and 2020.

2.2. Biofuel Markets

The demand for transport biofuels fell by 8% between 2019 and 2020, mainly due to the novel coronavirus, although it is expected to rebound in the years after COVID-19. While biofuel demand grew by an average of 5% yearly in the 2010–2019 interval, net zero emissions cannot be achieved by 2050 without a much higher average increase until 2030. Due to different regulations, directives, and policies, biofuels are especially crucial for truck, freight, and air transport, wherein only a few other low-carbon technologies are known. The share of biofuels produced from feedstocks (waste and residues) that are not used for food production is expected to increase. In the net zero emission 2050 pathway, biofuels from waste and residues are projected to achieve 45% of all biofuel needs by 2030, compared to only 7% of biofuels from waste and residues in 2020. Biofuels are calculated to account for 64% of the use of renewable energy by the transportation sector. Biofuel use will triple in the interval of 2019–2030, increasing to 12 EJ, which is 12% of the global fuel demand for transportation in 2030. At this moment, this ratio is only 3%, limited by high feedstock prices and the low blending mandates [15]. Some examples of how governments in different countries have responded to the impact of the COVID 19 epidemic are as follows: The Brazilian National Petroleum Agency set a target of 50% reduction in GHG targets for the transportation sector in 2020 in response to fuel shortages connected to the COVID-19 restriction and lowered its biodiesel blending mandate in 2021 from 13% to 10% to address the increasing costs of biodiesel feedstock. Indonesia delayed the introduction of the 40% biodiesel blending mandate to 2023. Argentina and Colombia have also postponed the introduction of biofuel policies due to high feedstock prices [18].

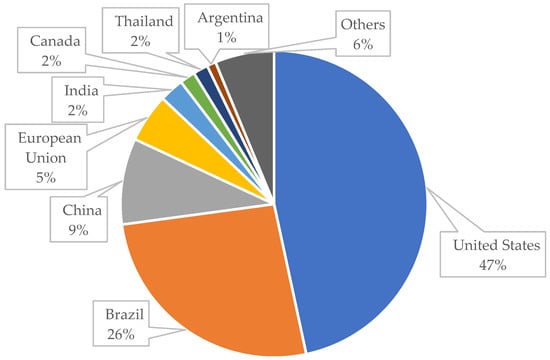

On the basis of the data from the RFA database, the following statements can be made. The USA has a 47% market share. Brazil is the second largest ethanol producer, with a market share of 26%. China’s production was 9%, while the EU’s share was 5% (Figure 3.). According to the OECD and the FAO forecast, no major structural changes are expected in the market by 2030, and therefore these countries are expected to be the largest producers [11]:

Figure 3.

World ethanol production, 2020. Source: authors’ composition based on [19].

- The United States will keep its position; however, its market proportion will fall to 43% from the current 47%;

- Brazil will remain in second place with a 26% market share;

- China will increase its production and achieve a 9% market share by 2030;

- The EU’s production will be almost unchanged, leading to a slightly lower market proportion;

- Thailand and India will increase their production and reach a 4% market proportion.

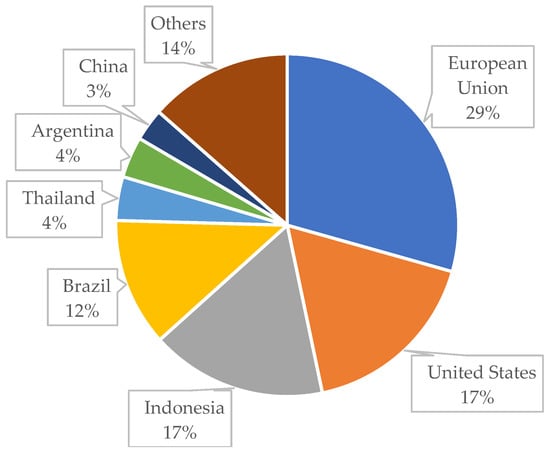

In terms of production, the biodiesel market is smaller than the ethanol market. Moreover, production is more fragmented (Figure 4.). The EU remains the largest producer, but its market share has decreased to 29% over the years. The USA and Indonesia follow the EU with a 17–17% market share. The other significant producers, Argentina and Brazil, have shares of 12% and 4%, respectively.

Figure 4.

World biodiesel production, 2020. Source: authors’ composition based on [11].

The OECD and FAO forecast a change in the ranking of the largest producers for the next 10 years. The data show that the EU will remain the largest producer, but its market share will decrease slightly to 28% by 2030. The other projections are as follows [11]:

- The next three countries will be Indonesia (19%), the USA (17%), and Brazil (12%);

- Argentina will come fourth with a 5% market share;

- Thailand will keep its 4% share.

2.3. Biofuel Regulations

Energy policies and directives play an important role in the use and composition of biofuels. These are the most effective tools for improving the use of renewable fuels. Section 2.2 confirmed that the EU (biodiesel) and the USA (ethanol) are the major producers; their legal framework is presented in detail.

2.3.1. U.S. Regulations

Pure biofuels are rarely used; they are usually blended with fossil fuels. A higher blending rate proportionally increases biofuel consumption. In most cases, blending mandates are supplemented by different tax incentives, for example, tax credits or exemptions. The USA has the largest ethanol production in the world. The Renewable Fuel Standard (RFS) program started in 2006, and the result was a stable feedstock background for the ethanol blending mandates.

The purpose of the Energy Policy Act (42 USC §13201 et seq. (2005)) is to take measures to help reduce dependence on foreign fossil energy sources for electricity generation. Many scientific projects seek to promote fuel substitution and minimize the use of indigenous biofuels such as coconut oil. In doing so, their aim is to increase the sources of renewable fuels and to promote and disseminate renewable technologies. This would be photovoltaics, wind, geothermal solar PV, hydrogen-fueled systems, biofuels, biomass-based systems, and hydropower. To this end, the Minister for Energy will initiate a research program to develop a commercial application in the field of bioenergy. Partnerships will be established to bring together industry and academic institutions. The aim of these partnerships is to develop advanced biotechnology processes that can produce biofuels and bioproducts, advanced biotechnology actions that implement the advancement of cheaper bioproducts, such as biofuels.

The aim of this legislation is to support the uptake and commercialization of biofuels. The goal of the 2005 Act was to achieve 1,000,000,000,000 gallons of cellulosic biofuel a year in 10 years and to make this type of production cost effective. This will be up to USD 100 billion over 1 year and up to USD 1000 billion over the lifetime of the project. A committee will be established to ensure the success of this task (the Energy Policy Act (42 USC 13201 et seq. (2005)).

Each state has established its own requirements separately. The following states have established targets for biofuels. New York’s goal is 70% renewable generation by 2030 and to be 100% carbon-free by 2040. It contains biomass, biofuel, wind, solar, hydro, geothermal, etc., resources. The state target of Virginia is to be 100% carbon-free by 2045. This requires similar energy resources as New York has planned.

According to the Renewable Fuel Standard, the regulation requires the use of 36 billion gallons of ethanol in 2022. The use of corn ethanol can be a maximum of 15 billion gallons. The remaining 21 billion gallons of fuel must consist of 16 billion gallons of cellulosic biofuel by 2022 and 1 billion gallons of biodiesel yearly by 2012 [20].

2.3.2. EU Regulations

In the EU, there is also a regulation on biofuels. Advanced fuels can be made from feedstocks listed in Annex IX, Part A of Directive 2018/2001. They can be (waste) forest residues, or straw, sludge, crude glycerin manure, algae, bagasse, etc. The same applies to biofuels (and biogas) produced from used cooking oils and animal fats, which are listed in Annex B of the legislation. These are not advanced biofuels; therefore, they do not count towards the advanced biofuels targets. Advanced biofuels are materials produced from non-edible feedstocks. They have a low risk of indirect land use. The Renewable Energy Directive has set a 10% renewable energy target for transport by 2020. As there is a conflict between feed and transport targets, Directive 2018/2001/EC sets lower targets. The main targets are as follows:

- -

- The 14% target sets a maximum share of 7% for first-generation biofuels, bioliquids, and biomass fuels for road and rail transport. This is to ensure that food supply is not threatened. The remaining 7% should be advanced biofuels and renewable energy (electricity, coal, and non-biological materials).

- -

- By 2030, the share of advanced fuels produced from feedstocks listed in Annex IX, Part A (e.g., algae, straw, bio-waste), should reach 3.5%. Feedstocks listed in Annex IX, Part B (used cooking oils and animal fats), should account for a maximum of 1.7% by 2030 [21].

- -

- RED II [1] double counts the raw materials in Annex IX in the calculations [22]. RED II sets out additional rules that must be achieved (14% share of renewables in the transport sector). For example, it is prohibited to produce biofuels from biomass that is grown in areas with particularly valuable and high-carbon stocks (e.g., wetlands, primary forests) [19,20].

So much has changed recently that the EU has set a target of 32% by 2030. This means that by that date, at least 14% of the energy used in road and rail transport will have to come from renewable energy sources [19].

3. Materials and Methods

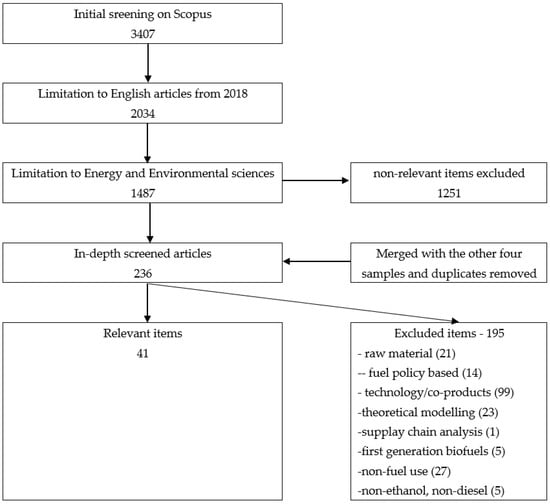

The five largest online databases (Scopus, Web of Science, JSTOR, ProQuest, and Science Direct) were used to find the relevant articles. The research keywords were advanced biofuels AND sustainability. The goal was to analyze articles that are connected to economic, social, and environmental aspects of sustainability. In the first round, keywords were searched for and downloaded from the Scopus database that provided the largest number of potential items. This step resulted in 3407 articles. We restricted them to English scientific articles from the last 5 years (between 2018 and 2022), which reduced the number of publications to 2034. The next step was to limit topics to energy and environmental sciences. This resulted in 1487 articles. The economic, social, and environmental aspects of the sustainability issues of advanced biofuels were the main goal; therefore, the following issues were excluded:

- biorefinery technology;

- non-ethanol and non-diesel use (e.g., electricity, biomethane);

- ethanol and biodiesel production technology;

- raw materials and coproducts;

- fuel or energy policy;

- theoretical modelling;

- supply chain analysis;

- only first-generation biofuels.

In the second step, the results generated were merged with the other databases (JSTOR, ProQuest, Science Direct, and Web of Science). Then, duplications were sorted out, leaving 235 scientific articles for the next step. In the final step, 195 articles were excluded because they dealt with general renewable energy/biofuels and technology/technology analysis. Finally, 41 articles remained for in-depth analysis (Figure 5.).

Figure 5.

Steps of the selection process.

The relevant articles showed an unequal distribution over the five years analyzed, with more items from 2018 and 2021. Even though the selection process was finished in the middle of 2022, 5 articles had already been published in this year.

The sources with the most publications were Renewable and Sustainable Energy Reviews and Renewable Energy. Of the 41 selected articles, 10 items were published here. Two articles were published in each of the following journals: Sustainable Energy and Fuels, Frontiers in Energy Research, and Energy. The remaining 25 papers were more diverse, as they appeared in 25 different journals.

4. Sustainability of Advanced Biofuels

The sustainability analysis of advanced biofuels is based on three pillars: economic, environmental, and social. The selected articles are processed along these pillars. However, it should be noted that these pillars are often interrelated. For example, the fuel vs. food problem is a central element of the debates about biofuels that concerns both pillars.

4.1. Economic Pillar

Ortega et al. [23] suggested the importance of combining chemical conversion of substances and biotechnology or the use of alternative sources (residues and different wastes). Advanced biofuels are particularly important in those sectors where there are no other alternatives, such as water or air transportation. They also emphasized the importance of the supportive energy policy, including blending mandates for advanced biofuels or incentivizing their production, because advanced biofuel production is not yet cost-competitive [24]. Tsita et al. [25] added a stable long-term legal framework and innovative policies to this list. This fuel vs. food problem is the reason why Oumer et al. [26] also argued for the use of non-food biomass, such as agricultural wastes, municipal wastes, waste vegetable oil, and microbial sources, because they cannot be used for human consumption and are abundantly available. They consider algae-based production for future due to its high productivity, energy density, low land need, and high CO2 utilization. However, there are many drawbacks to this technology. Besides being expensive due mainly to the pre-treatment of the feedstock and enzymatic hydrolysis, algae-based biofuels are less stable, and large-scale production requires huge amount of inputs [26,27]. It should be kept in mind that there are other potential rivalries. For example, Prussi et al. [28] emphasized competition with the use of biofuels in other sectors, especially road transportation.

Like Oumer et al. [26], Pikula et al. [29] also stressed the same advantages of advanced biodiesel production. They added higher resistance to different climatic conditions and pests and diseases, as well as potential rehabilitation of degraded lands. As for their disadvantages, they highlighted their lower oil yield high alcohol consumption during the production process. They identified used cooking oils, waste animal fats, and microalgal lipids as third-generation feedstocks. Although they provide promising options in terms of environmental, economic, and food security aspects, the collecting problems (used cooking oils and waste animal fats) and the less stable biodiesel and high nutrients requirement (microalgae) currently make advanced biodiesel production limited. Zore et al. [30] found that advanced biofuels are not yet commercialized, mostly because feedstocks are not available in sufficient quantities and their production is expensive. In addition, an optimized transport mode of feedstocks is important for a reduced production cost [31].

Prussi et al. [28] analyzed the EU’s aviation sector and found that high production cost derived mainly from feedstock cost is the main limiting factor of its production. According to [32], liquid sustainable aviation fuels (SAF) have an advantage over other solutions because they represent a mature technology and are compatible with current aircraft and logistics. They found biogenic sources to be a promising solution. Ahmad and Xu [33] collected the literature on the economic sustainability of SAF and found that SAF used less than 1% of the total demand for conventional jet fuel in commercial aviation. Its cost is up to five times that of conventional jet fuel, which is the main reason why companies do not want to use it. However, this is different if consumers are willing to pay more for airplane tickets. Supportive policies in areas such as capital markets, fuel markets, and environmental commodity markets are needed to promote the stable long-term development of SAF. Alam et al. [34] found that without co-product credit or other subsidies, conventional jet fuel (0.50 USD/l) was much cheaper than carinata-based SAF (USD 0.85/L to USD 1.28/L). When both co-product and renewable identification number (RIN) credits were included, the price ranged from USD 0.12 to USD 0.66 per liter. Even with low fixed costs and low co-product credit, subsidies are needed to produce SAF from carinata, especially when variable costs are high. According to the work of Bauen et al. [35], the price of fossil jet fuel is EUR 530 per tonne, while all electric battery prices are 3 times, bio-jet fuel is 3–5 times, and hydrogen-based fuel is 20 times more expensive. The authors suggested the use of a hybrid system wherein the cost of the additional electric system is compensated by savings on fuel expenditure. Bullerdiek et al. [36] also investigated the economic applicability of SAF. They found that its use results in a 5–45% increase in the price of aviation fuel compared to conventional aviation fuel. Tax revenues from aviation are mostly insufficient to cover these higher prices. One solution could be to increase the share of SAF. On the basis of their calculations, an increase in the share of SAF is more economically feasible than refueling for any type of fuel alternatives based on grass, wheat straw, palm oil, used cooking oil, and municipal solid waste. Doliente et al. [31] compared different feedstock and production methods and found that the production of hydroprocessed esters and fatty acids based on used cooking oil is the most economical option for the production of bio-aviation fuel at this moment. However, the potential feedstock must be carefully chosen, as its quality and the risk of downtime due to inadequate biomass supply are the most common problems in the bioenergy industry [37]. This is the reason for the need for diversified feedstocks [31]. In summary, only a national or regional policy framework in line with international agreements would provide a proper background to manage the complex ecosystem including SAF [33]. Even an international industry level would be useful for knowledge sharing and more efficient development [31].

Production technologies of advanced biofuels are generally more expensive; therefore, advanced biofuels are more expensive than either their fossil or conventional counterparts [2]. Amrullah and Hambali [38] found that conventional ethanol is more expensive than gasoline, while lignocellulose-based ethanol (second-generation biofuel) was even more expensive in Indonesia. This means that ethanol is still unable to compete with its fossil rival without government intervention. Mat Aron et al. [39] also reported that the cost of biofuels is higher than that of fossil fuels. According to their results, first-generation ethanol and biodiesel can be produced at costs of USD 0.49 and USD 0.86 per liter, respectively. In the case of second- and third-generation production, the cost range is from USD 0.30 to USD 2.07 per liter and USD 0.44 to USD 8.76 per liter, respectively. These values depend mainly on the feedstock and production method. Gray et al. [40] showed that all alternative fuels studied are more expensive than fossil fuels. One of the conditions for competitiveness is the acceptability of higher prices by consumers. This is likely to require government incentives and a higher carbon price in the short-to-medium term to encourage consumers to choose low-carbon fuels. From this point of view, it is worth mentioning the research of Lai et al. [41]. The authors collected literature on advanced biofuels and found that only 30% of the surveyed Swedish businesses were willing to pay more for advanced biofuels for their business trips. Stolz et al. [42] noted that the use of renewable fuels in the shipping industry can result in economic losses and increased operational efforts; therefore, it should be supported. In the case of microalgae oil production, a potential solution could be the co-production of other valuable products or the combination of microalgae cultivation with the production of fish, turtles, and shrimp production; however, even in these cases, microalgae-based biodiesel production is far from being commercialized [43]. Economies of scale and learning effects are crucial in the cost reduction process [44]. Due to the physical size and weight of the feedstocks currently used for the production of biofuels, proper logistics must be applied to plan the location of production units (biorefineries) to make production economically viable [45].

Production of advanced biofuels requires significant scientific efforts and investments [44,46]. This process is supported by the fact that the production of cheaper advanced biofuels is a topical research objective that foreshadows the possibility of future scientific breakthroughs [2]. At the policy level, tax reductions, tax exemptions, and public subsidies can accelerate this process [44,45]. From this aspect. it is worth noting that Ajanovic and Haas [47] experienced declining political support. Nonetheless, since several other mitigation methods/technologies are feasible, they should also be taken into account [30].

4.2. Environmental Pillar

Biofuels are considered sustainable if they achieve a certain GHG savings compared to conventional energy sources. This is at least 50% in the EU. This can increase to 65% depending on the establishment of the biofuel plant [18]. These biofuels are certified as meeting the EU’s sustainability standards. The EU regulation aims to reduce the greenhouse gas emissions of the newly established plants by setting at least 35% savings by 2017, and 50% from 1 January 2018 (for installations put into operation before 5 October 2015) and 60% from 2018 (for installations put into operation before 5 October 2015), in line with the U.S. life-cycle GHG emission cut objectives for advanced biofuels (50%) and cellulosic biofuels (60%) [48]. Table 3 introduces the impacts of GHG of particular biofuels.

Table 3.

GHG impacts of biofuels.

The amount of pollutants emitted in feedstock production is not significant, as a small proportion of arable land is used to produce feedstocks for biofuels [13]. Table 4. provides an overview of the GHG emissions saving potential of the different generations of biofuels. The results predict that all generations of biofuels, with the exception of nitrogen compounds, have a characteristic of reducing GHG emissions. Advanced biofuels provide significantly larger GHG emission savings compared to conventional biofuels [2]. Although the reduction in GHG of conventional biofuels compared to gasoline is between 20 and 82%, this is 70–85% for lignocellulosic biomass-based biofuels, and the net GHG emission can even be negative for third-generation production, while genetically modified microalgae can provide even greater carbon uptake [39].

Table 4.

GHG emission savings of the different generations of biofuels.

As the production of advanced biofuels is not economically viable, their environmental advantages should be considered [26,45]. On the basis of a review of the literature on bioenergy, Plante et al. [24] showed that advanced biofuels provide environmental benefits. Poulikidou et al. [55] analyzed the biomass-based 2-ethylhexanol, which can be blended into fuels with a high percentage. All three production pathways showed better environmental performance compared to either fossil fuels or conventional biofuels. Prussi et al. [28] concluded that aviation biofuels perform well environmentally. Sharma et al. [56] examined switchgrass-based ethanol for aviation fuel. This could decrease GHG emissions by up to 65% and increase welfare throughout the supply chain (feedstock producers, processors, and airlines). The higher the conversion rate of sustainable aviation fuel from biomass, the higher its competitiveness over conventional jet fuel.

According to Qin et al. [57], advanced biofuels can reduce life cycle GHG emissions by up to 85% and thus significantly improve air quality. They also highlighted the importance of considering land use change. To avoid or minimize negative impacts of feedstock production, e.g., biodiversity loss or water quality impacts, they suggested improved agricultural management and landscape planning. Similarly to Doliente et al. [31], Capaz et al. [58] also found that lignocellulosic residues have the highest potential for GHG reduction (−95% to −130%). They added that GHG emission savings occur only if residual feedstocks are used, and thus they are not diverted from their initial economic use. Millinger et al. [59] measured the environmental performance of different biofuel options in Germany by their long-term relative GHG abatement cost development. According to their results, sugar-beet-based ethanol provided the best option in the short and medium term, while silage-maize-based biomethane was the best option in the medium to long term.

Aside from the environmental advantages of renewable forest wood-based biofuels, Palander et al. [60] highlighted the importance of higher energy efficiency through transport optimization. Finnish wood procurement can be carbon neutral by replacing 30% of the total fossil fuel consumption of road freight transportation. Usmani [61] emphasized the value of advanced ethanol with regard to agroforestry residues in India due to its benefits to the climate and air. Moreover, this can reduce the country’s dependence on imported oil. Agroforestry residues can be produced on marginal land, which is another advantage of their production. Doliente et al. [31] suggested multiple transport modes for different feedstocks because transportation can have a significant impact on GHG emissions.

Sakthivel et al. [62] analyzed third-generation biodiesels derived from non-edible feedstocks. According to their results, they can be directly blended with diesel fuel. In line with the related literature, biodiesels decreased reduced toxic emissions and smoke while increasing CO2 and NOx emissions, resulting in lower fuel efficiency. Using an advanced biodiesel, Rassoulinejad-Mousavi et al. [63] were able to successfully substitute methane in a methane–air jet flame. The biofuel provided the same temperature distribution while resulting in significantly lower GHG emissions, including methane, water vapor, and CO2. This seems to be common with blended fuels [64]. Cotton, corn, and sunflower methyl ester can also be blended up to 50% with aviation fuel [65,66]. However, unlike Rassoulinejad-Mousavi et al. [63], other studies experienced higher CO2 emissions [66]. Doliente et al. [31] stated that the used cooking oil is the most environmentally friendly feedstock to produce bio-aviation fuels at this time. According to the calculations of Alam et al. [34], a relative carbon dioxide saving of 65% can be achieved with carinata-based SAF (918.67 g versus 2618 g CO2 equivalent/L) compared to conventional aviation fuel. Bauen et al. [35] experienced 20–90% CO2 savings with the use of bio-jet fuels depending on the different feedstocks. Moreover, even CO2-neutral fuel use can be reached with SAF if no fossil energy sources are used in the supply chain and production is based on sustainable biomass feedstock [36]. However, it is questionable as to whether biofuels can be produced in the quantities required by the aviation sector [40].

Stathatou et al. [67] tested used cooking oil in a dry bulk vessel. According to their results, up to 40% reduction in emissions, especially SO2 emissions, can be achieved when life cycle analysis is applied without operating problems. This implies a significant potential for advanced biodiesel in the shipping sector. Gray et al. (2021) argued that emissions relating primarily to feedstock and residual materials, such as waste and residues, result in lower emissions and have greater land requirements than energy crops grown for fuel. In addition to lower GHG emissions, much lower particulate matters values and more favorable composition can be achieved [68]. However, ignitability (ignition delay and combustion efficiency) of different biofuels should also be considered [69].

Pikula et al. [29] consider microalgal modification (fourth generation) to be the most promising option for the future, despite its serious problems, including environmental and human health risks. Abdullah et al. [70] also examined fourth-generation genetically modified algae. In accordance with the work of Oumer et al. [26], they identified similar advantages and disadvantages. On the basis of field trials, they stated that under certain circumstances, gene transfer can be avoided. From this point of view, disposal methods are of great importance [29]. Yaşar and Altun [71] showcased that the use of microalgae-based biodiesel increases fuel consumption and slightly decreases thermal efficiency, whereas, with the exception of NOx, it greatly reduces GHG emissions. On the basis of its combustion characteristics, microalgae-based biodiesel is completely suitable for substituting conventional diesel fuel up to 20%. However, it should be noted that when algae are fast growing, they have low oil content, and vice versa [27]. Similarly to Pikula et al. [29], Puricelli et al. [46] also highlighted the fourth generation as a promising future option. They emphasized that land use change should also be considered, which requires the use of different feedstocks, otherwise GHG emissions will be similar to that of fossil fuels. In addition to a great reduction in GHG emissions, advanced biofuel production, such as the use of algal species, can be used for wastewater treatment [27,72]. Due to the high ecosystem services that microalgae can provide, their cultivation has the highest potential for saving CO2 emissions, while the fourth generation can result in even greater savings in GHG emissions [31]. In general, the more advanced a biofuel is, the more sustainable its use in terms of environmental aspects [23].

4.3. Social Pillar

Given the lack of experience with third- and fourth-generation biofuels and due to the small number of these plants, it is not possible to comprehensively analyze and compare the employment impacts of these generations. Nevertheless, on the basis of the literature, the available social and employment experiences of biofuel production and use are presented. Srivastava et al. [72] drew attention to the positive employment effect of advanced biofuel production. This could be promoted, for example, by targeted subsidies. Tsita et al. [25] highlighted that blending mandates are of utmost importance in the promotion of advanced biofuels. Their production depends mainly on feedstock availability (e.g., used vegetable oil or animal fat provide limited sources) and production capacities (only biorefineries can be competitive, and advanced biofuel production is at the infant stage). They also highlighted the positive impact of advanced biofuel production on employment at the farm, production, and research levels. Due to the diverse and fragmented nature of different residues and wastes, integrated biomass management is of utmost importance. This also implies that there will not be only one best technology.

Wang et al. [73] used the input–output analysis approach to examine the contribution of sustainable aviation fuel production to the Brazilian economy. The analysis revealed net positive socio-economic impacts on employment and gross domestic product (GDP). Kamali et al. [74] provided an overview of the social aspects of the bio-jet fuel supply chains. According to their results, human health and safety, labor rights, and working conditions were the three most important issues. On the other hand, only a few studies addressed equity, cultural diversity, and social cohesion. The following answers were provided for the question of what should be included in the bio-jet certification schemes: human health and safety was the most important issue (97%), followed by working conditions (90%) and labor rights (87%). The least important issues for inclusion in these schemes were cultural diversity (30%), social cohesion (36%), and employment (43%). Ahmad and Xu [33] collected the social aspects of SAF and found that public awareness of SAF is limited. This is particularly true for third- and fourth-generation biofuels, although perceptions of SAF are generally positive [8]. Anderson et al. [8] suggested that research should be extended to include how political beliefs, media, and other factors influence perceptions, community, and market acceptance of SAF.

Moreover, second-generation feedstocks can be produced on poor quality land by using less water and fertilizer [26]. Ajanovic and Haas [47] also emphasized that the future of biofuels depends on the availability of land. However, there could be difficulties with either the construction or operation parts if biofuel plants are built in rural areas [43].

5. Summary and Conclusions

The three pillars of sustainability, namely, economic, environmental, and social, were analyzed with a systematic literature review. During this process, 41 of the 3407 articles initially screened were analyzed in depth. The economic aspect of sustainability was the most frequently analyzed, followed by the environmental aspect, while the number of articles related to the social aspect was limited. On the basis of this review, the results of the work of Ahmad et al. [33] can be confirmed in that the economic, and partly the environmental, dimensions dominate the international literature, while social impacts have been analyzed much less.

Food versus fuel is still an ongoing debate that promotes advanced biofuels as they are based on non-edible sources. From an economic point of view, all the analyzed articles agreed that advanced biofuels are far from commercialization; however, there are promising options related to different feedstocks or production technologies. Supportive, as well as innovative, energy polices play the most important role in this process via blending mandates or incentivization the production of advanced biofuels. This also includes, for example, international, industry-level knowledge sharing. The use of non-food biomass is of utmost importance, as the cost of feedstock should be as low as possible. This is the reason why different wastes and residues are the most promising options for the future. Used cooking oil turned out to be a cost-efficient raw material; however, the lack of a centralized system for collecting and unstable supply makes it unsuitable for large-scale biodiesel production. When energy plants are concerned, the use of marginal lands or the rehabilitation of degraded lands become important. The prices of the different advanced biofuels are higher than those of conventional biofuels or even higher than those of fossil fuels, which is the main reason for their limited spread. However, this can be supported if consumers are willing to accept higher prices for low carbon fuels.

Advanced biofuels perform unequivocally better environmentally than even conventional biofuels. In the case of third-generation biofuels, net GHG emission can even be negative, while fourth-generation biofuels can theoretically be produced from CO2. Environmental performance can be measured by GHG abatement cost as well. As advanced biofuels are not yet economically viable, the environmental advantages they provide should be taken into account. As land use change should also be considered, improved agricultural management and landscape planning are especially important. Due to the diverse nature of feedstocks, having multiple transport modes is important in order to not increase GHG emissions. Although modified microalgae are the most promising future option, they pose environmental and human health risks; however, gene transfer appears to be avoided with cautious production. Moreover, third- and fourth-generation production can provide further benefits, most notably high-ecosystem services such as wastewater treatment.

As for the social pillar, job creation was the core element of the analyzed articles. This can be experienced at the farm, production, and research levels. Integrated biomass management is of high importance due to the diverse nation of potential feedstocks. In addition to employment, human health and safety, labor rights, and working conditions can be important aspects of the social dimension. Land availability also has become an important concern, but poor-quality land in rural areas can be used for feedstock production and biofuel plants can be established near them. However, potential construction or operation-related difficulties may arise in those areas.

Figure 6 provides an overview of the systematic literature review. Each pillar of sustainability was simplified to some extent in the analyzed articles. The economic pillar was translated into being profitable, the environmental aspect concentrated on lowering GHG emissions, and social sustainability almost only covered higher employment. Nevertheless, sustainability must be located in the intersection of the three circles, representing the three pillars.

Figure 6.

Simplified interpretation of the three pillars and sustainability.

On the basis of the systematic literature review, fourth-generation biofuels clearly represent the future, as they perform much better environmentally and socially in comparison not only to fossil fuels but also conventional biofuels; however, they are far from commercialization at this stage. Moreover, fourth-generation biofuels require huge initial investment (bio-reactor) and provide lower engine performance compared to the other biofuels [27]. The commercialization of their production will take time, but humanity must turn to them to avoid the food versus fuel problem, as well as to successfully fight climate change and global warming. Although making advanced biofuels cheaper, including developing cheaper feedstocks, more efficient logistics, and simpler and cheaper technologies, is an important research focus, the engine of this process is a supportive energy policy.

Regarding potential research paths for the future, a more detailed analysis of every pillar of sustainability would be useful. This would provide a deeper insight into these aspects. An analysis broken down into developed and developing countries could also provide interesting results.

Author Contributions

Conceptualization, T.M.; methodology, T.M. and G.G.; formal analysis, T.M. and G.G.; resources, T.M.; data curation, T.M.; writing—original draft preparation, T.M. and G.G.; writing—review and editing, T.M. and G.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Publicly available datasets were analyzed in this study. They can be found under reference OECD/FAO and reference IRS.

Conflicts of Interest

The authors declare that they have no conflict of interest.

References

- Oh, Y.-K.; Hwang, K.-R.; Kim, C.; Kim, J.R.; Lee, J.-S. Recent developments and key barriers to advanced biofuels: A short review. Bioresour. Technol. 2018, 257, 320–333. [Google Scholar] [CrossRef] [PubMed]

- Mizik, T. Impacts of international commodity trade on conventional biofuels production. Sustainability 2020, 12, 2626. [Google Scholar] [CrossRef]

- Martins, J.; Brito, F. Alternative fuels for internal combustion engines. Energies 2020, 13, 4086. [Google Scholar] [CrossRef]

- Khan, M.A.H.; Bonifacio, S.; Clowes, J.; Foulds, A.; Holland, R.; Matthews, J.C.; Percival, C.J.; Shallcross, D.E. Investigation of Biofuel as a Potential Renewable Energy Source. Atmosphere 2021, 12, 1289. [Google Scholar] [CrossRef]

- Dickson, R.; Liu, J.J. A strategy for advanced biofuel production and emission utilization from macroalgal biorefinery using superstructure optimization. Energy 2021, 221, 119883. [Google Scholar] [CrossRef]

- Kolakoti, A.; Prasadarao, B.; Satyanarayana, K.; Setiyo, M.; Köten, H.; Raghu, M. Elemental, Thermal and Physicochemical Investigation of Novel Biodiesel from Wodyetia Bifurcata and Its Properties Optimization using Artificial Neural Network (ANN). Automot. Exp. 2022, 5, 3–15. [Google Scholar] [CrossRef]

- Brundtland, G.H. Our common future—Call for action. Environ. Conserv. 1987, 14, 291–294. [Google Scholar] [CrossRef]

- Anderson, B.J.; Mueller, D.W.; Hoard, S.A.; Sanders, C.M.; Rijkhoff, S.A. Social Science Applications in Sustainable Aviation Biofuels Research: Opportunities, Challenges, and Advancements. Front. Energy Res. 2022, 9, 946. [Google Scholar] [CrossRef]

- Li, J.; Guo, Z. Structure evolution of synthetic amino acids-derived basic ionic liquids for catalytic production of biodiesel. ACS Sustain. Chem. Eng. 2017, 5, 1237–1247. [Google Scholar] [CrossRef]

- Commodity Markets Outlook. In World Bank Report. Available online: https://openknowledge.worldbank.org/bitstream/handle/10986/37223/CMO-April-2022.pdf (accessed on 15 July 2022).

- Alalwan, H.A.; Alminshid, A.H.; Aljaafari, H.A. Promising evolution of biofuel generations. Subject review. Renew. Energy Focus 2019, 28, 127–139. [Google Scholar] [CrossRef]

- European Commission. Directive (EU) 2015/1513 of the European Parliament and of the Council of 9 September 2015 amending Directive 98/70/EC relating to the quality of petrol and diesel fuels and amending Directive 2009/28/EC on the promotion of the use of energy from renewable sources. Off. J. Eur. Union 2015, 239, 1–29. [Google Scholar]

- OECD/FAO. OECD-FAO Agricultural Outlook 2021–2030. Available online: https://stats.oecd.org/# (accessed on 10 July 2022).

- IRS. Yearly Average Currency Exchange Rates. Available online: https://www.irs.gov/individuals/international-taxpayers/yearly-average-currency-exchange-rates (accessed on 10 July 2022).

- Brown, A.; Waldheim, L.; Landälv, I.; Saddler, J.; Ebadian, M.; McMillan, J.D.; Bonomi, A.; Klein, B. Advanced biofuels—Potential for cost reduction. IEA Bioenergy 2020, 88, 1–3. [Google Scholar]

- Advanced Biofuels Tracking Database. Available online: https://www.biofuelsdigest.com/bdigest/tag/advanced-biofuels-tracking-database/ (accessed on 12 July 2022).

- Statista. Average Annual Brent Crude Oil Price from 1976 to 2022. Available online: https://www.statista.com/statistics/262860/uk-brent-crude-oil-price-changes-since-1976/ (accessed on 10 July 2022).

- November, T.R. IEA. Oil Market Report. Available online: https://www.iea.org/reports/transport-biofuels (accessed on 11 July 2022).

- RFA. Annual World Fuel Ethanol Production. Available online: https://ethanolrfa.org/statistics/annualethanol-production/ (accessed on 10 July 2022).

- U.S. Department of Energy. Summary of Legislation and Regulations Included in the Annual Energy Outlook 2022 U.S. Department of Energy. Available online: https://www.eia.gov/outlooks/aeo/assumptions/pdf/summary.pdf (accessed on 9 July 2022).

- Renewable Energy—Recast to 2030 (RED II). Available online: https://joint-research-centre.ec.europa.eu/welcome-jec-website/reference-regulatory-framework/renewable-energy-recast-2030-red-ii_en (accessed on 15 July 2022).

- Biofuels Annual Report. Available online: https://apps.fas.usda.gov/newgainapi/api/Report/DownloadReportByFileName?fileName=Biofuels%20Annual_The%20Hague_European%20Union_06-18-2021.pdf (accessed on 14 July 2022).

- Ortega, A.; Gkoumas, K.; Tsakalidis, A.; Pekár, F. Low-Emission Alternative Energy for Transport in the EU: State of Play of Research and Innovation. Energies 2021, 14, 7764. [Google Scholar] [CrossRef]

- Plante, L.; Sheehan, N.P.; Bier, P.; Murray, K.; Quell, K.; Ouellette, C.; Martinez, E. Bioenergy from biofuel residues and waste. Water Environ. Res. 2019, 91, 1199–1204. [Google Scholar] [CrossRef]

- Tsita, K.G.; Kiartzis, S.J.; Ntavos, N.K.; Pilavachi, P.A. Next generation biofuels derived from thermal and chemical conversion of the Greek transport sector. Therm. Sci. Eng. Prog. 2020, 17, 100387. [Google Scholar] [CrossRef]

- Oumer, A.N.; Hasan, M.M.; Baheta, A.T.; Mamat, R.; Abdullah, A.A. Bio-based liquid fuels as a source of renewable energy: A review. Renew. Sustain. Energy Rev. 2018, 88, 82–98. [Google Scholar] [CrossRef]

- Vignesh, P.; Pradeep Kumar, A.R.; Ganesh, N.S.; Jayaseelan, V.; Sudhakar, K. Biodiesel and green diesel generation: An overview. Oil Gas Sci. Technol. 2021, 76, 6. [Google Scholar] [CrossRef]

- Prussi, M.; O’Connell, A.; Lonza, L. Alternative aviation fuels: Assessment of supply potential in the EU. In Proceedings of the 26th European Biomass Conference and Exhibition Proceedings, Florence, Italy, 14–17 May 2018; pp. 1512–1515. [Google Scholar] [CrossRef]

- Pikula, K.; Zakharenko, A.; Stratidakis, A.; Razgonova, M.; Nosyrev, A.; Mezhuev, Y.; Tsatsakis, A.; Golokhvast, K. The advances and limitations in biodiesel production: Feedstocks, oil extraction methods, production, and environmental life cycle assessment. Green Chem. Lett. Rev. 2020, 13, 11–30. [Google Scholar] [CrossRef]

- Zore, Ž.; Čuček, L.; Kravanja, Z. Synthesis of sustainable production systems using an upgraded concept of sustainability profit and circularity. J. Clean. Prod. 2018, 201, 1138–1154. [Google Scholar] [CrossRef]

- Doliente, S.S.; Narayan, A.; Tapia, J.F.D.; Samsatli, N.J.; Zhao, Y.; Samsatli, S. Bio-aviation Fuel: A Comprehensive Review and Analysis of the Supply Chain Components. Front. Energy Res. 2020, 8, 110. [Google Scholar] [CrossRef]

- Cabrera, E.; Melo de Sousa, J.M. Use of Sustainable Fuels in Aviation—A Review. Energies 2022, 15, 2440. [Google Scholar] [CrossRef]

- Ahmad, S.; Xu, B. A cognitive mapping approach to analyse stakeholders’ perspectives on sustainable aviation fuels. Transp. Res. Part D Transp. Environ. 2021, 100, 103076. [Google Scholar] [CrossRef]

- Alam, A.; Masum, M.F.H.; Dwivedi, P. Break-even price and carbon emissions of carinata-based sustainable aviation fuel production in the Southeastern United States. GCB Bioenergy 2021, 13, 1800–1813. [Google Scholar] [CrossRef]

- Bauen, A.; Bitossi, N.; German, L.; Harris, A.; Leow, K. Sustainable Aviation Fuels: Status, challenges and prospects of drop-in liquid fuels, hydrogen and electrification in aviation. Johns. Matthey Technol. Rev. 2020, 64, 263–278. [Google Scholar] [CrossRef]

- Bullerdiek, N.; Neuling, U.; Kaltschmitt, M. A GHG reduction obligation for sustainableaviation fuels (SAF) in the EU and in Germany. J. Air Transp. Manag. 2021, 92, 102020. [Google Scholar] [CrossRef]

- Davis, M.R.; Kainer, D.; Tuskan, G.A.; Langholtz, M.H.; Hellwinckel, C.M.; Shedden, M.; Eaton, L. Modeled economic potential for Eucalyptus spp. production for jet fuel additives in the United States. Biomass Bioenergy 2020, 143, 105807. [Google Scholar] [CrossRef]

- Amrullah, I.; Hambali, E. Bioethanol prospect from agricultural crops and its biomass in Indonesia. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Bogor, Indonesia, 24–25 August 2020; p. 012019. [Google Scholar] [CrossRef]

- Mat Aron, N.S.; Khoo, K.S.; Chew, K.W.; Show, P.L.; Chen, W.H.; Nguyen, T.H.P. Sustainability of the four generations of biofuels—A review. Int. J. Energy Res. 2020, 44, 9266–9282. [Google Scholar] [CrossRef]

- Gray, N.; McDonagh, S.; O’Shea, R.; Smyth, B.; Murphy, J.D. Decarbonising ships, planes and trucks: An analysis of suitable low-carbon fuels for the maritime, aviation and haulage sectors. Adv. Appl. Energy 2021, 1, 100008. [Google Scholar] [CrossRef]

- Lai, Y.Y.; Christley, E.; Kulanovic, A.; Teng, C.C.; Björklund, A.; Nordensvärd, J.; Karakaya, E.; Urban, F. Analysing the opportunities and challenges for mitigating the climate impact of aviation: A narrative review. Renew. Sustain. Energy Rev. 2022, 156, 111972. [Google Scholar] [CrossRef]

- Stolz, B.; Held, M.; Georges, G.; Boulouchos, K. Techno-economic analysis of renewable fuels for ships carrying bulk cargo in Europe. Nat. Energy 2022, 7, 203–212. [Google Scholar] [CrossRef]

- Chen, J.; Li, J.; Dong, W.; Zhang, X.; Tyagi, R.D.; Drogui, P.; Surampalli, R.Y. The potential of microalgae in biodiesel production. Renew. Sustain. Energy Rev. 2018, 90, 336–346. [Google Scholar] [CrossRef]

- Kesieme, U.; Pazouki, K.; Murphy, A.; Chrysanthou, A. Biofuel as an alternative shipping fuel: Technological, environmental and economic assessment. Sustain. Energy Fuels 2019, 3, 899–909. [Google Scholar] [CrossRef]

- Mizik, T.; Gyarmati, G. Economic and sustainability of biodiesel production—A systematic literature review. Clean Technol. 2021, 3, 19–36. [Google Scholar] [CrossRef]

- Puricelli, S.; Cardellini, G.; Casadei, S.; Faedo, D.; van den Oever, A.E.M.; Grosso, M. A review on biofuels for light-duty vehicles in Europe. Renew. Sustain. Energy Rev. 2021, 137, 110398. [Google Scholar] [CrossRef]

- Ajanovic, A.; Haas, R. Renewable energy systems implementation in road transport: Prospects and impediments. Renew. Energy Environ. Sustain. 2021, 6, 39. [Google Scholar] [CrossRef]

- Renewable Fuel Standard US Department of Energy. Available online: https://afdc.energy.gov/laws/RFS (accessed on 10 July 2022).

- Miller, C.A. Characterizing Emissions from the Combustion of Biofuels; U.S. Environmental Protection Agency: Washington, DC, USA, 2008. [Google Scholar]

- Kumar, A.; Nerella, V.K.V. Experimental analysis of exhaust emissions from transit buses fuelled with biodiesel. Open Environ. Eng. J. 2009, 2, 81–96. [Google Scholar] [CrossRef][Green Version]

- Lozada, I.; Islas, J.; Grande, G. Environmental and economic feasibility of palm oil biodiesel in the Mexican transportation sector. Renew. Sustain. Energy Rev. 2010, 14, 486–492. [Google Scholar] [CrossRef]

- Yaqoob, H.; Teoh, Y.H.; Sher, F.; Farooq, M.U.; Jamil, M.A.; Kausar, Z.; Sabah, N.U.; Shah, M.F.; Rehman, H.Z.U.; Rehman, A.U. Potential of waste cooking oil biodiesel as renewable fuel in combustion engines: A review. Energies 2021, 14, 2565. [Google Scholar] [CrossRef]

- Keskin, A.; Yaşar, A.; Reşitoğlu, İ.; Akar, M.; Sugözü, İ. The influence of diesel fuel-biodiesel-ethanol-butanol blends on the performance and emission characteristics of a diesel engine. Energy Sources Part A Recovery Util. Environ. Eff. 2013, 35, 1873–1881. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Prathima, A.; Periyasamy, M.; Mahendran, G. Emission assessment of Kappaphycus Alvarezil-Brown algae biodiesel Al2O3 and C18H34O2. Mater. Today Proc. 2020, 33, 4192–4197. [Google Scholar] [CrossRef]

- Poulikidou, S.; Heyne, S.; Grahn, M.; Harvey, S.; Hansson, J. A comparative assessment of current and future fuels for the transport sector. In Proceedings of the 26th European Biomass Conference and Exhibition Proceedings, Florence, Italy, 14–17 May 2018; pp. 14–17. [Google Scholar] [CrossRef]

- Sharma, B.; Yu, T.-h.E.; English, B.C.; Boyer, C. Economic Analysis of Developing a Sustainable Aviation Fuel Supply Chain Incorporating with Carbon Credits: A Case Study of the Memphis International Airport. Front. Energy Res. 2021, 9, 775389. [Google Scholar] [CrossRef]

- Qin, Z.; Zhuang, Q.; Cai, X.; He, Y.; Huang, Y.; Jiang, D.; Lin, E.; Liu, Y.; Tang, Y.; Wang, M.Q. Biomass and biofuels in China: Toward bioenergy resource potentials and their impacts on the environment. Renew. Sustain. Energy Rev. 2018, 82, 2387–2400. [Google Scholar] [CrossRef]

- Capaz, R.S.; Posada, J.A.; Osseweijer, P.; Seabra, J.E.A. The carbon footprint of alternative jet fuels produced in Brazil: Exploring different approaches. Resour. Conserv. Recycl. 2021, 166, 105260. [Google Scholar] [CrossRef]

- Millinger, M.; Meisel, K.; Budzinski, M.; Thrän, D. Relative greenhouse gas abatement cost competitiveness of biofuels in Germany. Energies 2018, 11, 615. [Google Scholar] [CrossRef]

- Palander, T.; Haavikko, H.; Kärhä, K. Towards sustainable wood procurement in forest industry—The energy efficiency of larger and heavier vehicles in Finland. Renew. Sustain. Energy Rev. 2018, 96, 100–118. [Google Scholar] [CrossRef]

- Usmani, R.A. Potential for energy and biofuel from biomass in India. Renew. Energy 2020, 155, 921–930. [Google Scholar] [CrossRef]

- Sakthivel, R.; Ramesh, K.; Purnachandran, R.; Mohamed Shameer, P. A review on the properties, performance and emission aspects of the third generation biodiesels. Renew. Sustain. Energy Rev. 2018, 82, 2970–2992. [Google Scholar] [CrossRef]

- Rassoulinejad-Mousavi, S.M.; Mao, Y.; Zhang, Y. Reducing greenhouse gas emissions in Sandia methane-air flame by using a biofuel. Renew. Energy 2018, 128, 313–323. [Google Scholar] [CrossRef]

- Nour, M.; Elseesy, A.I.; Attia, A.; Li, X.; Nada, S. Adding n-butanol, n-heptanol, and n-octanol to improve vaporization, combustion, and emission characteristics of diesel/used frying oil biodiesel blends in DICI engine. Environ. Prog. Sustain. Energy 2021, 40, e13549. [Google Scholar] [CrossRef]

- Ibrahim, M.N.; Ali, A.H.H.; Ookawara, S. Performance assessment of turbojet engine operated with alternative biodiesel. In Proceedings of the ASME Power Conference, Boston, MA, USA, 29 July–1 August 2013. V001T001A026. [Google Scholar] [CrossRef]

- Ali, A.; Ibrahim, M. Performance and environmental impact of a turbojet engine fueled by blends of biodiesels. Int. J. Environ. Sci. Technol. 2017, 14, 1253–1266. [Google Scholar] [CrossRef]

- Stathatou, P.M.; Bergeron, S.; Fee, C.; Jeffrey, P.; Triantafyllou, M.; Gershenfeld, N. Towards decarbonization of shipping: Direct emissions & life cycle impacts from a biofuel trial aboard an ocean-going dry bulk vessel. Sustain. Energy Fuels 2022, 6, 1687–1697. [Google Scholar] [CrossRef]

- Attia, A.M.; Kulchitskiy, A.; Nour, M.; El-Seesy, A.I.; Nada, S.A. The influence of castor biodiesel blending ratio on engine performance including the determined diesel particulate matters composition. Energy 2022, 239, 121951. [Google Scholar] [CrossRef]

- Nursal, R.S.; Khalid, A.; Abdullah, I.S.; Jaat, N.; Darlis, N.; Koten, H. Autoignition behavior and emission of biodiesel from palm oil, waste cooking oil, tyre pyrolysis oil, algae and jatropha. Fuel 2021, 306, 121695. [Google Scholar] [CrossRef]

- Abdullah, B.; Muhammad, S.A.F.a.S.; Shokravi, Z.; Ismail, S.; Kassim, K.A.; Mahmood, A.N.; Aziz, M.M.A. Fourth generation biofuel: A review on risks and mitigation strategies. Renew. Sustain. Energy Rev. 2019, 107, 37–50. [Google Scholar] [CrossRef]

- Yaşar, F.; Altun, Ş. The effect of microalgae biodiesel on combustion, performance, and emission characteristics of a diesel power generator. Therm. Sci. 2018, 22, 1481–1492. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Shetti, N.P.; Reddy, K.R.; Aminabhavi, T.M. Biofuels, biodiesel and biohydrogen production using bioprocesses. A review. Environ. Chem. Lett. 2020, 18, 1049–1072. [Google Scholar] [CrossRef]

- Wang, Z.; Kamali, F.P.; Osseweijer, P.; Posada, J.A. Socioeconomic effects of aviation biofuel production in Brazil: A scenarios-based Input-Output analysis. J. Clean. Prod. 2019, 230, 1036–1050. [Google Scholar] [CrossRef]

- Kamali, F.P.; Borges, J.A.R.; Osseweijer, P.; Posada, J.A. Towards social sustainability: Screening potential social and governance issues for biojet fuel supply chains in Brazil. Renew. Sustain. Energy Rev. 2018, 92, 50–61. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).