Investigation of the Performance and Emission Characteristics of Diesel Engine Fueled with Biogas-Diesel Dual Fuel

Abstract

:1. Introduction

2. Methodology

Experimental Test Matrix

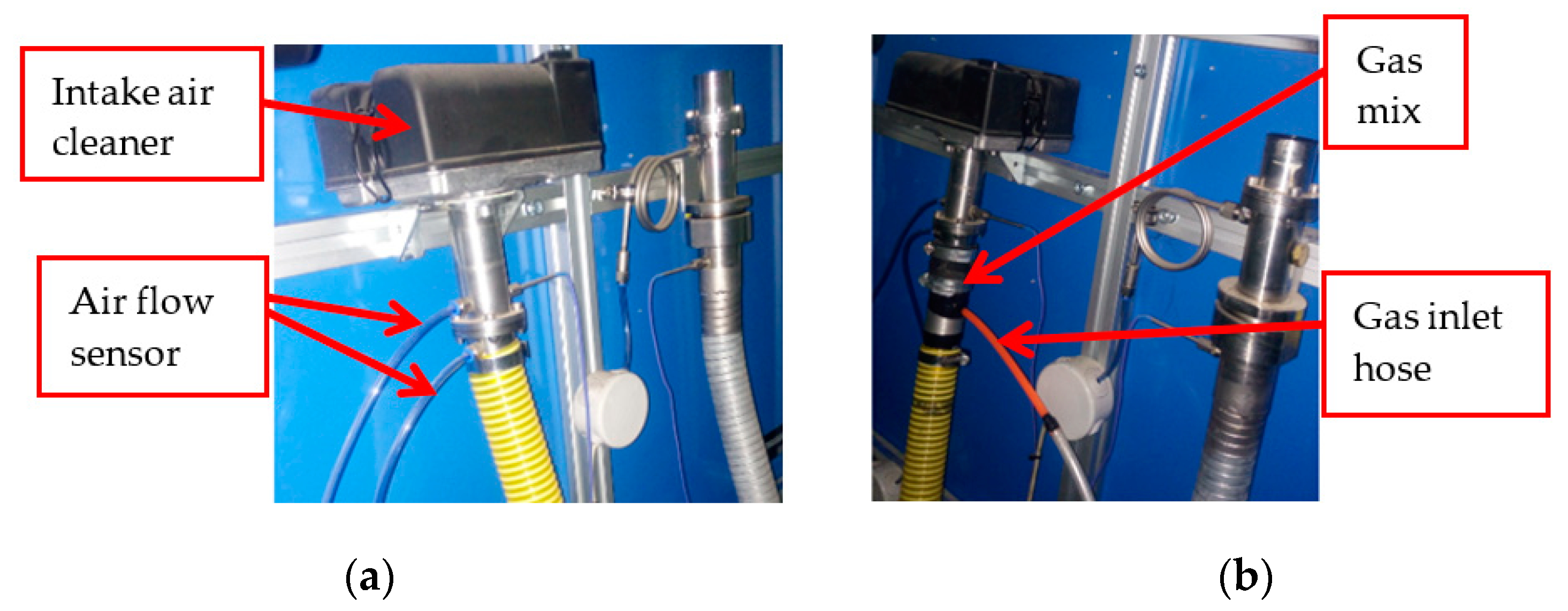

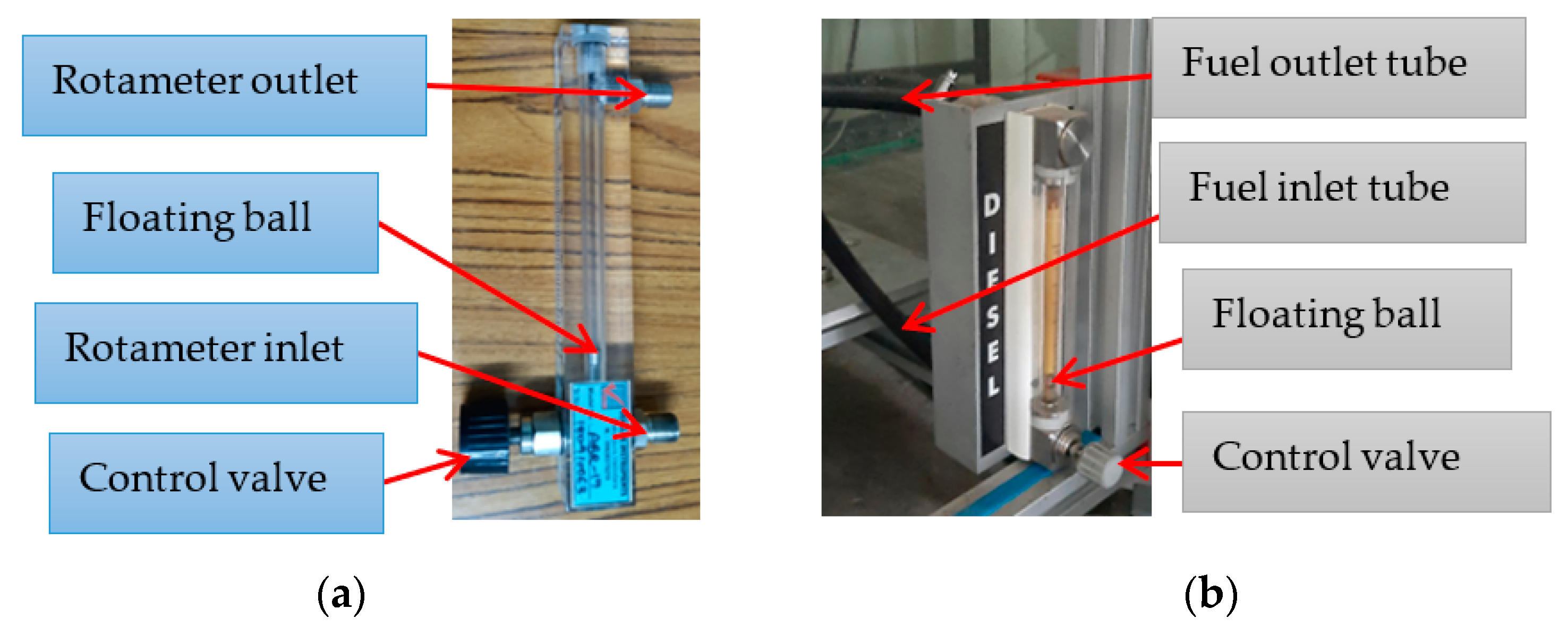

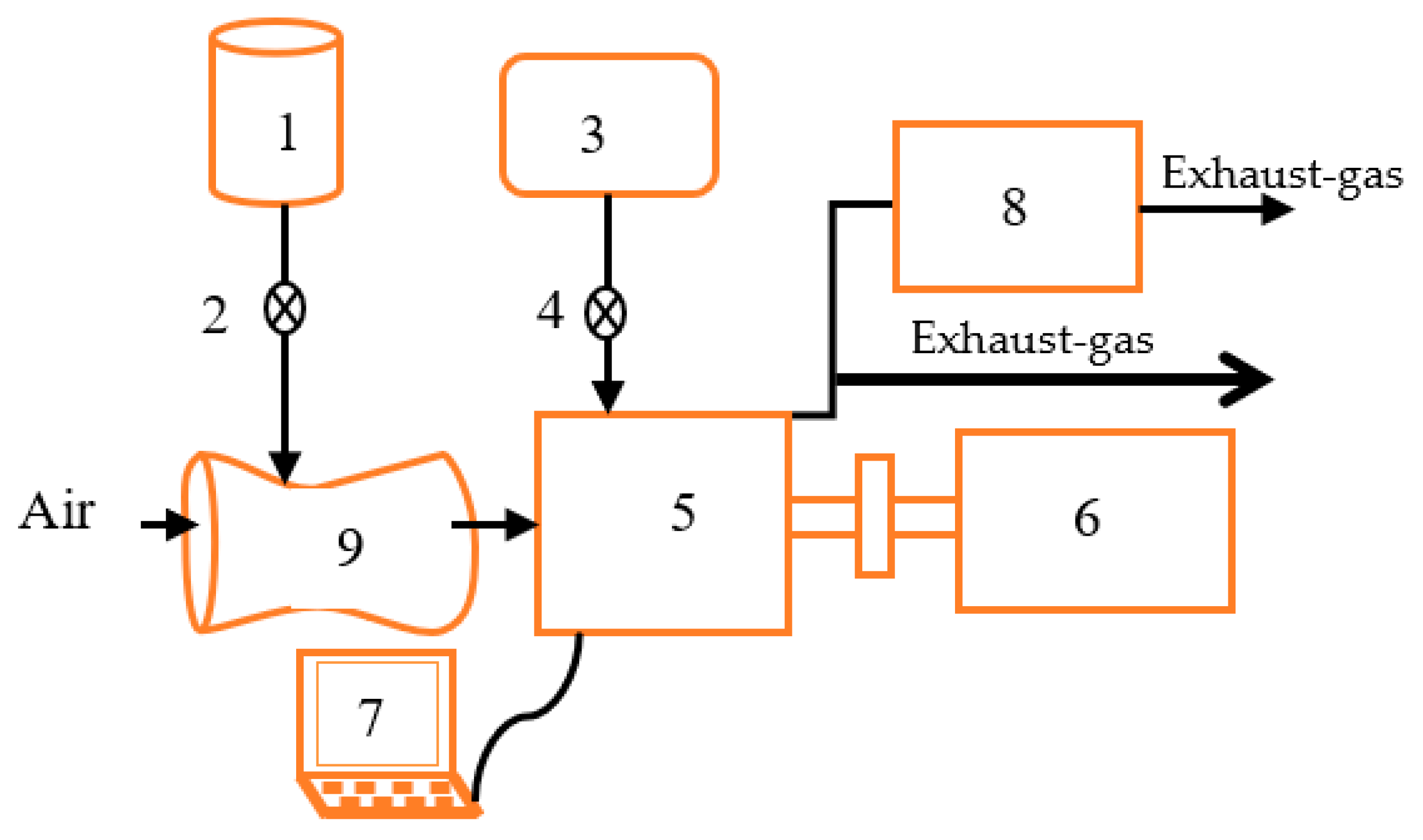

3. Experimental Setup

4. Result and Discussion

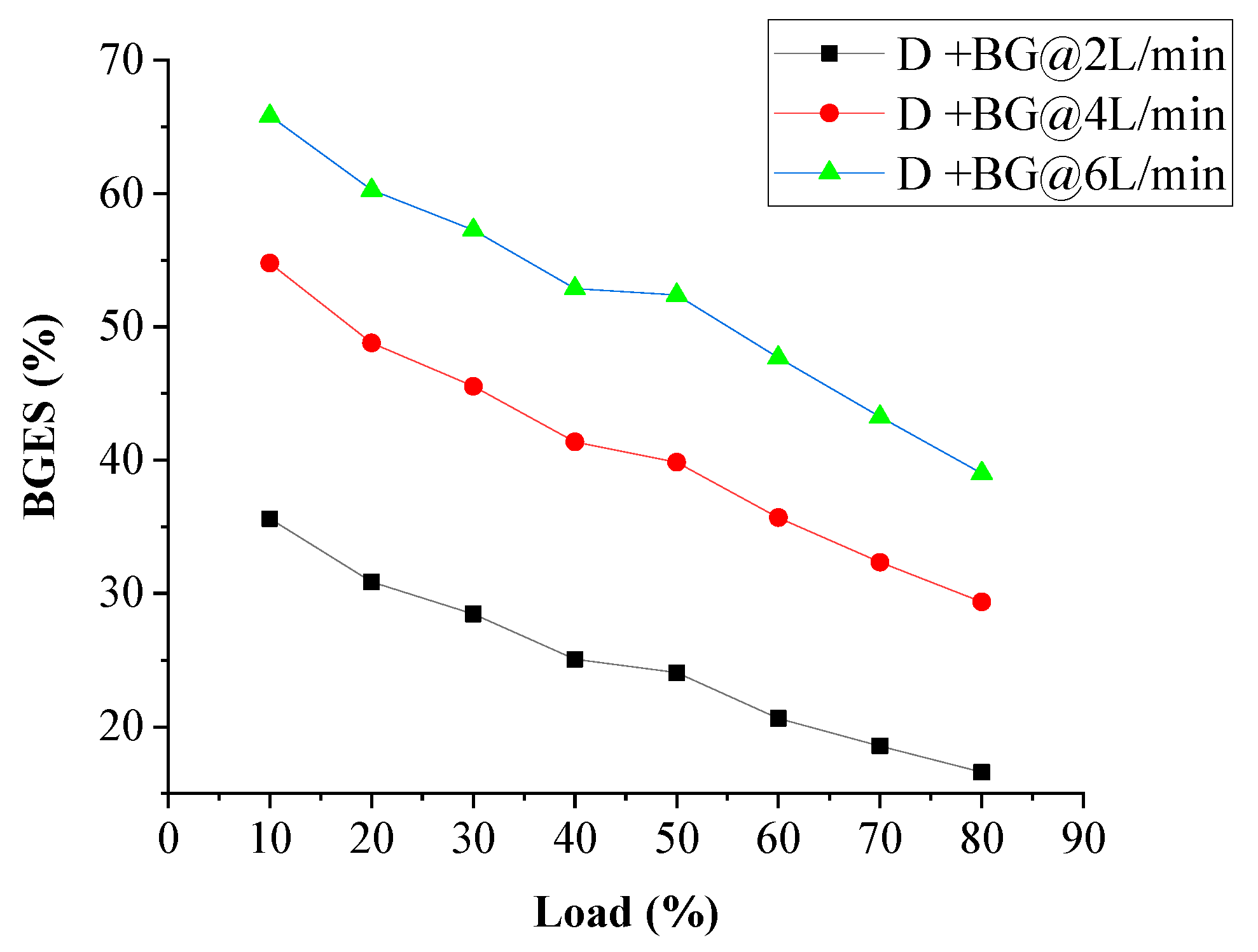

4.1. Mass Fraction of Biogas and Biogas Energy Share

- Mass fraction of biogas

- b

- Biogas energy share (BGES)

4.2. Engine Performance

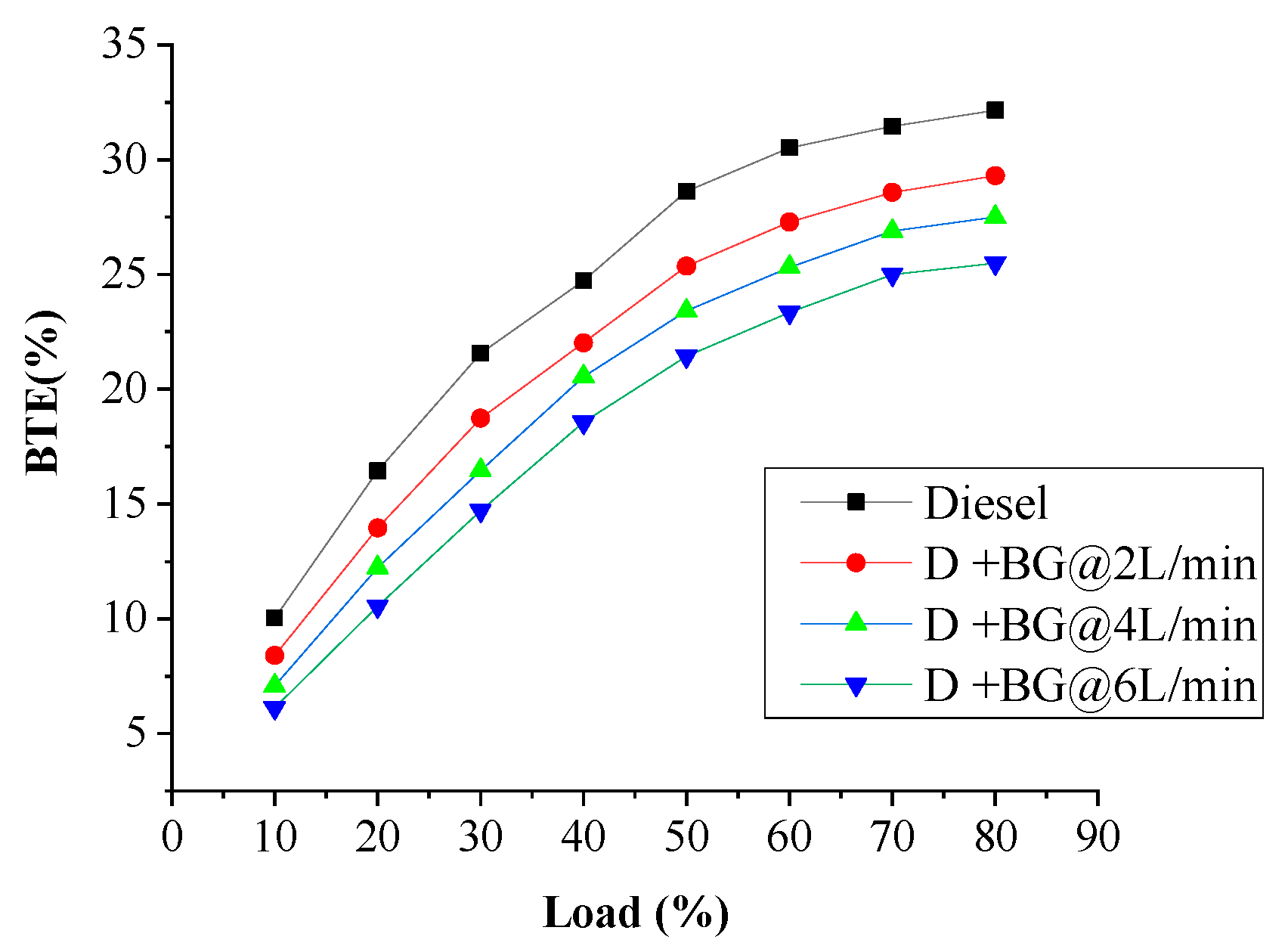

- Brake thermal efficiency (BTE)

- b

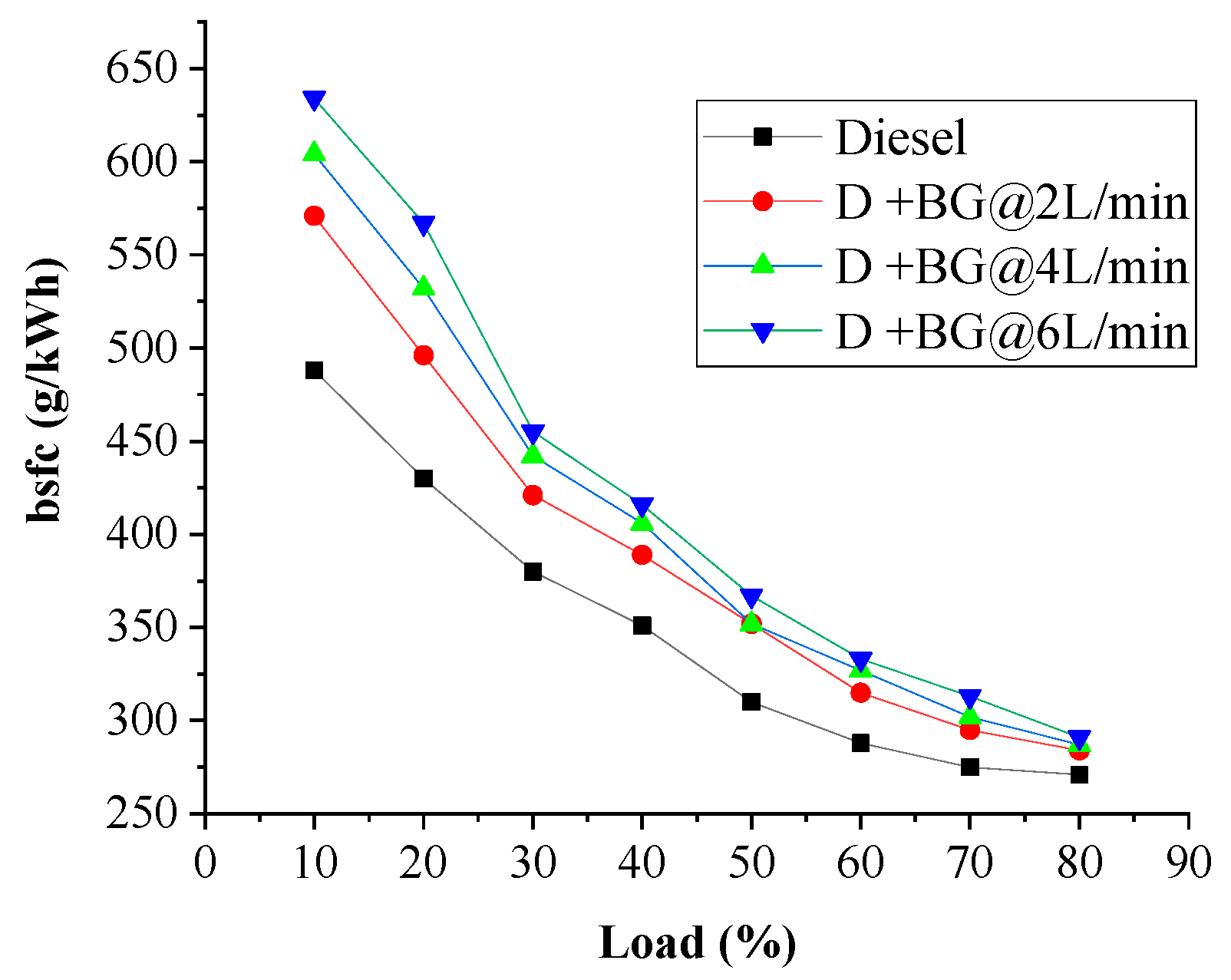

- Brake-specific fuel consumption (bsfc)

4.3. Emission characteristics

- Exhaust Emissions of Carbon Monoxide (% Vol.)

- b

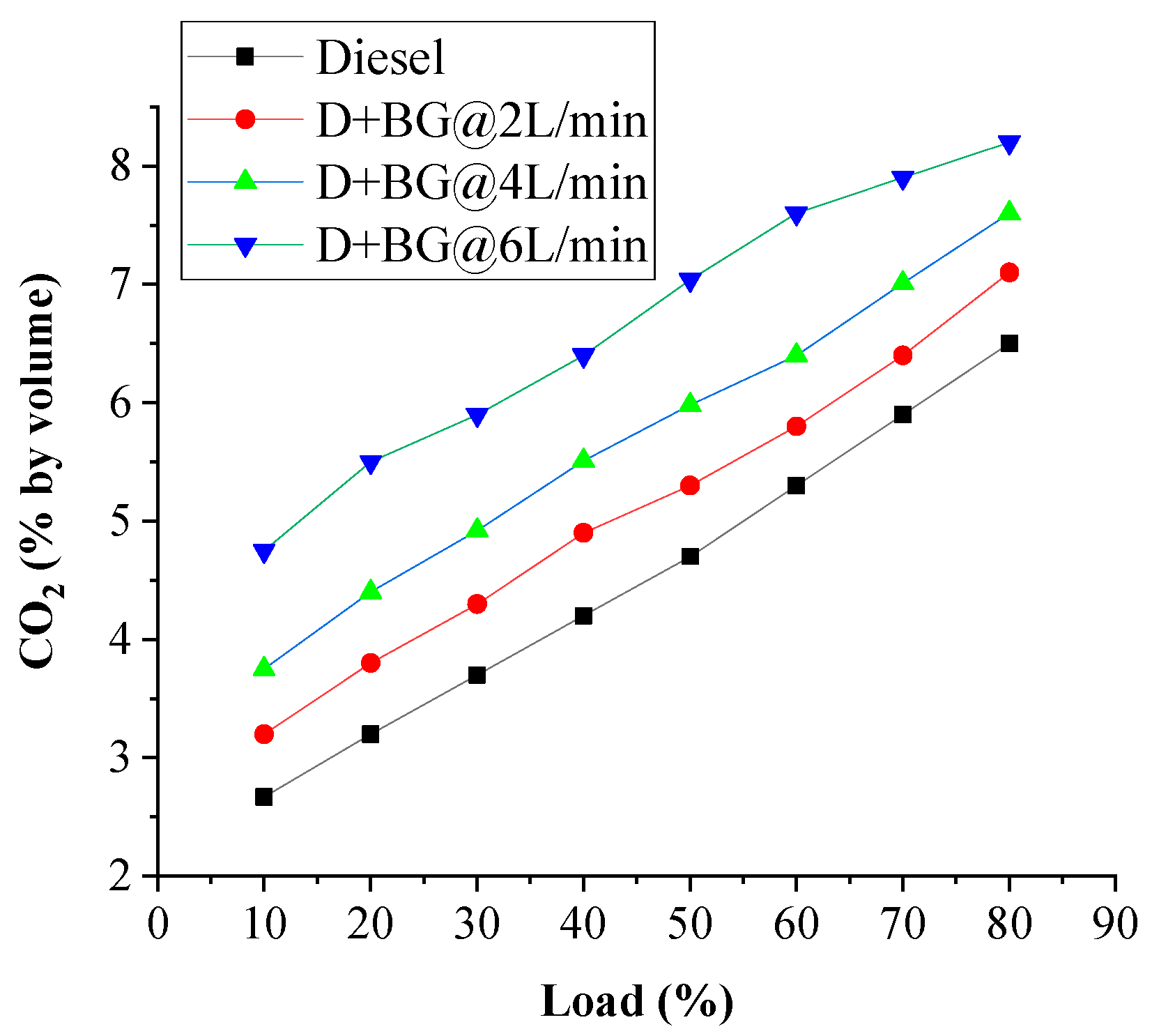

- Emissions of Carbon Dioxide

- c

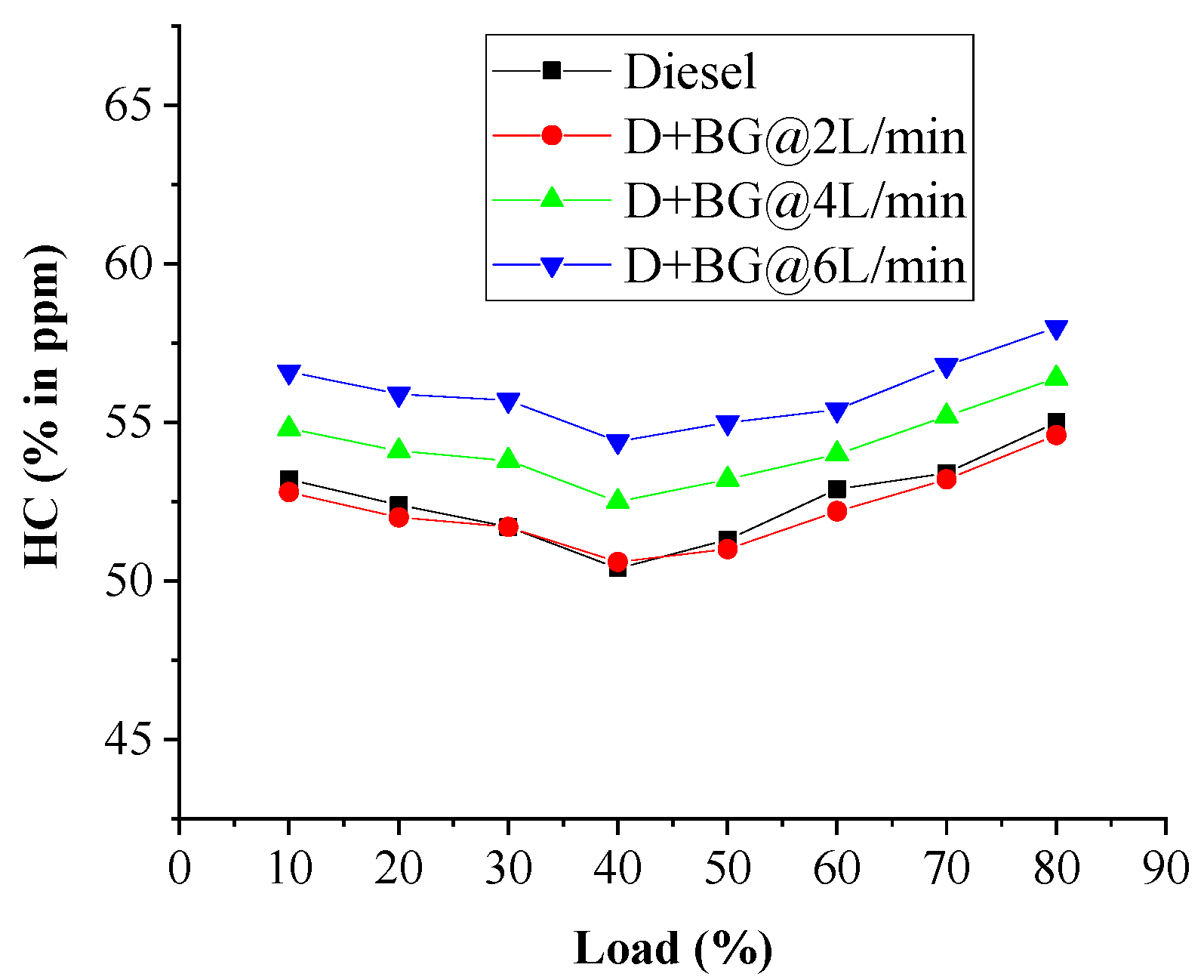

- Exhaust Emissions of Hydrocarbons

- d

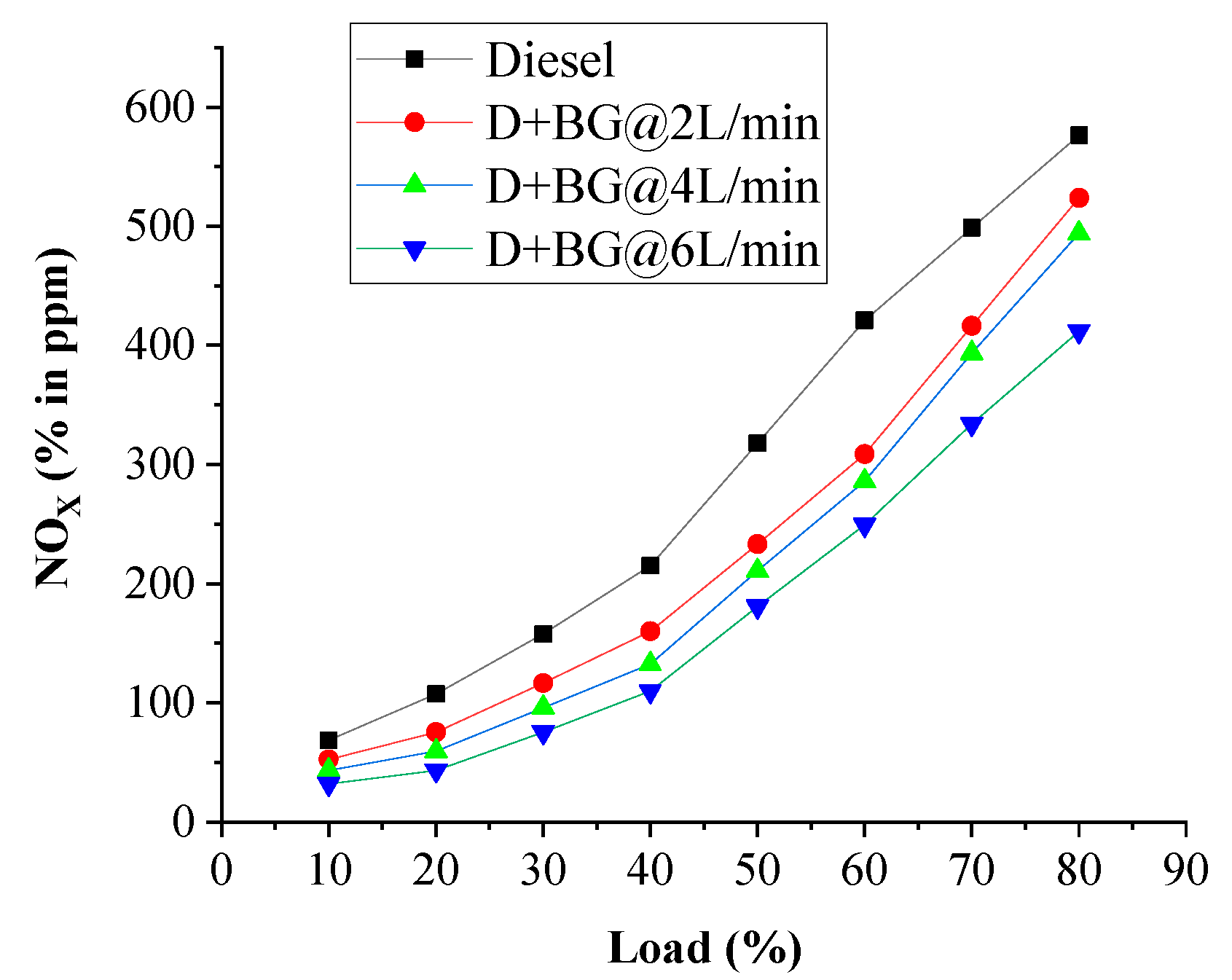

- Nitrogen Oxide Exhaust Emissions (ppm Vol.)

5. Conclusions

- ✓

- There is an increase in average biogas energy share of 24.98 to 52.32% and diesel fuel replacement ratio of 13.41 to 23.29%.

- ✓

- Relatively reduction in BTE from 11.19 to 25.72%, and an increment of BSFC from 11.81 to 20.87%.

- ✓

- Increment in emissions like CO by 1.05 to 21.40%, CO2 by 12.8 to 47.33%.

- ✓

- Reduction of HC by 0.52% at 2 L/min flow rate and increments by 3.26 and 6.54% at four and six L/min flow rates, respectively.

- ✓

- There is a reduction in NOx emission from 19.91 to 39.16%, respectively.

- i.

- Purification of biogas: Biogas must be purified before it can be used as a fuel in internal combustion engines. As a result, only methane is combustible among the various components of biogas. Because raw biogas contains less methane and a high amount of incombustible gas such as carbon dioxide, the in-cylinder temperature drops, allowing incomplete combustion to occur. Purified biogas, on the other hand, contains more than 90% methane content. As a result, when compared to diesel fuel, the use of purified biogas in CI engines results in improved performance and lower emissions.

- ii.

- Venturi mixer optimization: Even if the CI engine is supplied with purified biogas, a poorly mixed air–biogas mixture has a negative impact on performance and emission characteristics. All of the parameters of the venturi air-biogas mixer should be optimized using ANSYS fluent to achieve better mixing quality and, as a result, a more homogeneous air–biogas mixture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ambarita, H. Performance and emission characteristics of a small diesel engine run in dual-fuel (diesel-biogas) mode. Case Stud. Therm. Eng. 2017, 10, 179–191. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K. Eco friendly biofuels for CI engine applications. In Advances in Eco-Fuels for a Sustainable Environment; Woodhead Publishing Series in Energy; Woodhead Publishing: Vellore, India, 2019; pp. 407–440. [Google Scholar] [CrossRef]

- Ayade, M.; Latey, A. performance and emission characteristics of biogas-petrol dual fuel in SI engine. IJMET 2016, 7, 45–54. Available online: http://iaeme.com/Home/article_id/IJMET_07_02_006 (accessed on 10 July 2021).

- Barik, D.; Murugan, S. Investigation of combustion performance and emission characteristics of a DI diesel engine fueled with biogas-diesel in dual fuel mode. Energy 2014, 72, 760–771. [Google Scholar] [CrossRef]

- Bharathiraja, B.; Sudharsana, T.; Jayamuthunagai, J.; Praveenkumar, R.; Chozhavendhan, S.; Iyyappan, J. Biogas production—A review on composition, fuel properties, feedstock and principles of anaerobic digestion. Renew. Sustain. Energy Rev. 2018, 90, 570–582. [Google Scholar] [CrossRef]

- Bhuimbar, S.; Kumarappa, S. Engine Performance and Emission Characteristics of a Single Cylinder Four Stroke CI Engine on Dual Fuel Mode by Using Compressed Biogas as a Fuel. Int. J. Res. Appl. Sci. Eng. Technol. 2015, 3, 376–382. Available online: https://www.ijraset.com/fileserve.php?FID=3277 (accessed on 10 July 2021).

- Bouguessa, R.; Tarabet, L.; Loubar, K.; Belmrabet, T.; Tazerout, M. Experimental investigation on biogas enrichment with hydrogen for improving the combustion in diesel engine operating under dual fuel mode. Int. J. Hydrogy Energy 2020, 45, 9052–9063. [Google Scholar] [CrossRef]

- Deheri, C.; Acharya, K.; Thatoi, N.; Mohanty, P. A review on the performance of biogas and hydrogen on diesel engine in dual fuel mode. Fuel 2020, 260, 116337. [Google Scholar] [CrossRef]

- Gurung, D.; Rajvanshi, A.; Lalhriatpuia, S. Performance Analysis of Combined Biogas-Diesel Run Dual-Fuel Engine. Adv. Smart Grid Renew. Energy 2018, 435, 559–566. [Google Scholar] [CrossRef]

- Husen, I.; Maschal, M. Methane Gas Emission and its Management Practices from Solid Waste Stream, Case Study: Addis Ababa and its Surrounding Oromia Special Zone Towns. Environ. Pollut. Clim. Chang. 2018, 2, 10–4172. [Google Scholar] [CrossRef]

- Jagadish, C.; Gumtapure, V. Experimental investigation of methane-enriched biogas in a single-cylinder diesel engine by the dual-fuel mode. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 1–14. [Google Scholar] [CrossRef]

- Kamp, M.; Forn, B. Ethiopia’s emerging domestic biogas sector: Current status, bottlenecks, and drivers. Renew. Sustain. Energy Rev. 2016, 60, 475–488. [Google Scholar] [CrossRef] [Green Version]

- Karim, Z.A.; Sulaiman, S.A. Alternative Fuels for Compression Ignition Engines; Springer: Singapore, 2018; Available online: https://www.springer.com/gp/book/9789811077531 (accessed on 20 July 2021).

- Mustafi, N.; Agarwal, A. Biogas for Transport Sector: Current Status, Barriers, and Path Forward for Large-Scale Adaptation. In Energy, Environment, and Sustainability; Springer: Singapore, 2020; pp. 229–272. [Google Scholar] [CrossRef]

- Mustafi, N.; Agarwal, A. Combustion and Emission Characteristics and Emission Control of CNG Fueled Vehicles. In Energy, Environment, and Sustainability; Springer: Singapore, 2020; pp. 201–228. [Google Scholar] [CrossRef]

- Singh, H.N.; Layek, A. Experimental Study of the Effect of Compression Ratio on the Characteristics of a Biogas Fueled Dual Fuel Compression Ignition Engine. Int. J. Renew. Energy Res. 2018, 8, 2075–2084. [Google Scholar]

- Prajapati, K.; Randa, R.; Parmar, N. Experimental Study on Utilization of Biogas in IC Engine. Int. J. Eng. Sci. Res. Technol. 2015, 4, 827–835. Available online: http://www.ijesrt.com/issues/August-2015/121.pdf (accessed on 20 July 2021).

- Rosha, P.; Dhir, A.; Mohapatra, S. Influence of gaseous fuel induction on the various engine characteristics of a dual fuel compression ignition engine: A review. Renew. Sustain. Energy Rev. 2018, 82, 3333–3349. [Google Scholar] [CrossRef]

- Salve, D.; Kolekar, H.; Jadhav, M. Experimental Evaluation of Dual Fuel CI Engine Using Synthesized Biogas. IERJ 2016, 2, 1223–1229. Available online: http://www.ierjournal.org/pupload/mit/EE1-1.pdf (accessed on 20 July 2021).

- Sandalc, T.; Isın, O.; Galata, S.; Karagoz, Y.; Guler, I. Effect of hythane enrichment on performance, emission and combustion characteristics of an CI engine. Hydrog. Energy 2019, 44, 3208–3220. [Google Scholar] [CrossRef]

- Singh, A.; Agarwal, R.A.; Agarwal, A.K.; Dhar, A.; Shukla, M.K. Prospects of Alternative Transportation Fuels; Springer: Uttar Pradesh, India, 2018; Available online: https://www.amazon.com/Prospects-Alternative-Transportation-Environment-Sustainability-ebook/dp/B077GB4G5P (accessed on 20 July 2021).

- Singh, P.; Mustafi, N.; Sharma, Y. Introduction to Alternative Fuels and Their Utilization Strategies in Internal Combustion Engines. In Energy, Environment, and Sustainability; Springer: Singapore, 2020; pp. 3–6. [Google Scholar] [CrossRef]

- Solomon, S.; Sindibu, T.; Ermias, D. Biogas and Bio-fertilizer Production Potential of Abattoir Waste as Means of Sustainable Waste Management Option in Hawassa City, Southern Ethiopia. J. Appl. Sci. Environ. Manag. 2018, 22, 553–559. [Google Scholar] [CrossRef]

- Turco, M.; Ausiello, A.; Micoli, L. Treatment of Biogas for Feeding High-Temperature Fuel Cells: Removal of Harmful Compounds by Adsorption Processes; Springer: Naples, Italy, 2016; Available online: https://link.springer.com/content/pdf/10.1007%2F978-3-319-03215-3.pdf (accessed on 15 July 2021).

- Vanga, B.; Minhtu, B. Soot Emission Analysis in Combustion of Biogas Diesel Dual Fuel Engine. Environ. Sci. Sustain. Dev. 2019, 1, 67–79. Available online: https://creativecommons.org/licenses/by/4.0/ (accessed on 15 July 2021).

- Wei, L.; Geng, P. A review on natural gas/diesel dual-fuel combustion, emissions, and performance. Fuel Process. Technol. 2016, 142, 264–278. [Google Scholar] [CrossRef]

- Yonas, B.; Olav, L.; Ajebu, N.; Ayana, A.; Aune, B. Methane Emissions from Ruminant Livestock in Ethiopia: Promising Forage Species to Reduce CH4 Emissions. Agriculture 2019, 9, 130. [Google Scholar] [CrossRef] [Green Version]

- Yoon, H.; Lee, C. Experimental investigation on the combustion and exhaust emission characteristics of biogas–biodiesel dual-fuel combustion in a CI engine. Fuel Processing Technol. 2011, 92, 992–1000. [Google Scholar] [CrossRef]

| Contents | Percentage (% by Vol.) |

|---|---|

| CH4 | 44.5 |

| CO2 | 10.7 |

| O2 | 8.7 |

| H2O | 0 |

| Traces gases | 36.1 |

| Properties | Diesel | Biogas |

|---|---|---|

| Lower heating value (MJ/kg) | 42 | 20.3958 * |

| Density (kg/m3) | 840 | 1.12 * |

| Auto ignition temperature (°C) | 280 | 650 |

| Stoichiometric air-fuel ratio | 14.60 | 17 |

| Cetane number | 49 | - |

| Octane number | - | 130 |

| Laminar burning velocity (m/s) | 0.5 | 0.2 |

| Device | Measuring Ranges | Resolution | Accuracy | Relative Errors (%) |

|---|---|---|---|---|

| Rotameter | 0–50 L/min | ±0.1 L/min | ±5 L/min | ±1 |

| Mode of Operation | Engine Operating Parameters | Evaluating Engine Parameters | |

|---|---|---|---|

| Fixed CR, IP, and IT | Load | ||

| Diesel fuel mode | Set fixed as factories recommender | 0% |

|

| 10% | |||

| 20% | |||

| 30% | |||

| 40% | |||

| 50% | |||

| 60% | |||

| 70% | |||

| 80% | |||

| Mode of Operation | Engine Operating Parameters | Biogas Flow Rate | Evaluating Engine Parameters | |

|---|---|---|---|---|

| Fixed CR, IP, and IT | Load | |||

| Dual fuel mode$(Diesel-Biogas) | Set fixed as factories recommender | 0% | 2 L/min, 4 L/min, 6 L/min |

|

| 10% | 2 L/min, 4 L/min, 6 L/min | |||

| 20% | 2 L/min, 4 L/min, 6 L/min | |||

| 30% | 2 L/min, 4 L/min, 6 L/min | |||

| 40% | 2 L/min, 4 L/min, 6 L/min | |||

| 50% | 2 L/min, 4 L/min, 6 L/min | |||

| 60% | 2 L/min, 4 L/min, 6 L/min | |||

| 70% | 2 L/min, 4 L/min, 6 L/min | |||

| 80% | 2 L/min, 4 L/min, 6 L/min | |||

| Engine model | TBMC3-02 |

| Type of engine | Compression ignition |

| Fuel | Diesel |

| Number of cylinders | 1 |

| Type of air intake | Naturally aspirated |

| Cooling type | Air |

| Compression ratio, CR | 21:1 |

| Bore and Stroke diameter | 69 mm by 60 mm |

| No. of stroke | 4 stroke |

| Torque | 7.4 N.m |

| Engine power | 2.2 kW |

| Air inlet diameter (D) | 36 mm |

| Species | Measurement Range | Resolution | Allowed Error | Relative Error |

|---|---|---|---|---|

| HC | 0–1000 ppm | 1 ppm | ±12 ppm | ±5% |

| CO | 0–10.0 in % Vol. | 0.01% | ±0.06% | ±5% |

| CO2 | 0–20.0 in % Vol. | 0.1% | ±0.5% | ±5% |

| NOx | 0–800 ppm | 1 ppm | ±10 ppm | ±5 |

| Mode of Operation | Load (%) | BGES (%) | ||

|---|---|---|---|---|

| Dual-mode Diesel + Biogas at 2 L/min flow rate | 0 | 0.0995 | 0.1344 | 39.6 |

| 20 | 0.146 | 0.1344 | 30.88 | |

| 40 | 0.195 | 0.1344 | 25.07 | |

| 60 | 0.251 | 0.1344 | 20.63 | |

| 80 | 0.328 | 0.1344 | 16.59 | |

| Dual-mode Diesel + Biogas at 4 L/min flow rate | 0 | 0.0897 | 0.2688 | 59.26 |

| 20 | 0.137 | 0.2688 | 48.78 | |

| 40 | 0.185 | 0.2688 | 41.36 | |

| 60 | 0.235 | 0.2688 | 35.70 | |

| 80 | 0.314 | 0.2688 | 29.35 | |

| Dual-mode Diesel + Biogas at 6 L/min flow rate | 0 | 0.084 | 0.4032 | 70.08 |

| 20 | 0.129 | 0.4032 | 60.25 | |

| 40 | 0.175 | 0.4032 | 52.86 | |

| 60 | 0.215 | 0.4032 | 47.69 | |

| 80 | 0.306 | 0.4032 | 39.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leykun, M.G.; Mekonen, M.W. Investigation of the Performance and Emission Characteristics of Diesel Engine Fueled with Biogas-Diesel Dual Fuel. Fuels 2022, 3, 15-30. https://doi.org/10.3390/fuels3010002

Leykun MG, Mekonen MW. Investigation of the Performance and Emission Characteristics of Diesel Engine Fueled with Biogas-Diesel Dual Fuel. Fuels. 2022; 3(1):15-30. https://doi.org/10.3390/fuels3010002

Chicago/Turabian StyleLeykun, Melkamu Genet, and Menelik Walle Mekonen. 2022. "Investigation of the Performance and Emission Characteristics of Diesel Engine Fueled with Biogas-Diesel Dual Fuel" Fuels 3, no. 1: 15-30. https://doi.org/10.3390/fuels3010002

APA StyleLeykun, M. G., & Mekonen, M. W. (2022). Investigation of the Performance and Emission Characteristics of Diesel Engine Fueled with Biogas-Diesel Dual Fuel. Fuels, 3(1), 15-30. https://doi.org/10.3390/fuels3010002