Evaluation of Standard Electrical Bonding Strategies for the Hybrid Integration of Inkjet-Printed Electronics

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Sample Characterization before Connecting

3.2. Sample Characterization after Connecting

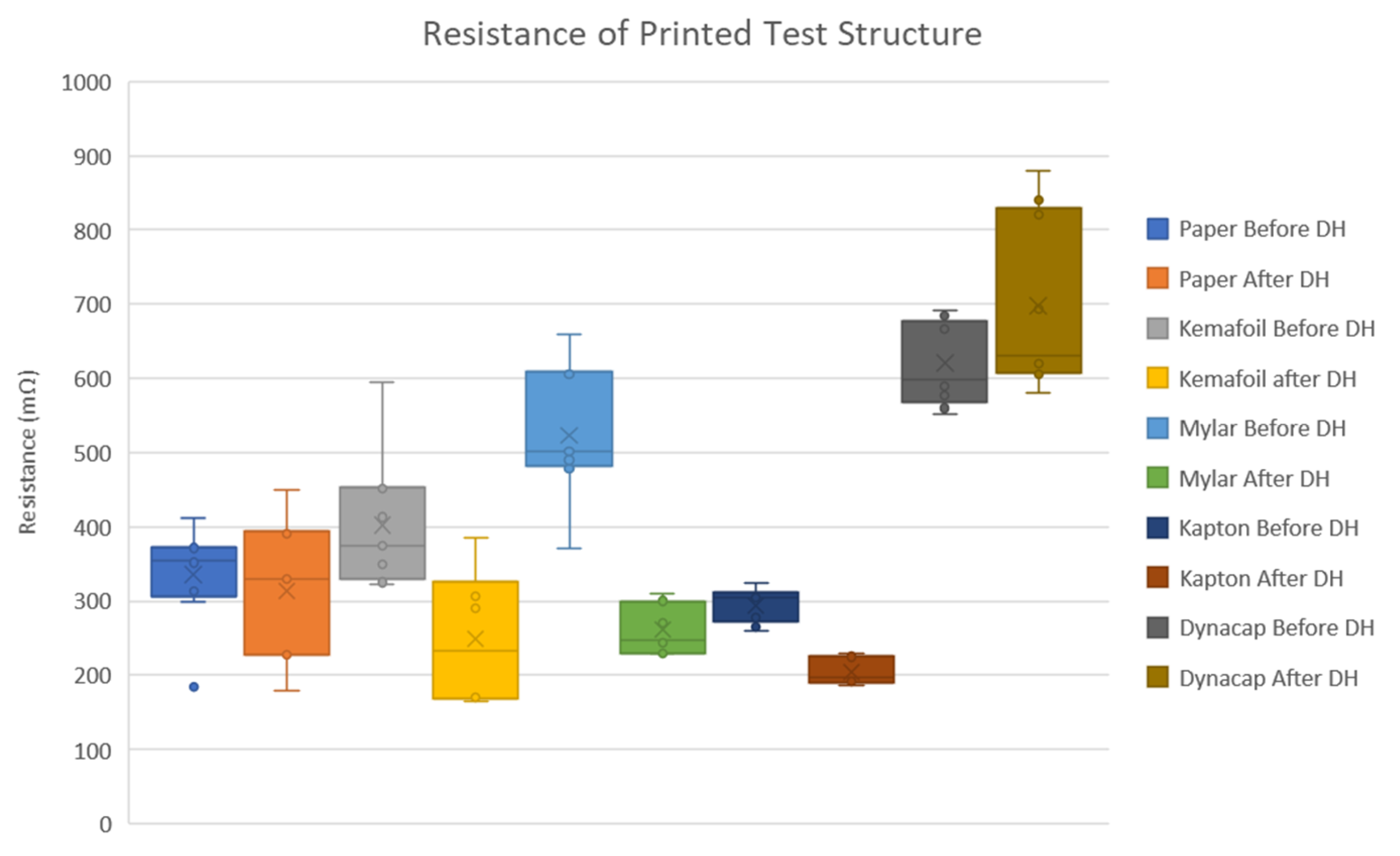

3.3. Sample Characterization after Damp-Heat Testing

3.4. Tensile Testing

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Beedasy, V.; Smith, P.J. Printed electronics as prepared by inkjet printing. Materials 2020, 13, 704. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chang, J.S.; Facchetti, A.F.; Reuss, R. A circuits and systems perspective of organic/printed electronics: Review, challenges, and contemporary and emerging design approaches. Eee J. Emerg. Sel. Top. Circuits Syst. 2017, 7, 7–26. [Google Scholar] [CrossRef]

- Mohammed, M.G.; Kramer, R. All-printed flexible and stretchable electronics. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef]

- Nag, A.; Mukhopadhyay, S.C.; Kosel, J. Wearable flexible sensors: A review. IEEE Sens. J. 2017, 17, 3949–3960. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Liu, M.; Bai, Y.; Zhang, J.; Liu, H.; Zhu, W. Recent progress in flexiblewearable sensors for vital sign monitoring. Sensors 2020, 20, 4009. [Google Scholar] [CrossRef] [PubMed]

- Sekine, T.; Sugano, R.; Tashiro, T.; Sato, J.; Takeda, Y.; Matsui, H.; Kumaki, D.; Santos, F.D.D.; Miyabo, A.; Tokito, S. Fully printed wearable vital sensor for human pulse rate monitoring using ferroelectric polymer. Sci. Rep. 2018, 8, 4442. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.; Ali, S.; Bermak, A. Recent developments in printing flexible and wearable sensing electronics for healthcare applications. Sensors 2019, 19, 1230. [Google Scholar] [CrossRef] [Green Version]

- Ali, S.; Khan, S.; Bermak, A. All-printed human activity monitoring and energy harvesting device for internet of thing applications. Sensors 2019, 19, 1197. [Google Scholar] [CrossRef] [Green Version]

- Agarwala, S.; Yeong, W.Y. Aerosol jet fabricated biodegradable antenna for bioelectronics application. In Proceedings of the Additive Manufacturing Meets Medicine, Lübeck, Germany, 12–13 September 2019. [Google Scholar]

- Khaleel, H.R. Design and fabrication of compact inkjet printed antennas for integration within flexible and wearable electronics. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 1722–1728. [Google Scholar] [CrossRef]

- Guo, L.G.; Jiaheng, M.; Kwee, L.F.C.; Agarwala, S.; Wai, Y.Y.; Zhang, Y.P. Inkjet-printed patch antenna emitter for wireless communication application. Virtual Phys. Prototyp. 2016, 11, 289–294. [Google Scholar]

- Krivec, M.; Stockinger, T.; Zikulnig, J.; Eibensteiner, F.; Müller, U. Printed 2D proton sensor for in-situ measurement in glue lines. Proceedings 2018, 2, 990. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Chiesura, G.; Vervust, T.; Bossuyt, F.; Luyckx, G.; Degriek, J.; Vanfleteren, J. Design and fabrication of a flexible dielectric sensor system for in situ and real-time production monitoring of glass fibre reinforced composites. Sens. Actuators A: Phys. 2016, 243, 103–110. [Google Scholar] [CrossRef]

- Zymelka, D.; Togashi, K.; Kobayashi, T. Concentric array of printed strain sensors for structural health monitoring. Sensors 2020, 20, 1997. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Anderson, N.; Bland, S.; Nutt, S.; Jursich, G.; Joshi, S. All-printed strain sensors: Building blocks of the aircraft structural health monitoring system. Sens. Actuators A: Phys. 2017, 253, 165–172. [Google Scholar] [CrossRef] [Green Version]

- Rausch, J.; Salun, L.; Griesheimer, S.; Ibis, M.; Werthschützky, R. Printed resistive strain sensors for monitoring of light-weight structures. In Proceedings of the Smart Sensor Phenomena, Technology, Networks, and Systems, San Diego, CA, USA, 15 April 2011; Volume 7982. [Google Scholar]

- Sowade, E.; Ramon, E.; Mitra, K.Y.; Martínez-Domingo, C.; Pedró, M.; Pallarès, J.; Loffredo, F.; Villani, F.; Gomes, H.L.; Terés, L.; et al. All-inkjet-printed thin-film transistors: Manufacturing process reliability by root cause analysis. Sci. Rep. 2016, 6, 33490. [Google Scholar] [CrossRef]

- Gu, Y.; Park, D.; Gonya, S.; Jendrisak, J.; Das, S.; Hines, D.R. Direct-write printed broadband inductors. Addit. Manuf. 2019, 30. [Google Scholar] [CrossRef]

- Correia, V.; Mitra, K.Y.; Rocha, J.G.; Sowade, E.; Baumann, R.R.; Lanceros-Mendez, S. Design and fabrication of multilayer inkjet-printed passive components for printed electronics circuit development. J. Manuf. Process. 2017, 31, 364–371. [Google Scholar] [CrossRef]

- Huber, B.A.; Popp, P.; Kaiser, M.; Ruediger, A.; Schindler, C. Fully inkjet printed flexible resistive memory. Appl. Phys. Lett. 2017. [CrossRef]

- Pang, Y.; Cao, Y.; Chu, Y.; Liu, M.; Snyder, K.; MacKenzie, D.; Cao, C. Additive manufacturing of batteries. Adv. Funct. Mater. 2019, 30. [Google Scholar] [CrossRef]

- Subramanian, V.; Chang, J.B.; Vornbrock, A.d.; Huang, D.C.; Jagannathan, L.; Liao, F.; Mattis, B.; Molesa, S.; Redinger, D.R.; Soltman, D.; et al. Printed electronics for low-cost electronic systems: Technology status and application development. In Proceedings of the ESSCIRC 2008—34th European Solid-State Circuits Conference, Edinburgh, UK, 15–19 September 2008. [Google Scholar]

- Khan, Y.; Thielens, A.; Muin, S.; Ting, J.; Baumbauer, C.; Arias, A.C. A new frontier of printed electronics: Flexible hybrid electronics. Adv. Mater. 2019. [CrossRef]

- Serpelloni, M.; Cantù, E.; Borghetti, M.; Sardini, E. Printed smart devices on cellulose-based materials by means of aerosol-jet printing and photonic curing. Sensors 2020, 20, 841. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Muhaisin, M.M.; Khan, R.A.; Telfort, J.; Heger, W.; Roberts, G.W. Opportunities and challenges in desktop-inkjet based flexible hybrid electronics. In Proceedings of the 2019 IEEE 62nd International Midwest Symposium on Circuits and Systems (MWSCAS), Dallas, TX, USA, 4–7 August 2019. [Google Scholar]

- Nilsson, H.-E.; Unander, T.; Sidén, J.; Andersson, H.; Manuilskiy, A.; Hummelgård, M.; Gulliksson, M. System Integration of Electronic Functions in Smart Packaging Applications. IEEE Trans. Compon. Packag. Manuf. Technol. 2012, 2, 1723–1734. [Google Scholar] [CrossRef]

- Roscher, F.; Thalheim, R.; Seifert, T.; Paul, S.-D.; Zichner, R.; Wiemer, M.; Otto, T. Joining two worlds—Hybrid integration of silicon based electronics and printed functionalities. In Proceedings of the Smart Systems Integration; 13th International Conference and Exhibition on Integration Issues of Miniaturized Systems, Barcelona, Spain, 10–11 April 2019. [Google Scholar]

- Kim, C.; Espalin, D.; Liang, M.; Xin, H.; Cuaron, A.; Varela, I.; Macdonald, E.; Wicker, R.B. 3D printed electronics with high performance. Multi-Layer. Electr. Interconnect IEEE Access 2017, 5, 25286–25294. [Google Scholar]

- Faller, L.-M.; Zikulnig, J.; Krivec, M.; Roshanghias, A.; Abram, A.; Zangl, H. Hybrid printing for the fabrication of smart sensors. J. Vis. Exp. 2019. [CrossRef]

- Faller, L.-M.; Lenzhofer, M.; Hirschl, C.; Kraft, M.; Zangl, H. Characterization of a robust 3D- and inkjet-printed capacitive position sensor for a spectrometer application. Sensors 2019, 19, 443. [Google Scholar] [CrossRef] [Green Version]

- Goh, G.L.; Agarwala, S.; Goh, G.D.; Tan, H.K.J.; Zhao, L.; Chuah, T.K.; Yeong, W.Y. Additively manufactured multi-material free-form structure with printed electronics. Int. J. Adv. Manuf. Technol. 2017, 94, 1309–1316. [Google Scholar] [CrossRef]

- DeGraff, J.; Liang, R.; Le, M.Q.; Capsal, J.-F.; Ganet, F.; Cottinet, P.-J. Printable low-cost and flexible carbon nanotube buckypaper. Mater. Des. 2017, 133, 47–53. [Google Scholar] [CrossRef]

- Rajala, S.; Tuukkanen, S.; Halttunen, J. Characteristics of piezoelectric polymer film sensors with solution-processable graphene-based electrode materials. IEEE Sens. J. 2015, 15. [Google Scholar] [CrossRef]

- Baptist, J.R.; Zhang, R.; Wei, D.; Saadatzi, M.N.; Popa, D.O. Fabrication of strain gauge based sensors for tactile skins. In Proceedings of the Smart Biomedical and Physiological Sensor Technology XIV, Anaheim, CA, USA, 22 May 2017; Volume 10216. [Google Scholar]

- Dimitrov, M.; Pelz, P.F.; Lyashenko, A.; Tehrani, A.H.; Dörsam, E. Measurement system by printed thin pressure sensor array. In Proceedings of the 9th International Fluid Power Conference, Aachen, Germany, 24–26 March 2014; Volume 3. [Google Scholar]

- Li, X.; Andersson, H.; Sidén, J.; Schön, T. Soldering surface mount components on screen printed Ag patterns on paper and Polyimide substrates for hybrid printed electronics. Flex. Print. Electron. 2018, 3. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, R.; Moon, K.; Liu, Y.; Hansen, K.; Le, T.; Wong, C.P. Highly conductive, flexible, polyurethane-based adhesives for flexible and printed electronics. Adv. Funct. Mater. 2012. [Google Scholar] [CrossRef]

- Wu, H.; Cheng, Y.; Liu, J.; Cui, X.; Xie, B.; Zhang, Z. A highly conductive thermoplastic electrically conductive adhesive for flexible and low cost electronics. In Proceedings of the 15th International Conference on Electronic Packaging Technology, Chengdu, China, 12–15 August 2014. [Google Scholar]

- Siegel, A.C.; Phillips, S.T.; Dickey, M.D.; Lu, N.; Suo, Z.; Whitesides, G.M. Foldable printed circuit boards on paper substrates. Adv. Funct. Mater. 2010. [Google Scholar] [CrossRef]

- Andersson, H.; Andres, B.; Manuilskiy, A.; Forsberg, S.; Hummelgard, M.; Bäckström, J.; Zhang, R.; Olin, H. Contacting paper-based supercapacitors to printed electronics on paper substrates. Nord. Pulp Pap. Res. J. 2018, 27, 476–480. [Google Scholar] [CrossRef] [Green Version]

- Perelaer, J.; Schubert, U.S. Inkjet printing of interconnects and contacts based on inorganic nanoparticles for printed electronics applications. In Inkjet-Based Micromanufacturing; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2012; pp. 347–364. [Google Scholar]

- Gordon, R. Electrically Conductive Adhesives 2016–2026; IDTechEx: London, UK, 1 April 2016; Available online: https://www.idtechex.com/research/reports/electrically-conductive-adhesives-2016-2026-000469.asp (accessed on 28 May 2018).

- Mattana, G.; Briand, D. Recent advances in printed sensors on foil. Mater. Today 2016, 19, 88–99. [Google Scholar] [CrossRef]

- Dankoco, M.D.; Tesfay, G.Y.; Benevent, E.; Bendahan, M. Temperature sensor realized by inkjet printing process on flexible substrate. Mater. Sci. Eng. B 2015. [Google Scholar] [CrossRef]

- Zikulnig, J.; Hirschl, C.; Rauter, L.; Krivec, M.; Lammer, H.; Riemelmoser, F.; Roshanghias, A. Inkjet printing and characterisation of a resistive temperature sensor on paper substrate. Flex. Print. Electron. 2019, 4. [Google Scholar] [CrossRef]

- Sung, K.-H.; Park, J.; Kang, H. Multi-layer inkjet printing of Ag nanoparticle inks andits sintering with a near-infrared system. Int. J. Precis. Eng. Manuf. 2018, 19, 303–307. [Google Scholar] [CrossRef]

- Huttunen, O.-H.; Happonen, T.; Hiitola-Keinänen, J.; Korhonen, P.; Ollila, J.; Hiltunen, J. Roll-To-Roll screen-printed silver conductors on a polydimethyl siloxane substrate for stretchable electronics. Ind. Eng. Chem. Res. 2019, 58, 19909–19916. [Google Scholar] [CrossRef]

- Rasul, J.S. Chip on paper technology utilizing anisotropically conductive adhesive for smart label applications. Microelectron. Reliab. 2004, 44, 135–140. [Google Scholar] [CrossRef]

- Andersson, H.A.; Manuilskiy, A.; Haller, S.; Hummelgard, M.; Sidén, J.; Hummelgard, C.; Olin, H.; Nilsson, H.-E. Assembling surface mounted components on ink-jet printed double sided paper circuit board. Nanotechnology 2014, 25. [Google Scholar] [CrossRef]

- Li, X.; Sidén, J.; Andersson, H.; Sawatdee, A.; Öhman, R.; Eriksson, J.; Genchel, T. Enabling paper-based flexible circuits with aluminium and copper conductors. Flex. Print. Electron. 2019, 4. [Google Scholar] [CrossRef]

- Zhu, J.; Koehl, M.; Hoffmann, S.; Berger, K.A.; Zamini, S.; Bennett, I.; Gerritsen, E.; Malbranche, P.; Pugliatti, P.; di Stefano, A.; et al. Changes of solar cell parameters during damp-heat exposure. Prog. Photovolt. 2016, 24, 1346–1358. [Google Scholar] [CrossRef] [Green Version]

- Faye, I.; Ndiaye, A.; Gecke, R.; Blieske, U.; Kobor, D.; Camara, M. Experimental study of observed defects in mini-modules based on crystalline silicone solar cell under damp heat and thermal cycle testing. Sol. Energy 2019, 191, 161–166. [Google Scholar] [CrossRef]

- Jagt, J.C. Reliability of electrically conductive adhesive joints for surface mount applications: A summary of the state of the art. IEEE Trans. Compon. Packag. Manuf. Technol. Part A 1998, 21, 215–225. [Google Scholar] [CrossRef] [Green Version]

- Ivanov, V.; Boehme, B.; Wolter, K.-J. Resistance of conductive adhesive joints on non-noble surface finishes. In Proceedings of the 35th International Spring Seminar on Electronics Technology, Bad Aussee, Austria, 9–13 May 2012. [Google Scholar]

- Neff, C.; Eston, E.; Schrand, A. Interconnections for additively manufactured hybridized printed electronics in harsh environments. Designs 2020, 4, 14. [Google Scholar] [CrossRef]

- Lee, S.H.; Cho, Y.J. Characterization of silver inkjet overlap-printing through cohesion and adhesion. J. Electr. Eng. Technol. 2012, 7, 91–96. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.H.; Shin, K.Y.; Hwang, J.Y.; Kang, K.T.; Kang, H.S. Silver inkjet printing with control of surface energy and substrate temperature. J. Micromech. Microeng. 2008, 18. [Google Scholar] [CrossRef]

- Öhlund, T.; Örtegren, J.; Forsberg, S.; Nilsson, H.-E. Paper surfaces for metal nanoparticle inkjet printing. Appl. Surf. Sci. 2012, 259, 731–739. [Google Scholar] [CrossRef]

- Jellesen, M.S.; Verdingovas, V.; Conseil, H.; Piotrowska, K.; Ambat, R. Corrosion in electronics: Overview of failures and countermeasures. In Proceedings of the European Corrosion Congress, Pisa, Italy, 11 September 2014. [Google Scholar]

- Puechagut, C.; Laügt, A.-M.; Guéné, E.; Anisko, R. Solder paste residue corrosivity assessment: Bono test. In Proceedings of the 2015 European Microelectronics Packaging Conference (EMPC), Friedrichshafen, Germany, 14–16 September 2015; pp. 1–7. [Google Scholar]

- Bollström, R.; Pettersson, F.; Dolietis, P.; Preston, J.; Österbacka, R.; Toivakka, M. Impact of humidity on functionality of on-paper printed electronics. Nanotechnology 2014, 25. [Google Scholar] [CrossRef]

- Andersson, H.; Manuilskiy, A.; Unander, T.; Lidenmark, C.; Forberg, S.; Nilsson, H.-E. Inkjet printed silver nanoparticle humidity sensor with memory effect on paper. IEEE Sens. J. 2012, 12, 1901–1905. [Google Scholar] [CrossRef]

- Andersson, H.; Manuilskiy, A.; Lindenmark, C.; Gao, J.; Öhlund, T.; Forsberg, S.; Örtegren, J.; Schmidt, W.; Nilsson, H.-E. The influence of paper coating content onroom temperature sintering of silvernanoparticle ink. Nanotechnology 2013, 24, 455203. [Google Scholar] [CrossRef]

- Tang, Y.; He, W.; Zhou, G.; Wang, S.; Yang, X.; Tao, Z.; Zhou, J. A new approach causing the patterns fabricated by silver nanoparticles to be conductive without sintering. Nanotechnology 2012, 23, 355304. [Google Scholar] [CrossRef] [PubMed]

- Zikulnig, J.; Roshanghias, A.; Rauter, L.; Hirschl, C. Evaluation of the sheet resistance of inkjet-printed ag-layers on flexible, uncoated paper substrates using van-der-pauw’s method. Sensors 2020, 20, 2398. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Substrate | Sintering Parameters |

|---|---|

| Type 4 paper (1) | Photonic curing with a sintering energy of 2.1 J/cm2 |

| Mylar PET (2) | Thermal sintering for 30 min at 130 °C |

| Kapton® (3) | Thermal sintering for 30 min at 150 °C |

| p_e:smart® (4) | Photonic curing with a sintering energy of 1 J/cm2 |

| Kemafoil® (5) | Thermal sintering for 30 min at 130 °C |

| Substrate | Avg. Resistance in mΩ | Std.Dev. in mΩ | Std.Dev. in % |

|---|---|---|---|

| Type 4 paper | 335 | 61 | 18 |

| Mylar® PET | 523 | 83 | 16 |

| Kapton® | 294 | 21 | 7 |

| p_e:smart® | 621 | 53 | 9 |

| Kemafoil® | 402 | 84 | 20 |

| Method | Sample Size | Avg. Thickness in mm | Std. Dev. in mm | Std. Dev. in % |

|---|---|---|---|---|

| Direct solder | 18 | 0.89 | 0.26 | 28.9 |

| Solder on pads | 30 | 0.66 | 0.23 | 34.6 |

| Adhesive bonding | 30 | 0.58 | 0.14 | 23.6 |

| Crimping | 5 | 1.14 | 0.11 | 10 |

| Substrate | Direct Solder | Solder on Pads | Adhesive Bonding | Crimp |

|---|---|---|---|---|

| Type 4 | ✓ | ✓ | ✓ | ✕ |

| Mylar® PET | ✕ | ✓ | ✓ | ~ |

| Kapton® | ✕ | ✓ | ✓ | ✕ |

| p_e:smart® | ✓ | ✓ | ✓ | ✕ |

| Kemafoil® | ~ | ✓ | ✓ | ~ |

| Substrate | Direct Solder | Solder on Pads | Adhesive Bonding | Crimp |

|---|---|---|---|---|

| Type 4 | ~ | ✕ | ✓ | excl. |

| Mylar® PET | ✕ | ✓ | ✓ | excl. |

| Kapton® | ✕ | ~ | ✓ | excl. |

| p_e:smart® | ✓ | ✓ | ✓ | excl. |

| Kemafoil® | ✕ | ~ | ✓ | excl. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rauter, L.; Zikulnig, J.; Sinani, T.; Zangl, H.; Faller, L.-M. Evaluation of Standard Electrical Bonding Strategies for the Hybrid Integration of Inkjet-Printed Electronics. Electron. Mater. 2020, 1, 2-16. https://doi.org/10.3390/electronicmat1010002

Rauter L, Zikulnig J, Sinani T, Zangl H, Faller L-M. Evaluation of Standard Electrical Bonding Strategies for the Hybrid Integration of Inkjet-Printed Electronics. Electronic Materials. 2020; 1(1):2-16. https://doi.org/10.3390/electronicmat1010002

Chicago/Turabian StyleRauter, Lukas, Johanna Zikulnig, Taulant Sinani, Hubert Zangl, and Lisa-Marie Faller. 2020. "Evaluation of Standard Electrical Bonding Strategies for the Hybrid Integration of Inkjet-Printed Electronics" Electronic Materials 1, no. 1: 2-16. https://doi.org/10.3390/electronicmat1010002

APA StyleRauter, L., Zikulnig, J., Sinani, T., Zangl, H., & Faller, L.-M. (2020). Evaluation of Standard Electrical Bonding Strategies for the Hybrid Integration of Inkjet-Printed Electronics. Electronic Materials, 1(1), 2-16. https://doi.org/10.3390/electronicmat1010002