Numerical Elucidation on the Dynamic Behaviour of Non-Premixed Flame in Meso-Scale Combustors

Abstract

1. Introduction

2. Numerical Method

2.1. Governing Equations

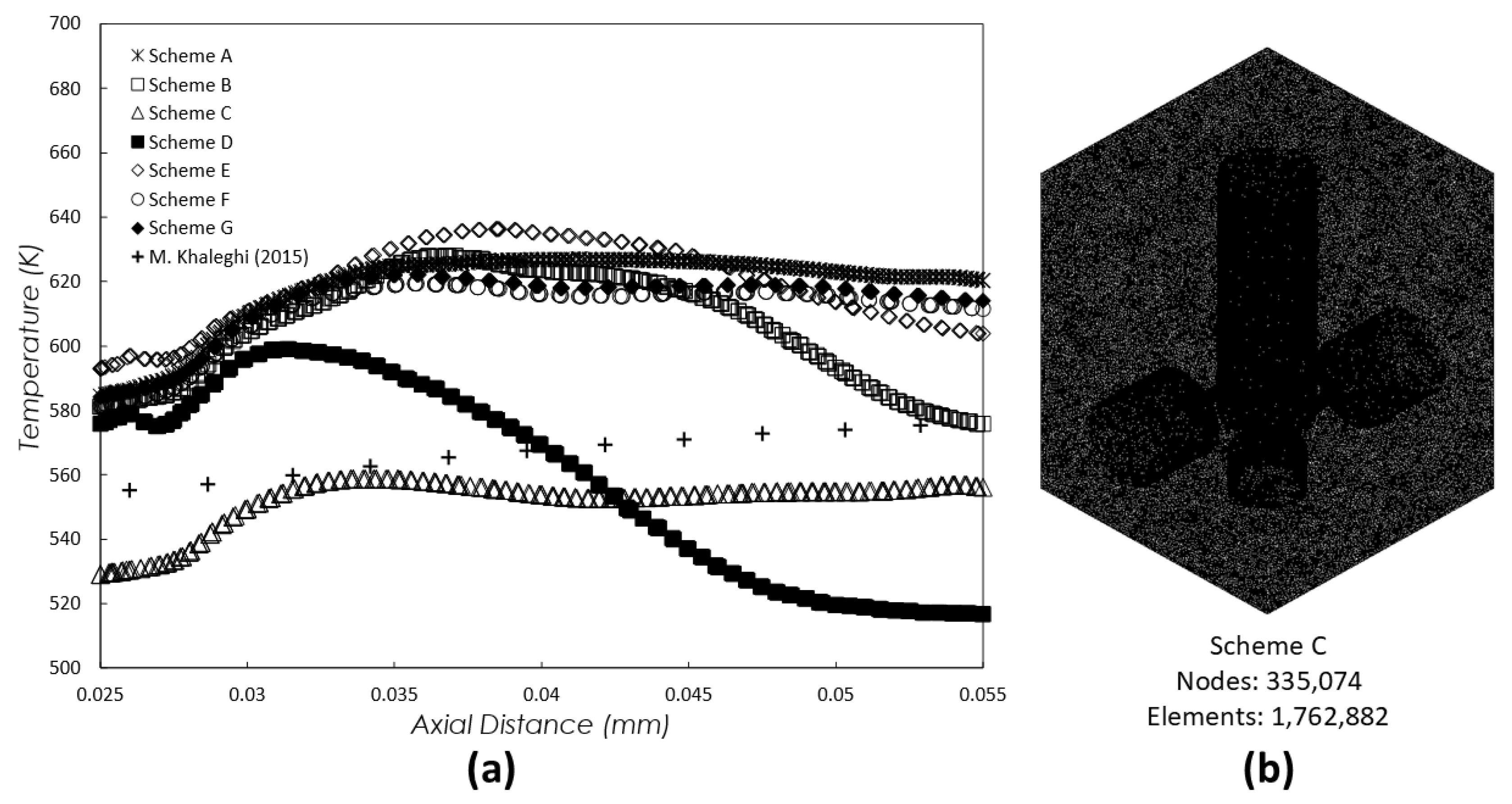

2.2. Computational Approach

3. Results and Discussion

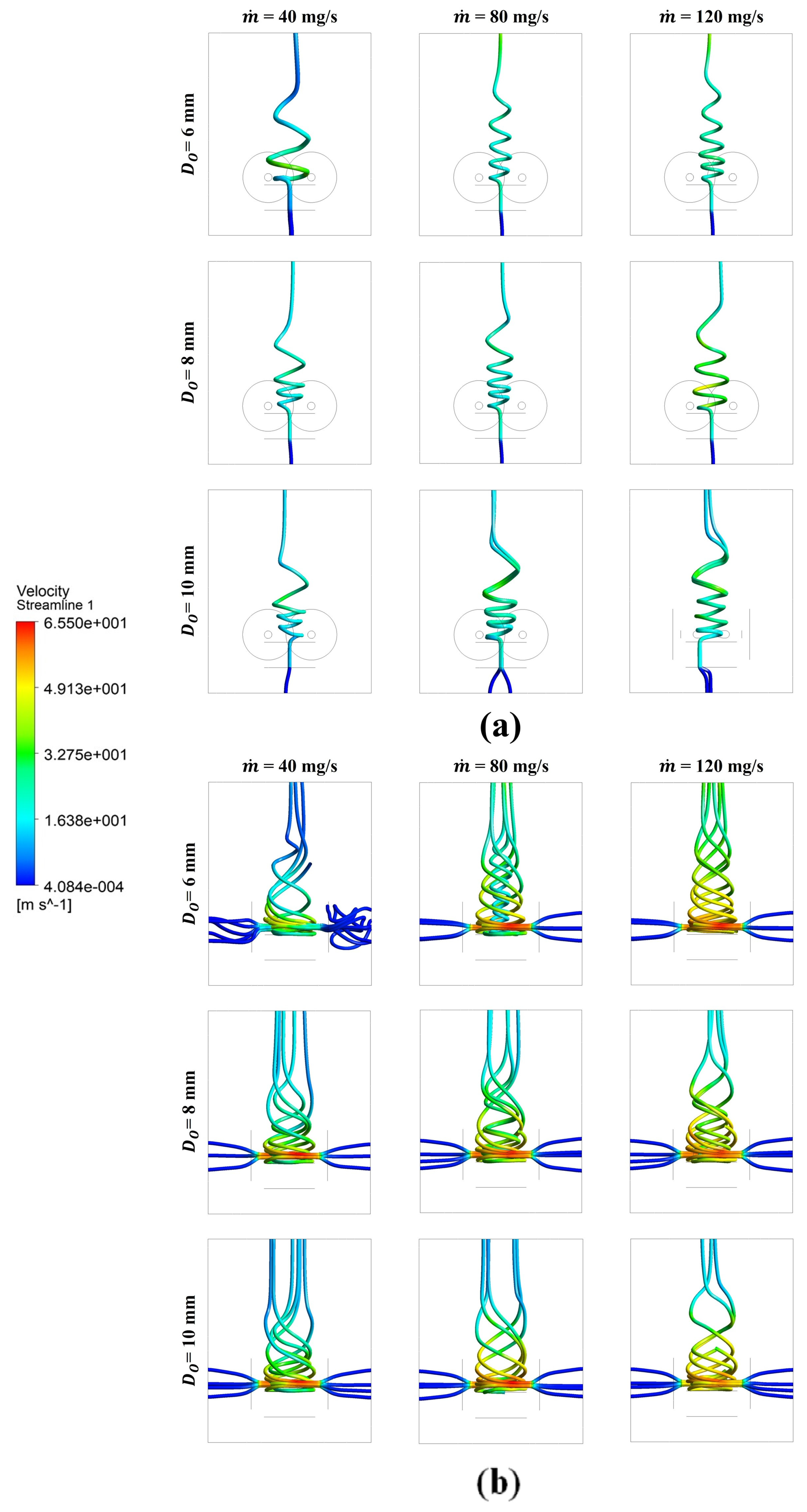

3.1. Interaction of Vortex Flow and Flame Behavior

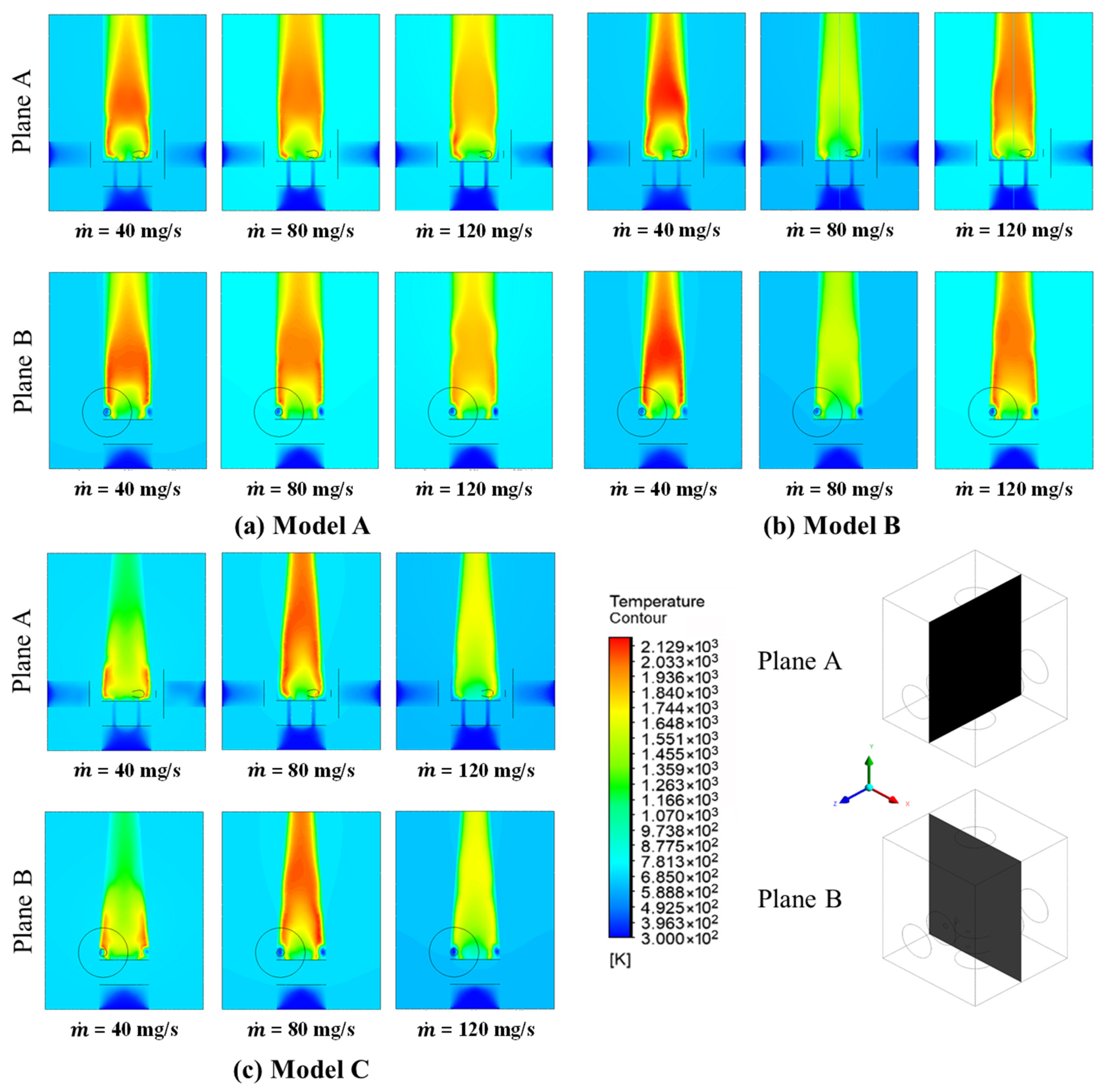

3.2. Combustion Analysis and Interpretation

3.2.1. Swirl-Induced Enhancement in Exhaust and Wall Temperatures

3.2.2. Flow Field Characterization and Flame Structure Visualization

3.2.3. Flame Shape and Vortex Core Structure

3.2.4. Flame Stability and CRZ Coupling

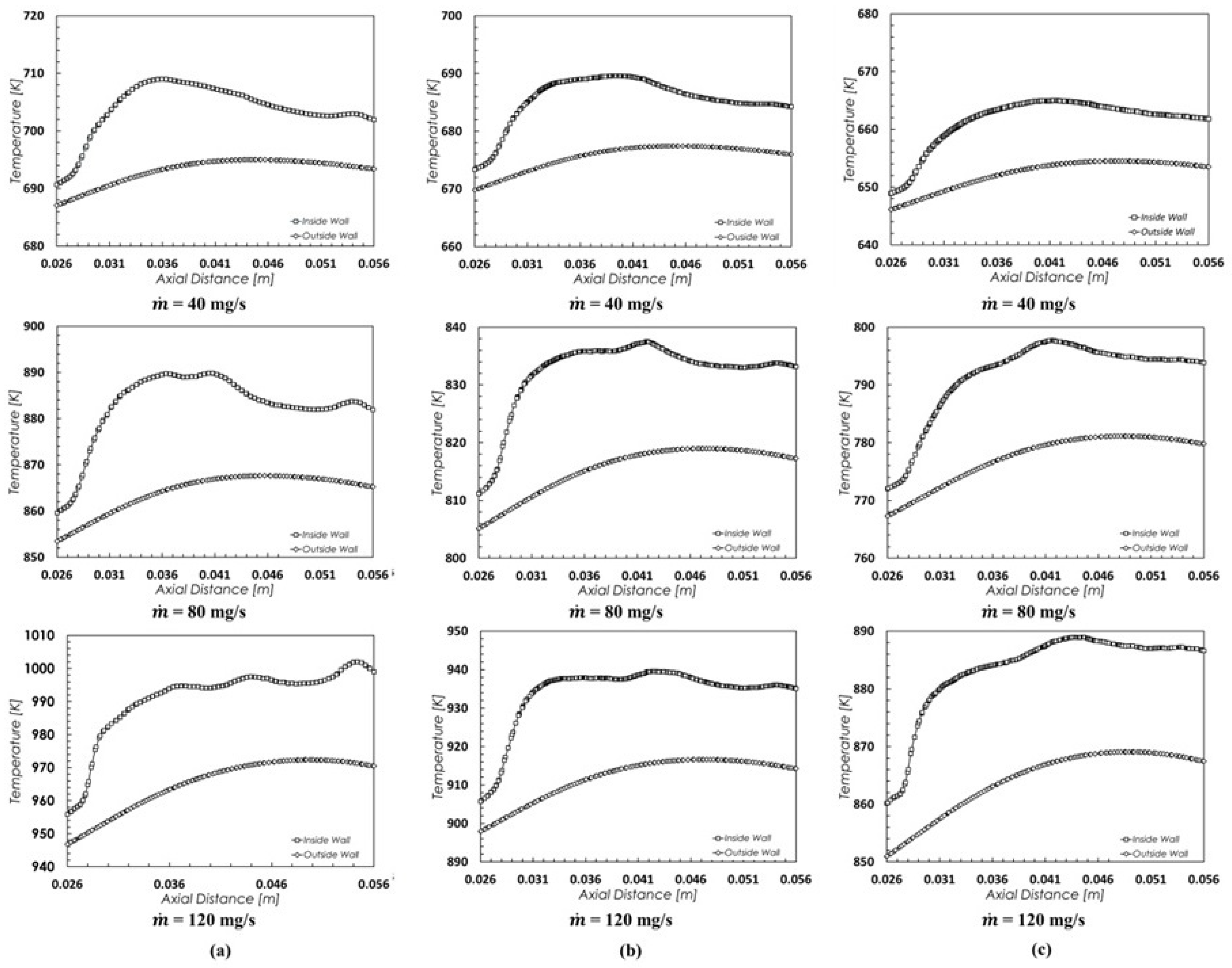

3.3. Design Implications for Temperature Distributions

3.3.1. Temperature Profile on Combustor Height

3.3.2. Combustor Heat Transfer

3.3.3. Exhaust Sensible-Enthalpy Fraction

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Minotti, A.; Sciubba, E. LES of a Meso Combustion Chamber with a Detailed Chemistry Model: Comparison Between the Flamelet and EDC Models. Energies 2010, 3, 1943–1959. [Google Scholar] [CrossRef]

- Sheykhbaglou, S.; Dimitriou, P. Numerical Analysis of Combustion and Thermal Performance of a Bluff-Body and Swirl-Stabilized Micro-Combustor with Premixed NH3/H2/Air Flames. Energies 2025, 18, 780. [Google Scholar] [CrossRef]

- Ren, Y.; Wang, Q.; Peng, Y.; Xu, L.; Xia, X.; Qi, F. Strong and weak interactions of a V-shaped premixed swirling flame with outer vortex rings. Combust. Flame 2024, 270, 113760. [Google Scholar] [CrossRef]

- Sharifzadeh, R.; Afshari, A. Numerical investigation of flow field effects on fuel–air mixing in a non-reacting trapped vortex combustor with different injection arrangements. Eur. J. Mech. B/Fluids 2020, 82, 106–122. [Google Scholar] [CrossRef]

- Tang, C.; Yao, Q.; Jin, W.; Li, J.; Yan, Y.; Yuan, L. Effect of swirler geometry on the outlet temperature profile performance of a model gas turbine combustor. Appl. Therm. Eng. 2025, 260, 124946. [Google Scholar] [CrossRef]

- Wu, S.; Laurent, T.D.C.; Abubakar, S.; Li, Y. Thermal performance characteristics of a micro-combustor with swirl rib fueled with premixed hydrogen/air. Int. J. Hydrogen Energy 2021, 46, 36503–36514. [Google Scholar] [CrossRef]

- Norton, D.G.; Vlachos, D.G. Combustion characteristics and flame stability at the microscale: A CFD study of premixed methane/air mixtures. Chem. Eng. Sci. 2003, 58, 4871–4882. [Google Scholar] [CrossRef]

- Maruta, K. Micro and mesoscale combustion. Proc. Combust. Inst. 2011, 33, 125–150. [Google Scholar] [CrossRef]

- Khaleghi, M.; Hosseini, S.E.; Wahid, M.A. Vortex combustion and heat transfer in meso-scale with thermal recuperation. Int. Commun. Heat Mass Transf. 2015, 66, 250–258. [Google Scholar] [CrossRef]

- Wan, J.; Zhao, H. Flammability limit of methane-air nonpremixed mixture in a micro preheated combustor with a flame holder. Chem. Eng. Sci. 2020, 227, 115914. [Google Scholar] [CrossRef]

- Choi, J.; Rajasegar, R.; Lee, T.; Yoo, J. Development and characterization of swirl-stabilized diffusion mesoscale burner array. Appl. Therm. Eng. 2020, 175, 115373. [Google Scholar] [CrossRef]

- Wang, H.Y.; Law, C.K.; Lieuwen, T. Linear response of stretch-affected premixed flames to flow oscillations. Combust. Flame 2009, 156, 889–895. [Google Scholar] [CrossRef]

- Tang, A.; Cai, T.; Deng, J.; Xu, Y.; Pan, J. Experimental investigation on combustion characteristics of premixed propane/air in a micro-planar heat recirculation combustor. Energy Convers. Manag. 2017, 152, 65–71. [Google Scholar] [CrossRef]

- Palies, P. Flow and Flame Mechanisms for Swirl-Stabilized Combustors. Aerospace 2025, 12, 430. [Google Scholar] [CrossRef]

- Zhou, T.; Zhao, K.; Li, F.; Wang, K.; Meng, N.; Wang, D. Effects of swirl numbers on the unsteady characteristics of pilot flame in a triple-swirler staged combustor. Case Stud. Therm. Eng. 2023, 44, 102846. [Google Scholar] [CrossRef]

- Wang, K.; Li, F.; Zhou, T.; Wang, D. Numerical simulations on the effect of swirler installation angle on outlet temperature distribution in gas turbine combustors. Appl. Therm. Eng. 2024, 240, 122252. [Google Scholar] [CrossRef]

- Ju, Y.; Maruta, K. Microscale combustion: Technology development and fundamental research. Prog. Energy Combust. Sci. 2011, 37, 669–715. [Google Scholar] [CrossRef]

- Fernández-Tarrazo, E.; Sanchez, A.; Linan, A.; Williams, F. A simple one-step chemistry model for partially premixed hydrocarbon combustion. Combust. Flame 2006, 147, 32–38. [Google Scholar] [CrossRef]

- Ehsan, R.; Masoud, D. Extending the Navier–Stokes solutions to transition regime in two-dimensional micro- and nanochannel flows using information preservation scheme. Phys. Fluids 2009, 21, 082001. [Google Scholar]

- Yetter, R.A.; Risha, G.A.; Son, S.F. Metal particle combustion and nanotechnology. Proc. Combust. Inst. 2009, 32, 1819–1838. [Google Scholar] [CrossRef]

- Turns, S.R. An Introduction to Combustion: Concepts and Applications, 2nd ed.; McGraw-Hill Education: Singapore, 2000. [Google Scholar]

- Choi, M.; Choi, K.W.; Muhammad, H.A.; Lee, Y.D. Experimental investigation of combustion characteristics of a CH4/O2 premixed flame: Effect of swirl intensity on flame structure, flame stability, and emissions. Case Stud. Therm. Eng. 2012, 55, 104069. [Google Scholar] [CrossRef]

- Tan, Y.; Jiaqiang, E.; Chen, J.; Liao, G.; Zhang, F.; Li, J. Investigation on combustion characteristics and thermal performance of a three rearward-step structure micro combustor fueled by premixed hydrogen/air. Renew. Energy 2022, 186, 486–504. [Google Scholar] [CrossRef]

- Sudarsanan, S.; Mohammad, A.; Selvaraj, P.; Juhany, K.A.; Alsulami, R.A.; Kumar, S.; Velamati, R.K. A state-of-the-art micro-mixing micro-combustor with enhanced flame stabilization characteristics using H2-air mixtures. Energy Convers. Manag. X 2025, 26, 101001. [Google Scholar] [CrossRef]

| Model | Settings | |

|---|---|---|

| Viscous model | K-epsilon (2 Equations) RNG, with swirl-dominated flow option | |

| Radiation model | Discrete ordinate (DO) | |

| Reaction model | Model of turbulence chemistry with volumetric species transport reaction and eddy dissipation | |

| Boundary conditions | Air inlet | Mass Flow Rate: Various |

| Temperature: 300 K | ||

| Concentration: O2 = 23%, N2 = 77% | ||

| Fuel inlet | Mass Flow Rate: Various | |

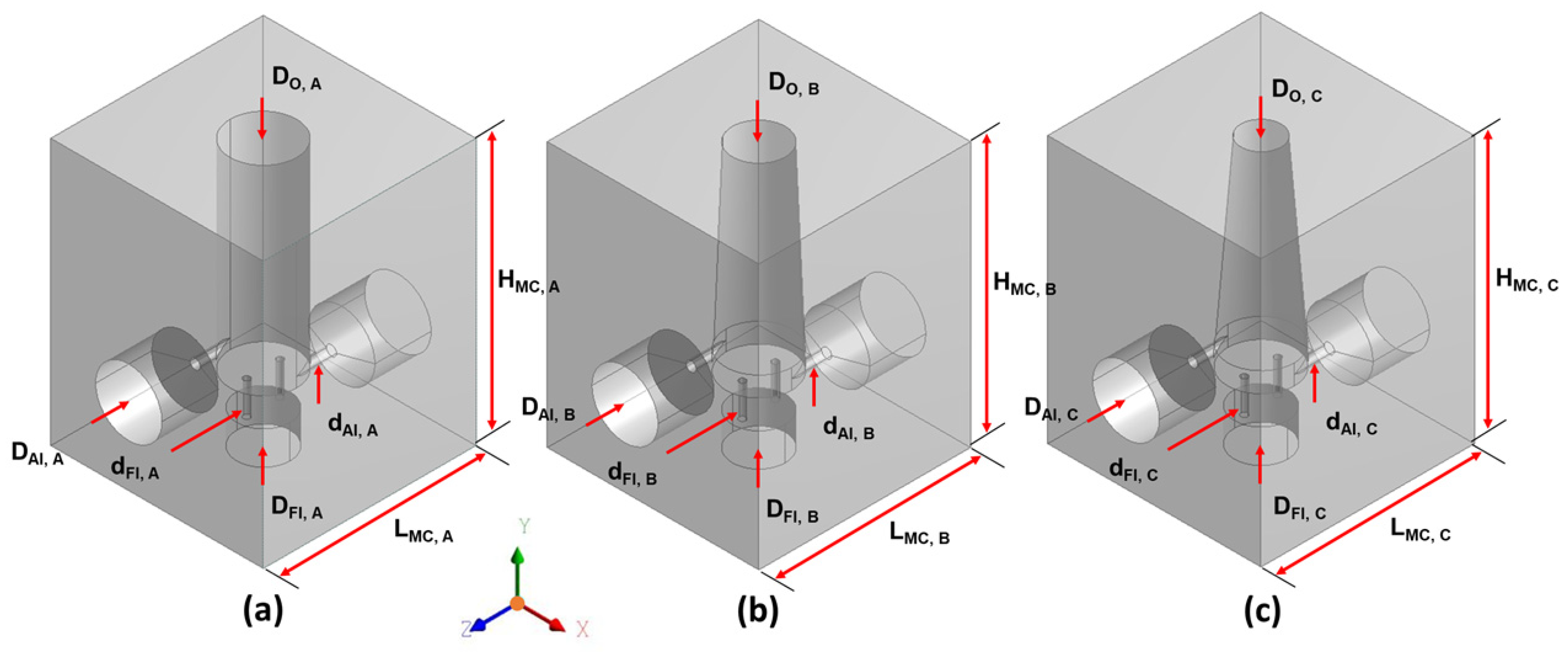

| Samples | Model A | Model B | Model C |

|---|---|---|---|

| Length of meso chamber, LMC | 32 | ||

| Height of meso chamber, HMC | 40 | ||

| Diameter outlet, DO | 10 | 8 | 6 |

| Diameter air inlet, DAI | 10 | ||

| Diameter fuel inlet, DFI | 10 | ||

| Diameter air inlet, dAI | 1.5 | ||

| Diameter fuel inlet, dFI | 1 | ||

| Height fuel inlet 1, HFI, 1 | 5 | ||

| Height fuel inlet 2, HFI, 2 | 5 | ||

| Center air inlet, CAI | 13.83 | ||

| Center meso-chamber, CMC | 19.42 | ||

| Height chamber, HC | 30 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abd Latif, M.L.; Mohd Nawi, M.A.-H.; Alias, M.A.R.; Khor, C.Y.; Fathurrahman Kamarudin, M.; Roslan, A.H.; Jaafar, H.J. Numerical Elucidation on the Dynamic Behaviour of Non-Premixed Flame in Meso-Scale Combustors. Modelling 2025, 6, 94. https://doi.org/10.3390/modelling6030094

Abd Latif ML, Mohd Nawi MA-H, Alias MAR, Khor CY, Fathurrahman Kamarudin M, Roslan AH, Jaafar HJ. Numerical Elucidation on the Dynamic Behaviour of Non-Premixed Flame in Meso-Scale Combustors. Modelling. 2025; 6(3):94. https://doi.org/10.3390/modelling6030094

Chicago/Turabian StyleAbd Latif, Muhammad Lutfi, Mohd Al-Hafiz Mohd Nawi, Mohammad Azrul Rizal Alias, Chu Yee Khor, Mohd Fathurrahman Kamarudin, Azri Hariz Roslan, and Hazrin Jahidi Jaafar. 2025. "Numerical Elucidation on the Dynamic Behaviour of Non-Premixed Flame in Meso-Scale Combustors" Modelling 6, no. 3: 94. https://doi.org/10.3390/modelling6030094

APA StyleAbd Latif, M. L., Mohd Nawi, M. A.-H., Alias, M. A. R., Khor, C. Y., Fathurrahman Kamarudin, M., Roslan, A. H., & Jaafar, H. J. (2025). Numerical Elucidation on the Dynamic Behaviour of Non-Premixed Flame in Meso-Scale Combustors. Modelling, 6(3), 94. https://doi.org/10.3390/modelling6030094