Non-Fourier Thermoelastic Peridynamic Modeling of Cracked Thin Films Under Short-Pulse Laser Irradiation

Abstract

1. Introduction

2. Theory

2.1. Generalized Thermoelastic Theory Based on C- and F-Heat Flux

- The C- and F-model asymptotically converges to hyperbolic heat transfer dynamics, characterized by a finite thermal propagation velocity through intrinsic relaxation time scaling, thereby eliminating the non-physical infinite-speed paradox inherent in classical Fourier diffusion. The governing equation with respect to temperature is given by

- The C- and F-model converges to Jeffreys-type parabolic heat conduction, wherein inherent wavefront discontinuities are regularized through Fourier-type diffusive coupling, ensuring physically consistent thermal field continuity. The temperature field is governed byIt is worth noting that the acknowledged Jeffrey-type heat conduction model is also classified as a generalized formulation; however, it essentially reduces to a Fourier-like diffusive model with an additional relaxation term.

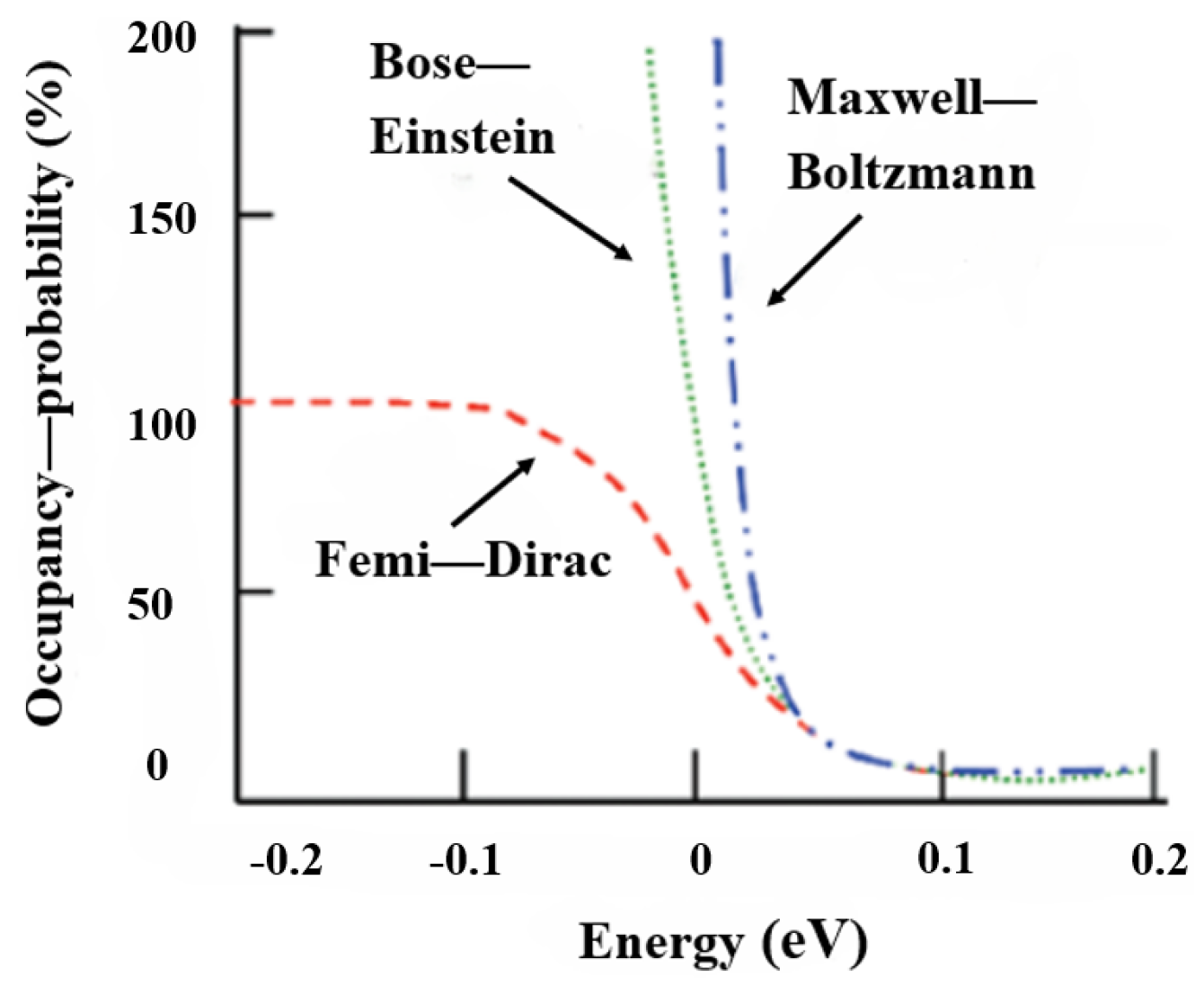

- The C- and F-model degenerates to the Fourier-type (parabolic) heat conduction processes, which has an infinite heat propagation speed. The evolution of temperature satisfies the equationwhere , and and c represent the material density and specific heat, respectively; S and are the external heat source or sink and relaxing time, respectively; and in the Cattaneo (Equation (2))- and Jeffrey (Equation (3))-type models. The hyperbolic model ( = 0) produces significantly more intense stress localization at the crack tips compared to the Fourier model ( = 1) due to its wave-like heat propagation that creates steeper thermal gradients. The intermediate Jeffreys-type model () exhibits transitional behavior between these two extremes. For picosecond-scale laser pulses, the ( = 0) model is crucial as it captures the strong transient thermal shocks that drive crack propagation, while the ( = 1) model substantially underestimates these dynamic effects. The choice of therefore critically determines the accuracy of predicted crack behavior under ultrafast heating conditions.

- : Equation (8) degenerates to a thermoelastic model wherein Jefferys-type thermal flux describes the thermal field:

- : Equation (8) degenerates to the classical linear thermoelasticity model in a Lagrangian configurationL

2.2. Mathematical Formulation of Coupled Thermomechanical Analysis

2.2.1. Mechanical Formulations

2.2.2. Non-Fourier Thermal Formulations

2.2.3. Thermomechanical Coupling

3. Numerical Implementations

3.1. Laser Heating-Imposing Technique in Peridynamic

3.2. Time Integration Scheme

4. Numerical Examples

4.1. Numerical Validations: 1D Danilovskakya Problem with Non-Fourier Effect

- Initial Conditions:

- Boundary Conditions:

4.2. Numerical Validations: Thermodynamics of a Cracked Plate with Fixed Temperature Boundaries

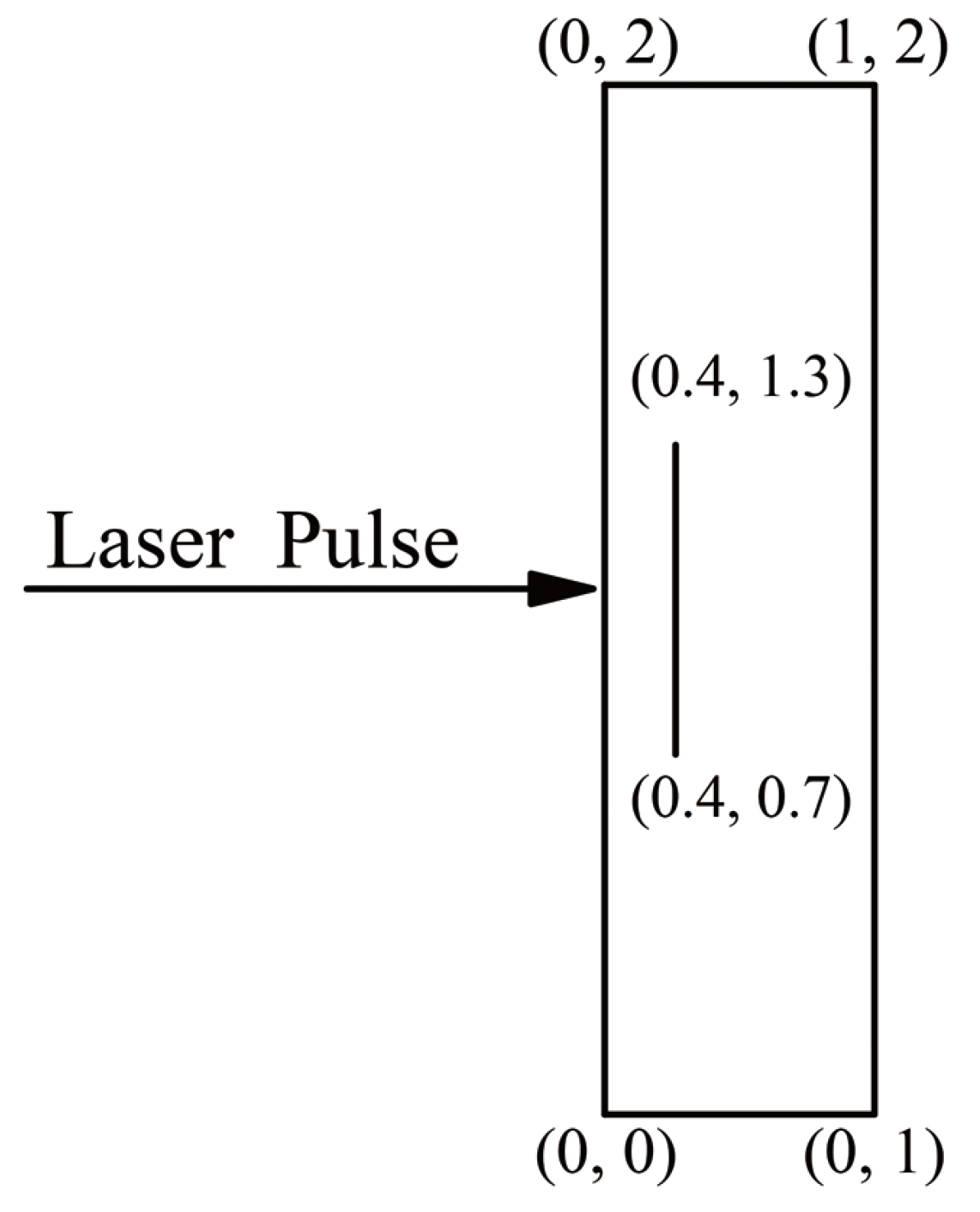

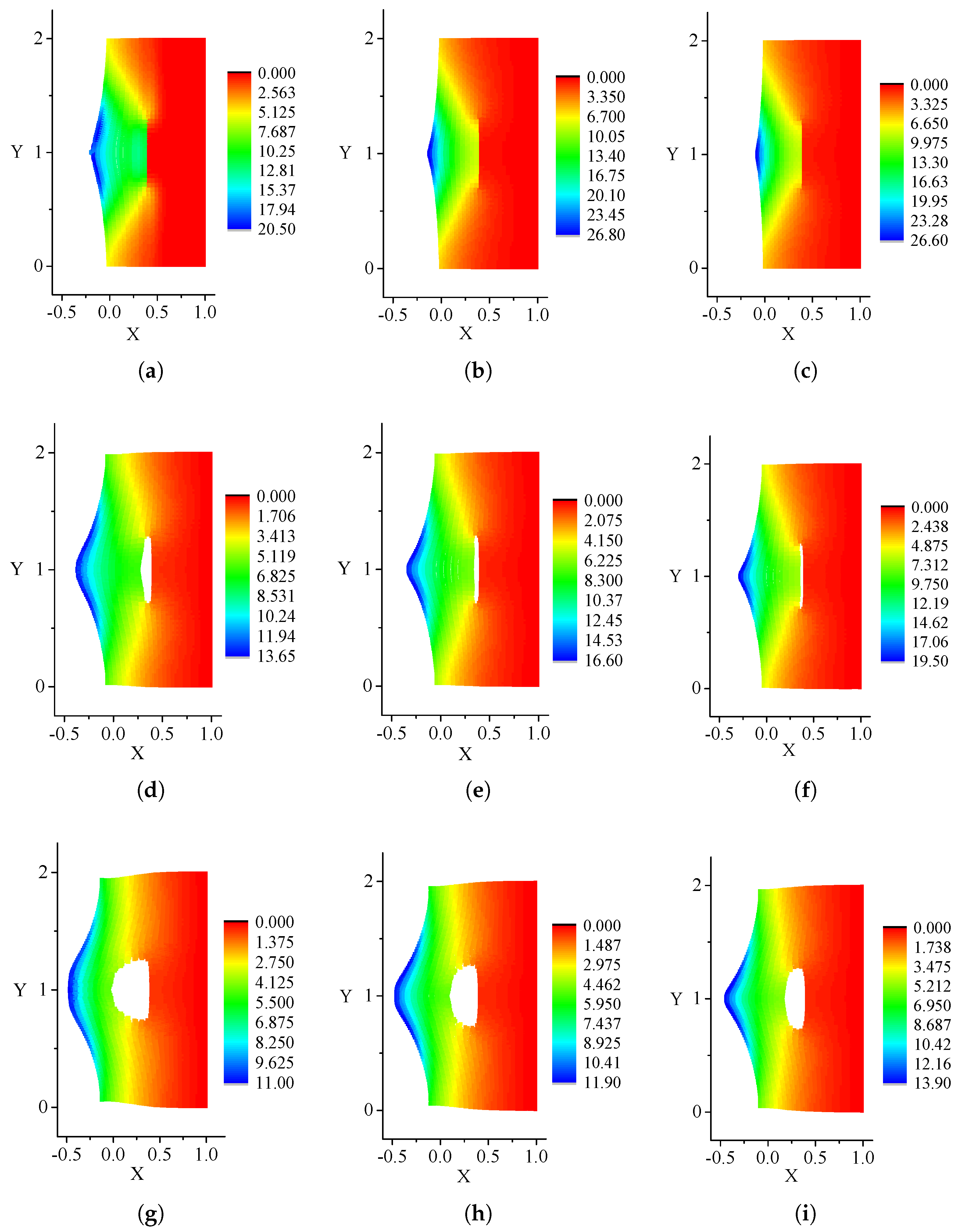

4.3. Thermodynamics of a Thin Film Under Short-Pulse Laser Heating

5. Conclusions

- The thermomechanical response of thin films under short-pulse laser heating demonstrates distinct heat propagation mechanisms governed by the selected thermal flux model. For the hyperbolic Cattaneo-type formulation (), thermal energy propagates at finite speeds, generating localized temperature gradients that induce pronounced structural deformation. In contrast, Fourier-type diffusion () assumes instantaneous heat distribution, resulting in smoother thermal fields and comparatively reduced mechanical distortions.

- A unified GSSSS i-Integration algorithm successfully synchronized first-order thermal and second-order mechanical fields, enabling stable simulations at picosecond timescales ( ps). By configuring algorithmic parameters () = (0, 0), maximal numerical dissipation was achieved, suppressing oscillations while preserving accuracy in resolving steep thermal gradients and stress localization. This approach proved robust for modeling ultrafast laser-induced phenomena, where conventional staggered schemes often fail due to tight multiphysics coupling.

- In the cracked plate, Cattaneo-type flux temperature propagation is hysteretic and shows wave-like propagation. For laser-irradiated films, Fourier models reduced peak stresses by 25% compared to hyperbolic models at ps, underscoring the dominance of hyperbolic conduction in high-gradient scenarios. These results align with experimental observations of stress-driven failures in ultrafast laser processing.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, H.L.; Chen, W.L.; Chang, W.J.; Wei, E.J.; Yang, Y.C. Analysis of dual-phase-lag heat conduction in short-pulse laser heating of metals with a hybrid method. Appl. Therm. Eng. 2013, 52, 275–283. [Google Scholar] [CrossRef]

- Chen, J.K.; Beraun, J.E.; Tzou, D.Y. Thermomechanical response of metals heated by ultrashort-pulsed lasers. J. Therm. Stress. 2002, 25, 539–558. [Google Scholar] [CrossRef]

- Xu, B.B.; Gao, X.W.; Cui, M. High precision simulation and analysis of non-Fourier heat transfer during laser processing. Int. J. Heat Mass Transf. 2021, 178, 121574. [Google Scholar] [CrossRef]

- Jiang, W.H.; Feng, G.; Liu, J.M.; Tan, X.Y.; Yu, Y. Preparation of Aluminum Titanate Film by Sol-gel Method and Its Fused Salt Corrosion Resistance. J. Synth. Cryst. 2010, 39, 917–921. [Google Scholar] [CrossRef]

- Jiang, W.H.; Feng, G.; Liu, J.M.; Tan, X.Y.; Yu, Y. Preparation of aluminum titanate film via nonhydrolytic sol-gel method and its fused salt corrosion resistance. J. Chin. Ceram. Soc. 2010, 38, 783–787. [Google Scholar] [CrossRef]

- Bao, Y.; Jiang, W.H.; Feng, G.; Liu, J.M.; Wu, Q. Low Temperature Preparation of Aluminum Titanate Film via Sol-Gel Method. Adv. Mater. Res. 2014, 936, 238–242. [Google Scholar] [CrossRef]

- Zhou, H.; Li, P.; Jiang, H.; Xue, H.; Bo, B. Nonlocal dual-phase-lag thermoelastic dissipation of size-dependent micro/nano-ring resonators. Int. J. Mech. Sci. 2022, 219, 107080. [Google Scholar] [CrossRef]

- Sun, W.; Yin, B.; Akbar, A.; Kodur, V.; Liew, K. A coupled 3D thermo-mechanical peridynamic model for cracking analysis of homogeneous and heterogeneous materials. Comput. Methods Appl. Mech. Eng. 2024, 418, 116577. [Google Scholar] [CrossRef]

- Joseph, D.D.; Preziosi, L. Heat waves. Rev. Mod. Phys. 1989, 61, 41. [Google Scholar] [CrossRef]

- Nowinski, J.L. Theory of Thermoelasticity with Applications; Sijthoff & Noordhoff International Publishers: Leiden, The Netherlands, 1978; Volume 3. [Google Scholar]

- Tzou, D.Y. A unified field approach for heat conduction from macro-to micro-scales. Trans.-Am. Soc. Mech. Eng. J. Heat Transf. 1995, 117, 8–16. [Google Scholar] [CrossRef]

- Fourier, J. Theorie Analytique de la Chaleur, par M. Fourier; Chez Firmin Didot, Père et Fils: Paris, France, 1822. [Google Scholar]

- Cattaneo, C. A form of heat conduction equation which eliminates the paradox of instantaneous propagation. Comptes Rendus L’académie Des Sci. 1958, 247, 431–433. [Google Scholar]

- Lord, H.W.; Shulman, Y. A generalized dynamical theory of thermoelasticity. J. Mech. Phys. Solids 1967, 15, 299–309. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Kothari, S.; Kumar, R. Dual phase-lag thermoelasticity. In Encyclopedia of Thermal Stresses; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1003–1019. [Google Scholar]

- Hetnarski, R.B.; Ignaczak, J. Generalized thermoelasticity: Response of semi-space to a short laser pulse. J. Therm. Stress. 1994, 17, 377–396. [Google Scholar] [CrossRef]

- Vishwakarma, V.; Das, A.K.; Das, P.K. Analysis of non-Fourier heat conduction using smoothed particle hydrodynamics. Appl. Therm. Eng. 2011, 31, 2963–2970. [Google Scholar] [CrossRef]

- Silling, S.A. Reformulation of elasticity theory for discontinuities and long-range forces. J. Mech. Phys. Solids 2000, 48, 175–209. [Google Scholar] [CrossRef]

- Silling, S.A.; Askari, E. A meshfree method based on the peridynamic model of solid mechanics. Comput. Struct. 2005, 83, 1526–1535. [Google Scholar] [CrossRef]

- Wen, Z.; Hou, C.; Zhao, M.; Wan, X. A peridynamic model for non-Fourier heat transfer in orthotropic plate with uninsulated cracks. Appl. Math. Model. 2023, 115, 706–723. [Google Scholar] [CrossRef]

- Li, W.J.; You, T.; Ni, T.; Zhu, Q.Z.; Hien Poh, L. The extended peridynamic model for elastoplastic and/or fracture problems. Int. J. Numer. Methods Eng. 2022, 123, 5201–5229. [Google Scholar] [CrossRef]

- Oterkus, S.; Madenci, E.; Agwai, A. Peridynamic thermal diffusion. J. Comput. Phys. 2014, 265, 71–96. [Google Scholar] [CrossRef]

- Oterkus, S.; Madenci, E.; Agwai, A. Fully coupled peridynamic thermomechanics. J. Mech. Phys. Solids 2014, 64, 1–23. [Google Scholar] [CrossRef]

- Chen, W.; Gu, X.; Zhang, Q.; Xia, X. A refined thermo-mechanical fully coupled peridynamics with application to concrete cracking. Eng. Fract. Mech. 2021, 242, 107463. [Google Scholar] [CrossRef]

- Gao, Y.; Oterkus, S. Ordinary state-based peridynamic modelling for fully coupled thermoelastic problems. Contin. Mech. Thermodyn. 2019, 31, 907–937. [Google Scholar] [CrossRef]

- D’Antuono, P.; Morandini, M. Thermal shock response via weakly coupled peridynamic thermo-mechanics. Int. J. Solids Struct. 2017, 129, 74–89. [Google Scholar] [CrossRef]

- Wang, Y.; Xue, T.; Tamma, K.K.; Maxam, D.; Qin, G. A three-time-level a posteriori error estimator for GS4-2 framework: Adaptive time stepping for second-order transient systems. Comput. Methods Appl. Mech. Eng. 2021, 384, 113920. [Google Scholar] [CrossRef]

- Aanjaneya, M.; Patkar, S.; Fedkiw, R. A monolithic mass tracking formulation for bubbles in incompressible flow. J. Comput. Phys. 2013, 247, 17–61. [Google Scholar] [CrossRef]

- Liu, P.; Gu, X.; Lu, Y.; Xia, X.; Madenci, E.; Zhang, Q. Peridynamics for mechanism analysis of soil desiccation cracking: Coupled hygro-mechanical model, staggered and monolithic solution. Comput. Methods Appl. Mech. Eng. 2023, 406, 115896. [Google Scholar] [CrossRef]

- Zienkiewicz, O.; Chan, A. Coupled problems and their numerical solution. In Advances in Computational Nonlinear Mechanics; Springer: Berlin/Heidelberg, Germany, 1989; pp. 139–176. [Google Scholar]

- Wang, Y.; Xue, T.; Tamma, K.K.; Maxam, D.; Qin, G. An accurate and simple universal a posteriori error estimator for GS4-1 framework: Adaptive time stepping in first-order transient systems. Comput. Methods Appl. Mech. Eng. 2021, 374, 113604. [Google Scholar] [CrossRef]

- Ramadan, K.; Tyfour, W.R.; Al-Nimr, M.A. On the Analysis of Short-Pulse Laser Heating of Metals Using the Dual Phase Lag Heat Conduction Model. J. Heat Transf. 2009, 131, 111301. [Google Scholar] [CrossRef]

- Zhang, G.; Dai, Z. A fully coupled thermomechanical peridynamic model for rock fracturing under blast loading considering initial pore damage. Comput. Geotech. 2024, 171, 106382. [Google Scholar] [CrossRef]

- Madenci, E.; Oterkus, E. Peridynamic theory. In Peridynamic Theory and Its Applications; Springer: Berlin/Heidelberg, Germany, 2013; pp. 19–43. [Google Scholar]

- Xue, T.; Tamma, K.K.; Zhang, X. A consistent Moving Particle System Simulation method: Applications to parabolic/hyperbolic heat conduction type problems. Int. J. Heat Mass Transf. 2016, 101, 365–372. [Google Scholar] [CrossRef]

- Tao, D. Finite element analysis of dynamic coupled thermoelasticity problems with relaxation times. J. Appl. Mech. 1983, 50, 817. [Google Scholar] [CrossRef]

- Wen-Hwa, C.; Chi-Lone, C. Heat conduction analysis of a plate with multiple insulated cracks by the finite element alternating method. Int. J. Solids Struct. 1994, 31, 1343–1355. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, T.; Xue, T.; Wang, Y.; Tamma, K. Non-Fourier Thermoelastic Peridynamic Modeling of Cracked Thin Films Under Short-Pulse Laser Irradiation. Modelling 2025, 6, 68. https://doi.org/10.3390/modelling6030068

Wu T, Xue T, Wang Y, Tamma K. Non-Fourier Thermoelastic Peridynamic Modeling of Cracked Thin Films Under Short-Pulse Laser Irradiation. Modelling. 2025; 6(3):68. https://doi.org/10.3390/modelling6030068

Chicago/Turabian StyleWu, Tao, Tao Xue, Yazhou Wang, and Kumar Tamma. 2025. "Non-Fourier Thermoelastic Peridynamic Modeling of Cracked Thin Films Under Short-Pulse Laser Irradiation" Modelling 6, no. 3: 68. https://doi.org/10.3390/modelling6030068

APA StyleWu, T., Xue, T., Wang, Y., & Tamma, K. (2025). Non-Fourier Thermoelastic Peridynamic Modeling of Cracked Thin Films Under Short-Pulse Laser Irradiation. Modelling, 6(3), 68. https://doi.org/10.3390/modelling6030068