Electrical Resistance as an Aggregate Characteristic of Coke Properties for Electrochemical and Coke Production

Abstract

1. Introduction

- -

- To ensure maximum energy intensity and optimal reactivity, coke should contain a maximum amount of carbon and a minimum amount of ash;

- -

- To ensure a uniform distribution of gases across the blast furnace cross-section by sieve (particle size distribution), coke must be uniform in size, have a minimum content of small (less than 25 mm) and large (more than 80 mm) fractions, and have high strength in cold and hot conditions;

- -

2. Materials and Methods

- -

- State standard of Ukraine 4096-2002 “Brown coal, hard coal, anthracite, combustible shale and coal briquettes. Methods of sample selection and preparation for laboratory tests” [6];

- -

- ISO 1171-97 “Solid mineral fuels. Methods for determination of ash” [7];

- -

- ISO 589-81 “Hard coal—Determination of total moisture” [8];

- -

- ISO 562:2010 “Hard coal and coke. Determination of volatile matter” [9]

- -

- ISO 334:2020 “Coal and coke. Determination of total sulfur. Eschka method” [10]

- -

- ISO 7404-3-84 “Methods for the petrographic analysis of bituminous coal and anthracite—Part 3: Method of determining maceral group composition” [11];

- -

- ISO 7404-5-85 “Methods for the petrographic analysis of coals—Part 5: Method of determining microscopically the reflectance of vitrinite” [12];

- -

- State standard of Ukraine 7722:2015 “Hard coal. Method of Determining Plastometric Characteristics” [13].

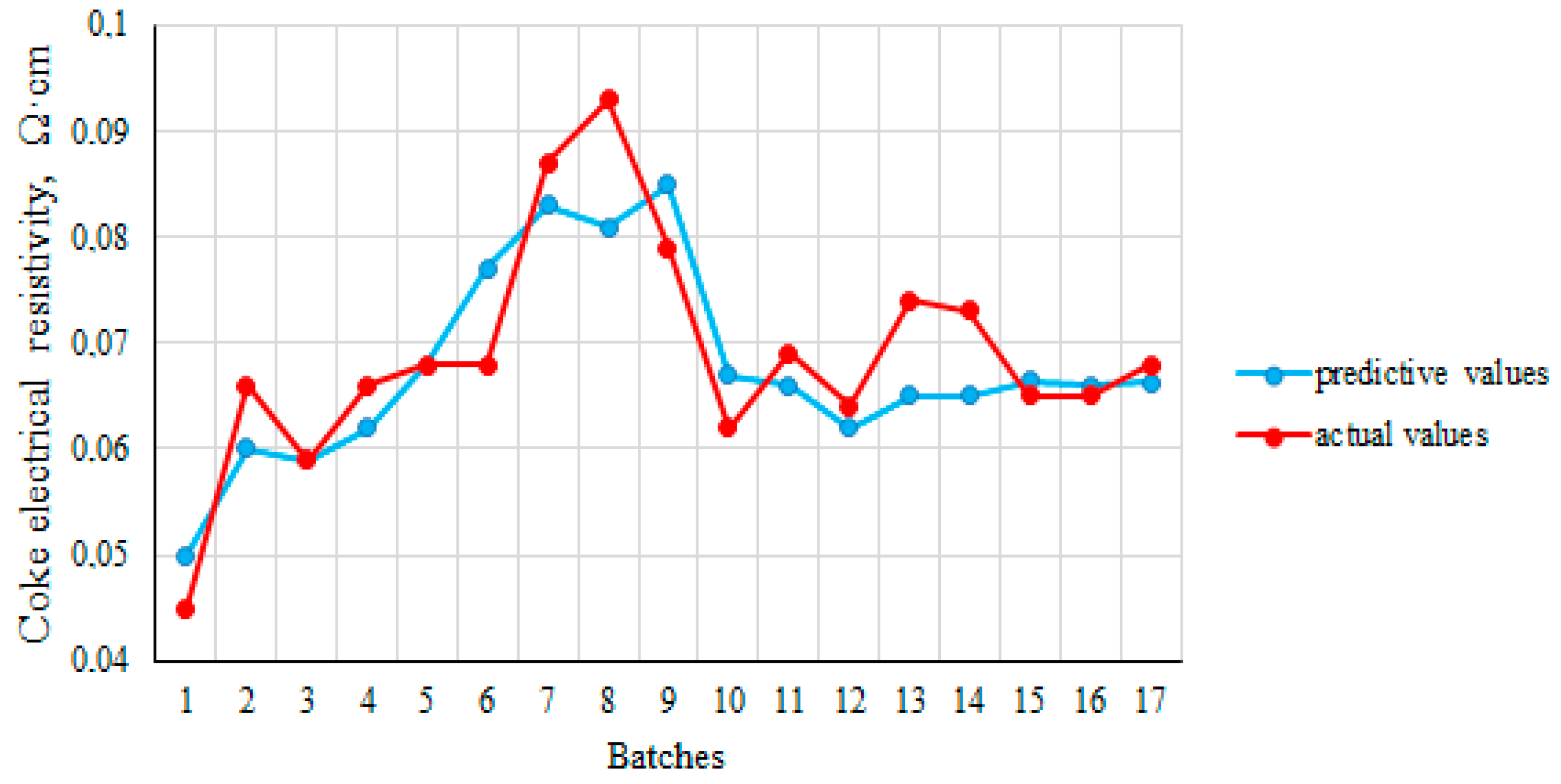

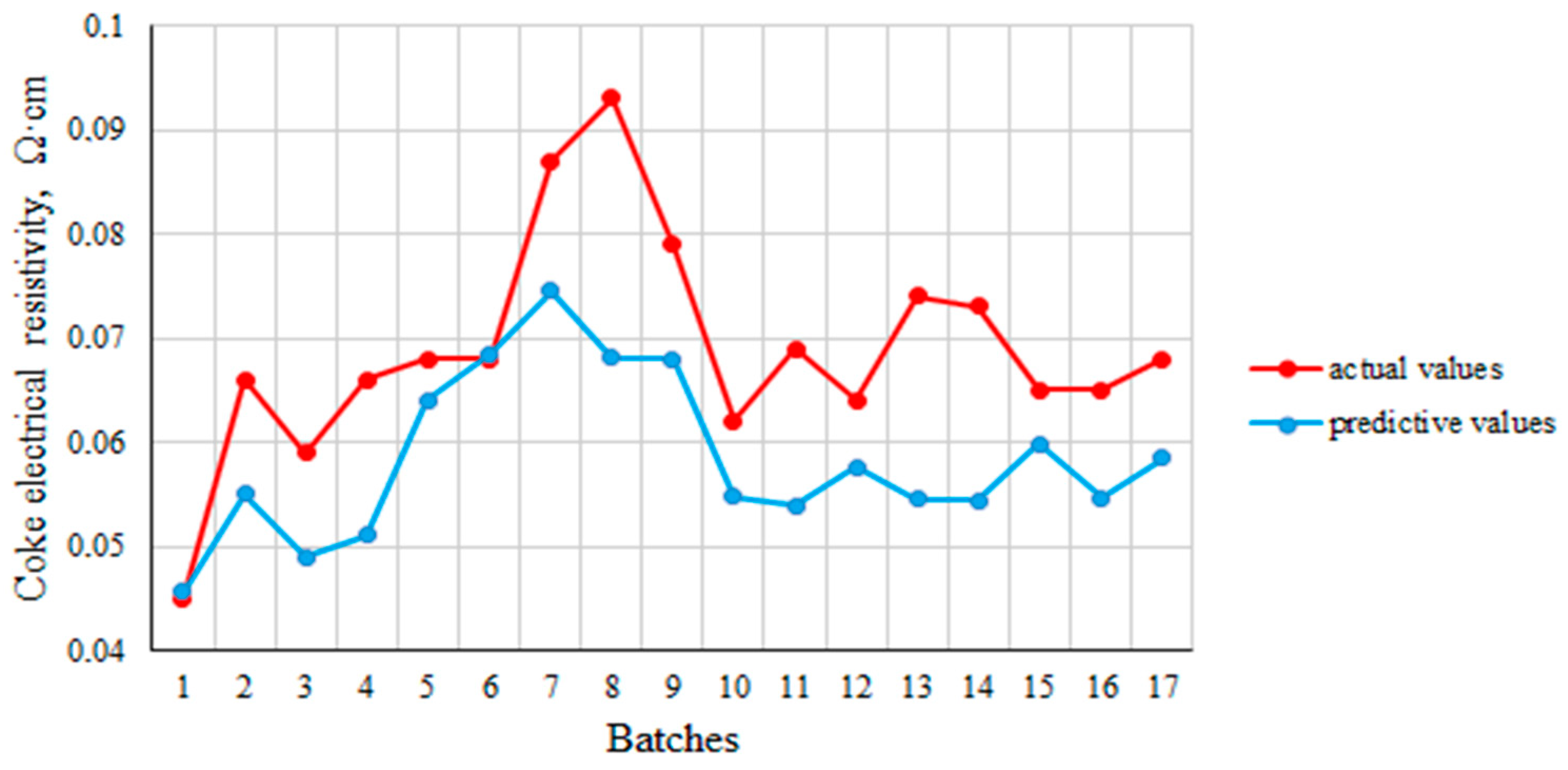

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

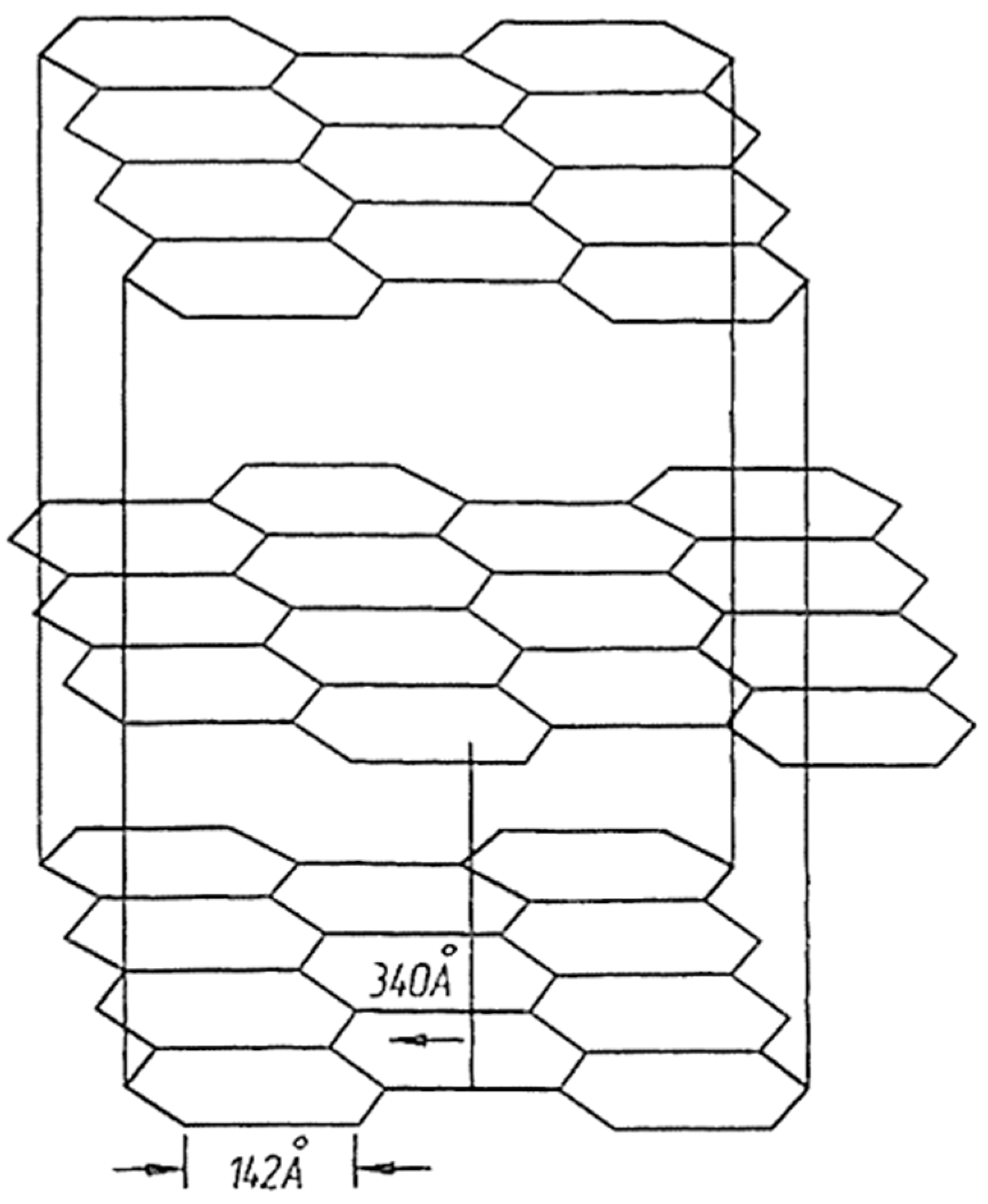

- Miroshnichenko, D.; Shmeltser, K.; Kormer, M. Factors Affecting the Formation the Carbon Structure of Coke and the Method of Stabilizing Its Physical and Mechanical Properties. C 2023, 9, 66. [Google Scholar] [CrossRef]

- Shmeltser, E.O.; Lyalyuk, V.P.; Sokolova, V.P.; Miroshnichenko, D.V. The using of coal blends with an increased content of coals of the middle stage of meta-morphism for the production of the blast-furnace coke. Message 2. Assessment of coke quality. Pet. Coal 2019, 61, 52–57. Available online: https://www.vurup.sk/wp-content/uploads/2019/01/PC_x_2018_Shmeltzer_155_rev1.pdf (accessed on 20 May 2024).

- Zhang, L.; Wang, G.; Xue, Q.; Zuo, H.; She, X.; Wang, J. Effect of preheating on coking coal and metallurgical coke properties: A review. Fuel Process. Technol. 2021, 221, 106942. [Google Scholar] [CrossRef]

- He, J.; Zou, C.; Zhao, J.; Yu, N.; Wang, Y.; Shi, R. Comparison of isothermal and nonisothermal combustion methods when evaluating semicoke for pulverized coal injection of blast furnace. Asia-Pac. J. Chem. Eng. 2022, 18, 2838. [Google Scholar] [CrossRef]

- Saranchuk, V.I.; Oshovsky, V.V.; Lavrenko, A.T.; Koshkarev, Y.M. Method for determining the value of electrical resistance of coal depending on temperature. Sci. J. DonNTU Chem. Chem. Technol. 2013, 134, 138–143. [Google Scholar]

- State Standard of Ukraine 4096-2002; Brown Coal, Hard Coal, Anthracite, Combustible Shale and Coal Briquettes. Methods of Sample Selection and Preparation for Laboratory Tests. Technical Committee of Ukraine on standardization TK-92: Kyiv, Ukraine, 2002.

- ISO 1171-97; Solid Mineral Fuels. Methods for Determination of Ash. International Organization for Standardization: Geneva, Switzerland, 1997.

- ISO 589-81; Hard Coal—Determination of Total Moisture. International Organization for Standardization: Geneva, Switzerland, 1981.

- ISO 562:2010; Hard Coal and Coke. Determination of Volatile Matter. International Organization for Standardization: Geneva, Switzerland, 1981.

- ISO 334:2020; Coal and Coke. Determination of Total Sulfur. Eschka Method. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 7404-3-84; Methods for the Petrographic Analysis of Bituminous Coal and Anthracite—Part 3: Method of Determining Maceral Group Composition. International Organization for Standardization: Geneva, Switzerland, 1984.

- ISO 7404-5-85; Methods for the Petrographic Analysis of Coal—Part 5: Method of Determining Microscopically the Reflectance of Vitrinite. International Organization for Standardization: Geneva, Switzerland, 1985.

- State Standard of Ukraine 7722:2015; Hard Coal. Method of Determining Plastometric Characteristics. State Enterprise “Ukrainian Scientific Research and Training Center for Problems of Standardization, Certification and Quality”: Kyiv, Ukraine, 2015.

- State Standard of Ukraine 3472:2015; Brown Coal, Hard Coal and Anthracite. Classification. UkrNDNC SE: Kyiv, Ukraine, 2015.

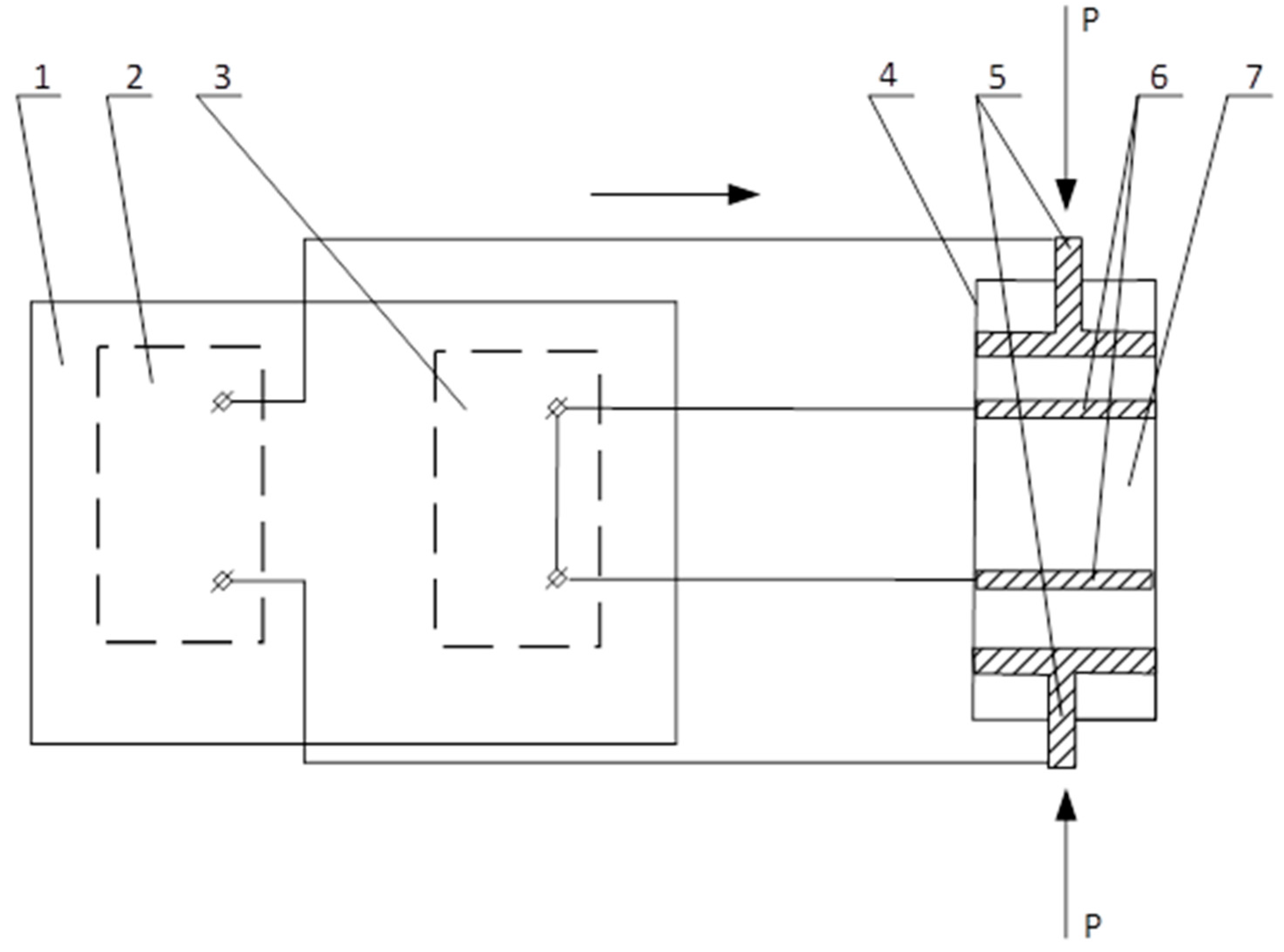

- DSTU 8831:2019; Coke. Method for Determining the Resistivity of Coal Coke Powder. UkrNDNC SE: Kyiv, Ukraine, 2019.

- ISO 18894:2006; Coke-Determination of Coke Reactivity Index (CRI) and Coke Strength after Reaction (CSR). International Organization for Standardization: Geneva, Switzerland, 2006.

- North, L.; Blackmore, K.; Nesbitt, K.; Mahoney, M.R. Models of coke quality prediction and the relationships to input variables: A review. Fuel 2018, 219, 446–466. [Google Scholar] [CrossRef]

- Flores, B.D.; Borrego, A.G.; Diez, M.A.; da Silva, G.L.; Zymla, V.; Vilela, A.; Osorio, E. How coke optical texture became a relevant tool for understanding coal blending and coke quality. Fuel Process. Technol. 2017, 164, 13–23. [Google Scholar] [CrossRef]

- Kumar, D.; Saxena, V.K.; Tiwari, H.P.; Nandi, B.K.; Verma, A.; Tiwary, V.K. Variability in Metallurgical Coke Reactivity Index (CRI) and Coke Strength after Reaction (CSR): An Experimental Study. ACS Omega 2022, 7, 1703–1711. [Google Scholar] [CrossRef] [PubMed]

- Vega, M.F.; Díaz-Faes, E.; Barriocanal, C. Influence of the Heating Rate on the Quality of Metallurgical Coke. ACS Omega 2021, 6, 34615–34623. [Google Scholar] [CrossRef] [PubMed]

- Surup, G.R.; Pedersen, T.A.; Chaldien, A.; Beukes, J.P.; Tangstad, M. Electrical Resistivity of Carbonaceous Bed Material at High Temperature. Processes 2020, 8, 933. [Google Scholar] [CrossRef]

- Sánchez-González, J.; Stoeckli, F.; Centeno, T.Á. The role of the electric conductivity of carbons in the electrochemical capacitor performance. J. Electroanal. Chem. 2011, 657, 176–180. [Google Scholar] [CrossRef]

- Miroshnichenko, D.; Zhylina, M.; Shmeltser, K. Modern uses of biochar in various technologies and industries. A review. Chem. Chem. Technol 2024, 18, 2. [Google Scholar] [CrossRef]

- Adinaveen, T.; Vijaya, J.J.; Kennedy, L. Comparative Study of Electrical Conductivity on Activated Carbons Prepared from Various Cellulose Materials. Arab. J. Sci. Eng. 2014, 41, 55–65. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Buryak, V.V.; Vasil’chenko, G.N.; Chirka, T.V.; Konstantinov, S.M. Specific Electrical Resistance of Carbon Materials. Refract. Ind. Ceram. 2013, 54, 215–219. [Google Scholar] [CrossRef]

- Bazaluk, O.; Kieush, L.; Koveria, A.; Schenk, J.; Pfeiffer, A.; Zheng, H.; Lozynskyi, V. Metallurgical Coke Production with Biomass Additives: Study of Biocoke Properties for Blast Furnace and Submerged Arc Furnace Purposes. Materials 2022, 15, 1147. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.; Pang, Q.; Yang, X.; Zhan, W.; He, Z. Effect of high temperature on macroscopic properties and microstructure of metallurgical coke. Fuel 2024, 356, 129543. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, Y.; Tuo, K.; Wang, L.; Chen, G. Structure, electrical conductivity, and dielectric properties of semi-coke derived from microwave-pyrolyzed low-rank coal. Fuel Process. Technol. 2018, 178, 139–147. [Google Scholar] [CrossRef]

- Ordabaeva, A.T.; Muldakhmetov, Z.M.; Kim, S.V.; Kasenova, S.B.; Sagintaeva, Z.I.; Gazaliev, A.M. Electrophysical Properties and Heat Capacity of Activated Carbon Obtained from Coke Fines. Molecules 2023, 28, 6545. [Google Scholar] [CrossRef] [PubMed]

| Blend | Batch Components (Coal Ranks), % | |||||||

|---|---|---|---|---|---|---|---|---|

| G1 | G2 | GZhP | GZh | Zh | K | PS | KS | |

| 1 | 6 | 44 | 6 | 16 | 13 | 15 | ||

| 2 | 10 | 3 | 33 | 15 | 2 | 14 | 23 | |

| 3 | 40 | 20 | 10 | 20 | 10 | |||

| 4 | 20 | 43 | 10 | 9 | 9 | 9 | ||

| 5 | 37 | 46 | 5 | 5 | 7 | |||

| 6 | 30 | 25 | 4 | 10 | 4 | 27 | ||

| 7 | 34 | 23 | 5 | 10 | 28 | |||

| 8 | 24 | 29 | 10 | 7 | 30 | |||

| 9 | 35 | 8 | 5 | 23 | 29 | |||

| 10 | 30 | 15 | 55 | |||||

| 11 | 31 | 12 | 57 | |||||

| 12 | 31 | 12 | 57 | |||||

| 13 | 31 | 12 | 57 | |||||

| 14 | 31 | 12 | 57 | |||||

| 15 | 42 | 58 | ||||||

| 16 | 43 | 57 | ||||||

| 17 | 43 | 57 | ||||||

| Batches | Proximate Analysis, % | Plastometric Parameters, y, mm | Petrographic Characteristics, % | ||||

|---|---|---|---|---|---|---|---|

| Total Moisture, Wrt | Ash, Adt | Total Sulfur, Sdt | Volatile Matter, Vdaf | Mean Vitrinite Reflection Coefficient, Ro, % | Content of Vitrinite, Vt, % | ||

| 1 | 9.9 | 7.5 | 0.51 | 29.7 | 14 | 1 | 71.6 |

| 2 | 8.6 | 8.7 | 0.96 | 30 | 17 | 1.01 | 74.9 |

| 3 | 9.9 | 7.8 | 0.8 | 29.8 | 16 | 1 | 73.2 |

| 4 | 9.1 | 9.7 | 0.56 | 31.9 | 18 | 0.95 | 73.7 |

| 5 | 10.4 | 9.5 | 1.84 | 32.4 | 20 | 0.95 | 79 |

| 6 | 10 | 11.3 | 1.59 | 35.1 | 12 | 0.86 | 77 |

| 7 | 10.4 | 12 | 1.54 | 35 | 13 | 0.91 | 86.8 |

| 8 | 7.8 | 12.1 | 1.47 | 34.1 | 15 | 0.85 | 81.7 |

| 9 | 8.2 | 11 | 1.82 | 35.8 | 14 | 0.83 | 84.6 |

| 10 | 8.7 | 8 | 1.34 | 32.3 | 15 | 0.95 | 81.7 |

| 11 | 8 | 7.3 | 1.32 | 32.7 | 18 | 0.98 | 80.2 |

| 12 | 8.8 | 7.8 | 1.17 | 32.8 | 16 | 1 | 87 |

| 13 | 8.7 | 7.3 | 1.23 | 31.3 | 15 | 1.02 | 85 |

| 14 | 8.6 | 7.4 | 1.24 | 32.9 | 16 | 0.97 | 86.1 |

| 15 | 9.1 | 8 | 1.34 | 32.9 | 14 | 1 | 82.4 |

| 16 | 8.2 | 8.4 | 1 | 30.7 | 14 | 1 | 82 |

| 17 | 8.7 | 7.7 | 1.19 | 32.6 | 14 | 1.02 | 87 |

| Indicators | Measurement Units | Numerical Value |

|---|---|---|

| Chamber height: | ||

| General | mm | 4300 |

| Useful | mm | 4000 |

| Chamber width: | ||

| Average | mm | 410 |

| On the machine side | mm | 385 |

| On the coke side | mm | 435 |

| Taper | mm | 50 |

| Chamber length: | ||

| General | mm | 14,000 |

| Useful | mm | 13,160 |

| Useful chamber volume | m3 | 21.6 |

| Heating system | PVR | |

| Heating method | Combined | |

| Method of supplying heating gas and air | Lateral | |

| Blend | Coking Period, Hours | Temperatures in Control Verticals, °C | |

|---|---|---|---|

| Machine Side | Coke Side | ||

| 1 | 23.46 | 1230 | 1265 |

| 2 | 19.69 | 1220 | 1260 |

| 3 | 37.58 | 1150 | 1170 |

| 4 | 58.74 | 1100 | 1160 |

| 5 | 50.09 | 1100 | 1160 |

| 6 | 28.11 | 1160 | 1180 |

| 7 | 21.05 | 1200 | 1240 |

| 8 | 17.56 | 1200 | 1230 |

| 9 | 36.8 | 1150 | 1170 |

| 10 | 18.9 | 1240 | 1265 |

| 11 | 18.7 | 1240 | 1265 |

| 12 | 18.41 | 1250 | 1270 |

| 13 | 18.30 | 1250 | 1280 |

| 14 | 18.9 | 1240 | 1275 |

| 15 | 24.26 | 1200 | 1245 |

| 16 | 22.55 | 1230 | 1265 |

| 17 | 21.26 | 1230 | 1265 |

| Blend | Thermochemical Properties, % | Electrical Resistivity, Ω·cm | |

|---|---|---|---|

| CRI | CSR | ||

| 1 | 34.3 | 49.5 | 0.045 |

| 2 | 41.7 | 34.4 | 0.066 |

| 3 | 39.6 | 41.6 | 0.059 |

| 4 | 41.9 | 37 | 0.066 |

| 5 | 46.1 | 30.9 | 0.068 |

| 6 | 51.5 | 23.8 | 0.068 |

| 7 | 54.9 | 20.2 | 0.087 |

| 8 | 53.9 | 22.2 | 0.093 |

| 9 | 56 | 21 | 0.079 |

| 10 | 43.8 | 41.6 | 0.062 |

| 11 | 43.4 | 40.5 | 0.069 |

| 12 | 41.3 | 42.6 | 0.064 |

| 13 | 42.5 | 42.7 | 0.074 |

| 14 | 43 | 40.7 | 0.073 |

| 15 | 43.8 | 39.2 | 0.065 |

| 16 | 43.4 | 40.8 | 0.065 |

| 17 | 43.6 | 40.4 | 0.068 |

| Ro | Vt | Vdaf | Wrt | Adt | Sdt | y | CRI | CSR | ρ | |

|---|---|---|---|---|---|---|---|---|---|---|

| Ro | 1 | |||||||||

| Vt | −0.07426 | 1 | ||||||||

| Vd | −0.61753 | 0.659324 | ||||||||

| Vdaf | −0.79845 | 0.546991 | 1 | |||||||

| Wrt | 0.012508 | −0.33014 | −0.04795 | 1 | ||||||

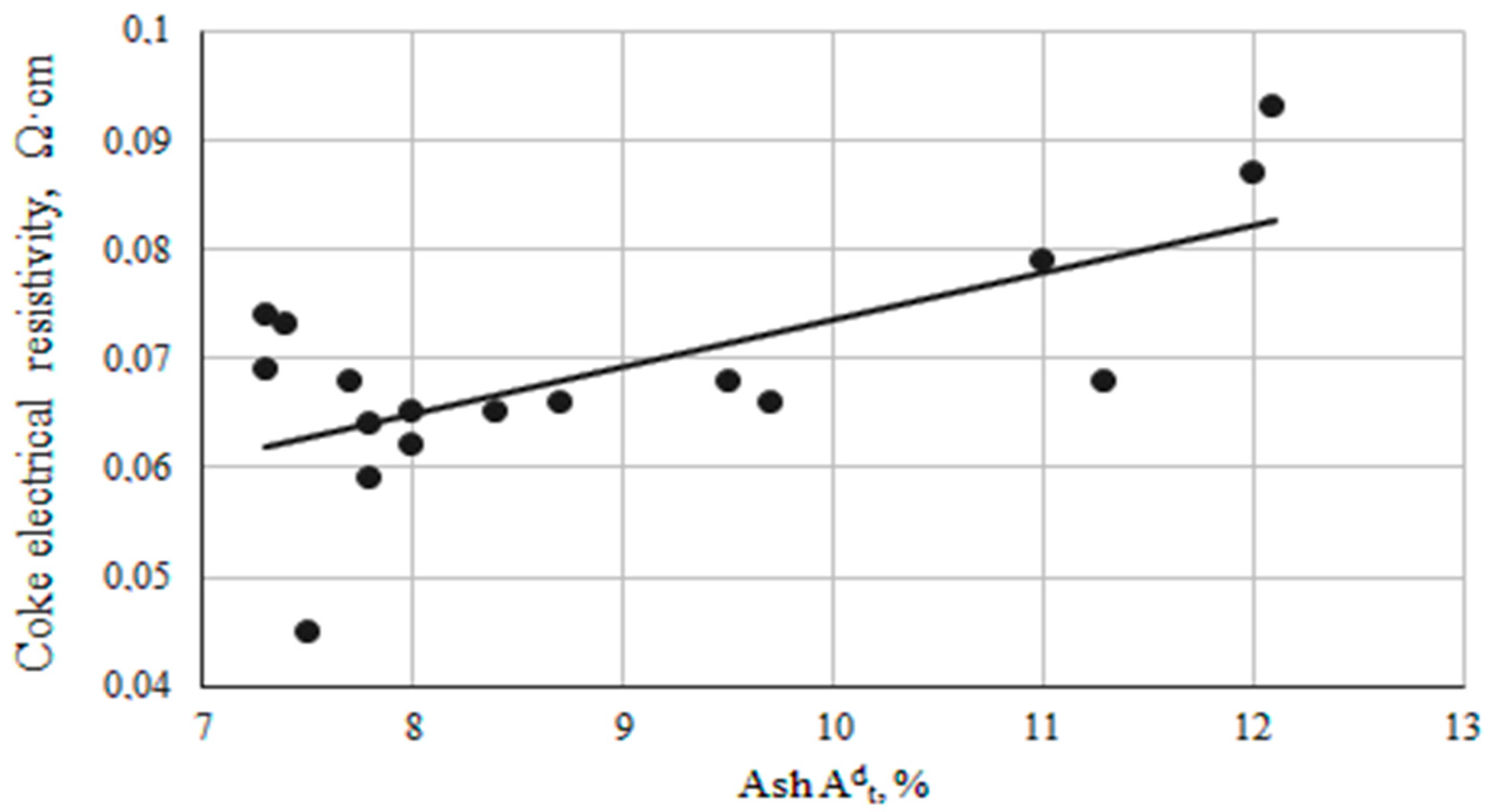

| Adt | −0.87171 | 0.037004 | 0.688635 | 0.169807 | 1 | |||||

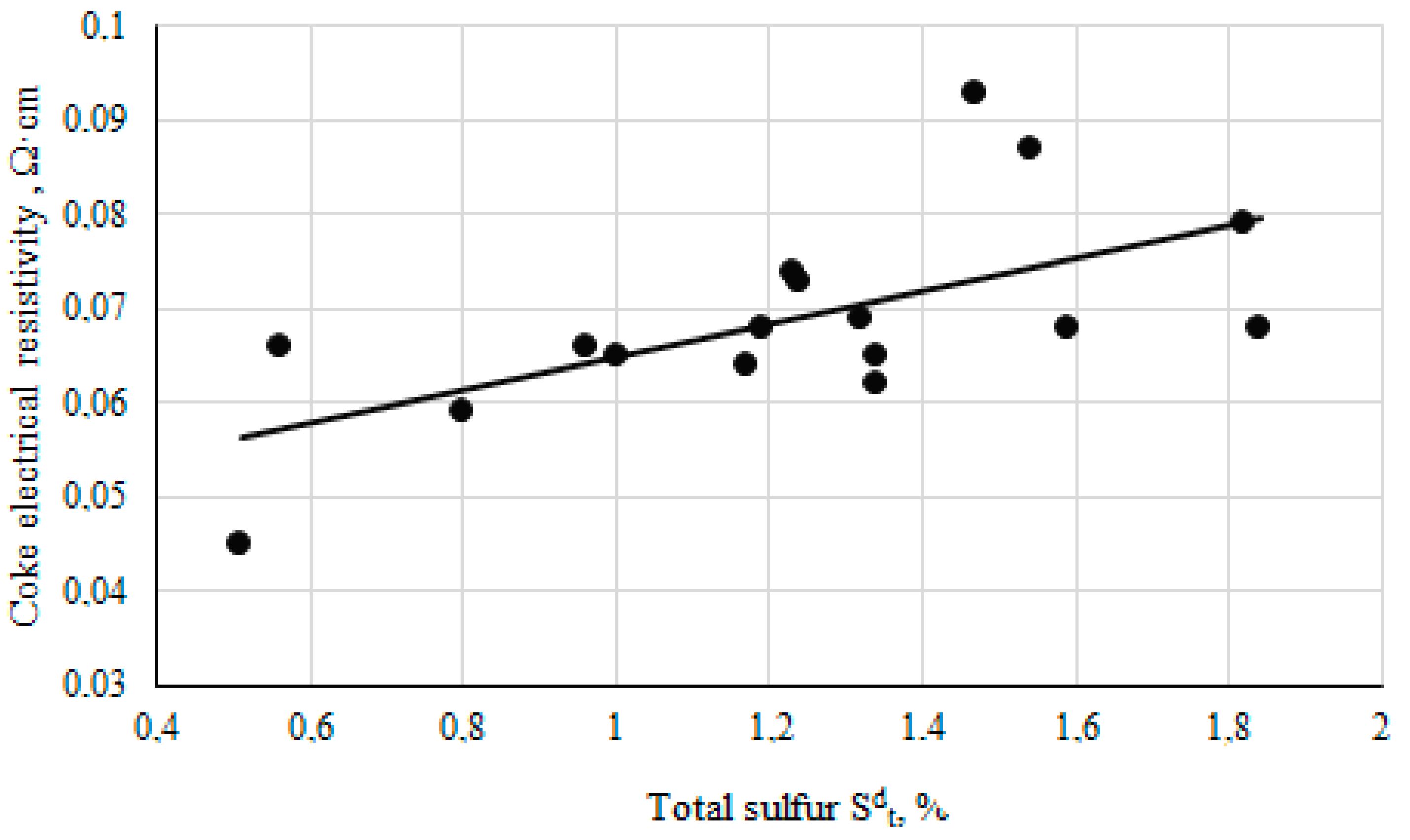

| Sdt | −0.59603 | 0.556968 | 0.77939 | −0.0028 | 0.490139 | 1 | ||||

| y | 0.265145 | −0.26499 | −0.3461 | −0.04235 | −0.27341 | −0.0909 | 1 | |||

| CRI | −0.85725 | 0.432163 | 0.883709 | −0.06813 | 0.861412 | 0.789118 | −0.32664 | 1 | ||

| CSR | 0.867639 | −0.18684 | −0.77504 | −0.07283 | −0.94936 | −0.67822 | 0.215319 | −0.94637 | 1 | |

| ρ | −0.60693 | 0.561369 | 0.696006 | −0.28618 | 0.679095 | 0.623354 | −0.11561 | 0.845227 | −0.7864 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miroshnichenko, D.; Shmeltser, K.; Kormer, M.; Soloviov, Y.; Pyshyev, S.; Korchak, B.; Shved, M.; Prysiazhnyi, Y. Electrical Resistance as an Aggregate Characteristic of Coke Properties for Electrochemical and Coke Production. Electrochem 2024, 5, 258-273. https://doi.org/10.3390/electrochem5020016

Miroshnichenko D, Shmeltser K, Kormer M, Soloviov Y, Pyshyev S, Korchak B, Shved M, Prysiazhnyi Y. Electrical Resistance as an Aggregate Characteristic of Coke Properties for Electrochemical and Coke Production. Electrochem. 2024; 5(2):258-273. https://doi.org/10.3390/electrochem5020016

Chicago/Turabian StyleMiroshnichenko, Denis, Kateryna Shmeltser, Maryna Kormer, Yevhen Soloviov, Serhiy Pyshyev, Bohdan Korchak, Mariia Shved, and Yuriy Prysiazhnyi. 2024. "Electrical Resistance as an Aggregate Characteristic of Coke Properties for Electrochemical and Coke Production" Electrochem 5, no. 2: 258-273. https://doi.org/10.3390/electrochem5020016

APA StyleMiroshnichenko, D., Shmeltser, K., Kormer, M., Soloviov, Y., Pyshyev, S., Korchak, B., Shved, M., & Prysiazhnyi, Y. (2024). Electrical Resistance as an Aggregate Characteristic of Coke Properties for Electrochemical and Coke Production. Electrochem, 5(2), 258-273. https://doi.org/10.3390/electrochem5020016