Separation Process of Biodiesel-Product Mixture from Crude Glycerol and Other Contaminants Using Electrically Driven Separation Technique with AC High Voltage

Abstract

1. Introduction

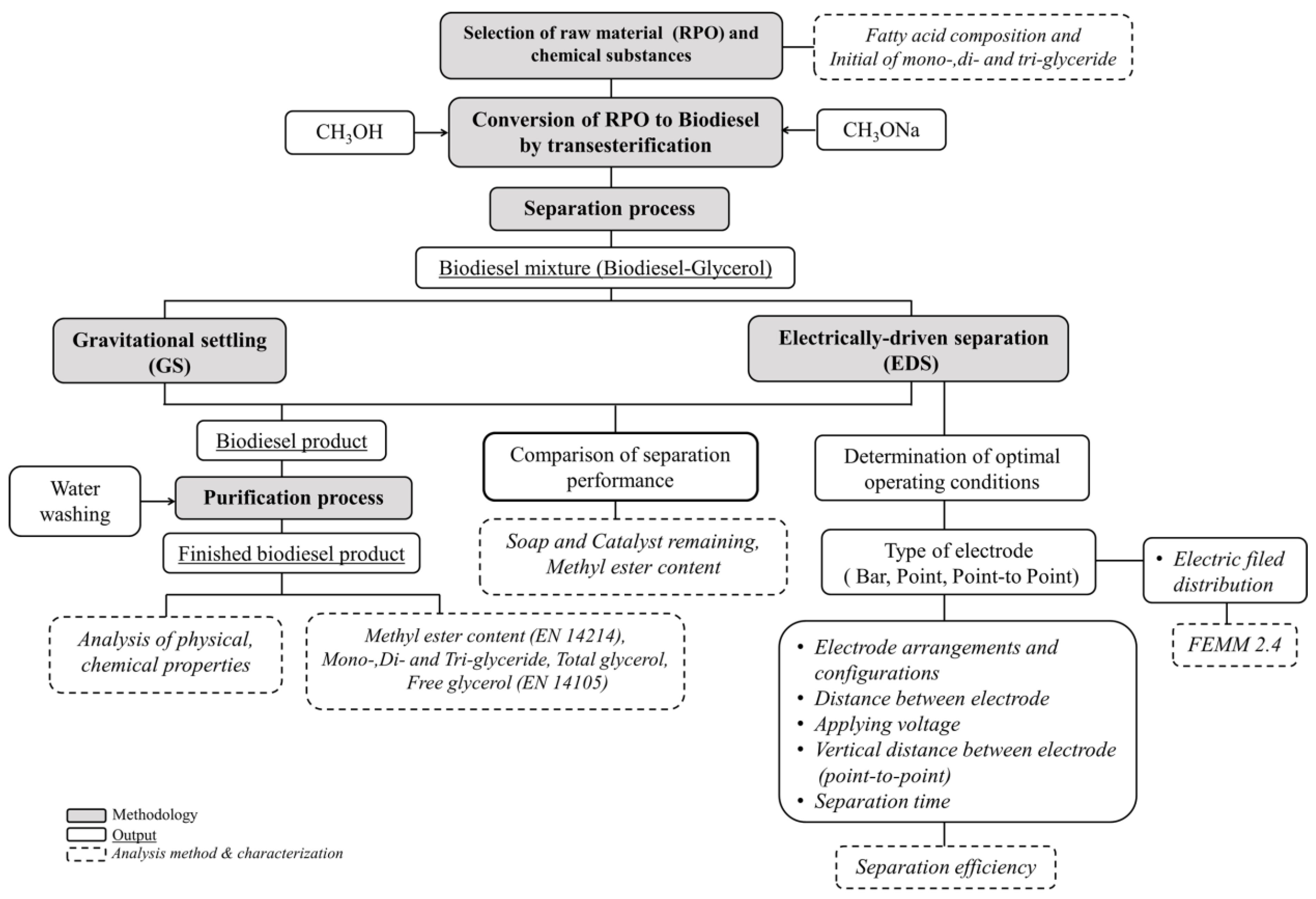

2. Materials and Methods

2.1. Raw Material and Catalyst for Biodiesel Production

2.2. Chemical Analysis

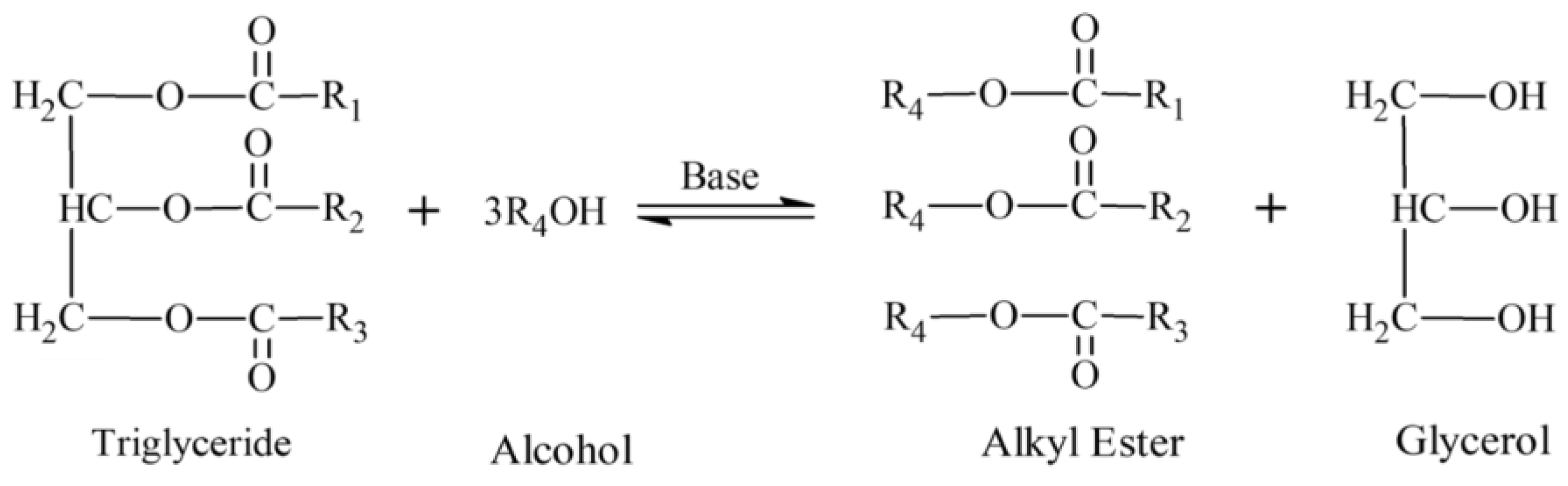

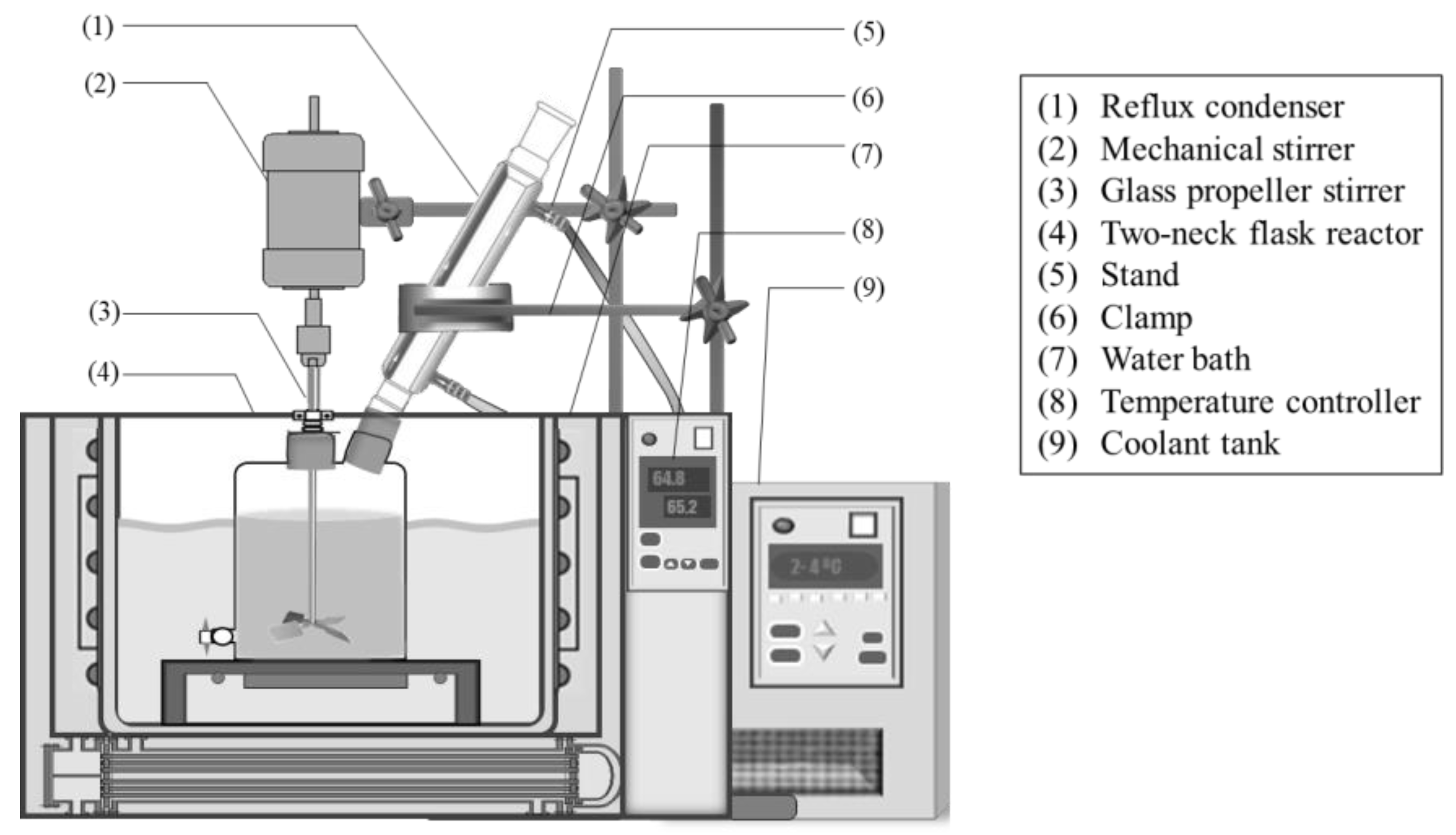

2.3. Transesterification Reaction

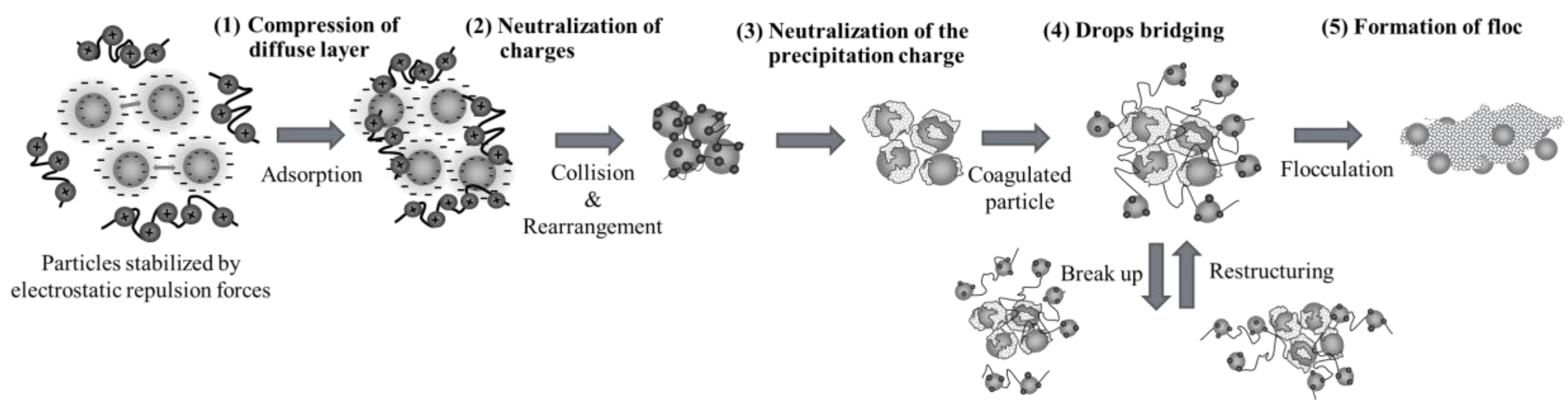

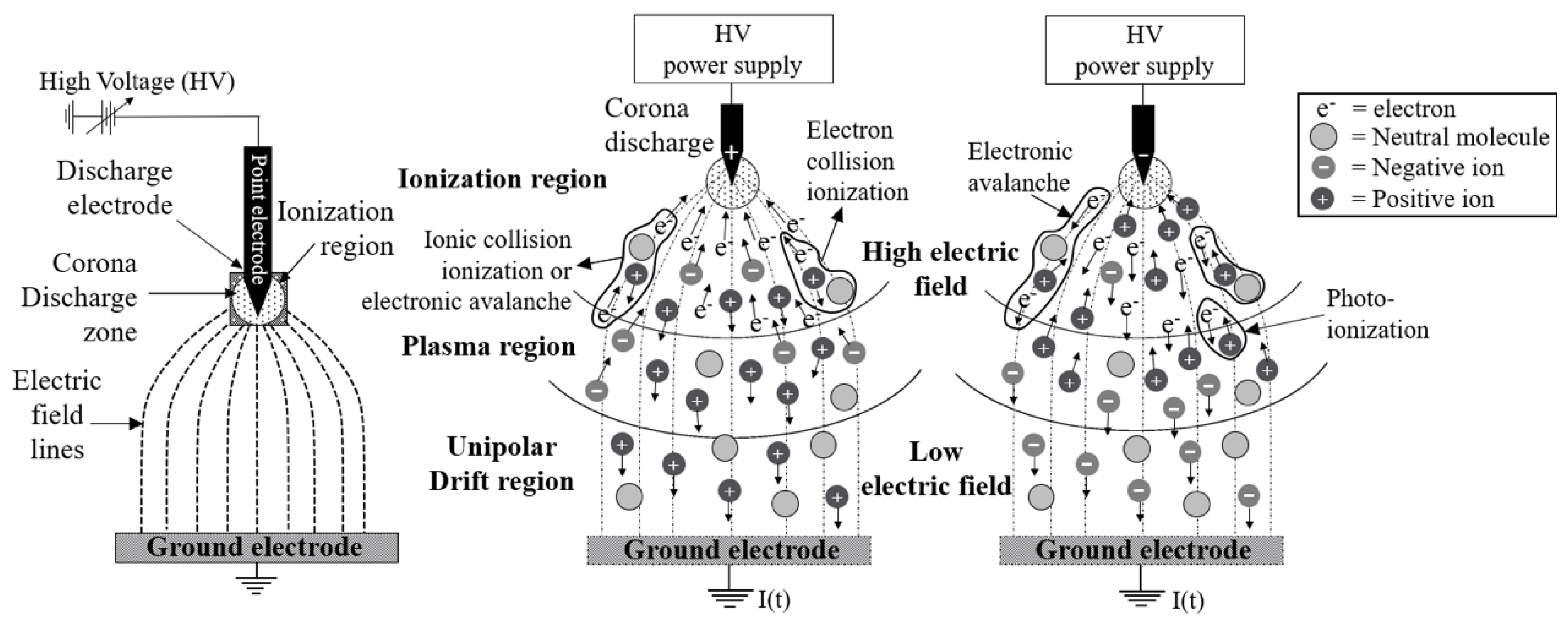

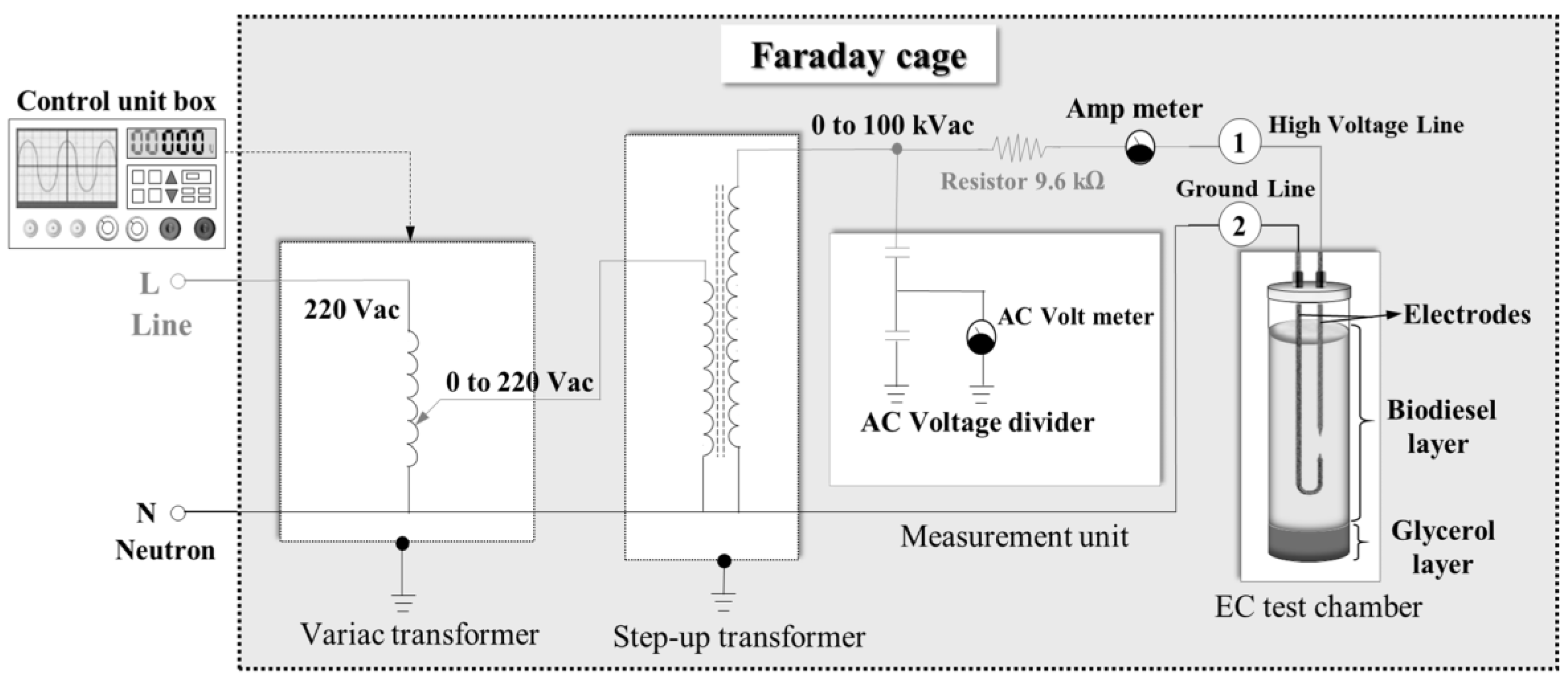

2.4. Electrically Driven Separation Process

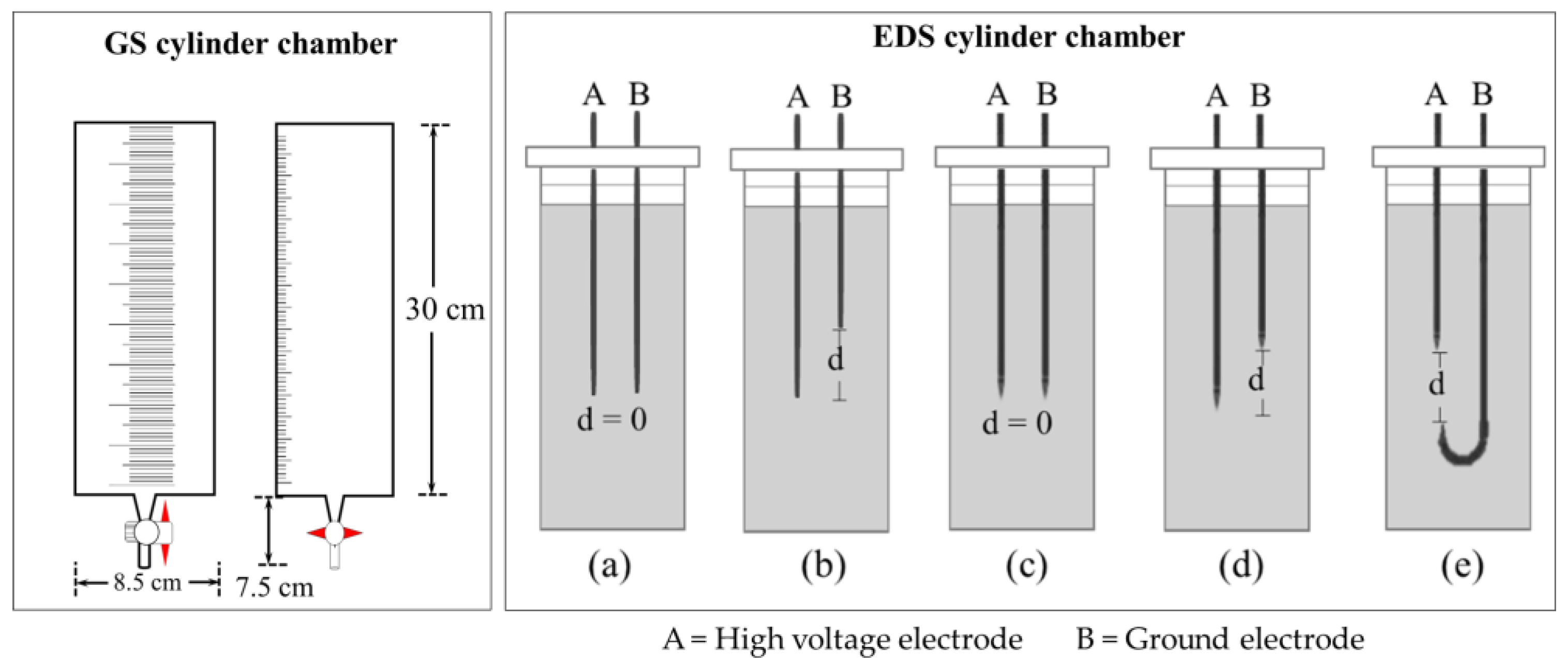

2.5. Comparison on Separation Performance between EDS and GS

2.6. Varying Factors

2.6.1. Type of Electrode Arrangements

2.6.2. Applying High Voltage

2.6.3. Separation Time

2.7. Analysis Method

2.7.1. Separation Efficiency

2.7.2. Soap and Catalyst Remaining Content

2.7.3. Methyl Ester Content

2.7.4. Free and Total Glycerol and Mono-, Di-, and Tri-Glycerides in Fatty Acid Methyl Esters

3. Results and Discussion

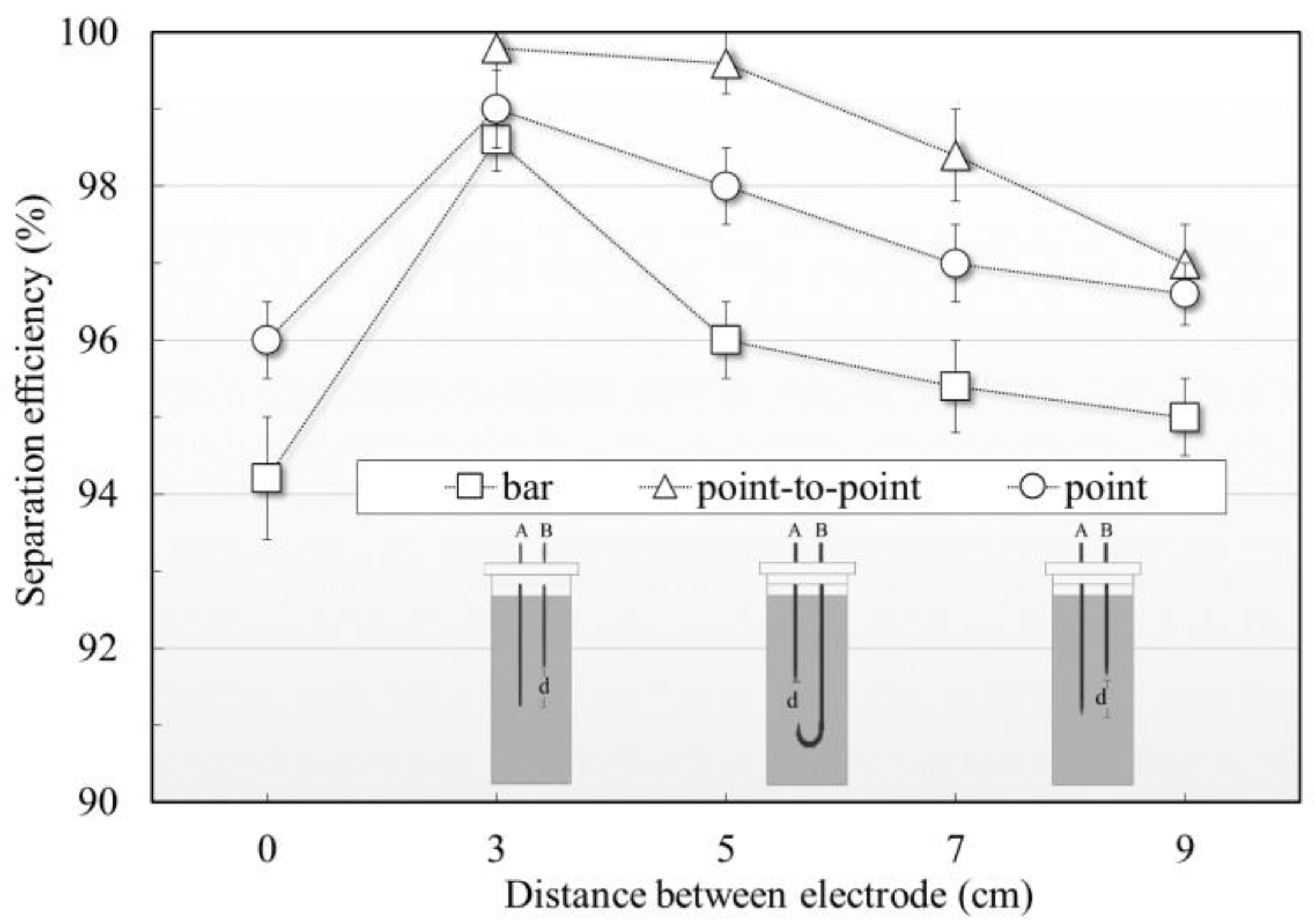

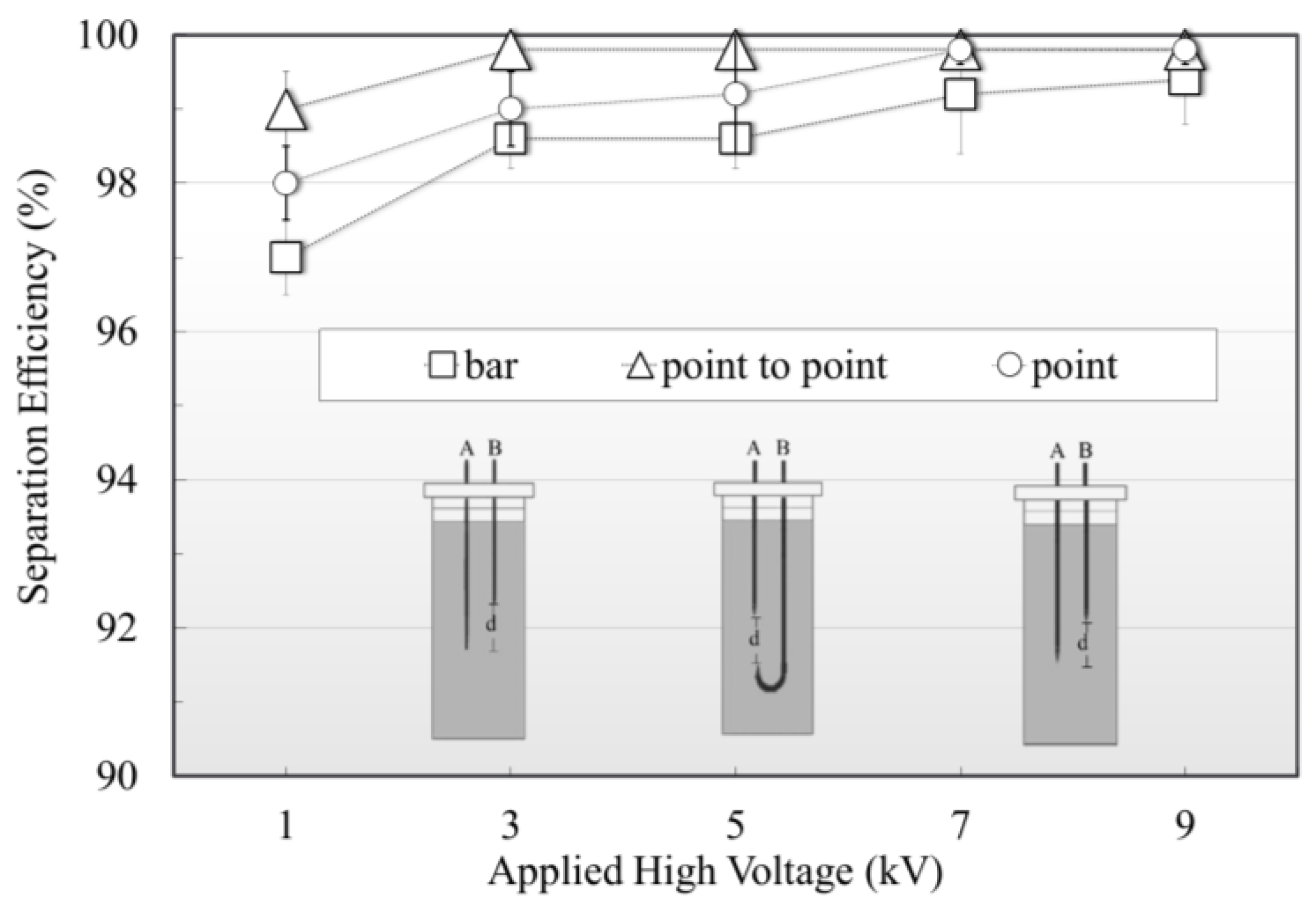

3.1. Electrode Arrangements and Electrode Configurations

3.1.1. Effect of Distance between Electrodes on Separation Efficiency

3.1.2. Effect of Applied AC at High Voltage on Separation Efficiency

3.1.3. Effect of Vertical Distance between Point-to-Point Electrodes

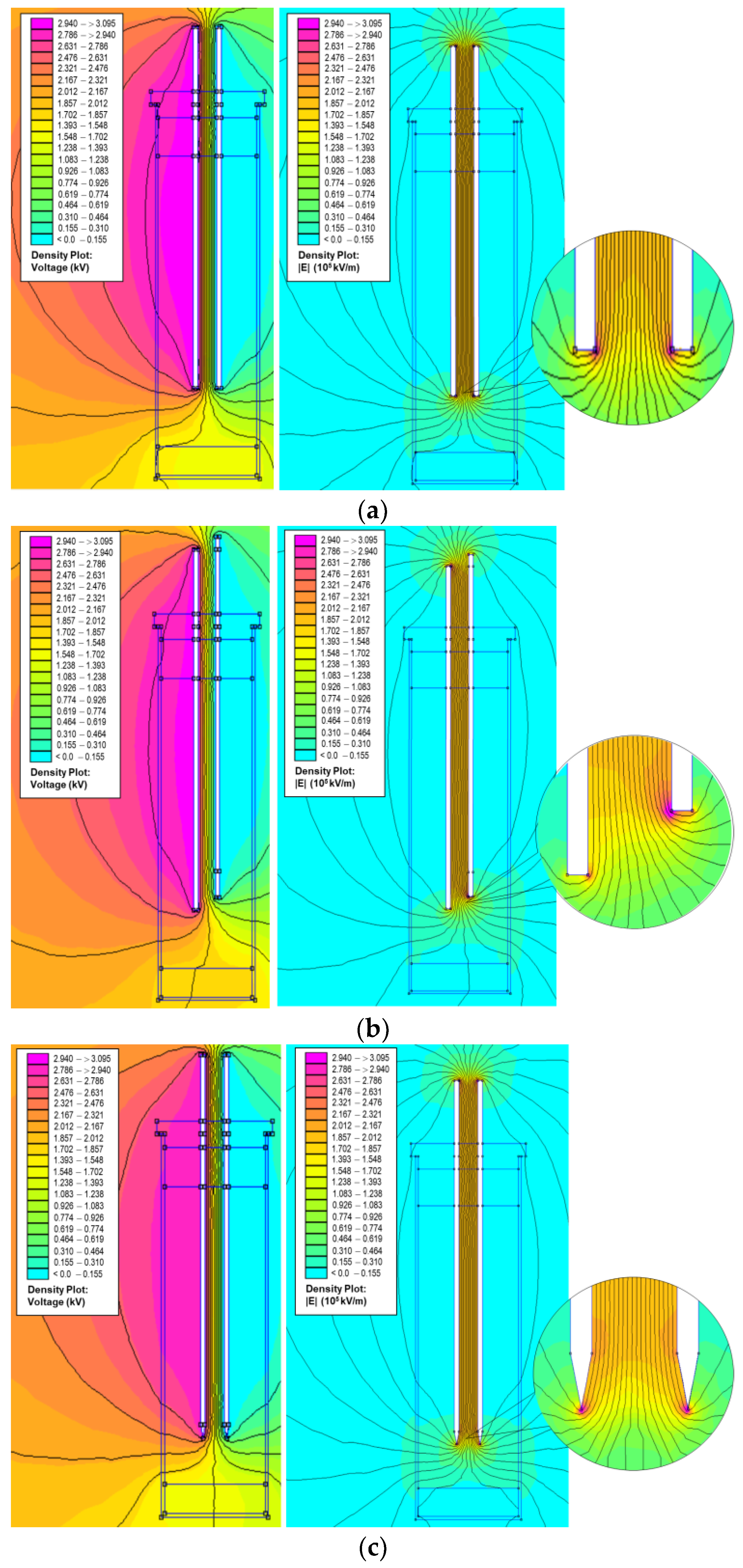

3.1.4. Electric Field Distribution Using Finite Element Method Magnetics Simulation

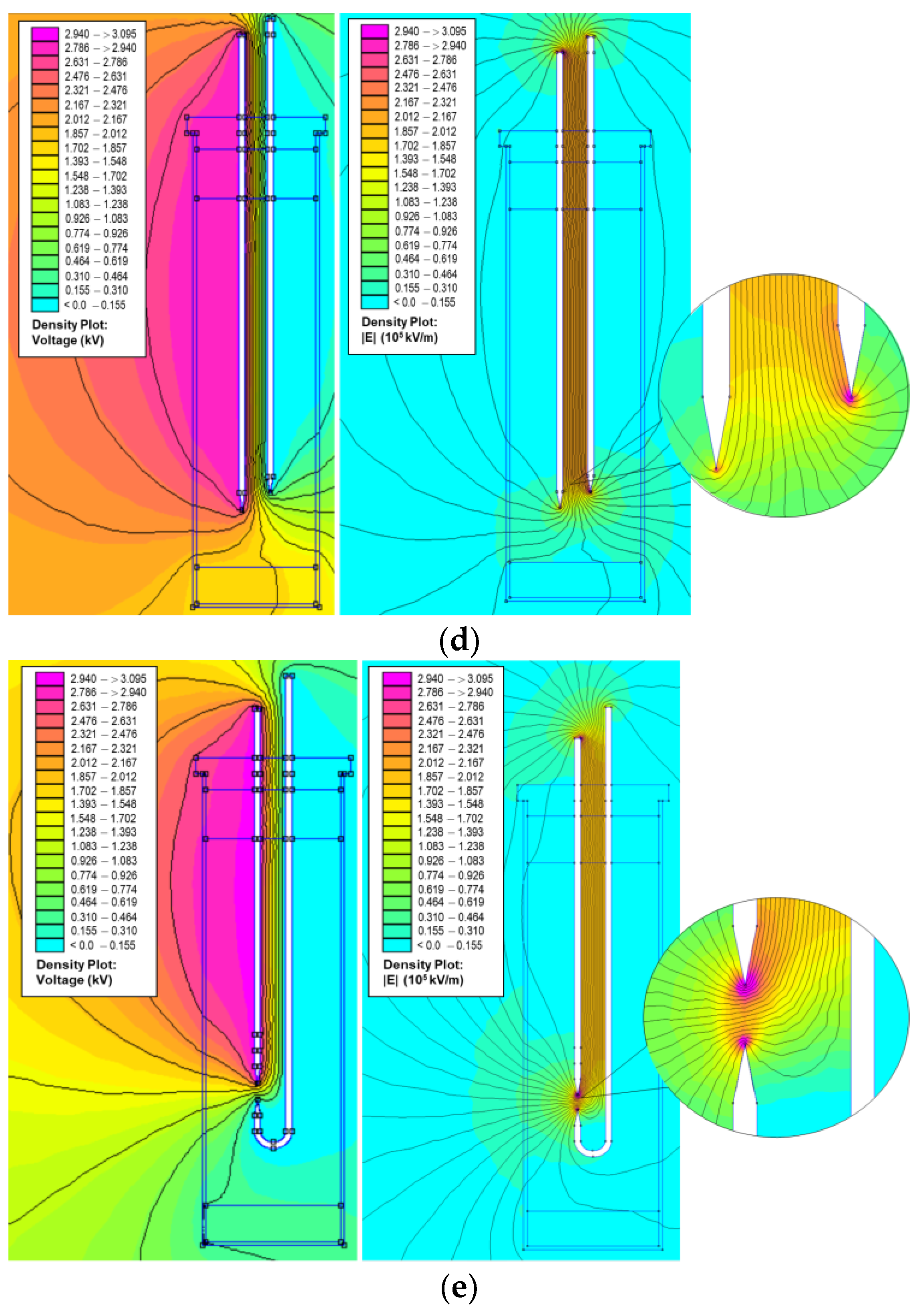

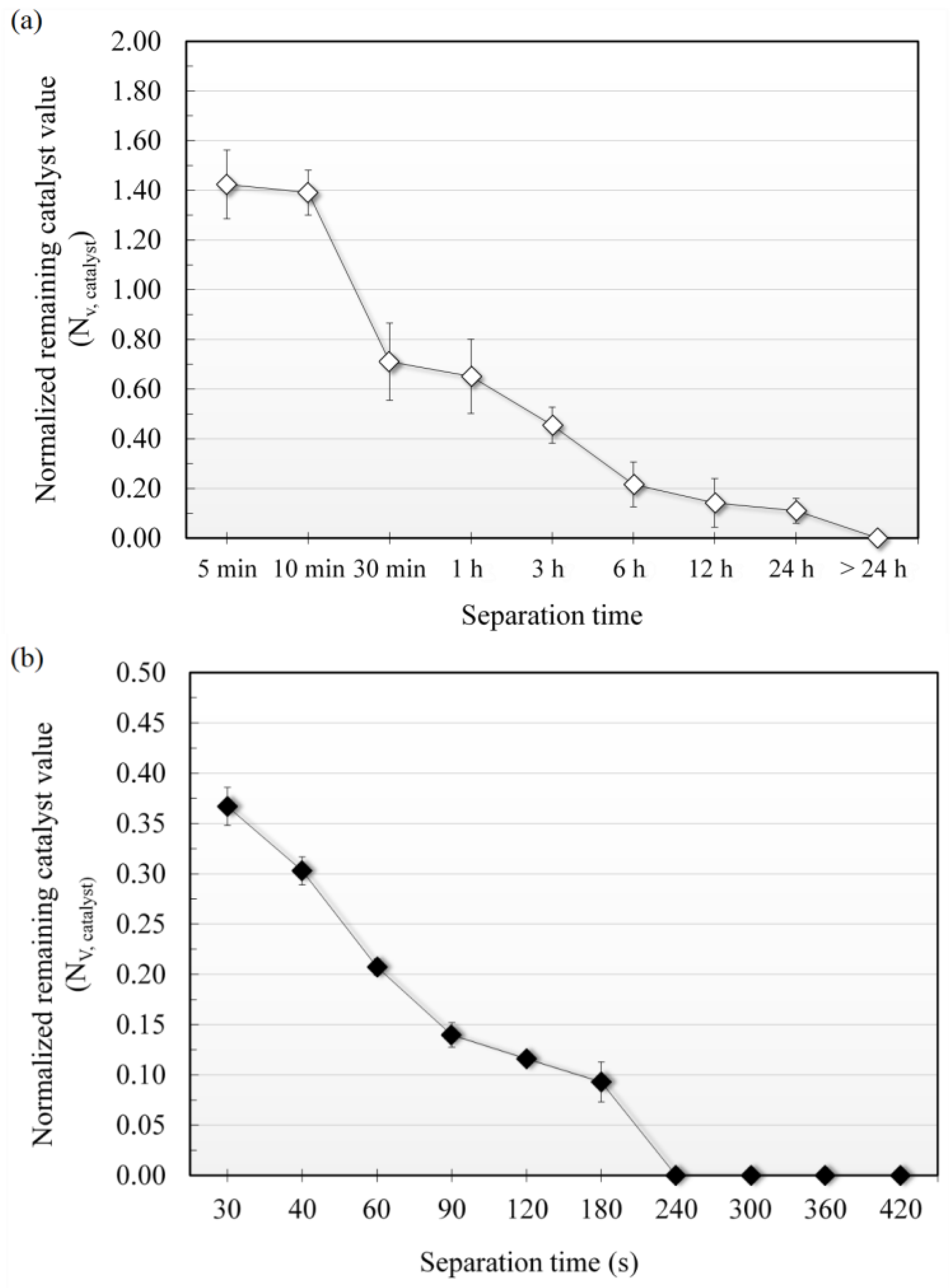

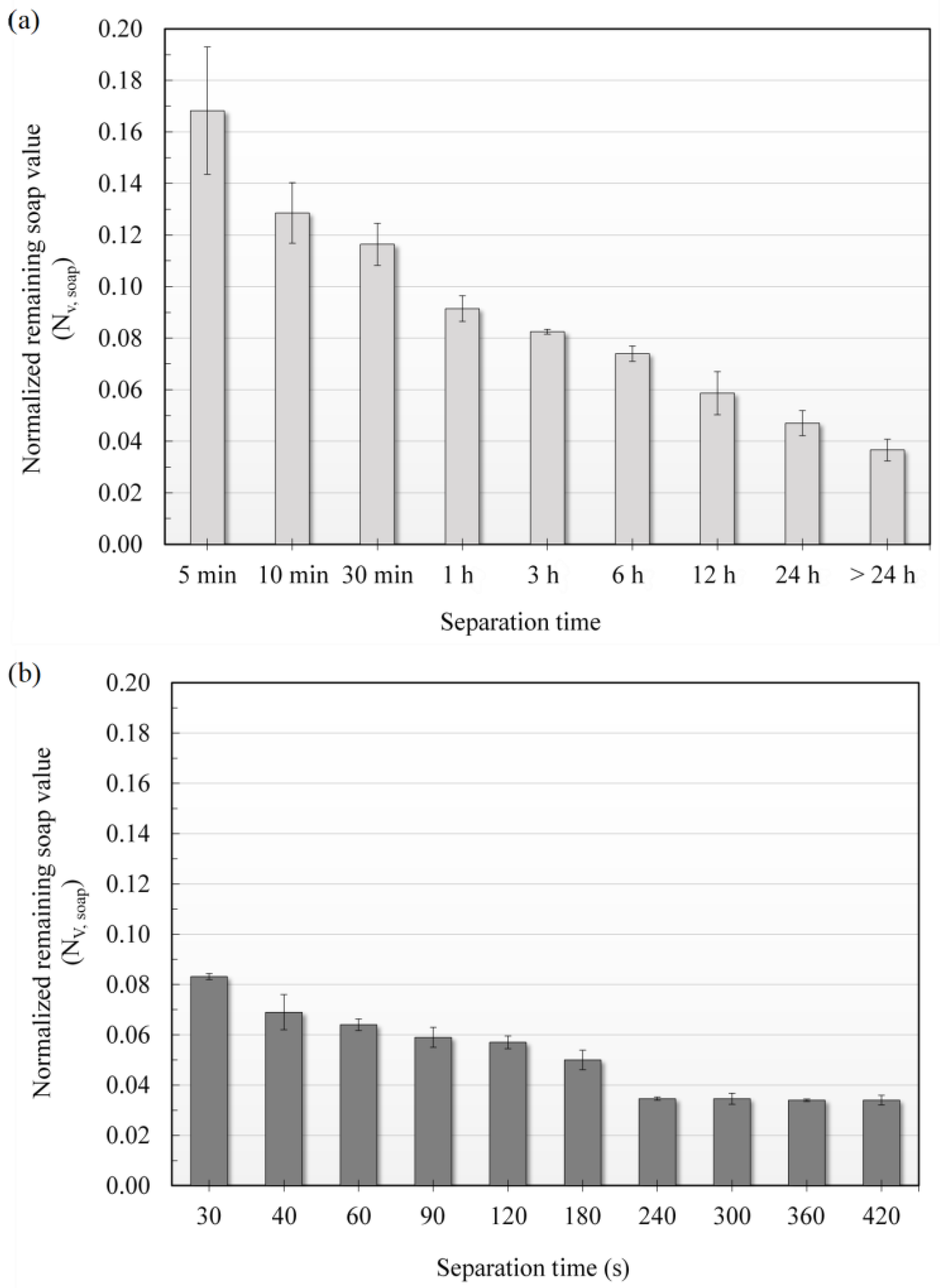

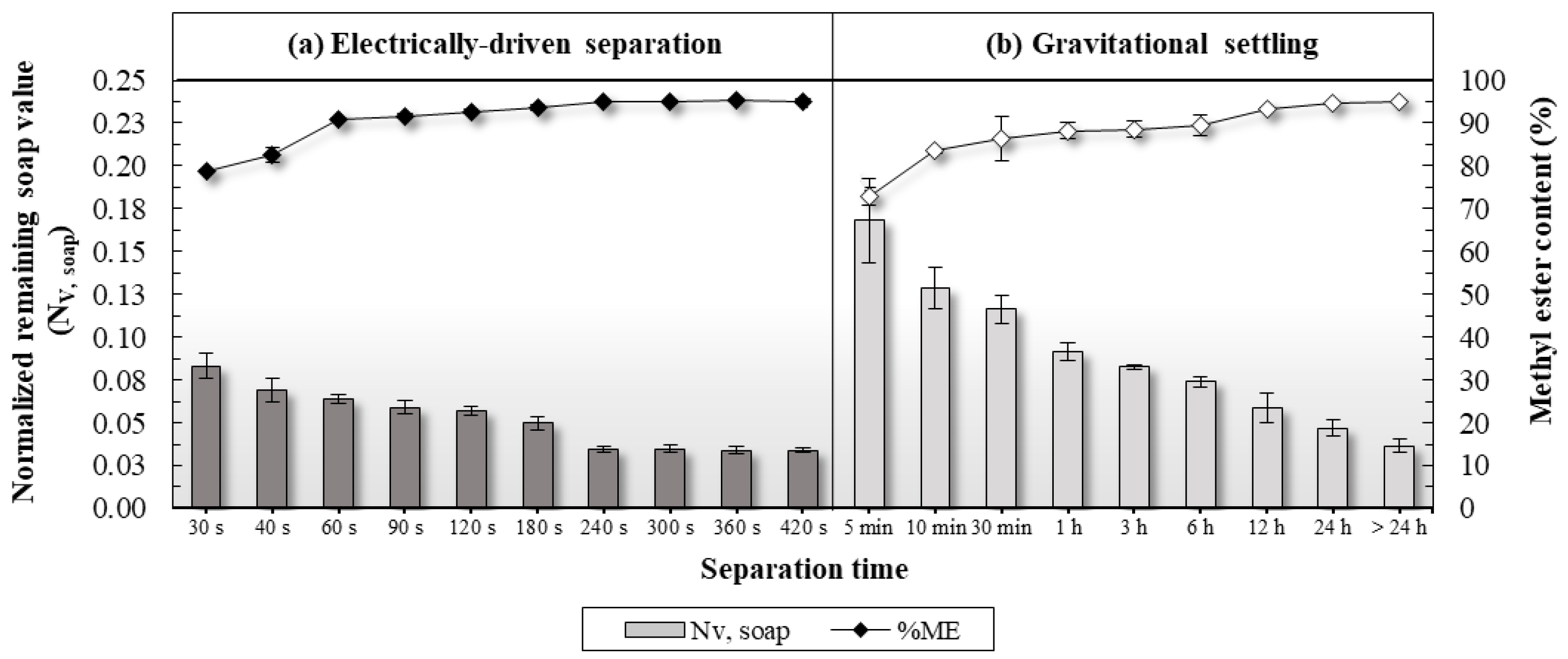

3.2. Effect of Separation Time

3.3. Effect of Remaining Catalyst Content

3.4. Effect of Remaining Soap Content

3.5. Effect of Methyl Ester Content

3.6. Characterization of Biodiesel from RPO

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Barnwal, B.K.; Sharma, M.P. Prospects of biodiesel production from vegetable oils in India. Renew. Sustain. Energy Rev. 2005, 9, 363–378. [Google Scholar] [CrossRef]

- Fukuda, H.; Kondo, A.; Noda, H. Biodiesel fuel production by transesterification of oils. J. Biosci. Bioeng. 2001, 92, 405–416. [Google Scholar] [CrossRef] [PubMed]

- Musa, I.A. The effects of alcohol to oil molar ratios and the type of alcohol on biodiesel production using transesterification process. Egypt. J. Pet. 2016, 25, 21–31. [Google Scholar] [CrossRef]

- Ma, F.; Hanna, M.A. Biodiesel production: A review. Bioresour. Technol. 1999, 70, 1–15. [Google Scholar] [CrossRef]

- Da Silva, N.D.L.; Garnica, J.A.G.; Batistella, C.B.; Maciel, M.R.W.; Filho, R.M. Use of experimental design to investigate biodiesel production by multiple-stage Ultra-Shear reactor. Bioresour. Technol. 2011, 102, 2672–2677. [Google Scholar] [CrossRef]

- Baroutian, S.; Aroua, M.K.; Raman, A.A.A.; Sulaiman, N.M.N. A packed bed membrane reactor for production of biodiesel using activated carbon supported catalyst. Bioresour. Technol. 2011, 102, 1095–1102. [Google Scholar] [CrossRef]

- Moyo, L.B.; Iyuke, S.E.; Muvhiiwa, R.F.; Simate, G.S.; Hlabangana, N. Application of response surface methodology for optimization of biodiesel production parameters from waste cooking oil using a membrane reactor. S. Afr. J. Chem. Eng. 2021, 35, 1–7. [Google Scholar] [CrossRef]

- Pitt, F.D.; Domingos, A.M.; Barros, A.A.C. Purification of residual glycerol recovered from biodiesel production. S. Afr. J. Chem. Eng. 2019, 29, 42–51. [Google Scholar] [CrossRef]

- Mendow, G.; Querini, C.A. High performance purification process of methyl and ethyl esters produced by transesterification. Chem. Eng. J. 2013, 228, 93–101. [Google Scholar] [CrossRef]

- Predojević, Z.J. The production of biodiesel from waste frying oils: A comparison of different purification steps. Fuel 2008, 87, 3522–3528. [Google Scholar] [CrossRef]

- Abbaszadeh, A.; Ghobadian, B.; Najafi, G.; Yusaf, T. An experimental investigation of the effective parameters on wet washing of biodiesel purification. Int. J. Automot. Mech. Eng. 2014, 9, 1525–1537. [Google Scholar] [CrossRef]

- KoohiKamali, S.; Tan, C.P.; Ling, T.C. Optimization of Sunflower Oil Transesterification Process Using Sodium Methoxide. Sci. World J. 2012, 1–8. [Google Scholar] [CrossRef]

- Gomes, M.C.S.; Arroyo, P.A.; Pereira, N.C. Influence of acidified water addition on the biodiesel and glycerol separation through membrane technology. J. Membr. Sci. 2013, 431, 28–36. [Google Scholar] [CrossRef]

- EN 14214; Liquid Petroleum Products—Fatty Acid Methyl Esters (FAME) for Use in Diesel Engines and Heating Applications—Requirements and Test Methods. European Committee for Standardization: Brussels, Belgium, 2012.

- Eyvaz, M.; Kirlaroglu, M.; Aktas, T.S.; Yuksel, E. The effects of alternating current electrocoagulation on dye removal from aqueous solutions. Chem. Eng. J. 2009, 153, 16–22. [Google Scholar] [CrossRef]

- Vasudevan, S.; Lakshmi, J.; Sozhan, G. Effects of alternating and direct current in electrocoagulation process on the removal of cadmium from water. J. Hazard. Mater. 2011, 192, 26–34. [Google Scholar] [CrossRef]

- Cerqueira, A.A.; Souza, P.S.A.; Marques, M.R.C. Effects of direct and alternating current on the treatment of oily water in an electroflocculation process. Braz. J. Chem. Eng. 2014, 31, 693–701. [Google Scholar] [CrossRef]

- Kamaraj, R.; Ganesan, P.; Lakshmi, J.; Vasudevan, S. Removal of copper from water by electrocoagulation process—Effect of alternating current (AC) and direct current (DC). Environ. Sci. Pollut. Res. 2012, 20, 399–412. [Google Scholar] [CrossRef]

- Xu, T.; Zhou, Y.; Hu, B.; Lei, X.; Yu, G. Comparison between sinusoidal AC coagulation and conventional DC coagulation in removing Cu2+ from printed circuit board wastewater. Ecotoxicol. Environ. Saf. 2020, 197, 110629. [Google Scholar] [CrossRef]

- Prica, M.; Adamovic, S.; Dalmacija, B.; Rajic, L.; Trickovic, J.; Rapajic, S.; Becelic-Tomin, M. The electrocoagulation/flotation study: The removal of heavy metals from the waste fountain solution. Process Saf. Environ. Prot. 2015, 94, 262–273. [Google Scholar] [CrossRef]

- Ehsani, H.; Mehrdadi, N.; Asadollahfardi, G.; Bidhendi, G.N.; Azarian, G. A new combined electrocoagulation-electroflotation process for pretreatment of synthetic and real Moquette-manufacturing industry wastewater: Optimization of operating conditions. J. Environ. Chem. Eng. 2020, 8, 104263. [Google Scholar] [CrossRef]

- Nasrullah, M.; Singh, L.; Wahid, Z.A. Treatment of sewage by electrocoagulation and the effect of high current density. Energy Environ. Eng. 2012, 1, 27–31. [Google Scholar] [CrossRef]

- Gregory, J. Flocculation Fundamentals. In Encyclopedia of Colloid and Interface Science; Tadros, T., Ed.; Springle: Berlin/Heidelberg, Germany, 2013; pp. 459–491. [Google Scholar]

- Eow, J.S.; Ghadiri, M.; Sharif, A.O.; Williams, T.J. Electrostatic enhancement of coalescence of water droplets in oil: A review of the current understanding. Chem. Eng. J. 2001, 84, 173–192. [Google Scholar] [CrossRef]

- Wang, Z.; Dong, K.; Tian, L.; Wang, J.; Tu, J. Numerical study on coalescence behavior of suspended drop pair in viscous liquid under uniform electric field. AIP Adv. 2018, 8, 85215. [Google Scholar] [CrossRef]

- Bashkir, I.; Defraeye, T.; Kudra, T.; Martynenko, A. Electrohydrodynamic Drying of Plant-Based Foods and Food Model Systems. Food Eng. Rev. 2020, 12, 473–497. [Google Scholar] [CrossRef]

- Sun, A.; Zhuang, J.; Huo, C. Formation mechanism of streamer discharges in liquids: A review. High Volt. 2016, 1, 74–80. [Google Scholar] [CrossRef]

- Tian, J.; Zhao, T.; Zhou, Z.; Chen, B.; Wang, J.; Xiong, J. Isolated moving charged droplet evaporation characteristics in electrostatic field with highly volatile R134a. Int. J. Heat Mass Transf. 2021, 178, 121583. [Google Scholar] [CrossRef]

- Chen, J.; Davidson, J.H. Model of the Negative DC Corona Plasma: Comparison to the Positive DC Corona Plasma. Plasma Chem. Plasma Proc. 2003, 23, 83–102. [Google Scholar] [CrossRef]

- Goldman, M.; Goldman, A.; Sigmond, R. The corona discharge, its properties and specific use. Pure Appl. Chem. 1985, 57, 1353–1362. [Google Scholar] [CrossRef]

- Vaddi, R.S.; Guan, Y.; Mamishev, A.; Novosselov, I. Analytical model for electrohydrodynamic thrust. Proc. R. Soc. A Math. Phys. Eng. Sci. 2020, 476, 20200220. [Google Scholar] [CrossRef]

- Johansson, K.S. Surface Modification of Plastics. In Applied Plastics Engineering Handbook; William Andrew Publishing: Norwich, NY, USA, 2017; pp. 443–487. [Google Scholar]

- Florkowski, M.; Krześniak, D.; Kuniewski, M.; Zydroń, P. Partial Discharge Imaging Correlated with Phase-Resolved Patterns in Non-Uniform Electric Fields with Various Dielectric Barrier Materials. Energies 2020, 13, 2676. [Google Scholar] [CrossRef]

- Basiry, M.; Esehaghbeygi, A. Electrohydrodynamic (EHD) drying of rapeseed (Brassica napus L.). J. Electrost. 2010, 68, 360–363. [Google Scholar] [CrossRef]

- Abdul Madhar, S.; Mráz, P.; Rodrigo Mor, A.; Ross, R. Study of Corona Configurations under DC Conditions and Recommendations for an Identification Test Plan. Int. J. Electr. Power Energy Syst. 2020, 118, 105820. [Google Scholar] [CrossRef]

- EN 14105; Fat and Oil Derivatives. Fatty acid Methyl Esters (FAME). Determination of Free and Total Glycerol and Mono-, di-, Triglyceride Contents (Reference Method). European Committee for Standardization: Brussels, Belgium, 2011.

- European Standard of EN 14103; Fat and Oil Derivatives–Fatty Acid Methyl Esters (FAME)—Determination of Ester and Linolenic Acid Methyl Ester Contents. European Committee for Standardization, Management Centre: Brussels, Belgium, 2003.

- AOCS. Official and Tentative Methods of the American Oil Chemists’ Society, 4th ed.; Methods Cc 15-60 and Cc17-95; AOCS: Champaign, IL, USA, 1989; Volume 4. [Google Scholar]

- Okullo, A.; Ogwok, P.; Temu, A.K.; Ntalikwa, J.W. Gas Chromatographic Determination of Glycerol and Triglycerides in Biodiesel from Jatropha and Castor Vegetable Oils. Adv. Mater. Res. 2013, 824, 436–443. [Google Scholar] [CrossRef]

- Baruah, N.; Maharana, M.; Nayak, S.K. An Electrode Model to Ascertain the Effects of Voltage and Tip Radius with Gap Distance on Electric Field of Transformer Oil. In Proceedings of the 2018 2nd International Conference on Power, Energy and Environment (ICEPE): Towards Smart Technology, Shillong, India, 1–2 June 2018. [Google Scholar]

- Takahashi, K.; Takaki, K.; Hiyoshi, I.; Enomoto, Y.; Yamaguchi, S.; Nagata, H. Development of a Corona Discharge Ionizer Utilizing High-Voltage AC Power Supply Driven by PWM Inverter for Highly Efficient Electrostatic Elimination. In Modern Applications of Electrostatics and Dielectrics; IntechOpen: London, UK, 2020. [Google Scholar]

- Ji, J.-H.; Hwang, J.; Bae, G.-N.; Kim, Y.-G. Particle charging and agglomeration in DC and AC electric fields. J. Electrost. 2004, 61, 57–68. [Google Scholar] [CrossRef]

- Kupershtokh, A.L.; Palchikov, E.I.; Karpov, D.I.; Vitellas, I.; Agoris, D.P.; Charalambakos, V.P. Stochastic model of breakdown initiation in dielectric liquids. J. Phys. D Appl. Phys. 2002, 35, 3106–3121. [Google Scholar] [CrossRef]

- Guerbas, F.; Zitouni, M.; Boubakeur, A.; Beroual, A. Barrier effect on breakdown of point–plane oil gaps under alternating current voltage. IET Gener. Transm. Distrib. 2010, 4, 1245. [Google Scholar] [CrossRef]

- Lee, J.-C.; Kim, W.-Y. Experimental Study on the Dielectric Breakdown Voltage of the Insulating Oil Mixed with Magnetic Nanoparticles. Phys. Procedia 2012, 32, 327–334. [Google Scholar] [CrossRef]

- Hao, J.; Feng, D.; Yang, L.; Liao, R.; Chen, X.; Li, J. Comparison of AC Breakdown Characteristics on Insulation Paper (Pressboard) Impregnated by Three-element Mixed Insulation Oil and Mineral Oil. High Voltage 2020, 5, 298–305. [Google Scholar]

- Gao, B.; Yu, R.; Hu, G.; Liu, C.; Zhuang, X.; Zhou, P. Development Processes of Surface Trucking and Partial Discharge of Pressboards Immersed in Mineral Oil: Effect of Tip Curvatures. Energies 2019, 12, 554. [Google Scholar] [CrossRef]

- Koppisetty, K.; Sozer, E.B.; Kirkici, H.; Schweickart, D.L. Helium Breakdown Characteristics under 100 kHz Range Pulsed Voltages in Partial Vacuum for Point-to-point Electrode Geometry. In Proceedings of the Conference Record of the 2006 Twenty-Seventh International Power Modulator Symposium, Arlington, VA, USA, 14–18 May 2006. [Google Scholar]

- Mo, W.; Song, H.; Huang, Q.; Chen, Y.; Wang, W. Differences in Characteristics of Long-Gap Lightning Impulse Breakdown between Vegetable and Mineral Insulating Oil. Trans. Electr. Electron. Mater. 2020, 22, 301–309. [Google Scholar] [CrossRef]

- Eppo Annual Report Energy Policy and Planning Office, Ministry of Energy, Characteristics and Specifications of Fatty Acid Methyl Ester. (FAME)-Typed Biodiesel of 2019. Available online: https://www.mtec.or.th/wp-content/uploads/MFE_1.pdf (accessed on 1 August 2020).

- ASTM D6751-09; Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels. ASTM International: West Conshohocken, PA, USA, 2009. Available online: https://www.astm.org/d6751-09.html (accessed on 2 October 2020).

| Type of Fatty Acids | Fatty Acid Name | Formula | Composition (%) |

|---|---|---|---|

| Saturated group | Lauric acid | C12:0 | 0.80 |

| Myristic acid | C14:0 | 1.10 | |

| Palmitic acid | C16:0 | 43.45 | |

| Stearic acid | C18:0 | 4.23 | |

| Arachidic acid | C20:0 | 0.16 | |

| Behenic acid | C22:0 | 0.06 | |

| Erucic acid | C24 isomer | 0.07 | |

| Unsaturated group | Oleic acid | C18:1 | 40.90 |

| Linoleic acid | C18:2 | 9.10 | |

| Linoleic acid | C18:3 | 0.24 | |

| Average molar mass (g mol−1) | 270.22 | ||

| Average molecular weight (g mol−1) | 848.70 | ||

| Saturated carbons | 49.87 | ||

| Monounsaturated carbons | 40.90 | ||

| Polyunsaturated carbons | 9.34 | ||

| Parameters | Units | Method | Limits | Results | |

|---|---|---|---|---|---|

| ASTM D6751 | EN14214 | ||||

| Ester content | % | EN14103 | N/S | ≥96.5 | 98.50 ± 0.25 |

| Free glycerol | %mass | EN14105 | - | 0.02 max | 0.03 |

| Monoglyceride | %mass | EN14105 | - | 0.8 max | 0.19 |

| Diglycerides | %mass | EN14105 | - | 0.2 max | 0.19 |

| Triglyceride | %mass | EN14105 | - | 0.2 max | 0.01 |

| Total glycerol | %mass | EN14105 | - | 0.25 max | 0.11 |

| Acid value | mg KOH/g of sample | ASTM D664 | N/S | 0.50 max | 0.043 |

| Iodine value (Wijs) | g iodine/100 g | EN14111-03 | N/S | 120 max | 53.0 |

| Kinematic viscosity; 40 °C | mm2/s | ASTM D445-17a | 1.9–6.0 | 3.5–5.0 | 4.781 |

| Pour point | °C | ASTM D5950-14 | N/S | N/S | 11 |

| Cloud point | °C | ASTM D5771-17 | N/S | N/S | 12 |

| Flash point | °C | ASTM D98-16a (method C) | 130 min | 101 min | 163 |

| Fire point | °C | 130 min | N/S | 168 | |

| Density at 50 °C | g cm−3 | N/S | N/S | 860–900 | 877 |

| Cetane number | ASTM D613 | 47 min | 51 min | 54 min | |

| Sulfur content | %mass | ASTM D2622 | 0.05 max | N/S | 0.02 |

| Parameters | Gravitational Setting (GS) | Electrically Driven Separation (EDS) |

|---|---|---|

| Separation Process | ||

| Electrode configuration | - | Point-to-point |

| Distance between electrode | - | 3 cm |

| Applying voltage | - | 3 kV |

| Separation time (clear interface *) | 1 h | 40 s |

| Separation efficiency | 94.8% | 98.4% |

| Separation time | 30 m | 60 s |

| Normalized catalyst remaining | 0.710 | 0.207 |

| Normalized soap remaining | 0.116 | 0.064 |

| Methyl ester content (%) | 86.4 ± 0.2 | 90.9 ± 0.5 |

| Separation efficiency | 99.8% | 99.8% |

| Separation time | >24 h | 240 s |

| Normalized catalyst remaining | Not found | Not found |

| Normalized soap remaining | 0.037 | 0.035 |

| Methyl ester content (%) | 95.1 ± 0.2 | 95.2 ± 0.2 |

| Purification with water wash | ||

| Number of washing times | 5 times | 2 times |

| Methyl ester content (%) | 97.50 ± 1.22 (STD) | 97.77 ± 0.80 (STD) |

| Number of washing times | 3 times | 3 times |

| Methyl ester content (%) | 95.1 ± 0.62 | 98.50 ± 0.25 (STD) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ampairojanawong, R.; Boripun, A.; Ruankon, S.; Suwanasri, T.; Cheenkachorn, K.; Kangsadan, T. Separation Process of Biodiesel-Product Mixture from Crude Glycerol and Other Contaminants Using Electrically Driven Separation Technique with AC High Voltage. Electrochem 2023, 4, 123-144. https://doi.org/10.3390/electrochem4010011

Ampairojanawong R, Boripun A, Ruankon S, Suwanasri T, Cheenkachorn K, Kangsadan T. Separation Process of Biodiesel-Product Mixture from Crude Glycerol and Other Contaminants Using Electrically Driven Separation Technique with AC High Voltage. Electrochem. 2023; 4(1):123-144. https://doi.org/10.3390/electrochem4010011

Chicago/Turabian StyleAmpairojanawong, Rossarin, Ajalaya Boripun, Sayan Ruankon, Thanapong Suwanasri, Kraipat Cheenkachorn, and Tawiwan Kangsadan. 2023. "Separation Process of Biodiesel-Product Mixture from Crude Glycerol and Other Contaminants Using Electrically Driven Separation Technique with AC High Voltage" Electrochem 4, no. 1: 123-144. https://doi.org/10.3390/electrochem4010011

APA StyleAmpairojanawong, R., Boripun, A., Ruankon, S., Suwanasri, T., Cheenkachorn, K., & Kangsadan, T. (2023). Separation Process of Biodiesel-Product Mixture from Crude Glycerol and Other Contaminants Using Electrically Driven Separation Technique with AC High Voltage. Electrochem, 4(1), 123-144. https://doi.org/10.3390/electrochem4010011