Design Simulation and Data Analysis of an Optical Spectrometer

Abstract

:1. Introduction

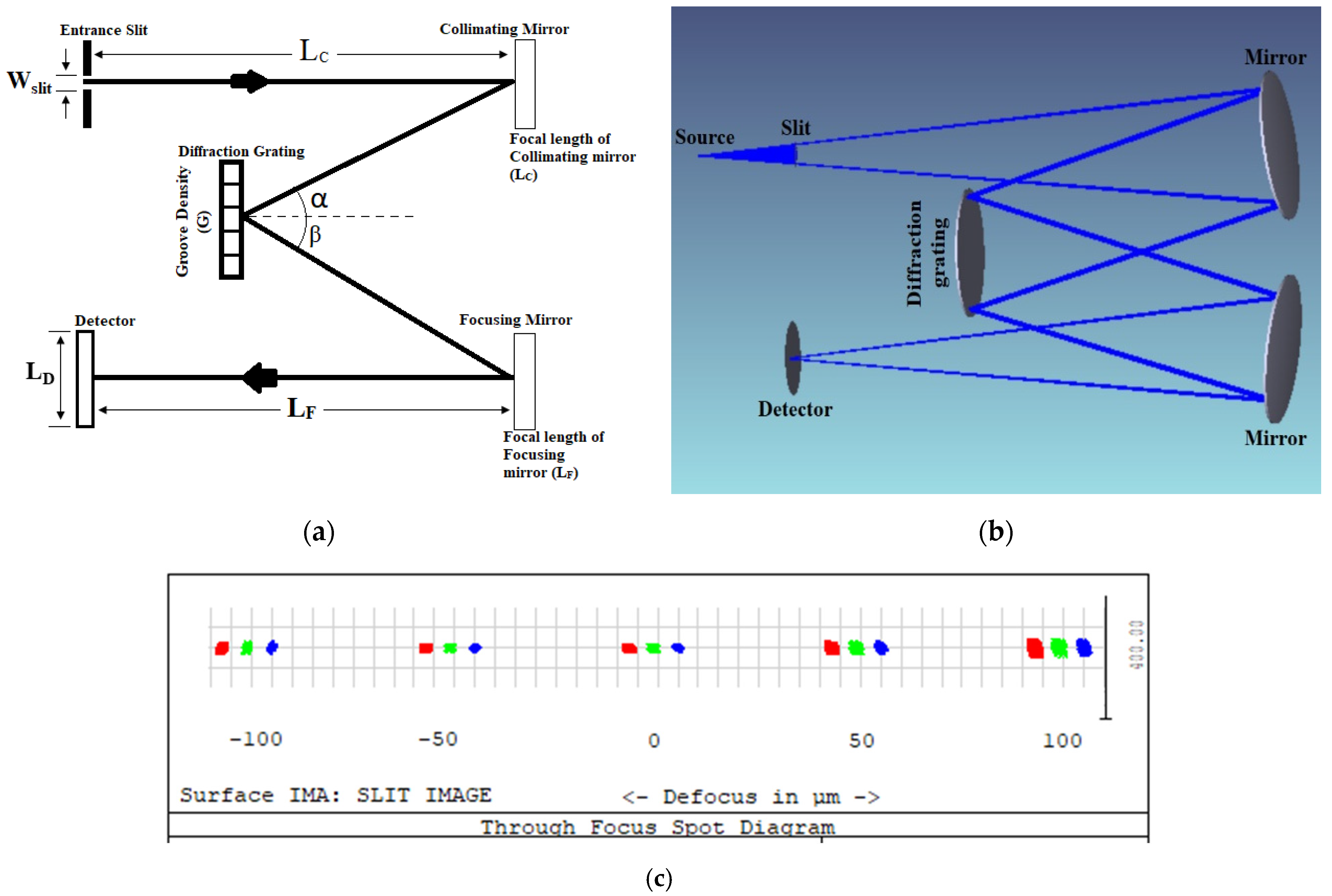

2. General View of an Optical Spectrometer

3. Design and Simulation of Optical Spectrometer

4. Simulation Results of the Spectrometer (Visible Range)

4.1. Spot Diagram

4.2. Image of the Spectral Irradiance

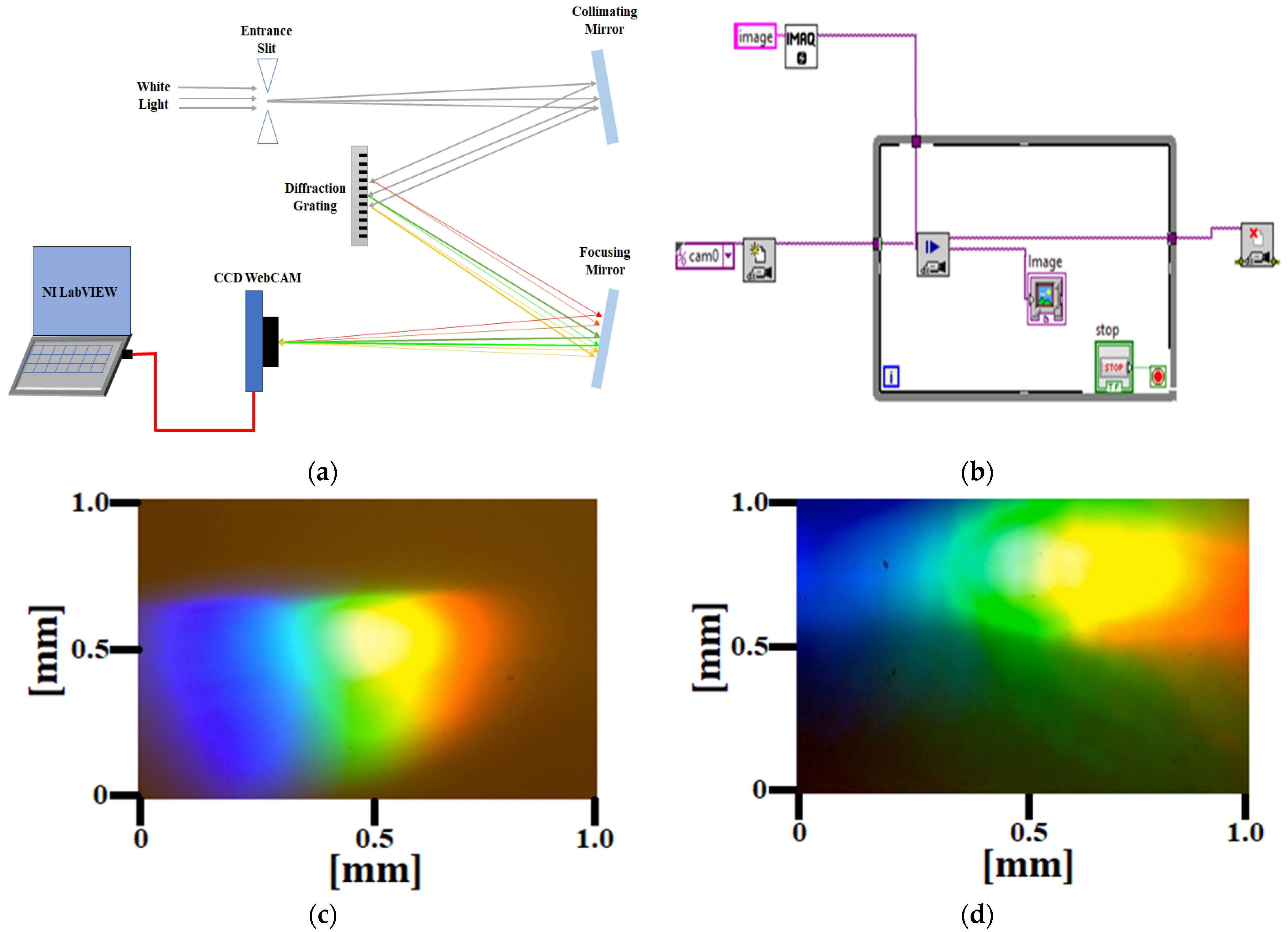

5. Experimental Setup and Results

Acquisition of Image

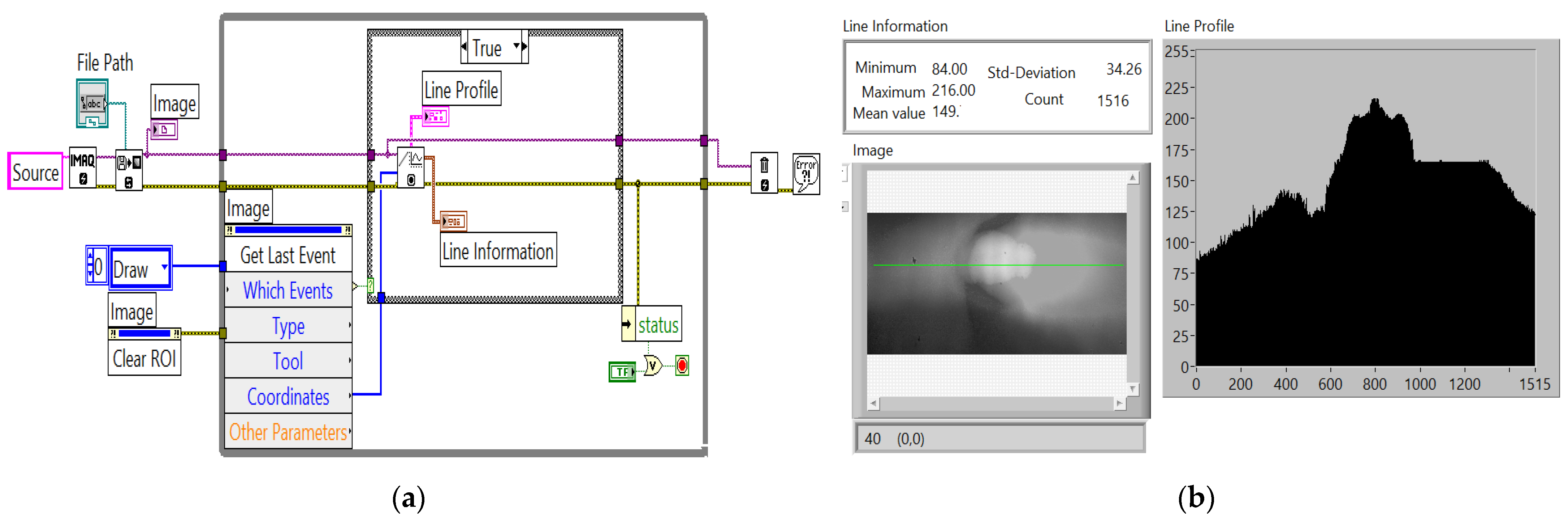

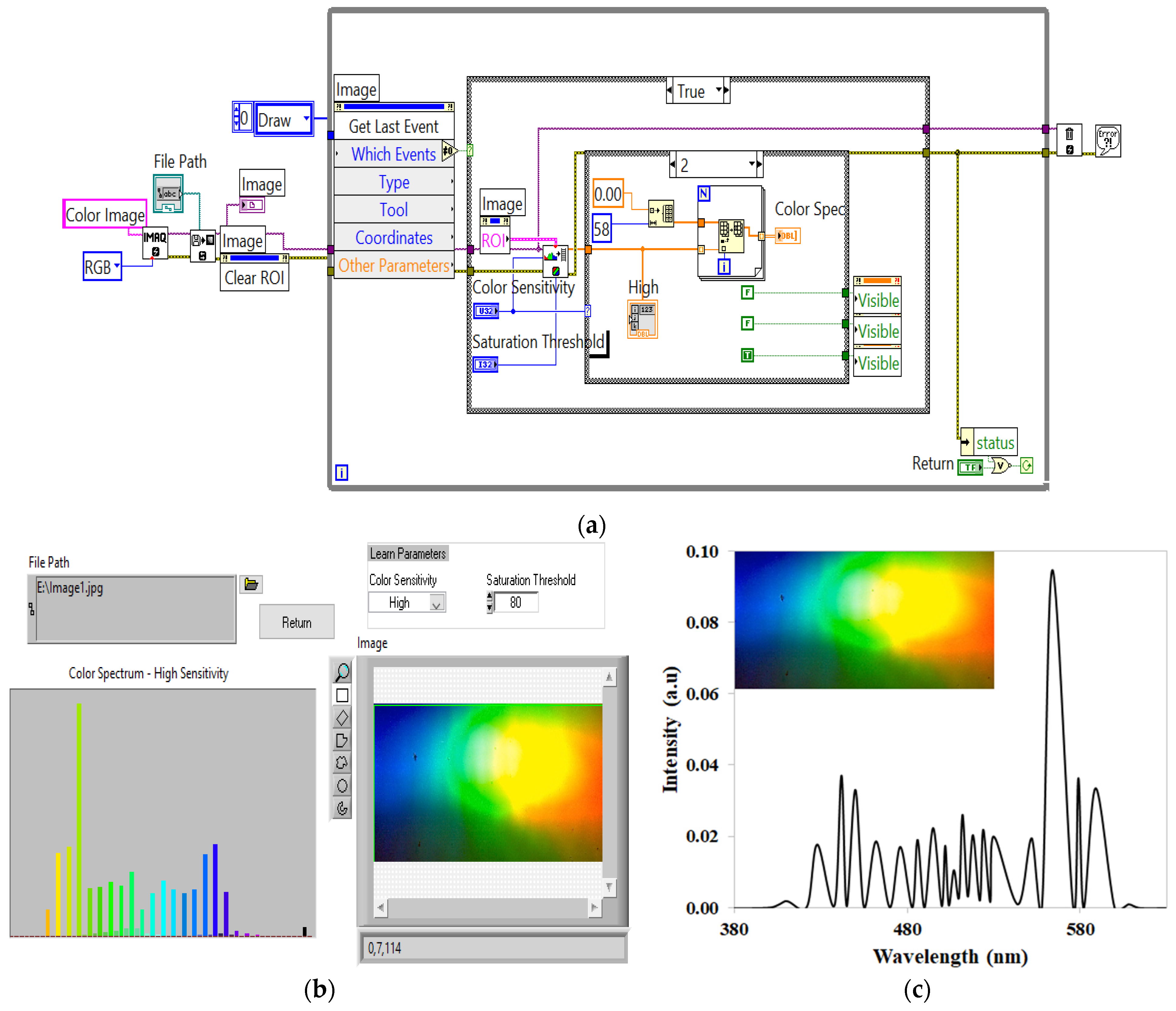

6. Analysis of Experimental Results Using LabVIEW

6.1. Formation of Array with Pixel-to-Pixel Values and Corresponding Graph

6.2. Color Spectrum of RGB (Color) Image

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Masson, C.R. A stable acousto-optical spectrometer for millimeter radio astronomy. Astron. Astrophys. 1982, 114, 270. [Google Scholar]

- Arzhantsev, S.; Maroncelli, M. Design and Characterization of a Femtosecond Fluorescence Spectrometer Based on Optical Kerr Gating. Appl. Spectrosc. 2005, 59, 206–220. [Google Scholar] [CrossRef] [PubMed]

- Herrera-Martínez, G.; Luna, A.; Carrasco, L.; Shcherbakov, A.; Sánchez, D.; Mendoza, E.; Renero, F. A Design of an Acousto-Optical Spectrometer. Rev. Mex. Astron. Astrofísica 2009, 37, 156–159. [Google Scholar] [CrossRef]

- Lei, F.; Wei, L.; Yang, L.; He, X.; Zhou, J. Modeling and Simulation of spectrometer based on prism. In Proceedings of the 2019 8th International Conference on Software and Information Engineering, Cairo, Egypt, 9–12 April 2019; pp. 132–135. [Google Scholar]

- Xu, D.; Sui, C.; Tong, J.; Yang, H. Optical Design of Micro Spectrometer. In Proceedings of the 2012 Second International Conference on Instrumentation, Measurement, Computer, Communication and Control, Harbin, China, 8–10 December 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 339–341. [Google Scholar]

- Kim, S.H.; Kong, H.J.; Lee, J.U.; Lee, J.H.; Lee, J.H. Design and construction of an Offner spectrometer based on geometrical analysis of ring fields. Rev. Sci. Instrum. 2014, 85, 83108. [Google Scholar] [CrossRef] [PubMed]

- Micó, G.; Gargallo, B.; Pastor, D.; Muñoz, P. Integrated Optic Sensing Spectrometer: Concept and Design. Sensors 2019, 19, 1018. [Google Scholar] [CrossRef] [PubMed]

- Naeem, M.; Fatima, N.-U.; Hussain, M.; Imran, T.; Bhatti, A.S. Design Simulation of Czerny–Turner Configuration-Based Raman Spectrometer Using Physical Optics Propagation Algorithm. Optics 2022, 3, 1–7. [Google Scholar] [CrossRef]

- Kao, C.-F.; Lu, S.-H.; Shen, H.-M.; Fan, K.-C. Diffractive Laser Encoder with a Grating in Littrow Configuration. Jpn J. Appl. Phys. 2008, 47, 1833–1837. [Google Scholar] [CrossRef]

- Nagdive, A.; Dongre, M.; Makkar, R. Design and simulation of NIR spectrometer using Zemax. In Proceedings of the 2017 International Conference on Innovations in Information, Embedded and Communication Systems (ICIIECS), Coimbatore, India, 17–18 March 2017; pp. 1–5. [Google Scholar]

- Zemax (An Ansys Company); OpticsAcademy (Optics Studio). Available online: https://www.zemax.com/products/opticstudio (accessed on 5 January 2022).

- Bergström, E.T.; Goodall, D.M.; Pokrić, B.; Allinson, N.M. A Charge Coupled Device Array Detector for Single-Wavelength and Multiwavelength Ultraviolet Absorbance in Capillary Electrophoresis. Anal. Chem. 1999, 71, 4376–4384. [Google Scholar] [CrossRef] [PubMed]

- Naeem, M.; Imran, T. Design and Simulation of Mach-Zehnder Interferometer by Using ZEMAX OpticStudio. Acta Sci. Appl. Phys. 2022, 2, 2–6. [Google Scholar]

- Kalkman, C.J. LabVIEW: A software system for data acquisition, data analysis, and instrument control. J. Clin. Monit. 1995, 11, 51–58. [Google Scholar] [CrossRef] [PubMed]

- Liao, H.; Qiu, Z.; Feng, G. The Design of LDF Data Acquisition System Based on LabVIEW. Procedia Environ. Sci. 2011, 10, 1188–1192. [Google Scholar] [CrossRef]

- Wang, W.; Li, C.; Tollner, E.W.; Rains, G.C. Development of software for spectral imaging data acquisition using LabVIEW. Comput. Electron. Agric. 2012, 84, 68–75. [Google Scholar] [CrossRef]

- Rojas-Laguna, R.; Avila-Garcia, M.S.; Alvarado-Mendez, E.; Andrade-Lucio, J.A.; Obarra-Manzano, O.G.; Torres-Cisneros, M.; Castro-Sanchez, R.; Estudillo-Ayala, J.M.; Ibarra-Escamilla, B. Implementation of a laser beam analyzer using the image acquisition card IMAQ (NI). In 4th Iberoamerican Meeting on Optics and 7th Latin American Meeting on Optics, Lasers, and Their Applications; SPIE: Tandil, Argentina, 2001; Volume 4419, pp. 301–304. [Google Scholar] [CrossRef]

- Hussain, M.; Imran, T. Design and characterization simulation of Ti: Sapphire-based femtosecond laser system using Lab2 tools in the NI LabVIEW. Microw. Opt. Technol. Lett. 2018, 60, 1732–1737. [Google Scholar] [CrossRef]

- Imran, T.; Hussain, M.; Figueira, G. Computer controlled multi-shot frequency-resolved optical gating diagnostic system for femtosecond optical pulse measurement. Microw. Opt. Technol. Lett. 2017, 59, 3155–3160. [Google Scholar] [CrossRef]

- Thomas, K. Image Processing with LabVIEW and IMAQ Vision. In Prentice Hall Professional; Bernard M. Goodwin: Washington, DC, USA, 2003. [Google Scholar]

- Tayyab, I.; Hussain, M. An overview of LabVIEW-based f-to-2f spectral interferometer for monitoring, data acquiring and stabilizing the slow variations in carrier-envelope phase of amplified femtosecond laser pulses. Optik 2018, 157, 1177–1185. [Google Scholar]

| Surf: Type | Comment | Radius [cm] | Thickness [cm] | Semi- Diameter [cm] | Lines/µm | |

|---|---|---|---|---|---|---|

| OBJ | Standard | Source | Infinity | 0.90 | 0.00 | |

| 1 | Standard | Entrance slit | Infinity | 4.55 | 0.08 | |

| 2 | Standard | Collimating mirror | −10 | −3.00 | 0.61 | |

| 3 | Diffraction Grating | Diffraction grating | Infinity | 3.00 | 0.52 | 0.600 |

| 4 | Standard | Focusing mirror | −10 | −4.55 | 0.61 | |

| IMG | Standard | Detector | Infinity | - | 0.30 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naeem, M.; Imran, T.; Hussain, M.; Bhatti, A.S. Design Simulation and Data Analysis of an Optical Spectrometer. Optics 2022, 3, 304-312. https://doi.org/10.3390/opt3030028

Naeem M, Imran T, Hussain M, Bhatti AS. Design Simulation and Data Analysis of an Optical Spectrometer. Optics. 2022; 3(3):304-312. https://doi.org/10.3390/opt3030028

Chicago/Turabian StyleNaeem, Muddasir, Tayyab Imran, Mukhtar Hussain, and Arshad Saleem Bhatti. 2022. "Design Simulation and Data Analysis of an Optical Spectrometer" Optics 3, no. 3: 304-312. https://doi.org/10.3390/opt3030028

APA StyleNaeem, M., Imran, T., Hussain, M., & Bhatti, A. S. (2022). Design Simulation and Data Analysis of an Optical Spectrometer. Optics, 3(3), 304-312. https://doi.org/10.3390/opt3030028