Micro-Machining of Diamond, Sapphire and Fused Silica Glass Using a Pulsed Nano-Second Nd:YVO4 Laser

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

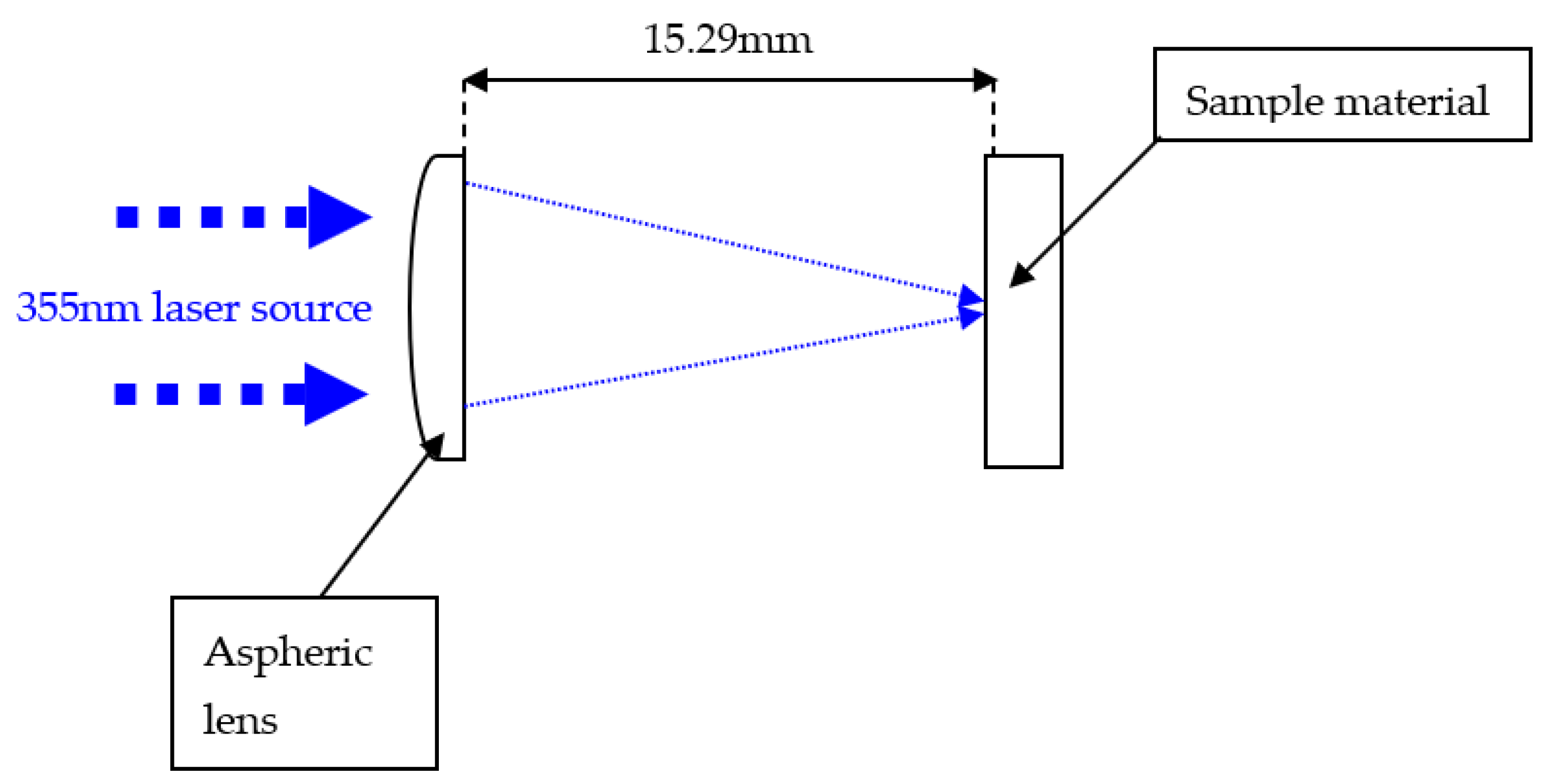

2.2. Laser Materials Processing

2.3. Analytical Techniques

3. Results and Discussion

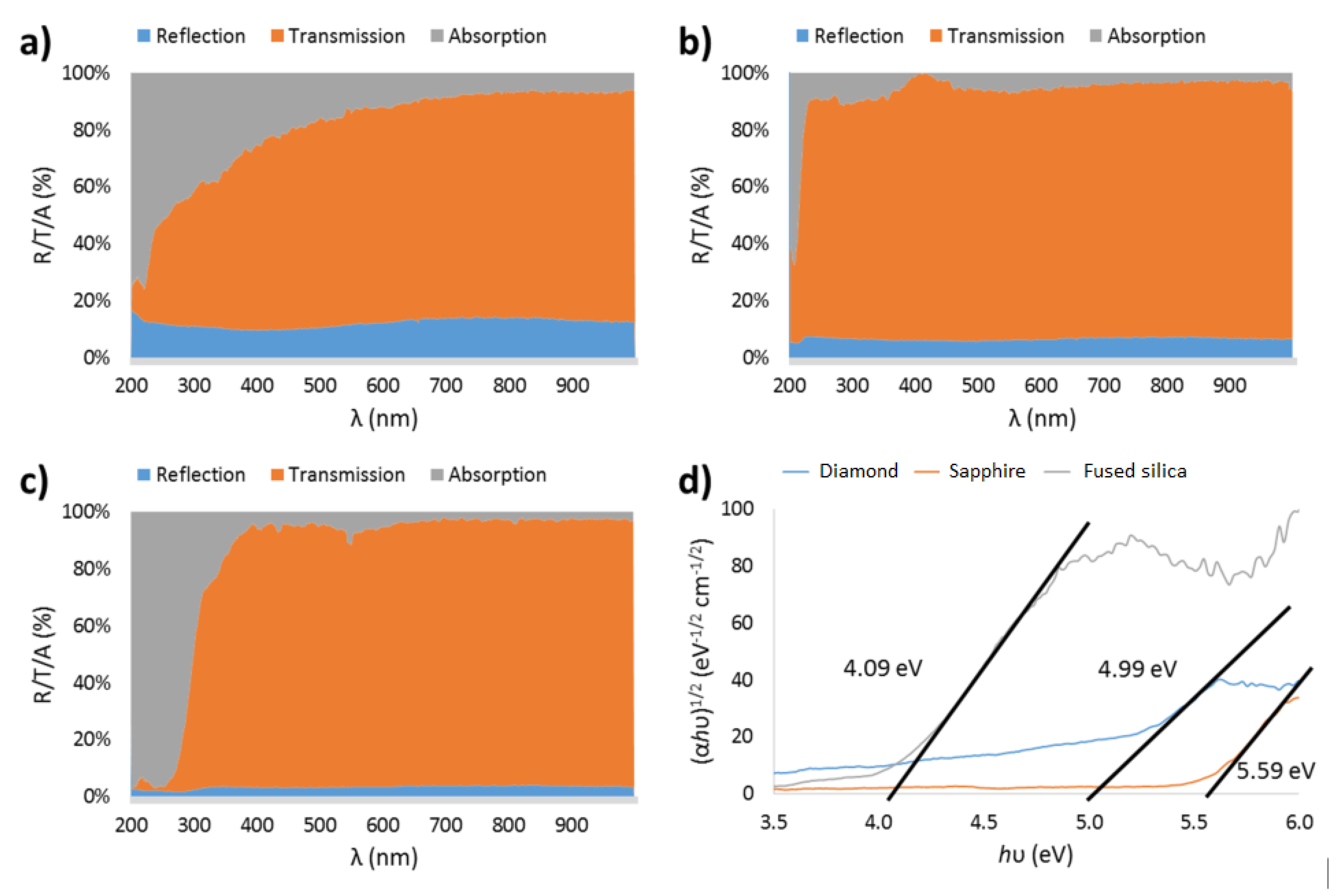

3.1. UV/Vis Absorption Characteristics of the Optically Transparent Materials

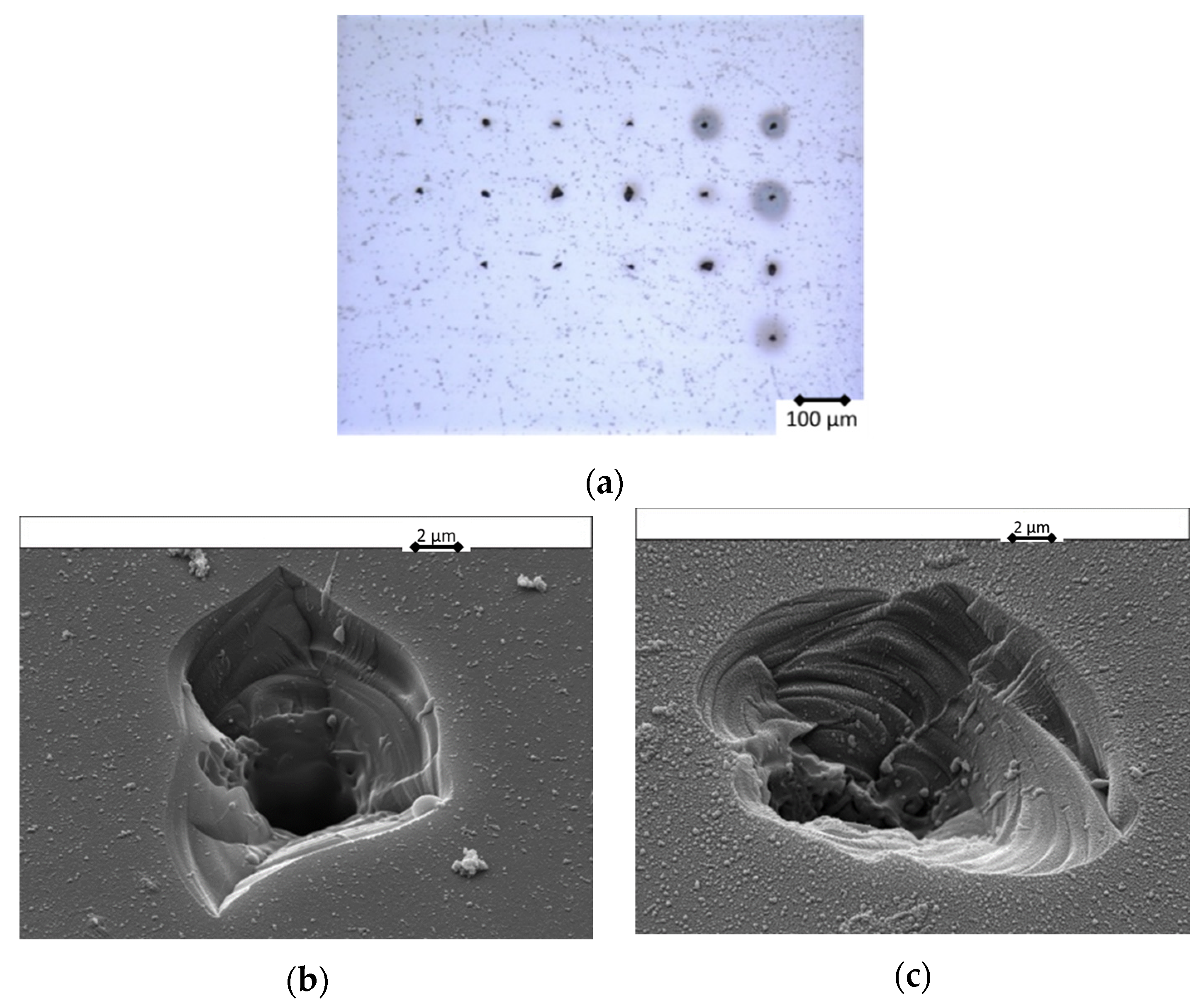

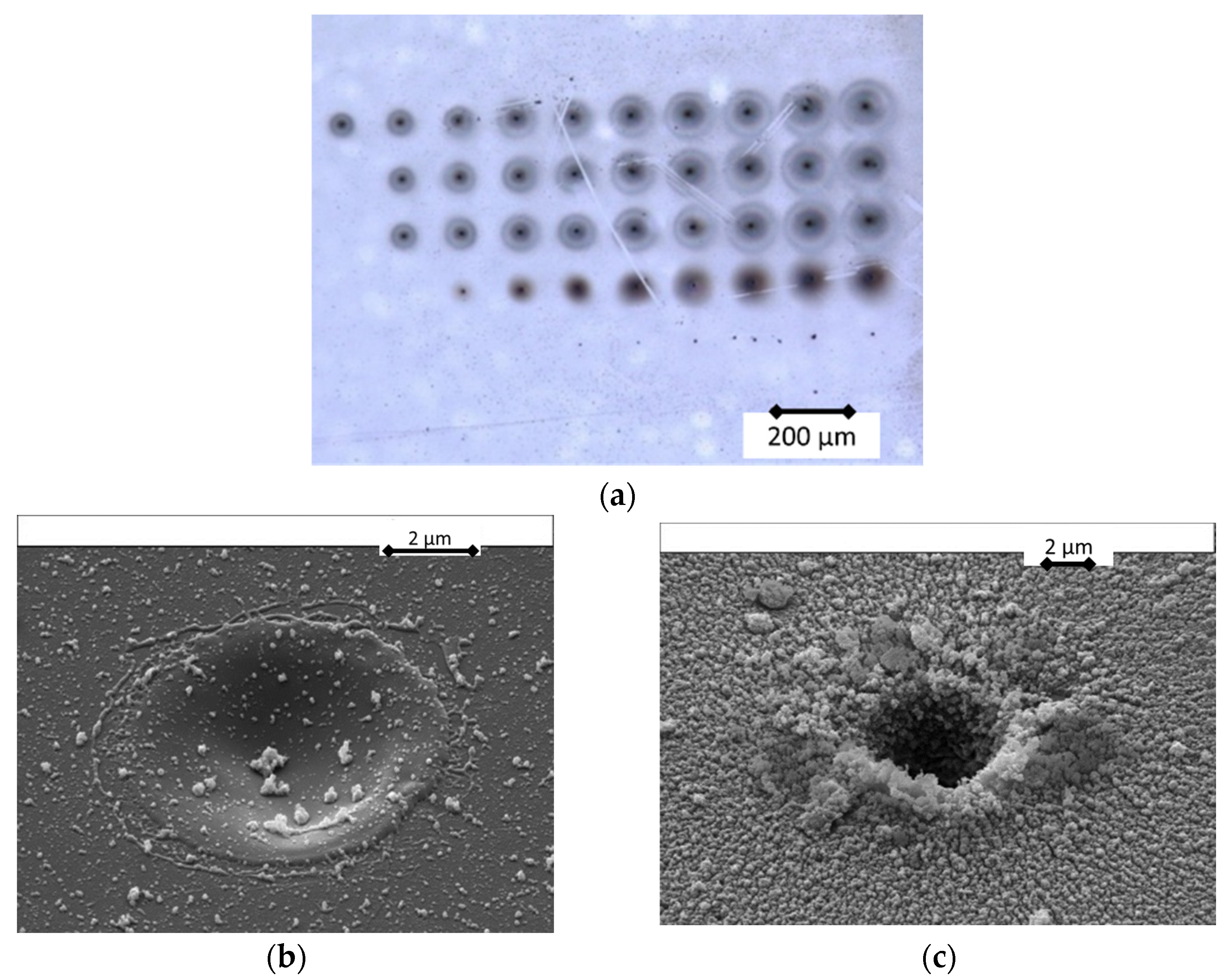

3.2. Laser Surface Modification of the Optically Transparent Materials

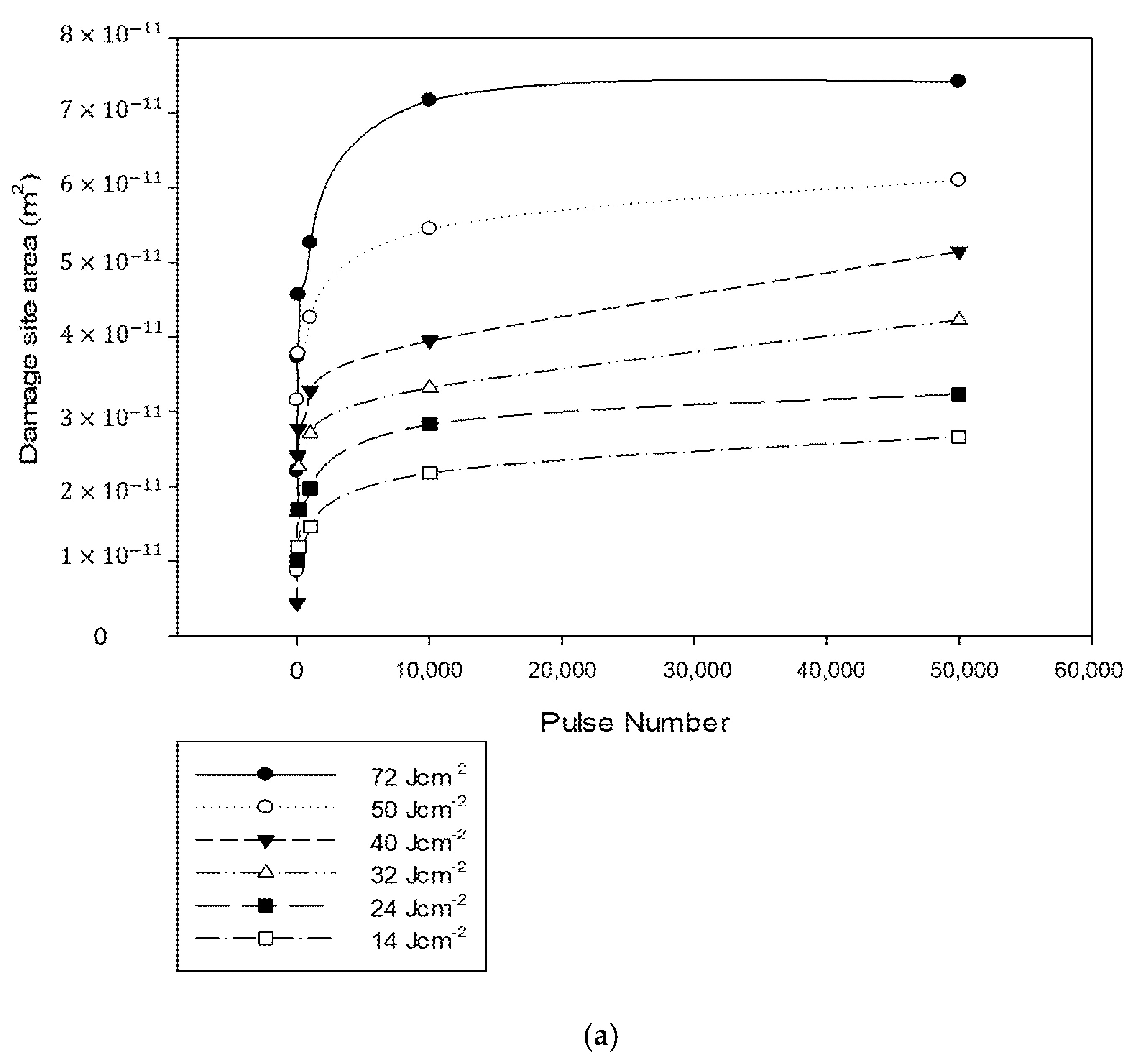

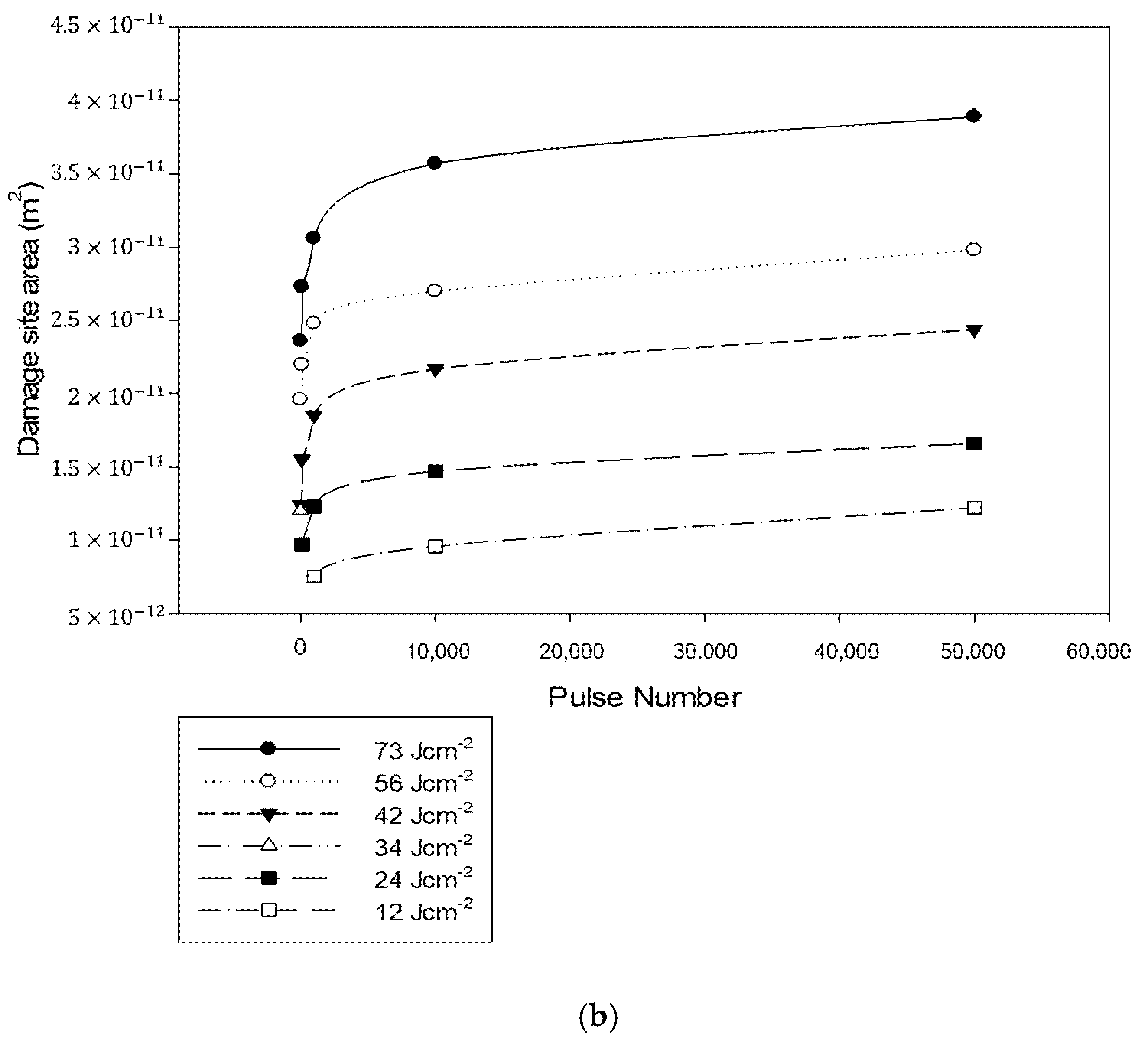

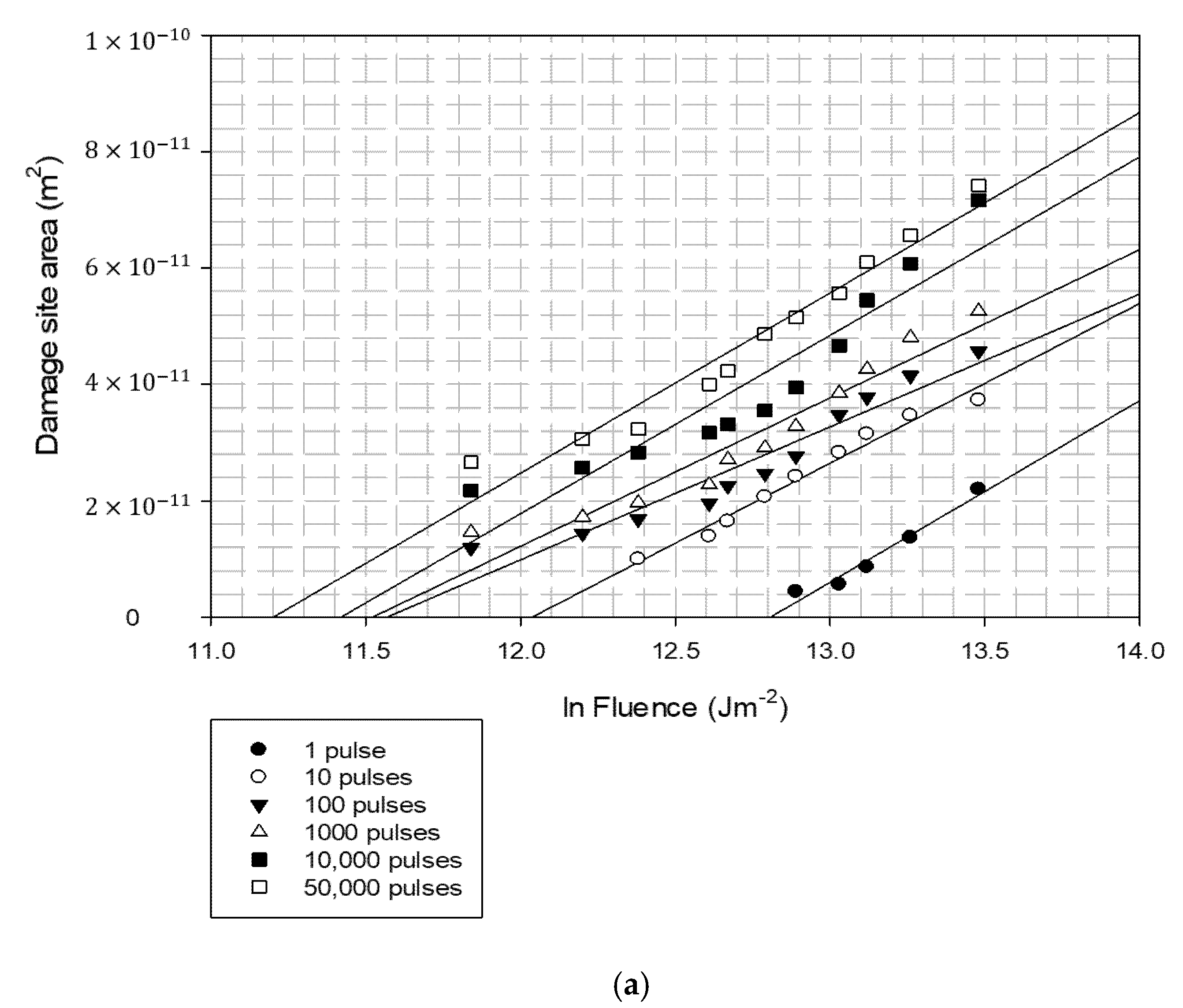

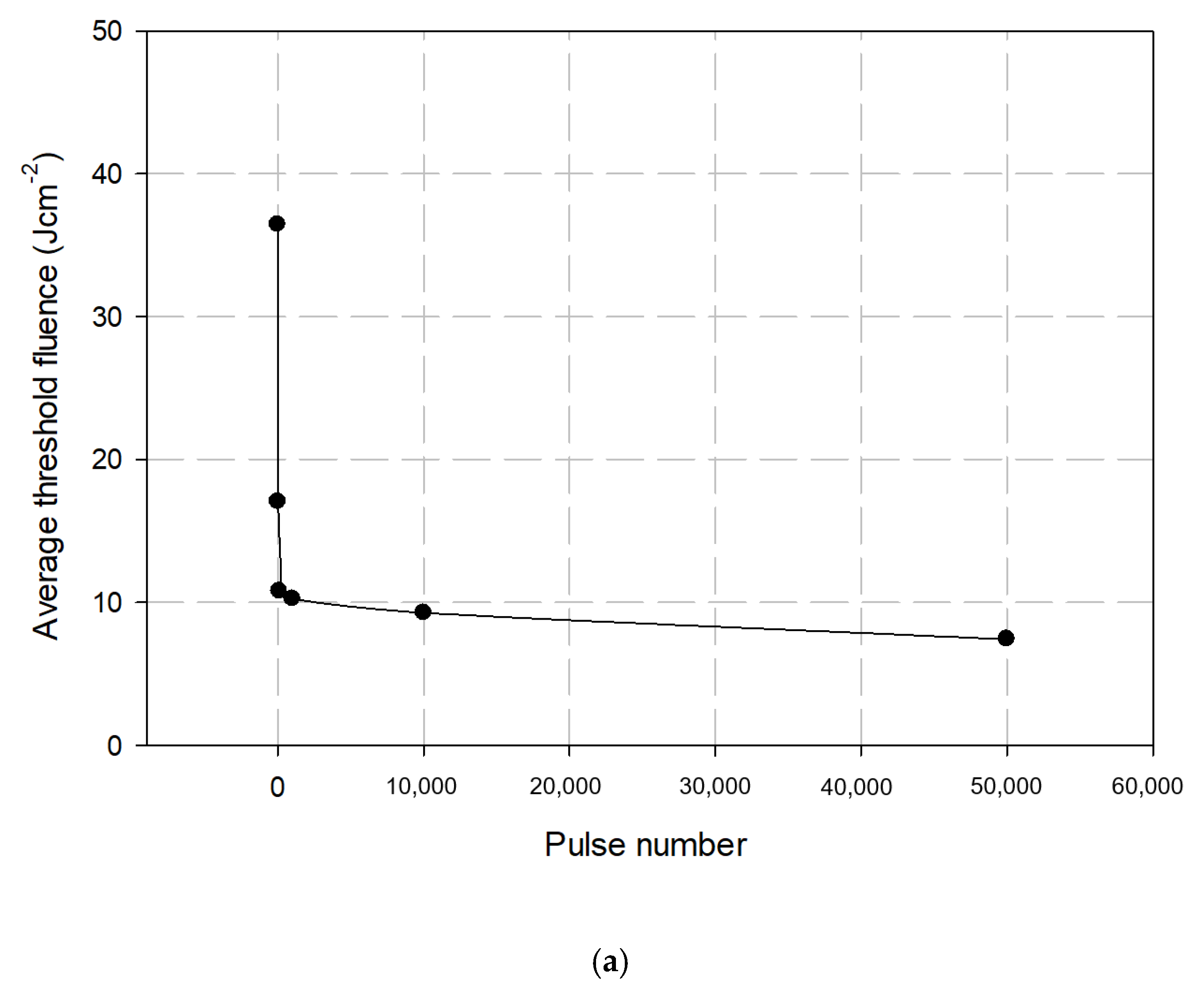

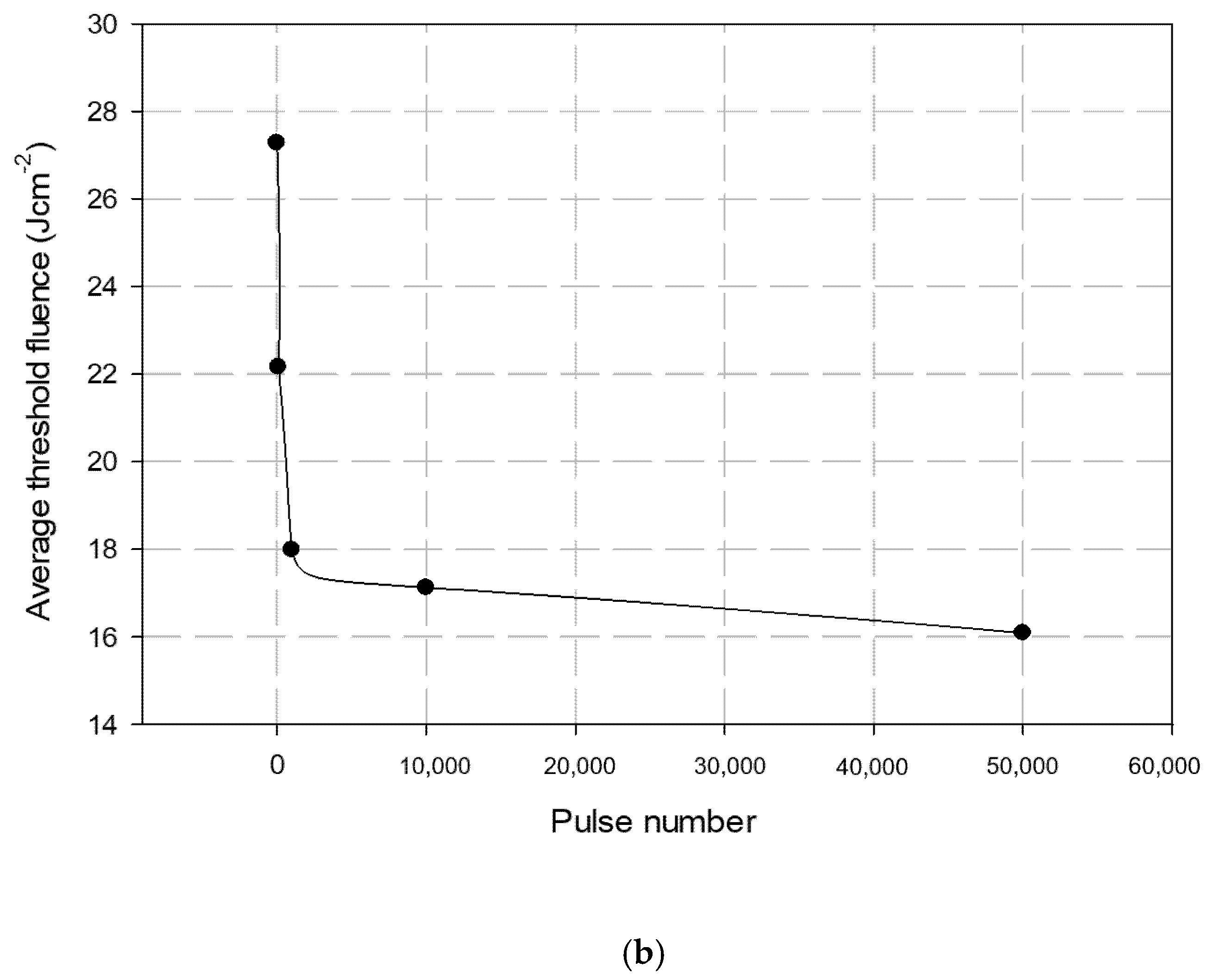

3.3. Threshold Fluence

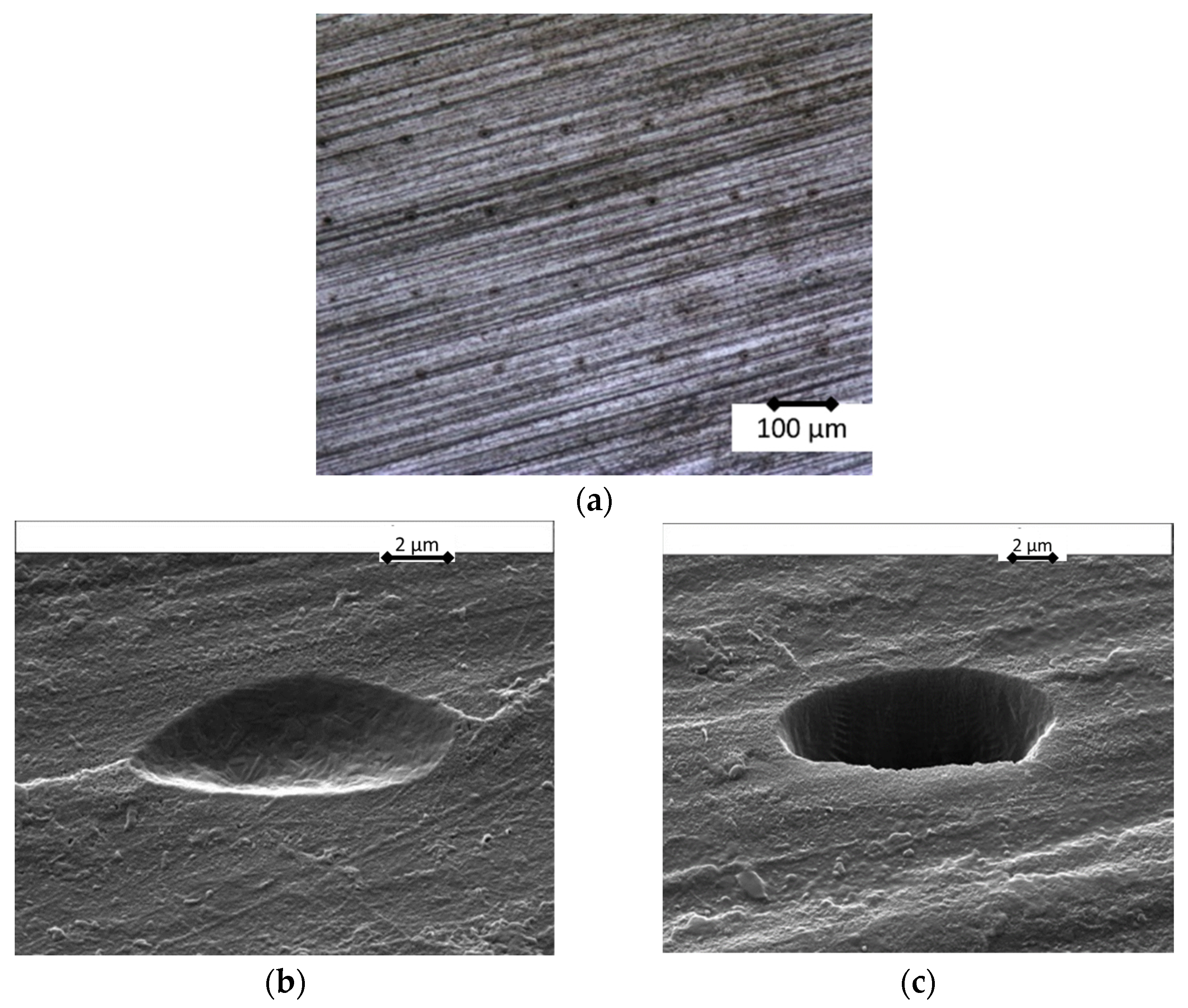

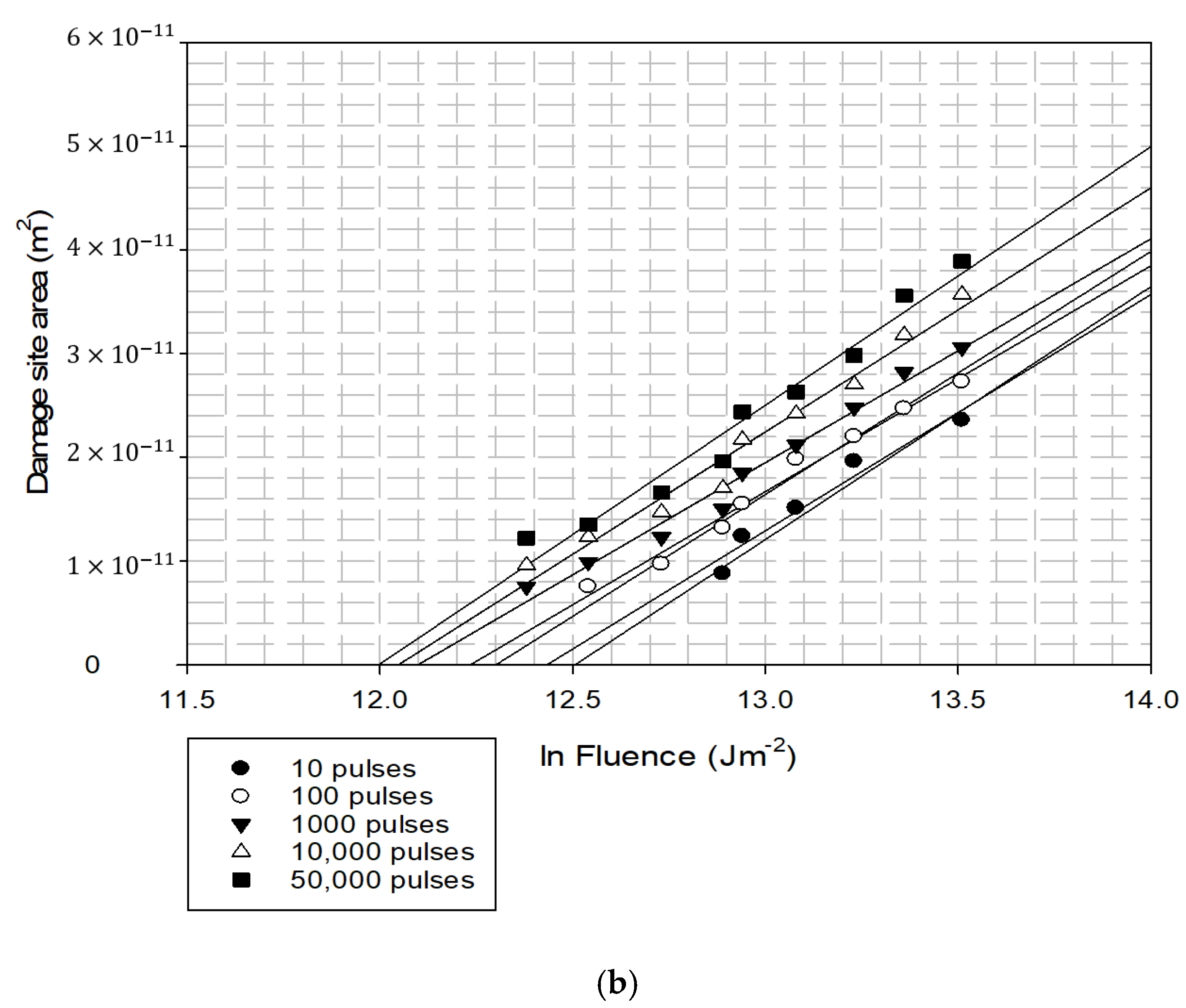

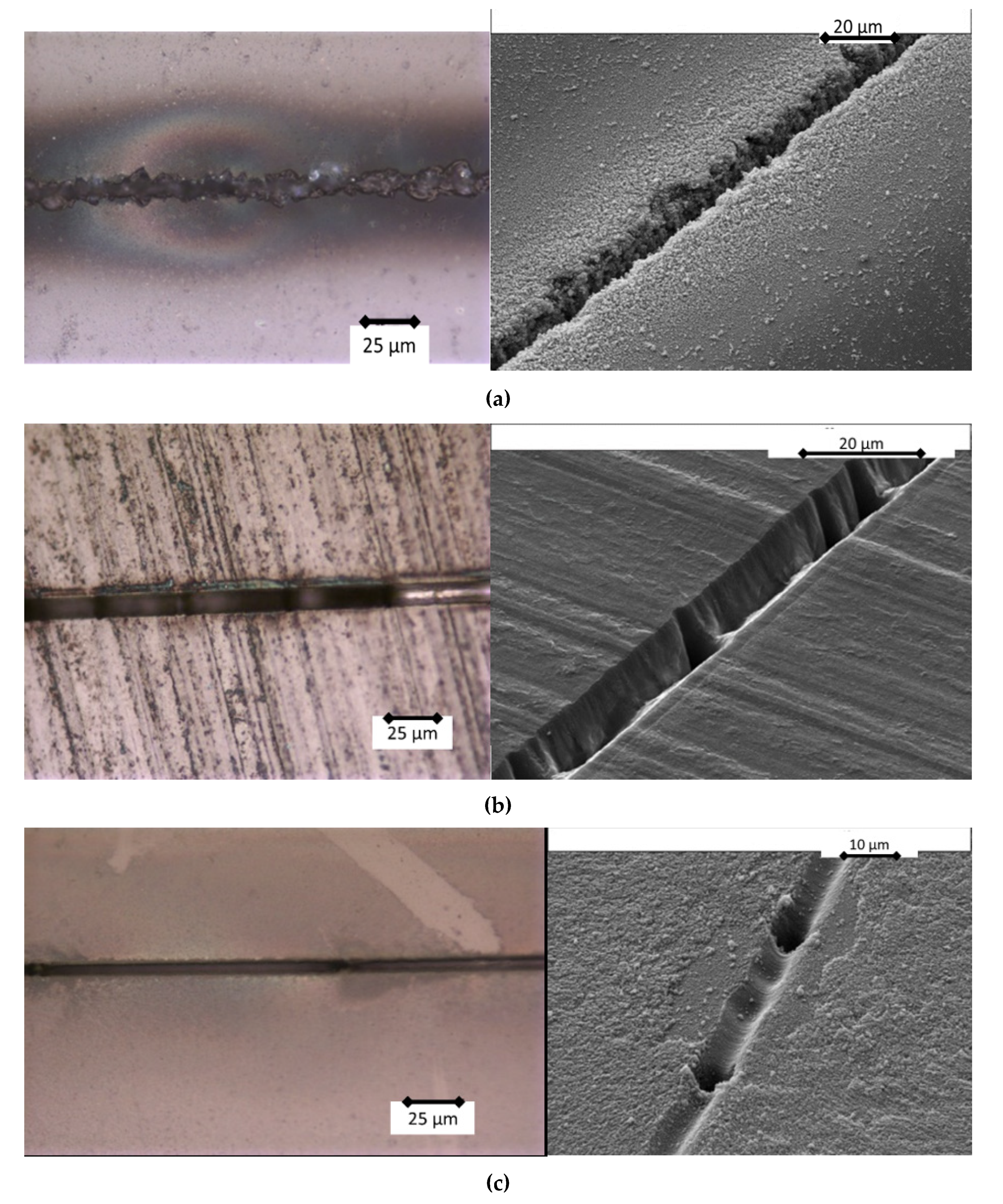

3.4. Nd:YVO4 Laser Processed Line Profiles

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Waugh, D.G.; Toccaceli, C.; Gillett, A.; Ng, C.H.; Hodgson, S.; Lawrence, J. Surface treatments to modulate bioadhesion. Rev. Adhes. Adhes. 2016, 4, 69. [Google Scholar] [CrossRef]

- Patel, V.K.; Gupta, A.; Singh, D.; Kant, R.; Bhattacharya, S. Surface functionalisation to mitigate fouling of biodevices: A critical review. Rev. Adhes. Adhes. 2015, 3, 444. [Google Scholar] [CrossRef]

- Shukla, P.; Waugh, D.G.; Lawrence, J. Laser Surface Structuring of Ceramics, Metals and Polymers for Biological Applications: A review. In Laser Surface Modification of Biomaterials: Techniques and Applications; Vilar, R., Overend, L., Eds.; Elsevier Ltd.: Oxford, UK, 2016. [Google Scholar]

- Thakur, S.; Neogi, S. Tailoring the adhesion of polymers using plasma for biomedical applications: A critical review. Rev. Adhes. Adhes. 2015, 3, 53. [Google Scholar] [CrossRef]

- Li, L.; Liu, X.; Dai, X.; Li, L.; Chen, Y. Surface wetting processing on BNNT films by selective plasma modes. Chin. Sci. Bull. 2013, 58, 3403. [Google Scholar] [CrossRef] [Green Version]

- Wei, Q.F.; Gao, W.D.; Hou, D.Y.; Wang, X.Q. Surface modification of polymer nanofibres by plasma treatment. Appl. Surf. Sci. 2005, 245, 16. [Google Scholar] [CrossRef]

- Arefi-Khonsari, F.; Tatoulian, M.; Bretagnol, F.; Bouloussa, O.; Rondelez, F. Processing of polymers by plasma technologies. Surf. Coat. Technol. 2005, 200, 14. [Google Scholar] [CrossRef]

- Ruiz, A.; Buzanska, L.; Gilliland, D.; Rauscher, H.; Sirghi, L.; Sobanski, T.; Zychowicz, M.; Ceriotti, L.; Bretagnol, F.; Coecke, S.; et al. Micro-stamped surfaces for the patterned growth of neural stem cells. Biomaterials 2008, 29, 4766. [Google Scholar] [CrossRef]

- Charest, J.L.; Bryant, L.E.; Garcia, A.J.; King, W.P. Hot embossing for micropatterned cell substrates. Biomaterials 2005, 25, 4767. [Google Scholar] [CrossRef]

- Csucs, G.; Michel, R.; Lussi, J.W.; Textor, M.; Danuser, G. Microcontact printing of novel co-polymers in combination with proteins for cell-biological applications. Biomaterials 2003, 24, 1713. [Google Scholar] [CrossRef]

- Moon, M.W.; Lee, S.H.; Sun, J.Y.; Oh, K.H.; Vaziiri, A.; Hutchinson, J.W. Wrinkled hard skins on polymers created by focused ion beam. Proc. Natl. Acad. Sci. USA 2007, 104, 1130. [Google Scholar] [CrossRef] [Green Version]

- Cui, F.Z.; Luo, Z.S. Biomaterials modification by ion-beam processing. Surf. Coat. Technol. 1999, 112, 278. [Google Scholar] [CrossRef]

- Sun, M.C.; Kim, G.; Lee, J.H.; Kim, S.W.; Kim, H.W. Patterning of Si nanowire array with electron beam lithography for sub-22 nm Si nanoelectronics technology. J. Microelec. Eng. 2013, 110, 141. [Google Scholar] [CrossRef]

- Ivanova, E.P.; Hasan, J.; Webb, H.K.; Gervinskas, G.; Juodkazis, S.; Truong, V.K.; Wu, A.H.F.; Lamb, R.N.; Baulin, V.A.; Watson, G.S.; et al. Bactericidal activity of black silicon. Nat. Commun. 2013, 4. [Google Scholar] [CrossRef]

- Tiaw, K.S.; Hong, M.H.; Teoh, S.H. Precision laser micro-processing of polymers. J. Alloys Comp. 2008, 449, 228. [Google Scholar] [CrossRef]

- Niino, H.; Yabe, A. Chemical surface modification of fluorocarbon polymers by excimer laser processing. Appl. Surf. Sci. 1996, 96–98, 550. [Google Scholar] [CrossRef]

- Pervolaraki, M.; Dyer, P.E.; Monk, P. Ablation studies using a diode-pumped Nd:YVO 4 micro-laser. Appl. Phys. A 2004, 79, 849. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, H.; Chen, J.; Han, B.; Shen, Z.; Lu, J.; Ni, X. Millisecond laser machining of transparent materials assisted by nanosecond laser. Opt. Express 2015, 23, 765. [Google Scholar] [CrossRef]

- Raji, A.R.; Salters, S.; Samuel, E.L.; Zhu, Y.; Volman, V.; Tour, J.M. Functionalized graphene nanoribbon films as a radiofrequency and optically transparent material. ACS Appl. Mater. Inter. 2014, 6, 16661. [Google Scholar] [CrossRef] [PubMed]

- Colomban, P.; Tournie, A.; Bellot-Gurlet, L. Raman identification of glassy silicates used in ceramics, glass and jewellery: A tentative differentiation guide. J. Raman Spect. 2006, 37, 841. [Google Scholar] [CrossRef] [Green Version]

- Thampy, A.S.; Dhamodharan, S.K. Performance analysis and comparison of MWCNT loaded ITO and TIO based optically transparent patch antennas for terahertz communications. Phys. E 2016, 78, 123. [Google Scholar] [CrossRef]

- Huang, L.; Salter, P.; Karpinksi, M.; Smith, B.; Payne, F.; Booth, M. Waveguide fabrication in KDP crystals with femtosecond laser pulses. Appl. Phys. A 2015, 118, 831. [Google Scholar] [CrossRef]

- Ferreira, P.H.D.; Stefanutti, R.; Pavinatto, F.J.; Mendoca, C.R. Femtosecond laser fabrication of waveguides in DR13-doped PMMA. Opt. Comm. 2014, 318, 53. [Google Scholar] [CrossRef]

- He, F.; Liao, Y.; Lin, J.; Song, J.; Qiao, L.; Cheng, Y.; Sugioka, K. Femtosecond Laser Fabrication of Monolithically Integrated Microfluidic Sensors in Glass. Sens. Actuator B-Chem. 2014, 14, 19402. [Google Scholar] [CrossRef] [PubMed]

- Haque, M.; Lee, K.K.; Ho, S.; Fernandes, L.A.; Herman, P.R. Chemical-assisted femtosecond laser writing of lab-in-fibers. Lab Chip 2014, 14, 3817. [Google Scholar] [CrossRef] [PubMed]

- Chmel, A.E. Cumulative effect in laser-induced damage of optical glasses: A review. Glass Phys.Chem. 2000, 26, 49. [Google Scholar]

- Ristau, D.E. Laser-Induced Damage in Optical Materials; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Liao, Y.; Ni, J.; Qiao, L.; Huang, M.; Bellouard, Y.; Sugioka, K.; Cheng, Y. High-fidelity visualization of formation of volume nanogratings in porous glass by femtosecond laser irradiation. Optica 2015, 2, 329. [Google Scholar] [CrossRef]

- Ferreira, P.H.D.; Otuka, A.J.G.; Barbano, E.C.; Manoel, D.S.; de Vincente, F.S.; Vollett, D.R.; Danatti, D.A.; Misoguti, L.; Mendoca, C.R. Femtosecond laser fabrication of waveguides in Rhodamine B-doped GPTS/TEOS-derived organic/silica monolithic xerogel. Opt. Mater. 2015, 47, 310. [Google Scholar] [CrossRef] [Green Version]

- Liao, C.R.; Wang, D.N. Review of femtosecond laser fabricated fiber Bragg gratings for high temperature sensing. Phot. Sens. 2013, 3, 97. [Google Scholar] [CrossRef] [Green Version]

- Fang, X.; Liao, C.R.; Wang, D.N. Femtosecond laser fabricated fiber Bragg grating in microfiber for refractive index sensing. Opt. Lett. 2010, 35, 1007. [Google Scholar] [CrossRef] [Green Version]

- Li, S.L.; Ye, Y.K.; Wang, M.W. Femtosecond laser written channel optical waveguide in Nd: YAG crystal. Opt. Laser Tech. 2014, 58, 89. [Google Scholar] [CrossRef]

- Komlenok, M.S.; Kononenko, V.V.; Ralchenko, V.G.; Pimenov, S.M.; Konov, V.I. Laser Induced Nanoablation of Diamond Materials. Phys. Proc. 2011, 12, 37. [Google Scholar] [CrossRef] [Green Version]

- Vitalii, V.K.; Taras, V.K.; Pimenov, S.M.; Sinyavskii, M.N.; Vitalii, I.K.; Dausinger, F. Effect of the pulse duration on graphitisation of diamond during laser ablation. Quant. Elec. 2005, 35, 252. [Google Scholar]

- Strekalov, V.N.; Konov, V.I.; Kononenko, V.V.; Pimenov, S.M. Early stages of laser graphitization of diamond. Appl. Phys. A 2003, 76, 603. [Google Scholar] [CrossRef]

- Kononenko, T.V.; Konov, V.I.; Pimenov, S.M.; Rossukanyi, N.M.; Rukovishnikov, A.I.; Romano, V. Three-dimensional laser writing in diamond bulk. Diam. Relat. Mater. 2011, 20. [Google Scholar] [CrossRef]

- Gedvilas, M.; Miksys, J.; Berzins, J.; Stankevic, V.; Raciukaitis, G. Multi-photon absorption enhancement by dual-wavelength double-pulse laser irradiation for efficient dicing of sapphire wafers. Sci. Rep. 2017, 7, 5218. [Google Scholar] [CrossRef]

- Capuano, L.; Pohl, R.; Tiggelaar, R.M.; Berenschot, J.W.; Gardeniers, J.G.E.; Romer, G.R.B.E. Morphology of single picosecond pulse subsurface laser-induced modifications of sapphire and subsequent selective etching. Opt. Express. 2018, 26, 29283. [Google Scholar] [CrossRef]

- Torres-Peiro, S.; Gonzalez-Ausejo, J.; Mendoza-Yero, O.; Minguez-Vega, C.; Lancis, J. Femtosecond laser micromachining with extended depth of focus by using diffractive lenses. Appl. Surf. Sci. 2014, 303, 393. [Google Scholar] [CrossRef]

- Shimotsuma, Y.; Hirao, K.; Qiu, J.; Miura, K. Nanofabrication in transparent materials with a femtosecond pulse laser. J. Non Cryst. Sol. 2006, 352, 646. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waugh, D.G.; Walton, C.D. Micro-Machining of Diamond, Sapphire and Fused Silica Glass Using a Pulsed Nano-Second Nd:YVO4 Laser. Optics 2021, 2, 169-183. https://doi.org/10.3390/opt2030016

Waugh DG, Walton CD. Micro-Machining of Diamond, Sapphire and Fused Silica Glass Using a Pulsed Nano-Second Nd:YVO4 Laser. Optics. 2021; 2(3):169-183. https://doi.org/10.3390/opt2030016

Chicago/Turabian StyleWaugh, David G., and Chris D. Walton. 2021. "Micro-Machining of Diamond, Sapphire and Fused Silica Glass Using a Pulsed Nano-Second Nd:YVO4 Laser" Optics 2, no. 3: 169-183. https://doi.org/10.3390/opt2030016

APA StyleWaugh, D. G., & Walton, C. D. (2021). Micro-Machining of Diamond, Sapphire and Fused Silica Glass Using a Pulsed Nano-Second Nd:YVO4 Laser. Optics, 2(3), 169-183. https://doi.org/10.3390/opt2030016