The Method of Cleaning Cutting Fluid Using Ultrasonic Treatment

Abstract

1. Introduction

- -

- Water-miscible and water-immiscible cutting fluids;

- -

- Emulsifiers and oil-based fluids for lubrication and cooling;

- -

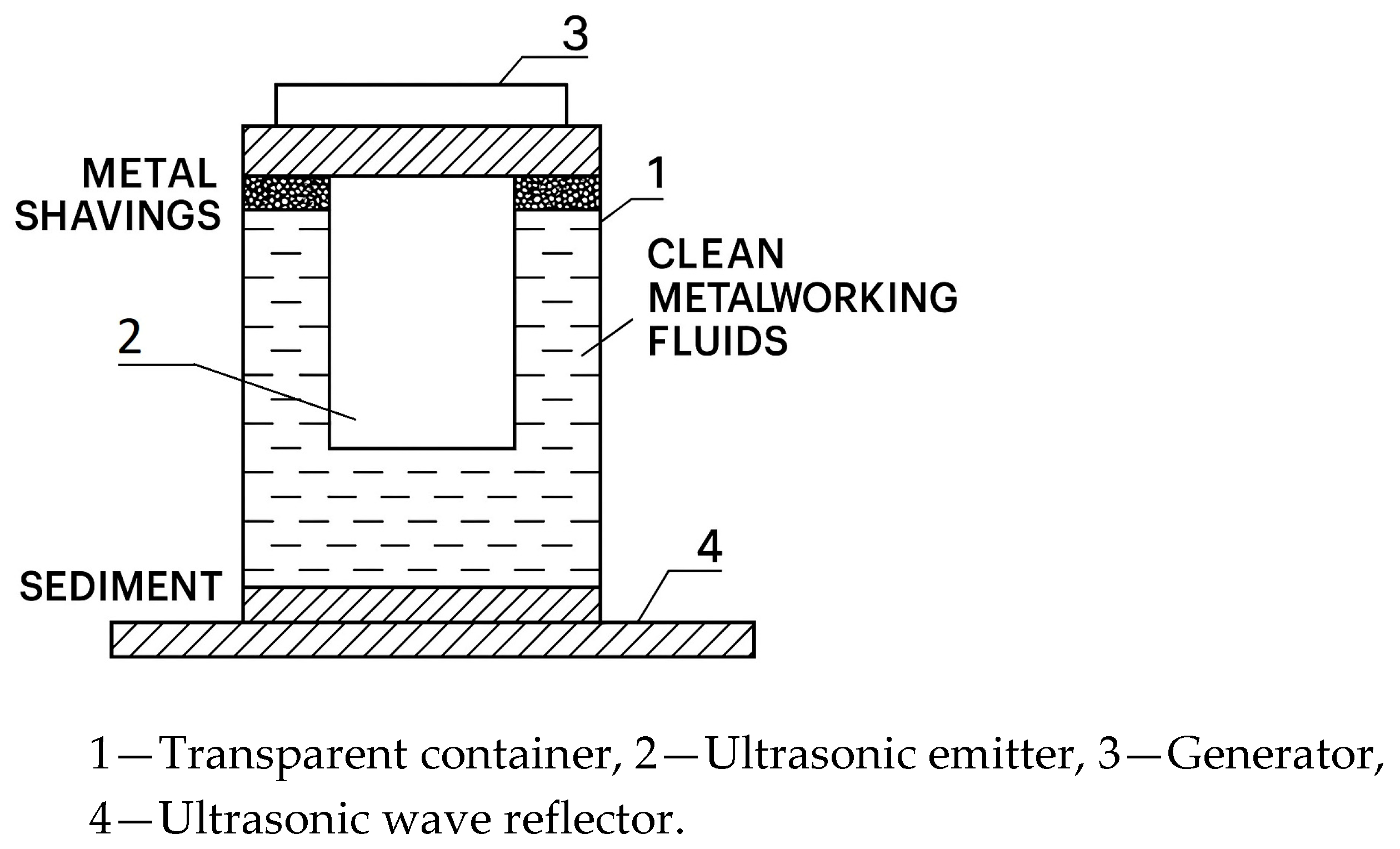

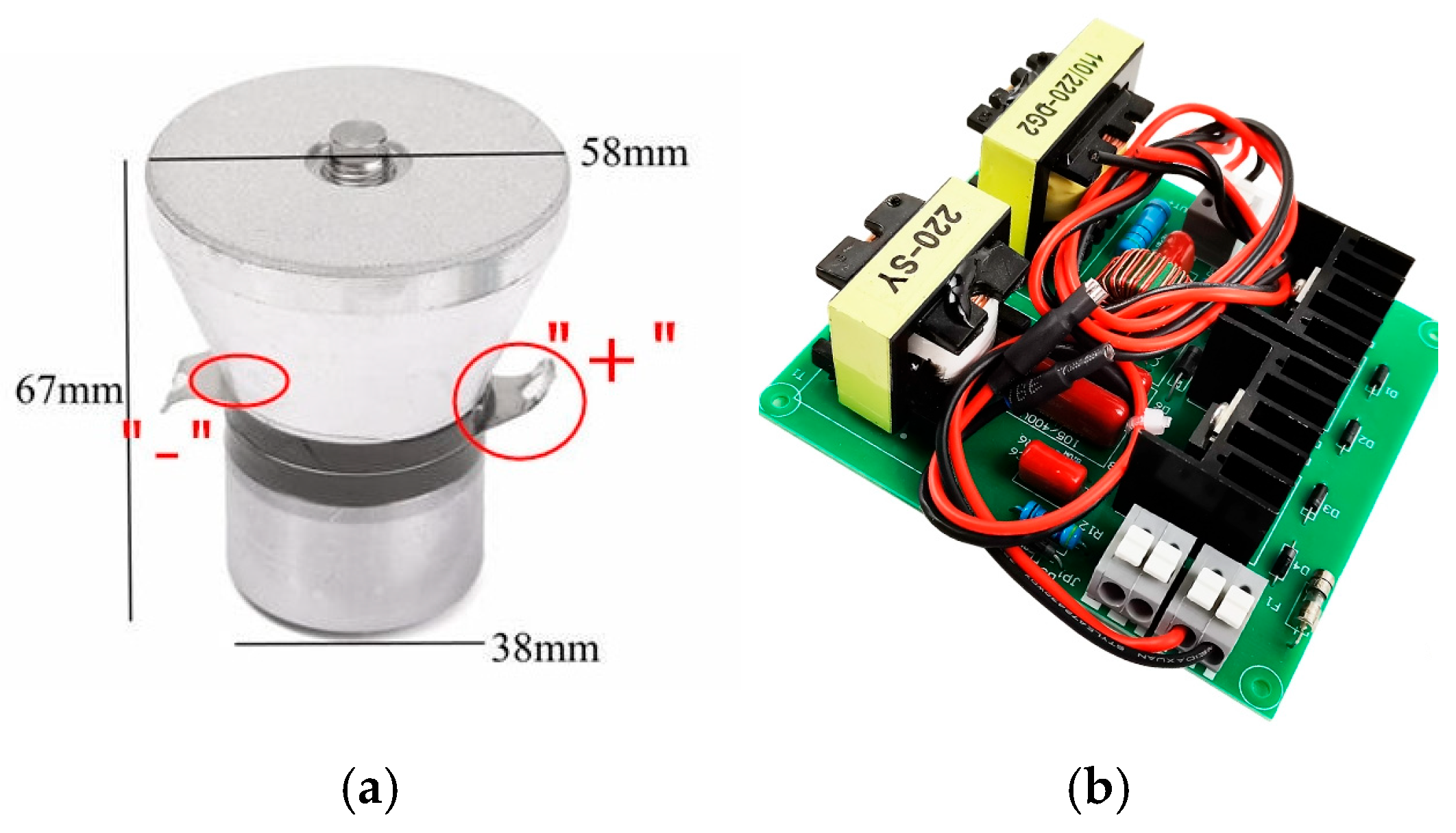

2. Materials and Methods

- -

- Shvedov flow regime—a flow mode characterized by a nearly intact internal structure, observed at very low flow velocities of only a few centimeters per second. In this regime, the medium exhibits an effective Newtonian viscosity ();

- -

- Bingham flow regime—a flow mode characterized by a continuously breaking internal structure, occurring at flow velocities of approximately 1.25 m/s. In this regime, the concept of structural viscosity () is introduced.

- -

- Pseudo-laminar flow regime—a regime in which the internal structure of the fluid is almost completely disrupted, observed at flow velocities of about 1.5 m/s. Under these conditions, the fluid exhibits a dynamic viscosity ();

- -

- Turbulent flow regime—observed at comparatively high flow velocities (greater than 2 m/s), where intense fluid mixing occurs, resulting in the manifestation of apparent viscosity ();

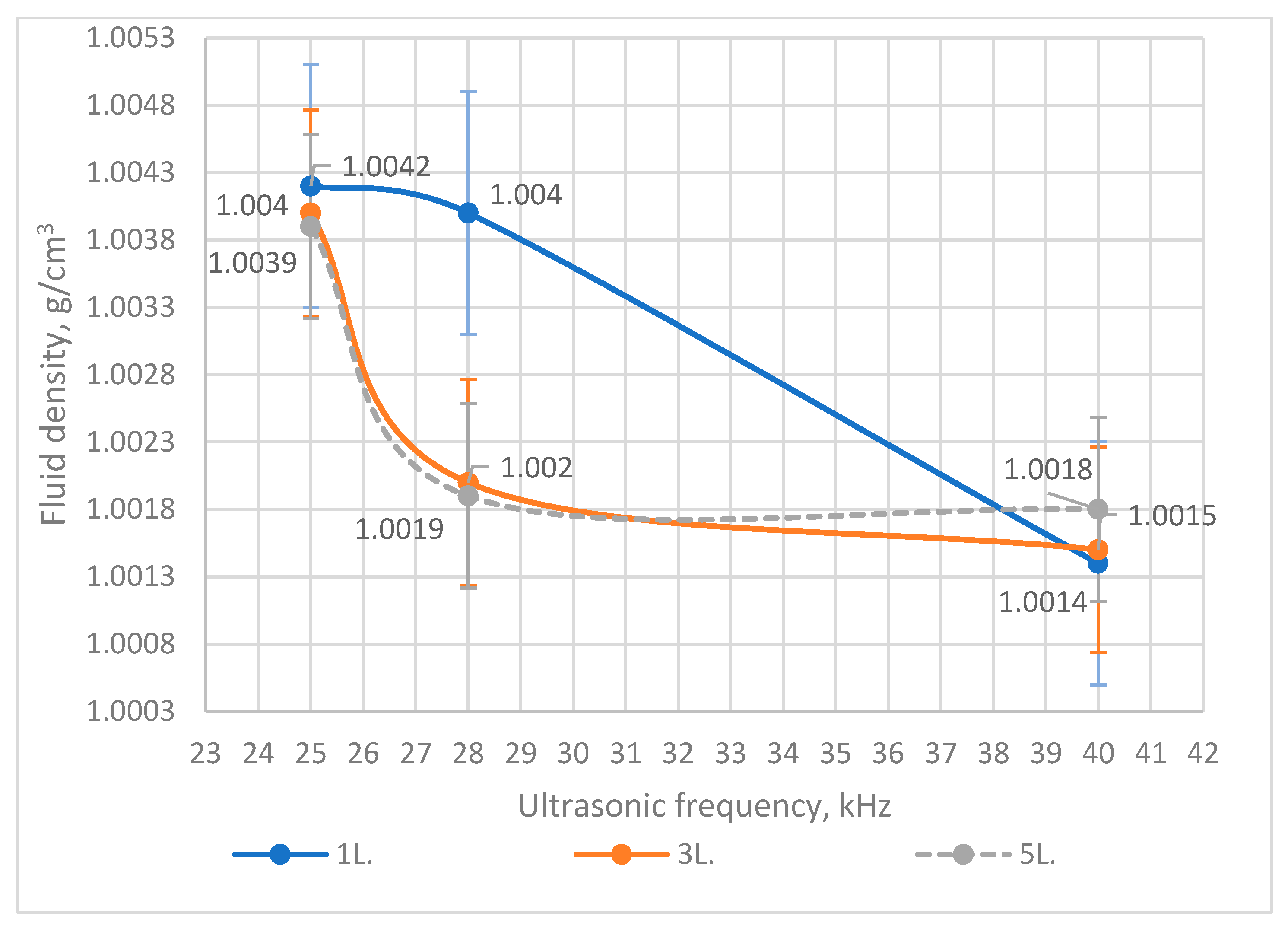

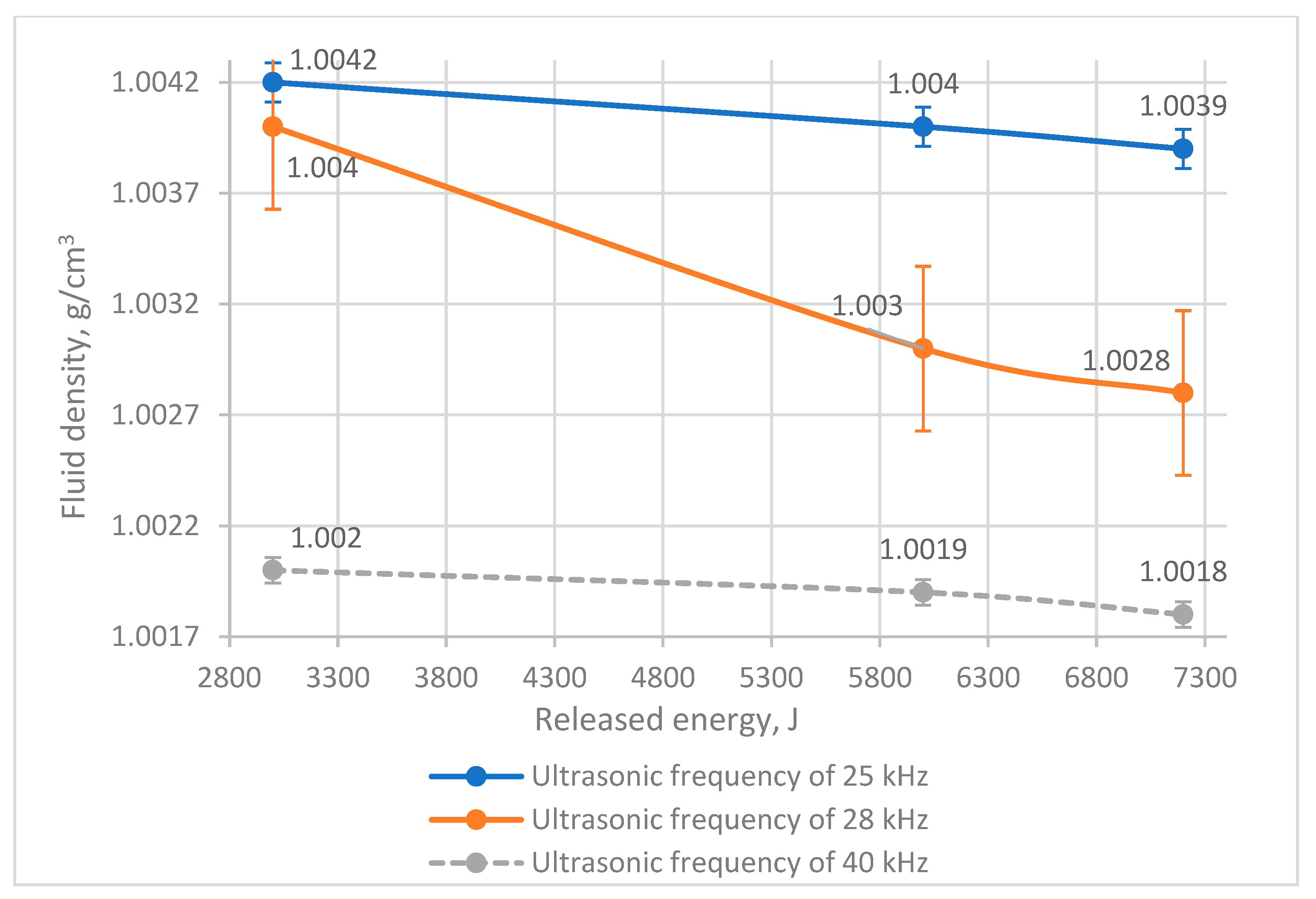

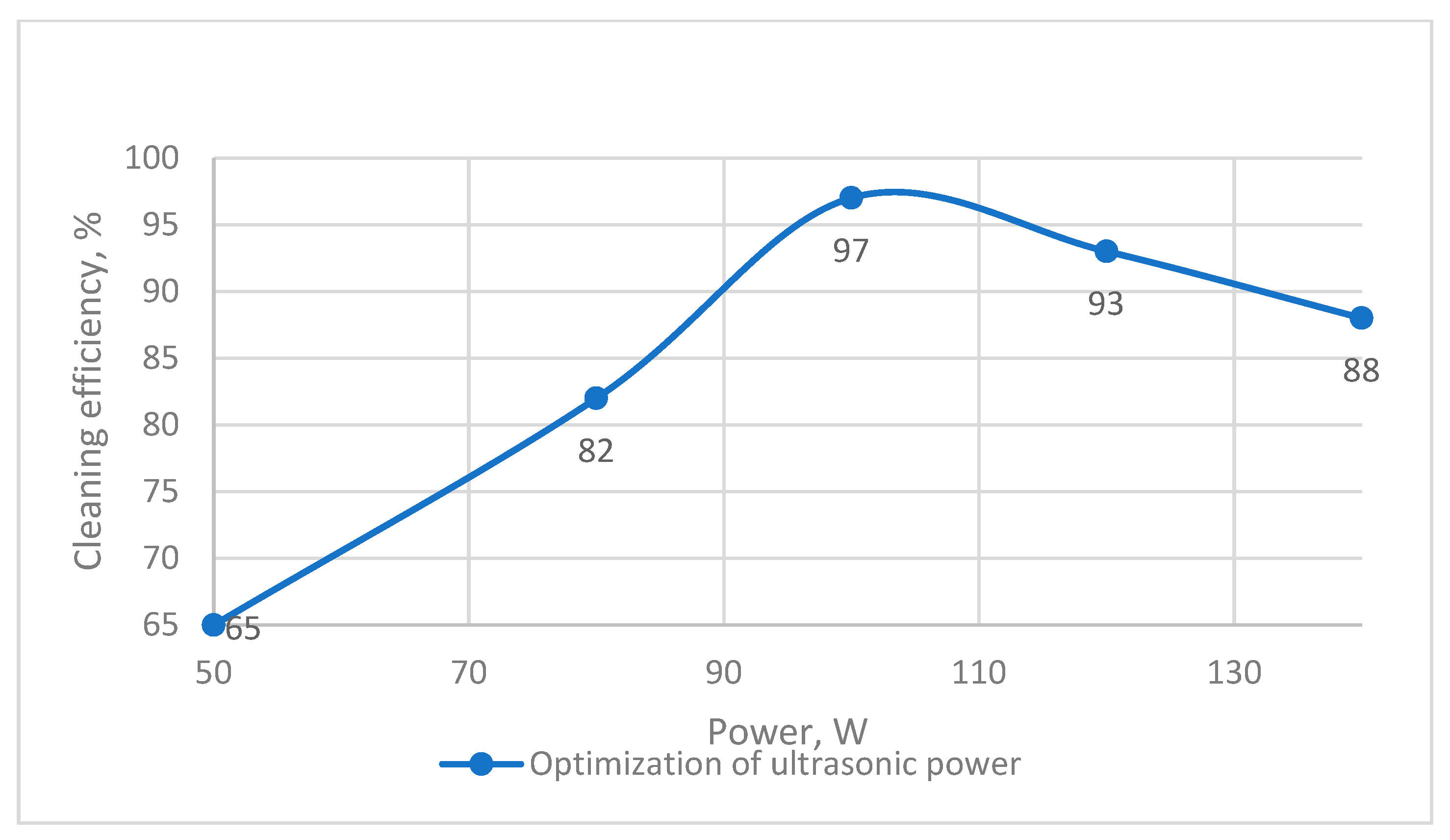

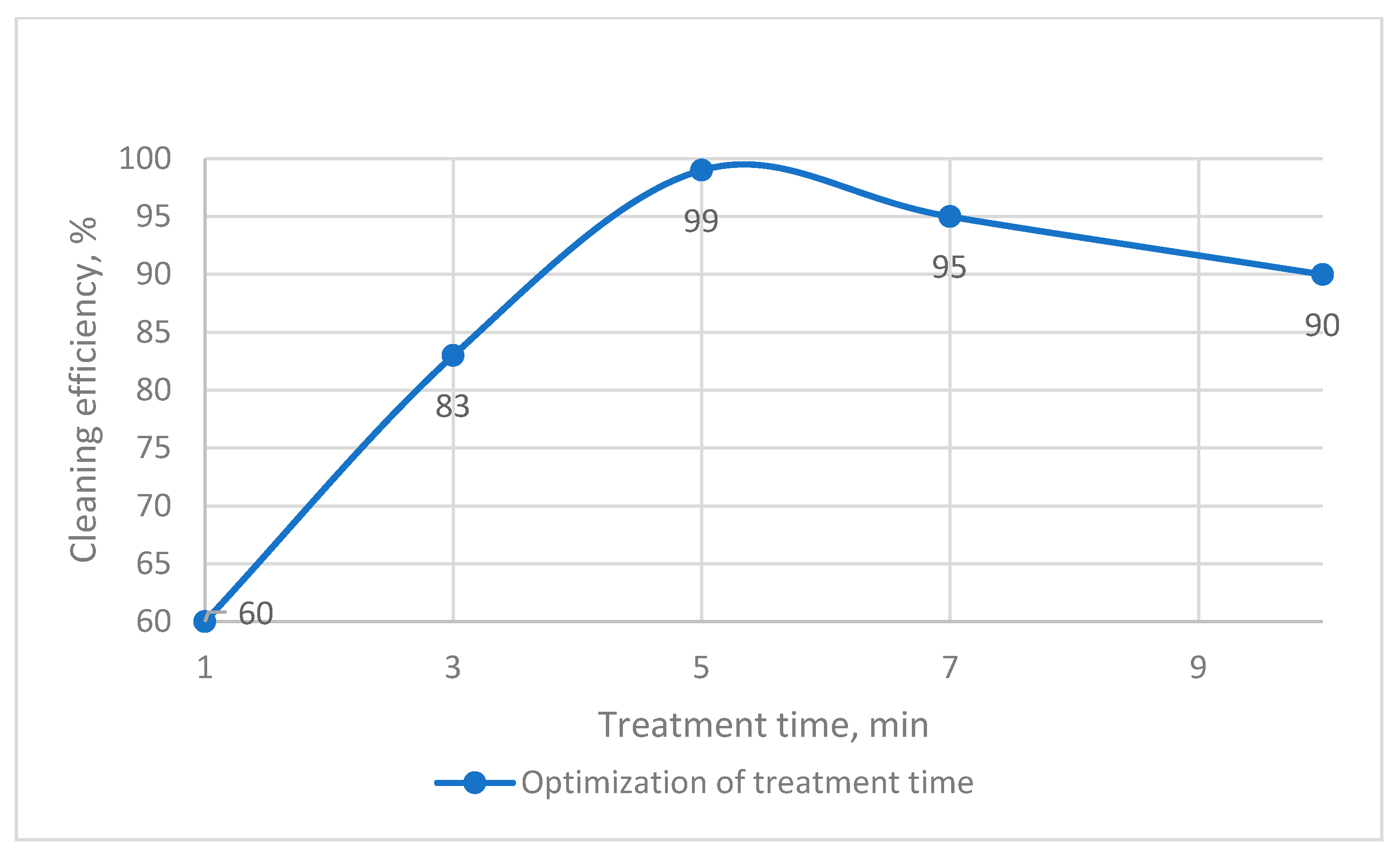

- Ultrasonic treatment was applied to cutting fluids placed in containers with volumes of 1, 3, and 5 L. The treatment was performed at frequencies of 25, 28, and 40 kHz, with an ultrasonic power of 100 W and a treatment duration of 5 min.Each experiment was repeated three times (n = 3) to ensure reproducibility. All measured values are reported as mean ± standard deviation. The temperature of the cutting fluid during ultrasonic exposure was continuously monitored and ranged from 23 °C to 35 °C, depending on the frequency and container material.

- Samples were collected by extracting equal fluid volumes from the upper and lower layers of each container.

- The refractive index of the cutting fluid in the container was measured using a refractometer.

- The mass of the fluid samples was determined using precision weighing.

- The treated fluid was then left undisturbed for 24 h, after which the measurements were repeated under the same conditions.

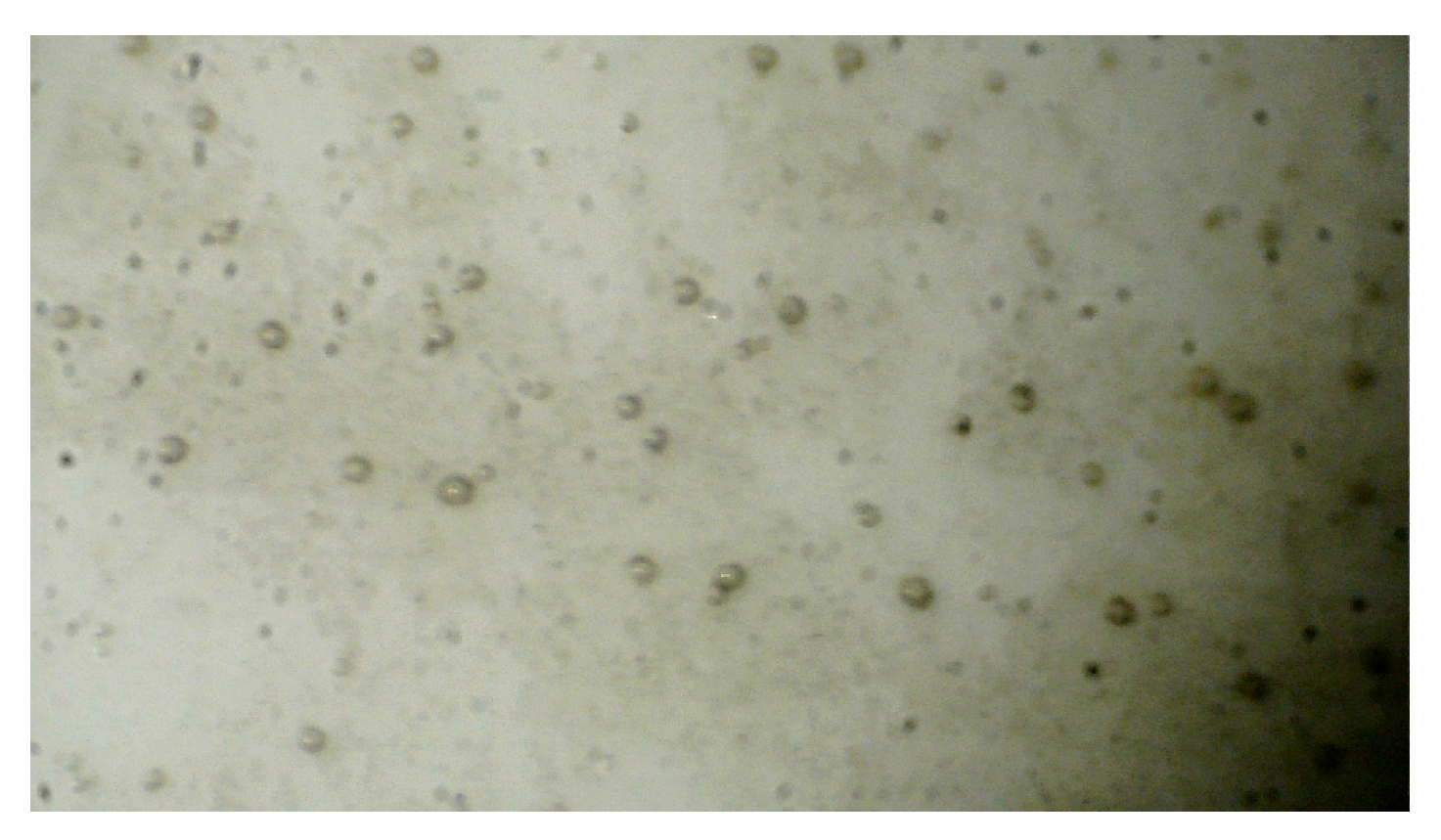

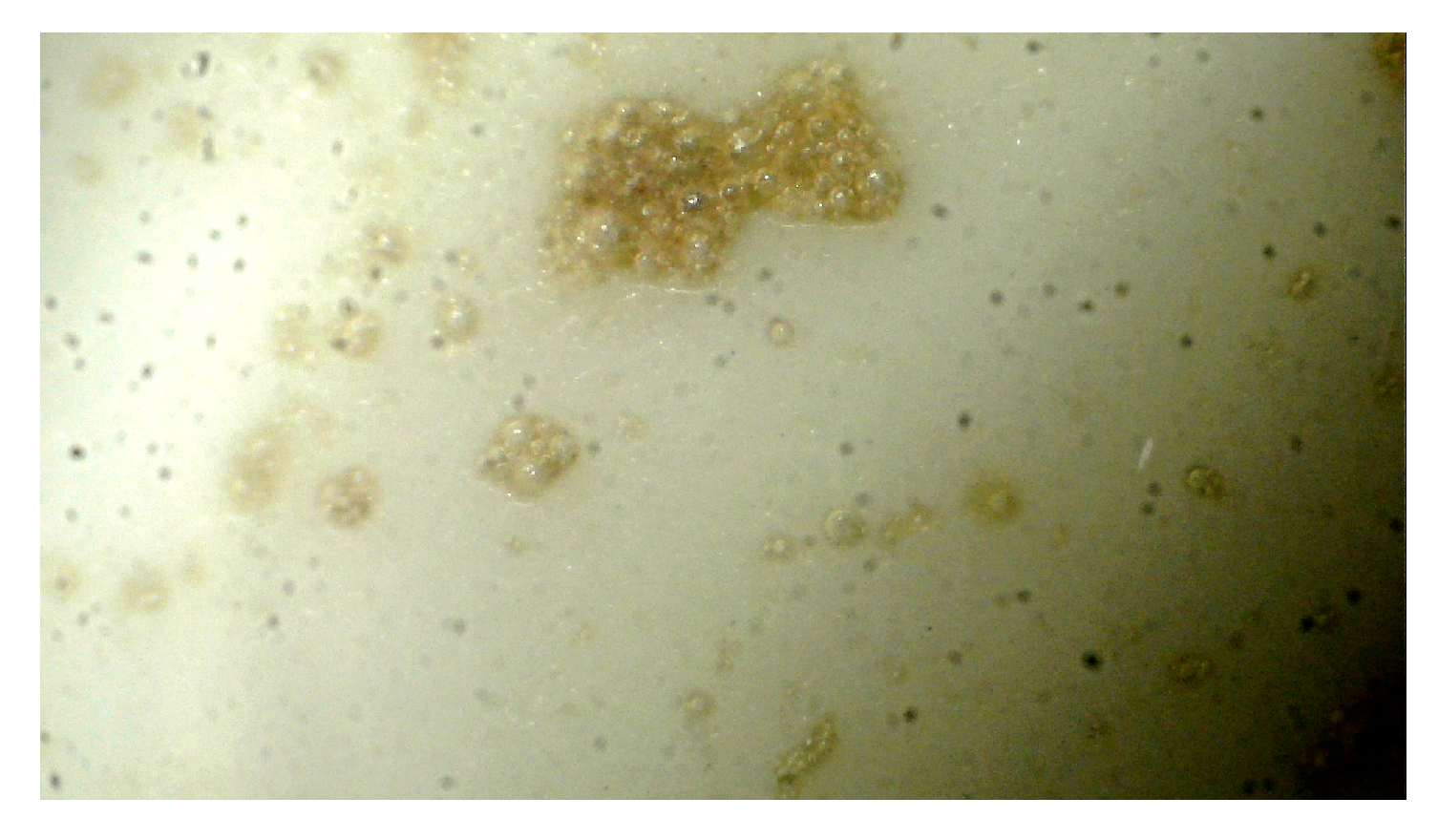

3. Results

4. Conclusions

- -

- Heating;

- -

- Cavitation;

- -

- Coagulation;

- -

- Dispersion.

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brinksmeier, E.; Meyer, D.; Huesmann-Cordes, A.G.; Herrmann, C. Metalworking fluids—Mechanisms and performance. CIRP Ann. 2015, 64, 605–628. [Google Scholar] [CrossRef]

- Singh, J.; Gill, S.S.; Dogra, M.; Singh, R. A review on cutting fluids used in machining processes. Eng. Res. Express 2021, 3, 012002. [Google Scholar] [CrossRef]

- Kui, G.W.A.; Islam, S.; Reddy, M.M.; Khandoker, N.; Chen, V.L.C. Recent progress and evolution of coolant usages in conventional machining methods: A comprehensive review. Int. J. Adv. Manuf. Technol. 2022, 119, 3–40. [Google Scholar] [CrossRef]

- Mayr, J.; Gebhardt, M.; Massow, B.B.; Weikert, S.; Wegener, K. Cutting Fluid Influence on Thermal Behavior of 5-axis Machine Tools. Procedia CIRP 2014, 14, 395–400. [Google Scholar] [CrossRef]

- Yan, P.; Rong, Y.; Wang, G. The effect of cutting fluids applied in metal cutting process. Eng. Manuf. 2016, 230, 19–37. [Google Scholar] [CrossRef]

- Fang, Z.; Obikawa, T. Influence of cutting fluid flow on tool wear in high-pressure coolant turning using a novel internally cooled insert. J. Manuf. Process. 2020, 56 Pt A, 1114–1125. [Google Scholar] [CrossRef]

- Xavior, M.A.; Adithan, M. Determining the influence of cutting fluids on tool wear and surface roughness during turning of AISI 304 austenitic stainless steel. J. Mater. Process. Technol. 2009, 209, 900–909. [Google Scholar] [CrossRef]

- Diniz, A.E.; Micaroni, R. Influence of the direction and flow rate of the cutting fluid on tool life in turning process of AISI 1045 steel. Int. J. Mach. Tools Manuf. 2007, 47, 247–254. [Google Scholar] [CrossRef]

- Liew, P.J.; Shaaroni, A.; Sidik, N.A.C.; Yan, J. An overview of current status of cutting fluids and cooling techniques of turning hard steel. Int. J. Heat Mass Transf. 2017, 114, 380–394. [Google Scholar] [CrossRef]

- Moura, R.R.; da Silva, M.B.; Machado, Á.R.; Sales, W.F. The effect of application of cutting fluid with solid lubricant in suspension during cutting of Ti-6Al-4V alloy. Wear 2015, 332–333, 762–771. [Google Scholar] [CrossRef]

- Tanaka, R.; Hosokawa, A.; Furumoto, T.; Okada, M.; Ueda, T. Influence of cutting fluid on tool edge temperature in end milling titanium alloy. J. Adv. Mech. Des. Syst. Manuf. 2015, 9, JAMDSM0074. [Google Scholar] [CrossRef]

- Irani, R.; Bauer, R.; Warkentin, A. A review of cutting fluid application in the grinding process. Int. J. Mach. Tools Manuf. 2005, 45, 1696–1705. [Google Scholar] [CrossRef]

- El Baradie, M.A. Cutting fluids: Part I. Characterisation. J. Mater. Process. Technol. 2009, 56, 786–797. [Google Scholar] [CrossRef]

- Araoyinbo, A.O.; Edun, M.B.; Samuel, A.U.; Rahmat, A.; Biodun, M.B.; Albakri, M.M. Influence of cutting fluid on machining processes: A review. J. Kejuruter. 2022, 34, 365–373. [Google Scholar] [CrossRef]

- Çakīr, O.; Yardimeden, A.; Ozben, T.; Kilickap, E. Selection of cutting fluids in machining processes. J. Achiev. Mater. Manuf. Eng. 2007, 25, 99–102. [Google Scholar]

- Boruah, P.K.; Ramu, P.; Babu, G.K.; Arunachalam, R. Green Metalworking Fluids for Sustainable Machining Operations: A Review. Metals 2022, 12, 1466. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Afonso, I.S.; Nobrega, G.; Lima, R.; Gomes, J.R.; Ribeiro, J.E. Conventional and Recent Advances of Vegetable Oils as Metalworking Fluids (MWFs): A Review. Lubricants 2023, 11, 160. [Google Scholar] [CrossRef]

- Tang, L.; Zhang, Y.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Biological Stability of Water-Based Cutting Fluids: Progress and Application. Chin. J. Mech. Eng. 2021, 35, 3. [Google Scholar] [CrossRef]

- Srinivas, M.S.; Kumar, D.; Suvin, P.S.; Kailas, S.V.; Pawar, S.; Choudhury, M.R. Green Lubricants in Action: Performance of Groundnut Oil-Based Cutting Fluids. Phys. Scr. 2023, 98, 075085. [Google Scholar] [CrossRef]

- Jeevan, T.; Jayaram, S. Tribological Properties and Machining Performance of Vegetable Oil Based Metal Working Fluids—A Review. Mod. Mech. Eng. 2018, 8, 42–65. [Google Scholar] [CrossRef]

- Ozcelik, B.; Kuram, E.; Demirbas, E.; Sik, E. Effects of vegetable-based cutting fluids on the wear in drilling. Sādhanā 2013, 38, 687–706. [Google Scholar] [CrossRef]

- Rapeti, P.; Krishna, V. Performance evaluation of vegetable oil-based nano cutting fluids in machining using Grey Relational Analysis—A step towards sustainable manufacturing. J. Clean. Prod. 2018, 172, 2862–2876. [Google Scholar] [CrossRef]

- Kim, A.; Petronienė, J.J.; Dzedzickis, A.; Bučinskas, V. Development of methodology for monitoring of metalworking fluids quality. J. Meas. Eng. 2025, 13, 1–14. [Google Scholar] [CrossRef]

- Gordon, T. Metalworking Fluid—The Toxicity of a Complex Mixture. J. Toxicol. Environ. Health Part A 2004, 67, 209–219. [Google Scholar] [CrossRef]

- Cheng, C.; Phipps, D.; Alkhaddar, R.M. Treatment of spent metalworking fluids. Water Res. 2005, 39, 4051–4063. [Google Scholar] [CrossRef] [PubMed]

- Clarens, A.F.; Zimmerman, J.B.; Keoleian, G.A.; Hayes, K.F.; Skerlos, S.J. Comparison of life cycle emissions and energy consumption for environmentally adapted metalworking fluid systems. Environ. Sci. Technol. 2008, 42, 8534–8540. [Google Scholar] [CrossRef]

- Zelenko, Y.; Bezovska, M.; Kuznetsov, V.; Muntian, A. Technological and ecological aspects of disposal of spent cutting fluids. J. Ecol. Eng. 2021, 22, 207–212. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, L.; Zhang, X.; Ge, B.; Qi, Y. Demulsification treatment of spent metalworking fluids by metal cations: The synergistic effect and efficiency evaluation. Processes 2021, 9, 1807. [Google Scholar] [CrossRef]

- Di Martino, P. Ways to improve biocides for metalworking fluid. AIMS Microbiol. 2021, 7, 13–27. [Google Scholar] [CrossRef] [PubMed]

- Feng, W.; Yin, Y.; de Lourdes Mendoza, M.; Wang, L.; Chen, X.; Liu, Y.; Cai, L.; Zhang, L. Freeze-thaw method for oil recovery from waste cutting fluid without chemical additions. J. Clean. Prod. 2017, 148, 84–89. [Google Scholar] [CrossRef]

- Trafny, E.A.; Lewandowski, R.; Kozłowska, K.; Zawistowska-Marciniak, I.; Stepińska, M. Microbial contamination and biofilms on machines of metal industry using metalworking fluids with or without biocides. Int. Biodeterior. Biodegrad. 2015, 99, 31–38. [Google Scholar] [CrossRef]

- Passman, F.J.; Küenzi, P. A differential adenosine triphosphate test method for differentiating between bacterial and fungal contamination in water-miscible metalworking fluids. Int. Biodeterior. Biodegrad. 2015, 99, 125–137. [Google Scholar] [CrossRef]

- Di Maiuta, N.; Rüfenacht, A.; Küenzi, P. Assessment of bacteria and archaea in metalworking fluids using massive parallel 16S rRNA gene tag sequencing. Lett. Appl. Microbiol. 2017, 65, 266–273. [Google Scholar] [CrossRef] [PubMed]

- Elansky, S.N.; Chudinova, E.M.; Elansky, A.S.; Kah, M.O.; Sandzhieva, D.A.; Mukabenova, B.A.; Dedov, A.G. Microorganisms in spent water-miscible metalworking fluids as a resource of strains for their disposal. J. Clean. Prod. 2022, 350, 131438. [Google Scholar] [CrossRef]

- Ruiz, C.; von Känel, G.; Burkard, S.; Küenzi, P. Fusarium spp. Metalworking Fluid Systems: Companions Forever. Pathogens 2024, 13, 990. [Google Scholar] [CrossRef]

- Marchand, G.; Lavoie, J.; Racine, L.; Lacombe, N.; Cloutier, Y.; Bélanger, É.; Lemelin, C.; Desroches, J. Evaluation of Bacterial Contamination and Control Methods in Soluble Metalworking Fluids. J. Occup. Environ. Hyg. 2010, 7, 358–366. [Google Scholar] [CrossRef]

- Rosenman, K. Occupational diseases in individuals exposed to metal working fluids. Curr. Opin. Allergy Clin. Immunol. 2015, 15, 131–136. [Google Scholar] [CrossRef]

- Thornéus, E.; Graff, P.; Bryngelsson, I.-L.; Nordenberg, E.; Ghafouri, B.; Johansson, H.; Fornander, L. Occupational Exposure to Metalworking Fluid and the Effect on Health Symptoms—An Intervention Study. J. Occup. Environ. Med. 2021, 63, e667–e672. [Google Scholar] [CrossRef]

- Friesen, M.C.; Costello, S.; Eisen, E.A. Quantitative exposure to metalworking fluids and bladder cancer incidence in a cohort of autoworkers. Am. J. Epidemiol. 2009, 169, 1471–1478. [Google Scholar] [CrossRef]

- Costello, S.; Friesen, M.C.; Christiani, D.C.; Eisen, E.A. Metalworking fluids and malignant melanoma in autoworkers. Epidemiology 2010, 22, 90–97. [Google Scholar] [CrossRef]

- CDC/NIOSH. Investigation of Dermal and Respiratory Exposures to Metalworking Fluid Mists: Implications for Skin and Lung Health. In Health Hazard Evaluation Report; Report No. HETA 2013 0075 3264; National Institute for Occupational Safety and Health: Morgantown, WV, USA, 2014. Available online: https://www.cdc.gov/niosh/hhe/reports/pdfs/2013-0075-3264.pdf (accessed on 25 August 2025).

- Lillienberg, L.; Andersson, E.M.; Järvholm, B.; Torén, K. Respiratory symptoms and exposure–response relations in workers exposed to metalworking fluid aerosols. Ann. Occup. Hyg. 2010, 54, 403–411. [Google Scholar] [CrossRef]

- Park, R.M. Risk assessment for metalworking fluids and cancer outcomes. Am. J. Ind. Med. 2018, 61, 198–203. [Google Scholar] [CrossRef]

- Lin, C.-C.; Wu, J.-M. A Novel Centrifugal Filtration Device. Separations 2022, 9, 129. [Google Scholar] [CrossRef]

- Wu, X.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Zhang, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Circulating purification of cutting fluid: An overview. Int. J. Adv. Manuf. Technol. 2021, 117, 2565–2600. [Google Scholar] [CrossRef]

- Popović, S.; Karadžić, M.; Cakl, J. Optimization of ultrafiltration of cutting oil wastewater enhanced by application of twisted tapes: Response surface methodology approach. J. Clean. Prod. 2019, 231, 320–330. [Google Scholar] [CrossRef]

- Chen, P.; Yin, D.; Song, P.; Liu, Y.; Cai, L.; Wang, H.; Zhang, L. Demulsification and oil recovery from oil-in-water cutting fluid wastewater using electrochemical micromembrane technology. J. Clean. Prod. 2020, 244, 118698. [Google Scholar] [CrossRef]

- Nam, C.T.H.; Hien, N.T.T.; Hiep, H.H.; Thuong, N.T. Treatment of Cutting Oil-in-Water Emulsion by Combining Flocculation and Fenton Oxidation and Membrane Filtration. J. Chem. 2021, 2021, 7248402. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Yu, J.J.; Wang, S.P.; Ma, H.J. Effect of freezing-air thawing pretreatment of cutting fluid wastewater on the organics’ distribution, transfer and transformation. J. Water Process Eng. 2023, 52, 103514. [Google Scholar] [CrossRef]

- Feng, W.; Yin, Y.; de Lourdes Mendoza, M.; Wang, L.; Chen, P.; Liu, Y.; Cai, L.; Zhang, L. Oil recovery from waste cutting fluid via the combination of suspension crystallization and freeze-thaw processes. J. Clean. Prod. 2018, 172, 481–487. [Google Scholar] [CrossRef]

- Dermouchi, A.; Lendormi, T.; Arris, S.; Zerdazi, R.; Lanoiselle, J.-L.; Bencheikh-Lehocine, M. The feasibility of combining an electrocoagulation process and a biological treatment for the degradation of cutting oil emulsions. Desalination Water Treat. 2021, 220, 265–276. [Google Scholar] [CrossRef]

- Garcia-Costa, A.L.; Luengo, A.; Zazo, J.A.; Casas, J.A. Cutting oil-water emulsion wastewater treatment by microwave assisted catalytic wet peroxide oxidation. Sep. Purif. Technol. 2021, 257, 117940. [Google Scholar] [CrossRef]

- Jalal, J.; Leong, T. Microstreaming and Its Role in Applications: A Mini-Review. Fluids 2018, 3, 93. [Google Scholar] [CrossRef]

- Antes, F.G.; Diehl, L.O.; Pereira, J.S.F.; Guimarães, R.C.L.; Guarnieri, R.A.; Ferreira, B.M.S.; Dressler, V.L.; Flores, E.M.M. Feasibility of low frequency ultrasound for water removal from crude oil emulsions. Ultrason. Sonochem. 2015, 25, 70–75. [Google Scholar] [CrossRef]

- Sadatshojaie, A.; Wood, D.A.; Jokar, S.M.; Rahimpour, M.R. Applying ultrasonic fields to separate water contained in medium-gravity crude oil emulsions and determining crude oil adhesion coefficients. Ultrason. Sonochem. 2021, 70, 105303. [Google Scholar] [CrossRef]

- Zakani, B.; Grecov, D. Effect of ultrasonic treatment on yield stress of highly concentrated cellulose nano-crystalline (CNC) aqueous suspensions. Carbohydr. Polym. 2022, 291, 119651. [Google Scholar] [CrossRef]

- Salehi, F.; Inanloodoghouz, M.; Karami, M. Rheological properties of carboxymethyl cellulose (CMC) solution: Impact of high-intensity ultrasound. Ultrason. Sonochem. 2023, 101, 106655. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Lyu, W.; Yang, P.; Wang, Z. Effect of ultrasound on the flocculation-sedimentation and thickening of unclassified tailings. Ultrason. Sonochem. 2020, 66, 104984. [Google Scholar] [CrossRef] [PubMed]

- Settnes, M.; Bruus, H. Forces acting on a small particle in an acoustical field in a viscous fluid. Phys. Rev. E 2012, 85, 016327. [Google Scholar] [CrossRef] [PubMed]

- Lauteri, C.; Ferri, G.; Piccinini, A.; Pennisi, L.; Vergara, A. Ultrasound Technology as Inactivation Method for Foodborne Pathogens: A Review. Foods 2023, 12, 1212. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Han, M.; He, F. A review of treating oily wastewater. Arab. J. Chem. 2017, 10 (Suppl. 2), S1913–S1922. [Google Scholar] [CrossRef]

- Cambiella, A.; Benito, J.M.; Pazos, C.; Coca, J. Centrifugal Separation Efficiency in the Treatment of Waste Emulsified Oils. Chem. Eng. Res. Des. 2006, 84, 69–76. [Google Scholar] [CrossRef]

- Fukami, K.; Ogata, N.; Yamamoto, K.; Kawamura, K.; Mitani, I.; Sakamoto, M. Treatment and Effective Removal of Metal Fine Particles from Waste Cutting Fluids by Flotation via Microbubbles and Skimming. Water 2022, 14, 2575. [Google Scholar] [CrossRef]

- Ibatov, M.K.; Kadyrov, A.S.; Pak, I.A.; Kadyrova, I.A.; Askarov, B.S. The results of experimental studies of the capacitive equipment of ultrasonic cleaning of exhaust gases of vehicles. Ugol/Coal 2020, 2, 73–78. [Google Scholar] [CrossRef]

- Kadyrov, A.; Bembenek, M.; Sarsembekov, B.; Kukesheva, A.; Nurkusheva, S. The Influence of the Frequency of Ultrasound on the Exhaust Gas Purification Process in a Diesel Car Muffler. Appl. Sci. 2024, 14, 5027. [Google Scholar] [CrossRef]

- Kadyrov, A.; Zhunusbekova, Z.; Ganyukov, A.; Kadyrova, I.; Kukesheva, A. General characteristics for loading the working elements of drilling and milling machines when moving in the clay solution. Commun. Sci. Lett. Univ. Zilina 2021, 23, B97–B105. [Google Scholar] [CrossRef]

- Bingham, E.C. An Investigation of the Laws of Plastic Flow. Bur. Stand. Bull. 1916, 13, 309. [Google Scholar] [CrossRef]

- Oldroyd, J.G. A Rational Formulation of the Equations of Plastic Flow for a Bingham Solid. Math. Proc. Camb. Philos. Soc. 1947, 43, 100–105. [Google Scholar] [CrossRef]

- Acheson, D.J. Elementary Fluid Dynamics; Oxford University Press: Oxford, UK, 1990. [Google Scholar]

- Georgiou, G.C. Fundamental Equations: Continuum Mechanics and Lattice Boltzmann Models; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

| Method | Typical Efficiency, % | Energy Consumption | Limitations |

|---|---|---|---|

| Sedimentation | 60–70 | Low | Long cycle time; ineffective for fine particles |

| Filtration (membrane) | 80–90 | Medium | Membrane fouling; high replacement cost |

| Flotation | 75–85 | High | Bubble coalescence; limited performance in viscous fluids |

| Centrifugation | 85–90 | Very high | High energy demand; expensive equipment |

| Ultrasonic cleaning | 90–98 | Low–medium | Effective for submicron particles; enhances rheological stability |

| Container Volume | Container Material | Ultrasonic Generator Frequency | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 25 kHz | 28 kHz | 40 kHz | ||||||||

| Clean Cutting Fluid | Medium Contamination | High Contamination | Clean Cutting Fluid | Medium Contamination | High Contamination | Clean Cutting Fluid | Medium Contamination | High Contamination | ||

| 1000 mL | Plastic container | Measuring Bx, %, t, C | ||||||||

| Glass container | Measuring Bx, %, t, C | |||||||||

| 3000 mL | Plastic container | Measuring Bx, %, t, C | ||||||||

| Glass container | Measuring Bx, %, t, C | Measuring Bx, %, t, C | Measuring Bx, %, t, C | Measuring Bx, %, t, C | Measuring Bx, %, t, C | Measuring Bx, %, t, C | Measuring Bx, %, t, C | Measuring Bx, %, t, C | Measuring Bx, %, t, C | |

| 5000 mL | Plastic container | Measuring Bx, %, t, C | ||||||||

| Glass container | Measuring Bx, %, t, C | |||||||||

| Container Volume | Container Material | Ultrasonic Generator Frequency | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 25 kHz | 28 kHz | 40 kHz | ||||||||

| Clean Cutting Fluid | Medium Contamination | High Contamination | Clean Cutting Fluid | Medium Contamination | High Contamination | Clean Cutting Fluid | Medium Contamination | High Contamination | ||

| 1000 mL | Plastic container | Bx = 1.5% t = 30 C ρ = 1.0058 g/ | ||||||||

| Glass container | Bx = 1.1% t = 35C ρ = 1.004 g/ | |||||||||

| 3000 mL | Plastic container | Bx = 1.6% t = 31C ρ = 1.0062 g/ | ||||||||

| Glass container | Bx = 5.1% t = 23.2 C ρ = 1.02 g/ | Bx = 1.1% t = 30C ρ = 1.004 g/ | Bx = 0.7% t = 32C ρ = 1.002 g/ | Bx = 5.2% t = 23.2C ρ = 1.0204g/ | Bx = 0.7% t = 34C ρ = 1.002 g/ | Bx = 0.5% t = 34C –– ρ = 1.002 g/ | Bx = 5.5%, t = 23.2C ρ = 1.021 g/ | Bx = 0.4% t = 30C ρ = 1.0015 g/ | Bx = 0.1% t = 35C ρ = 1.004 g/ | |

| 5000 mL | Plastic container | Bx = 1.7% t = 30C ρ = 1.0066 g/ | ||||||||

| Glass container | Bx = 0.7% t = 33C ρ = 1.0019 g/ | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, A.; Kadyrov, A.; Sinelnikov, K.; Sherov, K.; Yurchenko, V. The Method of Cleaning Cutting Fluid Using Ultrasonic Treatment. Appl. Mech. 2025, 6, 83. https://doi.org/10.3390/applmech6040083

Kim A, Kadyrov A, Sinelnikov K, Sherov K, Yurchenko V. The Method of Cleaning Cutting Fluid Using Ultrasonic Treatment. Applied Mechanics. 2025; 6(4):83. https://doi.org/10.3390/applmech6040083

Chicago/Turabian StyleKim, Anna, Adil Kadyrov, Kirill Sinelnikov, Karibek Sherov, and Vassiliy Yurchenko. 2025. "The Method of Cleaning Cutting Fluid Using Ultrasonic Treatment" Applied Mechanics 6, no. 4: 83. https://doi.org/10.3390/applmech6040083

APA StyleKim, A., Kadyrov, A., Sinelnikov, K., Sherov, K., & Yurchenko, V. (2025). The Method of Cleaning Cutting Fluid Using Ultrasonic Treatment. Applied Mechanics, 6(4), 83. https://doi.org/10.3390/applmech6040083