Micro-Structured Multifunctional Greener Coatings Obtained by Plasma Spray

Abstract

1. Introduction

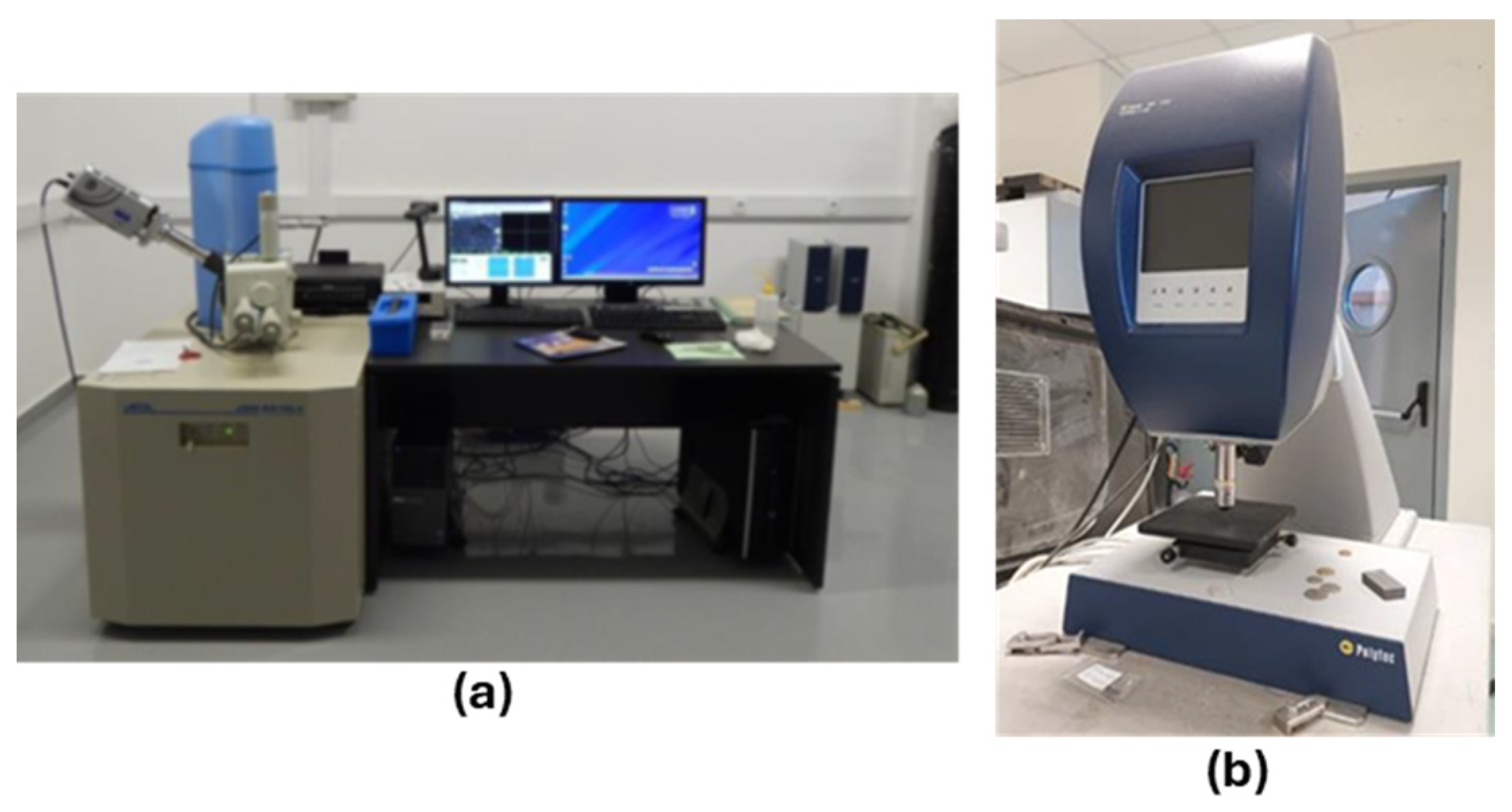

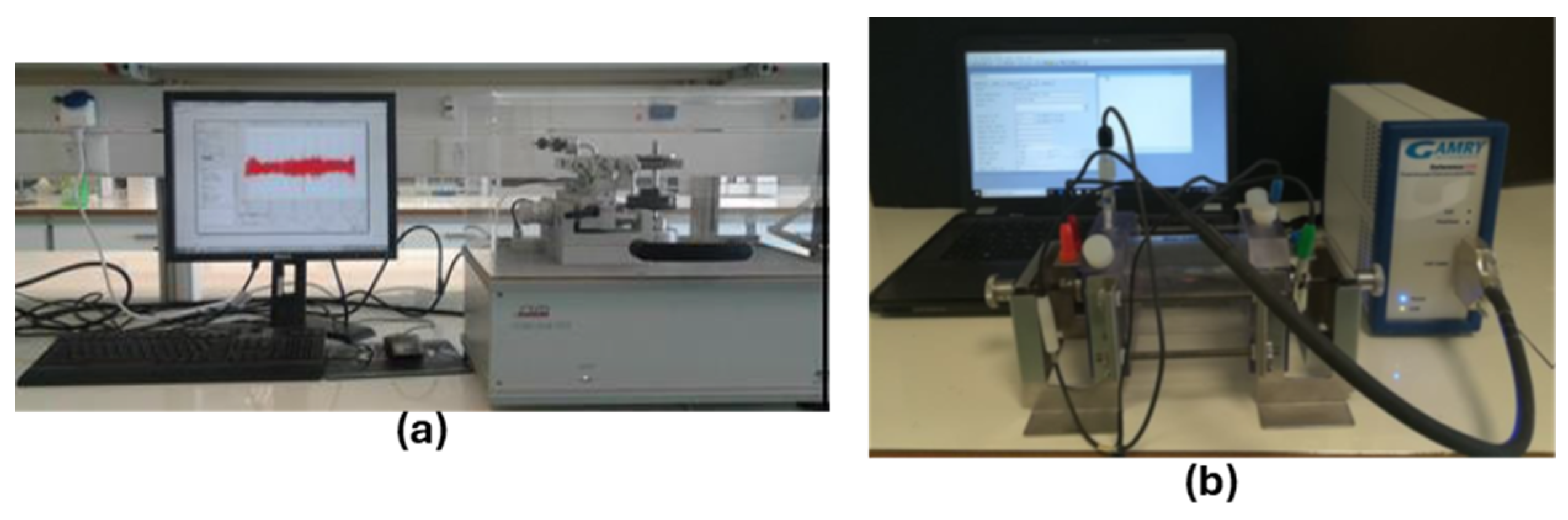

2. Materials and Methods

2.1. Materials

2.2. Plasma Spray Process

2.3. Methods

3. Results and Discussion

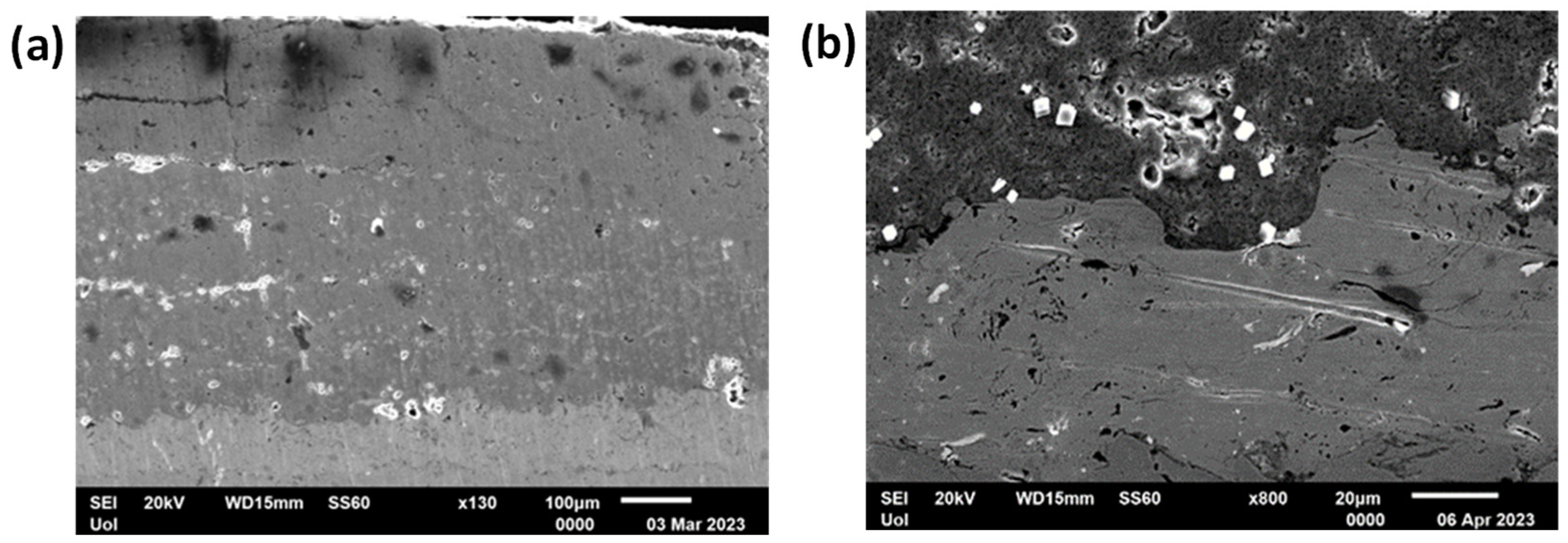

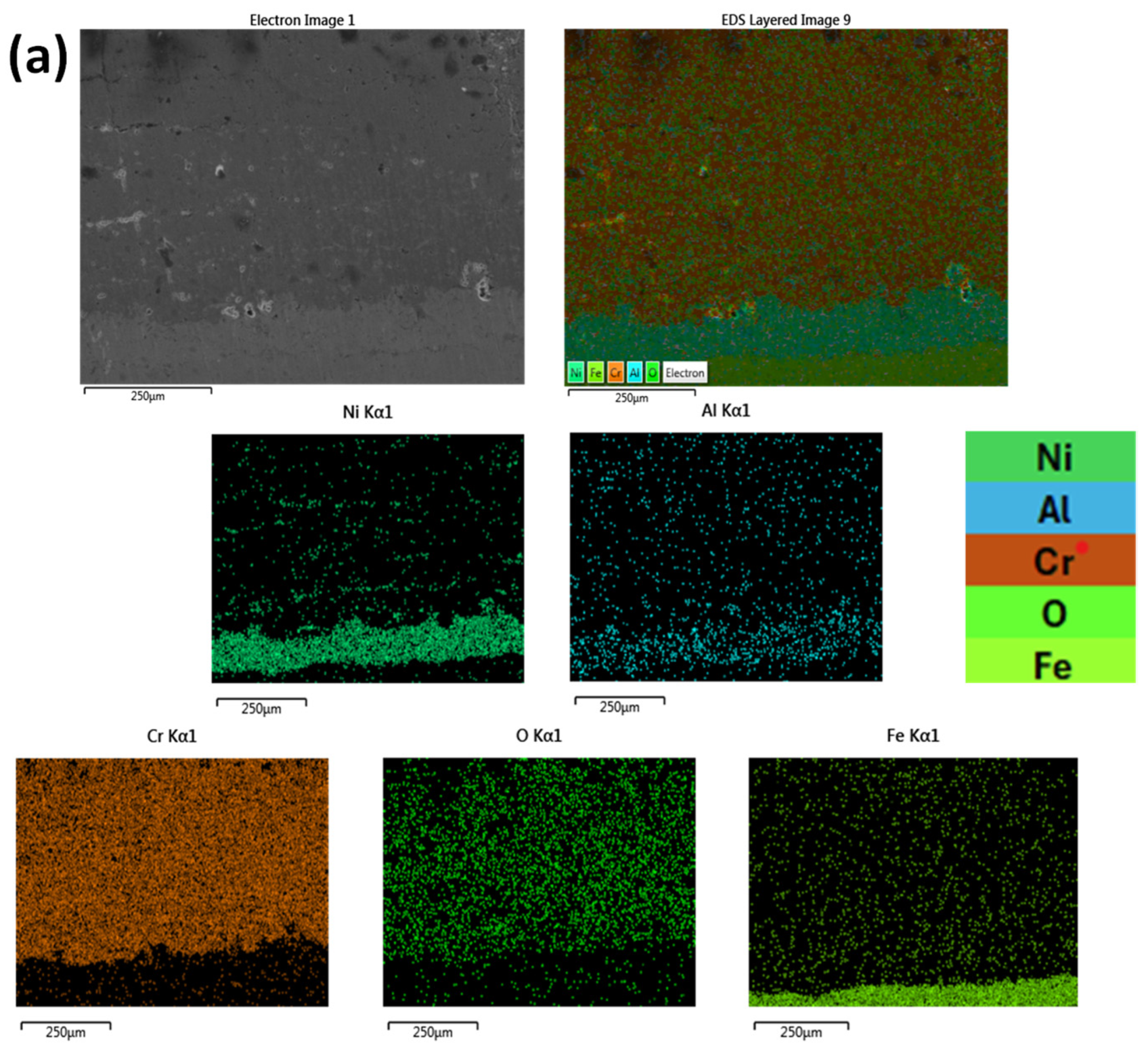

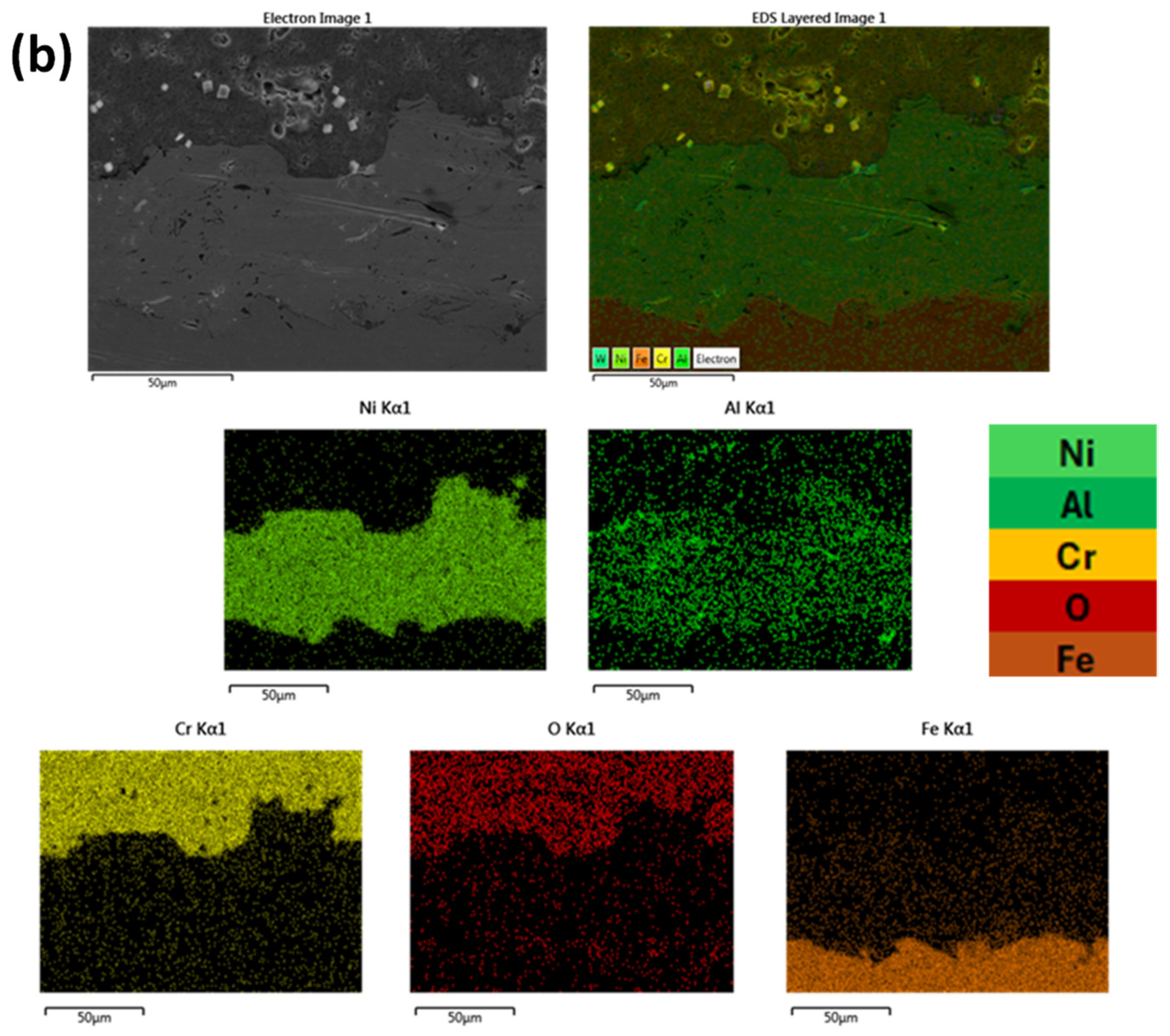

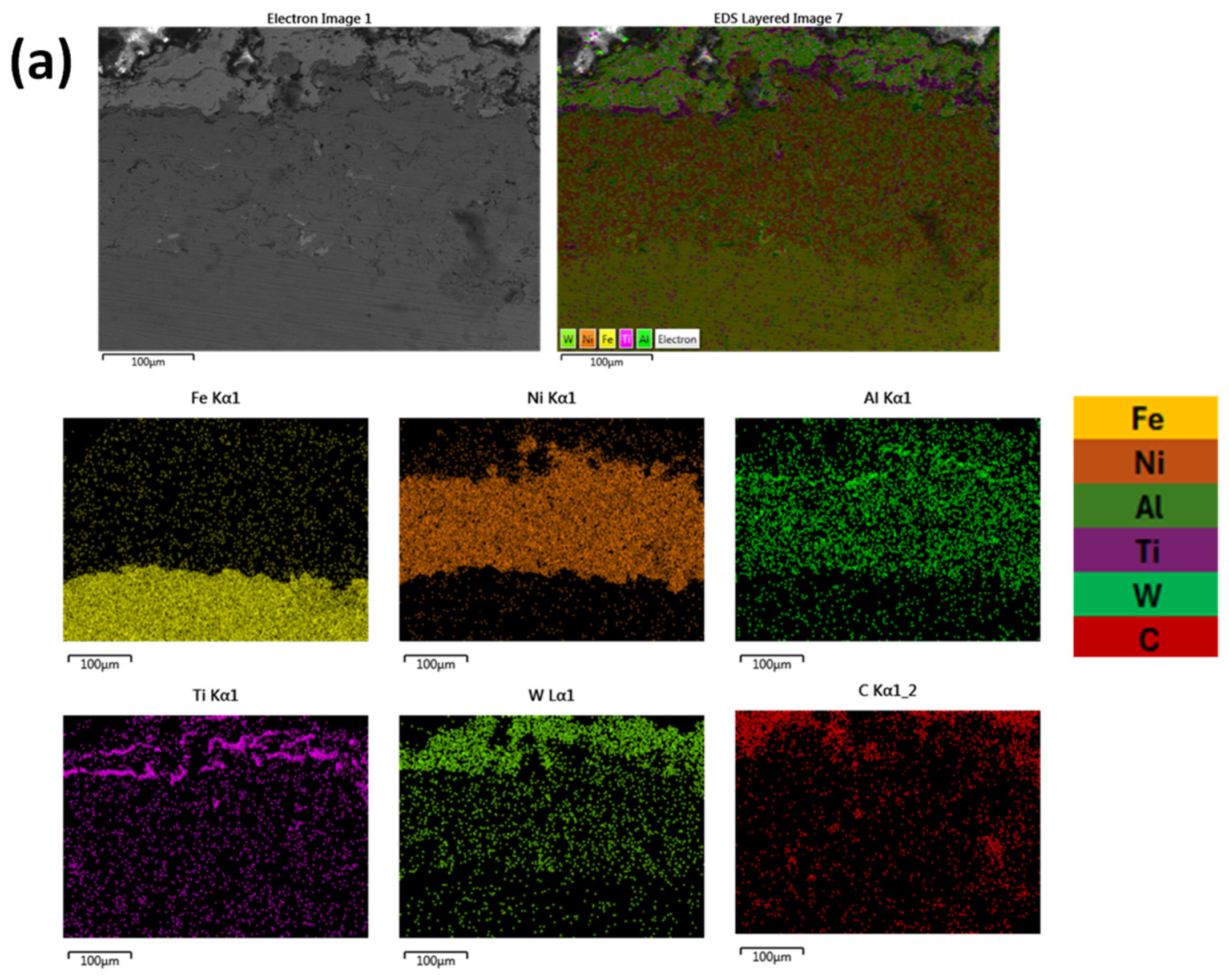

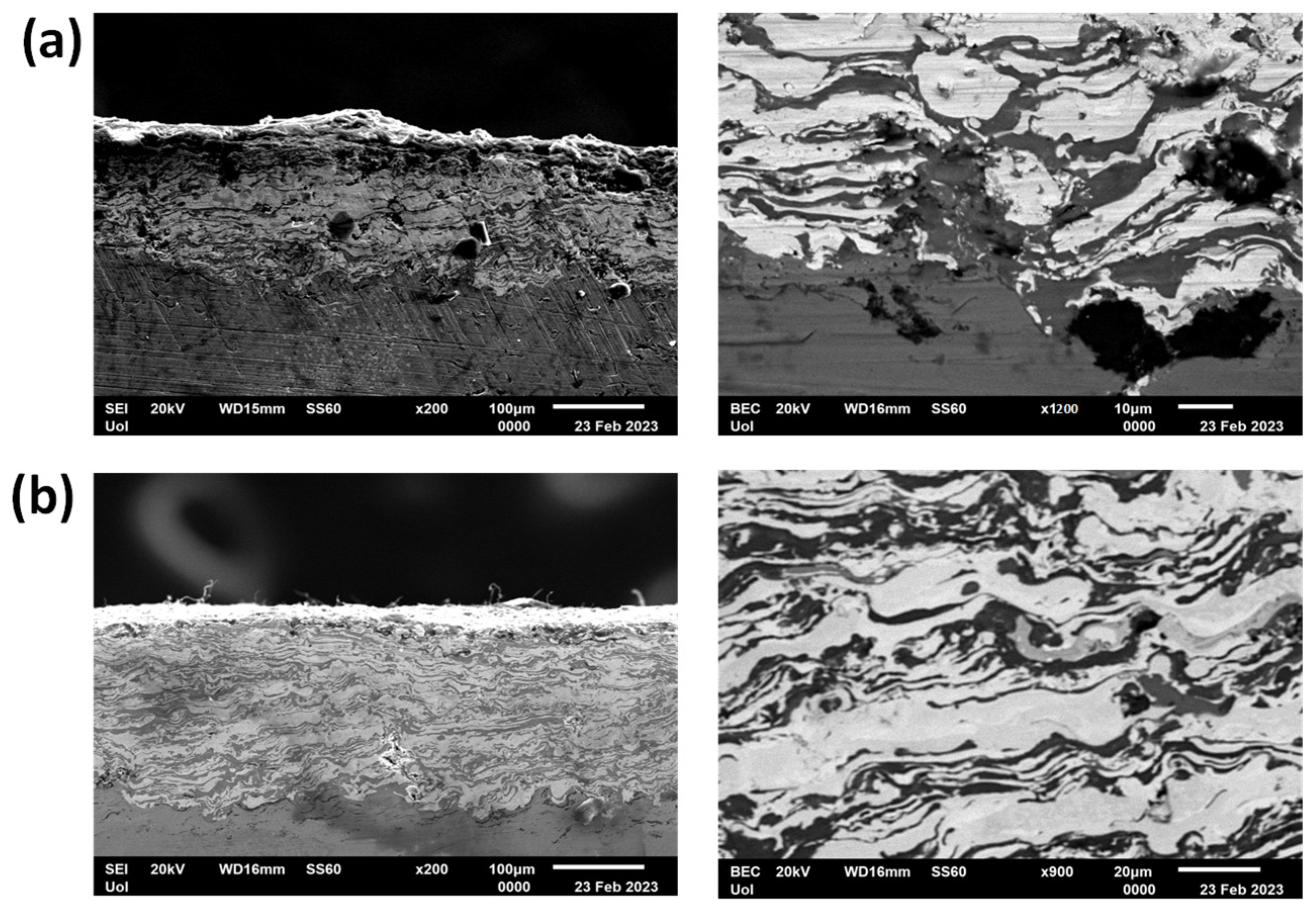

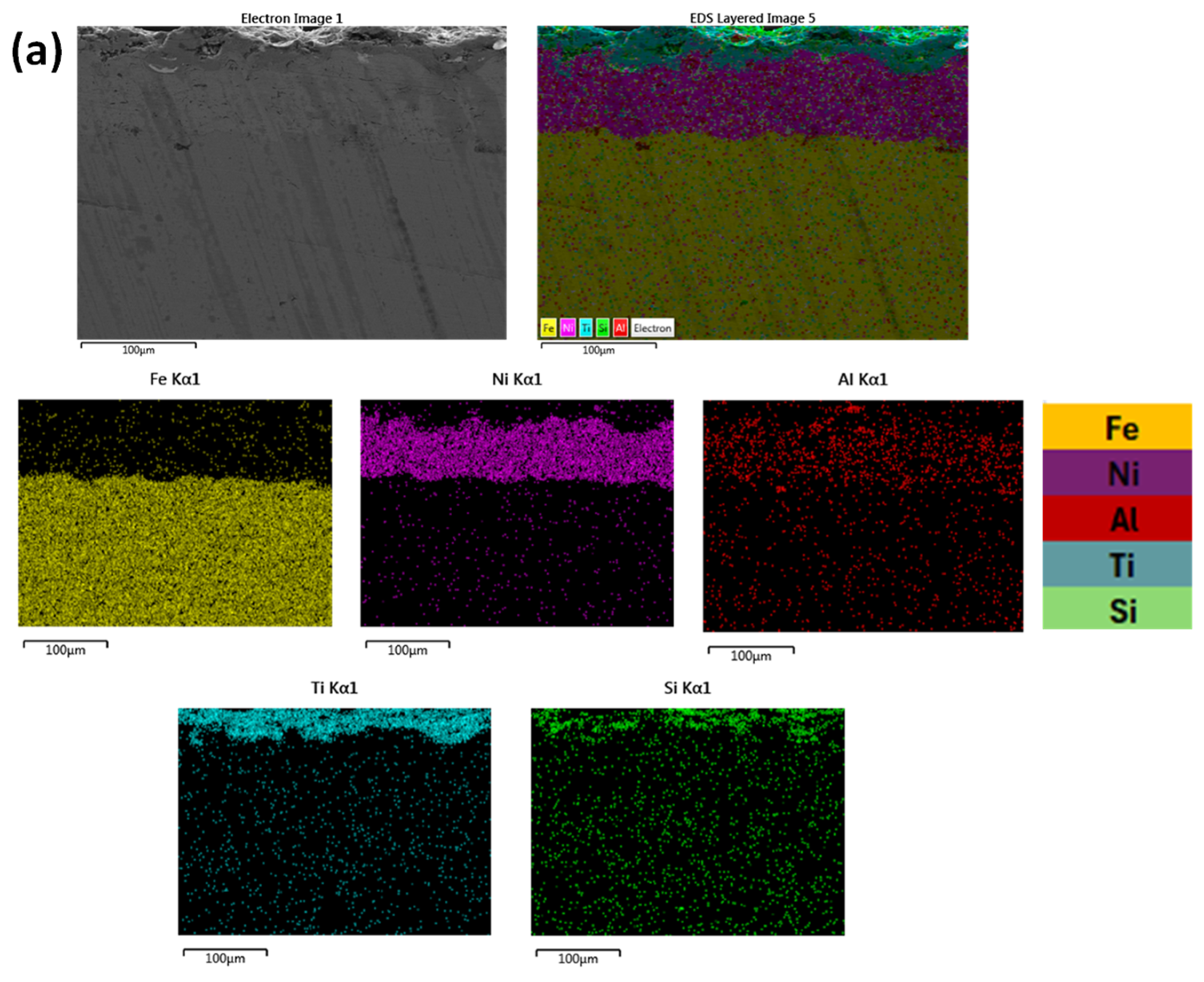

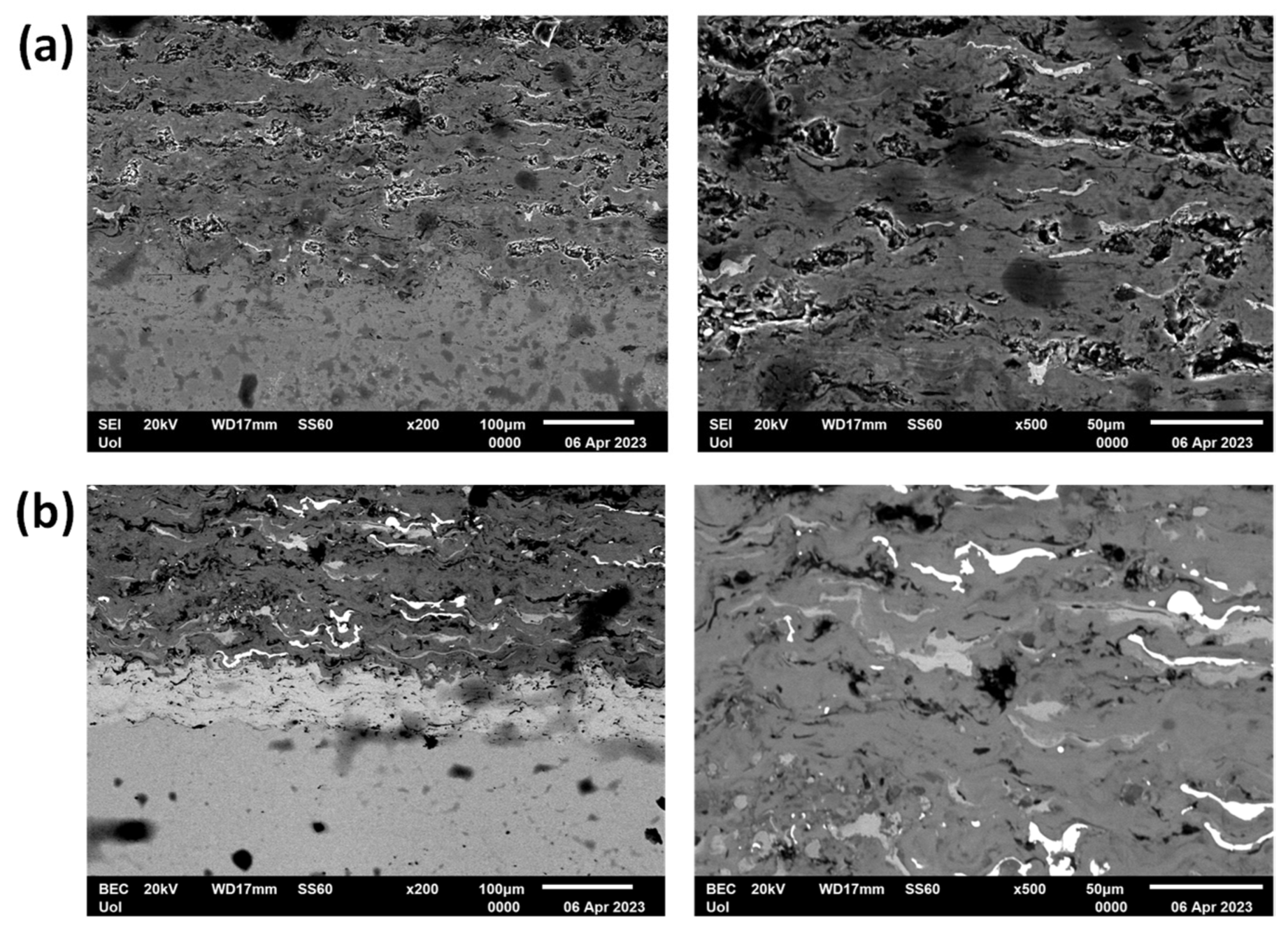

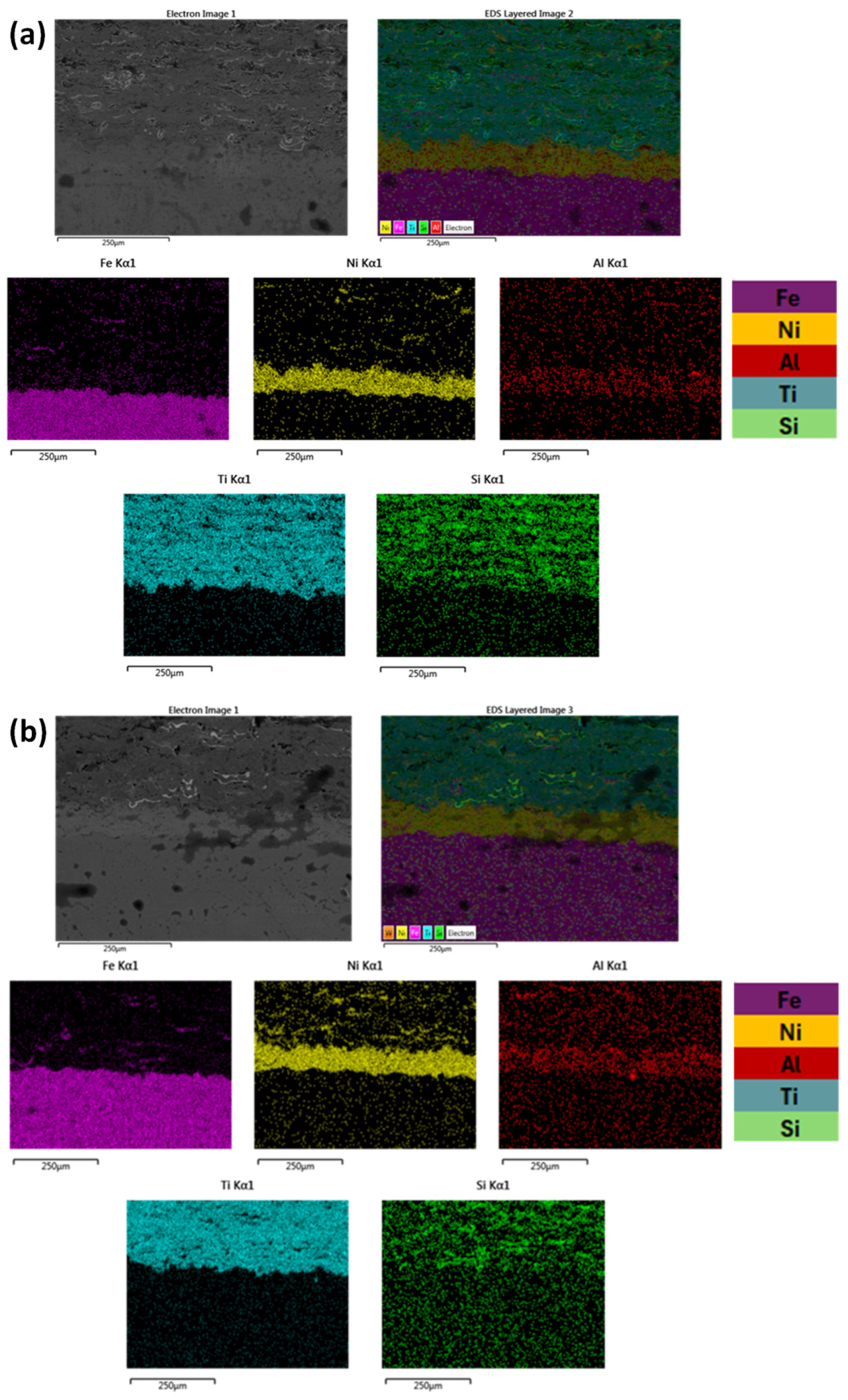

3.1. SEM-EDX Analysis

- (1)

- It was observed a variety of thickness between the different coatings. This phenomenon is associated with the manufacturing stage, where the coating thickness was not targeted as a strict parameter and, as such, the spraying conditions were not optimized towards this direction. The primary target was the feasibility or not to produce these different type of coatings, a target which was, in general, accomplished.

- (2)

- It is worth mentioning the potential tendency, as far as the different amperage used different coatings. Although not absolutely proved, it seems that in the case of the Ti-based system, the higher amperage led to slightly, occasionally, better coating quality by means of the presence and porosity and microcracks/flaws. This observation could most likely be attributed to the fact that higher amperage leads to higher temperatures, which in turn may cause more extensive melting and/or a more prolonged reservation of the liquid phase during deposition. In such cases, the presence of the preserved liquid phase restricts potential pores and/or microcracks to form or, at least, to propagate and expand. The authors, however, do recognize that a more thorough investigation is required towards this direction.

- (3)

- The cross-sectional SEM images showed continuous coating layers with limited pores and microcracks, which are indicative of satisfactory adhesion to the steel substrate. Although no direct adhesion test was performed, the absence of interfacial gaps and the stable wear and corrosion responses presented in later sections further support the conclusion that the coatings exhibit good cohesion and adhesion. Importantly, no continuous cracks or delamination were observed at the coating-substrate interfaces, indicating satisfactory adhesion.

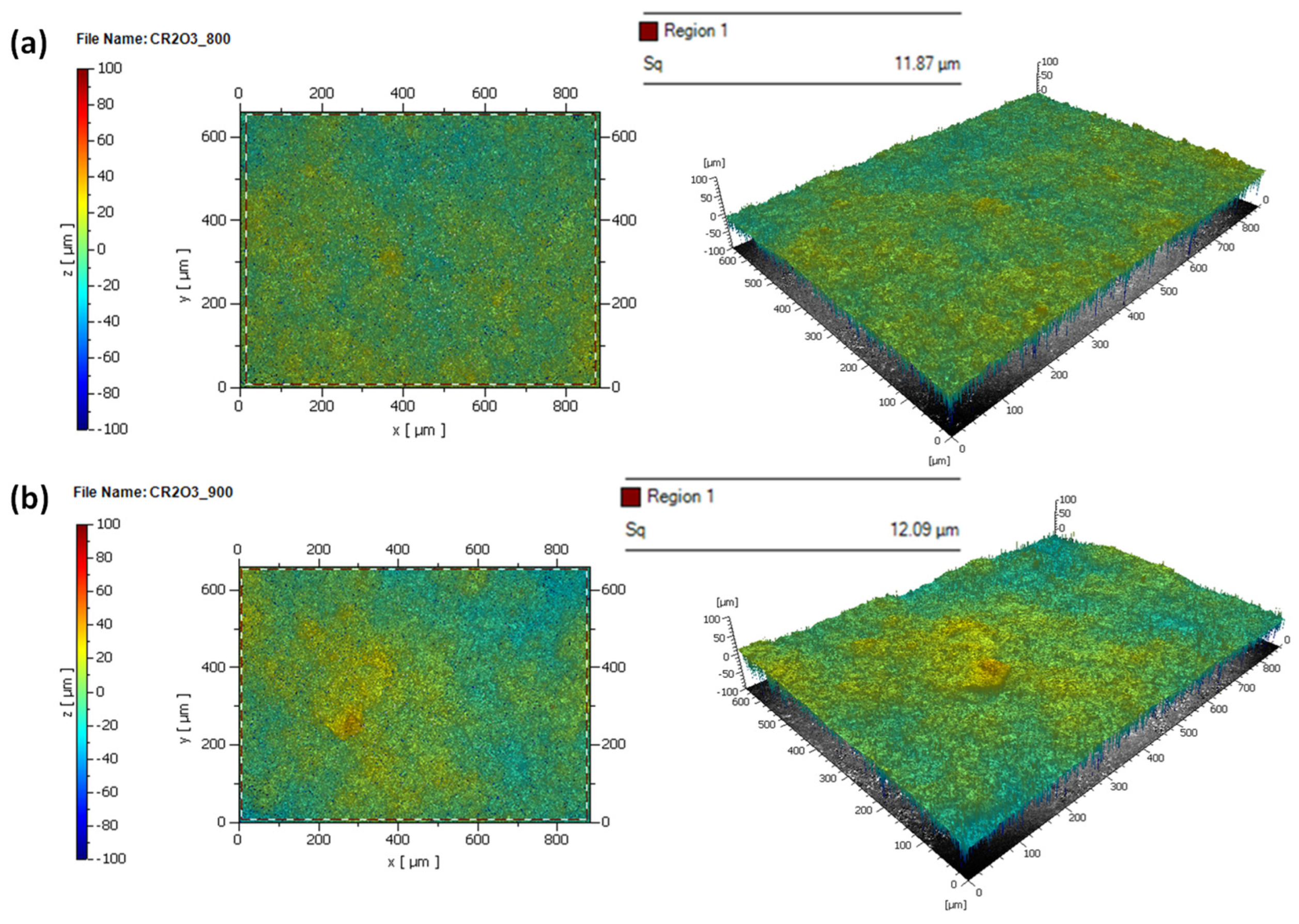

3.2. Profilometry Analysis

3.3. Wear Assessment

3.4. Corrosion Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sathish, M.; Radhika, N.; Saleh, B. Duplex and composite coatings: A thematic review on thermal spray techniques and applications. Met. Mater. Int. 2023, 29, 1229–1297. [Google Scholar] [CrossRef]

- Meghwal, A.; Anupam, A.; Murty, B.S.; Berndt, C.C.; Kottada, R.S.; Ang, A.S.M. Thermal spray high-entropy alloy coatings: A review. J. Therm. Spray Technol. 2020, 29, 857–893. [Google Scholar] [CrossRef]

- Smith, R.W.; Knight, R. Thermal spraying I: Powder consolidation—From coating to forming. JOM 1995, 47, 32–39. [Google Scholar] [CrossRef]

- Bhushan Mharat, G.B.K. Handbook of Tribology; McGraw-Hill Inc.: New York, NY, USA, 1991. [Google Scholar]

- Scott, K.; Kingswell, R. Advanced Surface Coatings; Rickerby, D.S., Mathews, A., Eds.; Chapman and Hall: New York, NY, USA, 1991. [Google Scholar]

- van den Berge, F.M.J. Thermal Spray Processes: An Overview. Adv. Mater. Process. 1998, 154, 31–35. [Google Scholar]

- Davis, J.R. Handbook of Thermal Spray Technology; ASM International: Almere, The Netherlands, 2004. [Google Scholar]

- Exarchos, D.A.; Sima, A.D.; Ananiadis, I.; Dalla, P.A.; Tragazikis, I.; Kordatou, T.; Farmaki, S.; Gontzamanis, A.; Kechagias, V.; Kechagias, L.; et al. Development and characterization of environmentally friendly multifunctional protective coatings. In NDE 4.0, Predictive Maintenance, and Communication and Energy Systems in a Globally Networked World; SPIE: Cergy, France, 2022; p. 5. [Google Scholar]

- Thakur, L.; Vasudev, H. Thermal Spray Coatings; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Boulos, M.I.; Fauchais, P.L.; Heberlein, J.V. Thermal Spray Fundamentals: From Powder to Part; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Latka, L.; Pawlowski, L.; Winnicki, M.; Sokolowski, P.; Małachowska, A.; Kozerski, S. Review of functionally graded thermal sprayed coatings. Appl. Sci. 2020, 10, 5153. [Google Scholar] [CrossRef]

- Pawłowski, L. The Science and Engineering of Thermal Spray Coatings, 2nd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2008. [Google Scholar]

- Smith, R. Plasma Spray Processing—The State of the Art and Future from a Surface to a Materials Processing Technology. In Proceedings of the 2nd Plasma-Technik-Symposium, Lucerne, Switzerland, 5–7 June 1991; pp. 17–38. [Google Scholar]

- Steffens, H.-D.; Mack, M. Plasma spraying as an advanced tool in surface engineering. Pure Appl. Chem. 1990, 62, 1801–1808. [Google Scholar] [CrossRef]

- Unabia, R.; Candidato, R.; Pawłowski, L. Current progress in solution precursor plasma spraying of cermets: A review. Metals 2018, 8, 420. [Google Scholar] [CrossRef]

- Zaat, J.H. A quarter of a century of plasma spraying. Annu. Rev. Mater. Sci. 1983, 13, 9–42. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, Z.; Zhang, X.; Kulczyk-Malecka, J.; Liu, H.; Kelly, P.; Withers, P.J.; Xiao, P. A conformable high temperature nitride coating for Ti alloys. Acta Mater. 2020, 189, 274–283. [Google Scholar] [CrossRef]

- Pasumarthi, V.; Chen, Y.; Bakshi, S.R.; Agarwal, A. Reaction synthesis of Ti3SiC2 phase in plasma sprayed coating. J. Alloy. Compd. 2009, 484, 113–117. [Google Scholar] [CrossRef]

- Li, C.; Zhou, Z.; Hu, L.; He, J.; Zheng, G.; Zhao, H.; Dong, Y.; Yang, Y.; Qin, Y.; Yin, F. Fabrication of plasma-sprayed TiC-Ti5Si3-Ti3SiC2 composite coatings from the annealed Ti/SiC powders. Surf. Coatings Technol. 2021, 417, 127227. [Google Scholar] [CrossRef]

- Ghadami, F.; Sohi, M.H.; Ghadami, S. Effect of bond coat and post-heat treatment on the adhesion of air plasma sprayed WC-Co coatings. Surf. Coatings Technol. 2015, 261, 289–294. [Google Scholar] [CrossRef]

- Sathish, S.; Geetha, M.; Asokamani, R. Comparative Studies on the Corrosion and Scratchbehaviors of Plasma Sprayed ZrO2 and WC-Co Coatings. Procedia Mater. Sci. 2014, 6, 1489–1494. [Google Scholar] [CrossRef][Green Version]

- Ettmayer, P.; Lengauer, W.J.P.M.I. The story of cermets. Int. J. Powder Metall. 1989, 21, 37–38. [Google Scholar][Green Version]

- Rajabi, A.; Ghazali, M.; Daud, A. Chemical composition, microstructure and sintering temperature modifications on mechanical properties of TiC-based cermet—A review. Mater. Des. 2015, 67, 95–106. [Google Scholar] [CrossRef]

- Bhaumik, S.; Upadhyaya, G.; Vaidya, M. Alloy design of WC-10Co hard metals with modifications in carbide and binder phases. Int. J. Refract. Met. Hard Mater. 1992, 11, 9–22. [Google Scholar] [CrossRef]

- Braic, M.; Vladescu, A.; Parau, A.C.; Pruncu, C.I.; Braic, V. Tribological properties of alloyed TiSi-stainless steel carbide coatings deposited by reactive cathodic arc method. Wear 2020, 460–461, 203456. [Google Scholar] [CrossRef]

- Idris, A.M.; El-Zahhar, A.A. Indicative properties measurements by SEM, SEM-EDX and XRD for initial homogeneity tests of new certified reference materials. Microchem. J. 2019, 146, 429–433. [Google Scholar] [CrossRef]

- Hassani, S.; Li, D.; Martinu, L.; Klemberg-Sapieha, J.E. Highly elastic hard PECVD TiSiC:H/a-SiC:H coatings with enhanced erosion and corrosion resistance: The trampoline effect. J. Vac. Sci. Technol. A 2023, 41, 043105. [Google Scholar] [CrossRef]

- Baiamonte, L.; Pulci, G.; Gisario, A.; Paglia, L.; Marino, A.L.; Tului, M.; Marra, F. WC-Ti coatings deposited via cold gas spray and modified by laser and furnace heat treatments. J. Therm. Spray Technol. 2021, 30, 2083–2098. [Google Scholar] [CrossRef]

- Moropoulou, A.; Delegou, E.; Vlahakis, V.; Karaviti, E. Digital processing of SEM images for the assessment of evaluation indexes of cleaning interventions on Pentelic marble surfaces. Mater. Charact. 2007, 58, 1063–1069. [Google Scholar] [CrossRef]

- Alexakis, E.; Delegou, E.; Lampropoulos, K.; Apostolopoulou, M.; Ntoutsi, I.; Moropoulou, A. NDT as a monitoring tool of the works progress and the assessment of materials and rehabilitation interventions at the Holy Aedicule of the Holy Sepulchre. Constr. Build. Mater. 2018, 189, 512–526. [Google Scholar] [CrossRef]

- Gambaro, S.; Valenza, F.; Cacciamani, G.; Muolo, M.; Passerone, A.; Toche, F.; Chiriac, R.; Dezellus, O. High-temperature-reactivity of Al-Ti alloys in contact with SiC. J. Alloy. Compd. 2020, 817, 152715. [Google Scholar] [CrossRef]

- Monisha, K.; Shariff, S.; Raju, R.; Manonmani, J.; Jayaraman, S. Titanium boride and titanium silicide phase formation by high power diode laser alloying of B4C and SiC particles with Ti: Microstructure, hardness and wear studies. Mater. Today Commun. 2022, 31, 103741. [Google Scholar] [CrossRef]

- Mitaľ, G.; Dobránsky, J.; Ružbarský, J.; Olejárová, Š. Application of laser profilometry to evaluation of the surface of the workpiece machined by abrasive waterjet technology. Appl. Sci. 2019, 9, 2134. [Google Scholar] [CrossRef]

- Islam, M.A.; Jiang, J.; Xie, Y.; Fiala, P. Investigation of erosion-corrosion behavior of (WTi)C based weld overlays. Wear 2017, 390–391, 155–165. [Google Scholar] [CrossRef]

- Travaglini, J.; Barsoum, M.; Jovic, V.; El-Raghy, T. The corrosion behavior of Ti3SiC2 in common acids and dilute NaOH. Corros. Sci. 2003, 45, 1313–1327. [Google Scholar] [CrossRef]

- Baboian, R. Corrosion Tests and Standards: Application and Interpretation; ASTM International: West Conshohocken, PA, USA, 2005; Volume 20. [Google Scholar]

- Hazra, S.; Sabiruddin, K.; Bandyopadhyay, P.P. Plasma and HVOF sprayed WC-Co coatings as hard chrome replacement solution. Surf. Eng. 2012, 28, 37–43. [Google Scholar] [CrossRef]

- Das, M.; Bysakh, S.; Basu, D.; Kumar, T.S.; Balla, V.K.; Bose, S.; Bandyopadhyay, A. Microstructure, mechanical and wear properties of laser processed SiC particle reinforced coatings on titanium. Surf. Coatings Technol. 2011, 205, 4366–4373. [Google Scholar] [CrossRef]

- Das, M.; Balla, V.K.; Basu, D.; Bose, S.; Bandyopadhyay, A. Laser processing of SiC-particle-reinforced coating on titanium. Scr. Mater. 2010, 63, 438–441. [Google Scholar] [CrossRef]

- Tang, J.; Saha, G.C.; Richter, P.; Kondás, J.; Colella, A.; Matteazzi, P. Effects of post-spray heat treatment on hardness and wear properties of Ti-WC high-pressure cold spray coatings. J. Therm. Spray Technol. 2018, 27, 1153–1164. [Google Scholar] [CrossRef]

- ASTM E2109-01; Standard Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings. ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM C633-13; Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM C1624-05; Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Coatings by Quantitative Single Point Scratch Testing. ASTM International: West Conshohocken, PA, USA, 2015.

- Borisov, Y.; Borisova, A.; Dyad’Ko, E. Composite Ti-Si-C System Coatings. Mater. Manuf. Process. 1995, 10, 831–835. [Google Scholar] [CrossRef]

- Fayyaz, O.; Bahgat Radwan, A.; Sliem, M.H.; Abdullah, A.M.; Hasan, A.; Shakoor, R.J.A.o. Investigating the properties of electrodeposited of Ni-P-ZrC nanocomposite coatings. ACS Omega 2021, 6, 33310–33324. [Google Scholar] [CrossRef] [PubMed]

- Fayyaz, O.; Khan, A.; Shakoor, R.A.; Hasan, A.; Yusuf, M.M.; Montemor, M.F.; Rasul, S.; Khan, K.; Faruque, M.R.I.; Okonkwo, P.C. Enhancement of mechanical and corrosion resistance properties of electrodeposited Ni-P-TiC composite coatings. Sci. Rep. 2021, 11, 5327. [Google Scholar] [CrossRef]

- Shahzad, K.; Radwan, A.B.; Fayyaz, O.; Shakoor, R.; Uzma, M.; Umer, M.A.; Baig, M.; Raza, A. Effect of concentration of TiC on the properties of pulse electrodeposited Ni-P-TiC nanocomposite coatings. Ceram. Int. 2021, 47, 19123–19133. [Google Scholar] [CrossRef]

| Material | Composition |

|---|---|

| Steel S235 (EN 10025-2) | C: 0.17–0.22%, Mn: ≤1.40%, Si: ≤0.50%, P: ≤0.035%, S: ≤0.035% |

| Cr2O3 | 99.5% |

| NiAl | Ni: 95%, Al: 5% |

| WC/Co | W: balance, Co: 17 wt%, C: 5.1 wt% |

| Ti | 99% |

| SiC | 99% |

| A/A | Substrate | Sandblasting | Middle Coating Ni-Al | Coating | Powder Deposition Methods | Thermal Spraying Technique | Treaty |

|---|---|---|---|---|---|---|---|

| 1 | Steel | ✓ | - | - | - | - | - |

| 2 | Steel | ✓ | ✓ | Ti-WC/Co | Powder mixing | Plasma Spray | 800 A |

| 3 | Steel | ✓ | ✓ | Ti-WC/Co | Powder mixing | Plasma Spray | 900 A |

| 4 | Steel | ✓ | ✓ | Ti-WC/Co | Layer by Layer | Plasma Spray | 800 A |

| 5 | Steel | ✓ | ✓ | Ti-WC/Co | Layer by Layer | Plasma Spray | 900 A |

| 6 | Steel | ✓ | ✓ | Ti-SiC | Powder mixing | Plasma Spray | 800 A |

| 7 | Steel | ✓ | ✓ | Ti-SiC | Powder mixing | Plasma Spray | 900 A |

| 8 | Steel | ✓ | ✓ | Ti-SiC | Layer by Layer | Plasma Spray | 800 A |

| 9 | Steel | ✓ | ✓ | Ti-SiC | Layer by Layer | Plasma Spray | 900 A |

| 10 | Steel | ✓ | ✓ | Cr2O3 | - | Plasma Spray | 800 A |

| 11 | Steel | ✓ | ✓ | Cr2O3 | - | Plasma Spray | 900 A |

| Linear Speed | 30 m/min |

| Spray Distance | 80 mm |

| Current | 800 A, Voltage: 43 V |

| 900 A, Voltage: 39.3 V | |

| Pressure | Ar = 50 psi |

| He = 100 psi | |

| Powder Ιnjection Angle | 90° |

| System Power | 40 KW |

| Flow Powder | 2 RPM |

| Cr2O3 (%wt) | Ti-WC (%wt) | Ti-SiC (%wt) | |||

|---|---|---|---|---|---|

| Deposition Methods | - | Layer by Layer | Mix | Layer by Layer | Mix |

| 800 A | Fe: 14.50 Ni: 19.28 Al: 1.22 Cr: 56.57 O: 8.43 | Fe: 1.91 Ni: 26.32 Al: 2.27 Ti: 6.2 W: 42.67 C: 16.93 Co: 3.69 | Ti: 29.04 W: 66.44 Co: 4.52 | Fe: 25.45 Ni: 26.05 Al: 1.35 Ti: 44.45 SiC: 2.71 | Fe: 35.75 Ni: 15.65 Al: 0.75 Ti: 40.61 SiC: 7.23 |

| 900 A | Fe: 2.49 Ni: 48.20 Al: 2.07 Cr: 22.62 O: 4.33 W: 1.29 | Fe: 11.53 Ni: 30.45 Al: 2.03 Ti: 15.79 W: 37.20 Co: 3.00 | Fe: 17.55 Ni: 18.08 Ti: 20.22 W: 37.22 C: 2.69 Co: 2.87 | Fe: 20.97 Ni: 26.12 Al: 1.27 Ti: 47.72 SiC: 3.92 | Fe: 52.55 Ni: 15.33 Al: 0.87 Ti: 29.84 SiC: 1.44 |

| Deposition Conditions | |||||||

|---|---|---|---|---|---|---|---|

| System | 800 A | 900 A | |||||

| Layer by Layer | Mix | Layer by Layer | Mix | ||||

| Cr2O3 | Porosity (%) | 11–13 | 11–13 | ||||

| Cr2O3 (μm) | 500 | 50–60 | |||||

| Ni-Al (μm) | 100 | 60–70 | |||||

| Ti-WC/Co | Porosity (%) | 15–16 | 2.5–4 | 5–6 | 3–3.5 | ||

| Ti-WC/Co (μm) | 65–85 | 150 | 70–120 | 100 | |||

| Ni-Al (μm) | 180–200 | 20 | 50–75 | 30–40 | |||

| Ti-SiC | Porosity (%) | 9–10 | 12–14 | 9–10 | 9.5–12.5 | ||

| Ti-SiC (μm) | 25–30 | 250 | 350 | 200 | |||

| Ni-Al (μm) | 50–75 | 60–80 | 100 | 60–75 | |||

| Cr2O3 (%wt) | Ti-WC/Co (%wt) | Ti-SiC (%wt) | |||

|---|---|---|---|---|---|

| Deposition Method | - | Layer by Layer | Mix | Layer by Layer | Mix |

| 800 A | −27% | −30% | −44% | −53% | −32% |

| 900 A | +4.4% | −58% | −45% | −41% | −36% |

| Ti-WC/Co Mix | Ti-WC/Co Layer | Ti-SiC Mix | Ti-SiC Layer | Cr2O3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 800 A | 900 A | 800 A | 900 A | 800 A | 900 A | 800 A | 900 A | 800 A | 900 A | |

| Eoc | −504 | −590 | −530 | −496 | −503 | −346 | −412 | −456 | −556 | −554 |

| Ecorr | −543 | −617 | −542 | −516 | −531 | −376 | −442 | −514 | −576 | −577 |

| Ecorr rev | −476.4 | −580 | −545.9 | −520.3 | −506 | −353 | −361 | −400 | −589.2 | −550 |

| Icorr | 8.03 | 4.82 | 2.35 | 6.61 | 5.15 | 5.58 | 4.2 | 2 | 19.2 | 8.32 |

| % Change in Icorr vs. Cr2O3 | ||

|---|---|---|

| 800 A | 900 A | |

| TiWC/Co Mix 800 A | −58% | −3% |

| TiWC/Co Mix 900 A | −78% | −42% |

| TiWC/Co Layer 800 A | −88% | −71% |

| TiWC/Co Layer 900 A | −65% | −20% |

| TiSiC Mix 800 A | −73% | −38% |

| TiSiC Mix 900 A | −71% | −33% |

| TiSiC Layer 800 A | −78% | −49% |

| TiSiC Layer 900 A | −89% | −76% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farmaki, S.G.; Exarchos, D.A.; Dalla, P.T.; Ananiadis, E.A.; Kechagias, V.; Karantzalis, A.E.; Matikas, T.E. Micro-Structured Multifunctional Greener Coatings Obtained by Plasma Spray. Appl. Mech. 2025, 6, 76. https://doi.org/10.3390/applmech6040076

Farmaki SG, Exarchos DA, Dalla PT, Ananiadis EA, Kechagias V, Karantzalis AE, Matikas TE. Micro-Structured Multifunctional Greener Coatings Obtained by Plasma Spray. Applied Mechanics. 2025; 6(4):76. https://doi.org/10.3390/applmech6040076

Chicago/Turabian StyleFarmaki, Spyridoula G., Dimitrios A. Exarchos, Panagiota T. Dalla, Elias A. Ananiadis, Vasileios Kechagias, Alexandros E. Karantzalis, and Theodore E. Matikas. 2025. "Micro-Structured Multifunctional Greener Coatings Obtained by Plasma Spray" Applied Mechanics 6, no. 4: 76. https://doi.org/10.3390/applmech6040076

APA StyleFarmaki, S. G., Exarchos, D. A., Dalla, P. T., Ananiadis, E. A., Kechagias, V., Karantzalis, A. E., & Matikas, T. E. (2025). Micro-Structured Multifunctional Greener Coatings Obtained by Plasma Spray. Applied Mechanics, 6(4), 76. https://doi.org/10.3390/applmech6040076