1. Introduction

Fiber-cement composites have been widely used globally due to their versatility in manufacturing building elements such as flat and corrugated sheets, and pipes for walls and other surfaces. These are prevalent in most residential, agricultural, and industrial buildings, particularly in developing regions [

1]. Consequently, fiber-cement is considered one of the best solutions for housing aimed at lower-income populations, owing to its reduced cost compared to other conventional construction solutions, especially for roofing [

2].

Fiber-cement composites are cementitious materials consisting of a cement matrix reinforced by fibers, along with additives and supplementary materials that may be incorporated. Thus, compared to other cementitious composites like mortars and concretes, fiber-cements are distinguished by the absence of fine aggregates (such as natural or artificial sand) or coarse aggregates (like crushed stone or gravel) in their composition.

The primary objective of incorporating fibers is to mitigate the brittleness of cement, thereby improving ductility. This also ensures the maintenance of strength even after matrix cracking, allowing for greater composite deformation before rupture, and providing enhanced impact resistance and toughness [

3,

4,

5]. Historically, the cement matrix was reinforced with asbestos fibers, but these have since been replaced by other synthetic or natural (vegetable) fibers, often maintaining or even improving the physical and mechanical properties of the composites [

6].

Vegetable fibers offer several advantages: they are biodegradable, renewable, widely available, non-hazardous to workers, and low-cost and require less energy for manufacturing [

7,

8]. However, the mechanical support effect of vegetable fibers in fiber-cements can be compromised when the highly alkaline pH (above 12) of the cement curing process causes alkaline hydrolysis of these fibers [

9]. To prevent this chemical attack by the matrix on the fibers, the two most common approaches in the literature are to thermally [

10] or chemically [

11,

12] treat the fibers and to add pozzolans to the matrix to reduce its pH [

13,

14]. Inducing a carbonation process in the matrix represents a third option, which has been considerably less explored to date.

Carbonation involves a chemical reaction that leads to the formation of calcium carbonate (CaCO

3), also known as limestone. Generally, this compound is formed by the reaction of carbon dioxide (CO

2) with calcium oxide (CaO), also known as lime. According to Tonoli et al. [

15], in composites reinforced with vegetable fibers, the carbonation of the composite is enhanced due to its high porosity, which facilitates CO

2 penetration, allowing CaCO

3 formation within the material. The consumption of alkalis (such as calcium hydroxide [Ca(OH)

2]), present in the material’s pores, leads to a decrease in the alkalinity of the environment (pH reduction), consequently providing a less aggressive environment for the fibers. Carbonation also results in increased material densification, raising the specific mass and, consequently, the values of mechanical strength and elastic modulus.

To enhance the carbonation process and further improve mechanical performance and durability, the incorporation of calcium-rich substances has already been addressed in the literature in order to stabilize the alkaline environment and improve the matrix–fiber interaction. If supplementary materials are applied, it may contribute to sustainability through waste valorization. The integration of such residues offers a pathway towards developing more sustainable and cost-effective construction materials by simultaneously addressing waste management and enhancing material properties.

Lime sludge cellulose refers to cellulosic fibers or waste derived from paper industry sludge, often characterized by its high lime content, and has significant applications, particularly in building materials. Recent studies highlight its utility in eco-friendly construction, where incorporating cellulose fibers from waste paper sludge into cement-based mortars and bricks can yield mechanical properties (such as compression and flexural strength) comparable to conventional counterparts [

16,

17]. Environmentally, using lime sludge cellulose in these materials contributes to substantial waste reduction, diverting industrial byproducts from landfills, lowering disposal costs, and decreasing the demand for virgin raw materials, thereby mitigating pollution. However, challenges exist, such as water repellency issues when lime sludge is used as a filler in paper, though these can be addressed with cationic polymers [

18]. Furthermore, the reactivity of fly ashes derived from cellulose industries, which contain lime sludge, may be limited due to surface coatings and high sulfate/alkali content, impacting their efficacy in certain applications like autoclaved aerated concrete [

17].

Considering the diverse advantages and limitations associated with the use of lime sludge in construction materials, the full potential of recycling this industrial byproduct for such purposes remains underexplored and its impact is not entirely clear. Therefore, this article investigates the effectiveness of accelerated carbonation as a strategy to enhance the performance of cellulose fiber-cement composites, specifically exploring the partial replacement of Portland cement with lime sludge.

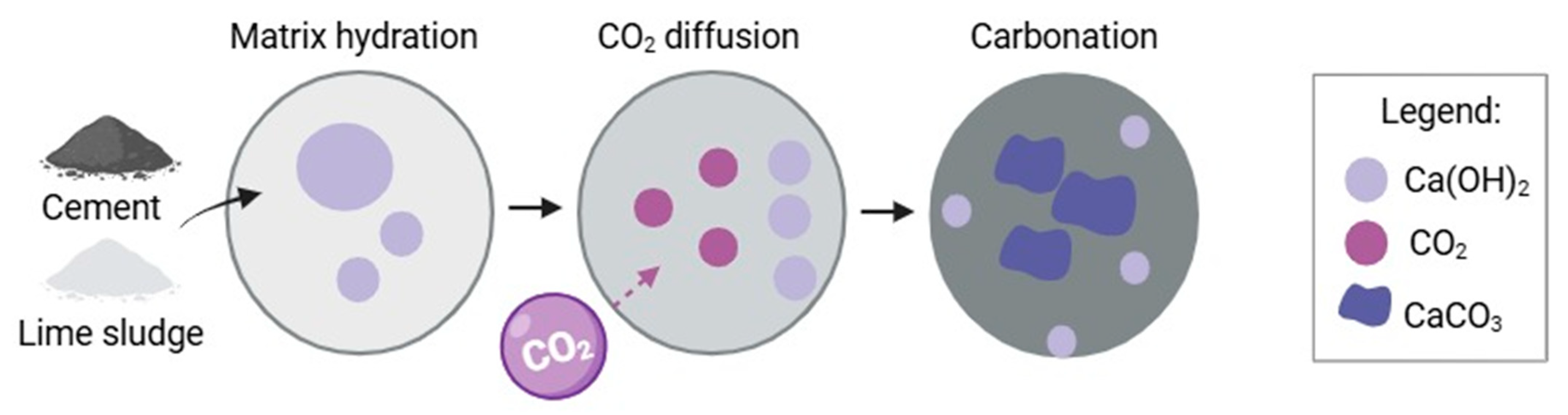

Figure 1 illustrates a schematic flowchart summarizing the key chemical and physical processes involved in this approach, including the hydration reactions of Portland cement, the role of lime sludge as a calcium-rich additive, the diffusion of atmospheric or injected CO

2, and the subsequent formation of calcium carbonate (CaCO

3) through induced carbonation.

This study aimed to determine whether combining lime sludge as a partial cement replacement with accelerated carbonation can enhance the strength, stiffness, toughness, and durability of cellulose fiber-cement composites, while elucidating the underlying mineralogical/microstructural mechanisms.

3. Results and Discussion

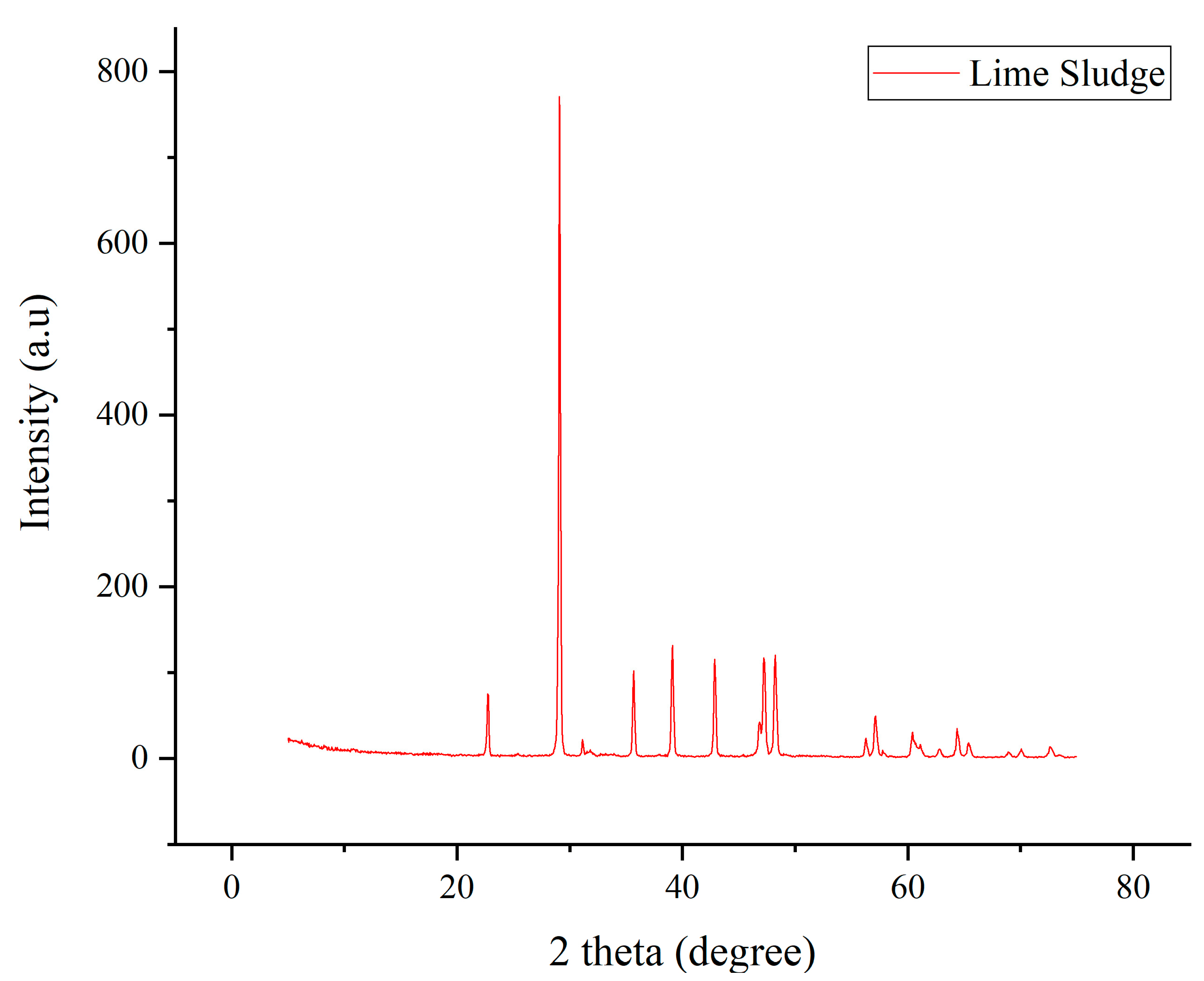

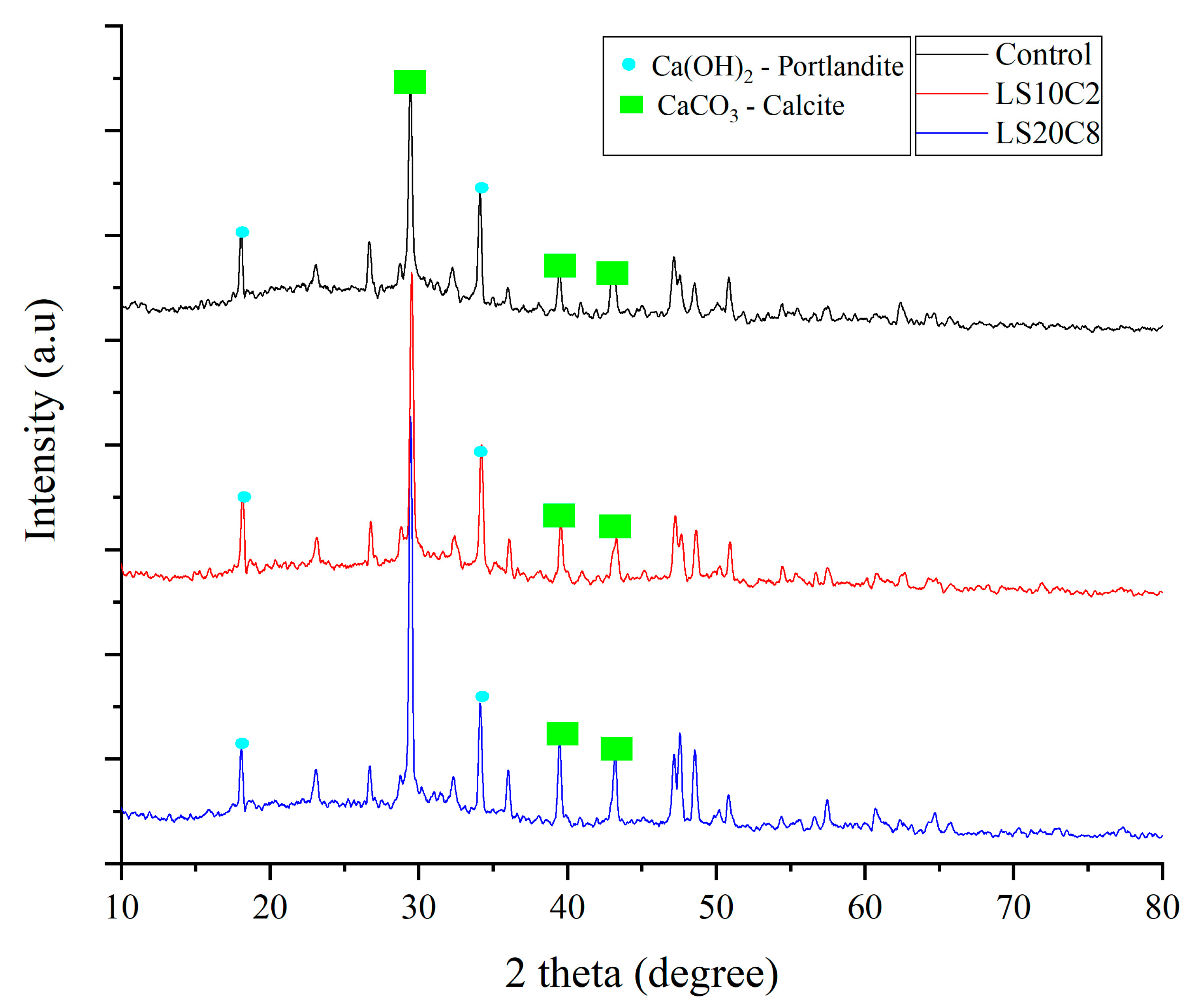

The XRD patterns (

Figure 5) visually illustrate significant mineralogical transformations induced by the carbonation process and the presence of lime sludge. No anomalous or unexpected phases were detected, confirming the controlled nature of the chemical reactions and the validity of the results within the context of cementitious materials. For the control samples (0% lime sludge and uncarbonated), prominent peaks corresponding to portlandite (calcium hydroxide, Ca(OH)

2) were observed, especially at 2θ = 18.0°, along with peaks for unreacted cement phases. As carbonation time increases and lime sludge content is introduced, a clear reduction in the intensity of portlandite peaks was observed. Concomitantly, new and increasingly intense peaks corresponding to calcium carbonate (CaCO

3), specifically calcite at 2θ = 29.4°, emerge and strengthen. This trend is particularly evident in the LS20-C8 group (20% lime sludge, 8 h carbonation), where the portlandite peaks are significantly diminished, and the calcite peaks show the highest intensity and sharpness, indicating a high degree of crystallization. This qualitative observation is supported by the quantitative data presented in

Table 1, which shows a progressive increase in the integrated area of calcite peaks and a corresponding rise in % CaCO

3 from 66.8% in the control to 74.0% in LS20-C8. These values provide numerical confirmation of the enhanced carbonation efficiency associated with greater lime sludge content and extended carbonation duration. This reaction densifies the matrix and reduces alkalinity, which preserves cellulose fibers and strengthens the fiber–matrix interface.

Theoretically, carbonation involves the reaction of atmospheric carbon dioxide (CO

2) with calcium hydroxide present in the cement matrix to form calcium carbonate and water. This reaction is represented as: Ca(OH)

2 + CO

2 → CaCO

3 + H

2O. The accelerated carbonation process intensifies this reaction. The presence of lime sludge, a calcium-rich byproduct, provides an additional source of calcium ions, effectively boosting the formation of calcium carbonate. This not only consumes the alkaline Ca(OH)

2, which lowers the matrix’s pH and creates a less aggressive environment for the cellulose fibers (thereby reducing fiber degradation), but also fills pore spaces, leading to increased material density and reduced porosity. The higher crystallinity of calcite observed in samples with increased lime sludge and carbonation time suggests a more complete and efficient carbonation reaction, resulting in a more stable and stronger microstructure. These XRD findings are highly consistent with established literature on carbonation of cementitious materials. Studies, like León-Martínez et al. [

27], consistently report the transformation of portlandite into calcite and aragonite (another CaCO

3 polymorph) upon carbonation, which leads to pore refinement and enhanced mechanical properties. The observation that increased calcium availability promotes more extensive carbonation aligns with the principles of chemical equilibrium and reactant availability in such systems.

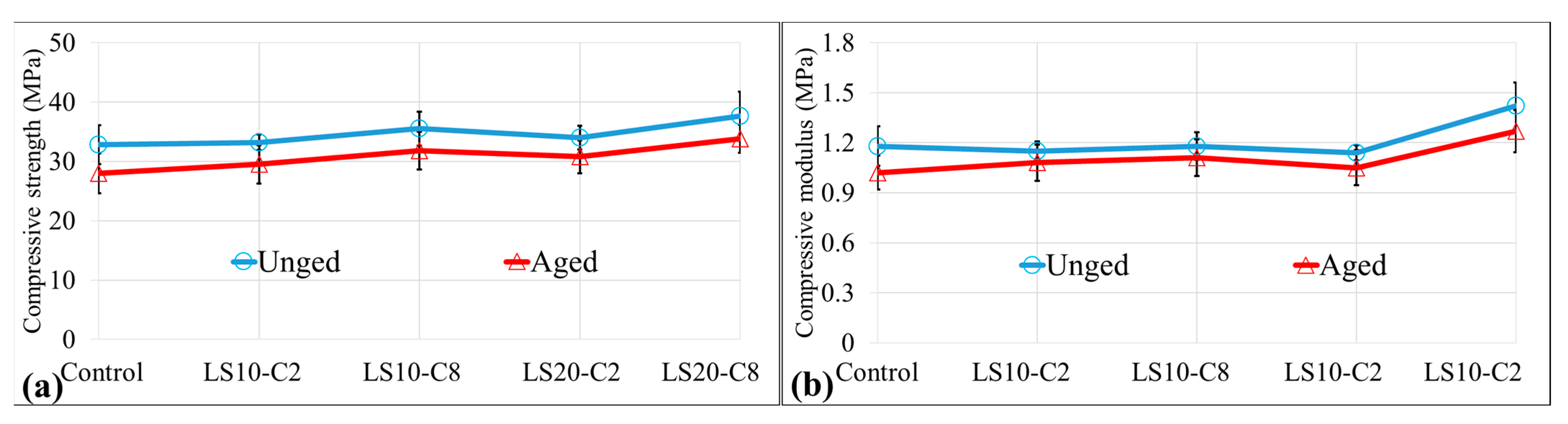

In

Figure 6a, it is observed that, for the unaged composites, the compressive strength shows a general increase with the incorporation of lime sludge and carbonation treatment. Comparatively to the control group with 32.8 MPa, the LS20-C8 group stood out, reaching 37.6 MPa, representing an increase of approximately 14.6%. Even the groups with 10% lime sludge (LS10-C2 and LS10-C8) showed improvements, with increments of about 1.22% and 8.23%, respectively. After aging, all groups exhibited a reduction in compressive strength compared to their unaged counterparts. The aged control group exhibited a 14.63% decrease compared to its unaged state. However, the aged LS20-C8 formulation maintained the highest strength, 33.8 MPa, with a smaller percentage loss of approximately 10.1% compared to its unaged condition, suggesting greater durability.

In

Figure 6b, the compressive modulus values followed a similar trend to strength. In the unaged composites, the modulus of the control group was 1.18 MPa. The LS20-C8 group again demonstrated the best performance, with a modulus of 1.42 MPa, representing a gain of approximately 20.34% relative to the control. Similarly, the LS10-C2 and LS10-C8 groups showed increases of approximately 5.88% and 8.82%, respectively. After aging, the compressive modulus also decreased in all groups. The aged Control group had a reduction of 13.56% (1.02 MPa) relative to the unaged condition. The percentage loss in modulus was smaller (c.a. 10.56%) for the carbonated lime sludge groups, especially the aged LS20-C8, which recorded 1.27 MPa, indicating greater material stability under wetting and drying cycles.

These results can be explained by the densification of the cementitious matrix due to the formation of calcium carbonate (CaCO

3) during carbonation, as discussed in

Section 1 and optical microscopy results. As confirmed by XRD patterns presented in

Figure 5, the carbonation process effectively converted portlandite into well-crystallized calcium carbonate, especially noticeable in samples with 20% lime sludge and longer carbonation times (LS20-C8). The presence of calcium-rich lime sludge provides additional substrate for this reaction, enhancing the effect. Carbonation consumes calcium hydroxide [Ca(OH)

2], reducing the alkalinity of the medium and promoting a more favorable environment for the preservation of cellulose fibers, which contributes to maintaining the integrity of the fiber-matrix interface and, consequently, to mechanical performance. The improvement in strength and modulus, especially for longer carbonation times and higher lime sludge contents, is consistent with literature describing carbonation as a process that refines pore structure and increases material density. The lower loss of strength and modulus in the aged lime sludge and carbonated groups, compared to the Control, indicates that these treatments enhance the material’s durability against degradation from wetting and drying cycles.

Results from other studies also corroborate these observations. Research by Dos Santos et al. [

28] and Ballesteros et al. [

29] highlights that the carbonation of vegetable fiber-reinforced cementitious composites can lead to greater densification and improved mechanical properties due to CaCO

3 formation and matrix pH reduction, protecting the fibers. Furthermore, the incorporation of calcium-rich residues, such as lime sludge, is a recognized strategy to increase sustainability and optimize carbonation reactions in construction materials, aligning with current trends in industrial waste valorization. The consistency of these findings with existing literature confirms the validity of the results obtained in this work and the effectiveness of the strategies employed.

The representative stress–strain curves shown in

Figure 7 displayed an initial linear elastic region, followed by a peak stress point, and then a gradual post-peak softening behavior leading to eventual failure. Visually, the curves for carbonated composites, particularly those with lime sludge incorporation, exhibit higher peak stresses and steeper initial slopes compared to the control group, reflecting their superior strength and stiffness. Similarly, the initial slope of the LS20-C8 curve in

Figure 7 appears notably steeper than that of the control, corresponding to the increase in compressive modulus reported in

Figure 6b.

Furthermore, certain carbonated groups show a broader post-peak region, indicating enhanced deformability and energy absorption capacity. These observed enhancements in both peak stress and initial stiffness can be directly linked to the microstructural improvements. The carbonation process, intensified by the calcium-rich lime sludge, leads to significant densification of the cementitious matrix through the formation of calcium carbonate (CaCO

3). This pore refinement and increased matrix density contribute to the material’s enhanced load-bearing capacity and rigidity. Moreover, the consumption of calcium hydroxide [Ca(OH)

2] during carbonation reduces the matrix’s alkalinity, creating a less aggressive environment for the cellulose fibers. This protection minimizes fiber degradation and preserves the integrity of the fiber-matrix interface, allowing for more effective stress transfer and a more ductile post-peak response, as indicated by broader softening regions in the stress–strain curves. The shape and characteristics of these stress–strain curves are consistent with observations from previous studies on fiber-reinforced cementitious composites. For example, research by Wei and Meyer [

30] described similar ductile post-peak behavior in fiber-cement systems, where fiber bridging mechanisms contribute to maintaining integrity beyond the peak load. The consistent behavior of the curves across different formulations, with clear differentiation based on treatment, confirms the reliability of the experimental methodology and the robust impact of carbonation and lime sludge incorporation on the mechanical performance of these composites.

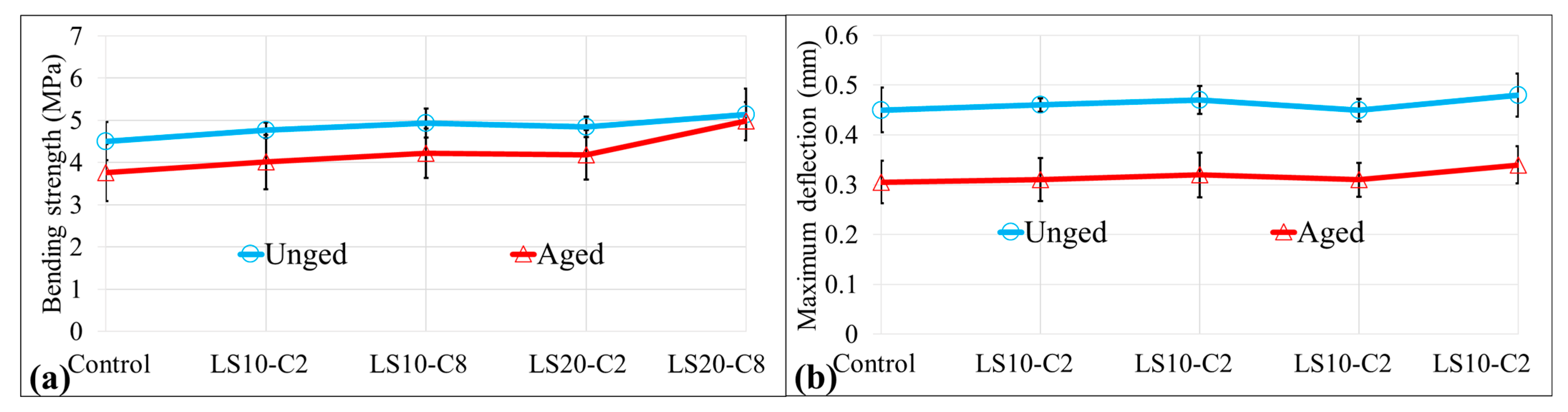

Figure 8 illustrates the flexural strength and maximum deflection (strain at break) of fiber-cement composites, both in unaged and aged conditions. In the unaged state, the flexural strength generally increased with the incorporation of lime sludge and carbonation. The Control group exhibited a flexural strength of 4.50 MPa. Notably, the LS20-C8 group (20% lime sludge, 8 h carbonation) achieved the highest flexural strength at 5.14 MPa, representing an approximate 14.22% increase compared to the control. The LS10-C8 group also showed a significant improvement of about 7.52%. For maximum deflection, the control group showed 0.45 mm. The LS20-C8 group reached 0.48 mm, indicating a 6.67% increase in deformability, suggesting enhanced ductility.

Upon aging, all composites experienced reduction in both flexural strength and maximum deflection. The aged control group’s flexural strength dropped to 3.76 MPa, a decrease of approximately 16.55% from its unaged counterpart. Similarly, its maximum deflection was reduced to 0.305 mm, a substantial loss of about 32.22%. In contrast, the aged LS20-C8 formulation exhibited superior retention of properties. While its flexural strength was reduced to 4.98 MPa, this represented a loss of only 3.11% from its unaged state, significantly outperforming the control’s retention. Its aged maximum deflection was 0.34 mm, a 29.17% reduction from its unaged condition, which, although a decrease, positioned it as the best-performing aged group.

These improvements in flexural performance, particularly the superior retention of properties in carbonated composites with lime sludge, are directly linked to the enhanced densification of the cementitious matrix and improved fiber-matrix interaction. As evidenced by the XRD patterns in

Figure 5, carbonation effectively transforms portlandite into well-crystallized calcium carbonate, especially pronounced in samples with 20% lime sludge and extended carbonation times (LS20-C8). This conversion not only densifies the matrix, contributing to increased strength (consistent with the compressive strength results in

Figure 6a, but also consumes calcium hydroxide [Ca(OH)

2]. The reduction in matrix alkalinity provides a less aggressive environment for the cellulose fibers, mitigating alkaline degradation and preserving fiber integrity. This enhanced fiber protection is crucial for maintaining the composite’s ability to deform and absorb energy, leading to higher maximum deflections and improved post-peak behavior.

The observed trends align well with existing literature on fiber-reinforced cementitious composites. Studies by Gutíerrez et al. [

4] and Da Silveira et al. [

12] have reported similar improvements in flexural strength and ductility in composites where fiber-matrix adhesion is enhanced or fiber degradation is mitigated, which were ascribed to fiber treatment or pozzzolan addition. The increased flexural strength in carbonated samples is consistent with the established understanding that CaCO

3 formation improves matrix density and strength. Furthermore, the ability of the LS20-C8 group to retain a high percentage of its initial flexural strength and deformability after aging cycles corroborates findings in the literature that highlight the role of carbonation in enhancing the long-term durability of fiber-cement systems [

31,

32]. No significant anomalies were observed, reinforcing the validity of the results and confirming the beneficial effects of lime sludge and accelerated carbonation on flexural toughness.

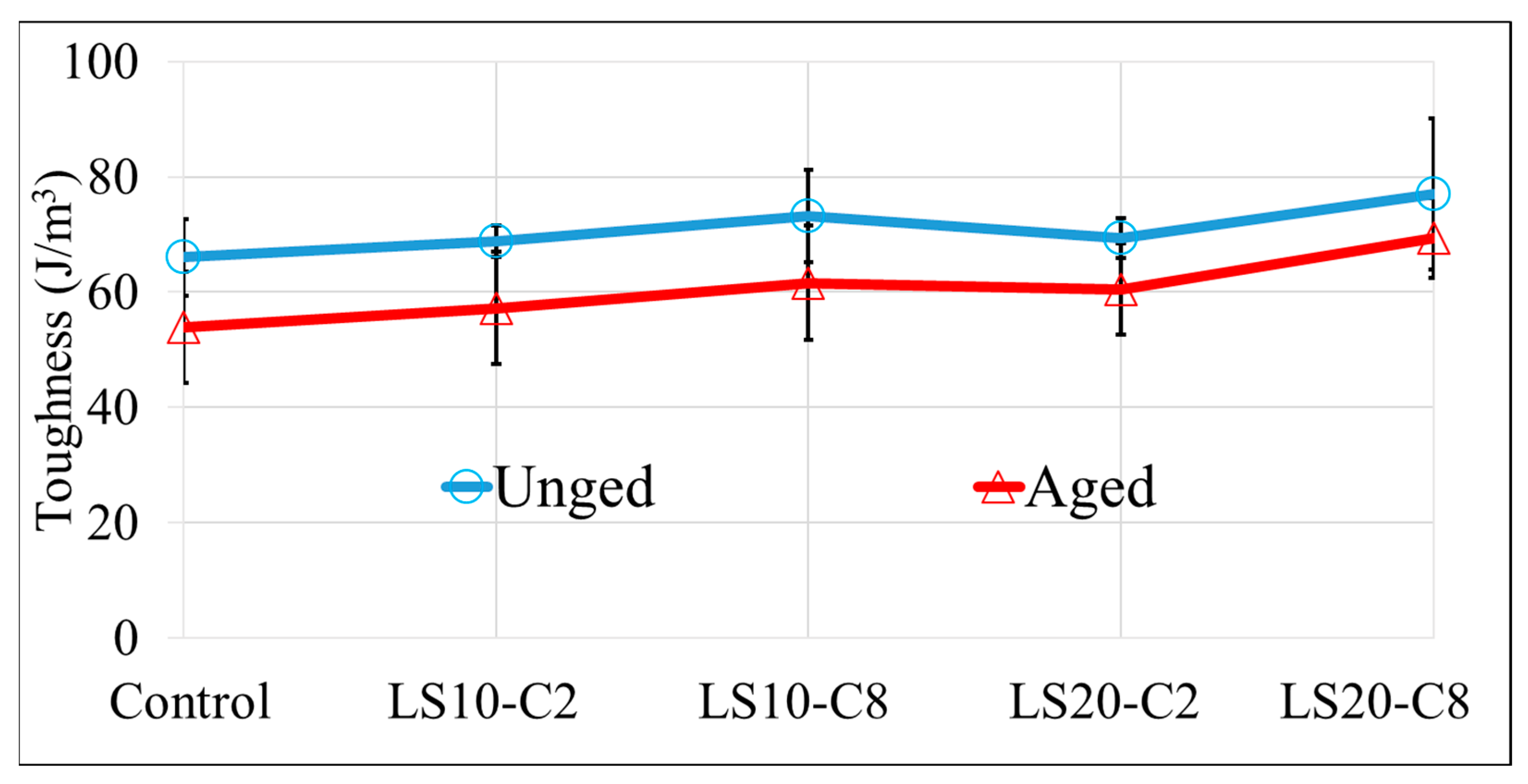

Figure 9 illustrates the flexural toughness of fiber-cement composites under both unaged and aged conditions. In the unaged state, the flexural toughness generally increased with the incorporation of lime sludge and carbonation. The Control group exhibited a toughness of 66 J/m

3. The LS20-C8 group (20% lime sludge, 8 h carbonation) achieved the highest toughness at 77 J/m

3, representing an approximate 16.67% increase compared to the Control. Other carbonated groups also showed improvements: LS10-C2 increased by approximately 4.17% (68.75 J/m

3), LS10-C8 by approximately 10.83% (73.15 J/m

3), and LS20-C2 by approximately 4.99% (69.3 J/m

3) relative to the Control. Upon aging, all composites experienced a reduction in flexural toughness. The aged Control group’s toughness dropped to 53.9 J/m

3, a significant decrease of approximately 18.33% from its unaged counterpart. However, the aged LS20-C8 formulation demonstrated superior retention, with a toughness of 69.3 J/m

3, representing a loss of only 10.00% compared to its unaged state, indicating enhanced durability against environmental degradation. This superior retention in LS20-C8 significantly outperforms other aged groups, which experienced losses ranging from 12.70% (LS20-C2) to 18.33% (Control).

These improvements in flexural toughness are closely linked to the overall enhanced mechanical performance and microstructural changes observed in the composites. The densification of the cementitious matrix due to calcium carbonate (CaCO

3) formation during carbonation, as confirmed by XRD in

Figure 5, contributes to a more robust and energy-absorbing material. This densification, in turn, is consistent with the increased compressive strength and modulus shown in

Figure 6. The presence of lime sludge, a calcium-rich by-product, amplifies these carbonation effects by providing additional precursors for CaCO

3 formation, which also leads to a reduction in the highly alkaline environment around the cellulose fibers. This less aggressive environment, coupled with improved fiber-matrix interaction (as suggested by the flexural strength and maximum deflection in

Figure 8), allows the fibers to more effectively bridge cracks and absorb energy, thereby increasing the composite’s overall toughness and its ability to resist crack propagation before catastrophic failure.

The trends observed for flexural toughness are in strong agreement with existing literature on fiber-reinforced cementitious composites. Studies by Neves Junior et al. [

33] have reported that matrix modifications, such as the addition of pozzolans or pH reduction via carbonation, can significantly enhance fiber-matrix bonding and, consequently, bending properties. The improved energy absorption capacity, particularly evident in the LS20-C8 group, corroborates findings that link denser microstructures and better fiber-matrix interfaces to superior mechanical performance, including toughness. For instance, the general trend of increased toughness in carbonated samples is well-established in research focusing on the long-term performance of cement-based materials [

34].

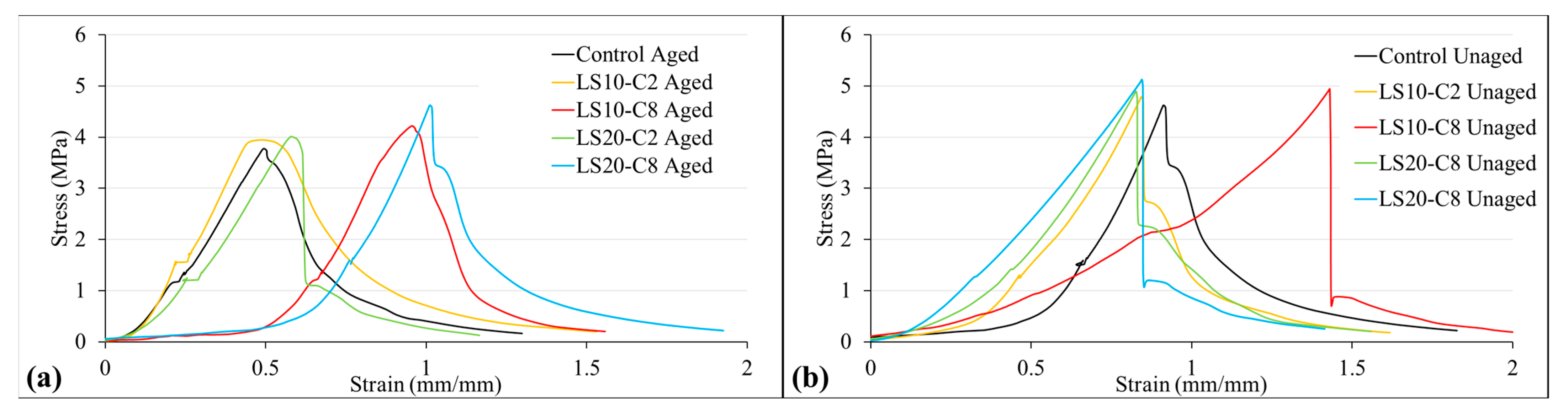

Figure 10 presents the representative stress–strain curves obtained from the three-point bending tests of the fiber-cement composites, under both unaged and aged conditions. Visually, these curves typically display an initial linear elastic region, a peak load, and a subsequent post-peak softening behavior, characteristic of fiber-reinforced cementitious materials where fibers provide residual strength after matrix cracking. For the unaged composites, the curves for groups incorporating lime sludge, particularly LS20-C8 (20% lime sludge, 8 h carbonation), exhibit higher peak loads and extended deflection ranges compared to the Control. This indicates superior flexural strength and enhanced ductility. For example, the peak load for LS20-C8 appears notably higher, reflecting its approximately 14.05% increase in flexural strength relative to the Control, as quantified in

Figure 8. The longer tail in the post-peak region for LS20-C8 also visually corresponds to its higher maximum deflection (6.67% increase compared to Control, as seen in

Figure 8) and superior flexural toughness (16.67% increase, as shown in

Figure 9), signifying greater energy absorption capacity. Upon aging, all curves show a reduction in both peak load and maximum deflection, indicating a decrease in mechanical performance. However, aged LS20-C8 demonstrates remarkable retention of its load-bearing capacity and deformability, maintaining a higher peak load and a more extended deflection range compared to the aged Control, consistent with its superior retention of flexural strength and toughness (

Figure 8 and

Figure 9).

These stress–strain characteristics are primarily attributed to the microstructural modifications induced by carbonation and lime sludge incorporation. The formation of well-crystallized calcium carbonate (CaCO

3), particularly pronounced in LS20-C8 as confirmed by XRD patterns in

Figure 5, leads to significant matrix densification. This improved density enhances the overall load-bearing capacity, contributing to higher peak loads. Furthermore, the consumption of calcium hydroxide [Ca(OH)

2] by the carbonation reaction, facilitated by the calcium-rich lime sludge, reduces the matrix’s alkalinity. This creates a less aggressive environment for the cellulose fibers, protecting them from alkaline degradation and preserving the integrity of the fiber-matrix interface. An intact and strong interface allows for more efficient stress transfer from the matrix to the fibers, enabling the fibers to effectively bridge cracks, delay catastrophic failure, and contribute to the ductile post-peak behavior and increased maximum deflection observed in the curves.

The stress–strain behavior observed in this study is consistent with findings in the literature on fiber-reinforced cementitious composites. Studies by Ardanuy et al. [

7] and Lima et al. [

35] have widely reported similar ductile responses, where fiber bridging mechanisms are critical for controlling crack propagation and enhancing the composite’s energy absorption capabilities. The improved performance in both peak load and post-peak behavior for carbonated and lime sludge-modified composites aligns with research indicating that matrix refinement and enhanced fiber protection lead to superior mechanical properties [

28,

36]. The consistency of these bedding features with established principles and previous works validates the effectiveness of accelerated carbonation, combined with lime sludge, in developing fiber-cement composites with improved mechanical performance and enhanced durability.

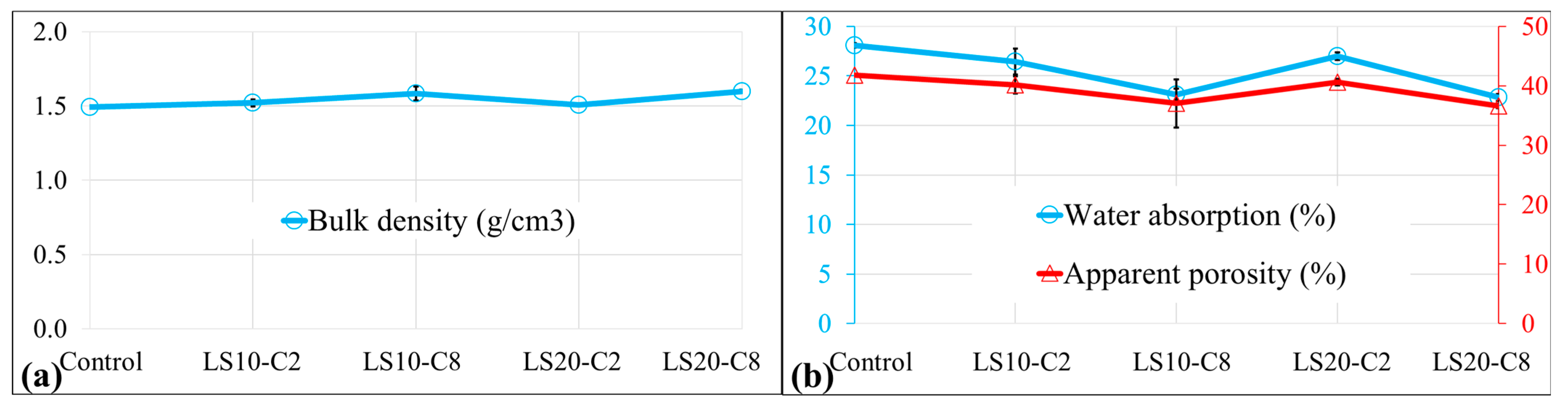

In

Figure 11a, the bulk density results demonstrate that the incorporation of lime sludge and carbonation treatment consistently enhanced the compactness of the fiber-cement composites. The control group presented a density of 1.49 g/cm

3, while all modified groups achieved higher values. The LS10-C8 formulation (10% lime sludge, 8 h carbonation) reached 1.58 g/cm

3, and the LS20-C8 formulation (20% lime sludge, 8 h carbonation) exhibited the highest density at 1.60 g/cm

3, corresponding to an increase of approximately 7.0% compared to the control. These gains in density reflect the progressive densification of the matrix due to the precipitation of calcium carbonate (CaCO

3), which efficiently fills pore spaces and strengthens the solid structure of the composites.

In

Figure 11b, the water absorption and apparent porosity values showed clear decreasing trends with increasing carbonation duration and lime sludge content. The control group had the highest water absorption (28.07%) and porosity (41.79%). With the introduction of lime sludge and carbonation, both properties declined substantially. For instance, the LS10-C8 group recorded water absorption of 23.13% and porosity of 37.03%, while the LS20-C8 formulation achieved the lowest values: 22.84% absorption and 36.64% porosity, representing reductions of 18.6% and 12.3% compared to the control, respectively. These results confirm that carbonation, intensified by the additional calcium supplied by lime sludge, not only transforms portlandite into well-crystallized calcite but also refines the pore structure, effectively limiting water ingress and decreasing the fraction of accessible voids. Comparable findings have been reported in the literature, where carbonation is identified as a mechanism that fills pores, reduces water absorption, and enhances the dimensional stability of fiber-cement composites [

27,

28,

29,

33].

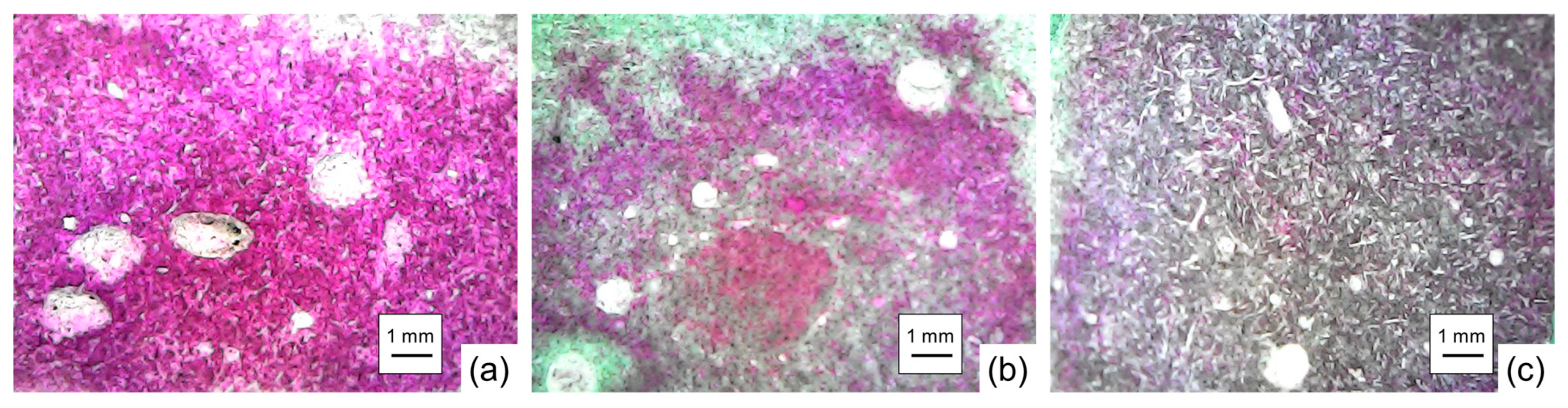

Figure 12 presents optical microscopy images that illustrate the microstructural differences between the control and carbonated fiber-cement composite samples, with specific focus on pore distribution and the fiber–matrix interface.

Figure 12a, representing the control group, shows a relatively porous matrix, with interconnected voids and noticeable gaps at the fiber–matrix interface, indicating limited bonding and a less cohesive microstructure. The application of phenolphthalein to this sample would result in an intense pink to purple coloration, confirming its highly alkaline nature and the absence of carbonation.

In contrast,

Figure 12b, corresponding to LS10-C2, demonstrates a partially carbonated microstructure. There is a moderate reduction in porosity compared to the control. The phenolphthalein test yielded a partial decolorization, reflecting an intermediate stage of carbonation and a gradual pH reduction.

Figure 12c, corresponding to LS20-C8, exhibits a much denser matrix with significantly reduced pore volume and enhanced continuity of the cementitious phase. The fiber–matrix interface is noticeably tighter, suggesting better encapsulation of fibers. In this case, phenolphthalein would yield mostly colorless or lightly colored regions, indicating the presence of calcium carbonate and a deeper carbonation front.

These observations correlate with the improvements in mechanical properties. The densification observed in images (b) and (c), especially in sample (c), directly relates to the increased compressive and flexural strengths shown in

Figure 6 and

Figure 8. Furthermore, the enhanced fiber–matrix integration supports higher deflection and toughness values, as illustrated in

Figure 8 and

Figure 9, due to improved stress transfer and energy dissipation capacity. The microstructural changes are consistent with the chemical transformations identified by XRD in

Figure 5, confirming the conversion of portlandite into well-crystallized calcium carbonate in carbonated samples. This process fills pores, reduces porosity, and lowers the matrix pH, providing a more favorable environment for cellulose fibers. Consequently, the degradation of fibers is minimized, preserving their reinforcing capability and structural contribution to the composite.

These results are in agreement with findings by Tonoli et al. [

15] and Azevedo et al. [

31], who consistently demonstrated that carbonation leads to a denser matrix and improved mechanical performance in fiber-reinforced cementitious composites. Similarly, the importance of a well-integrated fiber-matrix interface, as observed here, for increasing toughness and preventing premature failure, is widely documented [

35]. The visual evidence of improved microstructural quality in the carbonated samples, particularly those with lime sludge, further validates the effectiveness of the proposed strategies and aligns with the expected behavior of such modified materials.