Comparative Analysis of the Mechanical Properties of Eleven 3D Printing Filaments Under Different Printing Parameters

Abstract

1. Introduction

2. Materials and Methods

2.1. Printing Parameters and Filaments

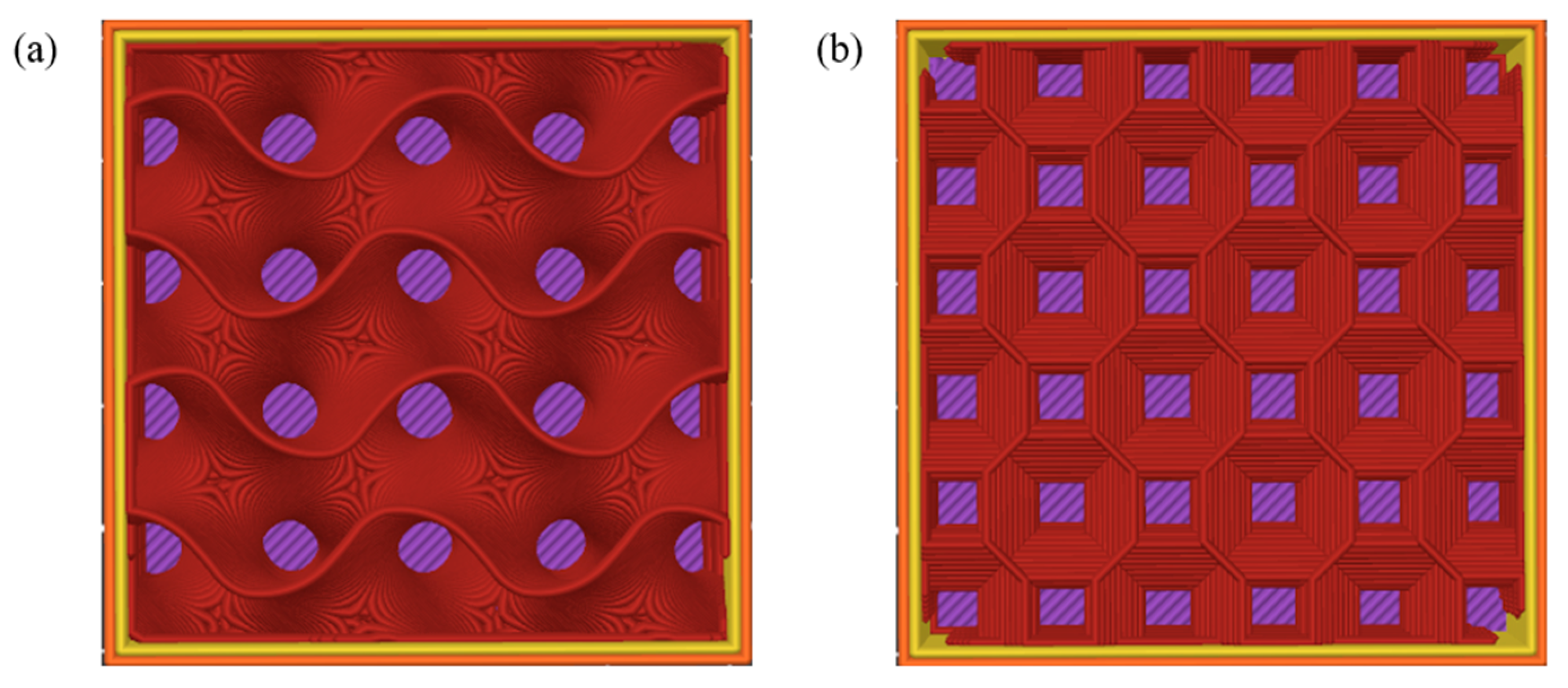

- Infill: 75%, Orientation: 0°, Shells: 4, Infill Pattern: gyroid

- Infill: 75%, Orientation: 0°, Shells: 4, Infill Pattern: 3D honeycomb

- Acrylonitrile Butadiene Styrene (ABS). Characterized by high impact resistance, good toughness, and strength, the ABS used in this study exhibits a tensile strength of 30 MPa [23]. It is recognized for its durability and superior temperature resistance compared to PLA. Previous studies have explored the influence of various printing parameters on its mechanical properties: Samykano et al. [24] investigated the effect of layer height, raster angle, and infill density, while Sood et al. [21] considered layer thickness, orientation, raster angle, raster width, and air gap. Daly et al. [25] also conducted a comprehensive parametric study, and Sumalatha et al. [26] examined the effects of build orientation and infill density. More recently, Haque et al. [27] evaluated its tensile, compressive, and flexural performance across varying key process parameters. Additionally, a recent study by Tzotzis et al. [28] analyzed the influence of structural characteristics on the tensile properties of FDM-fabricated ABS. While ABS’s mechanical properties have been extensively characterized under various printing conditions in the literature, this study distinguishes itself by systematically evaluating its performance under two specific optimized parameter combinations of 11 filaments, thereby including ABS provides a crucial benchmark for direct comparison with less-explored, specialized filaments.

- Bronzefill (BF). BF, PLA (60–70%) combined with bronze powder (40–30%), is characterized by a higher density than standard PLA (3.9 g/cm3 versus 1.3 g/cm3), which contributes to increased weight and enhanced surface hardness. Its tensile strength, typically around 20–30 MPa [29], is comparatively lower due to the inclusion of metal content. The literature on this filament remains limited, indicating a significant need for further research, except for the study by Kumar et al. [6], who investigated the mechanical properties of bronze infill polylactic acid composites by varying nozzle temperature, printing speed, layer thickness, and infill density, highlighting that tensile strength is primarily influenced by infill density, flexural strength by nozzle temperature, and impact strength predominantly by infill density.

- Glowfill (GF). Mechanically, GF is comparable to standard PLA, possessing a tensile strength of 50–70 MPa and a flexural strength of 60–80 Mpa [29]. The incorporation of phosphorescent materials (20–30%) into the PLA matrix (70–80%) results in a slight reduction in overall strength. While it has been explored for its bone-like Hounsfield Unit (HU) for CT calibration applications [11,12,13], its mechanical properties under varying printing parameters are yet to be thoroughly characterized.

- High Impact Polystyrene (HIPS), a flexible material made by polystyrene (85–95%) and rubber (15–5%), exhibits good impact resistance and toughness, with a tensile strength of 20–30 MPa and a flexural strength of 30–50 MPa. Existing studies include Sumalatha et al.’s work on the effect of build orientation and infill density [26], Xu et al.’s study on the effect of crisscross raster orientation, layer thickness, and infill density on the mechanical response of printed HIPS [30], and Pyka et al.’s static tensile and three-point bending tests [31].

- IronPLA exhibits increased density and hardness compared to regular PLA, though its tensile strength is reduced due to the 30–40% metal powder content, typically ranging from 20–30 MPa. Its magnetic properties, stemming from its iron content, have been a focus in existing literature, particularly for conductive and magnetic applications. However, despite its widespread use in various applications, including magnetic and biomedical devices, there is a distinct lack of studies characterizing its mechanical properties. More research in this area is crucial.

- Polyethylene Terephthalate Glycol-Modified (PETG) effectively combines strength and flexibility with good chemical resistance. It has a tensile strength of 50–70 MPa and a flexural strength of 60–80 MPa. PETG is less brittle and more durable than PLA [31]. Haque et al., evaluated its tensile, compressive, and flexural performance varying nozzle diameter, infill pattern, infill density, and layer height [27]. Dung et al., demonstrated that the mechanical properties of PETG are significantly influenced by printing speed and layer thickness, with these parameters tending to be inversely proportional to tensile strength [32].

- Polylactic Acid (PLA) is characterized by high stiffness and good tensile strength, typically 50–70 MPa, and a flexural strength of 60–80 MPa. It is biodegradable but has a lower impact and thermal resistance than ABS. Its mechanical properties have been widely studied and assessed in the literature [1,27,31,33,34].

- Stonefil Concrete (SFC) offers increased density and surface hardness compared to standard PLA, with the concrete powder (50%) influencing its mechanical properties, typically resulting in a tensile strength of around 40–60 MPa. Studies on this filament are currently sparse, with a primary focus on tissue and bone equivalence in terms of radiodensity [14,15]. There is a notable absence of research addressing the susceptibility of its mechanical properties to varying printing settings.

- Stonefil Granite (SFG), similar to SFC, provides enhanced surface hardness and density, with a tensile strength around 40–60 MPa, providing a stone-like appearance and feel due to the inclusion of 50% of granite powder into a PLA matrix. Recent studies have highlighted its suitability for biomedical imaging phantoms, particularly in CT-based applications, due to its bone-mimicking radiodensity and favorable interaction with ionizing radiation [16,17,18]. However, despite its promising imaging characteristics, there remains a significant lack of data regarding its mechanical properties in existing literature.

- Stonefil Terracotta (SFT), like other stone-filled filaments, exhibits an increased surface hardness and density, with a tensile strength of approximately 40–60 MPa. While its radiodensity and tissue-mimicking interaction with ionizing radiation have led to investigations for CT-based biomedical imaging applications [35], its mechanical performance, particularly concerning different printing parameters, is currently undocumented in the available literature.

- Woodfill (WF), made by a PLA matrix (70%), added with wood fibers (30%) [29], is characterized by a slightly lower tensile strength than standard PLA, typically around 30–50 MPa, while offering enhanced aesthetic properties due to wood fibers. Its fatigue behavior has been extensively studied [36,37,38,39], and the influence of specific parameter combinations on stiffness and elastic modulus was explored in a prior study [9], the results of which are incorporated here. The approach adopted in this study allows for a comparison of the achievable values with these filaments using the two optimized printing parameter combinations.

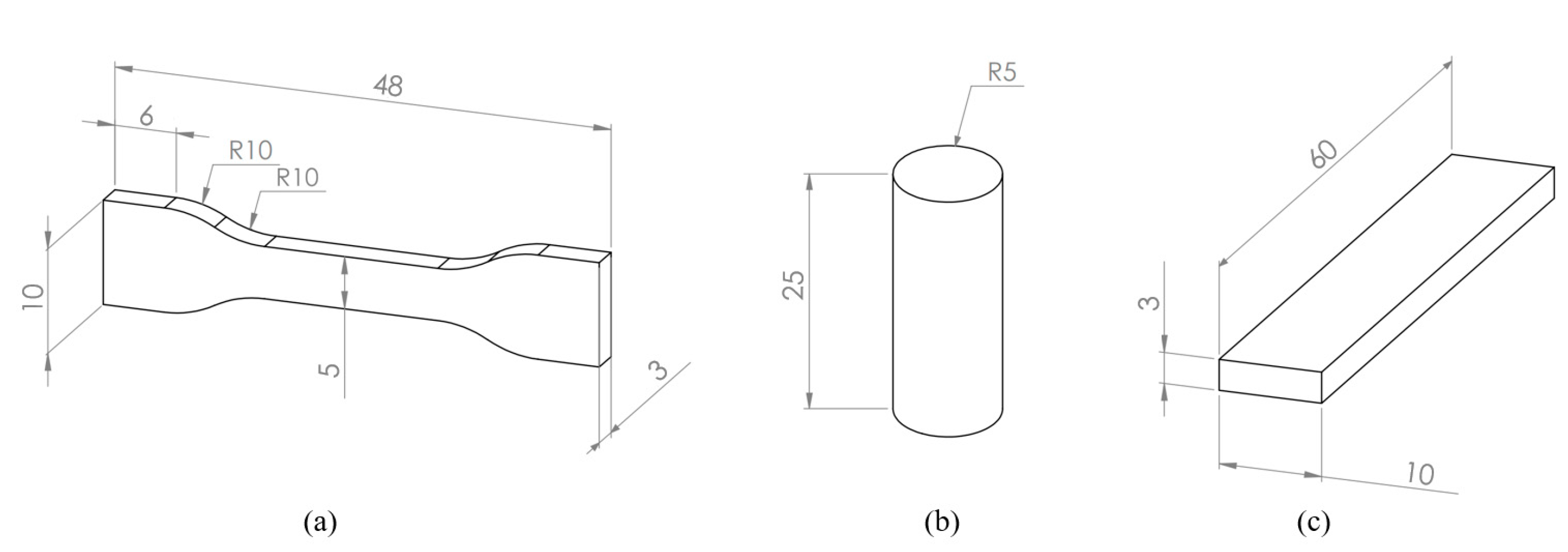

2.2. Specimen Geometry

2.3. Specimen Numerosity

2.4. Specimen Fabrication

2.5. Mechanical Testing Procedure

3. Results

3.1. General Overview

3.2. Influence of Infill Pattern on Mechanical Properties

3.3. Statistical Analysis

4. Discussion

5. Conclusions

- The choice of infill pattern significantly affects the stiffness and elastic modulus of printed materials featuring additives, e.g., metal, stone powder, phosphorescent agent, or wood fiber, highlighting the need for careful selection of this parameter based on the specific mechanical requirements and load scenarios. For example, the gyroid pattern led to significant increases in bending modulus, with up to 34.5% in ABS and 29.1% in SFT, and a 10–18% improvement in compressive stiffness in materials like HIPS, SFC, and BF.

- There is considerable variability in mechanical properties among the 11 materials tested. This variability underscores the importance of material-specific optimization in additive manufacturing to achieve desired performance outcomes.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mencarelli, M.M.; Sisella, M.; Puggelli, L.; Innocenti, B.; Volpe, Y. Sensitivity Analysis on 3D-Printing Parameters of Mechanical Properties of FDM-Printed PLA Parts for Biomechanical Modeling. Appl. Mech. 2025, 6, 17. [Google Scholar] [CrossRef]

- Yogeshwaran, K.; Das, S. Mechanical properties of fused deposition modelling processed parts: A review. Mater. Today Proc. 2022, 69 Part 2, 412. [Google Scholar] [CrossRef]

- Bouzaglou, O.; Golan, O.; Lachman, N. Process Design and Parameters Interaction in Material Extrusion 3D Printing: A Review. Polymers 2023, 15, 2280. [Google Scholar] [CrossRef] [PubMed]

- Ćwikła, G.; Grabowik, C.; Kalinowski, K.; Paprocka, I.; Ociepka, P. The influence of printing parameters on selected mechanical properties of FDM/FFF 3D-printed parts. IOP Conf. Ser. Mater. Sci. Eng. 2017, 227, 012033. [Google Scholar] [CrossRef]

- Gao, G.; Xu, F.; Xu, J.; Tang, G.; Liu, Z. A Survey of the Influence of Process Parameters on Mechanical Properties of Fused Deposition Modeling Parts. Micromachines 2022, 13, 553. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, T.P.; Batish, A. 3D printed tensile and flexural prototypes of thermoplastic matrix reinforced with multi-materials: A statistical analysis. Mater. Today Proc. 2021, 44, 79–85. [Google Scholar] [CrossRef]

- Chadha, A.; Haq, M.I.U.; Raina, A.; Singh, R.R.; Penumarti, N.B.; Bishnoi, M.S. Effect of fused deposition modelling process parameters on mechanical properties of 3D printed parts. World J. Eng. 2019, 16, 550–559. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kazancoglu, Y.; Sezer, M.D.; Top, N.; Sahin, I. Optimizing fused deposition modelling parameters based on the design for additive manufacturing to enhance product sustainability. Comput. Ind. 2022, 145, 103833. [Google Scholar] [CrossRef]

- Mencarelli, M.; Puggelli, L.; Volpe, Y.; Innocenti, B. Sensitivity on 3D-Printed Parameters of Stiffness and Young’s Modulus of FDM-Printed PLA, Stonefil TM Granite, and Woodfill Filaments: A Comparative Analysis. J. Mech. Med. Biol. 2025, 25, 2454054. [Google Scholar]

- Kantaros, A.; Soulis, E.; Petrescu, F.I.T.; Ganetsos, T. Advanced Composite Materials Utilized in FDM/FFF 3D Printing Manufacturing Processes: The Case of Filled Filaments. Materials 2023, 16, 6210. [Google Scholar] [CrossRef]

- Ma, X.; Buschmann, M.; Unger, E.; Homolka, P. Classification of X-Ray Attenuation Properties of Additive Manufacturing and 3D Printing Materials Using Computed Tomography from 70 to 140 kVp. Front. Bioeng. Biotechnol. 2021, 9, 763960. [Google Scholar] [CrossRef]

- Laidlaw, J.; Earl, N.; Shavdia, N.; Davis, R.; Mayer, S.; Karaman, D.; Richtsmeier, D.; Rodesch, P.-A.; Bazalova-Carter, M. Design and CT imaging of casper, an anthropomorphic breathing thorax phantom. Biomed. Phys. Eng. Express 2023, 9, 025008. [Google Scholar] [CrossRef]

- Silberstein, J.; Tran, S.; Wong, Y.H.; Yeong, C.H.; Sun, Z. Development of a 3D-Printed Chest Phantom with Simulation of Lung Nodules for Studying Ultra-Low-Dose Computed Tomography Protocols. Appl. Sci. 2025, 15, 309. [Google Scholar] [CrossRef]

- Goodall, S.K.; Rampant, P.; Smith, W.; Waterhouse, D.; Rowshanfarzad, P.; Ebert, M.A. Investigation of the effects of spinal surgical implants on radiotherapy dosimetry: A study of 3D printed phantoms. Med. Phys. 2021, 48, 4586–4597. [Google Scholar] [CrossRef] [PubMed]

- Kairn, T.; Zahrani, M.; Cassim, N.; Livingstone, A.G.; Charles, P.H.; Crowe, S.B. Quasi-simultaneous 3D printing of muscle-, lung- and bone-equivalent media: A proof-of-concept study. Phys. Eng. Sci. Med. 2020, 43, 701–710. [Google Scholar] [CrossRef] [PubMed]

- Hatamikia, S.; Kronreif, G.; Unger, A.; Oberoi, G.; Jaksa, L.; Unger, E.; Koschitz, S.; Gulyas, I.; Irnstorfer, N.; Buschmann, M.; et al. 3D printed patient-specific thorax phantom with realistic heterogenous bone radiopacity using filament printer technology. Z. Fur Med. Phys. 2022, 32, 438–452. [Google Scholar] [CrossRef]

- Bento, M.; Cook, H.; Anaya, V.M.; Bär, E.; Nisbet, A.; Lourenço, A.; Hussein, M.; Veiga, C. Characterisation of 3D-printable thermoplastics to be used as tissue-equivalent materials in photon and proton beam radiotherapy end-to-end quality assurance devices. Biomed. Phys. Eng. Express 2024, 10, 065005. [Google Scholar] [CrossRef]

- Mukwada, G.; Hirst, A.; Rowshanfarzad, P.; Ebert, M.A. Development of a 3D printed phantom for commissioning and quality assurance of multiple brain targets stereotactic radiosurgery. Phys. Eng. Sci. Med. 2024, 47, 455–463. [Google Scholar] [CrossRef]

- Murali, A.; Vakkattil, M.A.; Parameswaran, R. Investigating the Effect of Processing Parameters on Mechanical Behavior of 3D Fused Deposition Modeling Printed Polylactic Acid. J. Mater. Eng. Perform. 2022, 32, 1089–1102. [Google Scholar] [CrossRef]

- Vǎlean, C.; Marşavina, L.; Mǎrghitaşl, M.; Linul, E.; Razavi, N.; Berto, F. Effect of manufacturing parameters on tensile properties of FDM printed specimens. Procedia Struct. Integr. 2020, 26, 313–320. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Perveen, A.; Talamona, D. Fused deposition modelling: Effect of extrusion temperature on the accuracy of print. Mater. Today Proc. 2021, 44, 832–837. [Google Scholar] [CrossRef]

- 3DJake. Available online: www.3djake.it (accessed on 29 July 2025).

- Samykano, M.; Selvamani, S.K.; Kadirgama, K.; Ngui, W.K.; Kanagaraj, G.; Sudhakar, K. Mechanical property of FDM printed ABS: Influence of printing parameters. Int. J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Daly, M.; Tarfaoui, M.; Chihi, M.; Bouraoui, C. FDM technology and the effect of printing parameters on the tensile strength of ABS parts. Int. J. Adv. Manuf. Technol. 2023, 126, 5307–5323. [Google Scholar] [CrossRef] [PubMed]

- Sumalatha, M.; Chennaiah, M.B.; Shoaib, S.K.; Kumar, B.S.; Reddy, T.R.K.; Musthakheem, M.D. Investigation on the Mechanical Properties of 3d Printed CF/ABS Materials by Optimized Process Parameters Using Taguchi and ANOVA Analysis. In Lecture Notes in Mechanical Engineering; Mallaiah, M., Thapliyal, S., Bose, S.C., Eds.; Springer: Berlin/Heidelberg, Germany, 2025; pp. 225–239. [Google Scholar]

- Haque, M.M.M.; Dhrubo, S.R.; Pranto, A.-F.Z.; Ahmed, A.; Arefin, M.; Arifuzzaman, M.; Islam, S. Impact of process parameters and material selection on the mechanical performance of FDM 3D-Printed components. Hybrid Adv. 2025, 10, 100502. [Google Scholar] [CrossRef]

- Tzotzis, A.; Manavis, A.; Efkolidis, N.; García-Hernández, C.; Kyratsis, P. Analysis of the Influence of Structural Characteristics on the Tensile Properties of Fused Filament Fabricated ABS Polymer Using Central Composite Design. Appl. Mech. 2024, 5, 20–35. [Google Scholar] [CrossRef]

- ColorFabb. Available online: www.colorfabb.com (accessed on 29 July 2025).

- Xu, J.T.; Zhang, G.W.; Chen, M.M. Optimizing mechanical properties of HIPS fabricated with low-cost desktop 3D printers: Investigating the impact of process parameters. Adv. Manuf. 2024, 12, 379–395. [Google Scholar] [CrossRef]

- Pyka, D.; Slowinski, J.J.; Kurzawa, A.; Roszak, M.; Stachowicz, M.; Kazmierczak, M.; Stepczak, M.; Grygier, D. Research on Basic Properties of Polymers for Fused Deposition Modelling Technology. Appl. Sci. 2024, 14, 11151. [Google Scholar] [CrossRef]

- Dung, H.T.; Van-Long, T.; Quang-Tu, N. Study on Influencing of Processing Parameters on Tensile Strength of 3D Printing Sample. Stroj. Cas. 2025, 75, 27–38. [Google Scholar] [CrossRef]

- Murariu, A.C.; SÎRBU, N.-A.; Cocard, M.; Duma, I. Influence of 3D Printing Parameters on Mechanical Properties of the PLA Parts Made by FDM Additive Manufacturing Process. Eng. Innov. 2022, 2, 7–20. [Google Scholar] [CrossRef]

- Sagias, V.D.; Papageorgiou, D.G.; Pappas, A.; Stergiou, C.I. Mechanical Properties of AM Polymer Specimens Under Bending Stress. Appl. Mech. 2025, 6, 25. [Google Scholar] [CrossRef]

- Okkalidis, N.; Bliznakova, K.; Kolev, N. A filament 3D printing approach for CT-compatible bone tissues replication. Phys. Medica 2022, 102, 96–102. [Google Scholar] [CrossRef]

- Travieso-Rodriguez, A.J.; Zandi, M.D.; Jerez-Mesa, R.; Lluma-Fuentes, J. Fatigue behavior of PLA-wood composite manufactured by fused filament fabrication. J. Mater. Res. Technol. 2020, 9, 8507–8516. [Google Scholar] [CrossRef]

- Kianifar, M.; Azadi, M.; Heidari, F. Effect of simulated body fluid on the fatigue resistance of 3D-printed PLA and PLA-wood structures under cyclic bending loading. Int. J. Fatigue 2025, 195, 108876. [Google Scholar] [CrossRef]

- Guo, R.; Ren, Z.; Bi, H.; Song, Y.; Xu, M. Effect of toughening agents on the properties of poplar wood flour/poly (lactic acid) composites fabricated with Fusing Deposition Modeling. Eur. Polym. J. 2018, 107, 34–45. [Google Scholar] [CrossRef]

- Müller, M.; Šleger, V.; Kolář, V.; Hromasová, M.; Piš, D.; Mishra, R.K. Low-Cycle Fatigue Behavior of 3D-Printed PLA Reinforced with Natural Filler. Polymers 2022, 14, 1301. [Google Scholar] [CrossRef] [PubMed]

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 604:2002; Plastics—Determination of Compressive Properties. International Organization for Standardization: Geneva, Switzerland, 2002.

- ISO 178:2019; Plastics—Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 2019.

- Luo, J.; Luo, Q.; Zhang, G.; Li, Q.; Sun, G. On strain rate and temperature dependent mechanical properties and constitutive models for additively manufactured polylactic acid (PLA) materials. Thin-Walled Struct. 2022, 179, 109624. [Google Scholar] [CrossRef]

- ISO 5893:2019; Rubber and Plastics Test Equipment—Tensile, Flexural and Compression Types (Constant Rate of Traverse)—Specification. International Organization for Standardization: Geneva, Switzerland, 2019.

- Porter, J.H.; Cain, T.M.; Fox, S.L.; Harvey, P.S. Influence of infill properties on flexural rigidity of 3D-printed structural members. Virtual Phys. Prototyp. 2018, 14, 148–159. [Google Scholar] [CrossRef]

- Kwok, T.H.; Li, Y.; Chen, Y. A structural topology design method based on principal stress line, CAD Computer Aided Design. Comput. Des. 2016, 80, 19–31. [Google Scholar] [CrossRef]

- Yu, Z.; Savinov, R.; Matura, M.; Zhang, P.; Shi, J. Current research status on advanced lattice structures for impact and energy absorption applications: A systematic review. Thin-Walled Struct. 2025, 215, 113490. [Google Scholar] [CrossRef]

- Loughlan, J.; Yidris, N.; Cunningham, P.R. The effects of local buckling and material yielding on the axial stiffness and failure of uniformly compressed I-section and box-section struts. Thin-Walled Struct. 2011, 49, 264–279. [Google Scholar] [CrossRef]

- Shinde, V.V.; Wang, Y.; Salek, M.F.; Auad, M.L.; Beckingham, L.E.; Beckingham, B.S. Material Design for Enhancing Properties of 3D Printed Polymer Composites for Target Applications. Technologies 2022, 10, 45. [Google Scholar] [CrossRef]

| Filament | Composition | Tensile Strength (MPa) | Flexural Strength (MPa) | Key Characteristics | Relevant Literature |

|---|---|---|---|---|---|

| ABS | ABS (100%) | ≈30 | N/A | High impact resistance; good thermal resistance | [21,23,24,25,26,27,28] |

| BF | PLA (60–70%) + Bronze (30–40%) | 20–30 | N/A | High density and hardness; reduced strength due to metal | [6] |

| GF | PLA (70–80%) + Phosphorescent agents (20–30%) | 50–70 | 60–80 | Comparable to PLA; slightly reduced strength | [11,12,13] |

| HIPS | Polystyrene (85–95%) + Rubber (5–15%) | 20–30 | 30–50 | Good toughness and impact resistance | [27,30,31] |

| IronPLA | PLA + Iron Powder (30–40%) | 20–30 | N/A | Magnetic; increased density; lower tensile strength | N/A |

| PETG | PETG (100%) | 50–70 | 60–80 | Strong, flexible, chemical resistant | [27,31,32] |

| PLA | PLA (100%) | 50–70 | 60–80 | High stiffness; biodegradable; brittle | [1,27,31,33,34] |

| SFC | PLA + Concrete Powder (~50%) | 40–60 | N/A | Increased density and hardness | [14,15] |

| SFG | PLA + Granite Powder (~50%) | 40–60 | N/A | Bone-like appearance and radiodensity | [16,17,18] |

| SFT | PLA + Terracotta Powder (~50%) | 40–60 | N/A | Stone-like finish; radiodensity use | [35] |

| WF | PLA (70%) + Wood Fibers (30%) | 30–50 | N/A | Aesthetic, slightly lower strength | [9,36,37,38,39] |

| Nozzle Temperature (°C) | Bed Temperature (°C) | |

|---|---|---|

| ABS | 245 ± 15 | 90 ± 10 |

| BF | 205 ± 15 | 55 ± 5 |

| GF | 205 ± 15 | 55 ± 5 |

| HIPS | 250 ± 20 | 110 ± 5 |

| IronPLA | 200 ± 15 | 60 |

| PETG | 235 ± 5 | 75 ± 5 |

| PLA | 210 ± 5 | 60 ± 5 |

| SFC | 220 ± 5 | 60 ± 5 |

| SFG | 220 ± 5 | 60 ± 5 |

| SFT | 220 ± 5 | 60 ± 5 |

| Property | ABS | BF | GF | HIPS | Iron PLA | PETG | PLA | SFC | SFG | SFT | WF |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tensile Stiffness | 0.456 | 0.023 | 0.038 | 0.876 | 0.105 | 0.221 | 0.034 | 0.078 | 0.012 | 0.045 | 0.156 |

| Compression Stiffness | 0.789 | 0.145 | 0.217 | 0.654 | 0.324 | 0.543 | 0.267 | 0.412 | 0.026 | 0.187 | 0.042 |

| Bending Stiffness | 0.672 | 0.008 | 0.052 | 0.512 | 0.087 | 0.389 | 0.041 | 0.067 | 0.008 | 0.032 | 0.213 |

| Tensile E | 0.421 | 0.019 | 0.042 | 0.901 | 0.112 | 0.198 | 0.028 | 0.085 | 0.014 | 0.039 | 0.142 |

| Compression E | 0.832 | 0.162 | 0.195 | 0.723 | 0.298 | 0.612 | 0.312 | 0.3870 | 0.021 | 0.203 | 0.038 |

| Bending E | 0.715 | 0.011 | 0.061 | 0.589 | 0.076 | 0.432 | 0.037 | 0.059 | 0.007 | 0.028 | 0.198 |

| Filament | Finish | Cost (€/kg) |

|---|---|---|

| ABS | Smooth, slightly glossy | ~16 |

| BF | Metallic, shiny, bronze-like | ~82 |

| GF | Translucent, glow-in-the-dark | ~55 |

| HIPS | Smooth, matte | ~20 |

| IronPLA | Metallic, iron-like, slightly rough | ~92 |

| PETG | Smooth, semi-gloss | ~17 |

| PLA | Smooth, glossy | ~15 |

| SFC | Matte, concrete-like | ~67 |

| SFG | Slightly rough, granite-like texture | ~67 |

| SFT | Matte, terracotta-like | ~67 |

| WF | Wood-like, textured | ~70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mencarelli, M.; Puggelli, L.; Innocenti, B.; Volpe, Y. Comparative Analysis of the Mechanical Properties of Eleven 3D Printing Filaments Under Different Printing Parameters. Appl. Mech. 2025, 6, 70. https://doi.org/10.3390/applmech6030070

Mencarelli M, Puggelli L, Innocenti B, Volpe Y. Comparative Analysis of the Mechanical Properties of Eleven 3D Printing Filaments Under Different Printing Parameters. Applied Mechanics. 2025; 6(3):70. https://doi.org/10.3390/applmech6030070

Chicago/Turabian StyleMencarelli, Marta, Luca Puggelli, Bernardo Innocenti, and Yary Volpe. 2025. "Comparative Analysis of the Mechanical Properties of Eleven 3D Printing Filaments Under Different Printing Parameters" Applied Mechanics 6, no. 3: 70. https://doi.org/10.3390/applmech6030070

APA StyleMencarelli, M., Puggelli, L., Innocenti, B., & Volpe, Y. (2025). Comparative Analysis of the Mechanical Properties of Eleven 3D Printing Filaments Under Different Printing Parameters. Applied Mechanics, 6(3), 70. https://doi.org/10.3390/applmech6030070