Analysis of the Surface Quality Characteristics in Hard Turning Under a Minimal Cutting Fluid Environment

Abstract

1. Introduction

- To investigate the effects of cutting parameters (feed rate, cutting speed, depth of cut) on surface roughness parameters under the MCFA environment with eco-friendly cutting fluid during hard turning;

- To optimize cutting parameter settings to achieve superior surface quality while minimizing environmental impacts;

- To compare the effectiveness of the MCFA technique with a dry and MQL environment in hard turning processes.

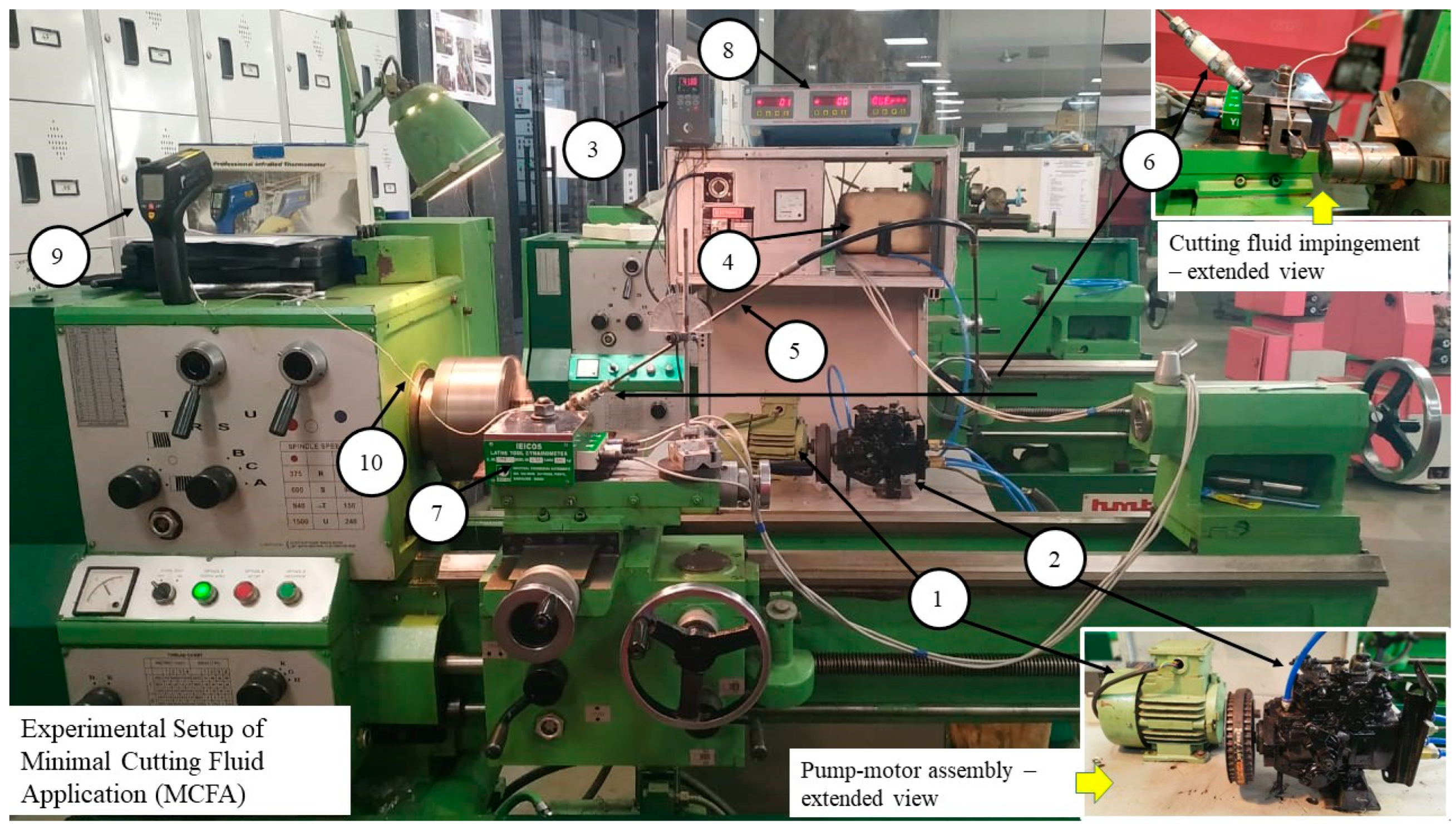

2. Materials and Methods

2.1. Workpiece Material

2.2. Cutting Tool and Inserts

2.3. Cutting Fluid and Application Parameters

2.4. Experimental Design

2.5. Surface Roughness Measurement

3. Result and Discussion

3.1. ANOVA for Surface Quality Characteristics

3.2. Effect of Cutting Parameters on the Surface Quality Characteristics

3.3. Comparative Study

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Acronyms | |

| MQL | Minimum Quantity Lubrication |

| CVD | Chemical Vapor Deposition (coating technique) |

| PVD | Physical Vapor Deposition (coating technique) |

| TiN | Titanium Nitride |

| TiCN | Titanium Carbonitride |

| Al2O3 | Aluminum Oxide |

| CBN | Cubic Boron Nitride |

| PCD | Polycrystalline Diamond (cutting tool material) |

| PCBN | Polycrystalline Cubic Boron Nitride |

| HRC | Hardness Rockwell C (scale for hardness) |

| S/N | Signal-to-Noise Ratio |

| ANOVA | Analysis of Variance |

| RSM | Response Surface Methodology |

| NF-MQL | Nano Fluid Minimum Quantity Lubrication |

| NGCF | Nano Green Cutting Fluid |

| MQCL | Minimum Quantity Cooling and Lubrication |

| MTCVD | Medium-temperature chemical vapor deposition |

| DF | Degree of Freedom |

| Seq SS | Sequential Sum of Squares |

| Adj MS | Adjusted Mean Square |

| F-Value | F-Ratio (test statistic used to determine significance in ANOVA) |

| List of Symbols | |

| v | Cutting Speed (m/min) |

| f | Feed Rate (mm/rev) |

| d | Depth of Cut (mm) |

| Ra | Arithmetic Average Roughness |

| Rt | Maximum peak-to-valley height |

| Rz | Average peak-to-valley height |

References

- Abbas, A.T.; Anwar, S.; Hegab, H.; Benyahia, F.; Ali, H.; Elkaseer, A. Comparative evaluation of surface quality, tool wear, and specific cutting energy for wiper and conventional carbide inserts in hard turning of aisi 4340 alloy steel. Materials 2020, 13, 5233. [Google Scholar] [CrossRef] [PubMed]

- Samantaraya, D.; Lakade, S. Hard Turning Cutting Tool Materials used in Automotive and Bearing Manufacturing Applications—A review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 814, 012005. [Google Scholar] [CrossRef]

- Anand, A.; Behera, A.K.; Das, S.R. An overview on economic machining of hardened steels by hard turning and its process variables. Manuf. Rev. 2019, 6, 4. [Google Scholar] [CrossRef]

- Singh, D.; Rao, P.V. A surface roughness prediction model for hard turning process. Int. J. Adv. Manuf. Technol. 2007, 32, 1115–1124. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, C.R.; Yao, Z. Experimental study and evaluation methodology on hard surface integrity. Int. J. Adv. Manuf. Technol. 2007, 34, 141–148. [Google Scholar] [CrossRef]

- Asiltürk, I.; Akkuş, H. Determining the effect of cutting parameters on surface roughness in hard turning using the Taguchi method. Meas. J. Int. Meas. Confed. 2011, 44, 1697–1704. [Google Scholar] [CrossRef]

- Aouici, H.; Yallese, M.A.; Chaoui, K.; Mabrouki, T.; Rigal, J.F. Analysis of surface roughness and cutting force components in hard turning with CBN tool: Prediction model and cutting conditions optimization. Meas. J. Int. Meas. Confed. 2012, 45, 344–353. [Google Scholar] [CrossRef]

- Shihab, S.K.; Khan, Z.A.; Mohammad, A.; Siddiquee, A.N. Optimization of surface integrity in dry hard turning using RSM. Sadhana Acad. Proc. Eng. Sci. 2014, 39, 1035–1053. [Google Scholar] [CrossRef]

- Sankar, R.R.B.R.; Umamaheswarrao, P.; Sharief, S.N.; Suresh, T. Parametric Investigations on Surface Roughness of Hard Turned AISI 52100 Steel. Appl. Mech. Mater. 2017, 867, 171–176. [Google Scholar]

- Wainstein, D.; Kovalev, A. Tribooxidation as a way to improve thewear resistance of cutting tools. Coatings 2018, 8, 223. [Google Scholar] [CrossRef]

- Allu, V.P.; Raju, D.L.; Ramakrishna, S. Performance investigation of surface roughness in hard turning of AISI 52100 steel—RSM approach. Mater. Today Proc. 2019, 18, 261–269. [Google Scholar] [CrossRef]

- Elsadek, A.A.; Gaafer, A.M.; Mohamed, S.S. Surface Roughness Prediction in Hard-Turning With Ann and Rsm. Int. J. Egypt. Soc. Tribol. 2020, 17, 13–22. [Google Scholar]

- Varadarajan, A.S.; Philip, P.K.; Ramamoorthy, B. Investigations on hard turning with minimal cutting fluid application (HTMF) and its comparison with dry and wet turning. Int. J. Mach. Tools Manuf. 2002, 42, 193–200. [Google Scholar] [CrossRef]

- Kumar, C.R.V.; Ramamoorthy, B. Performance of coated tools during hard turning under minimum fluid application. J. Mater. Process. Technol. 2007, 185, 210–216. [Google Scholar] [CrossRef]

- Kumar, C.R.V.; Nair, P.K.; Ramamoorthy, B. Performance of TiCN and TiAlN tools in machining hardened steel under dry, wet and minimum fluid application. Int. J. Mach. Mach. Mater. 2008, 3, 133–142. [Google Scholar] [CrossRef]

- Thepsonthi, T.; Hamdi, M.; Mitsui, K. Investigation into minimal-cutting-fluid application in high-speed milling of hardened steel using carbide mills. Int. J. Mach. Tools Manuf. 2009, 49, 156–162. [Google Scholar] [CrossRef]

- Sapian, N.F.; Omar, B.; Hamdi, M.; Shukor, A. Integrated Mechanical Pulse Jet Coolant Delivery System Performance for Minimal Quantity Lubrication. Int. J. Integr. Eng. 2010, 2, 53–68. [Google Scholar]

- Gnanadurai, R.R.; Varadarajan, A.S. The effect of an auxiliary pulsing jet of cutting fluid on cutting performance during hard turning with minimal fluid application. Int. J. Mach. Mach. Mater. 2012, 12, 321–336. [Google Scholar] [CrossRef]

- Paul, P.S.; Varadarajan, A.S. Performance evaluation of hard turning of AISI 4340 steel with minimal fluid application in the presence of semi-solid lubricants. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 738–748. [Google Scholar] [CrossRef]

- Paul, P.S.; Varadarajan, A.S.; Gnanadurai, R.R. Study on the influence of fluid application parameters on tool vibration and cutting performance during turning of hardened steel. Eng. Sci. Technol. Int. J. 2016, 19, 241–253. [Google Scholar] [CrossRef]

- Raj, A.; Wins, K.L.D.; George, K.E.; Varadarajan, A.S. Experimental Investigation of Soyabean Oil Based Cutting Fluid during Turning of Hardened AISI 4340 Steel with Minimal Fluid Application. Appl. Mech. Mater. 2015, 813–814, 337–341. [Google Scholar] [CrossRef]

- Raj, A.; Wins, K.L.D.; Varadarajan, A.S. Evaluation of the performance during hard turning of OHNS steel with minimal cutting fluid application and its comparison with minimum quantity lubrication. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012021. [Google Scholar] [CrossRef]

- Raj, A.; Wins, K.L.D.; Varadarajan, A.S. Comparison of surface roughness and chip characteristics obtained under different modes of lubrication during hard turning of AISI H13 tool work steel. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012017. [Google Scholar] [CrossRef]

- Benedicto, E.; Carou, D.; Rubio, E.M. Technical, Economic and Environmental Review of the Lubrication/Cooling Systems Used in Machining Processes. Procedia Eng. 2017, 184, 99–116. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Sankar, M.R. Role of Eco-friendly Cutting Fluids and Cooling Techniques in Machining. In Materials Forming, Machining and Post Processing; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Kumar, P.; Jain, A.K.; Chaurasiya, P.K.; Damodar, T.; Gopalan, A.; Dhanraj, J.A.; Solomon, J.M.; Sivakumar, A.; Velmurugan, K.; Rushman, J.F. Sustainable Machining Using Eco-Friendly Cutting Fluids: A Review. Adv. Mater. Sci. Eng. 2022, 1–16. [Google Scholar] [CrossRef]

- Mane, S.; Kumar, S. Analysis of surface roughness during turning of AISI 52100 hardened alloy steel using minimal cutting fluid application. Adv. Mater. Process. Technol. 2022, 8 (Suppl. S1), 138–149. [Google Scholar] [CrossRef]

- Dhar, N.R.; Ahmed, M.T.; Islam, S. An experimental investigation on effect of minimum quantity lubrication in machining AISI 1040 steel. Int. J. Mach. Tools Manuf. 2007, 47, 748–753. [Google Scholar] [CrossRef]

- Dhar, N.R.; Kamruzzaman, M.; Ahmed, M. Effect of minimum quantity lubrication (MQL) on tool wear and surface roughness in turning AISI-4340 steel. J. Mater. Process. Technol. 2006, 172, 299–304. [Google Scholar] [CrossRef]

- Hadad, M.; Sadeghi, B. Minimum quantity lubrication-MQL turning of AISI 4140 steel alloy. J. Clean. Prod. 2013, 54, 332–343. [Google Scholar] [CrossRef]

- Davim, J.P.; Sreejith, P.S.; Silva, J. Turning of brasses using minimum quantity of lubricant (MQL) and flooded lubricant conditions. Mater. Manuf. Process. 2007, 22, 45–50. [Google Scholar] [CrossRef]

- Roy, S.; Kumar, R.; Sahoo, A.K.; Panda, A. Cutting Tool Failure and Surface Finish Analysis in Pulsating MQL-Assisted Hard Turning. J. Fail. Anal. Prev. 2020, 20, 1274–1291. [Google Scholar] [CrossRef]

- Hamran, N.N.N.; Ghani, J.A.; Ramli, R.; Haron, C.H.C. A review on recent development of minimum quantity lubrication for sustainable machining. J. Clean. Prod. 2020, 268, 122165. [Google Scholar] [CrossRef]

- Zaman, P.B.; Dhar, N.R. Multi-objective Optimization of Double-Jet MQL System Parameters Meant for Enhancing the Turning Performance of Ti–6Al–4V Alloy. Arab. J. Sci. Eng. 2020, 45, 9505–9526. [Google Scholar] [CrossRef]

- Chavan, A.; Sargade, V. Surface integrity of AISI 52100 steel during hard turning in different near-dry environments. Adv. Mater. Sci. Eng. 2020, 2020, 4256308. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.F.; Wang, Y.W. Tool life and cutting forces in end milling Inconel 718 under dry and minimum quantity cooling lubrication cutting conditions. J. Clean. Prod. 2012, 32, 81–87. [Google Scholar] [CrossRef]

- Elmunafi, M.H.S.; Kurniawan, D.; Noordin, M.Y. Use of Castor Oil as Cutting Fluid in Machining of Hardened Stainless Steel with Minimum Quantity of Lubricant. Procedia CIRP 2015, 26, 408–411. [Google Scholar] [CrossRef]

- Do, T.V.; Nguyen, Q.M.; Pham, M.T. Optimization of Cutting Parameters for Improving Surface Roughness during Hard Milling of AISI H13 Steel. Key Eng. Mater. 2020, 831, 35–39. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Suvin, P.S.; Kailas, S.V.; Rajurkar, K.P.; Sankar, M.R. Machining of hard materials using textured tool with minimum quantity nano-green cutting fluid. CIRP J. Manuf. Sci. Technol. 2021, 35, 410–421. [Google Scholar] [CrossRef]

- Ibrahim, A.M.M.; Omer, M.A.E.; Das, S.R.; Li, W.; Alsoufi, M.S.; Elsheikh, A. Evaluating the effect of minimum quantity lubrication during hard turning of AISI D3 steel using vegetable oil enriched with nano-additives. Alexandria Eng. J. 2022, 61, 10925–10938. [Google Scholar] [CrossRef]

- Tuan, N.M.; Duc, T.M.; Long, T.T.; Hoang, V.L.; Ngoc, T.B. Investigation of Machining Performance of MQL and MQCL Hard Turning Using Nano Cutting Fluids. Fluids 2022, 7, 143. [Google Scholar] [CrossRef]

- Sarikaya, M.; Gupta, M.K.; Tomaz, I.; Danish, M.; Mia, M.; Rubaiee, S.; Jamil, M.; Pimenov, D.Y.; Khanna, N. Cooling techniques to improve the machinability and sustainability of light-weight alloys: A state-of-the-art review. J. Manuf. Process. 2021, 61, 179–201. [Google Scholar] [CrossRef]

- Mallick, R.; Kumar, R.; Panda, A.; Sahoo, A.K. Hard Turning Performance Investigation of AISI D2 Steel under a Dual Nozzle MQL Environment. Lubricants 2023, 11, 16. [Google Scholar] [CrossRef]

- Padhan, S.; Das, A.; Santoshwar, A.; Dharmendrabhai, T.R.; Das, S.R. Sustainability Assessment and Machinability Investigation of Austenitic Stainless Steel in Finish Turning with Advanced Ultra-Hard SiAlON Ceramic Tool under Different Cutting Environments. Silicon 2021, 13, 119–147. [Google Scholar] [CrossRef]

- Kawade, P.; Bokade, S. Review of cooling techniques used in metal cutting processes. Adv. Mater. Process. Technol. 2022, 9, 1137–1182. [Google Scholar] [CrossRef]

- Li, D.; Zhang, T.; Zheng, T.; Zhao, N.; Li, Z. A comprehensive review of minimum quantity lubrication (MQL) machining technology and cutting performance. Int. J. Adv. Manuf. Technol. 2024, 133, 2681–2707. [Google Scholar] [CrossRef]

- Çetindağ, H.A.; Çiçek, A.; Uçak, N.; Aslantas, K. Performance of conventional and wiper CBN inserts under various cooling conditions in hard turning of AISI 52100 steel. Mater. Test. 2024, 66, 228–298. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Ross, N.S.; Sivalingam, V. Implementation of green cooling/lubrication strategies in metal cutting industries: A state of the art towards sustainable future and challenges. Sustain. Mater. Technol. 2023, 36, e00641. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; da Silva, L.R.R.; Machado, A.R.; França, P.H.P.; Pintaude, G.; Unune, D.R.; Kuntoğlu, M.; Krolczyk, G.M. A comprehensive review of machinability of difficult-to-machine alloys with advanced lubricating and cooling techniques. Tribol. Int. 2024, 196, 109677. [Google Scholar] [CrossRef]

- Ali, S.H.; Yao, Y.; Wu, B.; Zhao, B.; Ding, W.; Jamil, M.; Khan, A.; Baig, A.; Liu, Q.; Xu, D. Recent developments in MQL machining of aeronautical materials: A comparative review. Chin. J. Aeronaut. 2024, 38, 102918. [Google Scholar] [CrossRef]

- Mane, S.; Kumar, S. Optimization of Cutting and Cutting Fluid Application Parameters in Turning of AISI 52100 Hardened Alloy Steel Under Minimal Cutting Fluid Application. In Proceedings of the ICIMA 2020: International Conference on Intelligent Manufacturing and Automation, Mumbai, India, 27–28 March 2020. [Google Scholar] [CrossRef]

| S. No | v (m/min) | f (mm/rev) | d (mm) | Surface Roughness (µm) | |||

|---|---|---|---|---|---|---|---|

| Ra (µm) | Rt (µm) | Rz (µm) | S/N Ratio | ||||

| 1 | 80 | 0.05 | 0.1 | 0.289 | 1.844 | 1.447 | −2.67422 |

| 2 | 80 | 0.05 | 0.3 | 0.226 | 1.991 | 1.529 | −3.25857 |

| 3 | 80 | 0.05 | 0.5 | 0.314 | 2.205 | 1.621 | −4.03021 |

| 4 | 110 | 0.05 | 0.1 | 0.243 | 2.034 | 1.780 | −3.91469 |

| 5 | 110 | 0.05 | 0.3 | 0.209 | 1.847 | 1.308 | −2.36029 |

| 6 | 110 | 0.05 | 0.5 | 0.319 | 2.216 | 1.804 | −4.40218 |

| 7 | 140 | 0.05 | 0.1 | 0.189 | 1.868 | 1.146 | −2.07586 |

| 8 | 140 | 0.05 | 0.3 | 0.303 | 2.000 | 1.540 | −3.33340 |

| 9 | 140 | 0.05 | 0.5 | 0.404 | 2.439 | 1.938 | −5.17098 |

| 10 | 80 | 0.10 | 0.1 | 0.469 | 2.787 | 2.400 | −6.61097 |

| 11 | 80 | 0.10 | 0.3 | 0.406 | 2.589 | 2.038 | −5.65108 |

| 12 | 80 | 0.10 | 0.5 | 0.478 | 2.829 | 2.455 | −6.76989 |

| 13 | 110 | 0.10 | 0.1 | 0.415 | 2.661 | 2.166 | −6.00054 |

| 14 | 110 | 0.10 | 0.3 | 0.389 | 2.989 | 2.007 | −6.40597 |

| 15 | 110 | 0.10 | 0.5 | 0.446 | 2.964 | 2.236 | −6.68507 |

| 16 | 140 | 0.10 | 0.1 | 0.287 | 2.433 | 1.596 | −4.54856 |

| 17 | 140 | 0.10 | 0.3 | 0.252 | 1.976 | 1.521 | −3.20944 |

| 18 | 140 | 0.10 | 0.5 | 0.429 | 2.843 | 2.198 | −6.40080 |

| 19 | 80 | 0.15 | 0.1 | 0.671 | 3.225 | 2.830 | −7.98415 |

| 20 | 80 | 0.15 | 0.3 | 0.613 | 3.012 | 2.687 | −7.44759 |

| 21 | 80 | 0.15 | 0.5 | 0.670 | 2.713 | 2.713 | −7.03854 |

| 22 | 110 | 0.15 | 0.1 | 0.558 | 3.001 | 2.654 | −7.36691 |

| 23 | 110 | 0.15 | 0.3 | 0.459 | 2.829 | 2.455 | −6.76418 |

| 24 | 110 | 0.15 | 0.5 | 0.543 | 3.010 | 2.269 | −6.84444 |

| 25 | 140 | 0.15 | 0.1 | 0.396 | 2.512 | 1.567 | −4.73363 |

| 26 | 140 | 0.15 | 0.3 | 0.334 | 2.415 | 1.861 | −4.96335 |

| 27 | 140 | 0.15 | 0.5 | 0.406 | 2.654 | 2.049 | −5.80048 |

| Source | DF | Seq SS | Contr. | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Regression | 9 | 0.450409 | 96.68% | 0.050045 | 55.08 | 0.000 |

| v | 1 | 0.065884 | 14.14% | 0.065884 | 72.51 | 0.000 |

| f | 1 | 0.258480 | 55.49% | 0.258480 | 284.47 | 0.000 |

| d | 1 | 0.013558 | 2.91% | 0.013558 | 14.92 | 0.001 |

| v × v | 1 | 0.000516 | 0.11% | 0.000516 | 0.57 | 0.461 |

| f × f | 1 | 0.000000 | 0.00% | 0.000000 | 0.00 | 0.996 |

| d × d | 1 | 0.024491 | 5.26% | 0.024491 | 26.95 | 0.000 |

| v × f | 1 | 0.072230 | 15.50% | 0.072230 | 79.49 | 0.000 |

| v × d | 1 | 0.006769 | 1.45% | 0.006769 | 7.45 | 0.014 |

| f × d | 1 | 0.008480 | 1.82% | 0.008480 | 9.33 | 0.007 |

| Error | 17 | 0.015447 | 3.32% | 0.000909 | ||

| Total | 26 | 0.465855 | 100.00% |

| Source | DF | Seq SS | Contr. | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Regression | 9 | 4.2063 | 89.35% | 0.46737 | 15.85 | 0.000 |

| v | 1 | 0.2346 | 4.98% | 0.23461 | 7.96 | 0.012 |

| f | 1 | 2.6657 | 56.63% | 2.66574 | 90.43 | 0.000 |

| d | 1 | 0.1263 | 2.68% | 0.12634 | 4.29 | 0.054 |

| v × v | 1 | 0.1418 | 3.01% | 0.14178 | 4.81 | 0.042 |

| f × f | 1 | 0.3467 | 7.37% | 0.34672 | 11.76 | 0.003 |

| d × d | 1 | 0.1603 | 3.40% | 0.16028 | 5.44 | 0.032 |

| v × f | 1 | 0.2230 | 4.74% | 0.22304 | 7.57 | 0.014 |

| v × d | 1 | 0.1265 | 2.69% | 0.12649 | 4.29 | 0.054 |

| f × d | 1 | 0.1813 | 3.85% | 0.18130 | 6.15 | 0.024 |

| Error | 17 | 0.5011 | 10.65% | 0.02948 | ||

| Total | 26 | 4.7074 | 100.00% |

| Source | DF | seq SS | Contr. | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| Regression | 9 | 5.21028 | 92.22% | 0.57892 | 22.40 | 0.000 |

| v | 1 | 1.02913 | 18.22% | 1.02913 | 39.82 | 0.000 |

| f | 1 | 2.70049 | 47.80% | 2.70049 | 104.49 | 0.000 |

| d | 1 | 0.15999 | 2.83% | 0.15999 | 6.19 | 0.024 |

| v × v | 1 | 0.09143 | 1.62% | 0.09143 | 3.54 | 0.077 |

| f × f | 1 | 0.07676 | 1.36% | 0.07676 | 2.97 | 0.103 |

| d × d | 1 | 0.16412 | 2.90% | 0.16412 | 6.35 | 0.022 |

| v × f | 1 | 0.64403 | 11.40% | 0.64403 | 24.92 | 0.000 |

| v × d | 1 | 0.25931 | 4.59% | 0.25931 | 10.03 | 0.006 |

| f × d | 1 | 0.08501 | 1.50% | 0.08501 | 3.29 | 0.087 |

| Error | 17 | 0.43937 | 7.78% | 0.02585 | ||

| Total | 26 | 5.64965 | 100.00% |

| Level | v | f | d |

|---|---|---|---|

| 1 | −5.718 | −3.469 | −5.101 |

| 2 | −5.638 | −5.809 | −4.822 |

| 3 | −4.471 | −6.549 | −5.905 |

| Delta | 1.248 | 3.080 | 1.083 |

| Rank | 2 | 1 | 3 |

| Run. No | V (m/min) | f (mm/rev) | d (mm) | The Average Value of (Ra) at Three Experimental Runs (µm) | % Reduction of (Ra) When Compared to Dry Environment | % Reduction of (Ra) When Compared to MQL Environment | ||

|---|---|---|---|---|---|---|---|---|

| Dry | MQL | MCFA | ||||||

| 1 | 80 | 0.05 | 0.1 | 0.537 | 0.381 | 0.289 | 46.182 | 24.147 |

| 4 | 110 | 0.05 | 0.1 | 0.401 | 0.307 | 0.243 | 39.401 | 20.847 |

| 7 | 140 | 0.05 | 0.1 | 0.334 | 0.246 | 0.189 | 43.413 | 23.171 |

| 11 | 80 | 0.1 | 0.3 | 0.701 | 0.523 | 0.406 | 42.083 | 22.371 |

| 14 | 110 | 0.1 | 0.3 | 0.521 | 0.461 | 0.389 | 25.336 | 15.618 |

| 17 | 140 | 0.1 | 0.3 | 0.446 | 0.334 | 0.252 | 43.498 | 24.551 |

| 21 | 80 | 0.15 | 0.5 | 0.871 | 0.772 | 0.670 | 23.077 | 13.212 |

| 24 | 110 | 0.15 | 0.5 | 0.667 | 0.605 | 0.543 | 18.591 | 10.248 |

| 27 | 140 | 0.15 | 0.5 | 0.575 | 0.492 | 0.406 | 29.391 | 17.480 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mane, S.; Patil, R.B.; Roy, A.; Shah, P.; Sekhar, R. Analysis of the Surface Quality Characteristics in Hard Turning Under a Minimal Cutting Fluid Environment. Appl. Mech. 2025, 6, 5. https://doi.org/10.3390/applmech6010005

Mane S, Patil RB, Roy A, Shah P, Sekhar R. Analysis of the Surface Quality Characteristics in Hard Turning Under a Minimal Cutting Fluid Environment. Applied Mechanics. 2025; 6(1):5. https://doi.org/10.3390/applmech6010005

Chicago/Turabian StyleMane, Sandip, Rajkumar Bhimgonda Patil, Anindita Roy, Pritesh Shah, and Ravi Sekhar. 2025. "Analysis of the Surface Quality Characteristics in Hard Turning Under a Minimal Cutting Fluid Environment" Applied Mechanics 6, no. 1: 5. https://doi.org/10.3390/applmech6010005

APA StyleMane, S., Patil, R. B., Roy, A., Shah, P., & Sekhar, R. (2025). Analysis of the Surface Quality Characteristics in Hard Turning Under a Minimal Cutting Fluid Environment. Applied Mechanics, 6(1), 5. https://doi.org/10.3390/applmech6010005