A Design Method for Low-Pressure Venturi Nozzles

Abstract

:1. Introduction

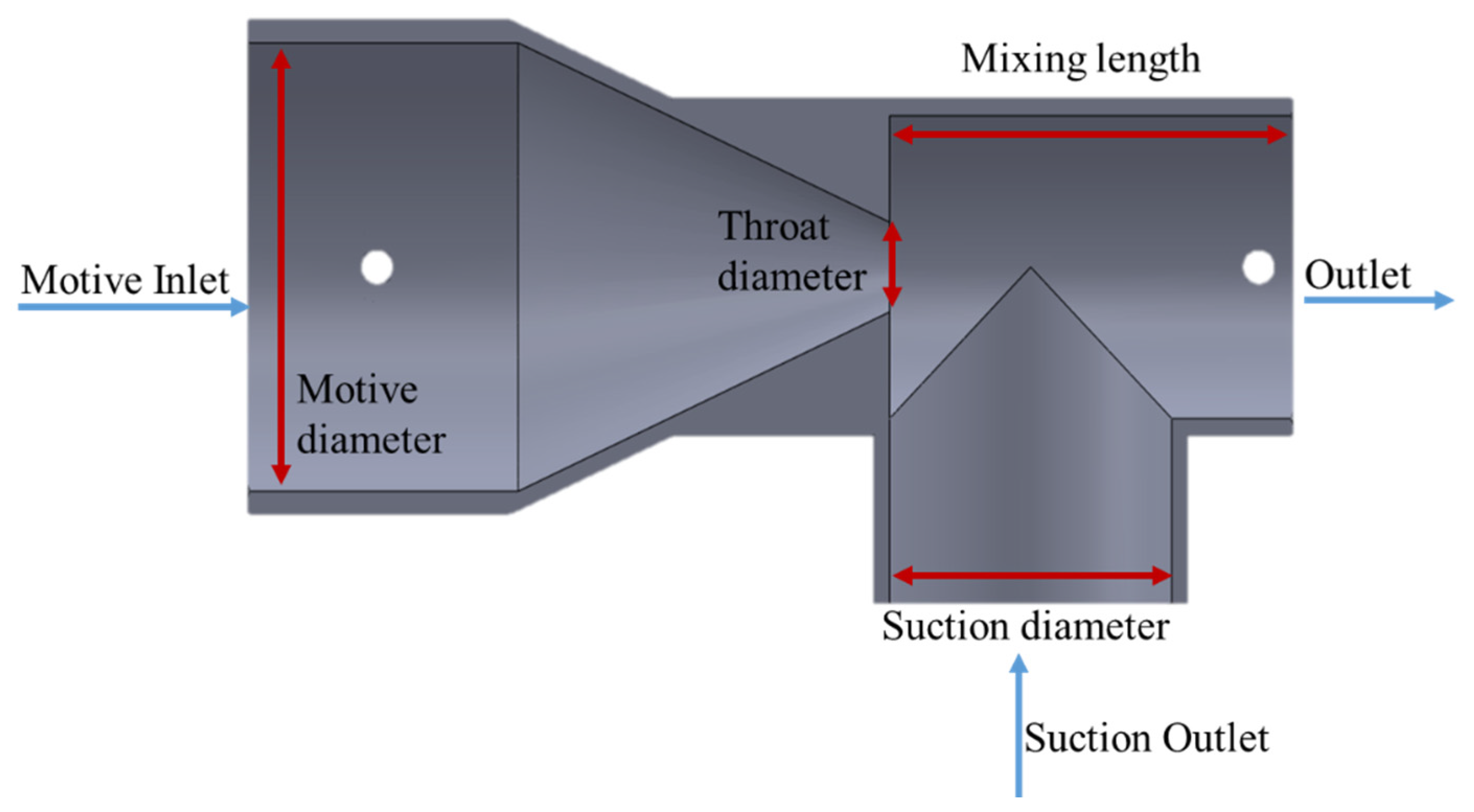

2. Simulation and Experimental Validation Methodology

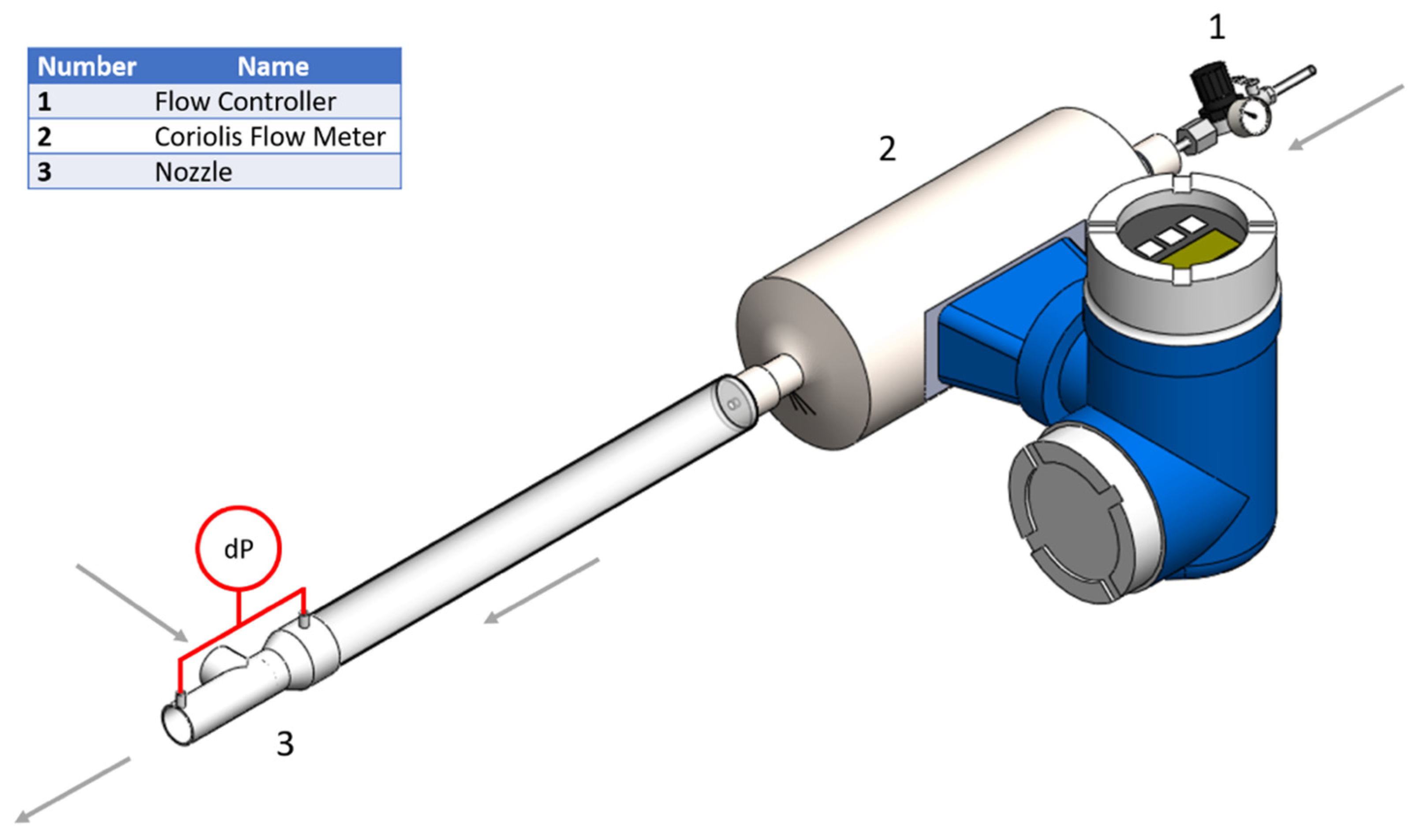

2.1. Air Mixing Experiment

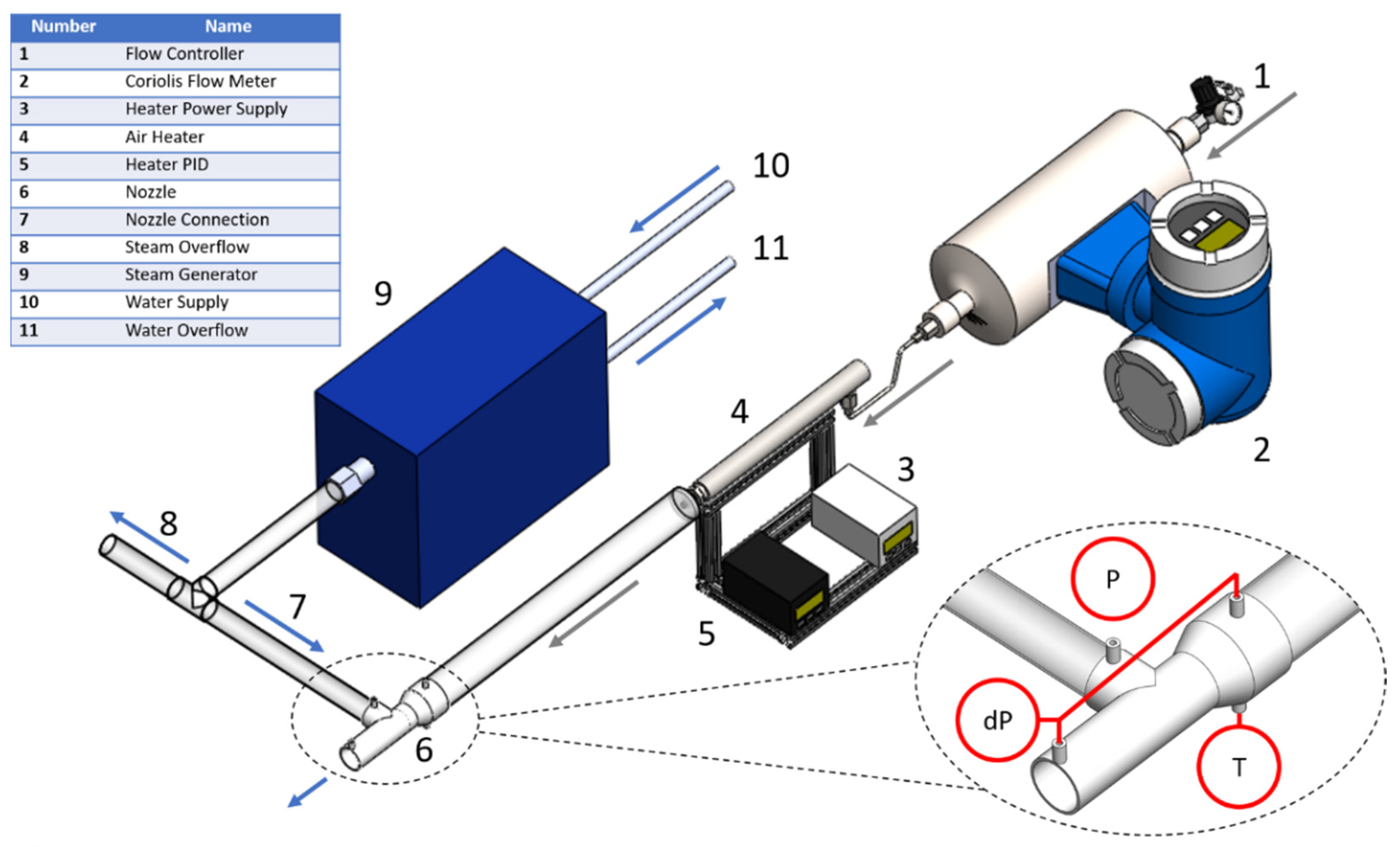

2.2. Air and Steam Mixing Experiment

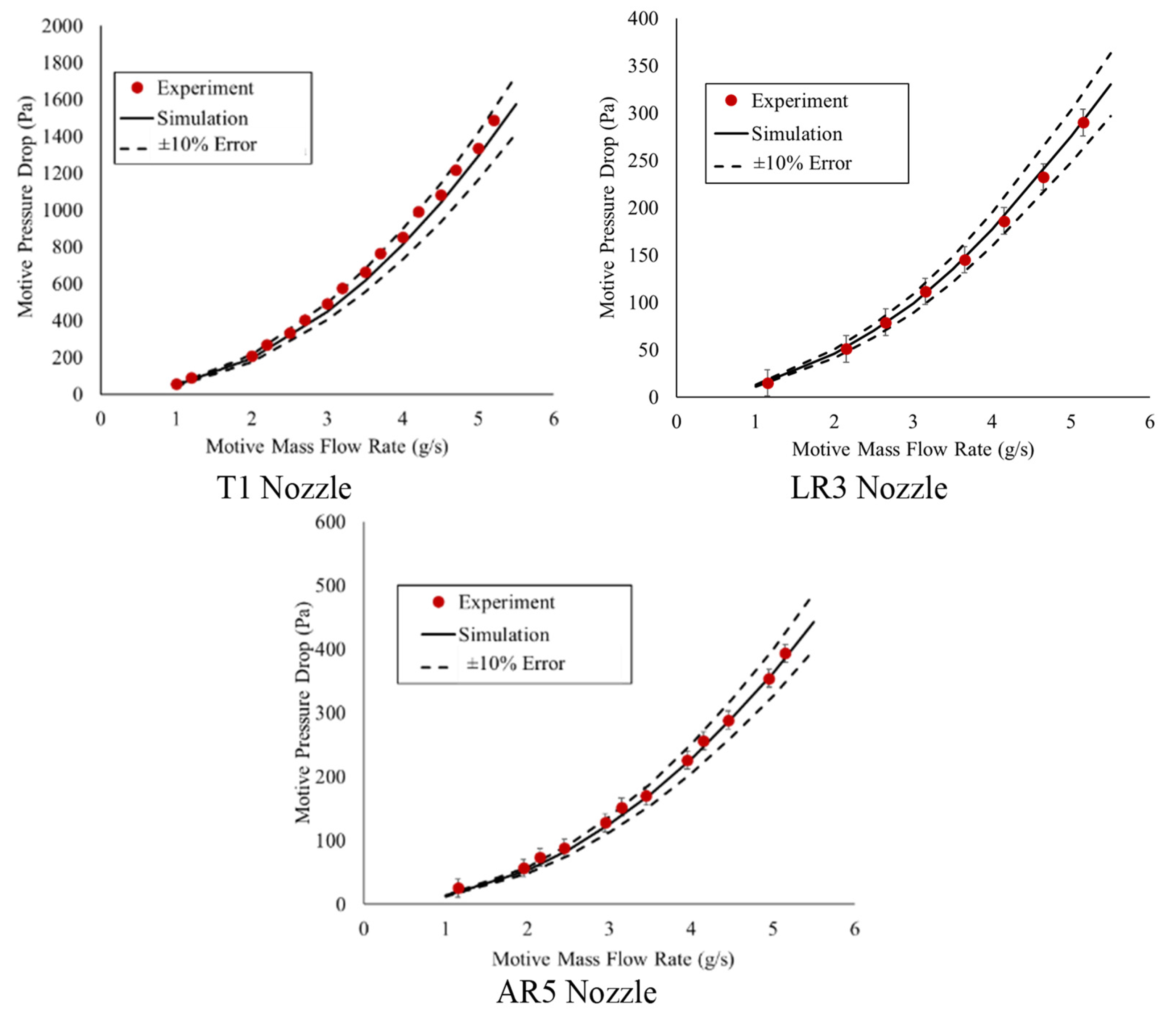

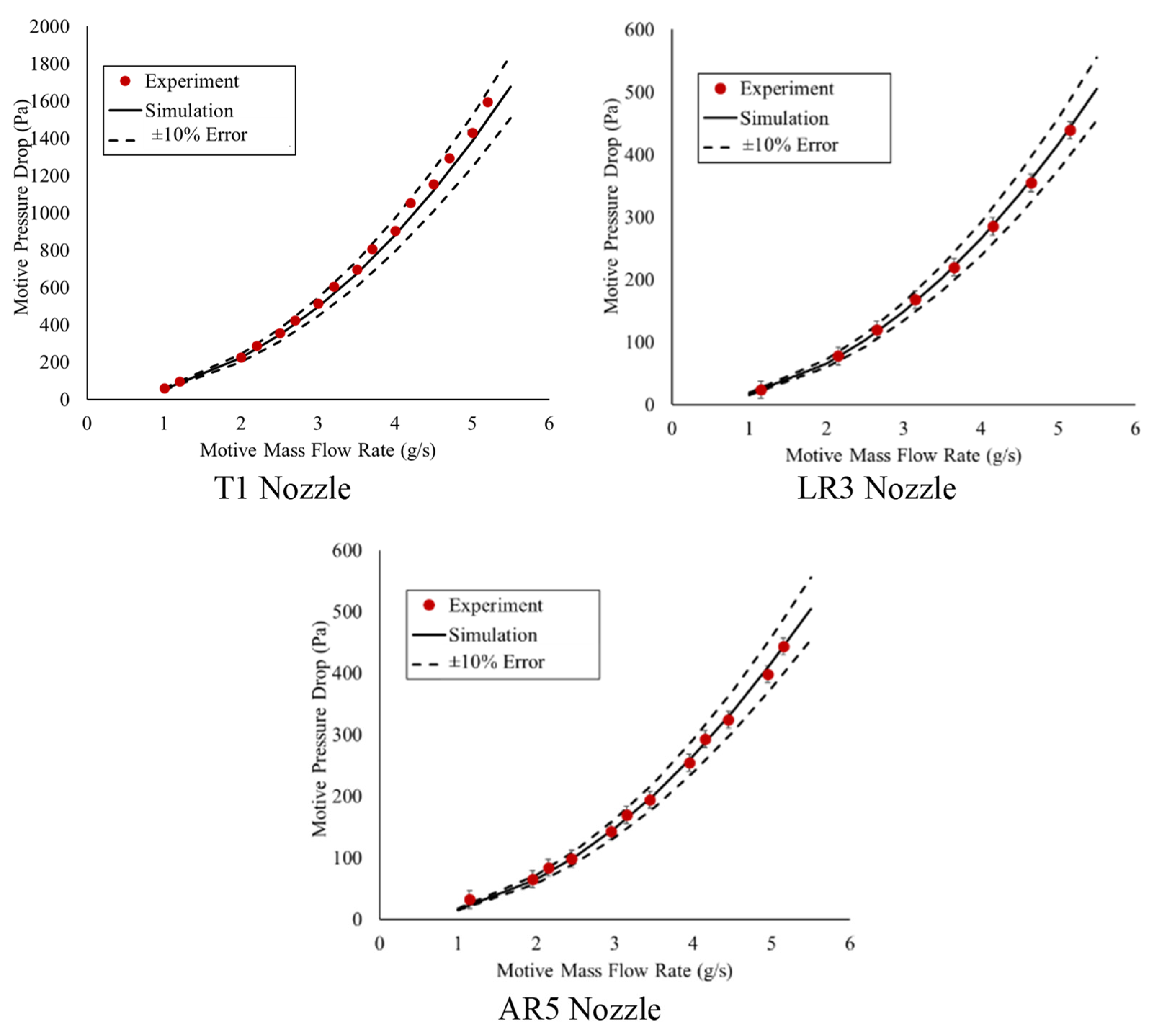

2.3. Air Mixing Determination and Validation

2.4. Air and Steam Mixing Determination and Validation

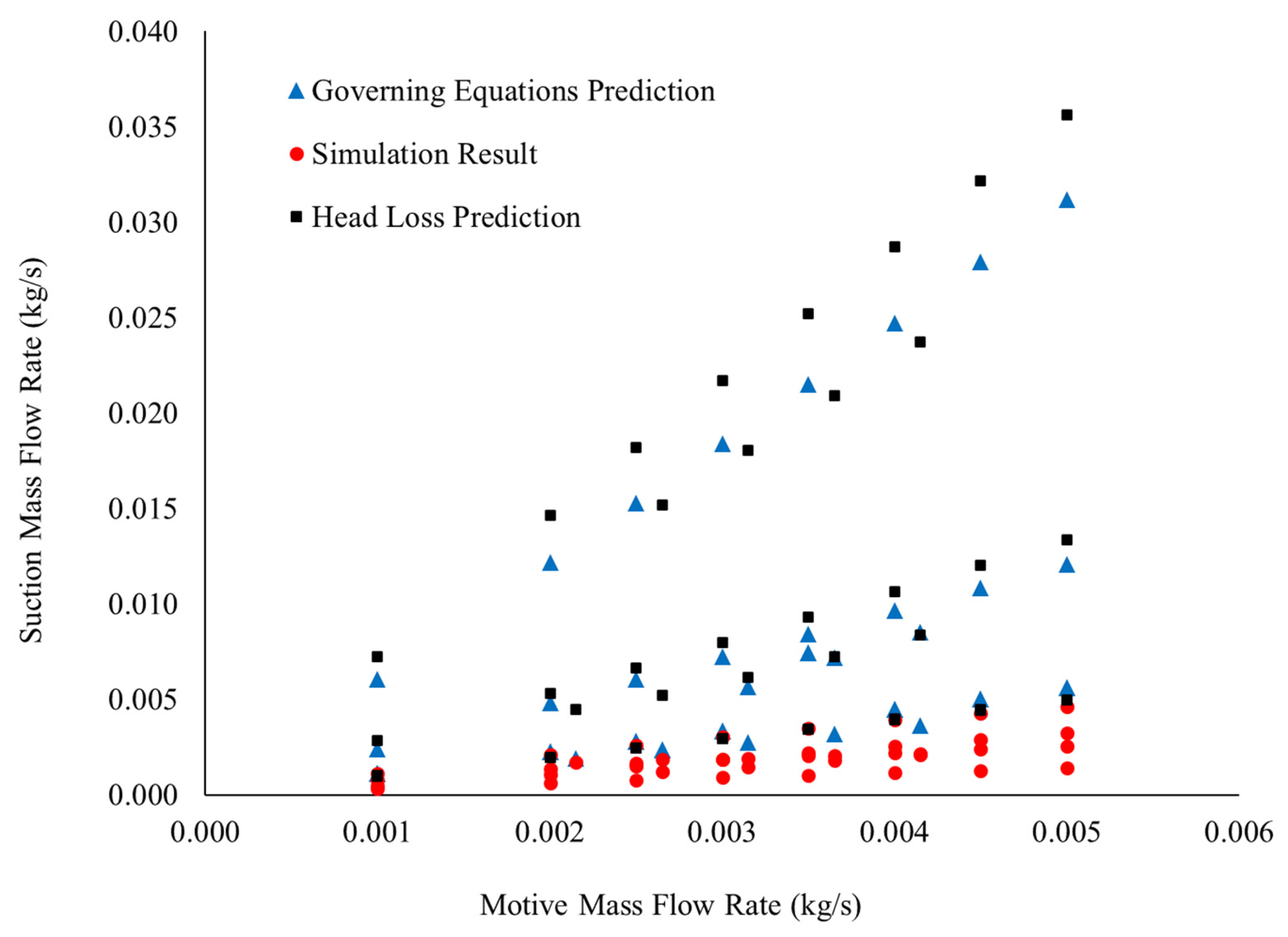

3. Governing Equations and Flow Head Calculations

4. Parametric Study

Empirical Model Formulation

5. Results

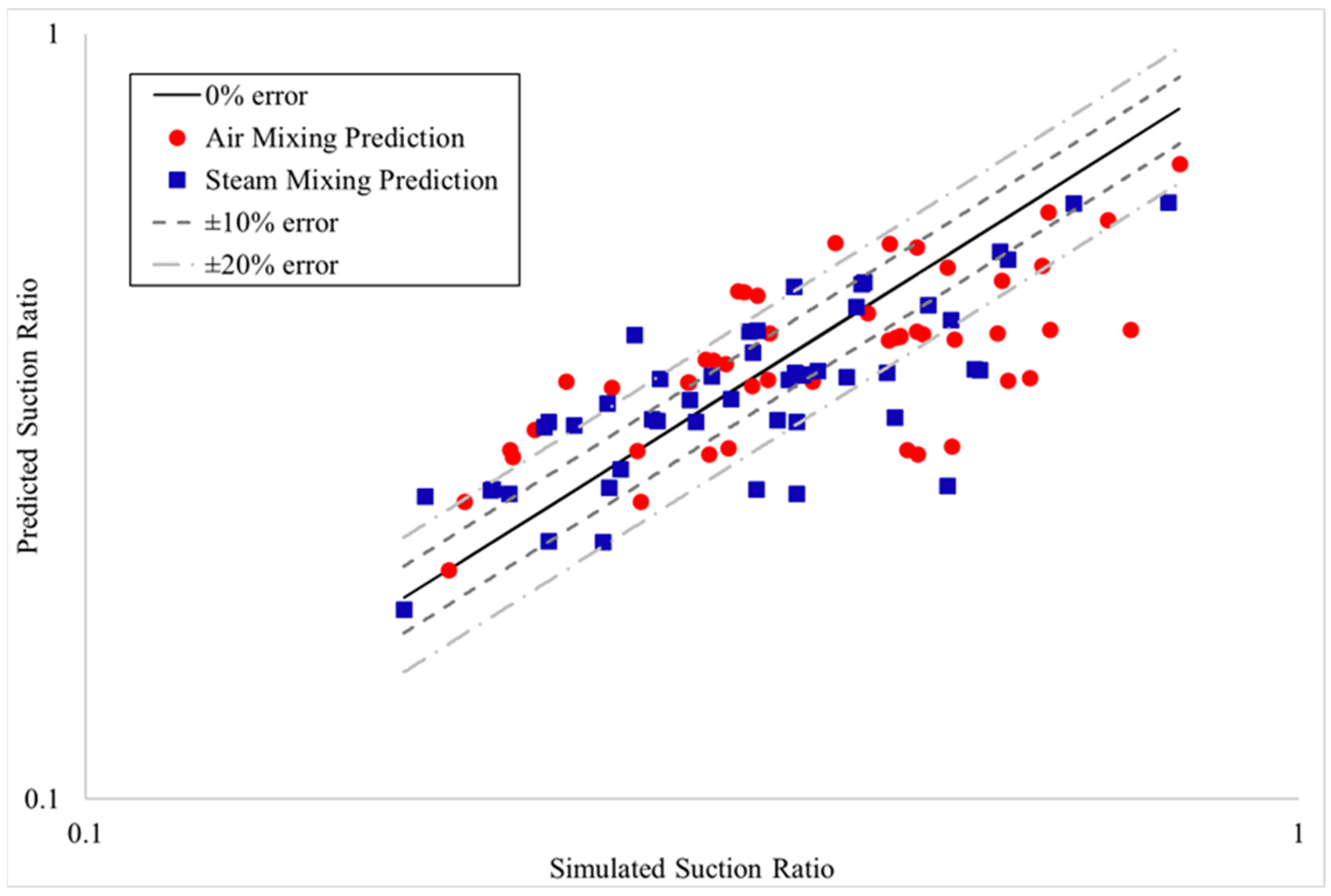

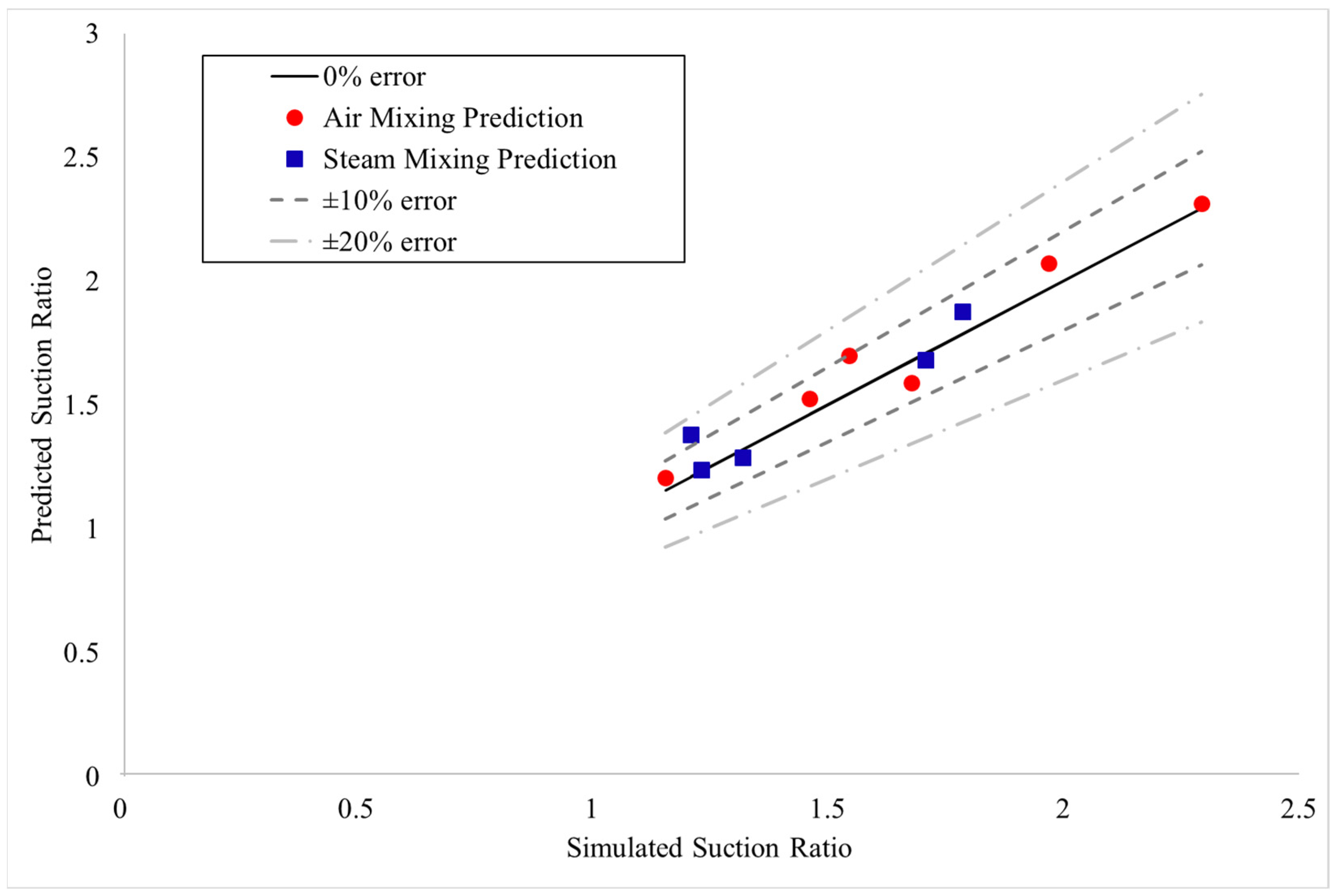

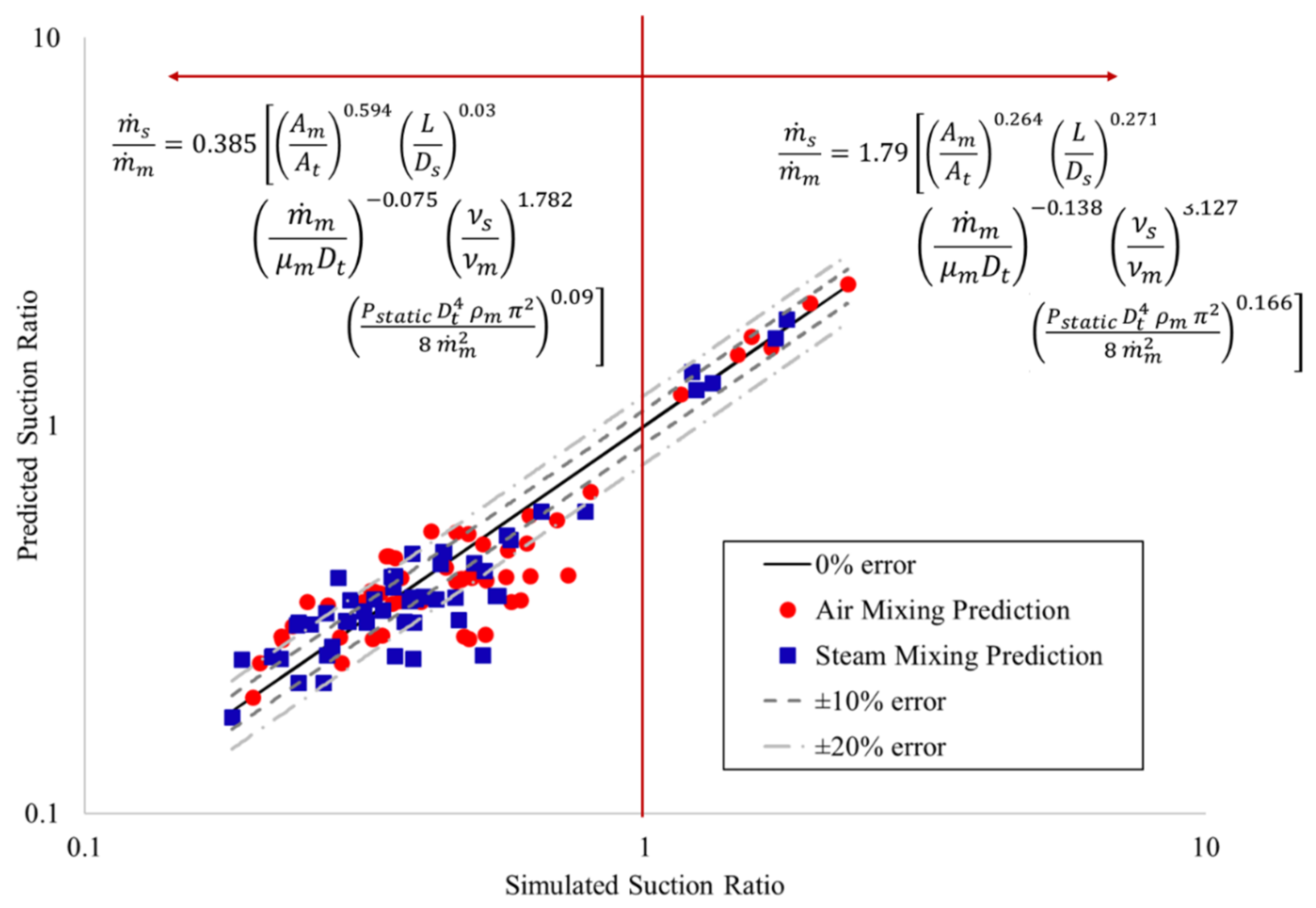

5.1. Suction Ratio Models

5.2. Momentum Ratio and Dynamic Pressure Ratio Models

| Empirical Model | MAPE | RSME | Applicability | Equation | |

|---|---|---|---|---|---|

| Global suction ratio | 22% | 27% | (17) | ||

| Air mixing, air and steam mixing | |||||

| Air only suction ratio | 22% | 26% | (18) | ||

| Air mixing | |||||

| Steam only suction ratio | 20% | 25% | (19) | ||

| Air and steam mixing | |||||

| Low suction ratio (suction ratio less than one) | 18% | 22% | (20) | ||

| Air mixing, air and steam mixing | |||||

| High suction ratio (suction ratio greater than one) | 5% | 6% | (21) | ||

| Air mixing, air and steam mixing | |||||

| Momentum Ratio | 28% | 36% | (22) | ||

| Air mixing, air and steam mixing | |||||

| Dynamic pressure ratio | 48% | 56% | (23) | ||

| Air mixing, air and steam mixing |

5.3. Venturi Nozzle Design Guide

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ariafar, K. Performance evaluation of a model thermocompressor using computational fluid dynamics. Int. J. Mech. 2012, 6, 35–42. [Google Scholar]

- Meakhail, T.A.; Zien, Y.; Elsallak, M.; Abdelhady, S. Experimental study of the effect of some geometric variables and number of nozzles on the performance of a subsonic air—Air ejector. Proc. Inst. Mech. Eng. 2008, 222, 809–818. [Google Scholar] [CrossRef]

- Manzano, J.; Palau, C.V.; Moreira de Azevedo, B.; do Bomfim, G.V.; Vasconcelos, D.V. Characterization and selection method of Venturi injectors for pressurized irrigation. Rev. Ciência Agronômica 2018, 49, 201–210. [Google Scholar] [CrossRef]

- Bilalis, D.; Karkanis, A.; Savvas, D.; Kontopoulou, C.-K.; Efthimiadou, A. Effects of fertilization and salinity on weed flora in common bean (‘Phaseolus vulgaris’ L.) grown following organic or conventional cultural practices. Aust. J. Crop Sci. 2014, 8, 178–182. [Google Scholar]

- Okzan, F.; Ozturk, M.; Baylar, A. Experimental investigations of air and liquid injection by venturi tubes. Water Environ. J. 2006, 20, 114–122. [Google Scholar]

- Little, A.B.; Garimella, S. A critical review linking ejector flow phenomena with component- and system-level performance. Int. J. Refrig. 2016, 70, 243–268. [Google Scholar] [CrossRef]

- Little, A.B.; Bartosiewicz, Y.; Garimella, S. Visualization and validation of ejector flow field with computational and first-principal analysis. J. Fluids Eng. 2015, 137, 1107. [Google Scholar] [CrossRef]

- Lin, C.; Cai, W.; Li, Y.; Hu, Y.; Giridharan, K. Numerical investigation of geometry parameters for pressure recovery of an adjustable ejector in multi-evaporator refrigeration system. Appl. Therm. Eng. 2013, 61, 649–656. [Google Scholar] [CrossRef]

- Varga, S.; Oliveira, A.C.; Ma, X.; Omer, S.A.; Zhang, W.; Riffat, S.B. Experimental and numerical analysis of a variable area ratio steam ejector. Int. J. Refrig. 2011, 34, 1668–1675. [Google Scholar] [CrossRef]

- Sun, D.-W. Variable geometry ejectors and their applications in ejector refrigeration systems. Energy 1996, 10, 919–929. [Google Scholar] [CrossRef]

- Huang, B.J.; Hu, S.S.; Le, S.H. Development of an ejector cooling system with thermal pumping effect. Int. J. Refrig. 2006, 29, 476–484. [Google Scholar] [CrossRef]

- Li, X.; Wang, T.; Day, B. Numerical analysis of the performance of a thermal ejector is a steam evaporator. Appl. Therm. Eng. 2010, 30, 2708–2717. [Google Scholar] [CrossRef]

- Bora, B.J.; Debnath, B.K.; Gupta, N.; Saha, U.K.; Sahoo, N. Investigation on the flow behaviour of a venturi type gas mixer designed for dual fuel diesel engines. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 202–209. [Google Scholar]

- Papadakis, E.; Raptopoulos, F.; Koskinopoulou, M.; Maniadakis, M. On the use of vacuum technology for applied robotic systems. In Proceedings of the 2020 6th International Conference on Mechatronics and Robotics Engineering (ICMRE), Barcelona, Spain, 12–15 February 2020; pp. 73–77. [Google Scholar]

- Rodrigues, A.; Camargo, E.; Ciolfi, M. Venturi Tube Application to Improve the Vacuum Assistance for Brake Systems; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Xu, J.; Liu, X.; Pang, M. Numerical and experimental studies on transport properties of powder ejector based on double venturi effect. Vacuum 2016, 134, 92–98. [Google Scholar] [CrossRef]

- Kroll, E.A. The design of jet pumps. Chem. Eng. Prog. 1947, 1, 21–24. [Google Scholar]

- Eames, I.W. A new prescription for the design of supersonic jet pumps: The constant rate of momentum change method. Appl. Therm. Eng. 2002, 22, 121–131. [Google Scholar] [CrossRef]

- Hoggarth, M.L. The design and performance of high-pressure injectors and gas jet boosters. Proc. Inst. Mech. Eng. 1970, 185, 755–766. [Google Scholar] [CrossRef]

- Munday, J.T.; Bagster, D.F. A new theory applied to steam jet refrigeration. Ind. Eng. Chem. Process Des. Dev. 1997, 16, 442–449. [Google Scholar] [CrossRef]

- Riffat, S.B.; Everitt, P. Experimental and CFD modeling of an ejector system for vehicle air conditioning. J. Inst. Energy 1999, 72, 41–47. [Google Scholar]

- Bartosiewicz, Y.; Aidoun, Z.; Desevaux, P.; Mercadier, Y. Numerical and experimental investigations on supersonic ejectors. Int. J. Heat Fluid Flow 2005, 1, 56–70. [Google Scholar] [CrossRef]

- Fu, W.; Liu, Z.; Li, Y.; Wu, H.; Tang, Y. Numerical study for the influences of primary steam nozzle distance and mixing chamber throat diameter on steam ejector performance. Int. J. Therm. Sci. 2018, 132, 509–516. [Google Scholar] [CrossRef]

- Keenan, J.H.; Neumann, E.P. A simple air ejector. ASME J. Appl. Mech. 1942, 62, 75–81. [Google Scholar] [CrossRef]

- McGovern, R.K.; Narayan, G.P.; Lienhard V, J.H. Analysis of reversible ejectors and definition of an ejector efficiency. Int. J. Therm. Sci. 2012, 54, 153–166. [Google Scholar] [CrossRef]

- Yang, X.; Long, X.; Yao, X. Numerical investigation on the mixing process in a steam ejector with different nozzle structures. Int. J. Therm. Sci. 2012, 56, 95–106. [Google Scholar] [CrossRef]

- Ouzzane, M.; Aidoun, Z. Model development and numerical procedure for detailed ejector analysis and design. Appl. Therm. Eng. 2003, 23, 2337–2351. [Google Scholar] [CrossRef]

- Shin, D.H.; Gim, Y.; Sohn, D.K.; Ko, H.S. Development of venturi-tube with spiral-shaped fin for water treatment. J. Fluids Eng. 2019, 141, 051303. [Google Scholar] [CrossRef]

- Rudolf, P.; Hudec, M.; Stefan, D. Numerical and experimental investigation of the cavitating flow within venturi tube. J. Fluids Eng. 2019, 141, 1101. [Google Scholar]

- Frankel, S. Large eddy simulation of turbulent-cavitation interactions in a venturi nozzle. J. Fluids Eng. 2010, 132, 121301. [Google Scholar]

- Sundararaj, S.; Selladurai, V. Numerical and experimental study on jet trajectories and mixing behavior of venturi-jet. J. Fluids Eng. 2010, 132, 101104. [Google Scholar] [CrossRef]

- Chen, W.; Chong, D.; Yan, J.; Liu, J. The numerical analysis of the effect of geometrical factors on natural gas ejector performance. Appl. Therm. Eng. 2013, 59, 21–29. [Google Scholar] [CrossRef]

- Hu, J.; Cao, X.; He, H.; Meng, Z.; Ding, M. Numerical optimization on the geometrical factors of subsonic air-air ejector. In Proceedings of the 9th International Symposium on Symbiotic Nuclear Power Systems for 21st Century, Harbin, China, 9–11 July 2018. [Google Scholar]

- Maqsood, A. A study of subsonic air-air ejectors with short bent mixing tubes. Diss. Abstr. Int. 2008, 69, 1911. [Google Scholar]

- Vaclav, D. Air to air ejector with various divergent mixing chambers. Appl. Mech. Mater. 2014, 493, 50–55. [Google Scholar]

- O’Hern, H.; Nikooei, N.; Zhang, X.; Hagen, C.; AuYeung, N.; Tew, D.; Abbasi, B. Reducing the water intensity of hydraulic fracturing: A review of treatment technologies. Desalin. Water Treat. 2021, 221, 121–138. [Google Scholar] [CrossRef]

- Abbasi, B.; Zhang, X.; O’Hern, H.; Nikooei, E. Method and System for Purifying Contaminated Water. U.S. Patent Application No. 16/985,043, 4 August 2020. [Google Scholar]

- Ansys Academic Research Fluent, Release 19.2. Ansys, Canonsburg, PA, USA. Available online: https://www.ansys.com/academic (accessed on 18 November 2021).

- Celik, I.B.; Ghia, U.; Roache, P.J.; Freitas, C.J. Procedure for estimation and reporting of uncertainty due to discretization in CFD applications. J. Fluids Eng. 2008, 130, 078001. [Google Scholar]

- Cengel, Y.A.; Cimbala, J.M. Fluid Mechanics, Fundamentals and Applications; McGraw-Hill: New York City, NY, USA, 2014. [Google Scholar]

- Transtrum, M.K.; Sethna, J.P. Improvements to the Levenberg-Marquardt algorithm for nonlinear least-squares minimization. arXiv 2012, arXiv:1201.5885. [Google Scholar]

- Elhashimi, M.; Zhang, X.; Abbasi, B. Empirical prediction of saline water atomization pressure loss and spray phase change using local flow pressure analysis. Desalination 2021, 514, 115156. [Google Scholar] [CrossRef]

- McMaster-Carr. Available online: https://www.mcmaster.com/venturi/water-aspirator-pumps/ (accessed on 18 November 2021).

- McMaster-Carr. Available online: https://www.mcmaster.com/venturi/fixed-flow-air-powered-vacuum-pumps-7/ (accessed on 18 November 2021).

- Steel Venturi Style Pneumatic Air Blower. Grainger, Lakeforest, IL, USA. Available online: https://www.grainger.com/product/ALLEGRO-Steel-Venturi-Style-Pneumatic-3TCK2 (accessed on 18 November 2021).

- Aluminum Venturi Nozzle For Blow Gun M 12x1.25 (MT). Tameson, Eindhoven, The Netherlands. Available online: https://tameson.com/pneumatics/air-tools/air-nozzles/venturi/aluminum-venturi-nozzle-for-blow-gun-m-12x1p25-mt.html?id_currency=4 (accessed on 18 November 2021).

| Nozzle Name/Code | Motive Diameter (m) | Throat Diameter (m) | Suction Diameter (m) | Mixing Length (m) | Motive Mass Flow Rate (g/s) | Suction Inlet Condition |

|---|---|---|---|---|---|---|

| T1 | 0.04 | 0.012 | 0.027 | 0.0385 | 1–5 | Sealed and Open |

| LR3 | 0.04 | 0.016 | 0.027 | 0.08 | 1–5 | Sealed and Open |

| AR5 | 0.04 | 0.016 | 0.0175 | 0.0385 | 1–5 | Sealed and Open |

| Grid Specifications | Number of Cells: Case I: 4,702,076, Case II: 1,439,997, Case III:828,620 | |

|---|---|---|

| Physical Parameter (φ) | Suction Mass Flow Rate (kg/s) | Motive Pressure Drop (Pa) |

| 0.004325 | 8980.95 | |

| 0.004489 | 9020.66 | |

| 0.004617 | 9151.77 | |

| 1.64 × 10−4 | 39.71 | |

| 1.28 × 10−4 | 31.11 | |

| 1.59 | 1.56 | |

| 0.00414 | 8934.04 | |

| 0.00411 | 8926.41 | |

| 3.8% | 0.4% | |

| 2.8% | 0.3% | |

| 4.6% | 0.5% | |

| 9.2% | 1.1% | |

| 5.5% | 0.7% |

| Name/Code | Motive Diameter (m) | Throat Diameter (m) | Suction Diameter (m) | Mixing Length (m) |

|---|---|---|---|---|

| D2 | 0.04 | 0.016 | 0.027 | 0.0385 |

| AR1 | 0.05 | 0.016 | 0.027 | 0.0482 |

| AR2 | 0.05 | 0.016 | 0.02 | 0.0482 |

| AR3 | 0.03 | 0.016 | 0.027 | 0.0289 |

| AR4 | 0.05 | 0.016 | 0.0175 | 0.0482 |

| AR5 * | 0.04 | 0.016 | 0.0175 | 0.0385 |

| AR6 | 0.035 | 0.016 | 0.015 | 0.0337 |

| LR1 | 0.04 | 0.016 | 0.027 | 0.03 |

| LR2 | 0.04 | 0.016 | 0.027 | 0.06 |

| LR3 * | 0.04 | 0.016 | 0.027 | 0.08 |

| T1 * | 0.04 | 0.012 | 0.027 | 0.0385 |

| T2 | 0.04 | 0.01 | 0.027 | 0.0385 |

| T3 * | 0.04 | 0.008 | 0.027 | 0.0385 |

| S1 | 0.04 | 0.016 | 0.015 | 0.0385 |

| S2 | 0.04 | 0.016 | 0.02 | 0.0385 |

| Asterisks denote a geometry that was experimentally validated. | ||||

| Name/Code | Motive Flow Rate (g/s) | Suction Static Pressure (Pa) | Suction Fluid |

|---|---|---|---|

| D2 | 20.8 | 10,100,500 | Air, Steam |

| 5.2 | 10,500 | Air, Steam | |

| AR1 | 20.8 | 10,100,500 | Air, Steam |

| AR2 | 20.8 | 10,100,500 | Air, Steam |

| AR3 | 20.8 | 10,100,500 | Air, Steam |

| AR4 | 20.8 | 10,100,500 | Air, Steam |

| AR5 | 20.8 | 10,100,500 | Air, Steam |

| AR6 | 20.8 | 10,100,500 | Air, Steam |

| LR1 | 20.8 | 10,100,500 | Air, Steam |

| 5.2 | 10,500 | Air, Steam | |

| LR2 | 20.8 | 10,100,500 | Air, Steam |

| LR3 | 20.8 | 10,100,500 | Air, Steam |

| 5.2 | 10,500 | Air, Steam | |

| T1 | 20.8 | 10,100,500 | Air, Steam |

| 5.2 | 10,500 | Air, Steam | |

| T2 | 20.8 | 10,100,500 | Air, Steam |

| T3 | 20.8 | 10,100,500 | Air, Steam |

| 5.2 | 10,100,500 | Air, Steam | |

| S1 | 20.8 | 10,100,500 | Air, Steam |

| 5.2 | 100 | Air, Steam | |

| S2 | 20.8 | 10,100,500 | Air, Steam |

| 5.2 | 100 | Air, Steam |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

O’Hern, H.; Murphy, T.; Zhang, X.; Liburdy, J.; Abbasi, B. A Design Method for Low-Pressure Venturi Nozzles. Appl. Mech. 2022, 3, 390-411. https://doi.org/10.3390/applmech3020024

O’Hern H, Murphy T, Zhang X, Liburdy J, Abbasi B. A Design Method for Low-Pressure Venturi Nozzles. Applied Mechanics. 2022; 3(2):390-411. https://doi.org/10.3390/applmech3020024

Chicago/Turabian StyleO’Hern, Hannah, Timothy Murphy, Xiang Zhang, James Liburdy, and Bahman Abbasi. 2022. "A Design Method for Low-Pressure Venturi Nozzles" Applied Mechanics 3, no. 2: 390-411. https://doi.org/10.3390/applmech3020024

APA StyleO’Hern, H., Murphy, T., Zhang, X., Liburdy, J., & Abbasi, B. (2022). A Design Method for Low-Pressure Venturi Nozzles. Applied Mechanics, 3(2), 390-411. https://doi.org/10.3390/applmech3020024