Paint Coating Removal by Heating for High-Strength Bolted Joints in Steel Bridge and Its Influence on Bolt Axial Force

Abstract

:1. Introduction

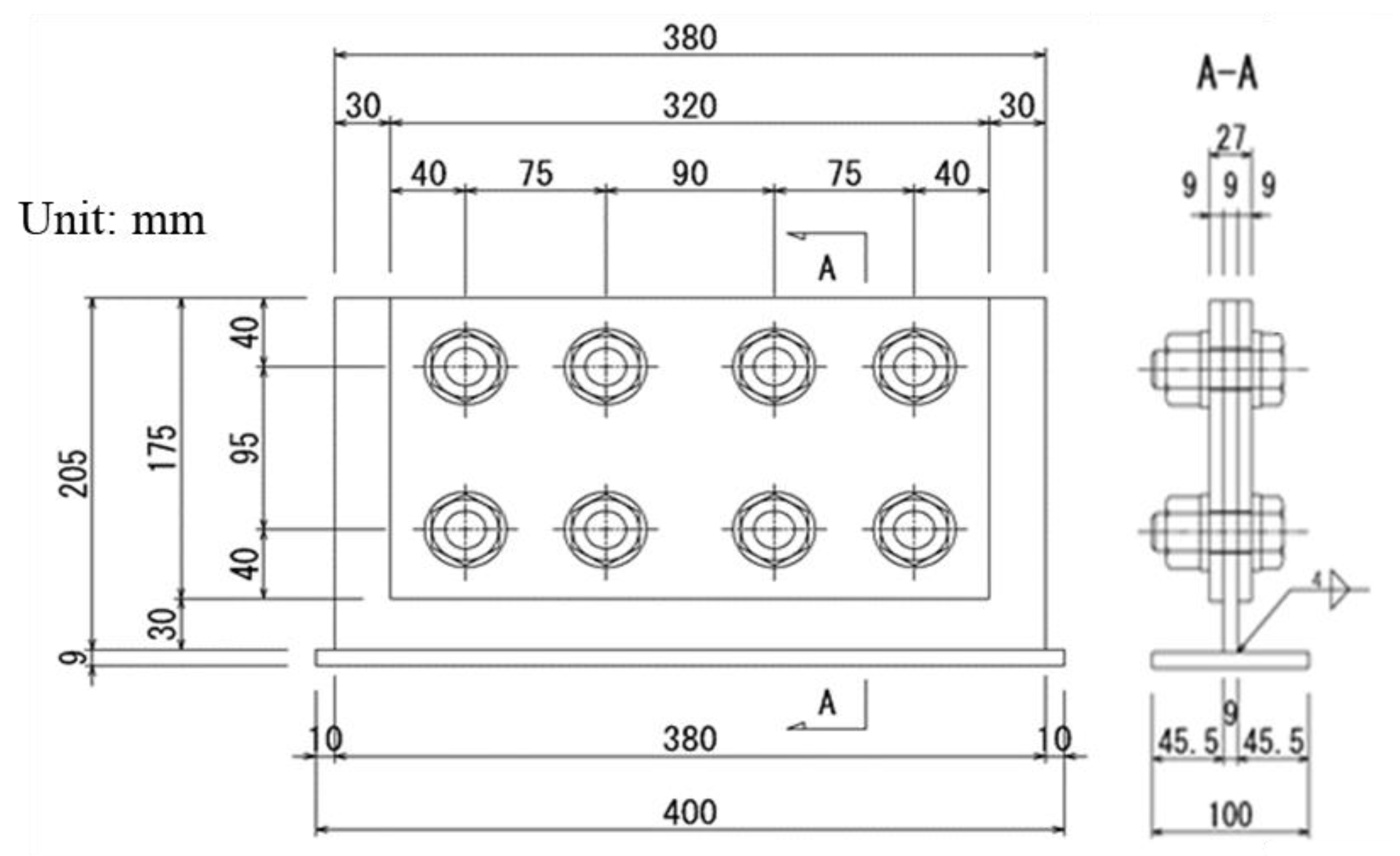

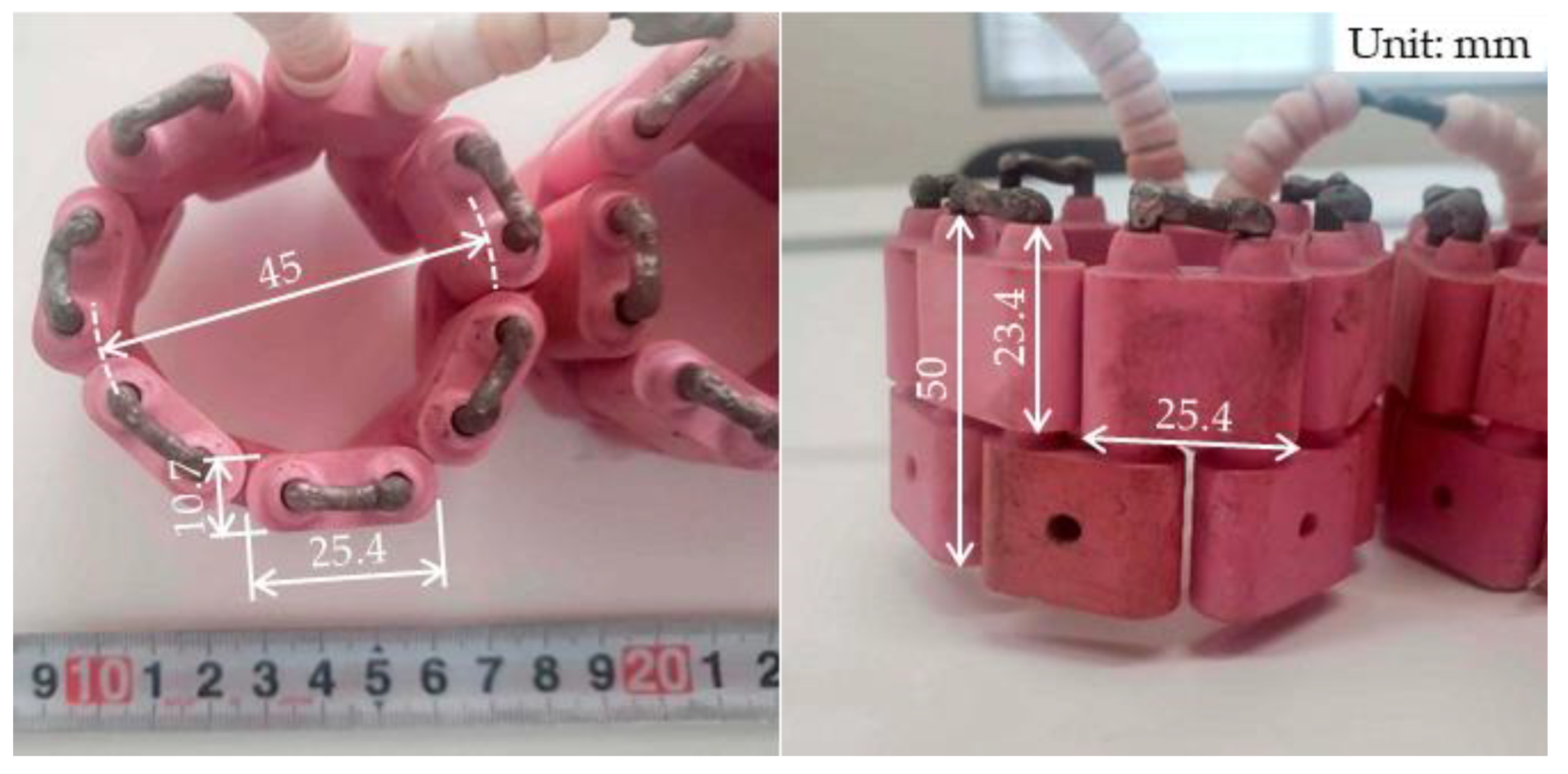

2. Experimental Specimen

3. Experimental Procedure

3.1. Device for Heating of Bolted Joints

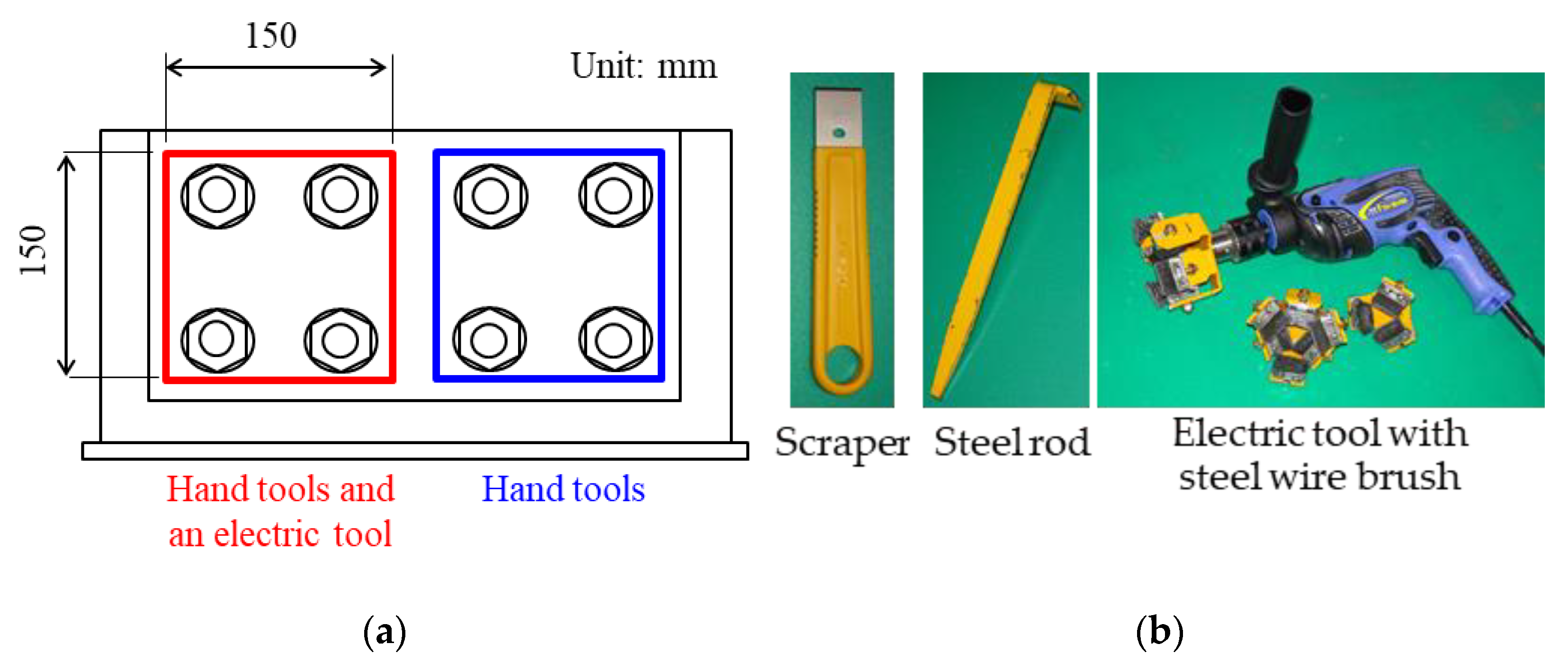

3.2. Paint Coating Removal

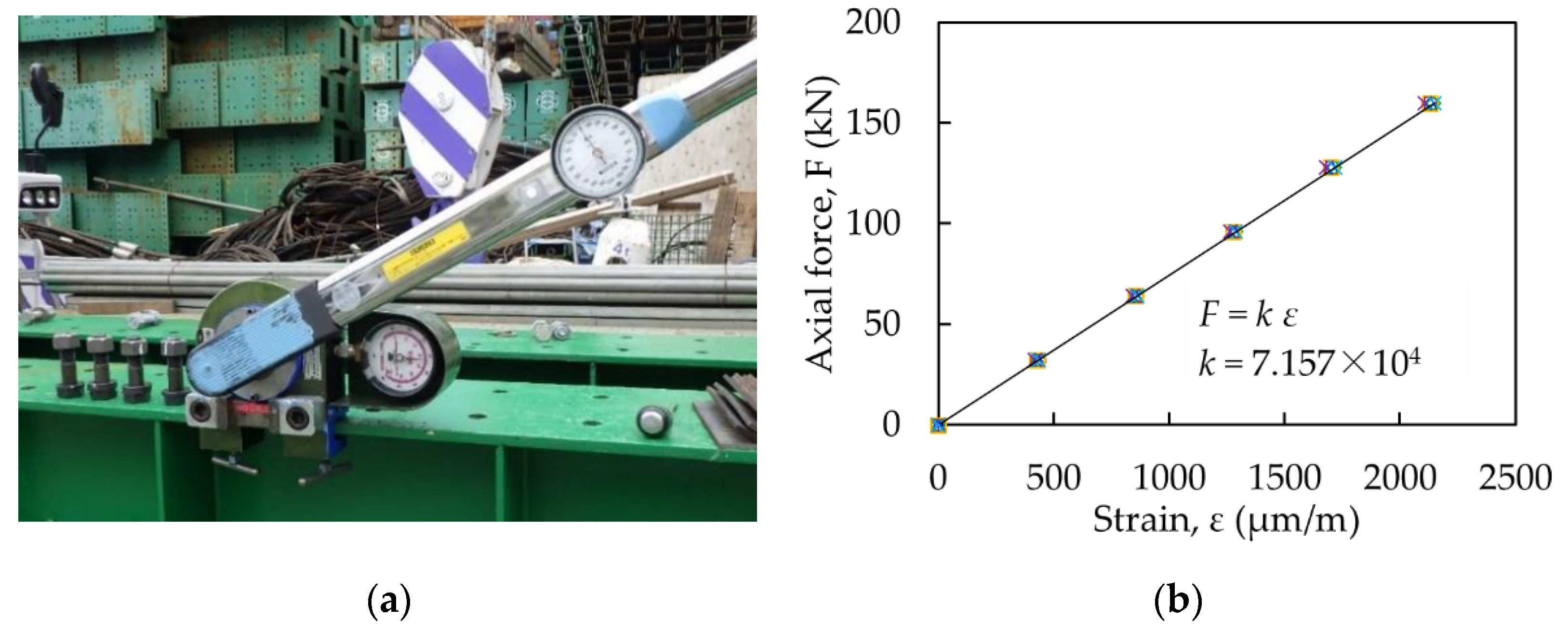

3.3. Strain Measurement of Bolts

4. Results and Discussions

4.1. Temperature Histories

4.2. Degree of Paint Coating Removal

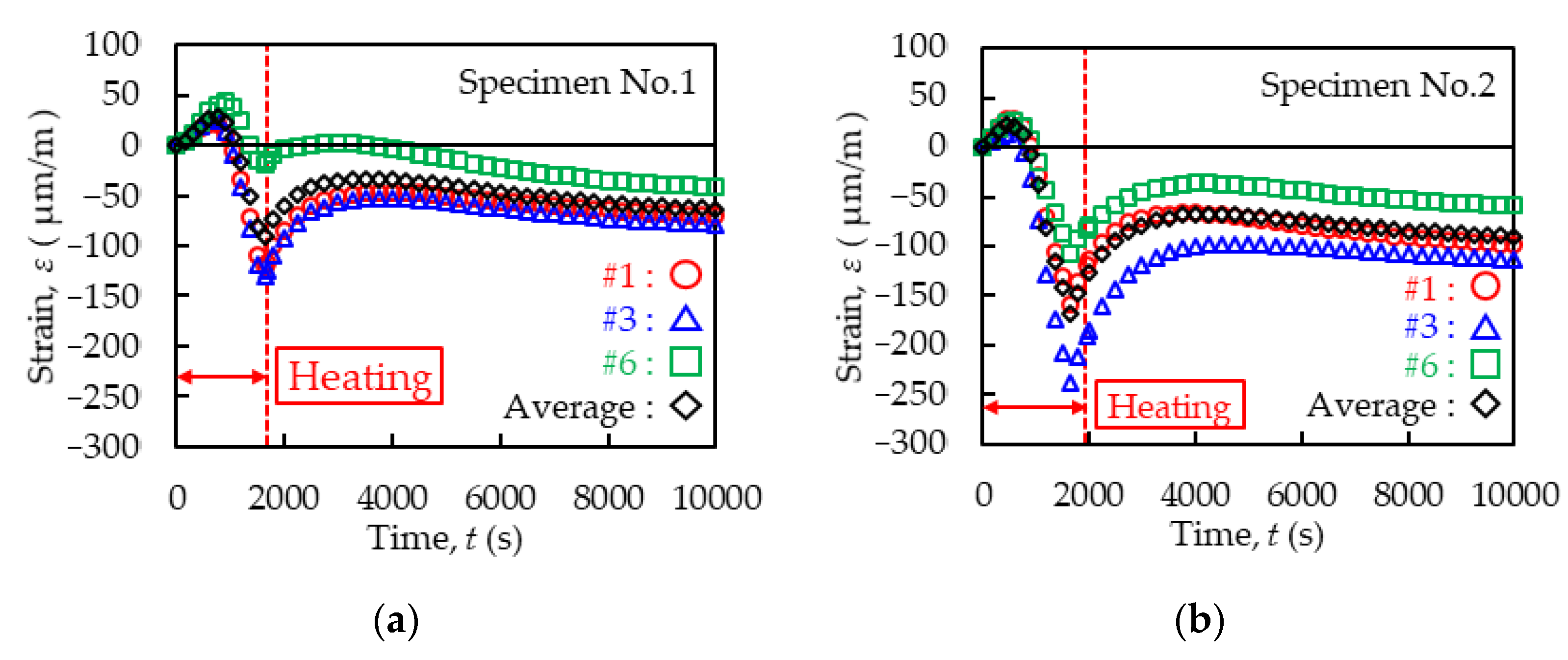

4.3. Behaviour of Axial Strain of Bolts

4.4. Estimation of Axial Forces of Bolts

4.5. Power Consumption Estimation and a Proposal of Work Procedure for Paint Coating Removal

5. Conclusions

- (1)

- The accuracy of temperature control by the heating device was confirmed. The bolted joints specimens could be heated to the target temperature of 200 °C without extreme overheating. After the heating, the paint coating around the bolts and the nuts could be removed by using hand tools and an electric tool with a wire brush.

- (2)

- The reduction in the axial force of the bolts was examined by monitoring the change in strain during the heating process. The heating of the nuts expanded the bolts in the former stage and the bolts might be yielded. The thermal expansion of the base plates and the cover plates were restrained by the bolts in the later heating stage; therefore, the plates around the bolt holes might be yielded. These yielding might cause the reduction in the axial force of the bolts.

- (3)

- The reduction in the axial force of the bolts was 2.6% of the originally installed axial force, on average. It was within the safety margin in the design of bolted joints for steel bridges.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kage, I.; Matsui, K.; Kawabata, F. Minimum maintenance steel plates and their application technologies for bridge—Life cycle cost reduction technologies with environmental safeguards for preventing social infrastructure assets. JFE Tech. Rep. 2005, 5, 37–44. [Google Scholar]

- Kreisolva, K.; Geiplova, H. Evaluation of corrosion protection of steel bridges. Procedia Eng. 2012, 40, 229–234. [Google Scholar] [CrossRef] [Green Version]

- Kline, E.S. Steel bridges: Corrosion protection for 100 years. J. Prot. Coat. Linings 2008, 25, 20–31. [Google Scholar]

- Itoh, Y.; Hirohata, M.; Hosoi, A.; Sugiura, Y. Anticorrosive performance of repair painting as remedy for deterioration in metallised steel. Corros. Eng. Sci. Technol. 2013, 48, 537–551. [Google Scholar] [CrossRef]

- Hopwood, T., II; Oberst, C.M. The Removal of Lead-Based Paint from Steel Bridges. In Research Report; Kentucky Transportation Center: Lexington, KY, USA, 1993; pp. 20–23. [Google Scholar]

- Li, X.; Wang, H.; Yu, W.; Wang, L.; Wang, D.; Cheng, H.; Wang, L. Laser paint stripping strategy in engineering application: A systematic review. Opt. Int. J. Light Electron Opt. 2021, 241, 167036. [Google Scholar] [CrossRef]

- Madhukar, Y.K.; Mullick, S.; Nath, A.K. Development of a water-jet assisted laser paint removal process. Appl. Surf. Sci. 2013, 286, 192–205. [Google Scholar] [CrossRef]

- RPR Technologies. Available online: https://www.rprtech.com/ (accessed on 16 September 2021).

- Nakamura, M.; Hirohata, M.; Inoue, K.; Konishi, H. Applicability of Induction Heating on Paint Coating Removal of Steel Bridge Member. In Proceedings of the 9th International Symposium on Steel Structures, Jeju, Korea, 1–4 November 2017; pp. 401–403. [Google Scholar]

- Konishi, H.; Suzuki, N.; Tanaka, M.; Sameshima, C.; Nishitani, T.; Hirohata, M. Application of induction heating for removal coating in Kyoda steel bridges. Bridge Found. Eng. 2017, 7, 14–20. (In Japanese) [Google Scholar]

- Konishi, H.; Ihaya, T.; Fukushima, N.; Matsui, T.; Hayashi, M.; Hirohata, M. Field test of coating removal by induction heating in Ichikawa bridge. Bridge Found. Eng. 2020, 6, 18–23. (In Japanese) [Google Scholar]

- Hirohata, M. Effect of post weld heat treatment on steel plate deck with trough rib by portable heat source. Weld. World 2017, 61, 1225–1235. [Google Scholar] [CrossRef]

- Aung, M.P.; Hirohata, M. Numerical study on post-weld heat treatment of non-stiffened welded box section member. Int. J. Steel Struct. 2019, 19, 1521–1533. [Google Scholar] [CrossRef]

- Hirohata, M.; Toyoshima, D.; Konishi, H. Paint coating removal technique for bolted joints by portable heating device. In Proceedings of the 10th International Symposium on Steel Structures, Jeju, Korea, 13–16 November 2019; p. O-022. [Google Scholar]

- Uno, N.; Nagata, M.; Kanisawa, H.; Azuma, K. Super-high-strength bolt, “SHTB®”. Nippon. Steel Tech. Rep. 2008, 97, 95–104. [Google Scholar]

- Kim, I.T.; Itoh, Y. Accelerated exposure tests as evaluation tool for estimating life of organic coatings on steel bridges. Corros. Eng. Sci. Technol. 2007, 42, 242–252. [Google Scholar] [CrossRef]

- Gündüz, G.; Kisakürek, D.; Kayadan, S. Flame retardant alkyd paint. Polym. Degrad. Stab. 1999, 64, 501–504. [Google Scholar] [CrossRef]

- Gonçalves, G.S.; Baldissera, A.F.; Rodrigues, L.F., Jr.; Martini, E.M.A.; Ferreira, C.A. Alkyd coatings containing polyanilines for corrosion protection of mild steel. Synth. Met. 2011, 161, 313–323. [Google Scholar] [CrossRef] [Green Version]

- Kodur, V.; Yahyai, M.; Rezaeian, A.; Eslami, M.; Poormohamadi, A. Residual mechanical properties of high strength steel bolts subjected to heating-cooling cycle. J. Constr. Steel Res. 2017, 131, 122–131. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO10721-1 Steel Structures—Part 1: Materials and Design; International Organization for Standardization: Geneva, Switzerland, 1997; pp. 75–76. [Google Scholar]

- Jiménez-Peña, C.; Talemi, R.H.; Rossi, B.; Debruyne, D. Investigations on the fretting fatigue failure mechanism of bolted joints in high strength steel subjected to different levels of pre-tension. Tribol. Int. 2017, 108, 128–140. [Google Scholar] [CrossRef]

- Ahn, J.-H.; You, J.M.; Huh, J.; Kim, I.-T.; Jeong, Y.-S. Residual clamping force of bolt connections caused by sectional damage of nuts. J. Constr. Steel Res. 2017, 136, 204–214. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, T.H.; Kim, J.T. Image-based bolt loosening detection technique of bolt joint in steel bridge. In Proceedings of the 6th International Conference on Advances in Experimental Structural Engineering, 11th International Workshop on Advanced Smart Materials and Smart Structures Technology, Urbana, IL, USA, 1–2 August 2015. [Google Scholar]

- Zhang, Y.; Zhao, X.; Sun, X.; Su, W.; Xue, Z. Bolt loosening detection based on audio classification. Adv. Struct. Eng. 2019, 22, 2882–2891. [Google Scholar] [CrossRef]

- Nah, H.-S.; Lee, H.-J.; Kim, K.-S.; Kim, J.-H.; Kim, W.-B. Evaluating relaxation of high-strength bolts by parameters of slip faying surfaces of bolted connections. Int. J. Steel Struct. 2010, 10, 295–303. [Google Scholar] [CrossRef]

| Material | Yield Strength (N/mm2) | Tensile Strength (N/mm2) | Elongation (%) |

|---|---|---|---|

| Plate: SS400 | 323 | 440 | 33 |

| Bolt (rot 1): F10T | 1022 | 1076 | 20 |

| Bolt (rot 2): F10T | 1023 | 1077 | 20 |

| Process | Paint Type | Thickness (μm) |

|---|---|---|

| Surface preparation | Grinding, ISO St3 | - |

| Undercoat | Anti-corrosion paint without Pb and Cr | 35 × 3 layers |

| Middle coat | Long oil alkyd resin | 30 |

| Topcoat | Long oil alkyd resin | 25 |

| Specimen No.1 | Specimen No.2 | Average (Standard Deviation) | |||||

|---|---|---|---|---|---|---|---|

| #1 | #3 | #6 | #1 | #3 | #6 | ||

| Initial axial force (kN) | 241 | 232 | 221 | 217 | 234 | 243 | 231 (10.5) |

| Axial force reduction (kN) | 5.6 | 5.7 | 3.2 | 8.0 | 9.2 | 4.7 | 6.1 (2.2) |

| Reduction percentage (%) | 2.3 | 2.4 | 1.4 | 3.6 | 3.9 | 1.9 | 2.6 (0.97) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakahara, T.; Hirohata, M.; Kondo, S.; Furuichi, T. Paint Coating Removal by Heating for High-Strength Bolted Joints in Steel Bridge and Its Influence on Bolt Axial Force. Appl. Mech. 2021, 2, 728-738. https://doi.org/10.3390/applmech2040042

Nakahara T, Hirohata M, Kondo S, Furuichi T. Paint Coating Removal by Heating for High-Strength Bolted Joints in Steel Bridge and Its Influence on Bolt Axial Force. Applied Mechanics. 2021; 2(4):728-738. https://doi.org/10.3390/applmech2040042

Chicago/Turabian StyleNakahara, Tomonori, Mikihito Hirohata, Shinsuke Kondo, and Toru Furuichi. 2021. "Paint Coating Removal by Heating for High-Strength Bolted Joints in Steel Bridge and Its Influence on Bolt Axial Force" Applied Mechanics 2, no. 4: 728-738. https://doi.org/10.3390/applmech2040042

APA StyleNakahara, T., Hirohata, M., Kondo, S., & Furuichi, T. (2021). Paint Coating Removal by Heating for High-Strength Bolted Joints in Steel Bridge and Its Influence on Bolt Axial Force. Applied Mechanics, 2(4), 728-738. https://doi.org/10.3390/applmech2040042