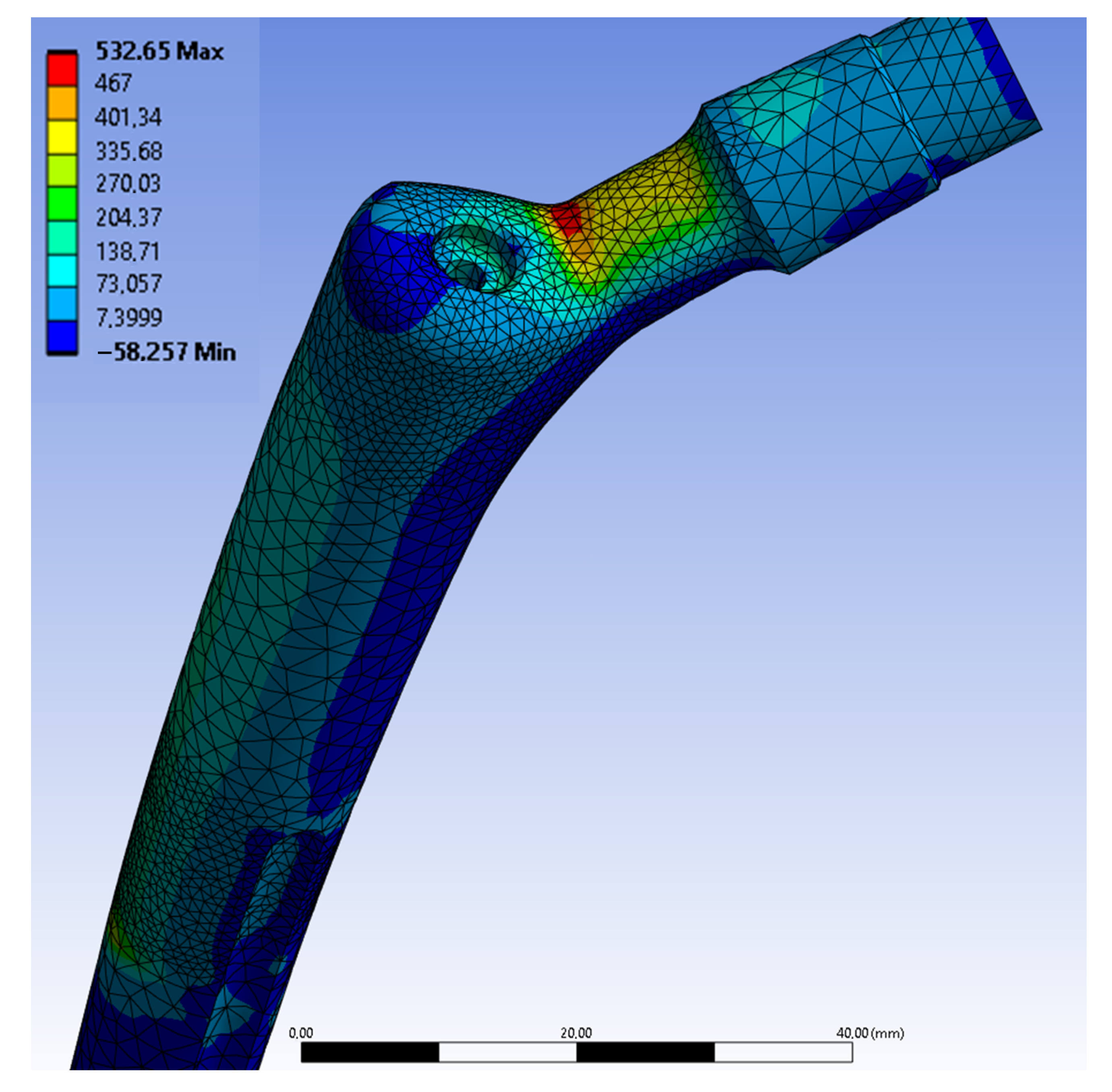

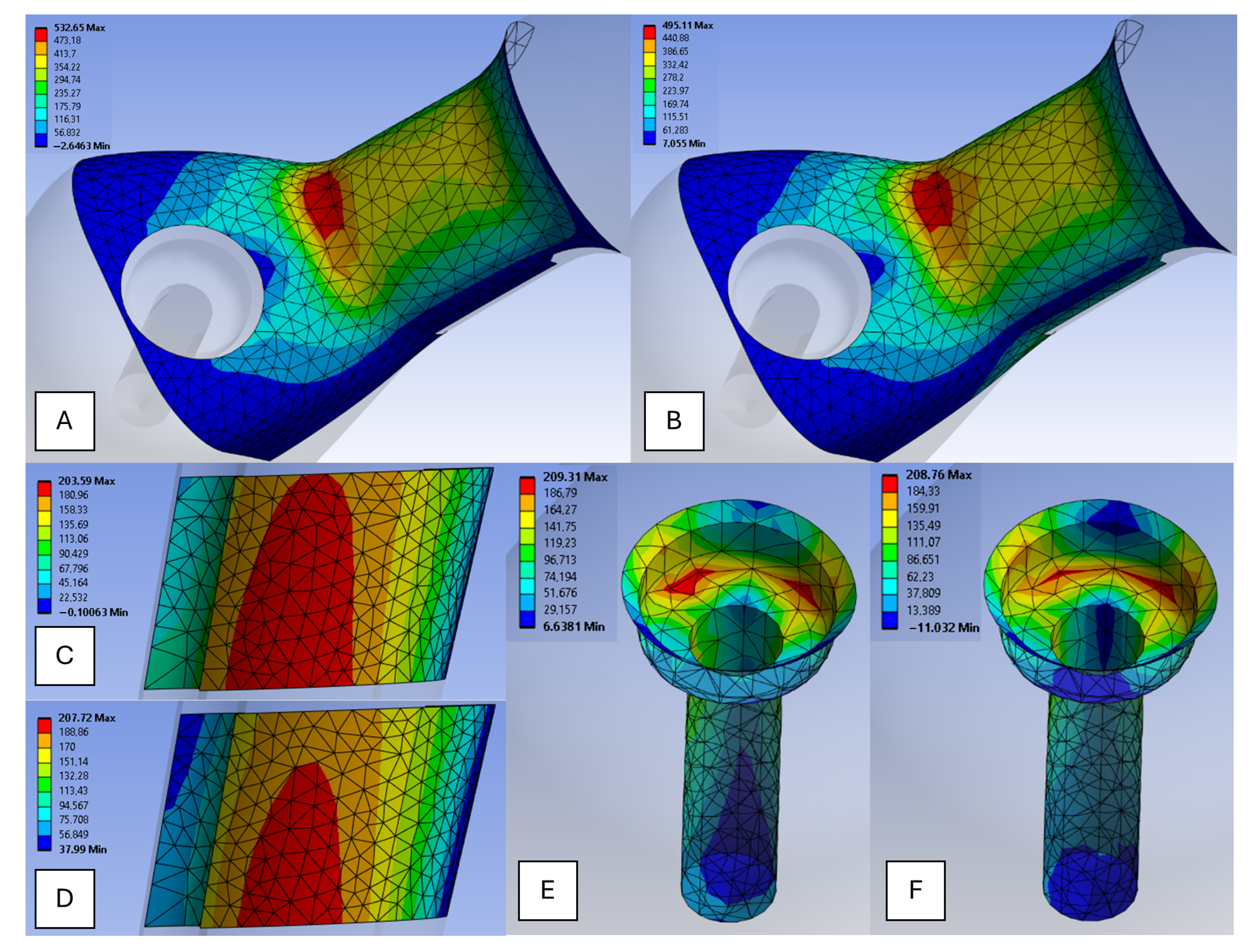

Starting with the neck region, shown in

Figure 5A,B, it can be observed that this is the most highly stressed area, due to its function in transferring loads from the implant head to the stem. Owing to its narrow geometry, the transition creates a condition of elevated stress, subjecting the region to significant bending and torsional forces during load application. This makes it a critical point for stress concentration. The combination of high loading and unfavorable geometric factors renders the neck particularly vulnerable.

As illustrated in

Figure 5E,F, the driver hole also exhibits stress accumulation, primarily due to its geometry and structural role. This region acts as a geometric notch, interrupting the continuity of the prosthesis and naturally creating a stress riser under loading conditions. Consequently, the stress distribution in the driver hole is non-uniform, with localized peaks concentrated in specific zones.

The potting level, shown in

Figure 5C,D, displays a much smoother stress distribution compared to the more critical regions such as the neck and driver hole. This behavior is attributable to the more uniform geometry of the potting area, which facilitates a gradual transfer of stresses from higher to lower values. As a result, the stress distribution in this region tends to be more balanced, with minimal concentration peaks.

The stresses shown in the contour map exhibit values significantly higher than those computed during the mesh sensitivity analysis. For example, in

Figure 5A, the Maximum Principal stress reaches a peak of 532 MPa, which has been excluded by applying the 97.5% percentile criterion. This approach discards extreme values that are not representative of the actual stress distribution (see Section Mesh and Sensitivity Analysis).

Table 6 summarizes the final results, highlighting the maximum stress values observed in the key regions of the prosthesis.

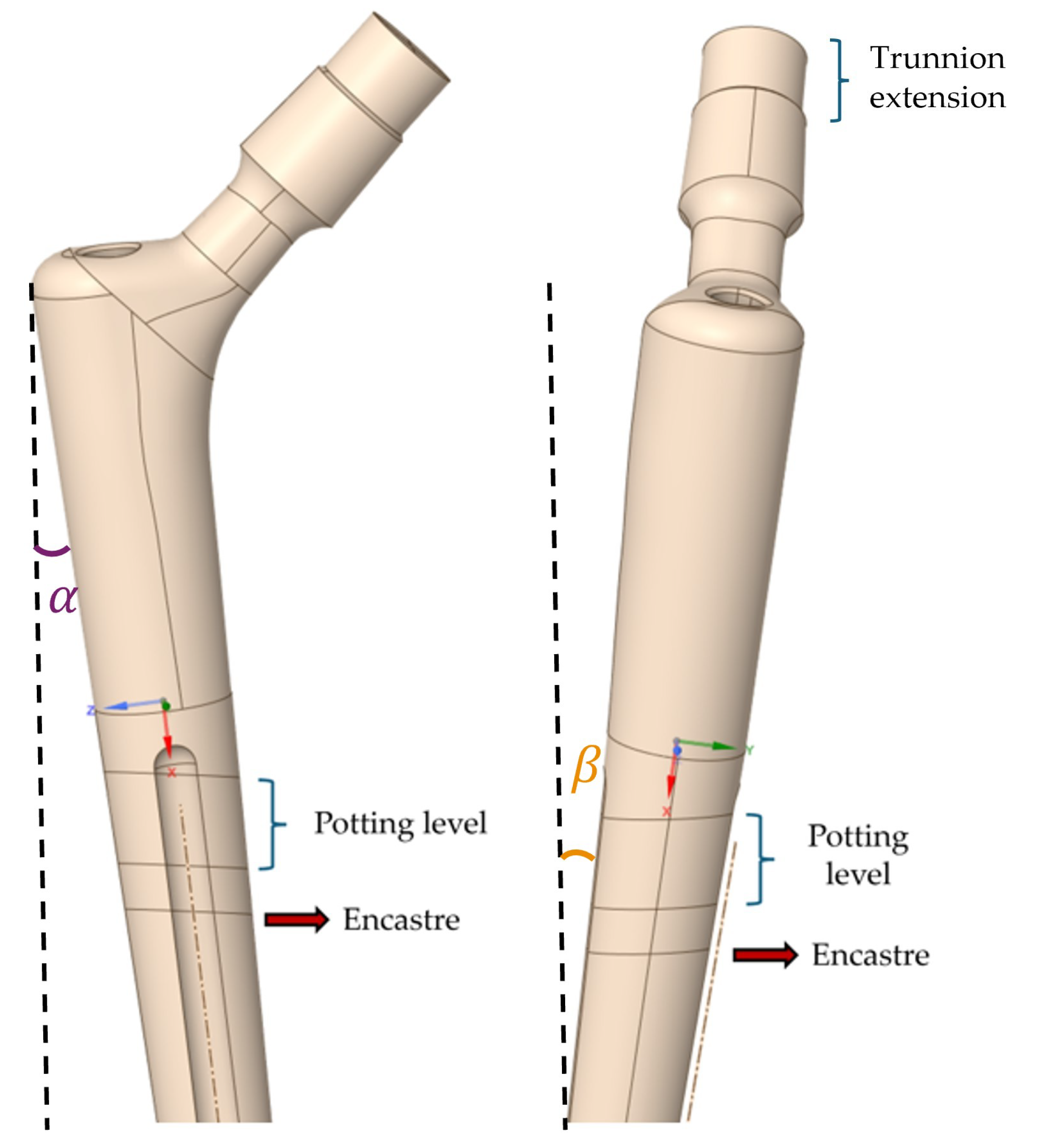

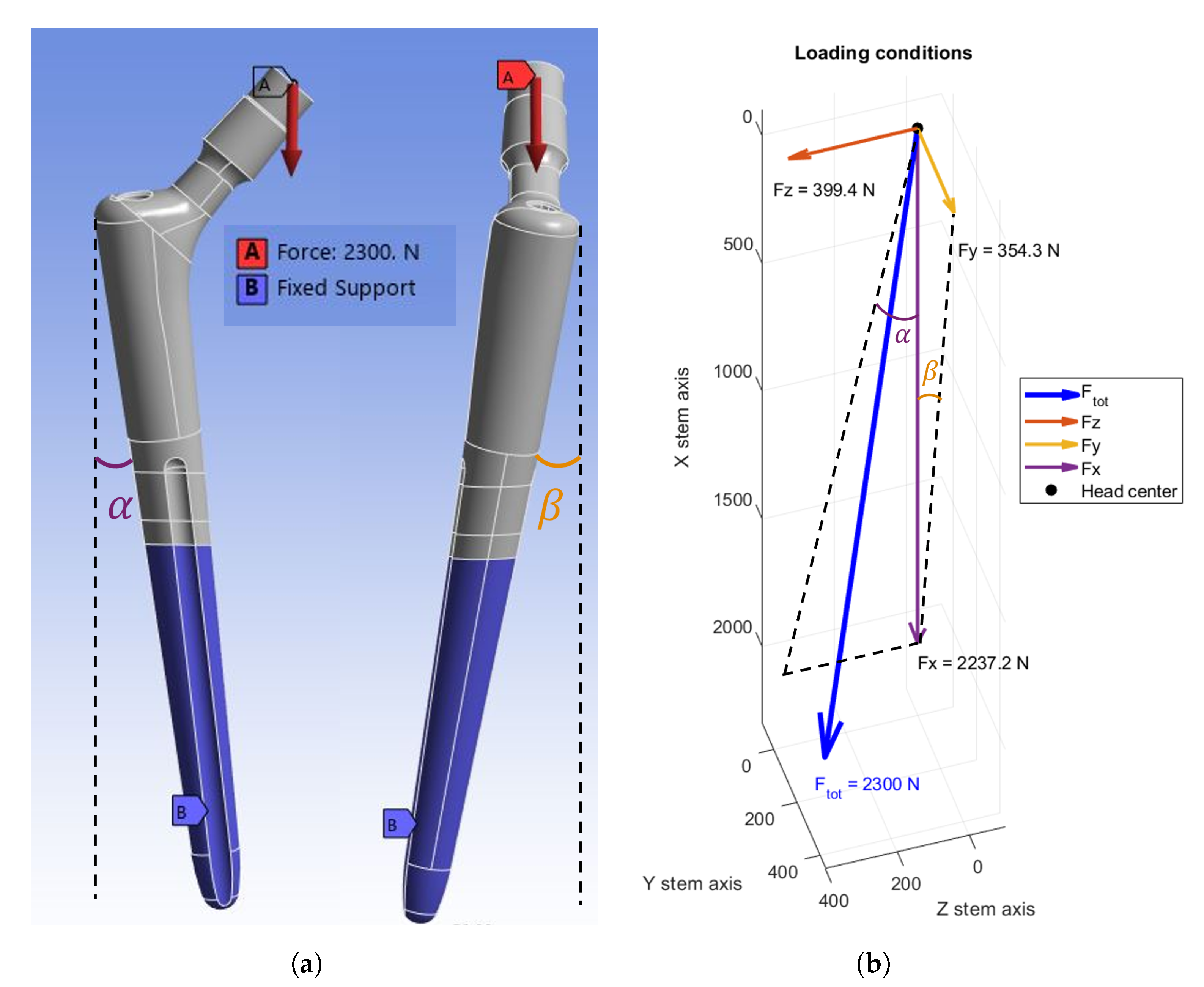

3.1. Hip Stem Orientation

The considered spectrum of possible combinations for the

and

angle variations consists of a 4 × 4 matrix, which reflects the force components described in

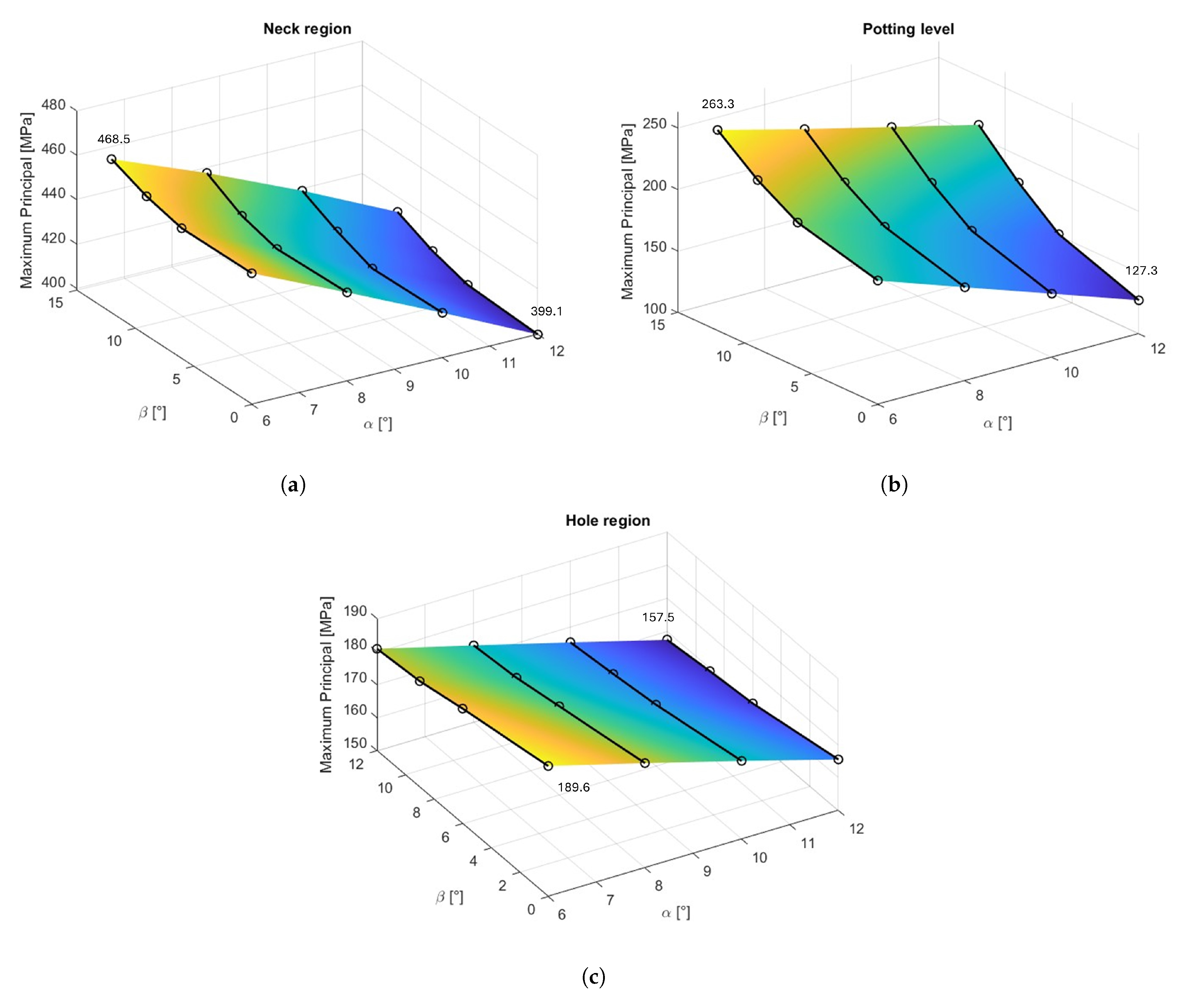

Section 2.2. The corresponding results are presented in

Figure 6, where the stress behavior in the three regions of interest is plotted using 3D curves. These curves are constructed based on the maximum stress values (97.5% percentile) obtained from each simulation.

The graph is composed of two axes representing the orientation angles, and a third axis displaying the corresponding stress values. The latter is also qualitatively conveyed through the surface color, which ranges from yellow (indicating higher stresses) to blue (indicating lower stresses). This surface map reveals a trend associated with the varying orientations of the prosthesis.

Table 7 reports the force values used to generate the figure above. At first glance, some differences can be observed between the regions: all exhibit the highest stress values at the lowest

angle (6°). However, with respect to the

angle, the behavior differs: the neck (

Figure 6a) and the potting level (

Figure 6b) reach their maximum stress at the highest

considered (12°), while for the driver hole region (

Figure 6c), the maximum is observed at the lowest

(0°). It can be inferred that the

component (corresponding to the out-of-frontal-plane direction) does not influence the hole region stress as significantly as it does in the other two regions. Due to the geometric configuration and the relative position of the hole with respect to the head center, the torsional effects introduced by

are less impactful compared to the bending effects caused by

. In contrast, for the neck and potting level,

plays a more prominent role.

To quantify the amplitude of stress variation, the two variables (

and

) are alternately held constant, allowing the dependence of the Maximum Principal stress on each angle to be analyzed independently across all regions. For example, by fixing

at a given value, the variation is computed between the stress values obtained at

° and

°; this procedure is repeated for each value of

. The same analysis is performed in reverse, fixing

and computing the variation between stresses at

° and

°. The results of these calculations are summarized in

Table 8.

From this table, the effect of the different prosthesis orientations for the three sets can be summarized in a few points:

When reducing the adduction angle , the stress is higher for all three regions;

The neck is the least affected region, and the maximum change (ca. 12%) is registered by varying the adduction angle;

The driver hole behaves similarly to the neck in terms of magnitude of variation, but it presents an opposite trend with the flexion angle , albeit with negligible effects;

The potting level is strongly dependent on both the adduction and flexion angles.

Based on these calculations, it can be concluded that the influence of the orientation angles is far from negligible when evaluating stress in the potting level region. For the other regions, the variation is also appreciable, with the angle playing a predominant role.

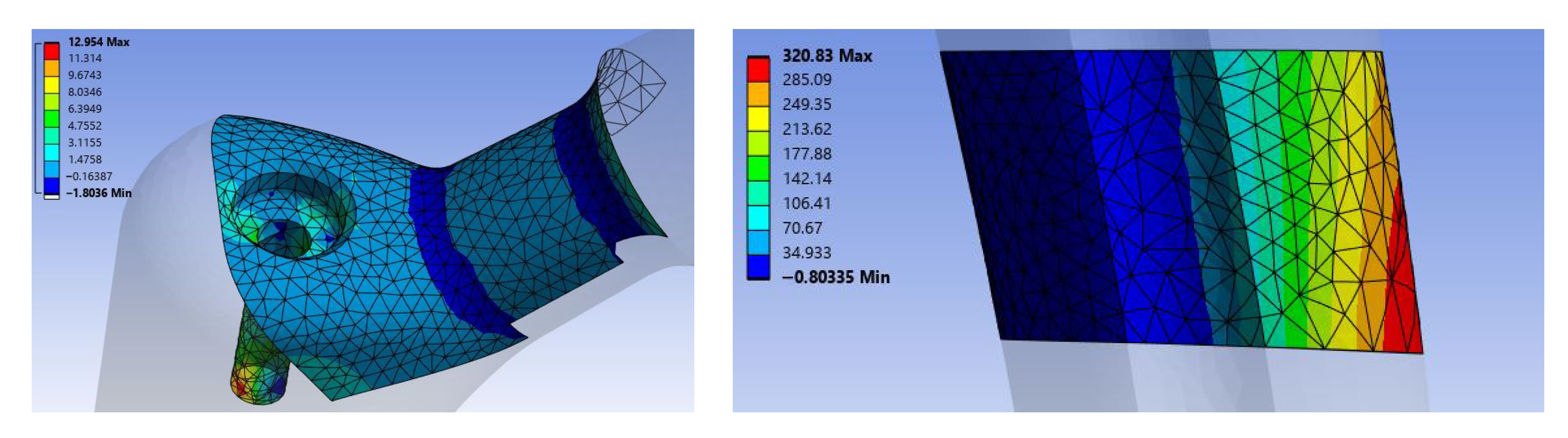

When the load is aligned with the neck axis, the stress distribution changes notably compared to the standard configuration (

Figure 7). Bending and torsional effects are minimized, reducing neck region stresses to around 10 MPa, far below values seen previously. Slightly higher stresses appear at the potting level, and the location of maximum stress shifts to the right side of the stem in the frontal view.

3.2. Trunnion Extension

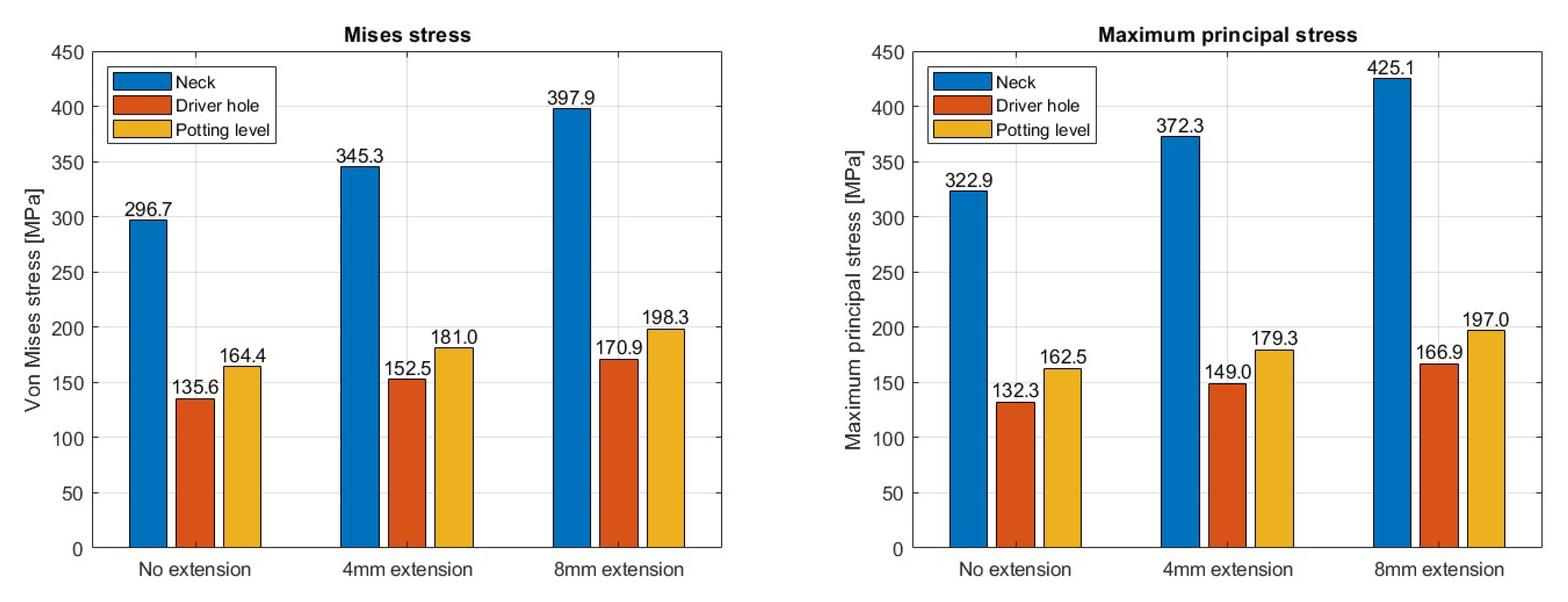

In this section, the results corresponding to the variations of the trunnion are presented. As shown in

Figure 8, both Von Mises stress and Maximum Principal were computed for each region: all the cases were obtained with the same approach as that described in

Section 2.1 regarding the 8mm extension.

As clearly expected, increasing the trunnion extension leads to higher stress values in all regions. Regarding the Maximum Principal stress, the trend is nearly linear, with increases of approximately 13%, 11%, and 9% for the neck, driver hole, and potting level, respectively. Notably, the neck is the most sensitive region, showing a substantial increase of about 24% when comparing the 8 mm extension to the no-extension case. These percentage changes refer to the Maximum Principal stress, but the Von Mises stress follows a similar trend.

In conclusion, the inclusion of the trunnion is a key factor that must be explicitly specified, as it significantly affects the peak stress values, even though it does not alter the overall stress distribution.