Assessment of Maximum Torque in Implant-Supported Prostheses: A Pilot Laboratory Study

Abstract

1. Introduction

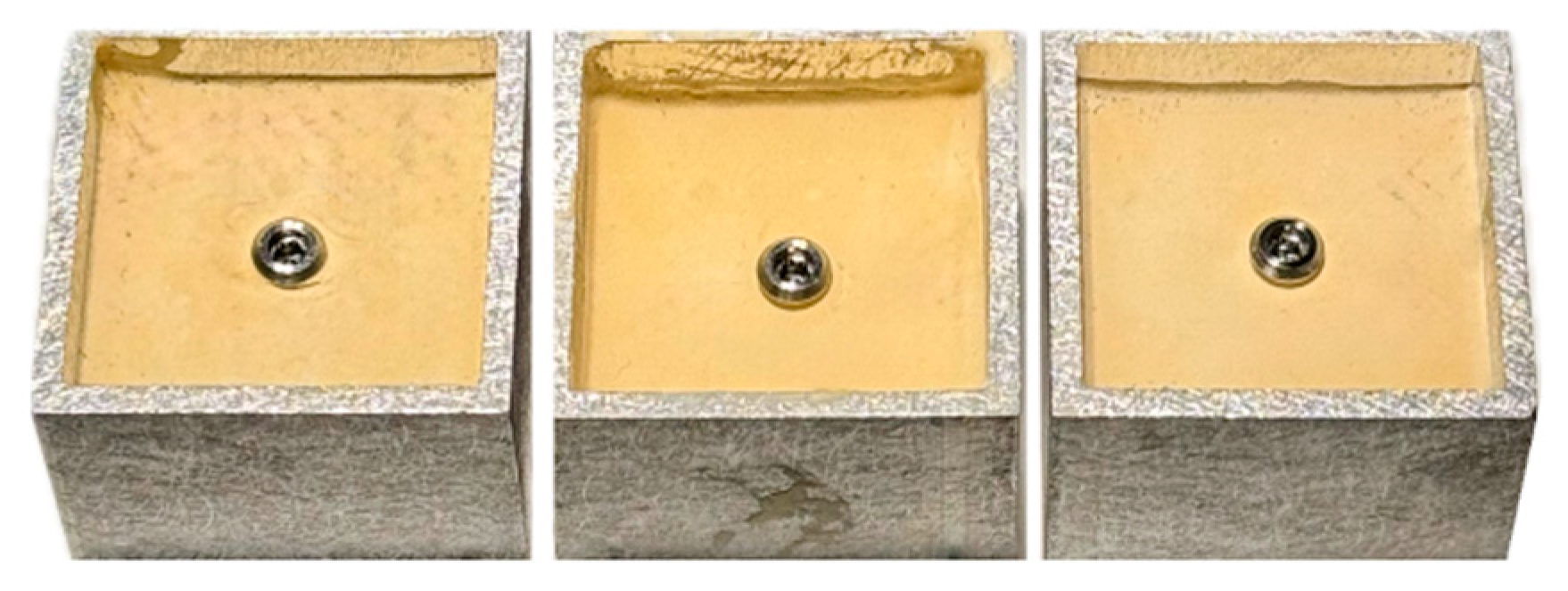

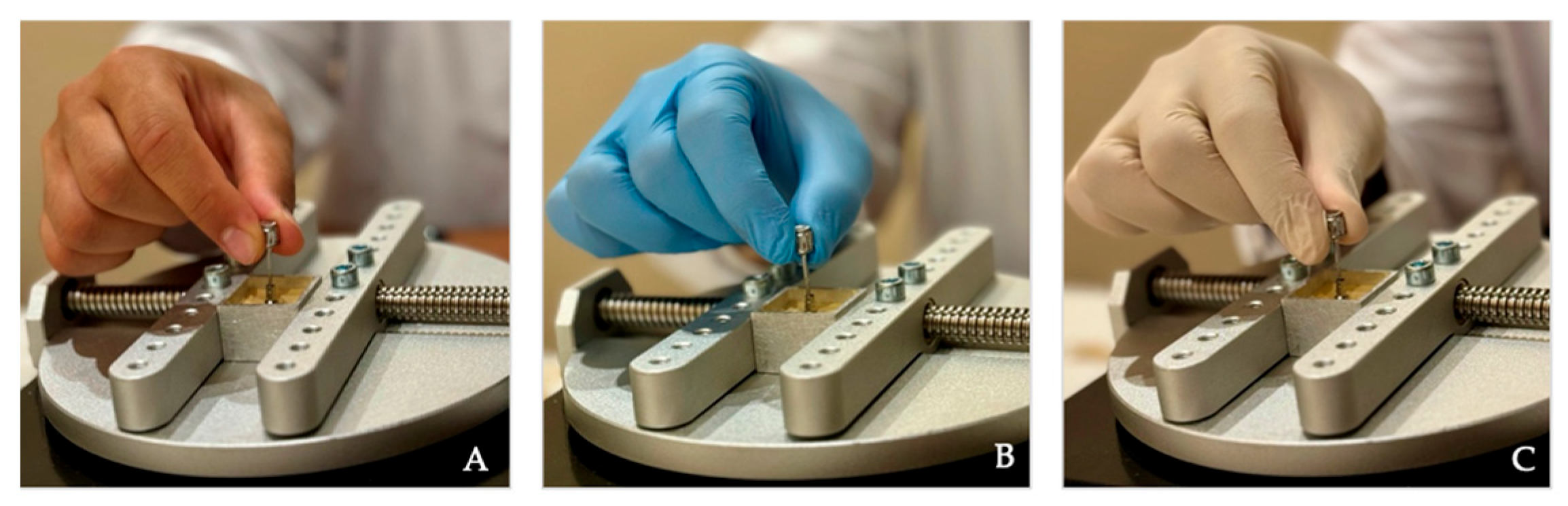

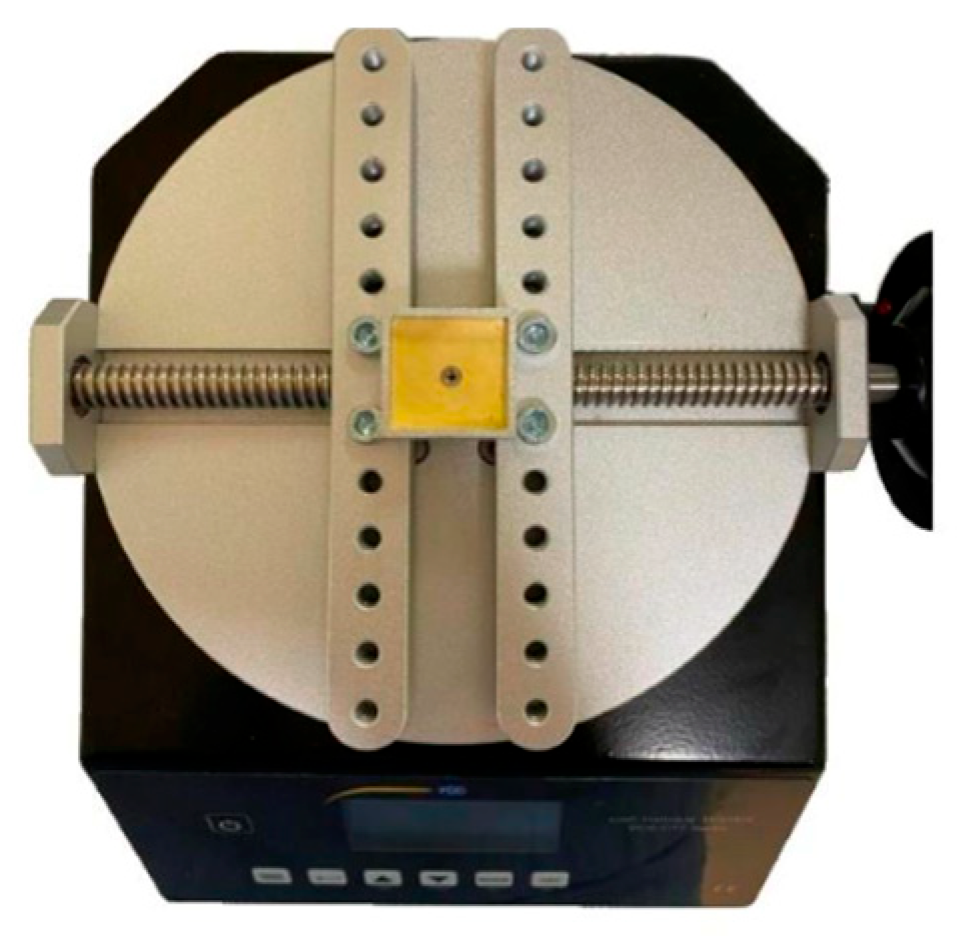

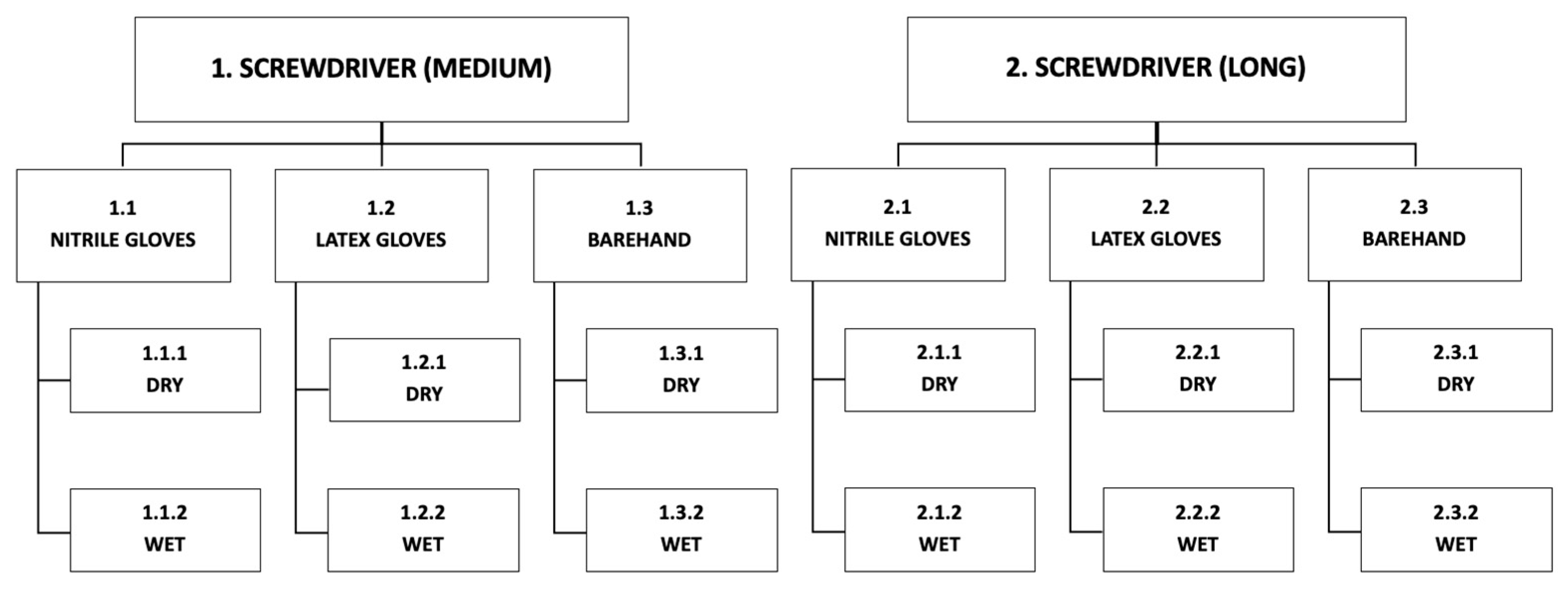

2. Materials and Methods

3. Results

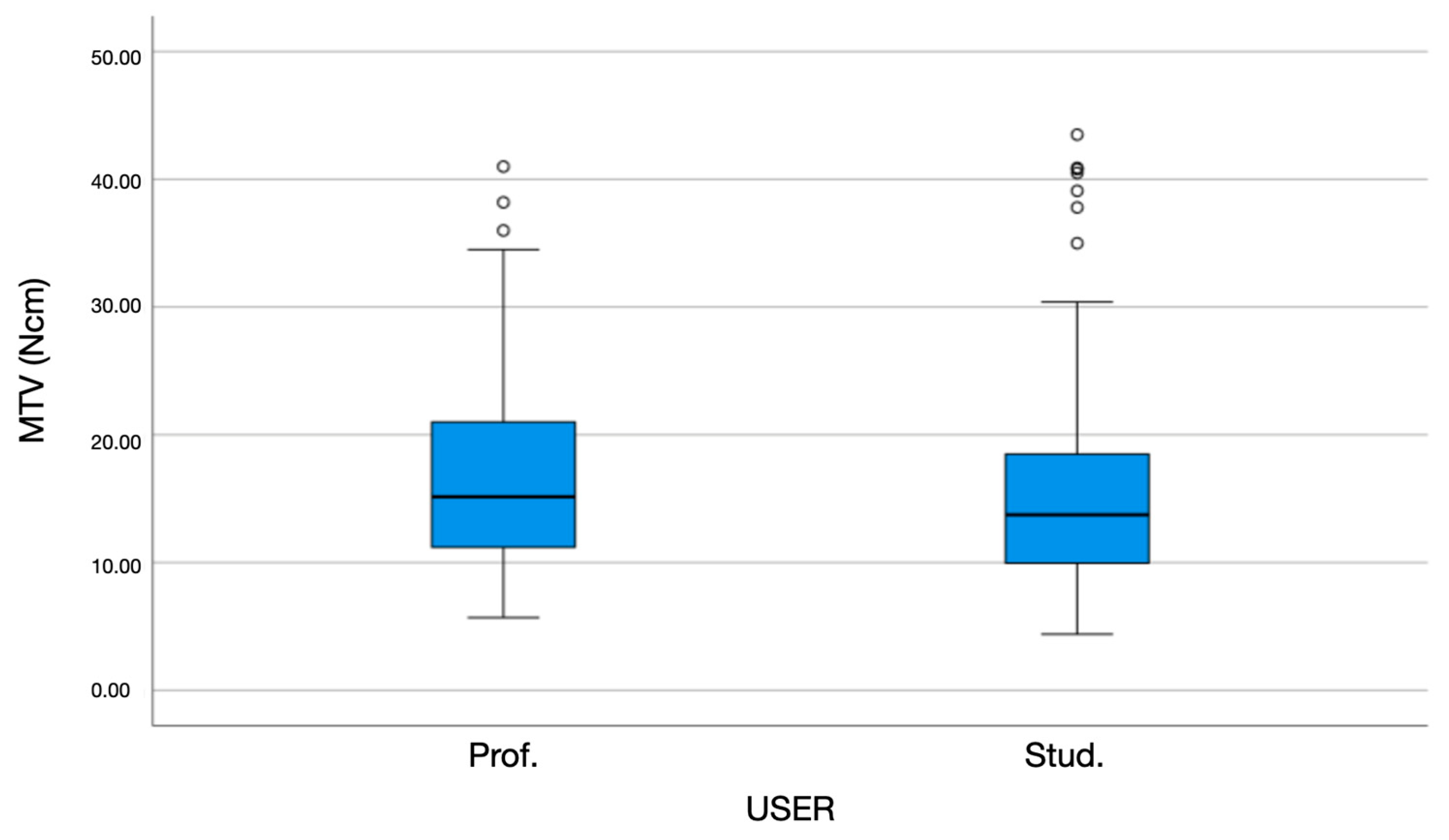

3.1. User Experience

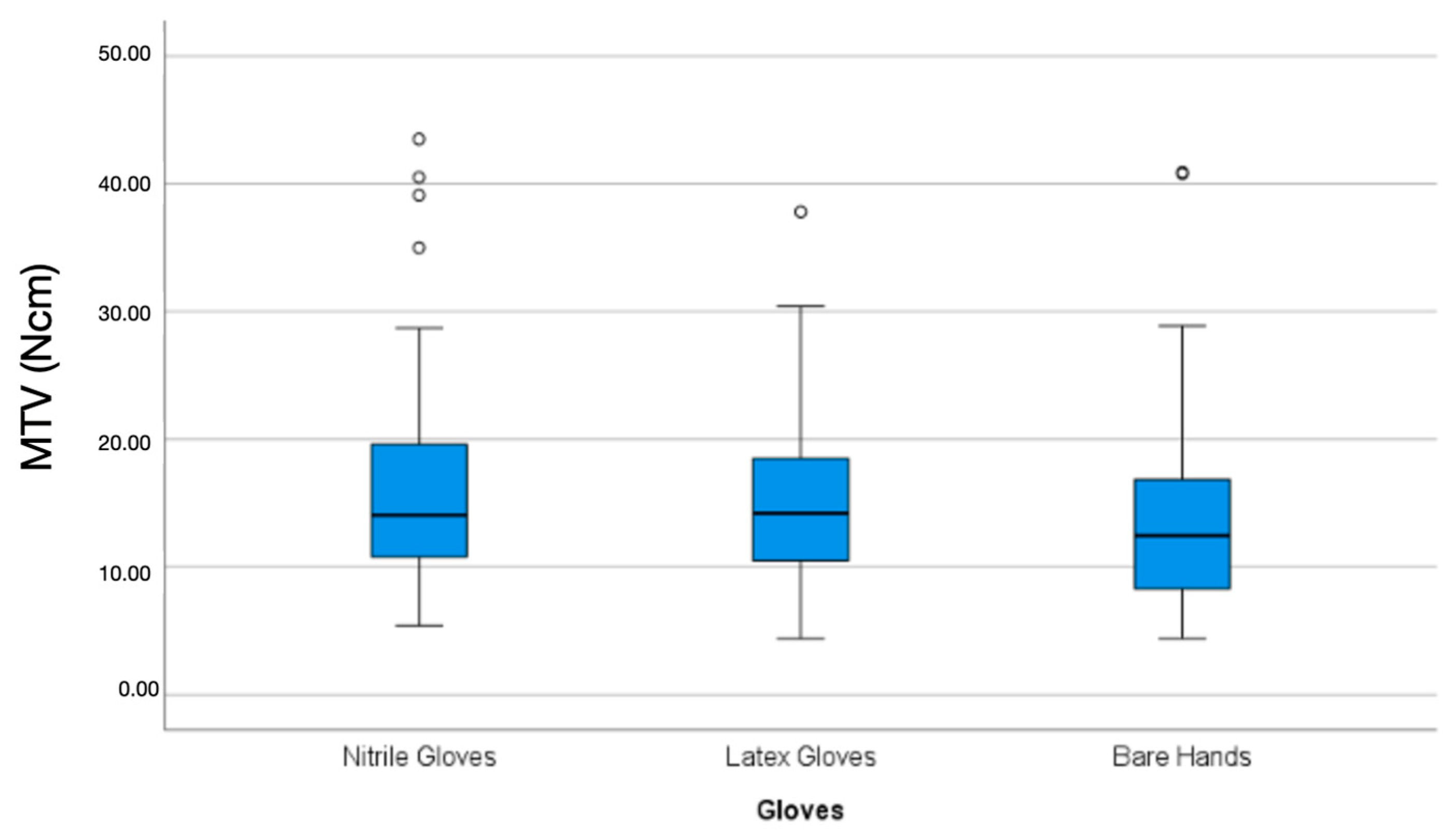

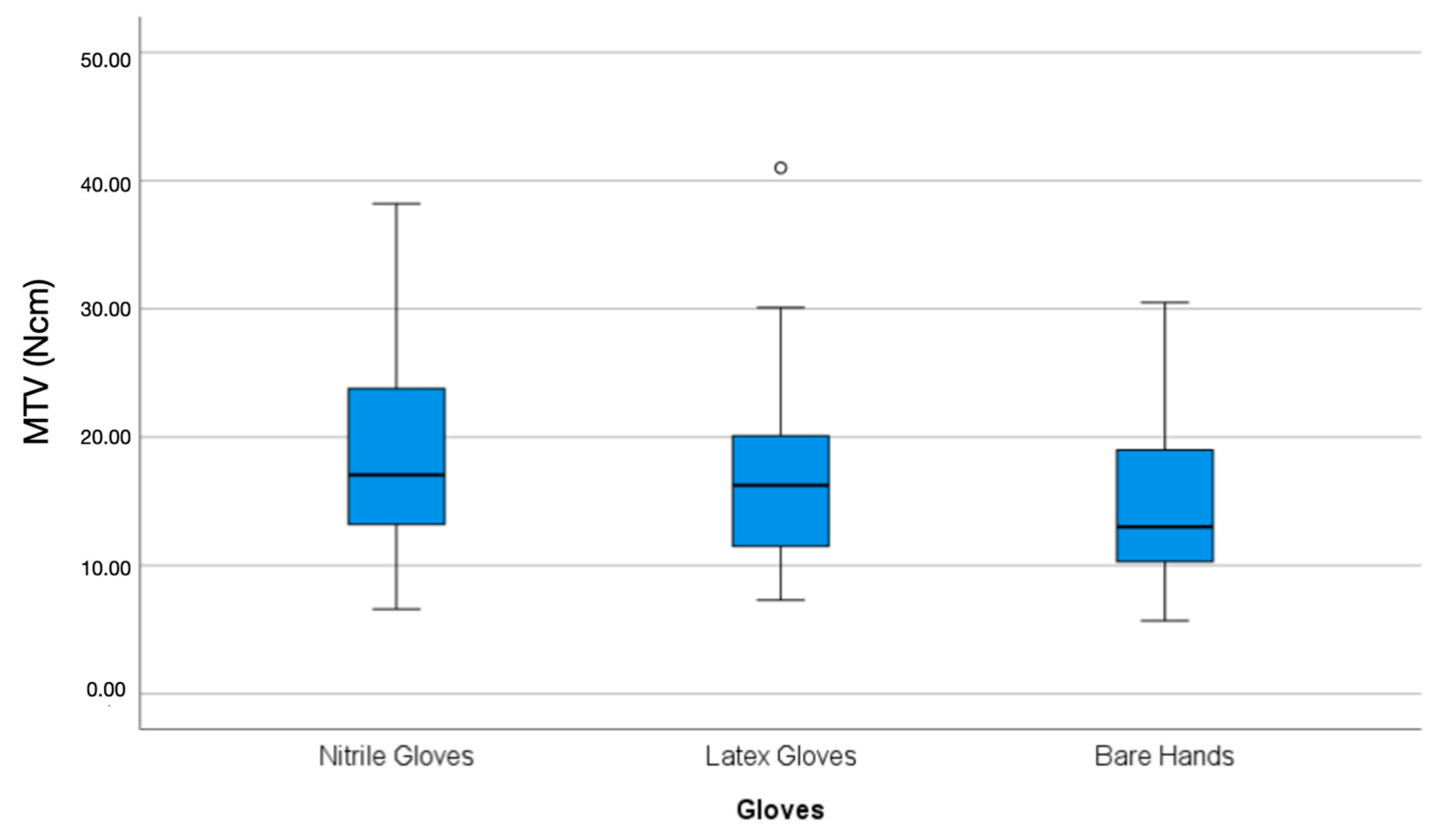

3.2. Glove Type

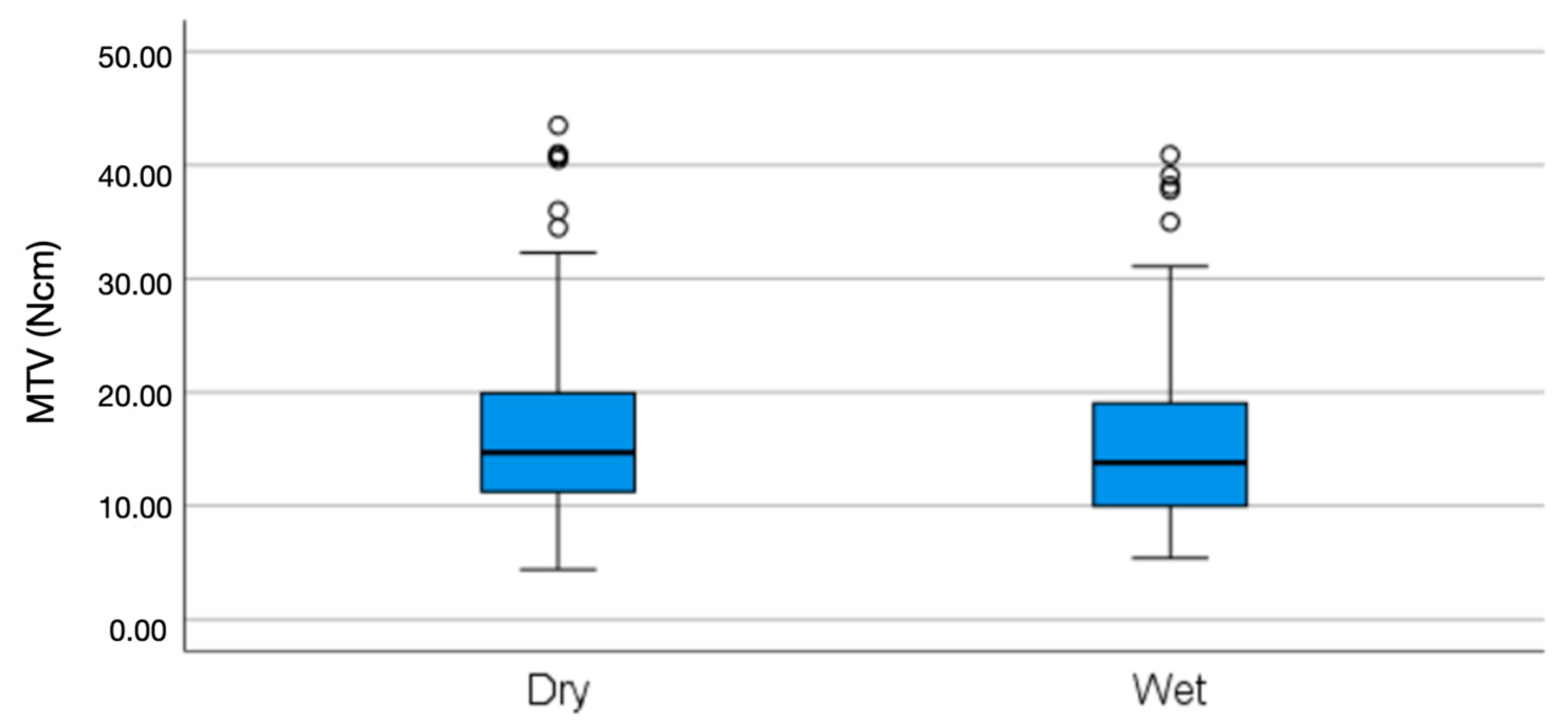

3.3. Moisture Condition

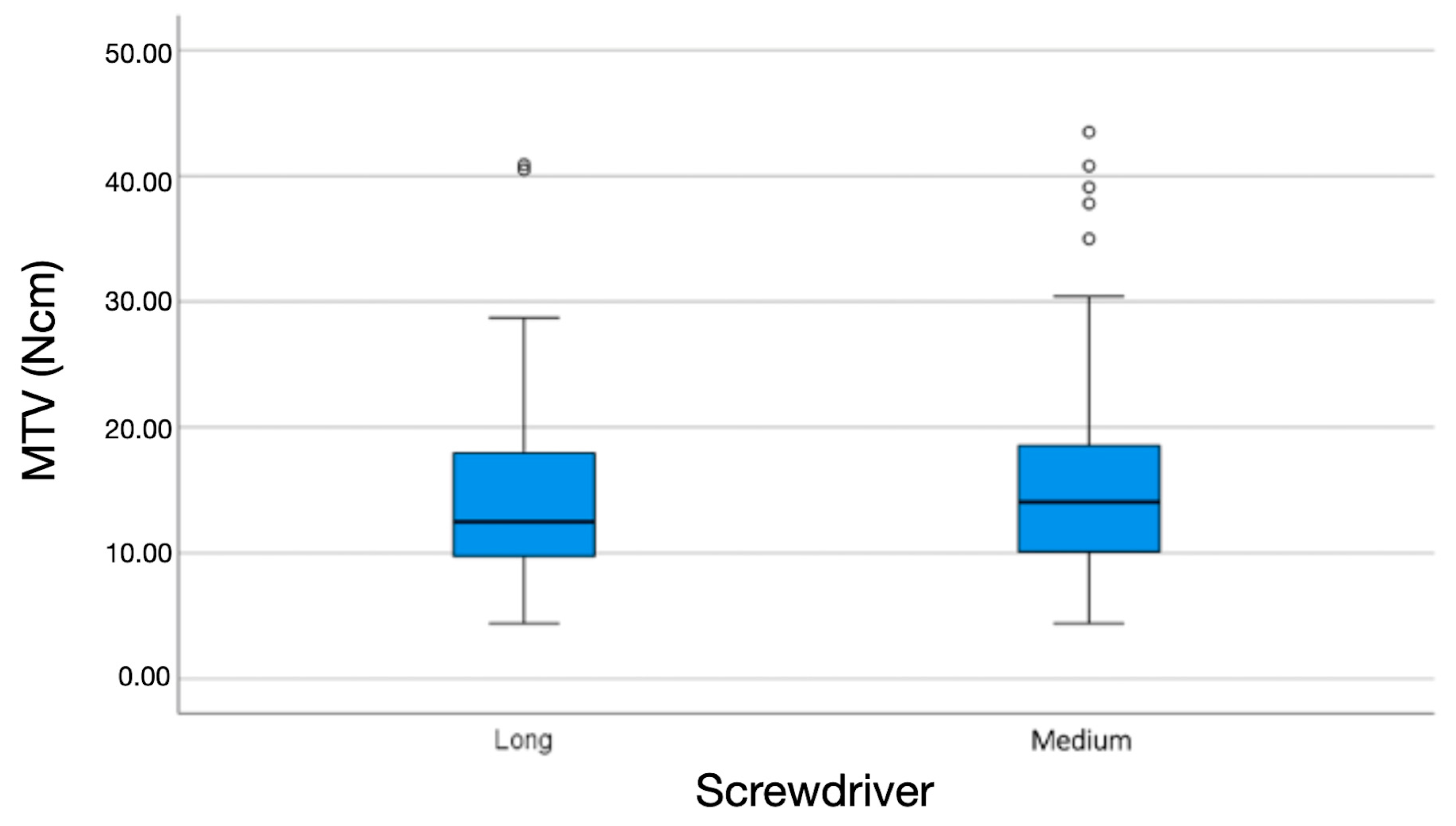

3.4. Screwdriver Length

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BMI | Body Mass Index |

| CES | Ethics Committee for Health |

| FMD-UCP | Faculty of Dental Medicine—Universidade Católica Portuguesa |

| MIMD | Integrated Master in Dental Medicine |

| MTV | Maximum torque value |

| Ncm | Newton centimeter (unit of torque) |

| PCE-CTT 2 | Model of the digital torque meter used (PCE Instruments™) |

| RT | Regular TorcFitTM (Straumann’s connection system) |

| SCS | Screw Carrying System |

References

- Zarb, G.A.; Schmitt, A. The longitudinal clinical effectiveness of osseointegrated dental implants: The Toronto study. Part III: Problems and complications encountered. J. Prosthet. Dent. 1990, 64, 185–194. [Google Scholar] [CrossRef] [PubMed]

- Adell, R.; Eriksson, B.; Lekholm, U.; Branemark, P.I.; Jemt, T. Long-term follow-up study of osseointegrated implants in the treatment of totally edentulous jaws. Int. J. Oral. Maxillofac. Implant. 1990, 5, 347–359. [Google Scholar]

- Buser, D.; Sennerby, L.; De Bruyn, H. Modern implant dentistry based on osseointegration: 50 years of progress, current trends and open questions. Periodontol. 2000 2017, 73, 7–21. [Google Scholar] [CrossRef] [PubMed]

- Pandey, C.; Rokaya, D.; Bhattarai, B.P. Contemporary Concepts in Osseointegration of Dental Implants: A Review. Biomed. Res. Int. 2022, 2022, 6170452. [Google Scholar] [CrossRef] [PubMed]

- Buser, D.; Ingimarsson, S.; Dula, K.; Lussi, A.; Hirt, H.P.; Belser, U.C. Long-term stability of osseointegrated implants in augmented bone: A 5-year prospective study in partially edentulous patients. Int. J. Periodontics Restor. Dent. 2002, 22, 109–117. [Google Scholar]

- Roehling, S.; Schlegel, K.A.; Woelfler, H.; Gahlert, M. Zirconia compared to titanium dental implants in preclinical studies-A systematic review and meta-analysis. Clin. Oral. Implant. Res. 2019, 30, 365–395. [Google Scholar] [CrossRef] [PubMed]

- Albrektsson, T.; Wennerberg, A. On osseointegration in relation to implant surfaces. Clin. Implant. Dent. Relat. Res. 2019, 21 (Suppl. S1), 4–7. [Google Scholar] [CrossRef] [PubMed]

- Romanos, G.E.; Aydin, E.; Locher, K.; Nentwig, G.H. Immediate vs. delayed loading in the posterior mandible: A split-mouth study with up to 15 years of follow-up. Clin. Oral. Implant. Res. 2016, 27, e74–e79. [Google Scholar] [CrossRef] [PubMed]

- Vercruyssen, M.; Laleman, I.; Jacobs, R.; Quirynen, M. Computer-supported implant planning and guided surgery: A narrative review. Clin. Oral. Implant. Res. 2015, 26 (Suppl. S11), 69–76. [Google Scholar] [CrossRef] [PubMed]

- Esposito, M.; Grusovin, M.G.; Willings, M.; Coulthard, P.; Worthington, H.V. The effectiveness of immediate, early, and conventional loading of dental implants: A Cochrane systematic review of randomized controlled clinical trials. Int. J. Oral. Maxillofac. Implant. 2007, 22, 893–904. [Google Scholar]

- Delben, J.A.; Goiato, M.C.; Gennari-Filho, H.; Goncalves Assuncao, W.; Dos Santos, D.M. Esthetics in implant-supported prostheses: A literature review. J. Oral. Implantol. 2012, 38, 718–722. [Google Scholar] [CrossRef] [PubMed]

- Jeong, Y.N. The Role and Importance of Soft Tissues for Long-Term Success of Dental Implants; Hassan, M., Ed.; Springer: Cham, Switherland, 2023. [Google Scholar]

- Chee, W.; Jivraj, S. Screw versus cemented implant supported restorations. Br. Dent. J. 2006, 201, 501–507. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.; Okayasu, K.; Wang, H.L. Screw- versus cement-retained implant restorations: Current concepts. Implant. Dent. 2010, 19, 8–15. [Google Scholar] [CrossRef] [PubMed]

- Michalakis, K.X.; Hirayama, H.; Garefis, P.D. Cement-retained versus screw-retained implant restorations: A critical review. Int. J. Oral. Maxillofac. Implant. 2003, 18, 719–728. [Google Scholar]

- Warreth, A.; McAleese, E.; McDonnell, P.; Slami, R.; Guray, S.M. Dental implants and single implant-supported restorations. J. Ir. Dent. Assoc. 2013, 59, 32–43. [Google Scholar] [PubMed]

- Misch, C.E. Chapter 21—Single-Tooth Implant Restoration: Maxillary Anterior and Posterior Regions. In Dental Implant Prosthetics, 2nd ed.; Misch, C.E., Ed.; Mosby: St. Louis, MO, USA, 2015; pp. 499–552. [Google Scholar]

- Preiskel, H.W.; Tsolka, P. Cement- and screw-retained implant-supported prostheses: Up to 10 years of follow-up of a new design. Int. J. Oral. Maxillofac. Implant. 2004, 19, 87–91. [Google Scholar]

- Hebel, K.S.; Gajjar, R.C. Cement-retained versus screw-retained implant restorations: Achieving optimal occlusion and esthetics in implant dentistry. J. Prosthet. Dent. 1997, 77, 28–35. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Wang, J. Mechanism of and factors associated with the loosening of the implant abutment screw: A review. J. Esthet. Restor. Dent. 2019, 31, 338–345. [Google Scholar] [CrossRef] [PubMed]

- Bousquet, P.; Bennasar, I.C.; Tramini, P.; Jacquemot, M.; Cuisinier, F. Tightening of healing abutments: Influence of torque on bacterial proliferation risk, an in vitro investigation. Biomed. Tech. 2014, 59, 495–500. [Google Scholar] [CrossRef] [PubMed]

- Alikhasi, M.; Kazemi, M.; Jalali, H.; Hashemzadeh, S.; Dodangeh, H.; Yilmaz, B. Clinician-generated torque on abutment screws using different hand screwdrivers. J. Prosthet. Dent. 2017, 118, 488–492. [Google Scholar] [CrossRef] [PubMed]

- Straumann®. Assembly Instructions for Ratchet and Torque Control Device; Straumann: Basel, Switzerland, 2020; p. 1. [Google Scholar]

- Schoenbaum, T.R. Implant Prosthodontics: Protocols and Techniques for Fixed Implant Restorations, 1st ed.; Quintessence Publishing Co., Inc.: Batavia, IL, USA, 2021. [Google Scholar]

- Barone, A.; Alfonsi, F.; Derchi, G.; Tonelli, P.; Toti, P.; Marchionni, S.; Covani, U. The Effect of Insertion Torque on the Clinical Outcome of Single Implants: A Randomized Clinical Trial. Clin. Implant. Dent. Relat. Res. 2016, 18, 588–600. [Google Scholar] [CrossRef] [PubMed]

- Khaohoen, A.; Sornsuwan, T.; Chaijareenont, P.; Poovarodom, P.; Rungsiyakull, C.; Rungsiyakull, P. Biomaterials and Clinical Application of Dental Implants in Relation to Bone Density-A Narrative Review. J. Clin. Med. 2023, 12, 6924. [Google Scholar] [CrossRef] [PubMed]

- Alsubaiy, E.F. Abutment screw loosening in implants: A literature review. J. Fam. Med. Prim. Care 2020, 9, 5490–5494. [Google Scholar] [CrossRef] [PubMed]

- Guzaitis, K.L.; Knoernschild, K.L.; Viana, M.A. Effect of repeated screw joint closing and opening cycles on implant prosthetic screw reverse torque and implant and screw thread morphology. J. Prosthet. Dent. 2011, 106, 159–169. [Google Scholar] [CrossRef] [PubMed]

- Xia, D.; Lin, H.; Yuan, S.; Bai, W.; Zheng, G. Dynamic fatigue performance of implant-abutment assemblies with different tightening torque values. Biomed. Mater. Eng. 2014, 24, 2143–2149. [Google Scholar] [CrossRef] [PubMed]

- Shin, H.M.; Huh, J.B.; Yun, M.J.; Jeon, Y.C.; Chang, B.M.; Jeong, C.M. Influence of the implant-abutment connection design and diameter on the screw joint stability. J. Adv. Prosthodont. 2014, 6, 126–132. [Google Scholar] [CrossRef] [PubMed]

- Hanif, A.; Qureshi, S.; Sheikh, Z.; Rashid, H. Complications in implant dentistry. Eur. J. Dent. 2017, 11, 135–140. [Google Scholar] [CrossRef] [PubMed]

- Nishiuchi, T.; Sato, Y.; Kitagawa, N.; Osawa, T.; Isobe, A.; Shiba, H. Factors determining maximum torque and achievement of the recommended torque for manual implant drivers: A pilot study. Showa Univ. J. Med. Sci. 2021, 33, 82–87. [Google Scholar] [CrossRef]

- Zare, A.; Choobineh, A.; Jahangiri, M.; Malakoutikhah, M. How do medical gloves affect manual performance? Evaluation of ergonomic indicators. Int. J. Ind. Ergon. 2020, 81, 103062. [Google Scholar] [CrossRef]

- Jiries, Y.; Brosh, T.; Matalon, S.; Perlis, V.; Ormianer, Z. Effects of Aging Torque Controllers on Screw Tightening Force and Bacterial Micro-Leakage on the Implant-Abutment Complex. Materials 2022, 15, 620. [Google Scholar] [CrossRef] [PubMed]

- Yilmaz, B.; L’Homme-Langlois, E.; Beck, F.M.; McGlumphy, E. Effect of long-term steam autoclaving on changes in torque delivery of spring- and friction-type torque wrenches. J. Prosthet. Dent. 2016, 115, 718–721. [Google Scholar] [CrossRef] [PubMed]

- Erdem, M.A.; Karatasli, B.; Dincer Kose, O.; Kose, T.E.; Cene, E.; Aydin Aya, S.; Cankaya, A.B. The Accuracy of New and Aged Mechanical Torque Devices Employed in Five Dental Implant Systems. Biomed. Res. Int. 2017, 2017, 8652720. [Google Scholar] [CrossRef] [PubMed]

- Rajatihaghi, H.; Ghanbarzadeh, J.; Daneshsani, N.; Sahebalam, R.; Nakhaee, M.R. The Accuracy of Various Torque Wrenches Used in Dental Implant Systems. J. Dent. Mater. Tech. 2013, 2, 38–44. [Google Scholar]

- Kanawati, A.; Richards, M.W.; Becker, J.J.; Monaco, N.E. Measurement of clinicians’ ability to hand torque dental implant components. J. Oral. Implantol. 2009, 35, 185–188. [Google Scholar] [CrossRef] [PubMed]

- Parnia, F.; Yazdani, J.; Fakour, P.; Mahboub, F.; Vahid Pakdel, S.M. Comparison of the maximum hand-generated torque by professors and postgraduate dental students for tightening the abutment screws of dental implants. J. Dent. Res. Dent. Clin. Dent. Prospect. 2018, 12, 190–195. [Google Scholar] [CrossRef] [PubMed]

- Mylon, P.; Lewis, R.; Carré, M.J.; Martin, N. A critical review of glove and hand research with regard to medical glove design. Ergonomics 2014, 57, 116–129. [Google Scholar] [CrossRef] [PubMed]

- Sung, P.C. Effects of glovebox gloves on grip and key pinch strength and contact forces for simulated manual operations with three commonly used hand tools. Ergonomics 2014, 57, 1512–1525. [Google Scholar] [CrossRef] [PubMed]

- Jaarda, M.J.; Razzoog, M.E.; Gratton, D.G. Providing optimum torque to implant prostheses: A pilot study. Implant. Dent. 1993, 2, 50–52. [Google Scholar] [CrossRef] [PubMed]

- Haack, J.E.; Sakaguchi, R.L.; Sun, T.; Coffey, J.P. Elongation and preload stress in dental implant abutment screws. Int. J. Oral. Maxillofac. Implant. 1995, 10, 529–536. [Google Scholar]

- Yilmaz, B.; L’Homme-Langlois, E.; Beck, F.M.; McGlumphy, E. Accuracy of mechanical torque-limiting devices for dental implants after clinical service. J. Prosthet. Dent. 2015, 114, 378–382. [Google Scholar] [CrossRef] [PubMed]

- Albayrak, S.; Gul, C. Ceramic Coatings for Biomedical Applications. In Fiber and Ceramic Filler-Based Polymer Composites for Biomedical Engineering; Parameswaranpillai, J., Ganguly, S., Das, P., Gopi, J.A., Eds.; Springer Nature: Singapore, 2024; pp. 233–256. [Google Scholar]

- Ganguly, S.; Margel, S. Magnetic Polymeric Conduits in Biomedical Applications. Micromachines 2025, 16, 174. [Google Scholar] [CrossRef] [PubMed]

| TIMESTAMP | PROFESSORS (n) | MEDIUM SCREWDRIVER (Ncm) | LONG SCREWDRIVER (Ncm) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nitrile | Latex | Bare Hand | Nitrile | Latex | Bare Hand | ||||||||

| Dry | Wet | Dry | Wet | Dry | Wet | Dry | Wet | Dry | Wet | Dry | Wet | ||

| 06.05.25 9–9:30 | Prof-1 | 12.9 | 20.0 | 18.8 | 10.9 | 11.4 | 10.2 | 14.8 | 11.0 | 11.1 | 11.7 | 8.2 | 11.8 |

| 06.05.25 9:30–10 | Prof-2 | 14.6 | 15.3 | 21.2 | 12.1 | 15.8 | 16.0 | 22.5 | 19.2 | 17.6 | 19.4 | 13.8 | 13.3 |

| 06.05.25 10–10:30 | Prof-3 | 36.0 | 27.8 | 18.7 | 10.7 | 20.8 | 19.7 | 32.3 | 21.3 | 8.2 | 8.6 | 10.9 | 8.9 |

| 06.05.25 10:30–11 | Prof-4 | 7.3 | 6.6 | 22.4 | 14.8 | 9.6 | 11.7 | 12.3 | 9.7 | 29.3 | 20.8 | 15.3 | 21.8 |

| 06.05.25 11–11:30 | Prof-5 | 14.6 | 10.7 | 7.4 | 9.6 | 6.4 | 5.6 | 14.1 | 10.8 | 7.3 | 7.4 | 7.9 | 6.0 |

| 06.05.25 11:30–12 | Prof-6 | 11.7 | 15.8 | 18.3 | 30.1 | 10.9 | 10.1 | 13.5 | 15.6 | 18.3 | 21.4 | 12.3 | 11.4 |

| 06.05.25 14–14:30 | Prof-7 | 27.0 | 18.4 | 17.8 | 18.0 | 20.2 | 18.4 | 24.1 | 21.2 | 15.0 | 17.5 | 11.1 | 10.4 |

| 06.05.25 14:30–15 | Prof-8 | 34.5 | 38.2 | 41.0 | 28.9 | 30.5 | 23.1 | 30.5 | 31.1 | 25.0 | 26.4 | 29.8 | 19.6 |

| 06.05.25 15–15.30 | Prof-9 | 20.1 | 15.7 | 18.1 | 12.6 | 13.5 | 16.3 | 22.0 | 10.8 | 13.6 | 14.5 | 12.7 | 7.8 |

| 06.05.25 15:30–16 | Prof-10 | 29.4 | 29.4 | 13.6 | 11.7 | 28.7 | 24.5 | 23.5 | 16.1 | 11.3 | 13.8 | 14.0 | 14.1 |

| TOTAL VALUE (Ncm) | 19.67 | 19.79 | 19.73 | 15.94 | 16.78 | 15.57 | 20.96 | 16.68 | 15.67 | 16.15 | 13.60 | 12.51 | |

| TIMESTAMP | STUDENTS | MEDIUM SCREWDRIVER (Ncm) | LONG SCREWDRIVER (Ncm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nitrile | Latex | Bare Hand | Nitrile | Latex | Bare Hand | |||||||||

| n | Graduation Year | Dry | Wet | Dry | Wet | Dry | Wet | Dry | Wet | Dry | Wet | Dry | Wet | |

| 07.05.2025 9–9:30 | S-1 | 4 | 16.4 | 14.0 | 24.5 | 16.9 | 12.2 | 9.5 | 16.1 | 19.6 | 13.7 | 24.0 | 11.3 | 10.0 |

| 07.05.2025 9:30–10 | S-2 | 4 | 18.5 | 19.3 | 30.4 | 29.5 | 16.1 | 15.6 | 17.2 | 15.2 | 25.3 | 28.2 | 11.9 | 10.0 |

| 07.05.2025 10–10:30 | S-3 | 4 | 15.6 | 10.1 | 13.8 | 14.8 | 20.0 | 9.9 | 11.8 | 12.3 | 11.1 | 11.9 | 9.4 | 7.5 |

| 07.05.2025 10:30–11 | S-4 | 4 | 18.5 | 20.6 | 18.6 | 16.2 | 13.6 | 8.1 | 28.5 | 23.8 | 15.6 | 18.6 | 14.1 | 11.7 |

| 07.05.2025 11–11:30 | S-5 | 4 | 16.2 | 11.6 | 21.5 | 18.0 | 9.2 | 5.7 | 17.1 | 14.9 | 21.6 | 15.5 | 13.2 | 8.5 |

| 07.05.2025 11:30–12 | S-6 | 4 | 8.3 | 13.3 | 13.7 | 14.8 | 8.1 | 17.3 | 10.8 | 9.4 | 9.5 | 14.4 | 12.6 | 14.8 |

| 07.05.2025 14–14:30 | S-7 | 4 | 9.8 | 10.8 | 12.1 | 10.8 | 7.6 | 6.5 | 9.7 | 11.0 | 10.8 | 12.1 | 4.6 | 7.0 |

| 07.05.2025 14:30–15 | S-8 | 4 | 16.6 | 9.1 | 9.1 | 8.6 | 8.1 | 15.5 | 24.2 | 11.5 | 14.8 | 7.3 | 11.9 | 6.7 |

| 07.05.2025 15–15:30 | S-9 | 4 | 21.2 | 35.0 | 17.2 | 17.7 | 24.1 | 25.3 | 22.4 | 28.2 | 14.9 | 25.3 | 15.3 | 27.6 |

| 07.05.2025 15:30–16 | S-10 | 4 | 14.6 | 20.1 | 15.6 | 17.4 | 11.4 | 9.9 | 26.0 | 13.9 | 17.5 | 11.3 | 19.9 | 15.1 |

| 08.05.2025 9–9:30 | S-11 | 5 | 14.8 | 12.9 | 22.1 | 14.0 | 17.4 | 13.2 | 6.9 | 9.8 | 12.2 | 10.6 | 11.6 | 10.2 |

| 08.05.2025 9:30–10 | S-12 | 5 | 13.3 | 10.2 | 18.8 | 11.6 | 6.7 | 6.8 | 11.6 | 6.1 | 8.8 | 8.3 | 7.4 | 9.2 |

| 08.05.2025 10–10:30 | S-13 | 5 | 12.6 | 10.9 | 11.4 | 7.5 | 4.4 | 14.3 | 5.4 | 7.0 | 9.3 | 5.8 | 5.7 | 5.6 |

| 08.05.2025 10:30–11 | S-14 | 5 | 10.1 | 13.8 | 6.8 | 12.4 | 7.6 | 5.6 | 12.2 | 11.3 | 5.8 | 6.2 | 13.2 | 15.4 |

| 08.05.2025 11–11:30 | S-15 | 5 | 11.8 | 14.1 | 15.3 | 16.1 | 18.3 | 18.9 | 14.2 | 11.8 | 12.4 | 6.9 | 18.9 | 15.2 |

| 08.05.2025 11:30–12 | S-16 | 5 | 6.3 | 8.7 | 5.1 | 6.8 | 11.4 | 5.4 | 14.6 | 8.0 | 4.4 | 8.0 | 11.2 | 7.5 |

| 08.05.2025 14–14:30 | S-17 | 5 | 10.8 | 6.9 | 13.2 | 5.9 | 22.9 | 15.0 | 15.3 | 9.1 | 16.1 | 11.3 | 18.5 | 15.5 |

| 08.05.2025 14:30–15 | S-18 | 5 | 23.5 | 39.3 | 11.1 | 37.8 | 28.9 | 28.3 | 24.4 | 26.0 | 10.4 | 20.5 | 22.3 | 40.9 |

| 08.05.2025 15_15:30 | S-19 | 5 | 43.5 | 28.7 | 16.9 | 23.0 | 24.8 | 23.2 | 40.5 | 24.3 | 18.4 | 23.9 | 16.4 | 16.1 |

| 08.05.2025 15:30–16 | S-20 | 5 | 16.6 | 13.2 | 23.9 | 23.0 | 40.8 | 12.3 | 19.6 | 19.7 | 28.7 | 10.3 | 20.8 | 14.6 |

| TOTAL VALUE (Ncm) | 15.94 | 16.12 | 16.05 | 16.14 | 15.68 | 13.31 | 17.42 | 14.64 | 14.06 | 14.02 | 13.51 | 13.45 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaffashian, M.; Fazaeli, S.; Fialho, J.; Araújo, F.; Fonseca, P.; Correia, A. Assessment of Maximum Torque in Implant-Supported Prostheses: A Pilot Laboratory Study. Prosthesis 2025, 7, 83. https://doi.org/10.3390/prosthesis7040083

Kaffashian M, Fazaeli S, Fialho J, Araújo F, Fonseca P, Correia A. Assessment of Maximum Torque in Implant-Supported Prostheses: A Pilot Laboratory Study. Prosthesis. 2025; 7(4):83. https://doi.org/10.3390/prosthesis7040083

Chicago/Turabian StyleKaffashian, Mahoor, Seyedfarzad Fazaeli, Joana Fialho, Filipe Araújo, Patrícia Fonseca, and André Correia. 2025. "Assessment of Maximum Torque in Implant-Supported Prostheses: A Pilot Laboratory Study" Prosthesis 7, no. 4: 83. https://doi.org/10.3390/prosthesis7040083

APA StyleKaffashian, M., Fazaeli, S., Fialho, J., Araújo, F., Fonseca, P., & Correia, A. (2025). Assessment of Maximum Torque in Implant-Supported Prostheses: A Pilot Laboratory Study. Prosthesis, 7(4), 83. https://doi.org/10.3390/prosthesis7040083