Development of a 6-DoF Driving Simulator with an Open-Source Architecture for Automated Driving Research and Standardized Testing

Abstract

1. Introduction

2. Related Work

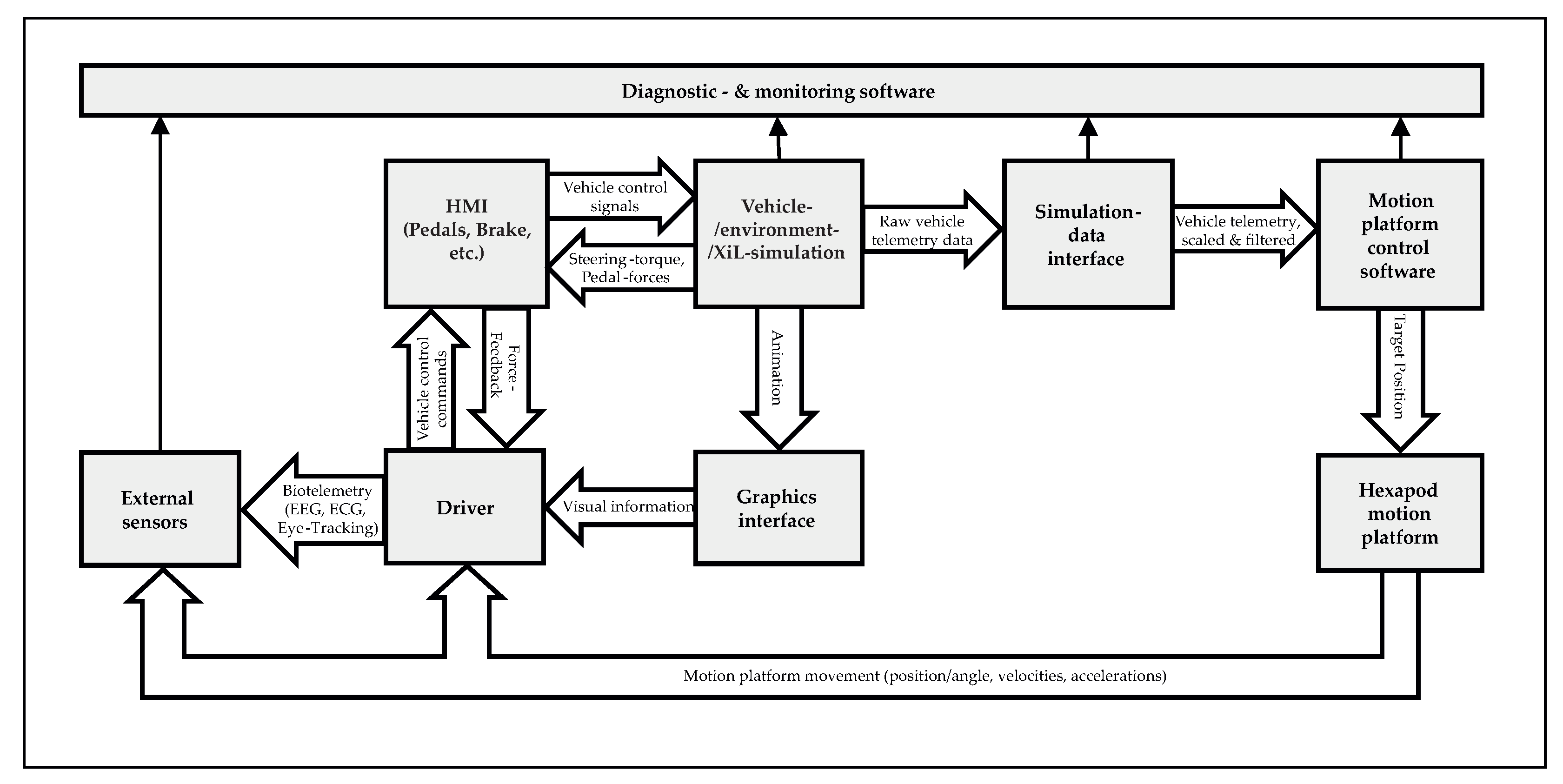

3. System Architecture Design

3.1. Vehicle-/Environment Simulation Software

3.2. XiL Testing

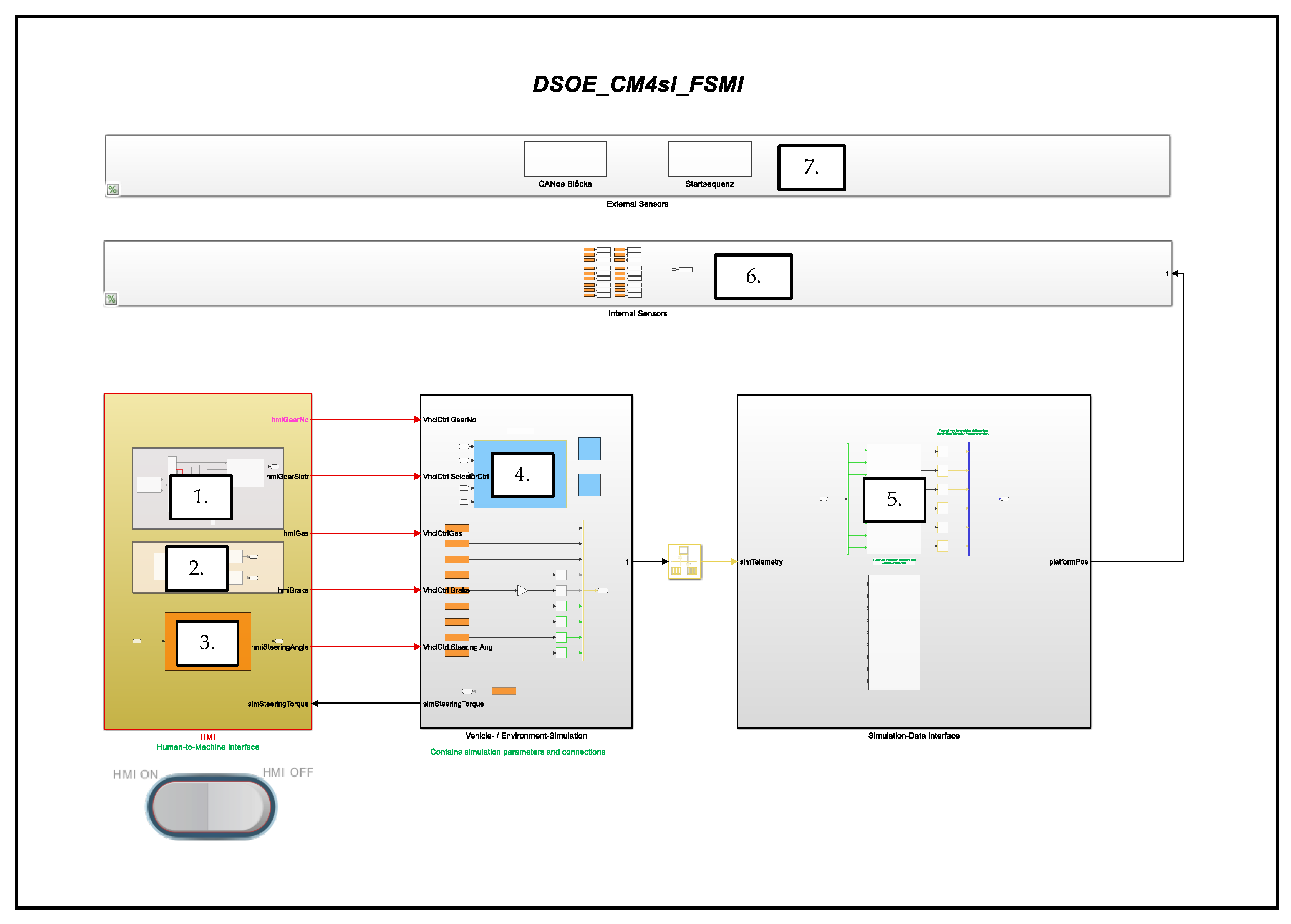

4. Development

4.1. Implementation of the Driving Simulator Operating Environment in Simulink

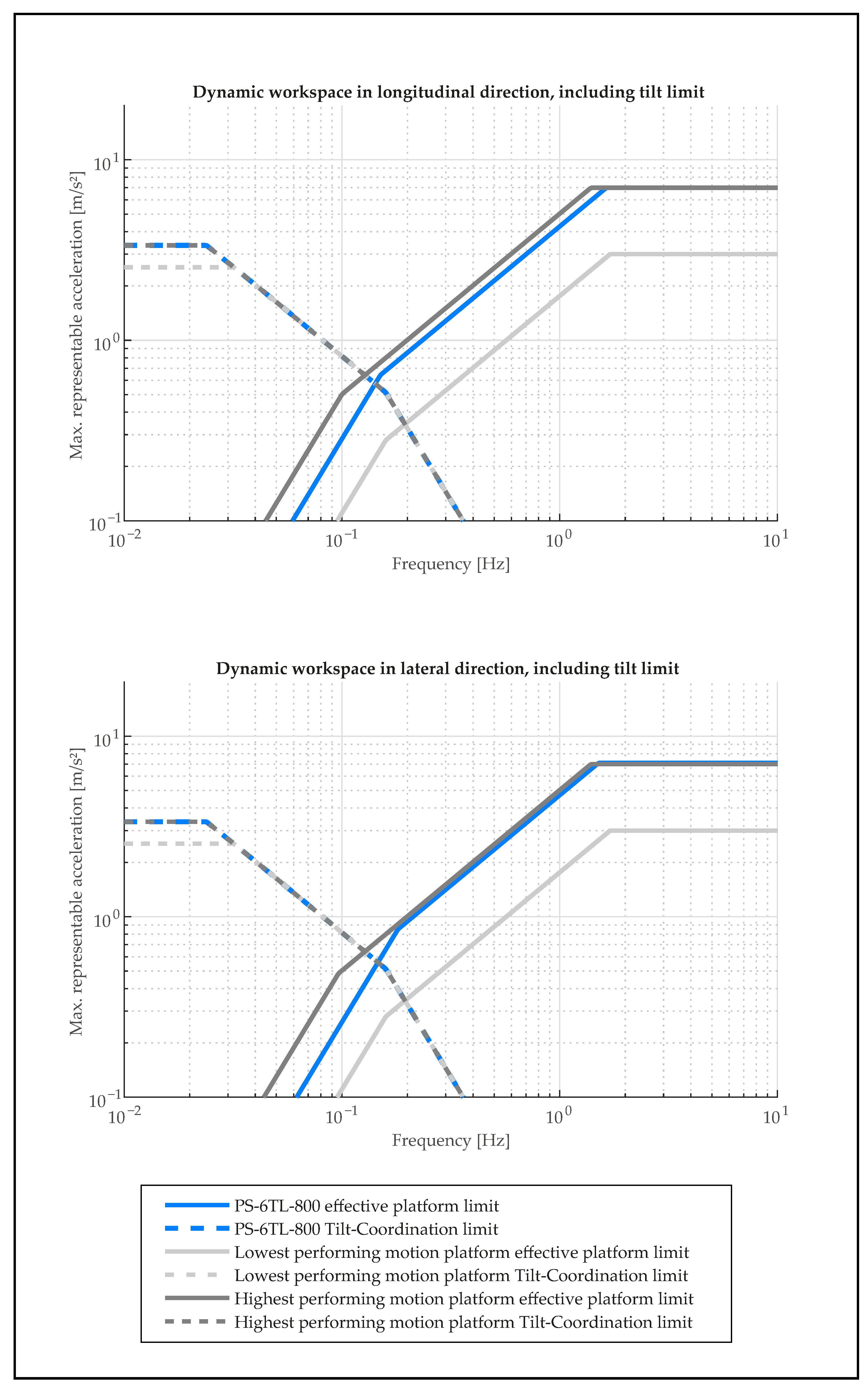

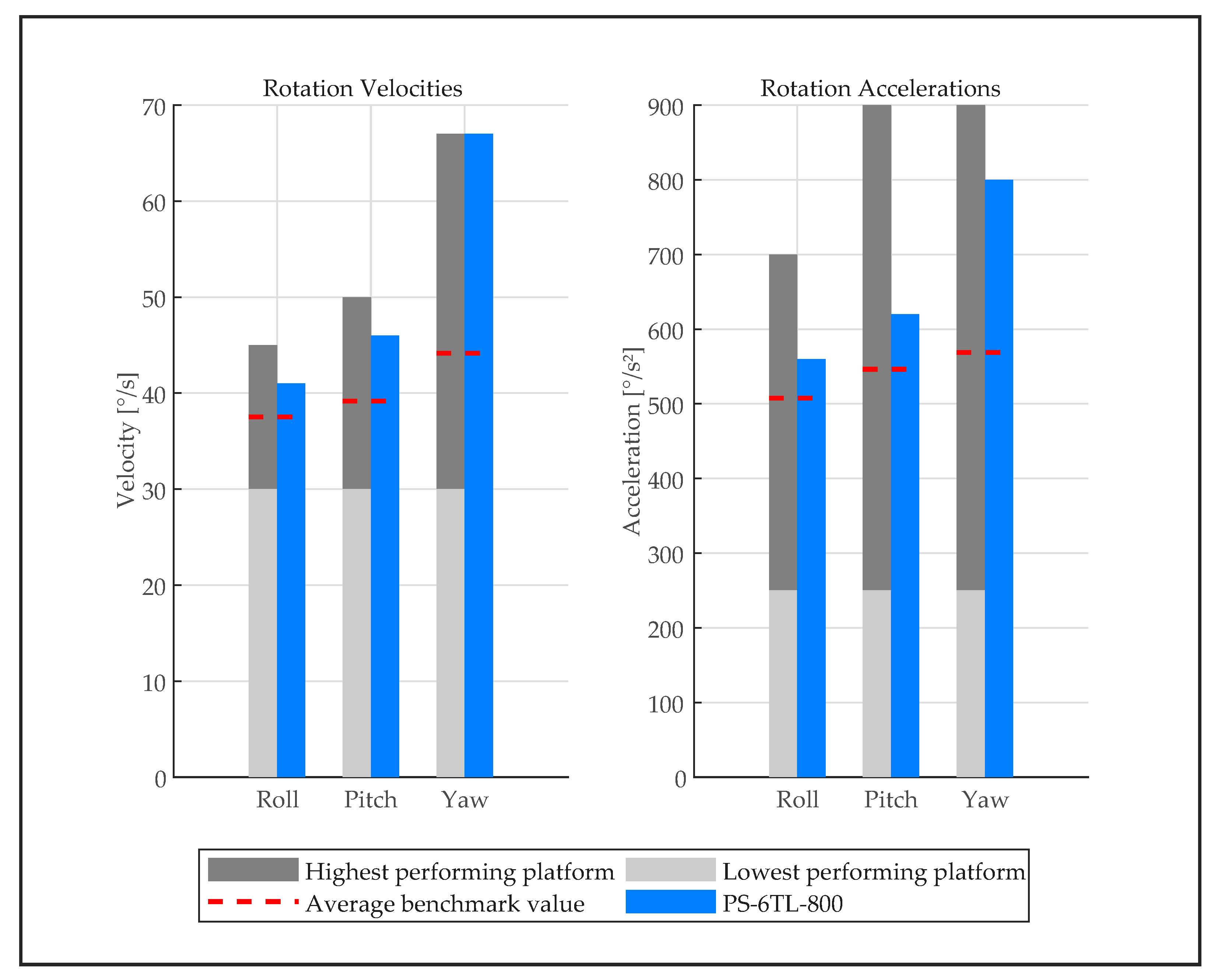

4.2. Motion Platform Choice

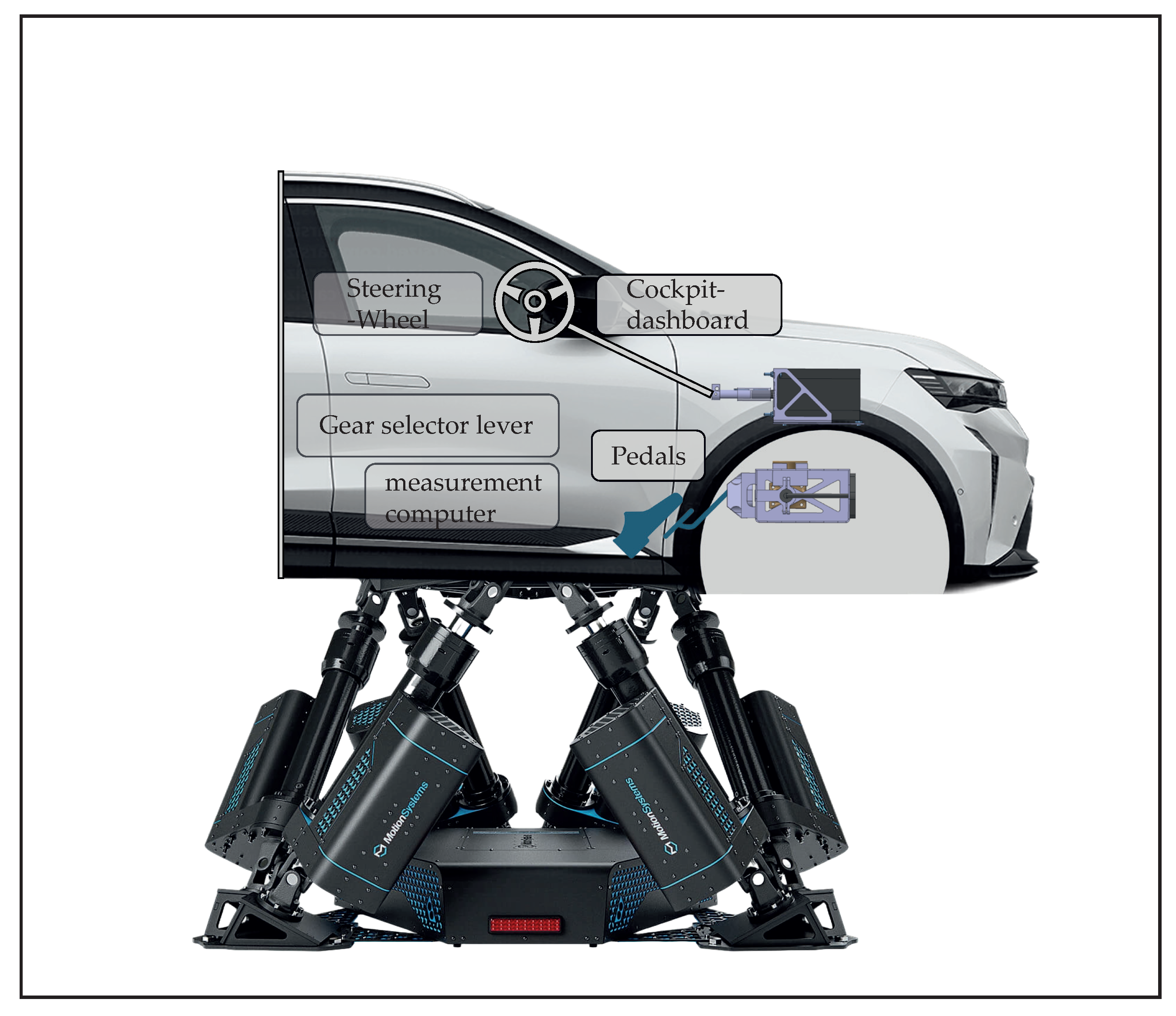

4.3. Driver’s Cabin and HMI Design

4.3.1. HMI Architecture Design

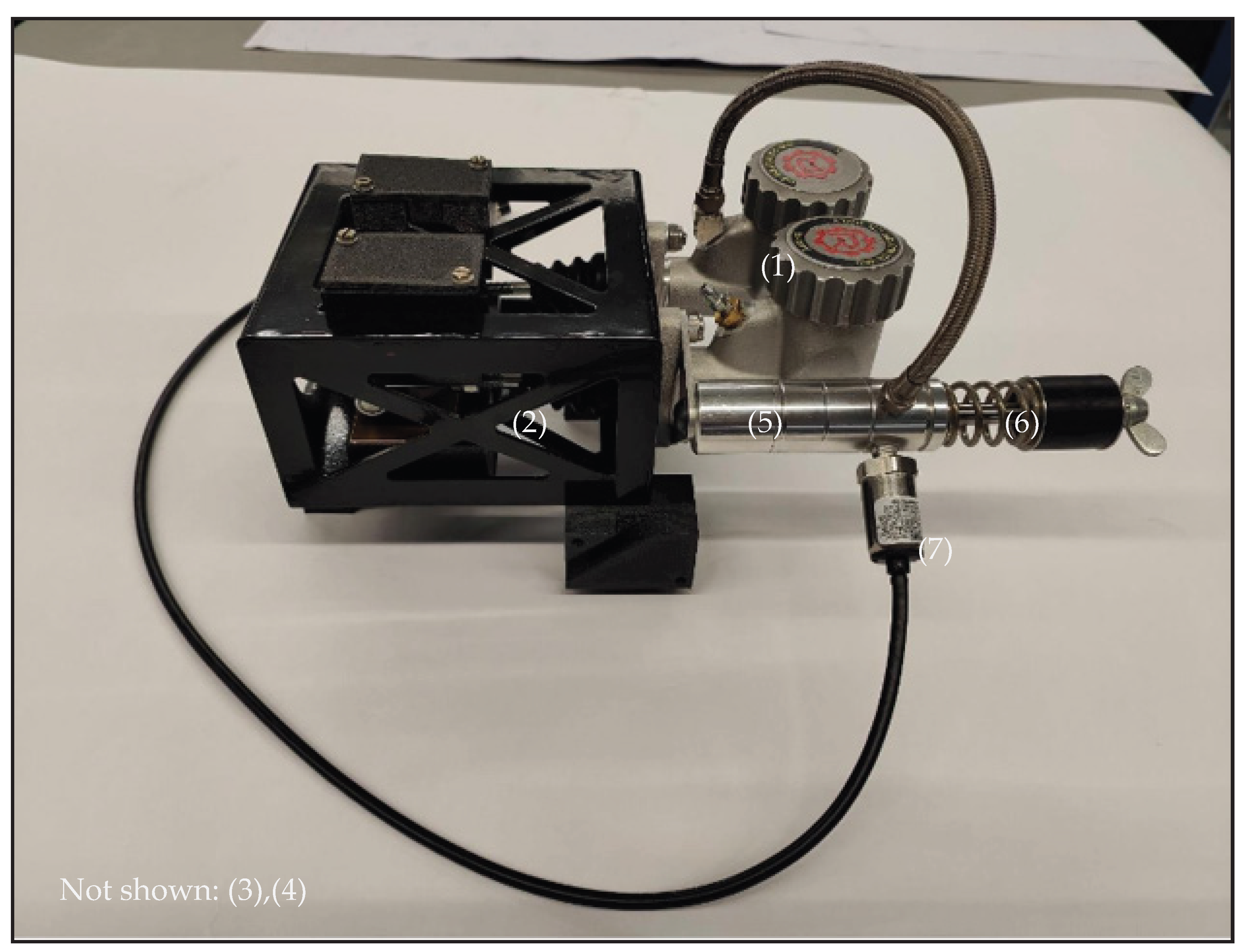

4.3.2. Pedals

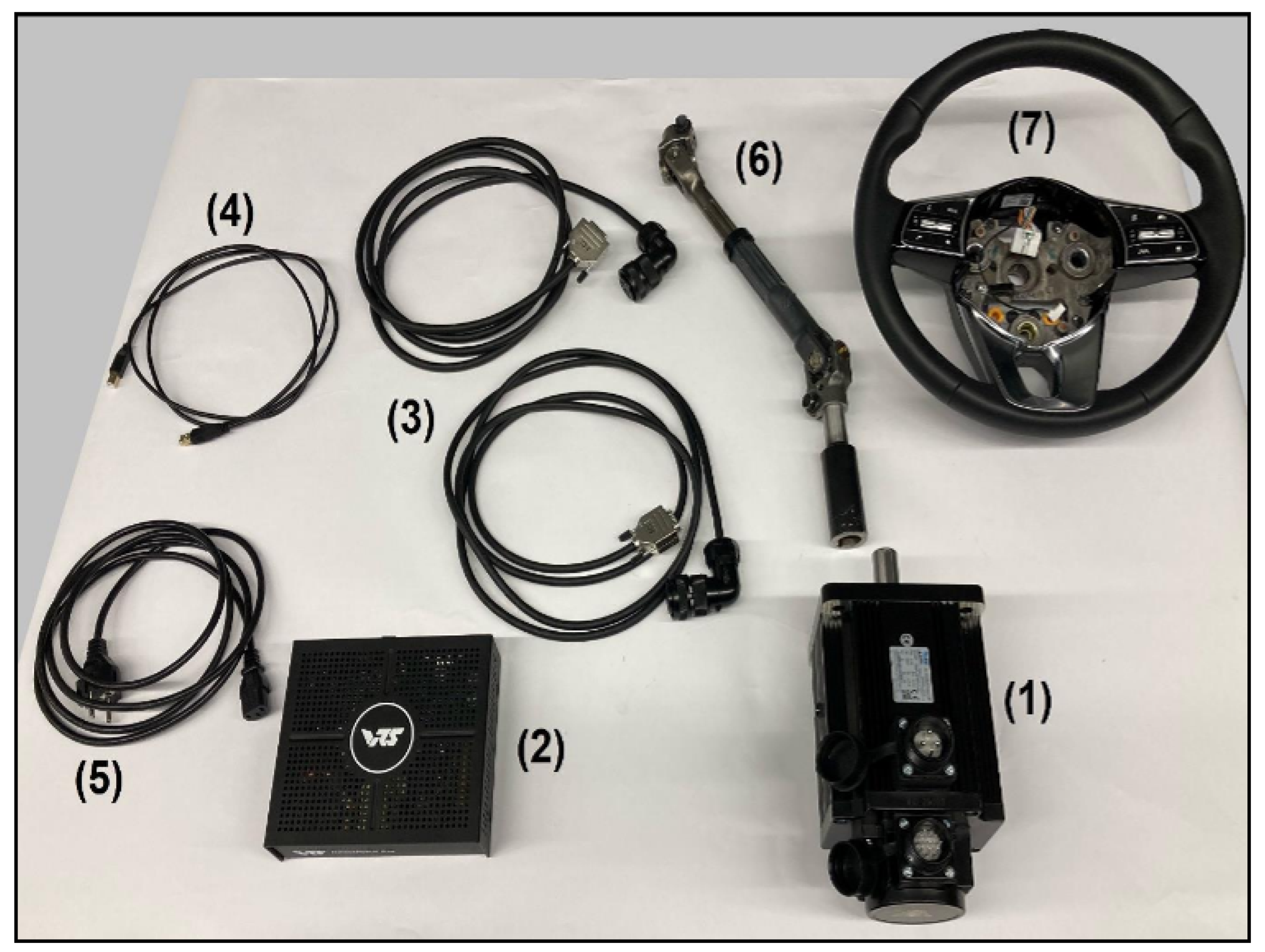

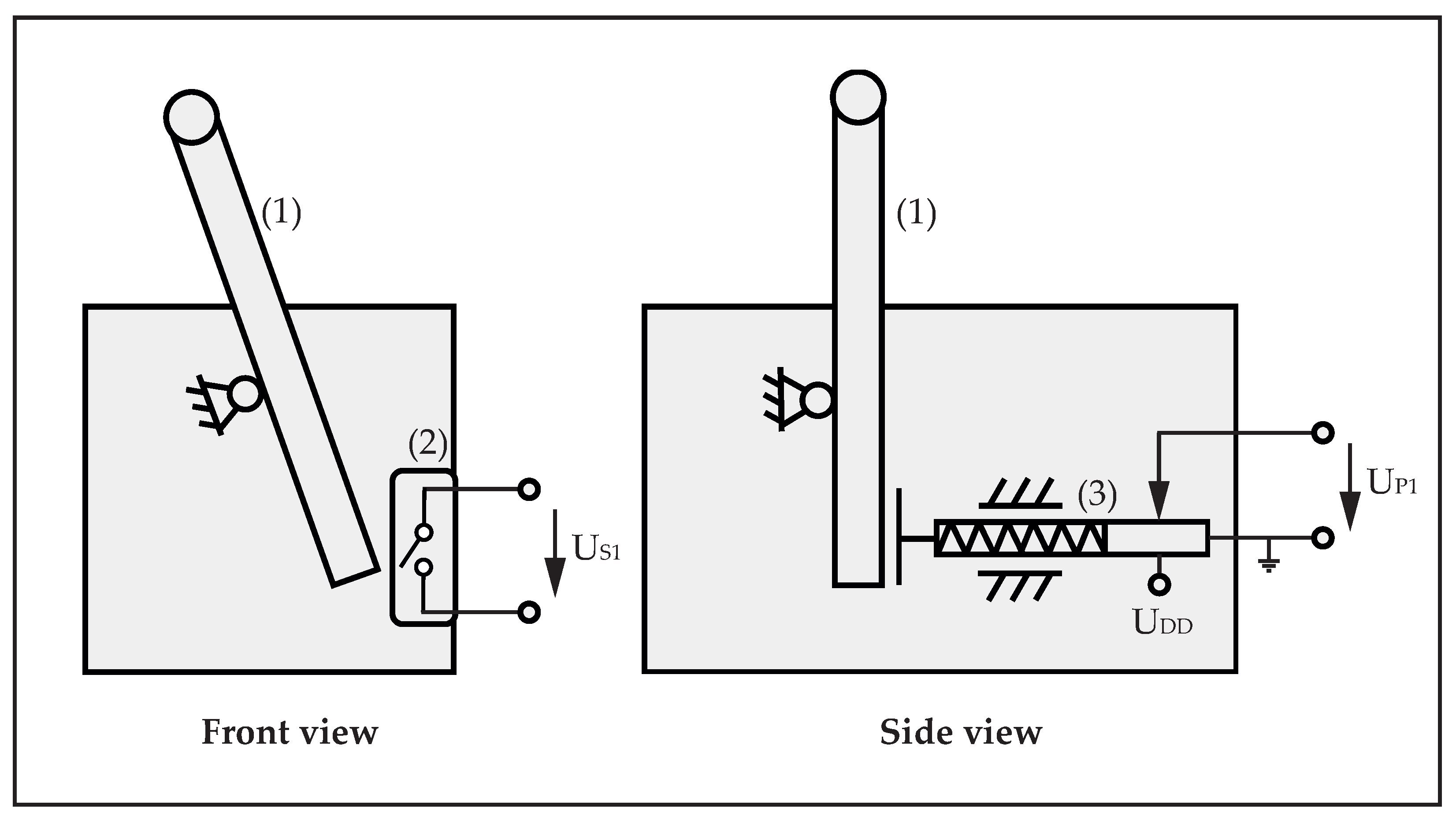

4.3.3. Steering

4.3.4. Gear-Shifter

4.3.5. Cockpit-Dashboard

4.3.6. Measurement Onboard Computer

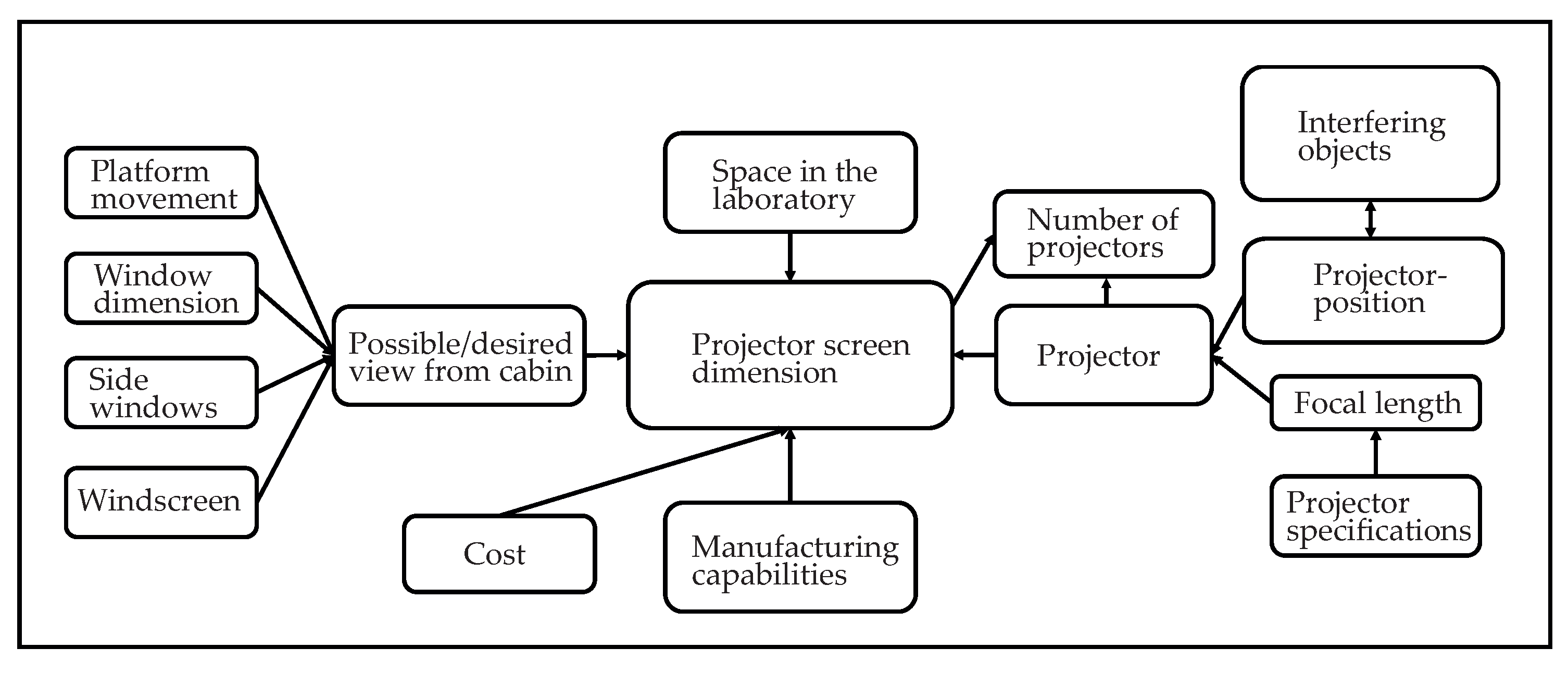

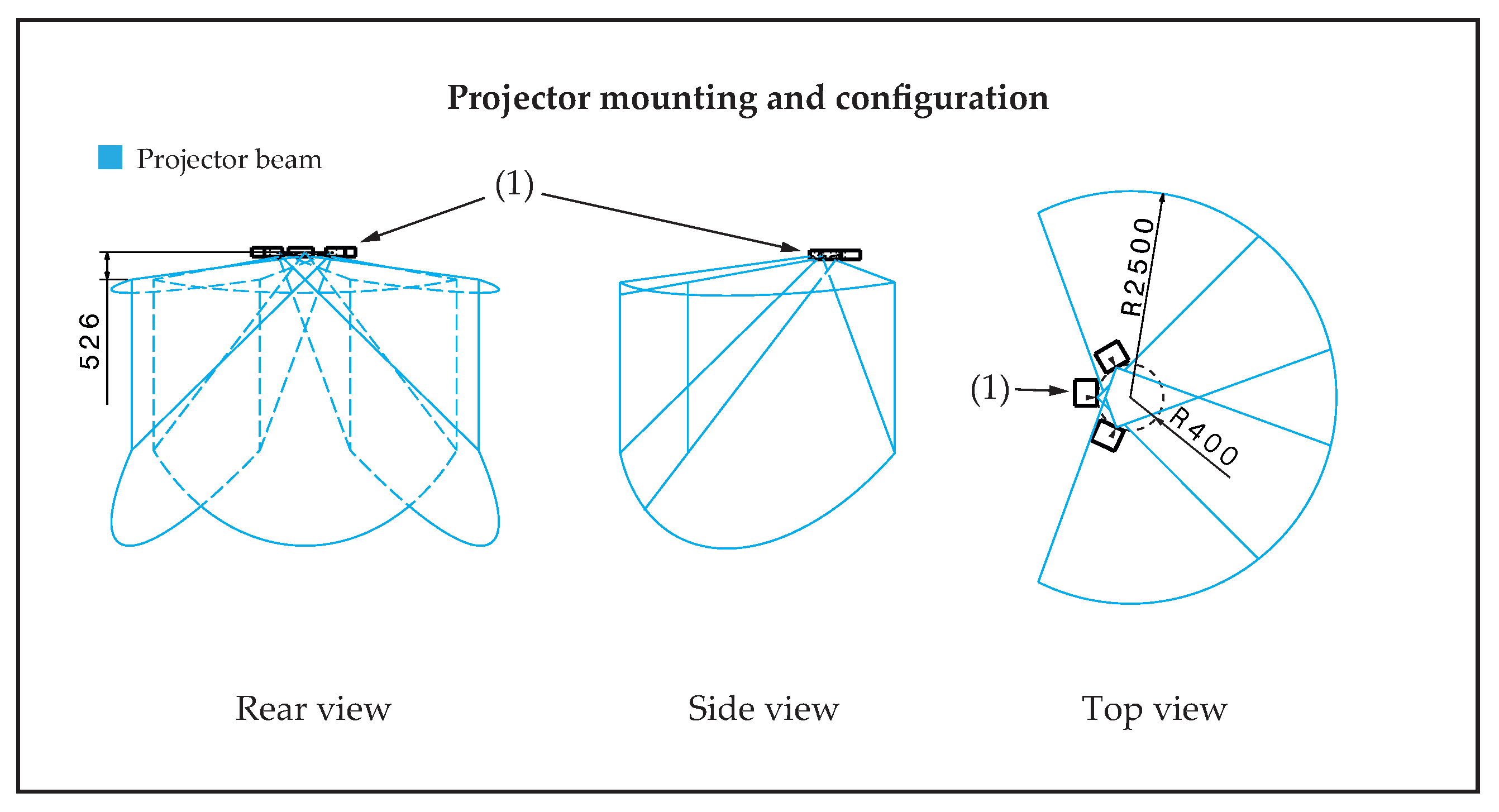

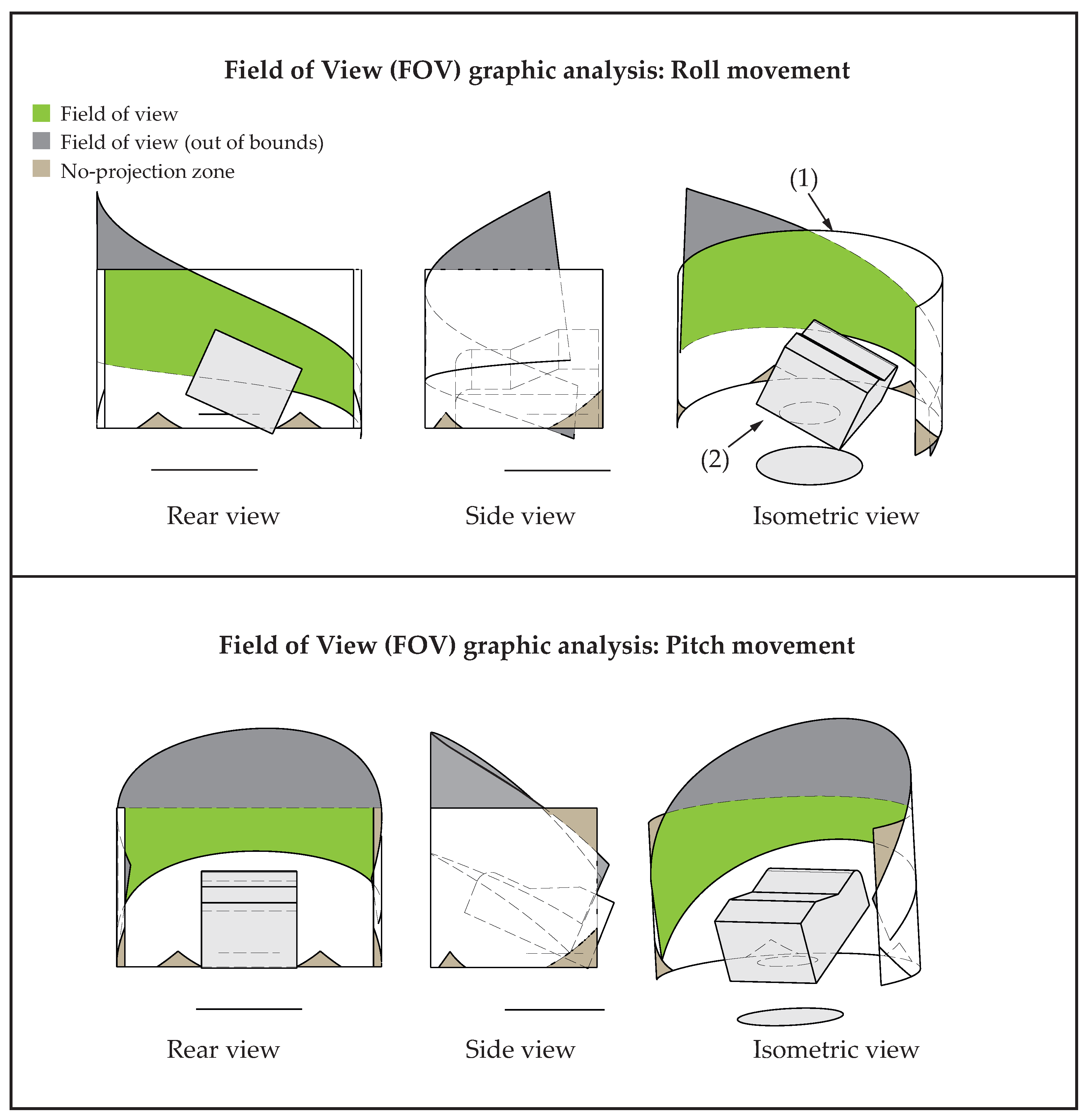

4.4. Visual Environment Design

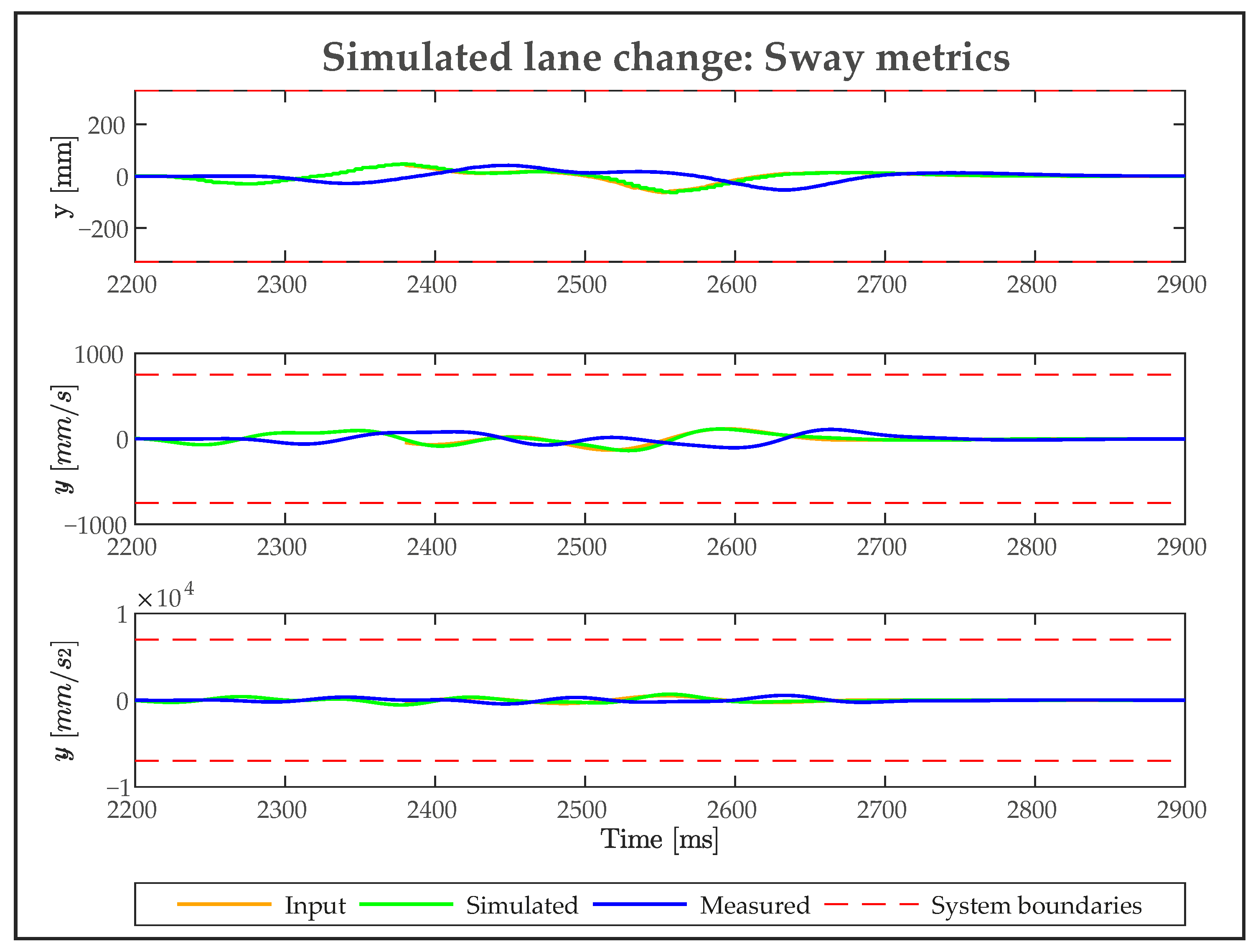

5. Testing and Validation

6. Conclusions/Discussion

7. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACE | Acceleration control engine |

| AD | Automated driving |

| ADAS | Advanced driver assistance system |

| CWA | Classical washout algorithm |

| DiL | Driver-in-the-Loop |

| DoF | Degree of freedom |

| DSOE | Driving simulator operating environment |

| ECG | Electrocardiogram |

| EEG | Electroencephalography |

| FOV | Field of view |

| HiL | Hardware-in-the-Loop |

| HMI | Human–machine interface |

| MCA | Motion cueing algorithm |

| SiL | Software-in-the-Loop |

| VR | Virtual reality |

| XiL | X-in-the-Loop |

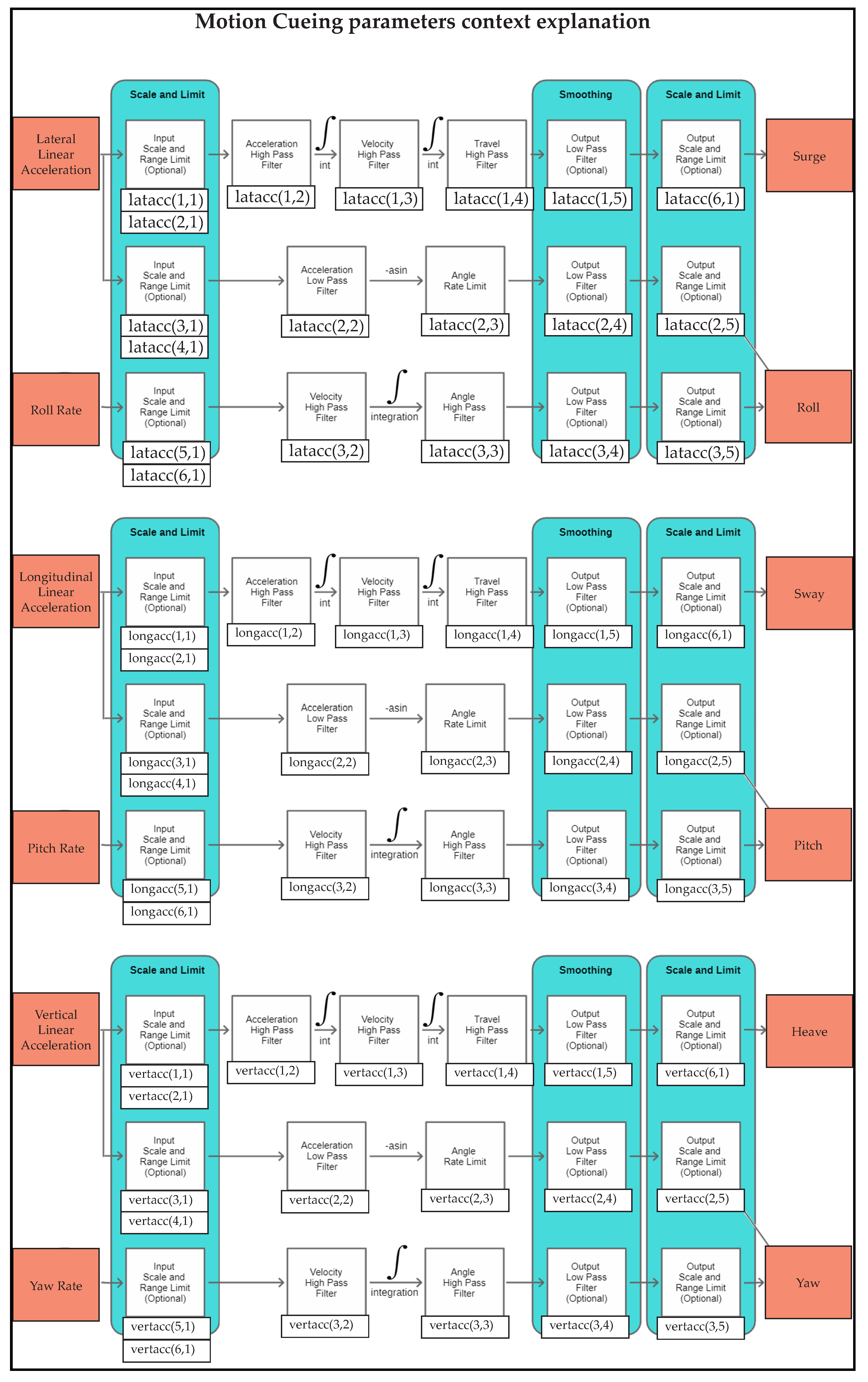

Appendix A

Appendix A.1

| Motion-Platform Benchmark | |||||||

|---|---|---|---|---|---|---|---|

| Company | Motion Systems (Poland) | Motion for Simulators (Belgium) | GFORCE Factory (Netherlands) | ||||

| Type | PS-6TL-350 | PS-6TL-800 | PS-6TL-1500 | MFS-6DOF-1 | MFS-6DOF-2 | MFS-6DOF-3 | EDGE 6D MOTION SIMULATOR |

| Source | [43] | [44] | [45] | [46] | [46] | [46] | [47] |

| Excursion | |||||||

| Surge [m] | 0.3 | 0.37 | 0.36 | 0.15 | 0.15 | 0.217 | 0.13 |

| Sway [m] | 0.26 | 0.33 | 0.32 | 0.15 | 0.15 | 0.185 | 0.1 |

| Heave [m] | 0.187 | 0.22 | 0.27 | 0.175 | 0.175 | 0.18 | 0.07 |

| Roll [°] | 20.6 | 24.5 | 21.3 | 21 | 21 | 22 | 15 |

| Pitch [°] | 19.9 | 23.6 | 20.4 | 25 | 25 | 25 | 15 |

| Yaw [°] | 27.8 | 37 | 24.9 | 20 | 20 | 20 | 15 |

| Velocity | |||||||

| Surge [m/s] | 0.68 | 0.68 | 0.7 | 0.32 | 0.32 | 0.6 | 0.5 |

| Sway [m/s] | 0.7 | 0.75 | 0.7 | 0.32 | 0.32 | 0.8 | 0.5 |

| Heave [m/s] | 0.37 | 0.40 | 0.4 | 0.32 | 0.32 | 0.6 | 0.3 |

| Roll [°/s] | 45 | 41 | 35 | 40 | 40 | 40 | 35 |

| Pitch [°/s] | 50 | 46 | 35 | 40 | 40 | 40 | 35 |

| Yaw [°/s] | 60 | 67 | 35 | 40 | 40 | 40 | 40 |

| Acceleration | |||||||

| Surge [m/s2] | 6.4 | 7 | 7 | 6.87 | 6.87 | 4.9 | 6 |

| Sway [m/s2] | 5 | 7.1 | 7 | 6.87 | 6.87 | 4.9 | 6 |

| Heave [m/s2] | 5 | 5 | 5 | 9.81 | 9.81 | 7.85 | 5 |

| Roll [°/s2] | 600 | 560 | 250 | 500 | 500 | 700 | 600 |

| Pitch [°/s2] | 650 | 620 | 250 | 500 | 500 | 900 | 600 |

| Yaw [°/s2] | 700 | 800 | 250 | 500 | 500 | 550 | 600 |

| Simulator-Benchmark | |||||||

| Company | Shenzen Uni Technology (China) | Suzhou Fondari Automation Equipment (China) | Brunner Innovation (Switzerland) | DOF Interact (Thailand) | |||

| Type | Custom 6DOF Platform | Hexapod 6-Dof Electric Motion Platform | 6DOF MOTION 1000 | 6DOF Motion Platform | |||

| Source | [48] | [49] | [50] | [51] | |||

| Excursion | |||||||

| Surge [m] | 0.3 | 0.5 | 0.14 | 0.15 | |||

| Sway [m] | 0.3 | 0.5 | 0.14 | 0.15 | |||

| Heave [m] | 0.3 | 0.5 | 0.125 | 0.15 | |||

| Roll [°] | 35 | 35 | 15 | 15 | |||

| Pitch [°] | 35 | 35 | 15 | 15 | |||

| Yaw [°] | 35 | 35 | 16 | 19 | |||

| Velocity | |||||||

| Surge [m/s] | 0.5 | 1 | 0.25 | 0.25 | |||

| Sway [m/s] | 0.5 | 1 | 0.28 | 0.28 | |||

| Heave [m/s] | 0.5 | 1 | 0.28 | 0.28 | |||

| Roll [°/s] | 35 | 60 | 30 | 30 | |||

| Pitch [°/s] | 35 | 60 | 30 | 30 | |||

| Yaw [°/s] | 35 | 60 | 30 | 30 | |||

| Acceleration | |||||||

| Surge [m/s2] | 19.61 | 9.81 | 3 | 16.67 | |||

| Sway [m/s2] | 19.62 | 9.81 | 3 | 15.69 | |||

| Heave [m/s2] | 19.62 | 9.81 | 4 | 19.62 | |||

| Roll [°/s2] | 300 | 200 | 250 | 50 | |||

| Pitch [°/s2] | 300 | 200 | 250 | 50 | |||

| Yaw [°/s2] | 300 | 200 | 250 | 50 | |||

| Simulator-Benchmark | |||||||

| Company | Servos & Simulation Inc. (USA) | VANHALTEREN (Netherlands) | DOF Reality (USA) | ||||

| Type | 710-6-1000-220 | 710-6-2000-220 | 710-6-4500-220 | eMotion-1500 | Consumer P6 | ||

| Source | [52] | [52] | [52] | [53] | [54] | ||

| Excursion | |||||||

| Surge [m] | n.a. | n.a. | n.a. | 0.63 | n.a. | ||

| Sway [m] | n.a. | n.a. | n.a. | 0.5 | n.a. | ||

| Heave [m] | 0.1 | 0.1 | 0.2 | 0.38 | n.a. | ||

| Roll [°] | 32 | 32 | 32 | 24 | 12.5 | ||

| Pitch [°] | 32 | 32 | 32 | 28 | 12.5 | ||

| Yaw [°] | 32 | 32 | 32 | 27 | 12.5 | ||

| Velocity | |||||||

| Surge [m/s] | 0.25 | 0.25 | 0.25 | 0.79 | n.a. | ||

| Sway [m/s] | 0.28 | 0.28 | 0.28 | 0.81 | n.a. | ||

| Heave [m/s] | 0.28 | 0.28 | 0.28 | 0.55 | n.a. | ||

| Roll [°/s] | 100 | 100 | 100 | n.a. | 105 | ||

| Pitch [°/s] | 100 | 100 | 100 | n.a. | 105 | ||

| Yaw [°/s] | 100 | 100 | 100 | n.a. | 105 | ||

| Acceleration | |||||||

| Surge [m/s2] | 7.3575 | 7.3575 | 7.3575 | 6.867 | 4.9 | ||

| Sway [m/s2] | 7.3575 | 7.3575 | 7.3575 | 6.867 | 4.9 | ||

| Heave [m/s2] | 7.3575 | 7.3575 | 7.3575 | 9.81 | 4.9 | ||

| Roll [°/s2] | 100 | 100 | 100 | 600 | n.a. | ||

| Pitch [°/s2] | 100 | 100 | 100 | 600 | n.a. | ||

| Yaw [°/s2] | 100 | 100 | 100 | 900 | n.a. | ||

Appendix A.2

| Test Documentation DiL Testbench | ||

|---|---|---|

| Date (DD/MM/YYYY): | 10/03/2025 | |

| Test number: | 14 | |

| Test iteration: | 2 | |

| Test name: | IPG CarMaker: Lane-change demonstration | |

| Test aim: | Demonstrate the function of the driving simulator. Extract simulator movement data for post-processing. | |

| Test description: | S. ISO 3888-2 [42]. The vehicle is controlled using the HMI. Lane passing velocity = 80 km/h. | |

| Test result: | System works as expected. For data evaluation see Section 5. | |

| Vehicle- Environment Simulation | ||

| Type | Description | |

| Simulation-Software | IPG CarMaker 12.0 | |

| Vehicle dataset | Demo_Kia_EV6 | |

| Scenario dataset | LaneChange_ISO3888-2.rd5 | |

| Environment dataset | Day, clear, no wind, dry, 24 °C | |

| Software framework | ||

| Type | Name | Description |

| Main operating framework | DSOE | Driving Simulator Operation System |

| Simulation data interface | FSPM Simulink | Motion Systems ForceSeat PM Simulink Plugin |

| Simulation data interface profile | FSMI_CM_ACE | 6-DoF classical washout algorithm of manufacturer |

| Motion cueing parameters | ||

| Lateral acceleration and roll rate | ||

| Variable | Value | Description |

| Tilt-Coordination | 1 | Flag for Tilt-Coordination enable/disable |

| latacc(1,1) | 3 | Input limitation Factor of the sigmoid function that scales and saturates the input |

| latacc(2,1) | 20 | Input limitation: maximum of absolute input value |

| latacc(3,1) | 0.3 | TC Input limitation Factor of the sigmoid function that scales and saturates the input |

| latacc(4,1) | 10 | TC Input limitation: maximum of absolute input value |

| latacc(5,1) | 2.2 | Roll Input limitation maximum value |

| latacc(6,1) | 300 | Roll Input limitation maximum value |

| latacc(1,2) | 8 | Acceleration filter Highpass cutoff frequency [Hz] |

| latacc(2,2) | 2 | Acceleration filter Lowpass cutoff frequency [Hz] |

| latacc(3,2) | 3 | Angular velocity filter Highpass cutoff frequency [Hz] |

| latacc(1,3) | 0.6 | Velocity filter Highpass cutoff frequency [Hz] |

| latacc(2,3) | 700 | Angle rate limit maximum rate [deg/s] |

| latacc(3,3) | 0.5 | Angle filter Highpass [Hz] |

| latacc(1,4) | 0.4 | Travel filter Highpass cutoff frequency [Hz] |

| latacc(2,4) | 2 | Angle output Lowpass 1 cutoff frequency [Hz] |

| latacc(3,4) | 3 | Angle output Lowpass 2 cutoff frequency [Hz] |

| latacc(1,5) | 25 | Travel Output filter Lowpass cutoff frequency [Hz] |

| latacc(2,5) | −0.75 | Angle output 1 factor: slope of linear function that scales the input |

| latacc(3,5) | −1 | Angle output 2 factor: slope of linear function that scales the input |

| latacc(1,6) | −1.5 | Travel Output Limit |

| Longitudinal acceleration and pitch rate | ||

| Variable | Value | Description |

| Tilt-Coordination | 1 | Flag for Tilt-Coordination enable/disable |

| longacc(1,1) | 0.5 | Input limitation Factor of the sigmoid function that scales and saturates the input |

| longacc(2,1) | 20 | Input limitation: maximum of absolute input value |

| longacc(3,1) | 0.1 | TC Input limitation Factor of the sigmoid function that scales and saturates the input |

| longacc(4,1) | 10 | TC Input limitation: maximum of absolute input value |

| longacc(5,1) | 2 | Roll Input limitation Factor |

| longacc(6,1) | 300 | Roll Input limitation maximum value |

| longacc(1,2) | 0.4 | Acceleration filter Highpass cutoff frequency [Hz] |

| longacc(2,2) | 1.5 | Acceleration filter Lowpass cutoff frequency [Hz] |

| longacc(3,2) | 3 | Angular velocity filter Highpass cutoff frequency [Hz] |

| longacc(1,3) | 0.2 | Velocity filter Highpass cutoff frequency [Hz] |

| longacc(2,3) | 700 | Angle rate limit maximum rate [deg/s] |

| longacc(3,3) | 0.5 | Angle filter Highpass cutoff frequency [Hz] |

| longacc(1,4) | 0.65 | Travel filter Highpass cutoff frequency [Hz] |

| longacc(2,4) | 2 | Angle output Lowpass 1 cutoff frequency [Hz] |

| longacc(3,4) | 3 | Angle output Lowpass 2 cutoff frequency [Hz] |

| longacc(1,5) | 3 | Travel Output filter Lowpass cutoff frequency [Hz] |

| longacc(2,5) | −1 | Angle output 1 factor |

| longacc(3,5) | −1 | Angle output 2 factor |

| longacc(1,6) | 1.1 | Travel Output Limit |

| Vertical acceleration and yaw rate | ||

| Variable | Value | Description |

| Tilt-Coordination | 0 | |

| vertacc(1,1) | 12 | Input limitation Factor of the sigmoid function that scales and saturates the input |

| vertacc(2,1) | 2.5 | Input limitation: maximum of absolute input value |

| vertacc(3,1) | 0.5 | TC Input limitation Factor of the sigmoid function that scales and saturates the input |

| vertacc(4,1) | 9.81 | TC Input limitation: maximum of absolute input value |

| vertacc(5,1) | 6 | Roll Input limitation Factor |

| vertacc(6,1) | 3000 | Roll Input limitation maximum value |

| vertacc(1,2) | 7 | Acceleration filter Highpass cutoff frequency [Hz] |

| vertacc(2,2) | 0 | Acceleration filter Lowpass cutoff frequency [Hz] |

| vertacc(3,2) | 4 | Angular velocity filter Highpass cutoff frequency [Hz] |

| vertacc(1,3) | 3 | |

| vertacc(2,3) | 0 | Angle rate limit maximum rate [deg/s] |

| vertacc(3,3) | 0.05 | Angle filter Highpass cutoff frequency [Hz] |

| vertacc(1,4) | 1 | Travel filter Highpass cutoff frequency [Hz] |

| vertacc(2,4) | 0 | Angle output Lowpass 1 cutoff frequency [Hz] |

| vertacc(3,4) | 1 | Angle output Lowpass 2 cutoff frequency [Hz] |

| vertacc(1,5) | 7 | Travel Output filter Lowpass cutoff frequency [Hz] |

| vertacc(2,5) | 0 | Angle output 1 factor: slope of linear function that scales the input |

| vertacc(3,5) | 1.3 | Angle output 2 factor: slope of linear function that scales the input |

| vertacc(1,6) | −0.7 | Travel Output Limit |

References

- Perrelli, M.; Cosco, F.; Polito, D.; Mundo, D. Development and Validation of a Vehicle Simulation Platform for Driver-in-the-Loop Testing. In Advances in Italian Mechanism Science; Springer International Publishing: Cham, Switzerland, 2022; pp. 355–360. [Google Scholar] [CrossRef]

- Hendrik, A.; Schmid, C. Driver-in-the-loop Simulation for Advanced Driver Assistance Systems. In Proceedings of the 12th International Symposium on Advanced Vehicle Control, AVEC 2014, Tokyo, Japan, 22–26 September 2014. [Google Scholar]

- Yu, C.; Jung, J.; Lee, H.; Gwon, Y.; Lee, H. A Study on the Establishment of VILS Based on Simulation for ADAS Inspection. Trans. Korean Soc. Automot. Eng. 2022, 30, 873–879. [Google Scholar] [CrossRef]

- Schwarz, C.; Ahmad, O.; Brown, T.; Gaspar, J.; Wagner, G.; McGehee, D.V. The Long and Winding Road: 25 Years of the National Advanced Driving Simulator. IEEE Comput. Graph. Appl. 2023, 43, 121–128. [Google Scholar] [CrossRef] [PubMed]

- Swanson, K.S.; Brown, A.A.; Brennan, S.N.; LaJambe, C.M. Extending Driving Simulator Capabilities Toward Hardware-in-the-Loop Testbeds and Remote Vehicle Interfaces. In Proceedings of the 2013 IEEE Intelligent Vehicles Symposium Workshops (IV Workshops), Gold Coast City, Australia, 23 June 2013; pp. 115–120. [Google Scholar] [CrossRef]

- Sekar, R.; Jacome, O.; Chrstos, J.; Stockar, S. Assessment of Driving Simulators for Use in Longitudinal Vehicle Dynamics Evaluation. SAE Tech. Pap. 2022, 2022, 1–10. [Google Scholar] [CrossRef]

- Campos, J.L.; Bédard, M.; Classen, S.; Delparte, J.J.; Hebert, D.A.; Hyde, N.; Law, G.; Naglie, G.; Yung, S. Guiding Framework for Driver Assessment Using Driving Simulators. Front. Psychol. 2017, 8, 1428–1431. [Google Scholar] [CrossRef] [PubMed]

- Quan, C.Y.; Mansor, S.; Jian, C.J.; Rahman, M.M.; Karim, H.A.; Weng, B.K. Modelling and Evaluation of Driving Simulator for Driving Education in Malaysia. J. Logist. Inform. Serv. Sci. 2023, 10, 211–220. [Google Scholar] [CrossRef]

- VI-grade GmbH. VI-Grade Simulators. Available online: https://www.vi-grade.com/en/solutions/driving_simulators/ (accessed on 13 August 2025).

- Dynisma Ltd. Dynisma Simulator. Available online: https://www.dynisma.com/dmg-1-automotive (accessed on 13 August 2025).

- Moog Inc. Moog Simulators. Available online: https://www.moog.de/maerkte/simulation/Driver_Simulators.html (accessed on 13 August 2025).

- TU Dresden. Dresden Driving Simulator. Available online: https://tu-dresden.de/bu/verkehr/kft/die-professur/ausstattung/fahrsimulator-1?set_language=en (accessed on 13 August 2025).

- IKA RWTH Aachen. Highly Dynamic Driving Simulator. Available online: https://www.ika.rwth-aachen.de/en/competences/equipment/simulator-center/highly-dynamic-driving-simulator.html (accessed on 13 August 2025).

- University of Leeds. Car Simulator (UoLDS). Available online: https://uolds.leeds.ac.uk/facility/driving-simulator/ (accessed on 13 August 2025).

- Michalík, D.; Jirgl, M.; Arm, J.; Fiedler, P. Developing an Unreal Engine 4-Based Vehicle Driving Simulator Applicable in Driver Behavior Analysis—A Technical Perspective. Safety 2021, 7, 25. [Google Scholar] [CrossRef]

- Čulík, K.; Kalašová, A.; Štefancová, V. Evaluation of Driver’s Reaction Time Measured in Driving Simulator. Sensors 2022, 22, 3542. [Google Scholar] [CrossRef] [PubMed]

- Remonda, A.; Hansen, N.; Raji, A.; Musiu, N.; Bertogna, M.; Veas, E.; Wang, X. A Simulation Benchmark for Autonomous Racing with Large-Scale Human Data. arXiv 2024. [Google Scholar] [CrossRef]

- Capustiac, A.; Banabic, D.; Schramm, D.; Ossendoth, U. Motion Cueing: From Design Until Implementation. Proc. Rom. Acad. Ser. A Math. Phys. Tech. Sci. Inf. Sci. 2011, 12, 249–256. [Google Scholar]

- Wynne, R.A.; Beanland, V.; Salmon, P.M. Systematic Review of Driving Simulator Validation Studies. Saf. Sci. 2019, 117, 138–151. [Google Scholar] [CrossRef]

- Hartfiel, B.; Tomaszek-Staude, W.; Buchholz, C.; Fresemann, C.; Stark, R. Use Case-Oriented Design Recommendations for Driving Simulators for Human-Centered Protection of Safety and Comfort Functions; [Use Case Orientierte Gestaltungsempfehlungen für Fahrsimulatoren zur Menschzentrierten Absicherung von Sicherheits-und Komfortfunktionen]. VDI Berichte 2018, 2018, 655–669. [Google Scholar]

- Miunske, T. Ein Szenarienadaptiver Bewegungsalgorithmus für die Längsbewegung eines Vollbeweglichen Fahrsimulators, 1st ed.; Number 55 in Wissenschaftliche Reihe Fahrzeugtechnik Universität Stuttgart; Springer Vieweg Wiesbaden: Wiesbaden, Germany, 2020; p. 5. [Google Scholar] [CrossRef]

- Schöner, H.P.; Häcker, J.; Nagel, K. Dynamische Fahrsimulatoren. In Handbuch Assistiertes und Automatisiertes Fahren; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2024; pp. 157–158. [Google Scholar] [CrossRef]

- Rothermel, T. Ein Assistenzsystem für die Sicherheitsoptimierte Längsführung von E-Fahrzeugen im Urbanen Umfeld, 1st ed.; Number 47 in Wissenschaftliche Reihe Fahrzeugtechnik Universität Stuttgart; Springer Vieweg Wiesbaden: Wiesbaden, Germany, 2018; p. 24. [Google Scholar] [CrossRef]

- van Doornik, J.; Brems, W.; Vries, E.D.; Wiedemann, J. Implementing Prediction Algorithms to Synchronize and Minimize Latency on a Driving Simulator. In Proceedings of the Driving Simulation Conference 2016 Europe, Paris, France, 7–9 September 2016; Driving Simulation Association: Paris, France, 2016; pp. 51–59. [Google Scholar]

- Melzi, S.; Previati, G. Driving Simulator: Analysing the Impact of Mechanical Latency on the Perception of Lateral Dynamics. J. Vib. Control 2025, 31, 1510–1523. [Google Scholar] [CrossRef]

- Koroglu, Y.; Wotawa, F. Towards a Review on Simulated ADAS/AD Testing. In Proceedings of the 2023 IEEE/ACM International Conference on Automation of Software Test (AST), Melbourne, Australia, 15–16 May 2023; pp. 112–122. [Google Scholar] [CrossRef]

- Association for Standardization of Automation and Measuring Systems (ASAM). OpenScenario. Available online: https://www.asam.net/standards/detail/openscenario-xml/ (accessed on 13 August 2025).

- CARLA Team. CARLA Simulator. Available online: https://carla.org/ (accessed on 13 August 2025).

- Microsoft. AirSim. Available online: https://microsoft.github.io/AirSim/ (accessed on 13 August 2025).

- OSRF. Gazebo. Available online: https://gazebosim.org/home (accessed on 13 August 2025).

- IPG Automotive. CarMaker. Available online: https://www.ipg-automotive.com/de/produkte-loesungen/software/carmaker/ (accessed on 13 August 2025).

- Deutsches Forschungszentrum für Künstliche Intelligenz GmbH (DFKI). OpenDS. Available online: https://opends.dfki.de/packages/ (accessed on 13 August 2025).

- Strachan, I. Visual and Motion Cues in the Real World and in Simulators, 2019. Updated version. Available online: https://www.raes-fsg.org.uk/directdocs/Sim%20&%20Real%20World%20Cueing%20-%20Paper_2019-11-21.pdf (accessed on 20 August 2025).

- Brems, W. Querdynamische Eigenschaftsbewertung in einem Fahrsimulator, 1st ed.; Wissenschaftliche Reihe Fahrzeugtechnik Universität Stuttgart; Springer Vieweg Wiesbaden: Wiesbaden, Germany, 2018; Volume 1, pp. 51–58. [Google Scholar] [CrossRef]

- Fischer, M. Motion-Cueing-Algorithmen für eine Realitätsnahe Bewegungssimulation; Technical Report; Deutsches Zentrum für Luft- und Raumfahrt e.V.: Köln, Deutschland, 2009. [Google Scholar]

- Groen, E.L.; Bles, W. How to Use Body Tilt for the Simulation of Linear Self Motion. J. Vestib. Res. 2004, 14, 375–385. [Google Scholar] [CrossRef]

- Reymond, G.; Kemeny, A. Motion Cueing in the Renault Driving Simulator. Veh. Syst. Dyn. 2000, 34, 249–259. [Google Scholar] [CrossRef]

- Sauer, Y.; Sipatchin, A.; Wahl, S.; García García, M. Assessment of Consumer VR-headsets’ Objective and Subjective Field of View (FoV) and Its Feasibility for Visual Field Testing. Virtual Real. 2022, 26, 1089–1101. [Google Scholar] [CrossRef]

- Filio, D.; Ziraldo, E.; Dony, L.; Gonzalez, D.; Oliver, M. Comparison between Wrap Around Screens and a Head Mounted Display on Driver Muscle and Kinematic Responses to a Pedestrian Hazard. Appl. Ergon. 2023, 106, 103878. [Google Scholar] [CrossRef] [PubMed]

- Blissing, B.; Bruzelius, F.; Eriksson, O. The Effects on Driving Behavior When Using a Head-mounted Display in a Dynamic Driving Simulator. ACM Trans. Appl. Percept. 2022, 19, 1–18. [Google Scholar] [CrossRef]

- Spector, R.H. Visual Fields. In Clinical Methods: The History, Physical, and Laboratory Examinations, 3rd ed.; Walker, H.K., Hall, W.D., Hurst, J.W., Eds.; Butterworths: Boston, MA, USA, 1990; Chapter 116. [Google Scholar]

- ISO/DIS3888-2:2025; Passenger cars - Test track for a severe lane-change manoeuvre - Part 2: Obstacle avoidance. International Organisation for Standardization: Geneva, Switzerland, 2025.

- Motion Systems. PS-6TL-350. 2023. Available online: https://motionsystems.eu/product/motion-platforms/ps-6tl-350/ (accessed on 21 October 2023).

- Motion Systems. PS-6TL-800. 2023. Available online: https://motionsystems.eu/product/motion-platforms/ps-6tl-800/ (accessed on 21 October 2023).

- Motion Systems. PS-6TL-1500. 2023. Available online: https://motionsystems.eu/product/motion-platforms/ps-6tl-1500/ (accessed on 21 October 2023).

- MOTION FOR SIMULATORS S.R.L. 6 DOF Motion Platforms Provide it All: Pitch, Roll, Heave, Sway, Surge and Yaw. 2023. Available online: https://motionforsimulators.com/6dofmotionplatforms/ (accessed on 22 October 2023).

- Gforcefactory B.V. About the EDGE 6D Motion Simulator. 2023. Available online: https://www.gforcefactory.com/edge-6d (accessed on 20 October 2023).

- Shenzhen UNI Technology Co., Ltd. Custom 6DOF Motion Platform AASD15A Drive. 2023. Available online: https://unite-ch.net/product/diy-6dof-motion-platform-amc-aasd15a-controller (accessed on 20 October 2023).

- Suzhou Fengda Automation Equipment Technology Co, Ltd. Hexapod 6-DOF Electric Motion Platform Stewart Platform Flight Simulator 6-Axis Motion Simulating. 2023. Available online: https://szfdra.en.made-in-china.com/product/pZATInqbIQai/China-Hexapod-6-Dof-Electric-Motion-Platform-Stewart-Platform-Flight-Simulator-6-Axis-Motion-Simulating.html (accessed on 21 October 2023).

- BRUNNER ELEKTRONIK AG. 6DOF Motion 1000. 2023. Available online: https://brunner-innovation.swiss/product/6dof_motion_1000/ (accessed on 20 October 2023).

- DOF Interact. 6 DOF Motion Platform. 2023. Available online: https://www.dofinteract.com/ (accessed on 21 October 2023).

- Servos and Simulation, Inc. Six-Axis (6DOF) Motion Base Platform Systems 710-6. 2023. Available online: https://servosandsimulation.com/motion-base-platforms-and-control-loader-products/six-axis-6dof-motion-base-platform-systems/ (accessed on 20 October 2023).

- Van Halteren Technologies. eMotion-1500. 2023. Available online: https://vanhalteren.com/wp-content/uploads/2025/01/DataSheet_VHT-eMotion1500_42024.pdf (accessed on 22 October 2023).

- DOF Reality Motion Simulators. Professional Motion Simulator Platform 6-AXIS DOF. 2023. Available online: https://dofreality.com/product/racing/motion-racing-rig-6-axis-pro-p6/?srsltid=AfmBOor7fkPCRhZHFp-iA99iC7r9DrqbaQu3pz7_9YMuHpGZHci0v8lm (accessed on 20 October 2023).

| Simulation | Open Source | Integration | ADAS/AD Capabilities | ||

|---|---|---|---|---|---|

| Graphics | Interfaces | Sensors | Scenario-Based Testing | ||

| CARLA | Yes |  |  |  |  |

| AirSim * | Yes |  |  |  |  |

| Gazebo | Yes |  |  |  |  |

| CarMaker | No |  |  |  |  |

| OpenDS * | Yes |  |  |  |  |

| Attribute | Details |

|---|---|

| Type | Optoma 4K440STx |

| Display/Image | |

| Resolution | UHD (3840 × 2160) |

| Contrast Ratio | 1,000,000:1 |

| Native Aspect Ratio | 16:9 |

| Horizontal Scan Rate | 31–135 Khz |

| Vertical Scan Rate | 24–120 Hz |

| Light Source | |

| Light Source Type | Lamp |

| Lamp Power | 240 W |

| Brightness | 4000 lm |

| Optical | |

| Throw Ratio | 0.5:1 |

| Projection Distance | 0.4–3.3 m |

| Focal Length | 7.51 mm |

| Lens Shift | Vertical +0% |

| Native Offset | 116% |

| Effective casted projection image (calculated) | |

| Width | 5847 mm |

| Height | 3289 mm |

| Diagonal | 6708 mm |

| Projection Distance | 2900 mm |

| Vertical Offset | 526 mm |

| Motion | Start Angle FOV-Loss [°] | Max. Angle Motion Platform [°] | Max. FOV-Loss [m2] | Eff. FOV Surface [m2] | Rel. FOV-Loss [%] |

|---|---|---|---|---|---|

| Roll | 11.2 | 24.5 | 2.3 | 21.15 | 11 |

| Pitch | 8.1 | 23.6 | 7.47 | 35 | |

| Yaw | 12.2 | 37 | 1.81 | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meiners, M.; Isken, B.; Kamau, E.N. Development of a 6-DoF Driving Simulator with an Open-Source Architecture for Automated Driving Research and Standardized Testing. Vehicles 2025, 7, 86. https://doi.org/10.3390/vehicles7030086

Meiners M, Isken B, Kamau EN. Development of a 6-DoF Driving Simulator with an Open-Source Architecture for Automated Driving Research and Standardized Testing. Vehicles. 2025; 7(3):86. https://doi.org/10.3390/vehicles7030086

Chicago/Turabian StyleMeiners, Martin, Benedikt Isken, and Edwin N. Kamau. 2025. "Development of a 6-DoF Driving Simulator with an Open-Source Architecture for Automated Driving Research and Standardized Testing" Vehicles 7, no. 3: 86. https://doi.org/10.3390/vehicles7030086

APA StyleMeiners, M., Isken, B., & Kamau, E. N. (2025). Development of a 6-DoF Driving Simulator with an Open-Source Architecture for Automated Driving Research and Standardized Testing. Vehicles, 7(3), 86. https://doi.org/10.3390/vehicles7030086