2.1. Maximum Braking Force

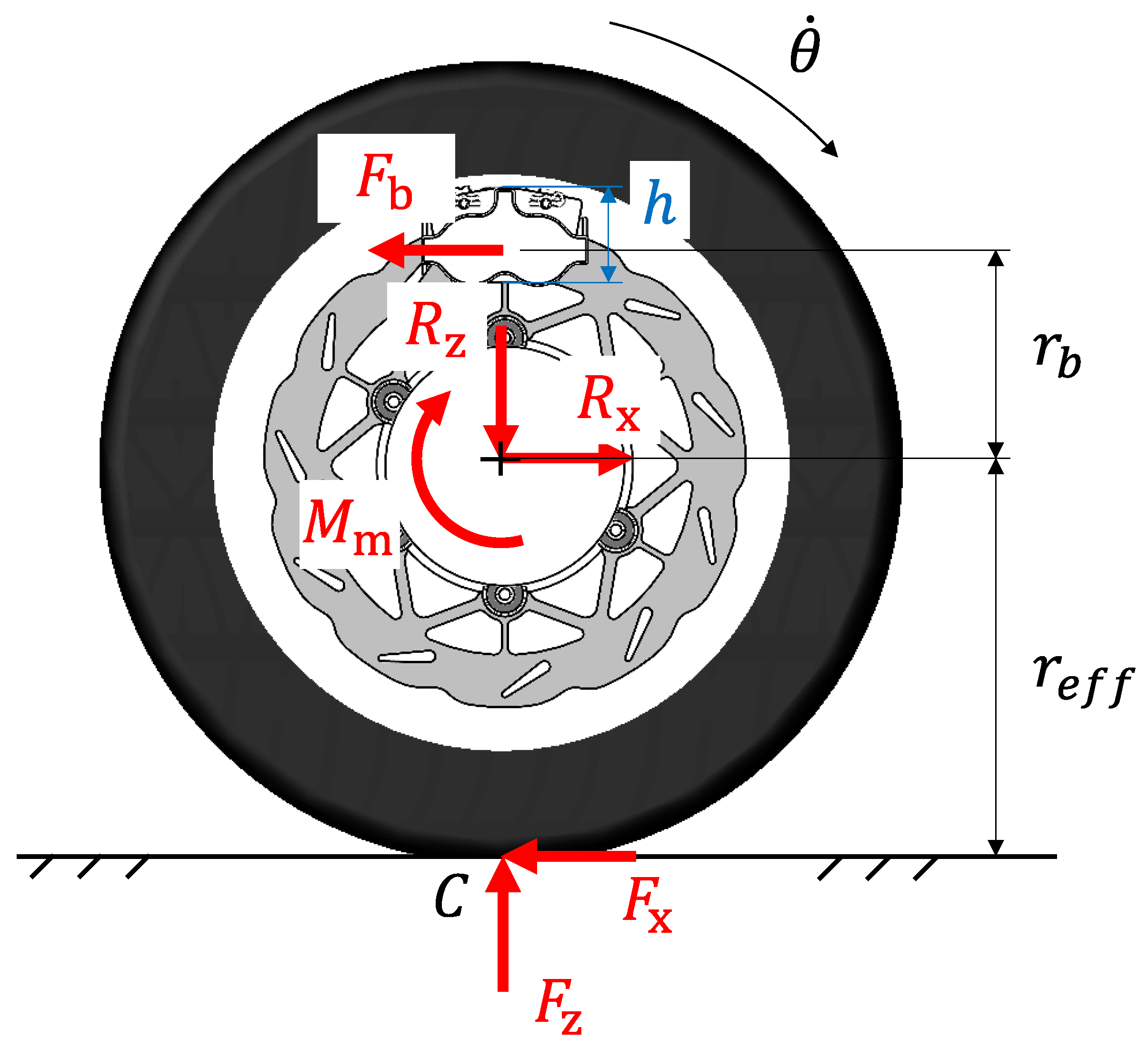

To accurately design a brake caliper and the entire braking system, it is crucial to understand the various factors affecting the required braking force. For this purpose, refer to

Figure 1, which describes the sub-assembly consisting of a single wheel and the brake disc during the braking phase.

Regardless of whether the front or rear wheel group is considered,

Rx and

Rz are the longitudinal and vertical forces exchanged between the wheel and the hub, the axis of which is located at a distance equal to the effective rolling radius

from the ground.

is the torque transmitted by the drive shaft (positive if it comes from the engine and negative if relevant to engine braking or regenerative braking), while

, positioned at a distance

from the wheel’s axis, is the resultant of the friction forces generated by the contact of the brake pads with the rotating brake disc. Lastly,

Fx and

Fz are the external forces exchanged between the tires and the ground through contact point

C in the longitudinal and vertical directions, respectively. Note that this simplified schematic deliberately neglects aerodynamic loads and the weight force of the wheel assembly, assuming negligible rolling resistance (i.e., the center of pressure

C of the contact forces is assumed to have no offset from the rotation axis). According to

Figure 1, the spin dynamic of a wheel assembly is described by the following expression:

where

is the moment of inertia of the considered system. Rearranging Equation (1), the following expression is obtained:

Equation (2) provides several interesting considerations and insights regarding the design of a brake caliper. When designing a brake system for a racing car, the objective is to maximize performance by creating a lightweight system capable of generating very high decelerations. This approach aims to delay the initiation of braking as much as possible, thereby reducing the duration of the braking phase. In general, achieving high deceleration (which is negative during braking) necessitates a substantial braking force . Typically, this results in relatively large and heavy brake calipers and associated components. However, this requirement conflicts with the well-established necessity to minimize unsprung mass, which includes the mass of the brake caliper. Therefore, it is essential to find a good compromise to reduce the braking force and, at the same time, to maximize the deceleration as much as possible.

In light of this, it is easier to interpret the role of each term in Equation (2) and to understand why the inertial component

, although usually negligible, has a detrimental effect (remember that

). Secondly, Equation (2) suggests that it is preferable to maximize the average radius

of the brake disc. However, increasing

undesirably raises both the moment of inertia and the (unsprung) mass of the disc. Similarly, a positive driving torque (

), although typically absent during braking, would require a higher braking force for the same angular deceleration

. Conversely, a negative torque

, either generated by the engine brake or through regenerative braking, is obviously advantageous for the lightweight design of the brake caliper. Finally,

, which describes the resultant of friction forces between the tyre and the asphalt, reaches its maximum value at the point of incipient wheel slip, immediately prior to wheel lock-up. At this instant, its value equals the static friction force, expressed as follows:

where

is the static longitudinal friction coefficient between the tires and (dry) asphalt (in this work,

). To estimate the value of

, it is useful to refer to the diagram in

Figure 2, where the longitudinal model of a race car is shown assuming it is symmetric and running on a perfectly flat track under constant acceleration/braking, inducing symmetric loads in the pitch plane (perfectly straight accelerations and braking).

In this model, four characteristics points are used to describe the system, i.e., the global center of mass G, the contact points of the rear and front wheels

CR and

CF, respectively, and the aerodynamic center of pressure

CoPa. A concentrated mass

mtot is applied to point

G to schematize both the driver and the car inertia, while the resultant aerodynamic lift

FL and drag forces

FD are applied at point

CoPa. With reference to this schematic, the following quasi-steady-state equations of motion can be written as follows [

18]:

where

is the longitudinal acceleration of the vehicle, and

IF and

IR are the moments of inertia of the front and the rear axles, respectively, while

Ie represents that of all rotating parts belonging to the engine. Finally,

e

are their corresponding angular accelerations. Note that

Fx and

Fz for both front and rear axles are multiplied by a factor of 2 because of the symmetry of the problem.

Then, rearranging these equations, an explicit formulation of both

FzF and

FzR can be defined as follows:

where the first term is related to the static distribution of mass, while the others are responsible for load transfer, them being non-zero only when the vehicle is in motion. More specifically, the second is the longitudinal inertial terms, the third and the fourth are aerodynamic contributions, and the last three terms are related to the inertia of the rotating parts. It should be noted that the two aerodynamic terms contribute differently to the load transfer. Indeed, the drag component

is always positive (

), while the lift component

is generally negative (

), as it actually is a downforce. Equation (5) suggests the highest vertical load during the brake, i.e., the highest braking force

, is that occurring at the front wheel (Equation (5)). Then, considering the front wheel and by ignoring for simplicity the contribution due to aerodynamic and to the inertia of the rotating parts, the relationship is significantly simplified and can be written as follows:

Assuming that, during the braking phase, the engine torque is zero and that the inertial component of the wheel assembly is negligible compared to the other forces, the following expression can be found by inserting Equation (6) into Equation (3) and then into Equation (2):

Equation (7) allows for an estimation of the maximum braking force required by the braking system and represents one of the key parameters in the sizing and design of the brake caliper. In the case under consideration, the parameters of the FSAE vehicle permit an estimation of a maximum braking force of approximately , corresponding to a braking torque of approximately with .

2.2. Preliminary Design

Given the maximum braking force, a detailed analysis of the brake caliper design can be undertaken, beginning with the delineation of its geometric details. This study is limited to considering the case of a hydraulic brake system, particularly a monoblock fixed caliper with one or more pairs of opposing pistons acting symmetrically with respect to the brake disc plane. Such a configuration is known for its advantages, including more uniform wear of the inner and outer pads, and typically requiring fewer parts compared to a floating-caliper design [

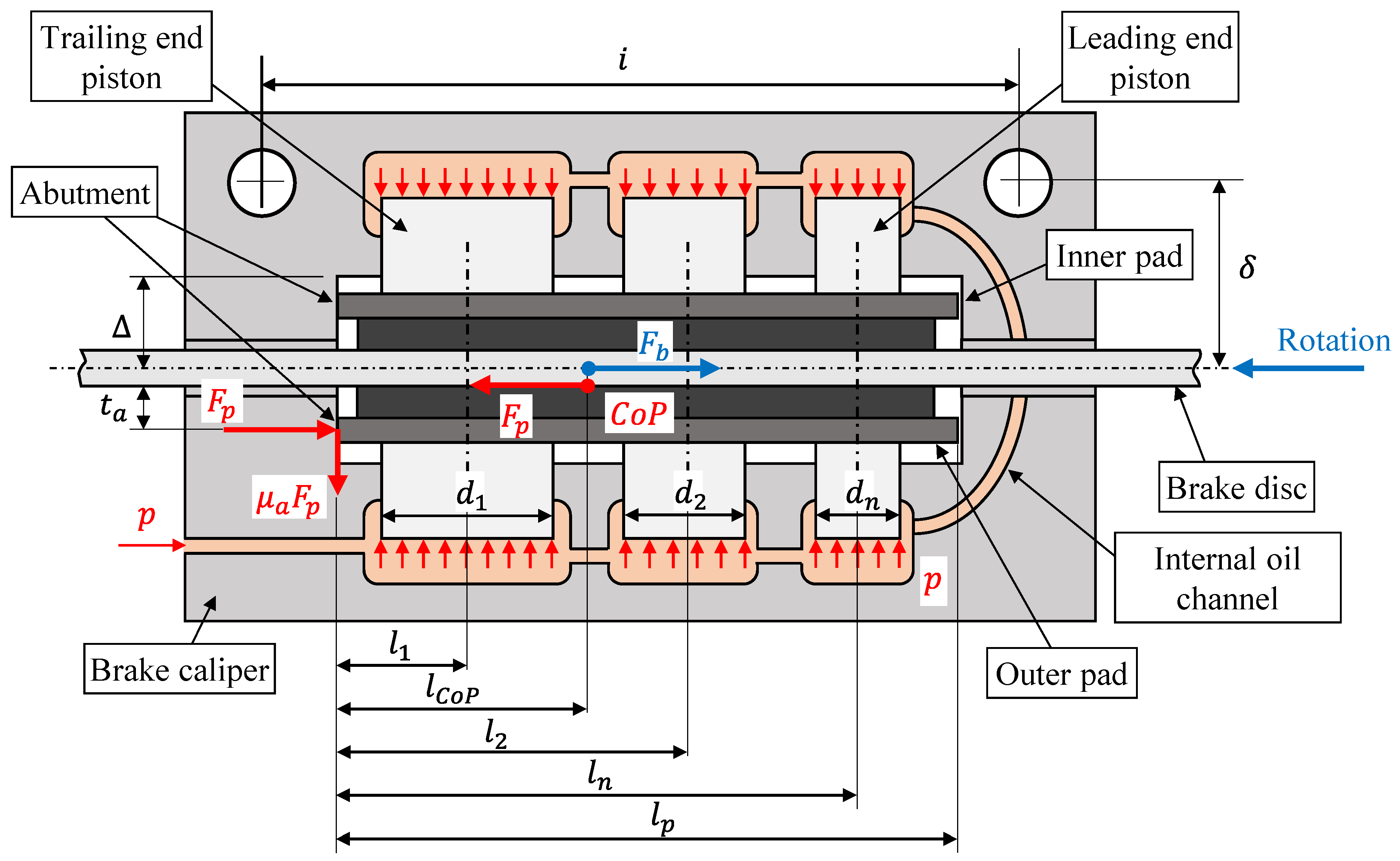

13]. A typical example of a fixed caliper design is illustrated in

Figure 3, which considers the case of a six-piston caliper.

Temporarily introducing the assumption that the forces generated by friction in the abutment

and the forces generated by the seals of each piston are negligible, the friction force generated at the interface between the disc and one pad is given by (

Figure 3):

where

is the friction coefficient between the brake disc and the lining material of the brake pad,

is the oil pressure in the hydraulic brake line,

is the total number of pistons, and

their corresponding diameters. It can be observed that the sizing of the caliper must be performed to ensure a braking capacity equal to or greater than the design value. This requirement translates into the following relation, obtained by comparing Equation (8) with Equation (9):

where the pressure

has been replaced with its maximum value

.

At this stage, the variables on the right-hand side of Equation (9) are completely defined, whereas those on the left-hand side need to be determined based on some design choices. The piston diameters

are somewhat constrained by the dimensions of the brake pad (or the backing plate) used, and larger diameters result in greater braking force, but also in an increase in the overall size and weight of the brake caliper. Typical values for FSAE applications range between 25 mm and 35 mm. Similar conclusions can be drawn for the number of pistons

, specifically, a higher number of pistons typically ensures greater force but also increases the overall size of the caliper. Additionally, the number of pistons depends on the type of pad used and can significantly affect the wear of the lining material [

19].

Regarding the choice of brake pads, it is generally more practical and economical to use a commercial pad or lining material with known performance characteristics rather than to develop a new pad material tailored to a specific caliper design [

13]. Subsequently, the selection among various commercial alternatives can be based on considerations related to cost, availability, and, most importantly, performance, usually in terms of friction coefficients (

in Equation (9)), wear resistance, and dimensions/geometry. Finally, the choice of maximum pressure

must be made to ensure compliance with the inequality in Equation (9). Noteworthily, the oil pressure

typically represents the critical design load for the brake caliper since it affects the size and weight of the brake caliper more than

. Consequently, it is preferable to design the system to minimize the pressure if it remains sufficiently high to guarantee the desired braking force

.

With these characteristics defined, the overall dimensions of the caliper must be determined by selecting the size and position of the pistons. An efficient method for making this decision is proposed by Sergent [

4]: he suggests using a simple model that assumes an in-plane 2D schematization of the brake caliper (as shown in

Figure 3, where the curvature of the brake disc at its mean radius has been rectified) to evaluate the position of the center of pressure (

CoP) of the contact forces between the disc and the pad and to optimize the position and size of the pistons to ensure uniform pad wear. Specifically, the caliper should be designed to ensure that the center of pressure is as close as possible to the centroid of the pad to avoid tapered wear and to ensure uniform wear across the entire surface of the pad [

13].

According to this model, in the static case, where a braking force is applied with the vehicle stopped, the friction forces in the abutment

are negligible, and the position of the

CoP on the pad coincides with the centroid of the pistons, calculated as the area-weighted average of the pistons as follows:

where

and

represent the positions of the pistons and the

CoP with respect to the abutment, respectively. Uniform wear is guaranteed if the following relation is satisfied [

12,

13]:

It must be emphasized that this simplified model assumes, among other hypotheses, an infinitely stiff pad and caliper. Therefore, when the design of the caliper is finished and its final geometry known, the real location of the

CoP is required to be checked through more accurate analyses, such as finite element analysis. Moreover, note that Equations (8) and (10) are valid only when the brake disc is stopped. Instead, when the pads are squeezed against the rotating brake disc, it drags them until they strike against the abutment, where a normal force

and a friction force

arise, the latter being no longer negligible due to the high value of the contact force

. Then, the friction force, located at a distance

from the pad–disc friction surface, opposes the motion of the pistons during the application of the load (

Figure 3) and displaces the

CoP compared to the static case (Equation (10)). Accordingly, referring to a single pad, the new friction force is less than that estimated by Equation (8) and can be calculated as follows:

which, properly rearranged, becomes:

Instead, the

updated for the case of the rotating disc can be estimated by imposing the equilibrium of moments about the

CoP itself:

Finally,

is obtained by rearranging Equation (14), and by exploiting Equation (13):

Equation (15) allows for designing the pistons’ diameters and locations since it points out explicitly the role of the main parameters affecting the position of the CoP. In particular, it must be noted that most of them (

,

,

,

, and, indirectly,

) depend on the shape and the material of the brake pad; so, the choice of the position and size of the pistons is specific for the considered brake pads. Moreover, other constraints must be considered, for example, technological feasibility and the need for a certain clearance between each piston to allow for the location of the seals. Eventually, a slightly larger diameter is typically chosen on the trail side compared to that on the leading side to compensate for the effects of the friction at the abutment (

in Equation (14)), the lever arm of the normal force (

in Equation (14)), and the elastic deformation of the caliper [

10,

12]. A more detailed discussion on this topic can be found in [

12,

13].

In the present investigation, a fixed caliper with four opposite pistons () was chosen, this configuration being a good compromise for minimum size of the caliper and optimal pressure distribution at the brake pad. The adopted commercial brake pads allow for a friction coefficient at the interface with the brake disc and an estimated value of at the abutment–backing plate interface. Furthermore, a new brake pad was considered and was used in the calculations, this value being dependent on the geometries of the caliper and pad, as well as on pad’s wear. Noteworthily, assuming that the value of coincides with the midpoint of the pad, allows us to observe that the terms in Equation (14) relevant to the friction at the abutment () and the lever arm of the normal force () assume comparable values. Specifically, in this case, the product is greater than .

At this point, it was possible to solve Equation (15) for the unknowns and by imposing that the CoP coincides with the midpoint of the pad (Equation (11)) to ensure uniform wear. Moreover, the diameters of the pistons had to be chosen to guarantee the required maximum braking force according to Equation (9). In doing so, it was also fundamental to consider only physically compatible solutions (e.g., solutions that do not locate a piston outside the pad or result in piston overlap) and to account for the necessary clearance between pistons to accommodate their seals.

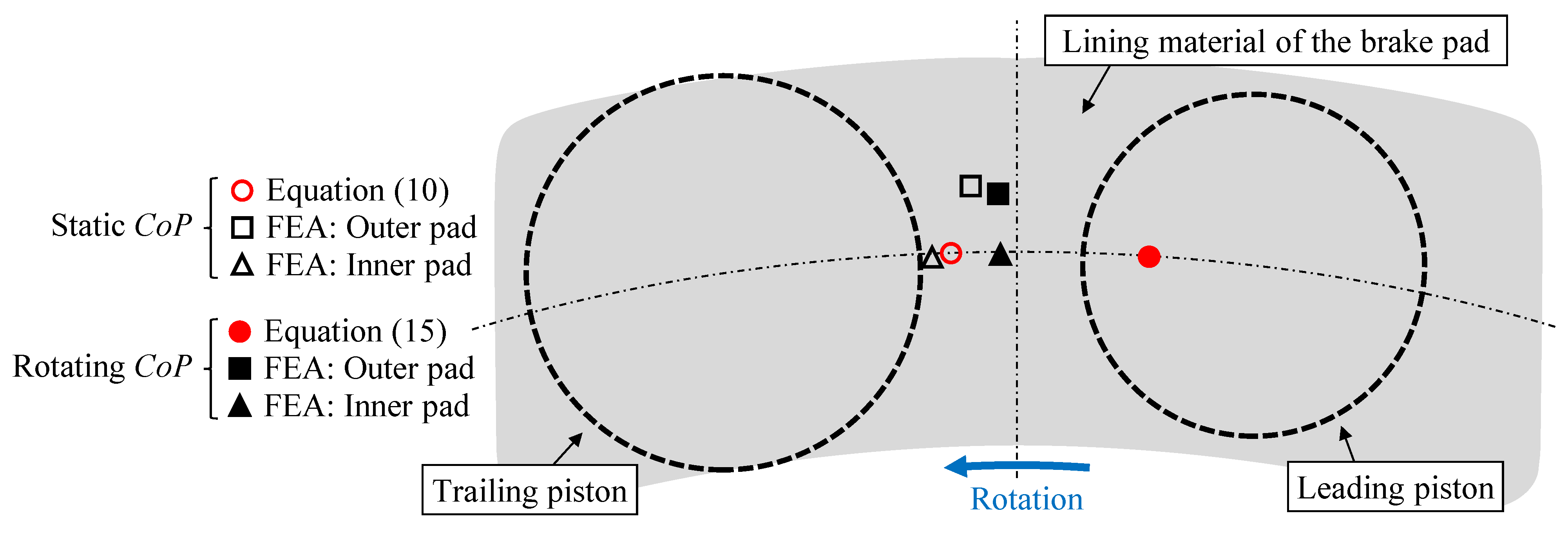

In this work, commercial values for pistons’ dimensions and their seals were used, resulting in diameters of

and

for the leading and trailing pistons, respectively. Concerning their position, the results are reported in

Figure 4, which also shows the corresponding

CoP for both the configurations with the static and rotating discs evaluated according to Equation (10) and Equation (15), respectively. The results show that the static

CoP (empty red marker in

Figure 4) is slightly to the left (toward the trail side) of the geometric center of the pad, while the

CoP with a rotating brake disc (filled red marker in

Figure 4) shifts to the right (toward the leading side), similarly to what was found in [

12]. In this particular case, to align the

CoP more closely to the center of the pad, it would have been necessary to reduce the friction coefficient at the abutment

, the height of the pad’s contact point on the abutment

, the clearance between the pistons, or to choose a smaller diameter on the leading side and a larger one on the trailing side. In the present investigation, the friction coefficient

and the height

were assumed to be fixed, their values being mainly dependent on the chosen brake pad. On the other hand, the clearance between the pistons had already been minimized, and further reduction would have fallen below the required limit to accommodate the hydraulic seals of the pistons (details of which will be presented later). Finally, a larger diameter

(on the trailing side) would have improved the

CoP position but reduced the maximum braking force (Equation (9)). Conversely, a larger diameter

(on the leading side) would have moved the

CoP closer to the piston’s axis, but it would have shifted the

CoP on the leading side since the distance

was constrained by the abutment geometry, the piston’s clearance, and the piston’s diameter

.

Finally, it is also important to recall that Equation (15) is an approximate expression, highly useful in the preliminary design phase, but requiring subsequent verification through more detailed analyses, such as finite element analysis, which can account for the caliper’s compliance and the contact between various components. Accordingly,

Figure 4 also shows the positions of the

CoP with static and rotating discs evaluated by the finite element analyses (black markers), which will be presented and discussed in the following paragraphs.

2.4. Topology Optimization

The topology optimization required defining the Design Space and Non-Design Space, both depending on the maximum overall dimensions of the caliper summarized by the parameters

,

, and

in

Figure 3 and by the height

h in

Figure 1. In general, small values for

,

, and

are preferred given that minimizing the volume of the caliper helps to reduce the overall mass and to reach a higher value of caliper’s stiffness. In more detail,

is primarily dependent on the thicknesses of the brake pad and disc. These factors also influence the choice of offset

(

Figure 3), whose value must consider enough space for the pistons’ stroke and for the oil chamber behind them. Similar considerations apply to the distance

(

Figure 3). Lastly, the height of the caliper (

h in

Figure 1) must be minimized and chosen according to the space available between the wheel rim and the hub carrier.

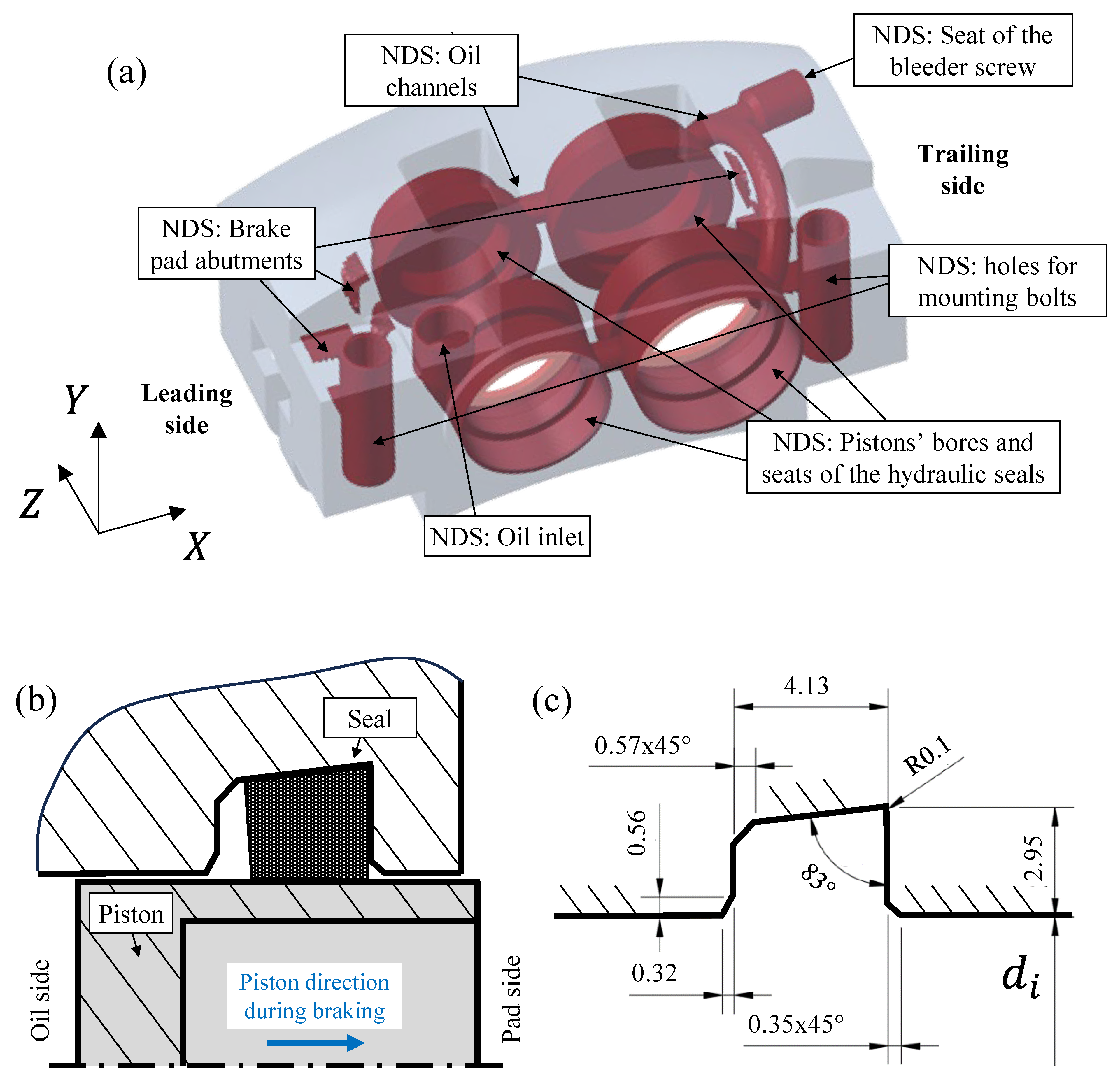

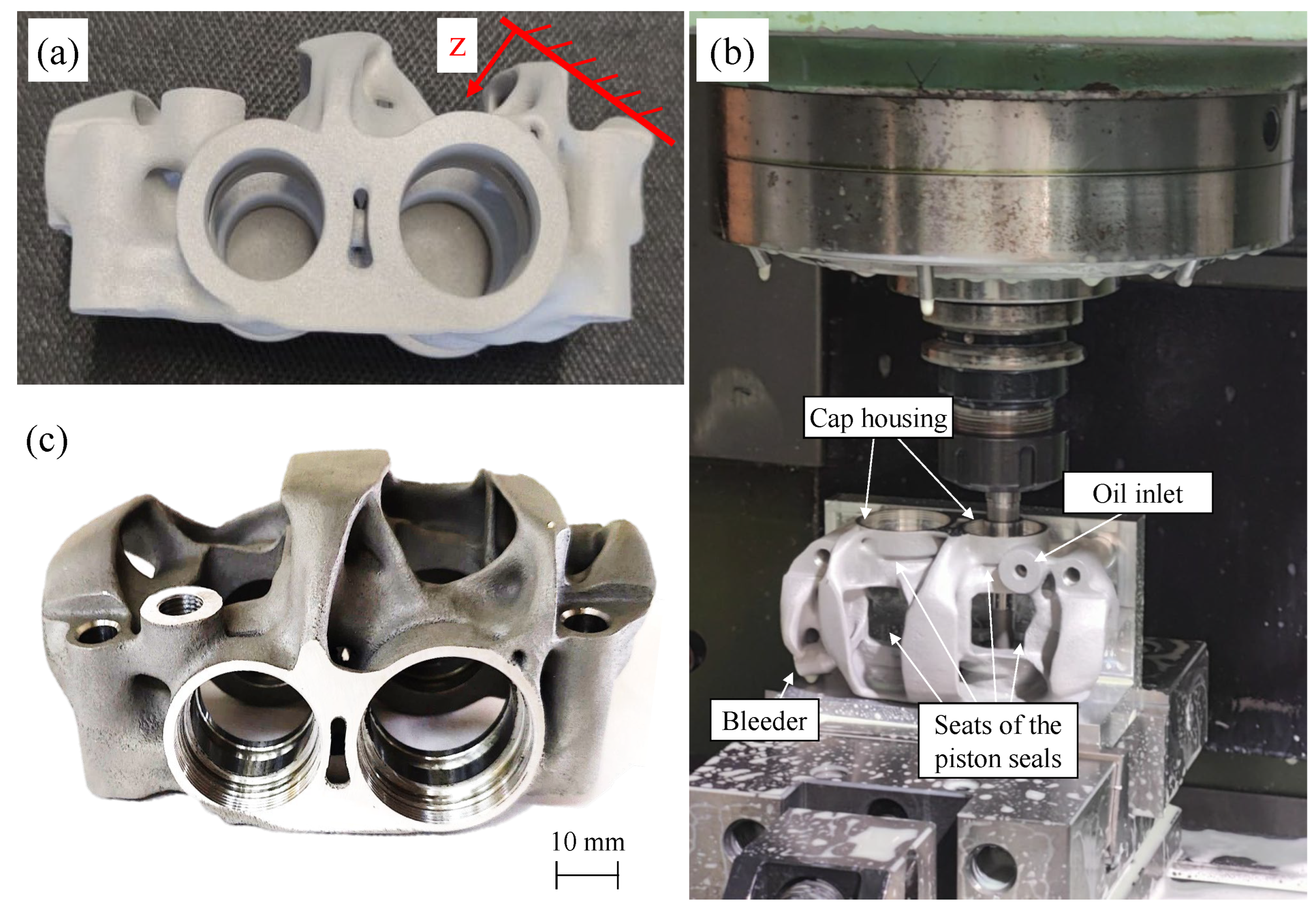

The Non-Design Space includes regions of the caliper such as the pistons’ bores, the seats for the seals, the brake pad abutments, the holes for the mounting bolts that secure the caliper to the hub carrier, and the oil inlet, as well as the internal oil channels and the seat of the bleeder screw (see

Figure 5a). Attention should be given to ensuring tolerances and facilitating post-printing machining operations for the pistons’ bores and their seals. To this end, it was decided to leave the bottoms of the pistons open on one side of the caliper and subsequently seal them with bore caps (see

Figure 5a).

Concerning the material, the brake caliper was made of an aluminum alloy with elastic modulus , Poisson’s ratio . Aluminum was preferred over titanium for this application due to its low density and high thermal conductivity that helps easily dissipating the heat generated during braking.

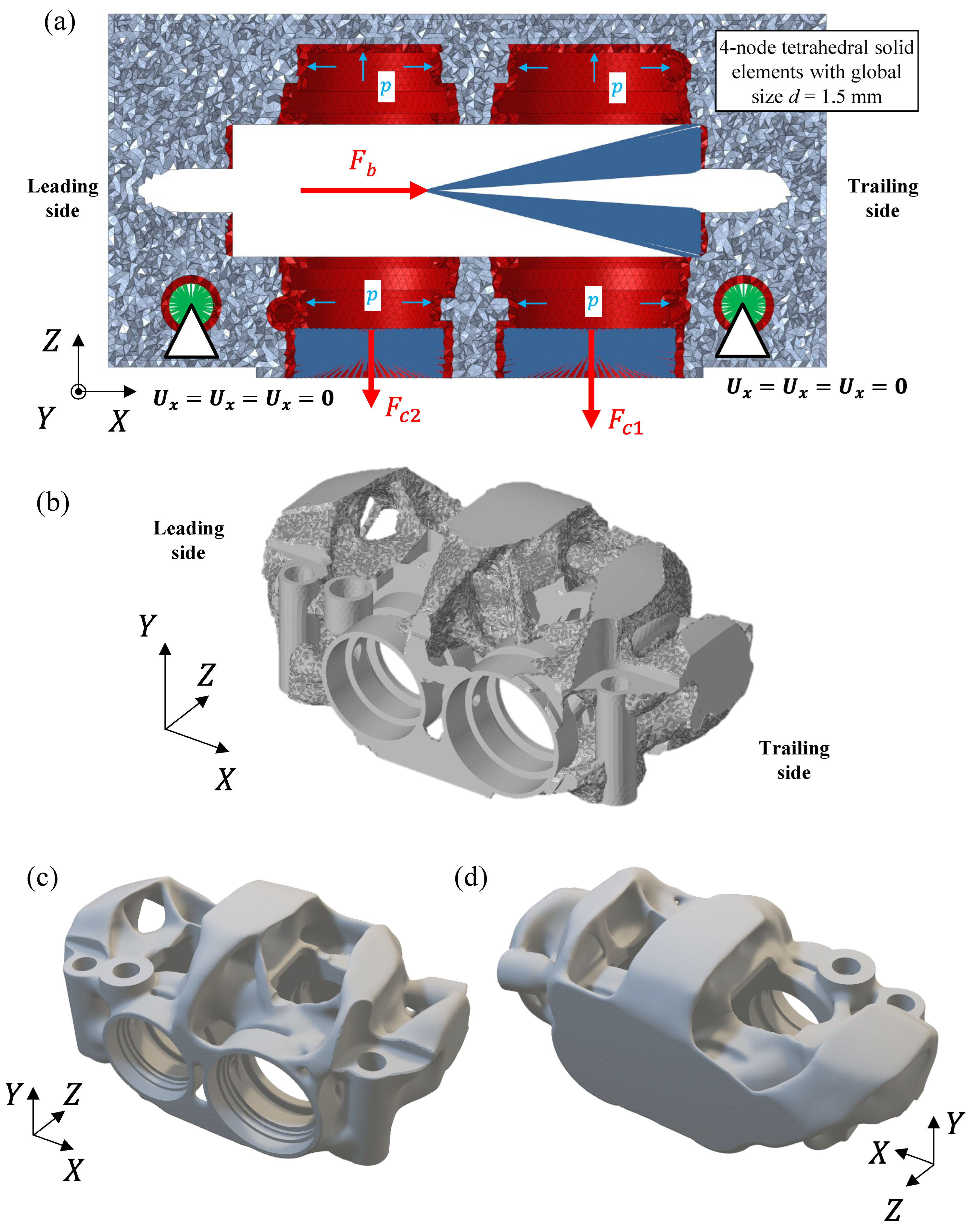

The model was generated within Altair

®’s Hypermesh-OptiStruct and subsequently discretized with a mesh of four-node tetrahedral elements, with an average size of 1.5 mm. The applied loads are as shown in

Figure 6a: a maximum braking force

applied at the theoretical

CoP and distributed to the abutment using

RBE3 elements, a maximum pressure

on all internal walls and channels in contact with the oil, forces

and

to simulate the force exerted by the internal pressure on the bore caps, and

RBE2 rigid elements to constrain the displacements of the internal nodes to the holes for the mounting bolts. The optimization parameters were included to minimize compliance (maximize stiffness) as the objective function. Eventually, a constraint on the final volume of 100,000 mm

3, i.e., a final weight of roughly 300 g, and a second constraint on the maximum Von Mises stress to be less than or equal to 170 MPa were imposed. In particular, the Von Mises stress limit was set at approximately 35% of the yield strength of Scalmalloy

®. This conservative value was chosen because the mesh used during the topology optimization phase was relatively coarse (to reduce computational time), and the peak stress values near the most critical notches were likely not fully converged. Selecting a higher target value at this stage could have resulted in geometries that were excessively stressed near the notches when analyzed with a refined mesh after the optimization process. Thereafter, the mesh generated by the optimization process (

Figure 6b) was refined within Ansys

® SpaceClaim and subsequently imported into Blender

® and nTopology

® for surface smoothing and final solid model generation (

Figure 6c,d).

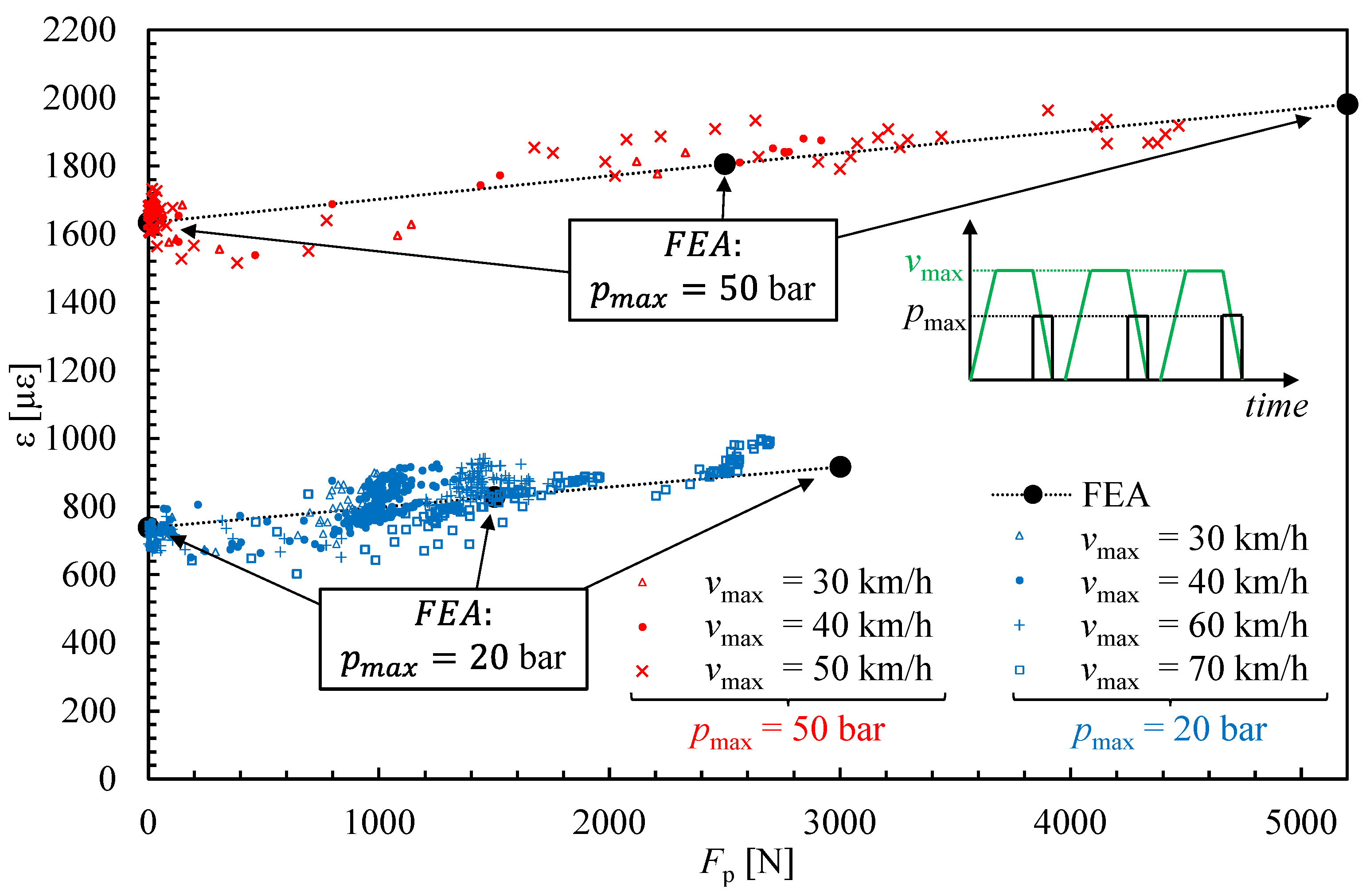

2.5. Finite Element Analyses and Manufacturing

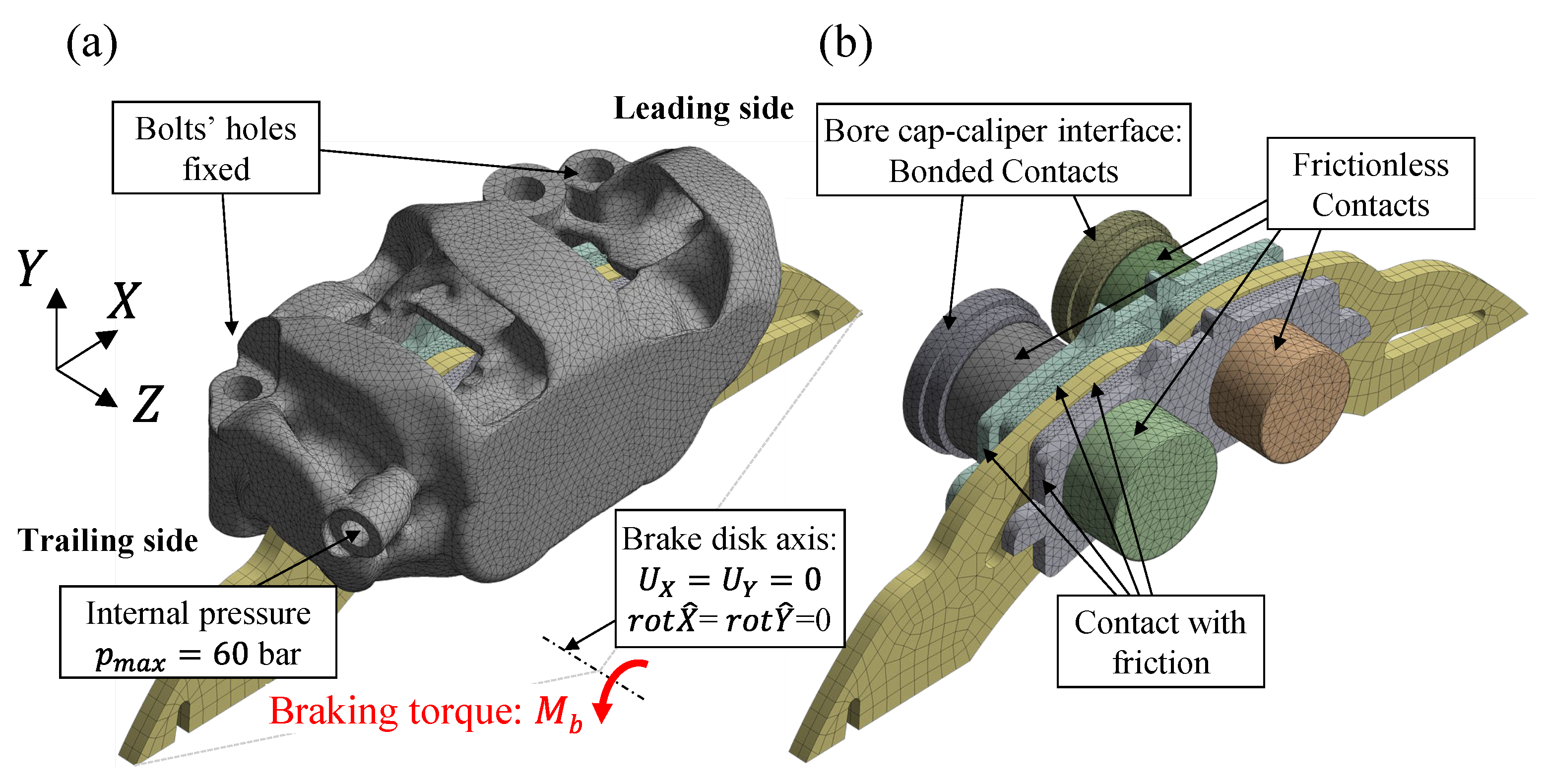

With the final CAD model (

Figure 6c,d), a structural finite element model was carried out to verify the correctness of the real

CoP’s location (

Figure 7a,b). In particular, the aim of this FE analysis was to evaluate the actual position of the

CoP with both static and rotating discs, considering contacts and stiffnesses of the various components comprising the caliper assembly (disc, pads, pistons, and the caliper body), and to check if it coincided with the geometric centroid of the pads. If discrepancies were found, the design choices would need to be reiterated, and the optimization process restarted.

To make the simulation as realistic as possible, the entire brake caliper assembly was modeled in Ansys

® Workbench considering all the different components as separate bodies in contact with each other (

Figure 7a,b). The hydraulic seals were omitted to avoid increasing the already significant complexity and computational time of the simulation, the latter being nonlinear due to the large number of contact regions. Consequently, the hydraulic seals were replaced with a unilateral holonomic frictionless constraint that precisely guides the axial movement of the pistons, which were placed in the cylinders without clearance. For simplicity, a unilateral holonomic frictionless constraint was also used at the piston–pad interface (

Figure 7b). In contrast, a contact with friction was applied at both the pad–disc and the pad–caliper abutment interfaces (

Figure 7b), with friction coefficients

and

, respectively. Finally, structural continuity was assumed at all the bore cap–caliper interfaces (“Bonded contacts” in

Figure 7b). The bore caps and caliper body were modeled in aluminum alloy, assuming an elastic modulus E = 71,000 MPa and a Poisson’s ratio

. The pistons were made of titanium alloy (E = 115,000 MPa,

) due to its low thermal conductivity, which helps isolate the oil and the body of the caliper from the heat generated by the brake pad. The Young’s modulus E = 210,000 MPa and Poisson’s ratio

of steel were used for both the brake disc and the brake pads, the latter with a 4.5 mm thick backing plate made of steel behind the lining material.

After defining the materials and contacts, the model was discretized with a mesh of 10-node tetrahedral elements for the caliper body and 4-node tetrahedral elements for all other parts, with an average element size of 1.5 mm in both cases (

Figure 7a,b). All nodal displacements at the nodes on the holes for the mounting bolts were constrained. The brake disc was restrained with a remote point at its center to block translations in the X and Y directions and rotations about these axes. Conversely, translation along the

Z-axis and rotation around the same axis were left free to correctly simulate the motion of the floating disc (

Figure 7b). The loads, applied in two different load steps, allowed for the simulation of both the static and the rotating disc configurations in a single FE analysis. In the first load step, only the internal pressure

was applied to all internal channels of the caliper, to the bore caps, and to the faces of the pistons in contact with the oil. In the second load step, an additional torque was applied to the disc to simulate the condition of the rotating disc.

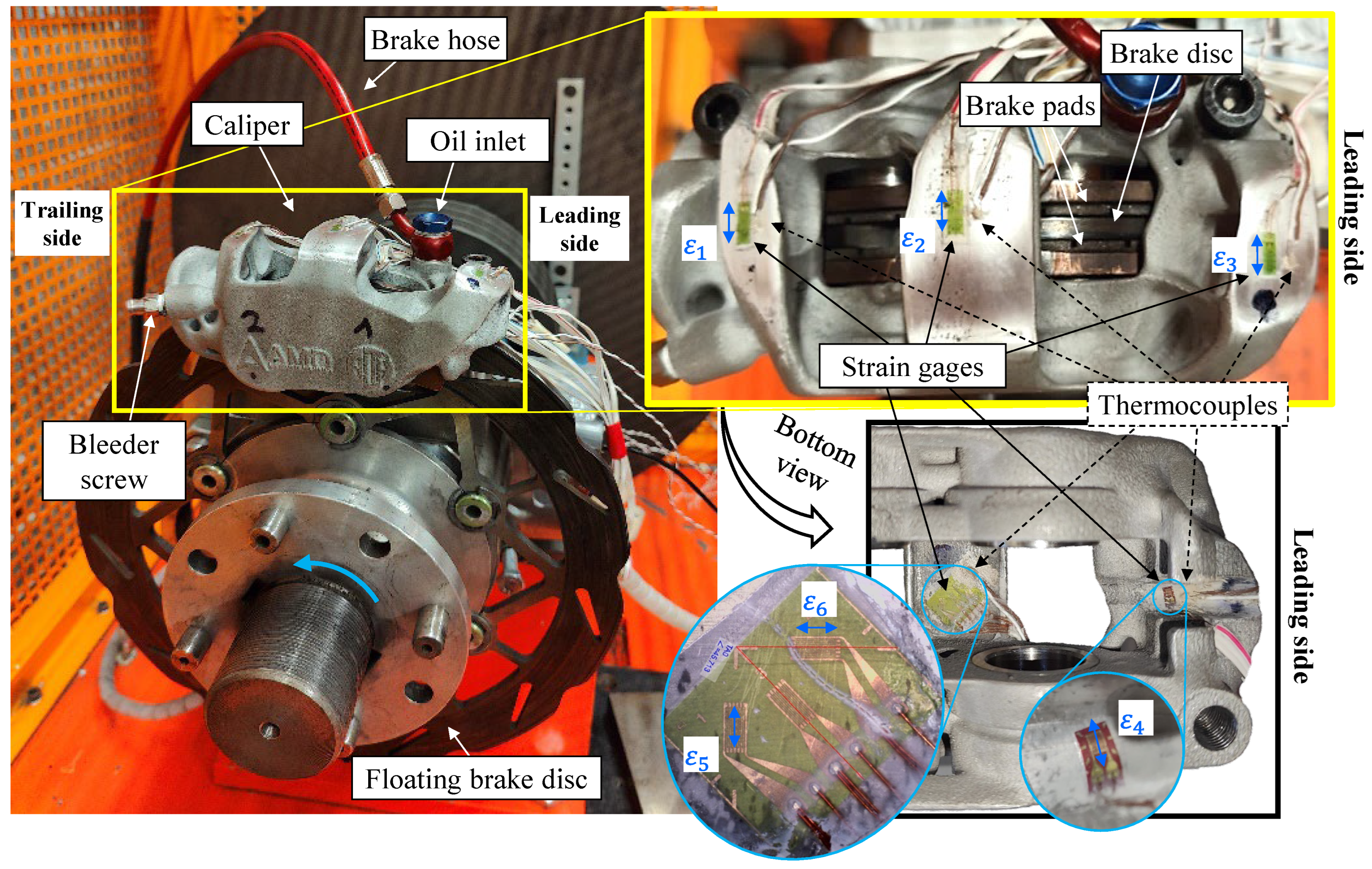

At the end of each substep of the simulation, the nodal values of the pressure on the face of each pad in contact with the disc were extracted and used to calculate the

CoP. The corresponding results are presented in

Figure 4 for both the static disc case (open black markers) and the rotating disc case (filled black markers), and for both the outer pad (square markers) and the inner pad (triangle markers). The results indicate that the deformation of the caliper, particularly the ‘opening up’ due to the bending of the bridge [

10], causes a slight upward shift of the

CoP for the outer pad compared to the inner pad (compare square markers with triangle markers in

Figure 4). Noteworthily, the

CoP determined from numerical analyses is very close to the geometric centroid of the inner and outer pads in all simulated cases (see black markers in

Figure 4), confirming the final caliper’s geometry. As discussed above, if this had not been the case, meaning the

CoP did not coincide with the geometric centroid of the pad, the position and size of the pistons would have needed to be iteratively adjusted, repeating the optimization and verification process until convergence was achieved.

The final geometry of the optimized caliper was additively manufactured in an aluminum alloy, specifically an Al-Mg-Sc alloy (Scalmalloy

®), using laser powder bed fusion (LPBF). In particular, an EOS M400-1 3D printer was adopted, with no pre-heating, and the platform temperature at approximately 35 °C. The powder diameter ranged from 80 to 100 μm and the building direction was that given in

Figure 8a. After the printing process, the caliper was shot-peened and sandblasted for support removal and then heat-treated for 240 min at 325 °C. The obtained component is shown in

Figure 8a. More details and parameters are omitted for confidentiality reasons.

Subsequently, the 3D-printed caliper was machined to refine regions requiring tight geometric tolerances. Specifically, the caliper was installed on a custom fixture designed for mounting on a three-axis CNC milling machine (

Figure 8b). This setup enabled the machining of the seats for the seals of the pistons and the caps (which required the use of custom-designed tools), as well as the oil inlet and the bleeder. The latter, being inclined relative to the milling machine axes, was machined using a tilting vise. The final caliper is shown in

Figure 8c.

Eventually, the entire brake caliper was assembled, and its overall dry weight was measured to be 429 g.