Abstract

Doce de leite (DL) is a product originating in South America, particularly in countries such as Brazil, Argentina, and Uruguay. The product is widely used for direct consumption and industrial applications and can be added with thickening agents to modify its rheological properties. This study aimed to produce DL with the addition of three different components (skimmed milk powder—SMP, whey protein concentrate—WPC, and microparticulated whey protein—MWP) in two different concentrations (2.1 and 4.2%). The composition of the products aligned with Mercosur regulations, except for the fat content, where the result was slightly lower. The HMF (5-hydroxymethylfurfural) concentration in the samples was also determined, showing no statistically significant differences between products. The products with SMP showed a higher browning index and color saturation compared to WPC and MWP formulations. The addition of MWP increased the hardness (from 10.2 to 467.8 g), gumminess (from 8.2 to 362.1 g), and viscosity (from 6.7 to 18.3 Pa.s) of the DL compared to the control product (SMP). These findings suggest that adding MWP can modulate the rheological and textural characteristics of such products without significantly altering their proximate composition, offering an alternative to using thickeners in this type of product.

1. Introduction

Doce de leite (DL) is a product obtained by concentrating and heating milk or reconstituted milk under normal or reduced pressure, with or without the addition of dairy solids and/or cream, and added sucrose (partially substituted or not by monosaccharides and/or other disaccharides) [1].

DL originates from South America, with Brazil, Argentina, and Uruguay having the largest consumer markets and highest production of this food [2]. In Brazil, the state that stands out in the production of DL is Minas Gerais, accounting for more than 60% of all national production [3]. This product is commonly produced by both large and small producers, thus resulting in a wide variability of its physicochemical and sensory characteristics in Brazil [4].

DL is widely used for direct consumption and in the food industry, so maintaining control over the product’s characteristics is essential for brand/market success [5]. DL intended for confectionery can be added with thickeners/stabilizers and/or humectants and must meet certain characteristics, especially high viscosity, which is requirement for creating relatively stable profiles and structures [6].

The advancement in the development of foods with better nutritional value has led the industry to seek alternatives to a) replace certain constituents, such as some additives, and b) to shorten the list of ingredients [7,8]. In this context, the dairy industry has incorporated different types of (milk) proteins into the manufacturing of various products while aiming to maintain their original characteristics. For example, supplementation with skim milk powder (SMP) and/or whey protein concentrates or isolates (WPCs or WPIs) is widely practiced [9]; however, some proteins, such as whey proteins, might have a high rate of thermal denaturation, which can generate undesirable characteristics in the product [10,11]. To overcome this problem, microparticulation has emerged as an alternative, since microparticulated proteins are already denatured, reducing problems such as phase separation [12].

Microparticulated whey proteins (MWPs) are obtained by a process that involves the denaturation and aggregation of these particles by heating, followed by controlled intense shearing steps, to monitor the aggregation and fragmentation of aggregates formed during heating [13]. In addition, pH adjustment, protein, lactose, minerals, and salt concentration play key roles in this process [14,15,16]. As a result, MWPs become a combination of denatured and native proteins, with particle sizes ranging from 0.1 µm to 10 µm [17,18]. This combination of native and aggregated particles can make proteins more resistant to (a downstream) heat treatment, since there is a reduction in the number of free thiol groups, which are responsible for the formation of disulfide (strong covalent) bonds generated during protein denaturation [19], and also results in water absorption, which affects the viscosity and texture of the product to which it is added [20,21].

Studies have reported the use of MWP in various products, such as yogurt, cheese, salad dressing, and ice cream [18,20,21,22,23,24]. That said, in the context of DL formulation, supplementing milk with microparticulated whey protein appears as a possible alternative for replacing thickeners, since it can modify the viscosity of the product while contributing to increasing its nutritional value [25]. In addition, this protein has the potential to mimic fat and, hence, to reduce the lipid content in a formulation, as well as to enhance flavor and improve the emulsifying capacity of foods [11,16,18].

In the dairy literature, we could not find any report on the use of MWP in DL manufacture. The present work aims to partially replace a portion of the milk used in a DL formulation with whey protein concentrate (WPC) and with microparticulated whey protein (MWP), each supplemented at two levels, and evaluate the physicochemical and rheological modifications of the products obtained in comparison to a conventional product with added skim milk powder (SMP) at the same level as the control.

2. Materials and Methods

2.1. Milk Substitutes and Control Sample

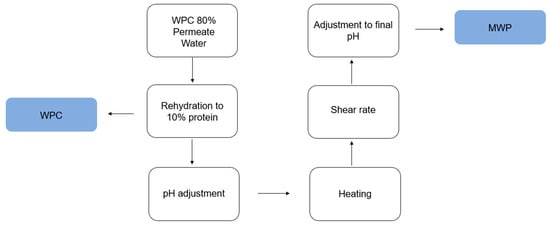

Skimmed milk powder (SMP), whey protein concentrate (WPC), and microparticulated whey protein (MWP) were used as (milk) substitutes in the DL prototypes’ production. The WPC solution was obtained and microparticulation of this solution (MWP) was carried out in this study. Deionized water, WPC 80% (80.0% (w.w−1) protein; 6.6%(w.w−1) lactose; 3.6% (w.w−1) ash; Manufactured by Sooro Renner Nutrition S.A. (Mal. Cândido Rondon-PR, Brasil)), and whey permeate powder (89.8% (w.w−1) lactose; 5.6% (w.w−1) ash; Manufactured by Sooro Renner Nutrition S.A. (Mal. Cândido Rondon, PR, Brasil)) were weighed, mixed, and then dissolved in water (22 ± 1 °C) to obtain a final solution with 10.0% (w.w−1) protein, 9.4% (w.w−1) lactose, and 20.0% (w.w−1) total solids, with the solution named WPC. A portion of the rehydrated WPC solution was also used to obtain the microparticulated whey protein solution (MWP) after adjusting its pH, as shown in Figure 1. In addition, the SMP (control supplement) was prepared from reconstituted skimmed milk powder (Itambé® (Lactalis, Sete Lagoas, MG, Brasil); 33.0% (w.w−1) protein; 48.0% lactose) to obtain a solution with a 10.0% (w.w−1) protein and 14.0% (w.w−1) lactose content.

Figure 1.

Schema utilized to prepare the liquid whey protein concentrate (WPC) and the microparticulated whey protein (MWP).

To characterize the microparticulation process, the particle size of the whey protein solutions (WPC and MWP) and the denaturation level induced by the process were analyzed before/after treatment by determining via high-performance liquid chromatography (HPLC) [26] the native α-lactalbumin (α-la) and β-lactoglobulin (β-lg) content. The particle size was determined by a particle size analyzer LS 13 320 (Beckman Coulter, Brea, CA, USA), coupled with a liquid module. The solutions before and after the microparticulation process (WPC and MWP) were added directly to the equipment’s reservoir for reading, and the results obtained are reported as the average particle size (Dv50).

The denaturation level induced by the microparticulation of the α-la and β-lg fractions was determined by HPLC (system Waters, model 1525, Milford, MA, USA), equipped with a UV-VIS detector (DAD, diode array detector) and a binary pump. Chromatographic separation was performed on a Phenomenex column Luna (5 μm, 250 mm × 4.6 mm), kept at 40 °C. The injection volume was 20 μL, and detection of β-lg and α-la was carried out at 214 nm. Gradient elution was performed using a mixture of two solvents at a flow rate of 0.5 mL min−1. The mobile phase comprised 0.1% TFA in ultrapure water (solvent A) and 0.09% TFA in 90% acetonitrile/10% ultrapure water (solvent B). A gradient program was initiated as follows: 0–3 min, 20–40% B; 3–5 min, 45–45% B; 5–7 min, 45–50% B; 7–9 min, 50–80% B; 9–14 min, 80–20% B; and 14–15 min, 20–20% B [26]. The determination of the percentage of protein denaturation was calculated based on the results obtained from the quantification of each of the protein fractions before and after the protein microparticulation process [10].

2.2. Doce De Leite Prototypes Production

Six DL samples (2 × 3) were formulated using a Thermomix process simulator (TM5, Vorwerk, Wuppertal, Germany) coupled to a load cell (Ramuza IDR 7.500, Santana de Parnaíba, Brazil). The production was carried out as described by Pinto et al., [27], in triplicate (n = 3). The DL was manufactured with partial substitution of milk at 2.1% and 4.2% of the total mass of the mixture. SMP, WPC, and MWP were used as (milk) substitutes in the production. Table 1 represents the quantity of each material used for the manufacture of the DL prototypes.

Table 1.

Ingredients and formulation used in doce de leite production.

The milk used to make the DL prototypes had the following average composition: 3.14 ± 0.16% (w.w−1) fat, 3.13 ± 0.10% (w.w−1) protein, 4.18 ± 0.16% (w.w−1) lactose, 87.89 ± 0.21% (w.w−1) moisture, and 6.68 ± 0.09 pH. Analyses were carried out on each of the batches of milk used to make the DL samples. Compositional analysis (moisture, soluble solids, fat, protein, carbohydrate, ash, pH, and lactic acid), quantification of Maillard reaction markers, colorimetry, browning index, texture, and rheology were assessed as described below.

2.3. Gross Composition and Physical–Chemical Parameters

Moisture content was determined using a thermogravimetric balance with infrared heating (Sartorius, model MA 150, Göttingen, Germany). The temperature used was 145 °C, and the moisture content was determined when the first variation in water loss of 0.05 g or less was observed [28].

The soluble solids index was determined by refractometry using a digital refractometer (Hanna, model HI96801, Cluj-Napoca, Romania); samples were taken at 22 ± 1 °C by carefully deposing a portion of the sample directly into the sample holder of the equipment [27].

For the determination of fat, the Gerber method was used [29]. The fixed mineral residue (ashes) was determined in a muffle furnace (Quimis, model Q318M21, Diadema, Brazil). The sample was incinerated at 550 °C for approximately 6 h, was weighed before and after incineration, and the percentage of ashes was calculated from the resulting mass [30]. The protein content was determined by the ISO8968-1 methodology [31], which details the Kjeldahl principle for determining the nitrogen and crude protein content in milk and dairy products. The carbohydrate content was measured by difference: 100–(water + protein + fat + ash) [32].

The pH was measured using a portable digital pH meter (Gehaka, model PH1400, Real Parque, Brazil) at a temperature of 22 ± 1 °C. The acidity index (lactic acid) was determined by titration following ISO/IDF methodology [33].

2.4. Quantification of Maillard Reaction Markers

Standards of 5-hydroxymethylfurfural (HMF), 2-furfuraldehyde (F), 5-methyl-2-furfural (MF), and 2-furylmethylketone (FMC), as well as the solvent acetonitrile, were obtained from Sigma-Aldrich in analytical grade. The analytes were quantified by reverse-phase HPLC (Waters, model 1525, Milford, MA, USA), with a UV-Vis detector (PDA—Photodiode Array Detector) and a binary pump. A gradient was used for elution at a flow rate of 1 mL.min−1, with a mobile phase composed of water and acetonitrile (ACN) in an initial ratio of (95.5:4.5) H2O:ACN; 5 min/(80:20) H2O:ACN; 9 min/(95.5:4.5) H2O:ACN and 10 min/(95.5:4.5) H2O:ACN. Chromatographic separation employed a Waters Spherisorb column (150 mm × 4.6 mm; particle size 3 µm), with a temperature set at 30 °C, injection volume of 20 µL, and analytes detected at a wavelength of 284 nm, as described in [34].

To prepare the sample, 1 g of DL was transferred to a 10 mL volumetric flask and the meniscus was adjusted with ultrapure water (MilliQ) at room temperature (22 ± 1 °C); then, a 1 mL aliquot was taken from this solution and added with 200 µL of ultrapure water (MilliQ) to an Eppendorf tube. The solution was vortexed in a vortex mixer K45-2810 (KASVI, Pinhais, Brazil) for 20 s. In total, 300 µL of 55% (w.v−1) trichloroacetic acid (TCA) was added, and the sample was vortexed again for another 20 s. This solution was centrifuged for 10 min in a KASVI K14-1215P centrifuge (KASVI, Pinhais, Brazil) (15,590× g), and then 500 µL of the supernatant was removed, to which 100 µL of ultrapure water and 300 µL of TCA were added. This new solution was centrifuged for 20 min, and the supernatant was collected and subsequently filtered through a 0.22 µm filter. After this preparation, the sample was manually injected into the HPLC apparatus [34].

2.5. Color Parameters (CIE-LAB) and Browning Index

For the color analysis of the different DL prototypes, the CIELab (Commission Internationale de l’Eclairage) scale was used, which consists of five parameters, L, a*, b*, C*, and h. The L parameter refers to the brightness of a product, with the scale ranging from 0 (black) to 100 (white). The a* scale varies from negative values (green) to positive values (red). The b* scale ranges from negative values (blue) to positive values (yellow). The C* parameter refers to the amount of saturation of a certain color, and the last parameter, h, refers to the hue of that color. All these parameters were determined using a colorimeter (Konica Minolta, model CR-400, Chiyoda, Tokyo, Japan), and the analysis was carried out directly on the sample [28].

The browning index (BI) was determined using the L, a*, and b* parameters from the colorimetric analysis by Equations (1) and (2) [35].

whereby

2.6. Texture

A texture analysis equipment (Brookfield, model CT3 Texture Analyzer, Middleboro, MA, USA) was used to measure hardness and gumminess parameters. The texture profile analysis (TPA) measurement method was employed, with a sample depth of 6.0 mm, trigger force of 6.8 g, and analysis speed of 0.50 mm/s. The TA11/1000 probe was used for the analyses. This analysis was carried out at a temperature of 22 °C.

2.7. Rheology

Rheological determinations were performed using a rheometer (Thermo Scientific, model Haake Viscotester iQ, Waltham, MA, USA). Parallel plate geometry with a dimension of 35 mm and an analysis temperature of 22 °C was used. Data acquisition was conducted with an ascent from 0.1 s−1 to 100.0 s−1 over a period of 200 s and descent from 100.0 s−1 to 0.1 s−1 over a period of 200 s.

2.8. Statistical Analysis

Statistical analyses were conducted at a significance level of 0.05 using the Tukey test applied with the assistance of R software version 4.1.2 (The R® Foundation for Statistical Computing, Vienna, Austria). All analyses were performed in triplicate.

3. Results and Discussion

3.1. Characterization of WPC and MWP Protein Solution

The protein solutions before (WPC) and after (MWP) microparticulation had an average particle size of 10.62 ± 3.76 µm and 4.88 ± 0.38 µm, respectively, demonstrating the effect of the microparticulation process on particle size.

Regarding the concentration of the major protein fractions, α-la and β-lg, initially (WPC before microparticulation) the concentrations were 0.63 ± 0.03 g.100 g−1 and 2.68 ± 0.22 g.100 g−1, respectively, and the final concentrations (MWP) were 0.23 ± 0.02 g.100 g−1 and 0.10 ± 0.02 g.100 g−1 after microparticulation, respectively. This resulted in a denaturation level caused by microparticulation of approximately 63.5% for α-la and 96.3% for β-lg.

3.2. Gross Composition and Physical–Chemical Parameters

The Mercosur establishes compositional limits for moisture concentration (maximum of 30% w.w−1), fat (from 6% to 9% w.w−1), ash (maximum of 2% w.w−1), and protein (minimum of 5% w.w−1) in DL [1]. All six prototypes showed values within the established limits for moisture, ash, and protein; however, the results obtained for fat were below the stipulated range for WPC and MWP products at both substitution concentrations (Table 2). The same result for fat was observed by Gwala et al., where the authors added WPI (whey protein isolate) and WPH (whey protein hydrolysate) in the manufacture of DL [9]. The results obtained for all compositional parameters were consistent with other studies reported in the literature [3,5,35].

Table 2.

Proximate composition of doce de leite samples supplemented with dairy proteins.

The parameters of moisture, fat, and lactic acid did not show statistical differences among the six produced DL samples. However, for the protein parameter, there were statistical differences (p < 0.05) between the three treatments with 4.2% supplementation, but not at the 2.1% substitution level. This difference might be attributed to the milk used in the manufacturing of the three prototypes, because the substitutes were standardized to 10% (w.w−1) protein.

Another attribute that showed a statistical difference was ash content. The SMP and MWP products, at the same substitute concentration, showed a significant statistical difference, probably due to the mineral content of the raw materials (e.g., whey permeate). No statistical difference was observed between the WPC and MWP DL products.

Regarding the carbohydrate content of the three DL prototypes, statistical differences (p < 0.05) were observed at both supplementation levels, but not within the same level. The pH values between the three prototypes were not statistically different (p > 0.05) within each supplementation level, but there were slight pH differences for the three prototypes between both levels (Table 2), with values ranging from 6.51 to 6.61, similar to those reported in the literature for this type of product [32].

3.3. Quantification of Maillard Reaction Markers

Four markers of the Maillard reaction, namely 5-hydroxymethylfurfural (HMF), 2-furaldehyde (F), 5-methyl-2-furfural (MF), and 2-furylmethylketone (FMC), were analyzed. Among the four products analyzed, only HMF was found in the DL samples (Table 2). The results obtained for the six products did not show statistical differences. However, even if there were no statistical differences between the concentrations of HMF obtained in the samples, it was observed that the products added with WPC and MWP had higher values of this intermediate than the control product (SMP). This statistical similarity is probably related to the high deviations (see the standard deviations in Table 2) obtained during the analysis, which are associated with the complexity of the study matrix.

The concentration of the determined HMF was close to that reported in a recent study, where the author varied the added sucrose concentration in DL production [3].

3.4. Color Parameters (CIE-LAB) and Browning Index

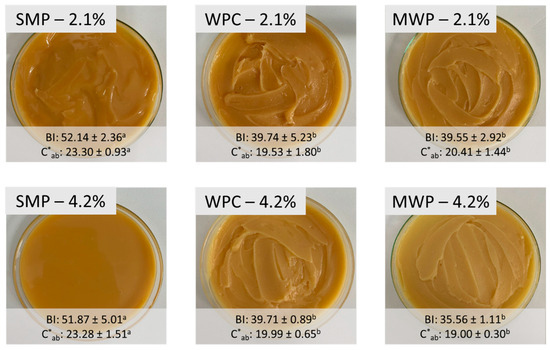

The color parameters and browning index of the DL products with 2.1% milk substitution showed similar behavior to the product with 4.2% substitution (Figure 2). The lighter color difference between the samples with 4.2% supplementation might be attributed to the lower carbohydrate level compared to those samples with 2.1% substitution. Moreover, the products added with WPC or MWP were lighter in color than the product made with SMP. This is surprising, because the carbohydrate and HMF contents of WPC and MWP products were, on average, higher than the SMP samples, suggesting that these two parameters are not enough to characterize color in DL. It is conceivable that the lower pH (6.51) of these samples (at 4.2% addition level) might be the reason for the color difference (see also Table 2). Comparing the results obtained for the saturation parameter (denoted as C*, see Figure 2 and point 2.5), the product using SMP showed higher saturation than the other two products (WPC and MWP) at both substitution concentrations. In both analyses, the substitution percentage did not generate statistical differences between products with the same milk substitute (SMP, WPC, and MWP).

Figure 2.

Browning index (BI) and saturation (C*ab) images of the laboratory prototypes of doce de leite, prepared with milk substitutes added at of 2.1% and 4.2% levels to the processing milk.

Averages followed by the same letter in the line do not differ from each other by the Tukey test at 5% probability. Abbreviation: SMP—skimmed milk powder; WPC—whey protein concentrate; MWP—microparticulated whey protein.

The browning index (BI) values of DL prototypes with SMP were close to the values reported in the literature for DL products with and without crystallization after production [35]. The BI of both SMP prototypes (2.1% and 4.2%) was clearly higher than that in the WPC and MWP samples. Interestingly, in the literature report, the use of MWP in bread production resulted in darker products after production [36].

The lighter color and lower browning index of DL samples with added WPC and MWP, compared to SMP, can be rationalized by differences in the carbohydrate–protein matrix and the reactivity of available substrates for the Maillard reaction. Conversely, whey proteins, especially in their microparticulated form, underwent extensive denaturation before incorporation into the DL system, exposing thiol and amino groups that may preferentially engage in protein–protein interactions rather than in glycation pathways. This structural behavior could partially divert reactive groups away from the Maillard reaction, limiting chromophore formation despite measurable levels of HMF. These factors provide a possible mechanistic explanation for the lighter appearance of DL with MWP, suggesting that protein state and matrix interactions play a more decisive role than sugar concentration alone in color development.

3.5. Texture

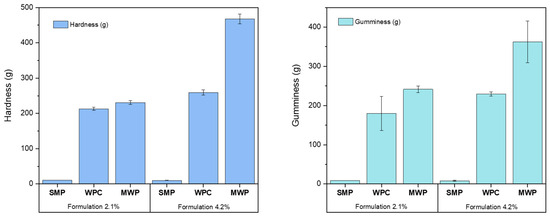

For texture analysis, the following two parameters were quantified: hardness and gumminess (Figure 3). Hardness refers to the resistance of a material to undergoing plastic deformation. This attribute was extremely high (467.8 ± 13.9 g) for the product added with 4.2% MWP compared to all other products. The DL products with 2.1%WPC, 4.2%WPC, and 2.1%MWP had similar hardness, being, respectively, 213.0 ± 4.6 g, 259.2 ± 7.3 g, and 230.8 ± 5.0 g. The two DL samples added with SMP (2.1% and 4.2%) showed lower hardness values (11.0 ± 0.1 g and 10.2 ± 0.3 g, respectively). From these results, a clear effect of the added whey proteins on the hardness of doce de leite is evident compared to the addition of skim milk powder.

Figure 3.

Texture properties (hardness and gumminess) of doce de leite samples, prepared with three milk replacers, each at two addition levels (2.1% and 4.2%): SMP—skimmed milk powder; WPC—whey protein concentrate; MWP—microparticulated whey protein.

Gumminess, a material property, can be understood as the energy required to disintegrate or chew a food; it indicates the difficulty in biting, chewing, or even swallowing a food. The results for gumminess in DL, as determined with the texture profile analyzer, followed the trend observed for hardness: the product with 4.2% MWP added had the highest value for this attribute (362.1 ± 53.2 g). Also, the two DL samples added with SMP showed the lowest gumminess values (8.9 ± 0.2 g and 8.2 ± 1.0 g, respectively, for 2.1%SMP and 4.2% SMP). The gumminess of the products with 2.1% WPC, 4.2% WPC, and 2.1% MWP were intermediate, at 180.0 ± 43.2 g, 229.8 ± 5.3 g, and 241.6 ± 8.6 g, respectively. These results let us infer that the addition of whey proteins in DL manufacture influences this property of the food, increasing the hardness and gumminess parameters.

Research reports showed that the use of MWP in the production of petit-suisse cheese did not generate statistical differences in the parameters of gumminess and hardness when fat was substituted by microparticulated whey proteins at three different levels [22]. Another study by Meng et al., showed that the use of MWP in different concentrations in cheese production increased the hardness of the formulated product [37], a result similar to that found in the present study (see Figure 3). The results of this study indicate that the influence of MWP addition on texture parameters depends on the type of product to which it is applied.

Comparing the results obtained for hardness and gumminess (Figure 3) between the control product (SMP) and the products with added whey protein (WPC and MWP), we can infer that the whey products indicate that microparticulated protein could be an alternative for the DL industry, especially because texture parameters can be modified to optimize the organoleptic characteristics of this product. Microparticulated protein has a great potential in the Brazilian dairy industry, even though is playing catching up with other areas of food product development; it is a new technology in the country.

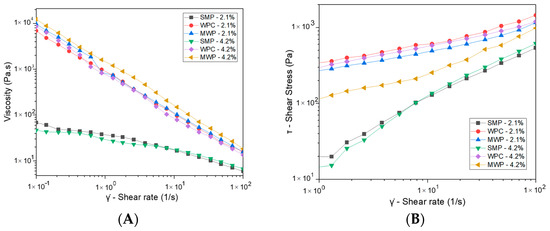

3.6. Rheology

Rheological analysis was carried out in the three prototypes and the following parameters were determined: apparent viscosity (Figure 4A) and shear stress by the shear rate applied to the products (Figure 4B). Products with the addition of MWP and WPC showed a higher apparent viscosity at 100 s−1 compared to products with SMP at both substitution concentrations. This was corroborated by the values calculated by the Herschel–Bulkley model (Table 3), which is the most appropriate model for flow data for DL, according to studies in the literature [38]. The results obtained might be associated with the size of the aggregates formed during the microparticulation and manufacture of DL (with MWP) and the aggregates of whey proteins during the manufacture of DL (with WPC). These results are consistent with yogurts produced with and without added microparticulated protein, where a higher viscosity was observed in products with MWP [25]. As the shear rate was applied, the apparent viscosity of the six products decreased, with the whey protein products showing a greater variation in viscosity compared to the product with skim milk powder. Shear stress was higher in products with whey proteins (WPC and MWP) compared to products with SMP at both substitution concentrations (Figure 4B). As mechanical stress was applied, the shear stress value increased, and the final values tended to converge for all treatments; similar results have been reported in the literature [24,32].

Figure 4.

(A) Apparent viscosity (Pa.s) of doce de leite prototypes based on upward shear rate (0.1 s−1 to 100 s−1) and (B) shear stress (Pa) based on downward shear rate (100 s−1 to 1.0 s−1), both measured at 22 °C during 200 s, addition at 2.1% and 4.2% level: SMP—skimmed milk powder; WPC—whey protein concentrate; MWP—microparticulated whey protein.

Table 3.

Herschel–Bulkley model parameters (increasing shear rate) and apparent viscosity at 100 s−1 determined in DL prototypes made with skim milk powder, whey protein concentrate, and microparticulated whey protein.

The K value in Table 3 relates to the consistency of the product, with the 4.2% MWP product showing the highest value. This result confirms again that microparticulated whey proteins at this level of addition have great potential to influence texture in DL. Additionally, since the n values were less than 1, all products exhibited a pseudoplastic profile, with the 4.2% MWP treatment showing the most pronounced characteristic [38]. Studies in the literature compare household and confectionery DL and show that the characteristics described here are consistent with a product to which starch has been added to increase viscosity and enable industrial use [38].

The pronounced increases in hardness, gumminess, and viscosity observed in DL supplemented with MWP can be explained by the structural characteristics of microparticulated proteins. During microparticulation, whey proteins undergo controlled denaturation and aggregation, resulting in spherical particles that mimic fat globules in size but retain a strong water-binding capacity. When incorporated into the DL matrix, these particles enhance protein–protein and protein–water interactions, promoting the formation of a more compact and cohesive gel network. This structural reinforcement is consistent with reports on yogurts and cheeses enriched with MWP, where higher viscosities and firmer textures have also been observed. Furthermore, unlike SMP, which contributes mainly casein micelles and lactose, WPC and especially MWP increase the concentration of denatured β-lactoglobulin, capable of forming disulfide-linked aggregates during heating, which intensifies the product’s resistance to deformation. These mechanisms help rationalize the technological potential of MWP as a clean-label alternative to hydrocolloids for modulating texture and rheology in DL.

From an industrial perspective, the incorporation of MWP into DL formulations highlights an opportunity to align technological functionality with consumer-driven trends toward cleaner labels and reduced additive use. The ability of MWP to increase viscosity and firmness without altering proximate composition suggests that manufacturers could replace or reduce hydrocolloids such as starches or gums, while still achieving desirable textural profiles. Moreover, the lighter color of MWP-supplemented DL may be advantageous for specific market niches, such as confectionery applications where uniformity and stability of color are critical. On a nutritional level, replacing some milk solids with whey-derived proteins also enhances the protein density of the product, which could meet the growing demand for high-protein dairy desserts. These combined functional and marketing advantages reinforce the rationale for adopting MWP as a strategic ingredient in DL production, offering both technological robustness and differentiation potential in competitive markets.

4. Conclusions

Doce de Leite (DL) was produced by replacing a portion pasteurized milk with skimmed milk powder (SMP), whey protein concentrate (WPC), and microparticulated whey protein (MWP) at two different percentages (2.1% and 4.2%). The composition of the DL products met the parameters established by Mercosur legislation, with the exception of the fat content, which was below the levels allowed for products made with added WPC and MWP. Only 5-hydromethylfurfural (HMF) was detected from the four markers chosen for the Maillard reaction, and the levels detected in all samples were in agreement with the range given in the literature; the HMF content was higher in DL products made using WPC and MWP compared to the standard (SMP). Despite of these results, the browning index and the saturation level were lower for the WPC and MWP products than the control (SMP), suggesting a lower progression in browning reactions and resulting in a lighter color.

From a rheological perspective, the addition of WPC and MWP increased the hardness, gumminess, and viscosity of the DL prototypes compared to the product made with SMP, which can be attributed to the interactions formed by the increased whey protein concentration in the medium, given the aggregates formed during microparticulation and/or heating. Several studies show that the use of microparticulated whey proteins can modulate rheological and textural characteristics, such as in yogurt and cheeses, and the present study shows that the same occurs in a product like doce de leite. In conclusion, for the first time, DL prototypes were made using MWP, and the results obtained open a new avenue for product improvements/developments (beyond whey valorization) without altering the compositional aspects of the final product.

Author Contributions

Conceptualization, J.M.P.d.M.V., Í.T.P. and R.S.; methodology, J.M.P.d.M.V., I.L.d.P., Í.T.P. and R.S.; validation, J.M.P.d.M.V., I.L.d.P. and P.F.L.; formal analysis, J.M.P.d.M.V., I.L.d.P. and P.F.L.; investigation, J.M.P.d.M.V., I.L.d.P. and P.F.L.; resources, Í.T.P. and R.S.; data curation, J.M.P.d.M.V., I.L.d.P., T.H., U.S., A.F.W.-P. and L.F.C.d.O.; writing—original draft preparation, J.M.P.d.M.V., I.L.d.P., T.H., U.S. and A.F.W.-P.; writing—review and editing, J.M.P.d.M.V., I.L.d.P., T.H., U.S., A.F.W.-P. and L.F.C.d.O.; supervision, Í.T.P. and R.S.; project administration, Í.T.P. and R.S.; funding acquisition, Í.T.P. and R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior -Brasil (CAPES)-Finance Code 001, CNPq (302515/2023-2), Alexander von Humboldt Foundation (88881.699118/2022-01), and Fundação de Amparo à Pesquisa do Estado de Minas Gerais (FAPEMIG)-Finance Code APQ-01169-22.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors are grateful to CNPq, FAPEMIG and CAPES for funding the research scholarships, Technische Universität Dresden, Federal University of Juiz de Fora and also the Alexander von Humboldt Foundation.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the result.

References

- Brasil. Brasil. Portaria MAPA n° 354, de 04 de Setembro de 1997—Regulamento Técnico de Identidade e Qualidade de Doce de Leite; Ministério da Agricultura, Pecuária e Abastecimento: Brasília, Brazil, 1997. [Google Scholar]

- Lima, P.C.; de Marco, I.; Stein, V.; Pagotto, C.K.; Rigo, E.; Cavalheiro, D.; Schogor, A.L.B. Obtaining and characterizing “dulce de leche” prepared with sheep’s and cow’s milk in different proportions. Food Sci. Technol. 2020, 40, 832–837. [Google Scholar] [CrossRef]

- Celestino, J.A.; Sad, M.E.; Silva, M.G.; Cunha, C.N.; Stephani, R.; Perrone, Í.T. Effect of sucrose content added to milk on the composition, yield, viscosity, color, and Maillard reaction chemical markers of dulce de leche. Eur. Food Res. Technol. 2024, 250, 1529–1536. [Google Scholar] [CrossRef]

- Carneiro, L.C.M.; Pinto, C.B.A.; Gomes, E.R.; de Paula, I.L.; Pombo, A.F.W.; Stephani, R.; Carvalho, A.F.; Perrone, Í.T. A química e a tecnologia do doce de leite: Uma revisão. Res. Soc. Dev. 2021, 10, e155101119408. [Google Scholar] [CrossRef]

- Gaze, L.V.; Oliveira, B.R.; Ferrao, L.L.; Granato, D.; Cavalcanti, R.N.; Conte Júnior, C.A.; Cruz, A.G.; Freitas, M.Q. Preference mapping of dulce de leche commercialized in Brazilian markets. J. Dairy Sci. 2015, 98, 1443–1454. [Google Scholar] [CrossRef] [PubMed]

- Stephani, R.; Francisquini, J.A.; Perrone, Í.T.; de Carvalho, A.F.; De Oliveira, L.F.C. Dulce de Leche—Chemistry and Processing Technology. In Milk Production, Processing and Marketing; IntechOpen: London, UK, 2019; pp. 1–18. [Google Scholar] [CrossRef]

- Leddomado, L.S.; Silva, R.; Guimarães, J.T.; Balthazar, C.F.; Ramos, G.L.P.A.; Freitas, M.Q.; Duarte, M.C.K.H.; Neto, R.P.C.; Tavares, M.I.B.; Pimentel, T.C.; et al. Technological benefits of using inulin and xylooligosaccharide in dulce de leche. Food Hydrocoll. 2021, 110, 106158. [Google Scholar] [CrossRef]

- Figueroa, L.E.; Brugnoni, L.I.; Staffolo, M.D.; Genovese, D.B. Development of a functional dulce de leche (milk jam) with prebiotic carbohydrates and Lacticaseibacillus rhamnosus GG. Int. Dairy J. 2024, 156, 105975. [Google Scholar] [CrossRef]

- Gwala, S.; Tang, Q.; Hogan, S.A.; Giblin, L.; Brodkorb, A. Textural aspects and digestibility of a high-protein dessert using INFOGEST’S adult and older adult static in vitro digestion models. Food Res. Int. 2025, 188, 116552. [Google Scholar] [CrossRef]

- Çakır-Fuller, E. Enhanced heat stability of high protein emulsion systems provided by microparticulated whey proteins. Food Hydrocoll. 2015, 47, 41–50. [Google Scholar] [CrossRef]

- Dissanayake, M.; Liyanaarachchi, S.; Vasiljevic, T. Functional properties of whey proteins microparticulated at low pH. J. Dairy Sci. 2012, 95, 1667–167910. [Google Scholar] [CrossRef]

- Kerche, F.; Weterings, M.; Beyrer, M. The effect of temperature and shear upon technological properties of whey protein concentrate: Aggregation in a tubular heat exchanger. Int. Dairy J. 2016, 60, 32–38. [Google Scholar] [CrossRef]

- Shewan, H.M.; Stokes, J.R. Review of techniques to manufacture micro-hydrogel particles for the food industry and their applications. J. Food Eng. 2013, 119, 781–792. [Google Scholar] [CrossRef]

- Nunes, L.; Tavares, G.M. Thermal treatments and emerging technologies: Impacts on the structure and techno-functional properties of milk proteins. Trends Food Sci. Technol. 2019, 90, 88–99. [Google Scholar] [CrossRef]

- Sampson, H.A.; Cooke, S. The antigenicity and allergenicity of microparticulated proteins: Simplesse®. Clin. Exp. Allergy 1992, 22, 963–969. [Google Scholar] [CrossRef] [PubMed]

- Toro-Sierra, J.; Schumann, J.; Kulozik, U. Impact of spray-drying conditions on the particle size of microparticulated whey protein fractions. Dairy Sci. Technol. 2013, 93, 487–503. [Google Scholar] [CrossRef]

- Renard, D.; Lavenant, L.; Sanchez, C.; Hemar, Y.; Horne, D. Heat-induced flocculation of microparticulated whey proteins (MWP); consequences for mixed gels made of MWP and β-lactoglobulin. Colloids Surf. B Biointerfaces 2002, 24, 73–85. [Google Scholar] [CrossRef]

- Sun, C.; Liu, R.; Wu, T.; Liang, B.; Shi, C.; Zhang, M. Effect of superfine grinding on the structural and physicochemical properties of whey protein and applications for microparticulated proteins. Food Sci. Biotechnol. 2015, 24, 1637–1643. [Google Scholar] [CrossRef]

- Dissanayake, M.; Vasiljevic, T. Functional properties of whey proteins affected by heat treatment and hydrodynamic high-pressure shearing. J. Dairy Sci. 2009, 92, 1387–1397. [Google Scholar] [CrossRef]

- Hinrichs, R.; Götz, J.; Noll, M.; Wolfschoon, A.; Eibel, H.; Weisser, H. Characterization of the water holding capacity of fresh cheese samples by means of low resolution nuclear magnetic resonance. Food Res. Int. 2004, 37, 667–676. [Google Scholar] [CrossRef]

- Guinee, T.P. Effect of high-temperature treatment of milk and whey proteins denaturation on the properties of rennet-curd cheese: A review. Int. Dairy J. 2021, 12, 105095. [Google Scholar] [CrossRef]

- Sánchez-Obando, J.D.; Cabrera-Trujillo, M.A.; Olivares-Tenorio, M.L.; Klotz, B. Use of optimized microparticulated whey protein in the process of reduced-fat spread and petit-suisse cheeses. Learn. Technol. 2020, 120, 108933. [Google Scholar] [CrossRef]

- Torres, I.C.; Janhøj, T.; Mikkelsen, B.Ø.; Ipsen, R. Effect of microparticulated whey protein with varying content of denatured protein on the rheological and sensory characteristics of low-fat yoghurt. Int. Dairy J. 2011, 21, 645–655. [Google Scholar] [CrossRef]

- Spiegel, T. Thermische Denaturierung und Aggregation von Molkenproteinen in Ultrafiltrationsmolkenkonzentraten. Ph.D. Dissertation, Technische Universität München, Freising, Germany, 1999. [Google Scholar]

- Hossain, M.K.; Keidel, J.; Hensel, O.; Diakité, M. The impact of extruded microparticulated whey proteins in reduced-fat, plain-type stirred yogurt: Characterization of physicochemical and sensory properties. Learn. Technol. 2020, 134, 109961. [Google Scholar] [CrossRef]

- de Paula, I.L.; Cunha, C.N.; Pinto, C.B.; Vitral, J.; Lazzarini, P.; da Costa, J.C.; Tavares, G.M.; Perrone, Í.T.; de Oliveira, L.F.; Stephani, R. Development and Validation of a Methodology for Quantification of Whey Protein Fractions in Microparticulate Ingredients. Quim. Nova 2024, 48, e20250038. [Google Scholar] [CrossRef]

- Pinto, C.B.A.; Renhe, I.R.T.; Viana, C.C.R.; Perrone, Í.T.; De Oliveira, L.F.C.; Stephani, R. Lactose-free Dulce de leche: Compositional characterization, browning and texture profile. J. Dairy Res. 2021, 88, 452–456. [Google Scholar] [CrossRef]

- de Paula, I.L.; Teixeira, E.B.S.; Francisquini, J.D.A.; Stephani, R.; Perrone, Í.T.; de Carvalho, A.F.; De Oliveira, L.F.C. Buffalo powder dairy products with and without lactose hydrolysis: Physical-chemical and technical-functional characterizations. Learn. Technol. 2021, 151, 112124. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International; AOAC: Washington, DC, USA, 2016. [Google Scholar]

- AOAC. Association Official Methods of Analysis; AOAC: Washington, DC, USA, 2005. [Google Scholar]

- ISO 8968-1:2014 | IDF 20-1:2014; Milk and Milk Products—Determination of Nitrogen Content. International Organization for Standardization: Geneva, Switzerland, 2014.

- Sulejmani, E.; Boran, O.S.; Huppertz, T.; Hayaloglu, A.A. Rheology, microstructure and sensory properties of low-fat milk jam: Influence of inulin type, sucrose content, sodium bicarbonate and calcium chloride. Int. Dairy J. 2021, 123, 105162. [Google Scholar] [CrossRef]

- ISO/TS 11869:2012; Fermented Milks—Determination of Titratable Acidity—Potentiometric Method. International Organization for Standardization: Geneva, Switzerland, 2012.

- Pinto, C.B.A.; Cunha, C.N.; Mesa, N.C.; Sad, M.E.L.D.S.; Stephani, R.; Perrone, Í.T.; Costa, J.C.D. Determination of Maillad reaction markers in Doce de Leite by HPLC. Quim. Nova 2024, 47, e20240041. [Google Scholar] [CrossRef]

- Netto, G.G.; Francisquini, J.A.; de Carvalho, A.F.; Stephani, R.; Perrone, I.T. The effect of induced crystallization of lactose on dulce de leche properties. Eur. Food Res. Technol. 2023, 249, 283–294. [Google Scholar] [CrossRef]

- Kim, B.K.; Cho, A.R.; Chun, Y.G.; Park, D.J. Effect of microparticulated wheat bran on the physical properties of bread. Int. J. Food Sci. Nutr. 2013, 64, 122–129. [Google Scholar] [CrossRef]

- Meng, R.; Feng, R.; Fu, R.; Wang, Z.; Zhang, B. Mechanism of microparticulated whey protein replacing milk fat during the production stages of renneted casein gel. Food Hydrocoll. 2025, 164, 111248. [Google Scholar] [CrossRef]

- Rovedo, C.O.; Viollaz, P.E.; Suarez, C. The effect of pH and temperature on the rheological behavior of dulce de leche, a typical dairy Argentine product. J. Dairy Sci. 1991, 74, 1497–1502. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).