Laboratory Tests to Optimize the Milking Machine Settings with Air Inlet Teat Cups for Sheep and Goats

Abstract

:1. Introduction

2. Material and Methods

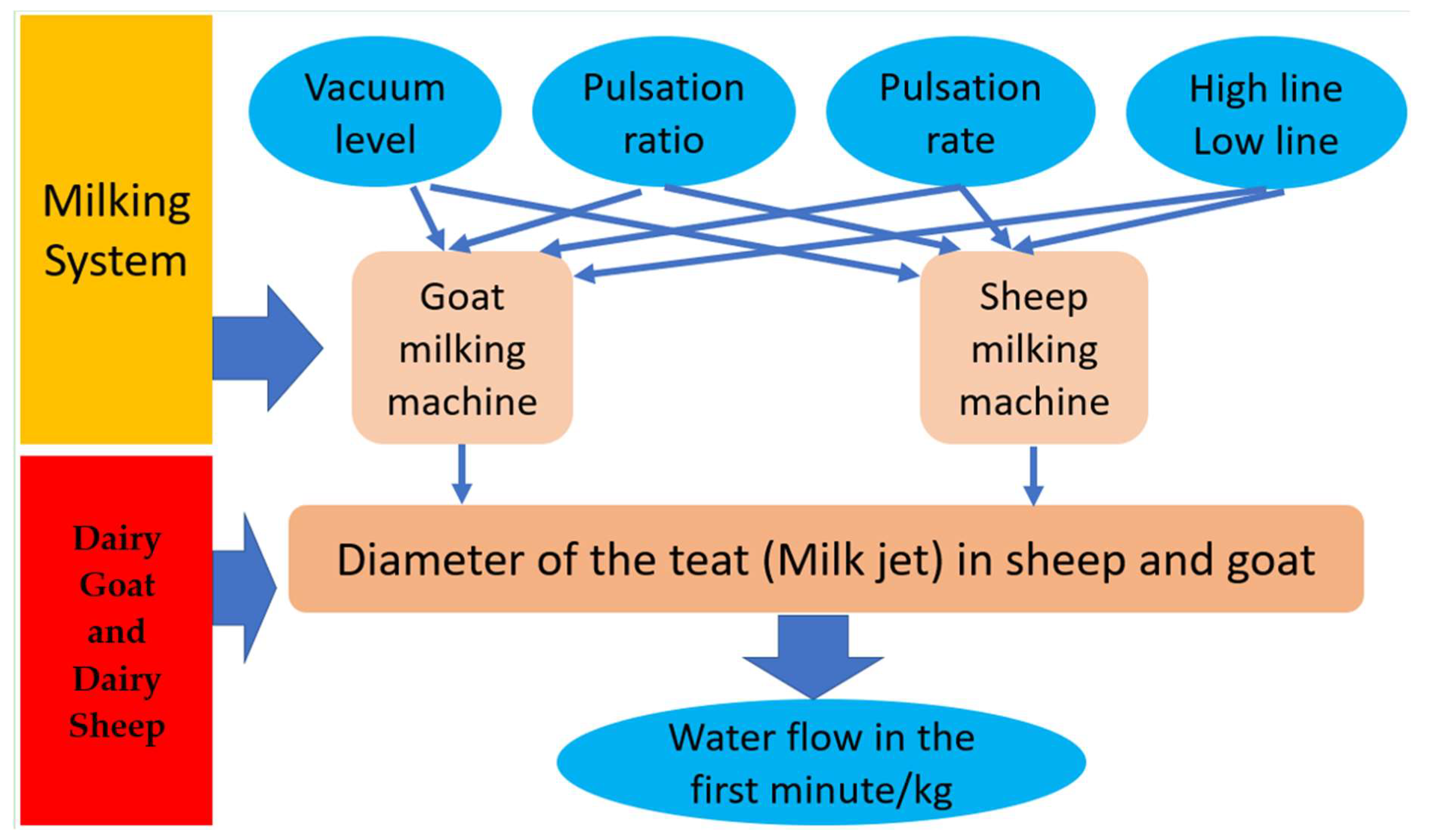

2.1. Experimental Design

- The milking system used is a milking unit with the following parts: two two-chamber teat cups, each with a short milk-and-pulse line, as well as a claw and a long milk- and-pulse line. Each teat cup has an air inlet and is divided into two spaces: the pulse chamber and the inner chamber. Many parameters can be evaluated in this area. We focused on the vacuum level, pulsation rate, pulsation ratio and height of the milk line. All teat cups are equipped with silicone teat liners.

- The animals (dairy goat and sheep) are the second area and are represented here as the diameter of the milk jet, corresponding to the teat diameter of the udder of goats and sheep.

- The water flow in the first minute/kg (1st WF/kg) is displayed here, i.e., the amount of water received (milked) in kilograms in the first minute after teat attachment. The 1st WF/kg of the milking process was measured as a consistent indicator for evaluating the best combination in the milking machine.

2.2. Milking Laboratory

2.3. Investigation Parameters

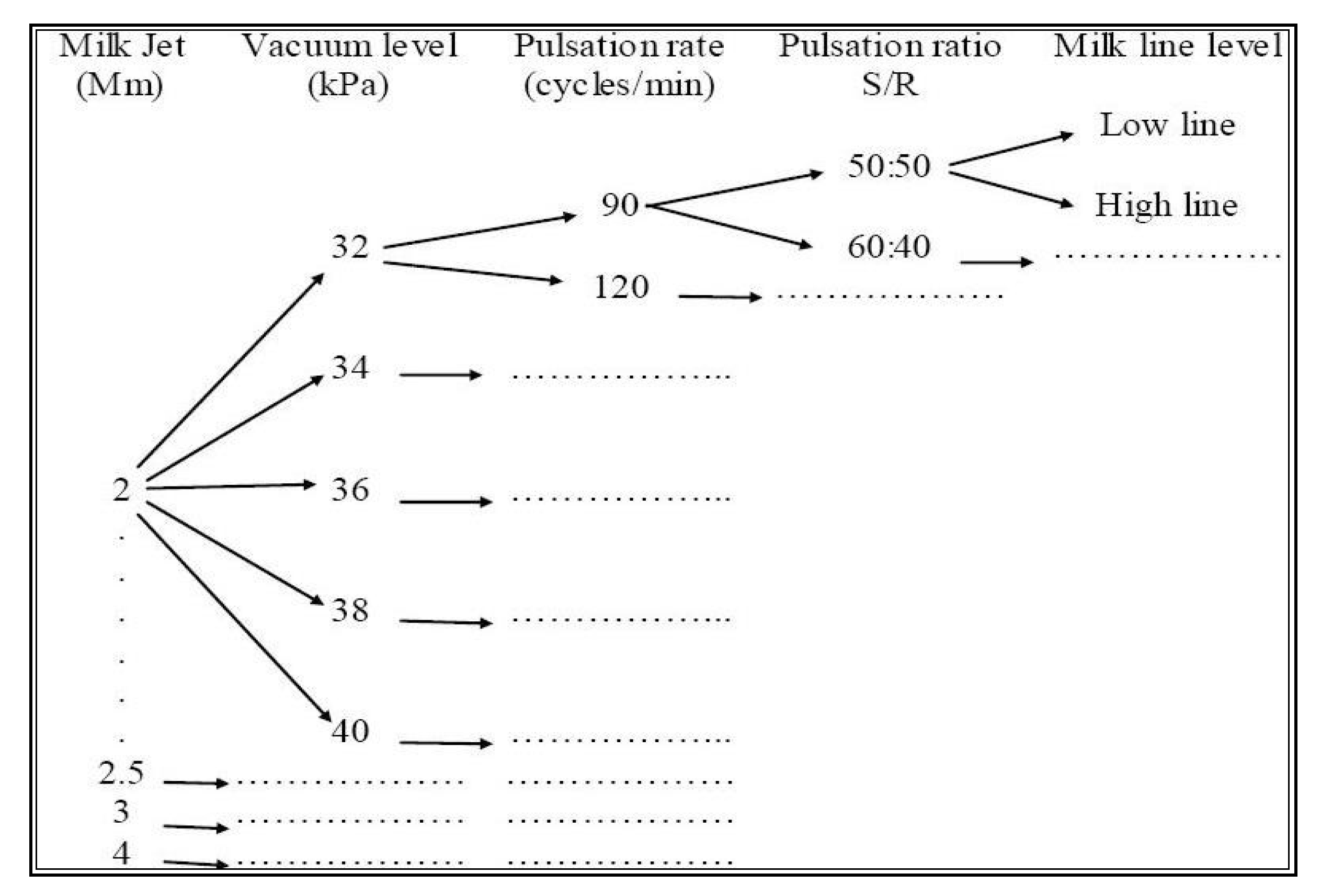

- Different diameters (2, 2.5, 3 and 4 mm) of milk jets were tested, which could be similar to the diameter of the streak canal of the teats in sheep and goats (ranging from 1.8 to 3.1 mm) [28];

- Multiple vacuum levels: 32, 34, 36, 38 and 40 kPa;

- Two pulsation rates: 90 cycles/min for the goat milking machine and 120 cycles/min for the sheep milking machine;

- Two pulsation ratios: 50:50 and 60:40 suction phase/rest phase (S/R);

- Two levels of the milk pipeline: high milk pipeline and low milk pipeline.

2.4. Milking Process

2.5. Statistical Analyses

3. Results and Discussion

3.1. Vacuum Levels, Pulsation Rates and Ratios and Height of the Milk Line for the Optimization of the Milking Machine for Sheep and Goats

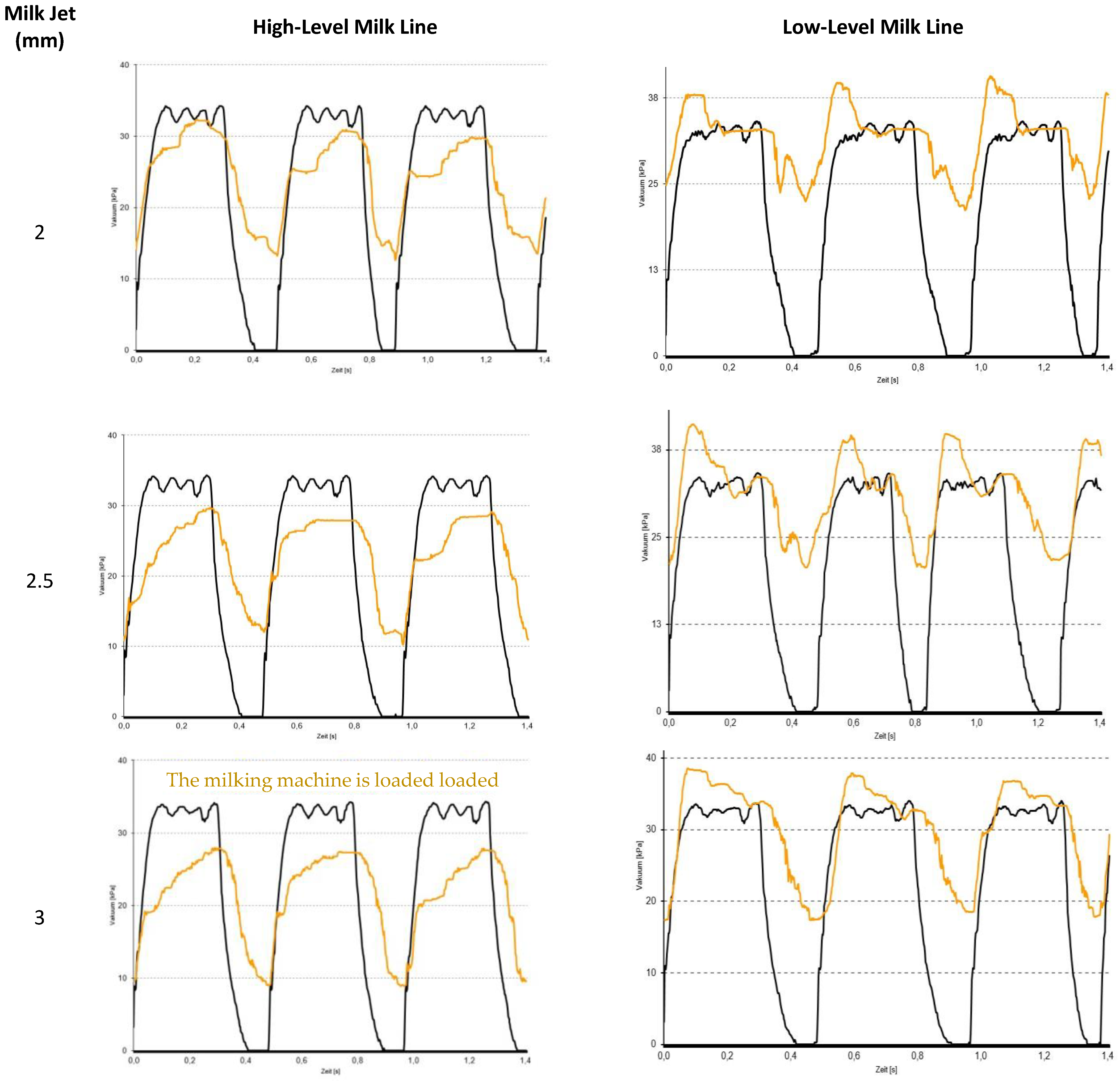

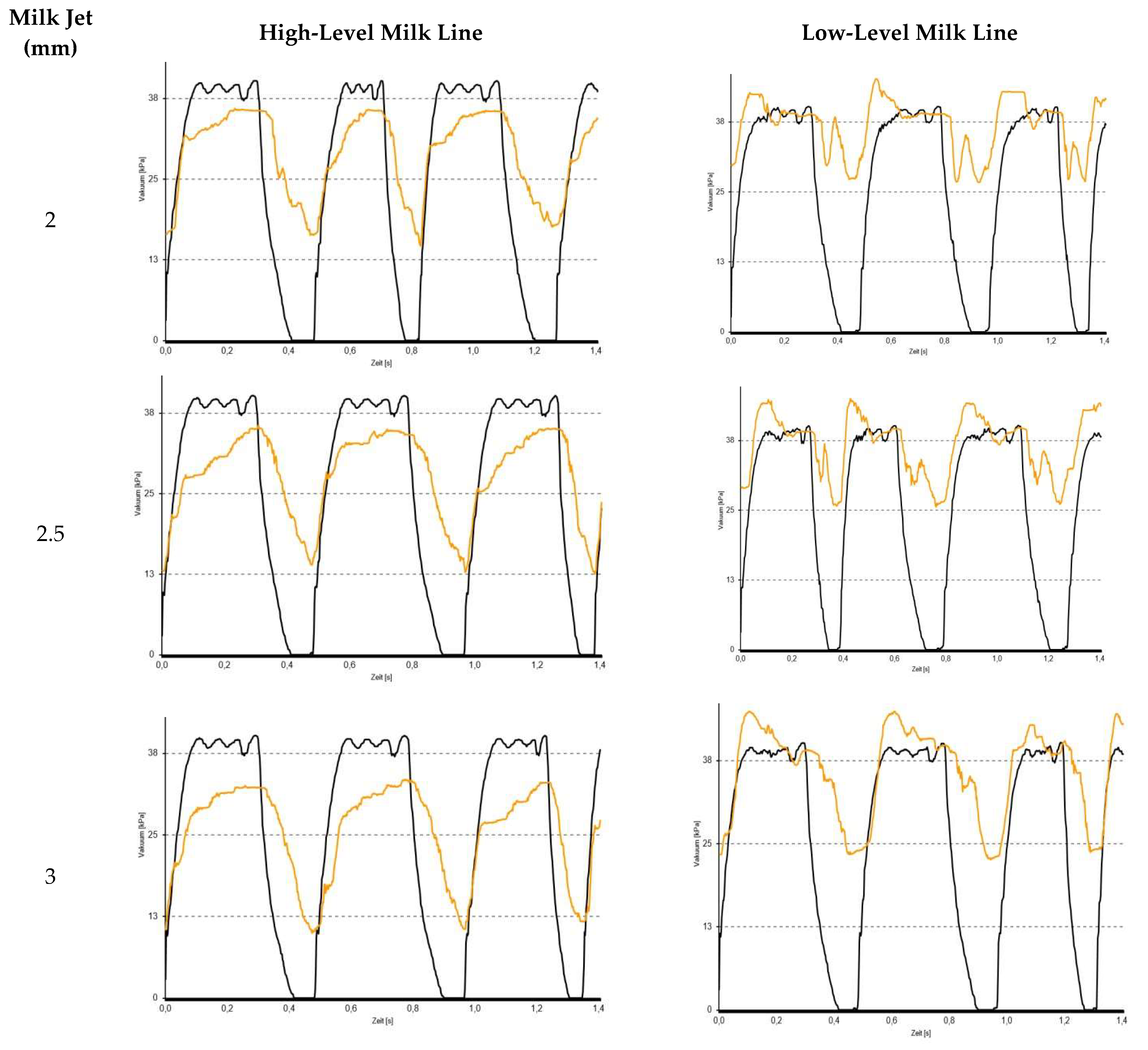

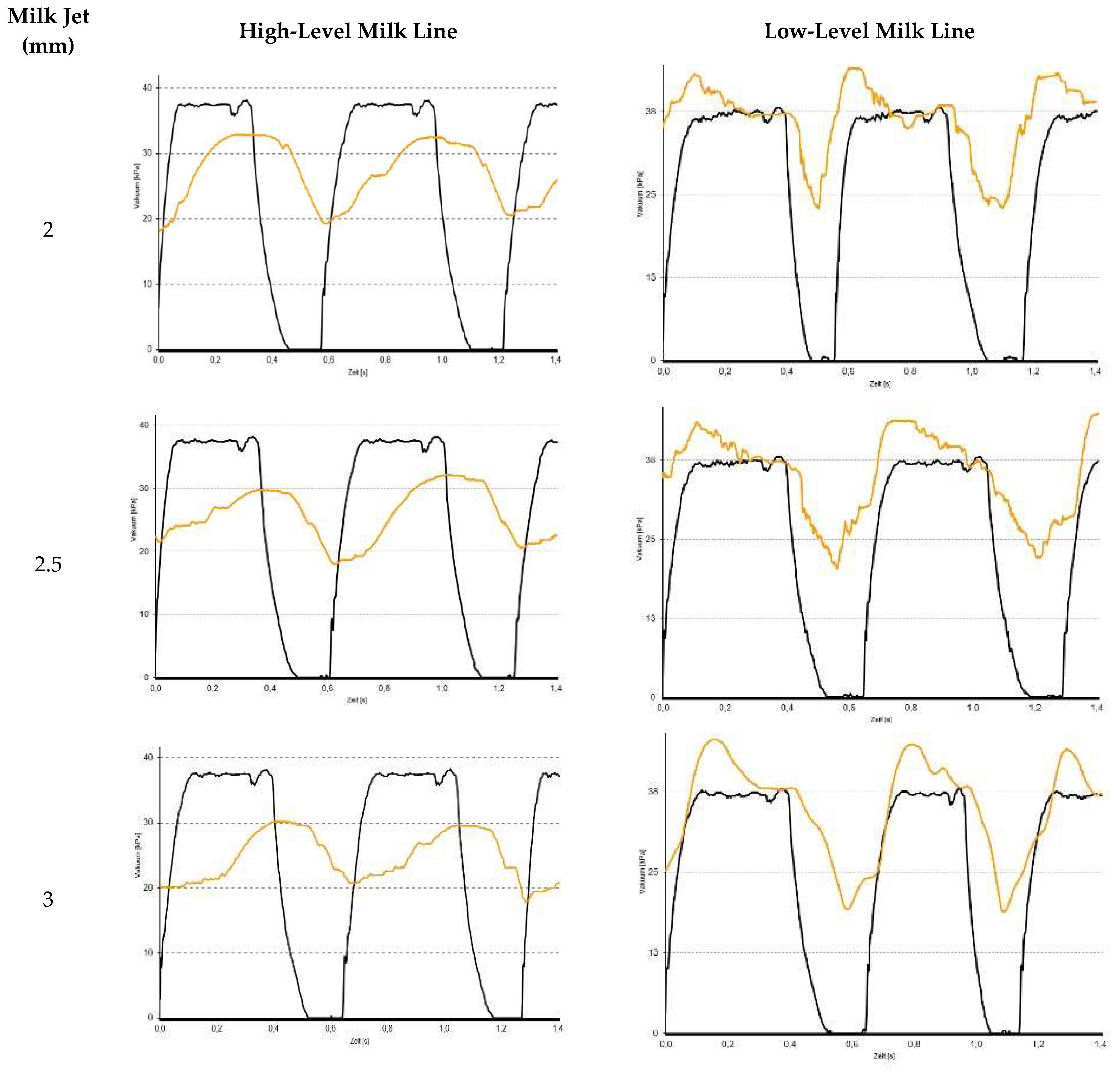

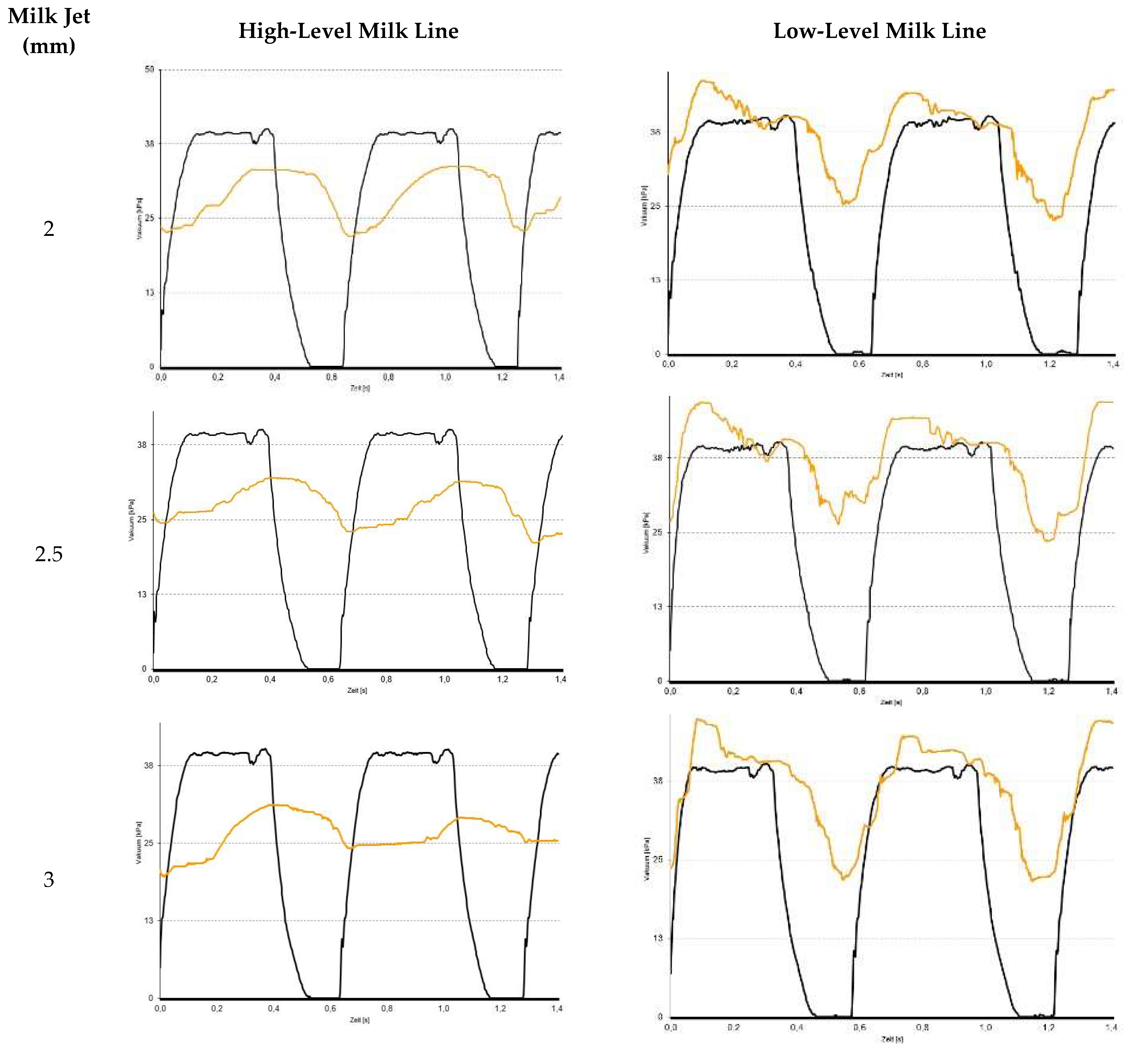

3.2. Cyclical Vacuum Fluctuations in the Pulsation and Inner Chambers of the Teat Cup during the 1st Wf in the Sheep Milking Machine

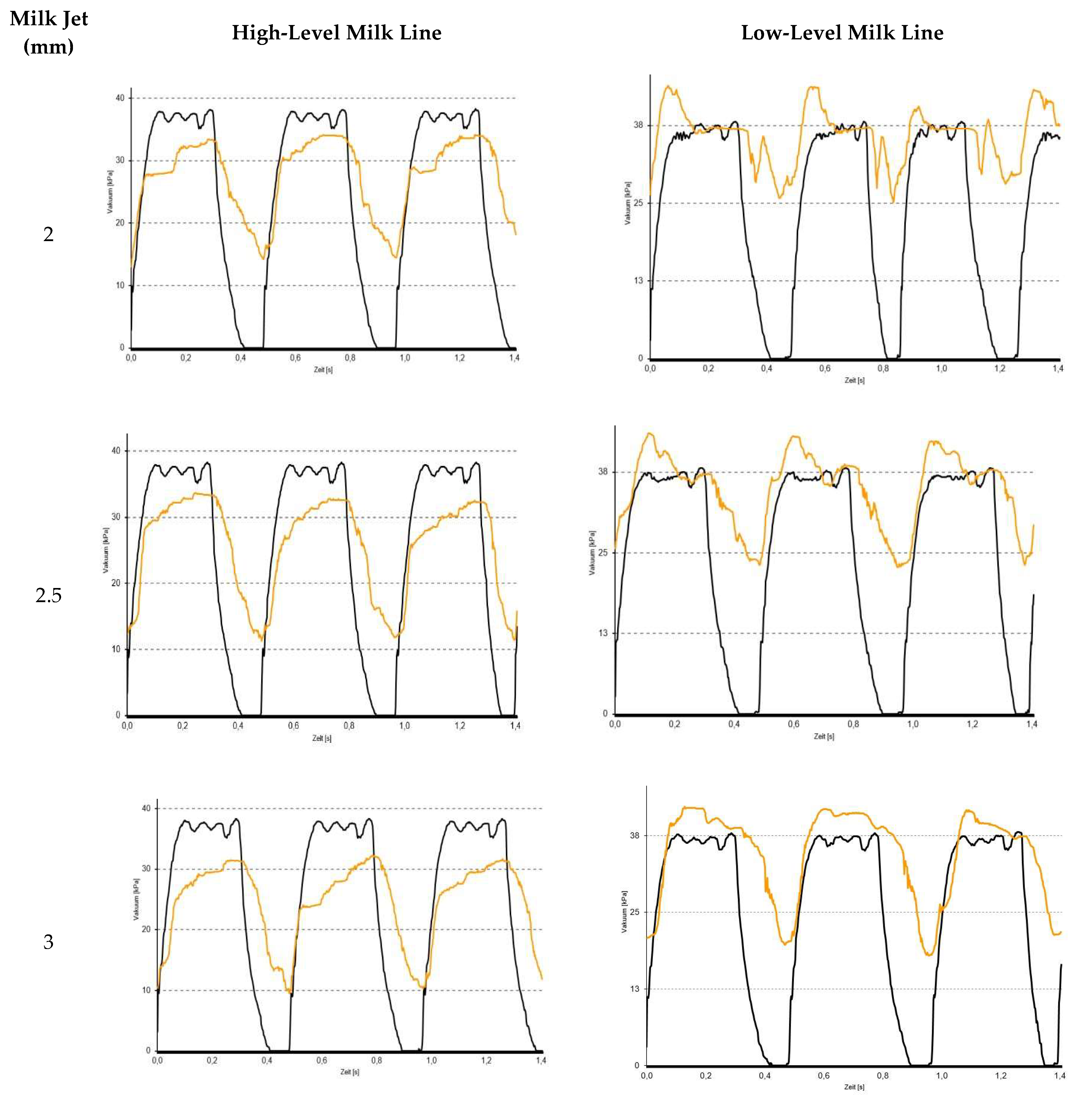

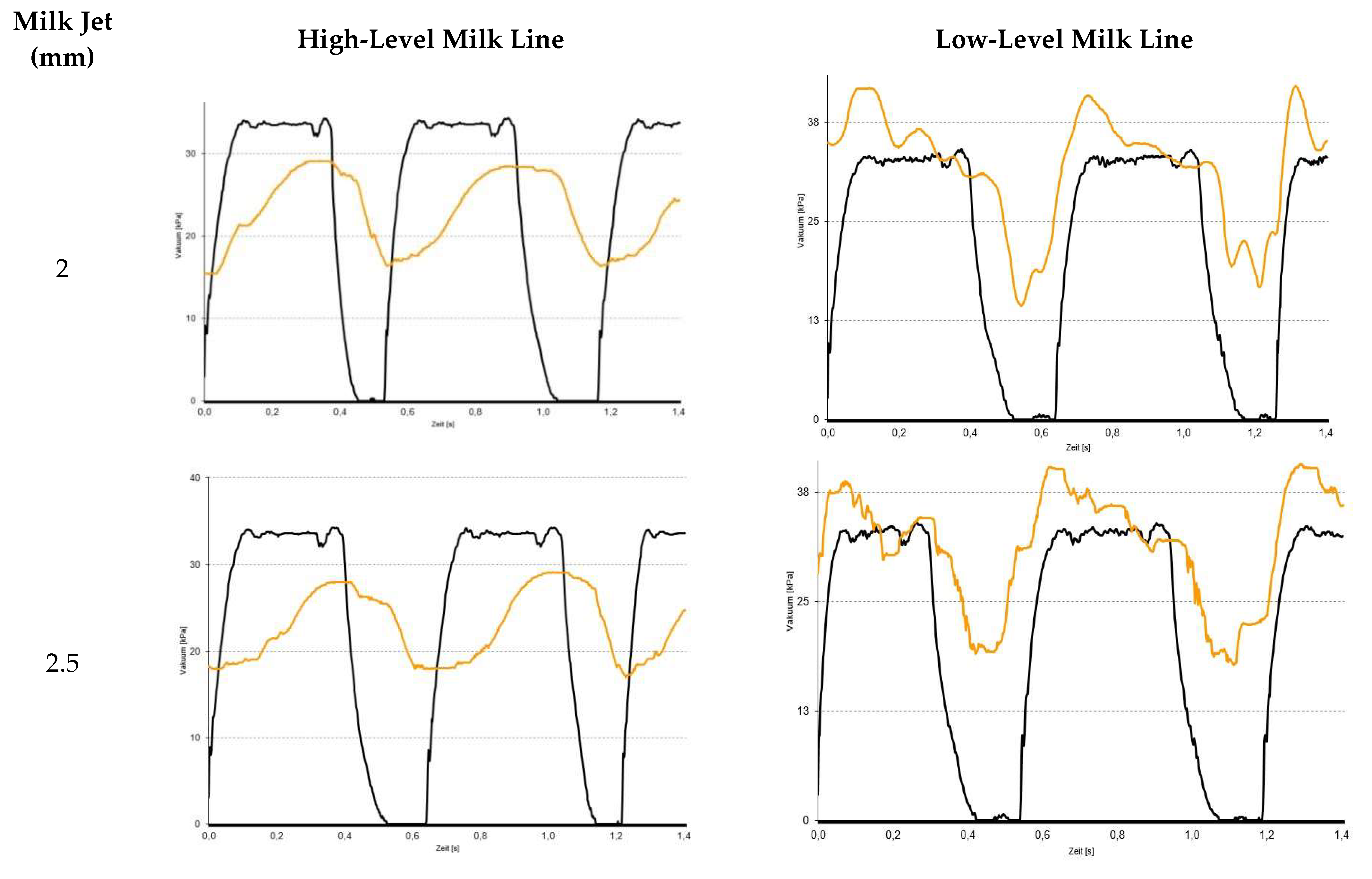

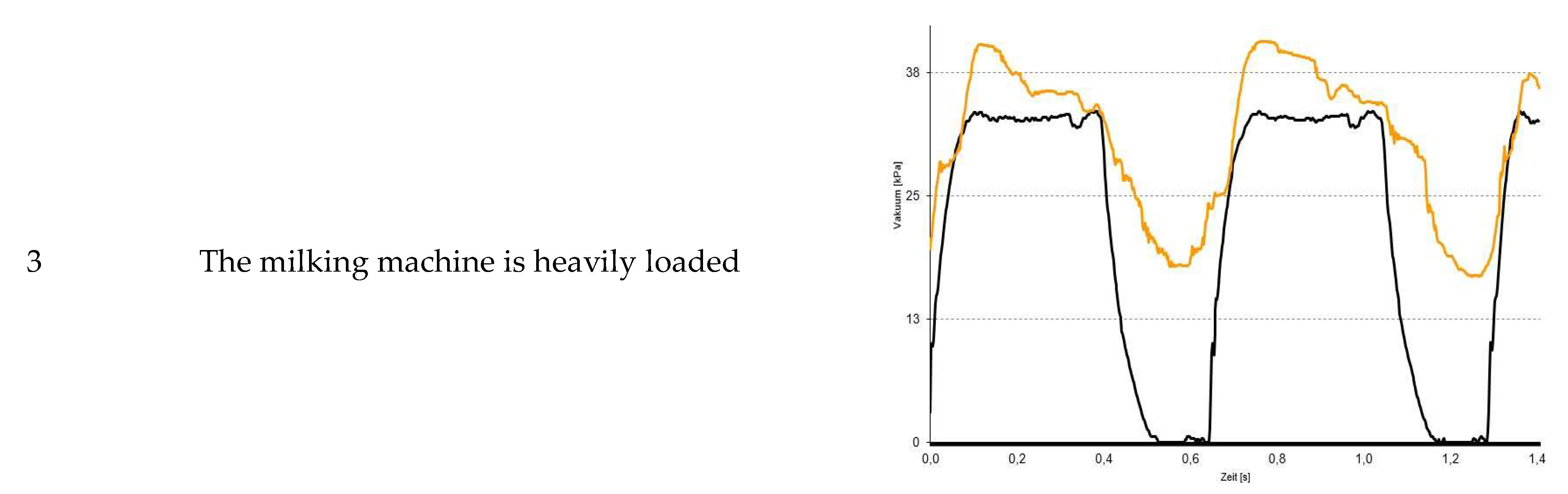

3.3. Cyclical Vacuum Fluctuations in the Pulsation and Inner Chambers of the Teat Cup during the 1st Wf in the Goat Milking Machine

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fernandez, G.; Diaz, J.R.; Peris, C.; Rodriguez, M.; Molina, M.P.; Torres, A. Machine milking parameters for the Manchega sheep breed. In Milking and Milk Production of Dairy Sheep and Goats, Proceedings of the Sixth International Symposium on the Milking of Small Ruminants, 26 September–1 October 1998; EAAP Publication: Athens, Greece, 1999; Volume 95, p. 6568. [Google Scholar]

- Muhlherr, J.E.; Zweifel, C.; Corti, S.; Blanco, J.E.; Stephan, R. Microbiological quality of raw goats and ewes’ bulk-tank milk in Switzerland. J. Dairy Sci. 2003, 86, 3849–3856. [Google Scholar] [CrossRef]

- Diaz, J.R.; Peris, C.; Rodriguez, M.; Molina, M.P.; Fernandez, N. Effect of milking pipeline height on machine milking efficiency and milk quality in sheep. J. Dairy Sci. 2004, 87, 1675–1683. [Google Scholar] [CrossRef] [Green Version]

- Luengo, C.; Sanchez, A.; Corrales, J.C.; Fernandez, C.; Contreras, A. Influence of intramammary infection and non-infection factors on somatic cell counts in dairy goats. J. Dairy Res. 2004, 71, 169–174. [Google Scholar] [CrossRef] [PubMed]

- Skapetas, B.; Bampidis, V.; Christodoulou, V.; Kalaitizidou, M. Fatty acid profile, somatic cell count and microbiological quality of total machine milk and hand stripped milk of Chios ewes. Mljekarstvo 2017, 67, 146–154. [Google Scholar] [CrossRef] [Green Version]

- Sinapis, E.; Hatziminaoglu, I.; Marnet, P.G.; Abas, Z.; Bolou, A. Influence of vacuum level, pulsation rate and pulsator ratio on machine milking efficiency in local Greek goats. Livest. Prod. Sci. 2000, 64, 175–181. [Google Scholar] [CrossRef]

- Peris, C.; Diaz, J.R.; Balasch, S.; Beltran, M.C. Influence of vacuum level and over milking on udder health and teat thickness changes in dairy ewes. J. Dairy Sci. 2003, 86, 3891–3898. [Google Scholar] [CrossRef] [Green Version]

- Peris, C.; Diaz, J.R.; Segura, C.; Marti, A.; Fernandez, N. Influence of pulsation rate on udder health and teat thickness changes in dairy ewes. J. Dairy Sci. 2003, 86, 530–537. [Google Scholar] [CrossRef] [Green Version]

- Alejandro, M.; Roca, A.; Romero, G.; Diaz, J.-R. Effects of over milking and liner type and characteristics on teat tissue in small ruminants. J. Dairy Res. 2014, 81, 1–8. [Google Scholar] [CrossRef]

- Salama, A.A.K.; Such, X.; Caja, G.; Rovai, M.; Casals, R.; Albanell, E.; Marin, M.P.; Marti, A. Effect of once versus twice daily milking throughout lactation on milk yield and milk composition in dairy goats. J. Dairy Sci. 2003, 86, 1673–1680. [Google Scholar] [CrossRef]

- Capote, J.; Castro, N.; Caja, G.; Fernandez, G.; Briggs, H.; Arguello, A. Effects of the frequency of milking and lactation stage on milk fractions and milk composition in Tinerfena dairy goats. Small Rumi. Res. 2008, 75, 252–255. [Google Scholar] [CrossRef]

- Macuhova, L.; Tancin, V.; Macuhova, J. The effect of milking frequency on milk yield and milk composition in ewes. Czech J. Ani. Sci. 2020, 65, 41–50. [Google Scholar] [CrossRef]

- Labussiere, J. Review of physiological and anatomical factors influencing the milking ability of ewes and the organization of milking. Livest. Prod. Sci. 1988, 18, 253–274. [Google Scholar] [CrossRef]

- Marnet, P.G.; Combaud, J.F.; Dano, Y. Relationships between characteristics of the teat and milkability in Lacaune ewes. In Milking and Milk Production of Dairy Sheep and Goats, Proceedings of the sixth International Symposium on the Milking of Small Ruminants, 26 September–1 October 1998; EAAP Publication: Athens, Greece, 1999; Volume 95, pp. 41–44. [Google Scholar]

- Katanos, J.; Skapetas, B.; Laga, V. Machine milking ability and milk composition of some imported dairy goat breeds and some crosses in Greece. Czech J. Ani. Sci. 2005, 50, 394–401. [Google Scholar] [CrossRef] [Green Version]

- Skapetas, B.; Katanos, J.; Laga, V.; Sinapis, E.; Hatziminaoglou, I. Vacuum level for opening the teat sphincter and the change in the teat end wall thickness in response to the machine milking of indigenous Greek goats. Czech J. Ani. Sci. 2008, 53, 112–118. [Google Scholar] [CrossRef] [Green Version]

- Skapetas, B.; Laga, V.; Katanos, I.; Bampidis, V.; Nistor, E.; Nitas, D.; Aggelopoulos, S.; Nistor, G. Milking parlors’ throughput for dairy sheep and factors that influence it. Lucr. Stiintifice Zooteh. Si Biotehnol. 2009, 42, 505–510. [Google Scholar]

- Poulet, J.-L. Interactions animal-milking machine-milker, contributions of milking time tests in small ruminants. In Proceedings of the seventh International Symposium on Sheep, Goat and Other Non-Cow Milk, Limassol, Cyprus, 23–25 March 2015. [Google Scholar]

- Billon, P.; Romero, G.; Diaz, J.R. Husbandry of dairy animals: Goat: Milking management. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Gökdai, A.; Sakarya, E.; Contiero, B.; Gottardo, F. Milking characteristics, hygiene and management practices in Saanen goat farms: A case of Canakkale province, Turkey. Ital. J. Ani. Sci. 2020, 19, 213–221. [Google Scholar] [CrossRef]

- Caria, M.; Boselli, C.; Murgia, L.; Rosati, R.; Pazzona, A. Influence of low vacuum levels on milking characteristics of sheep, goat and buffalo. J. Agric. Eng. 2013, 44, e43.217–e43.220. [Google Scholar] [CrossRef]

- Laga, V.; Skapetas, B.; Katanos, I.; Sinapis, E.; Hatziminiaoglou, I. Efficiency of milking machines for dairy ewes in Central Macedonia, Greece. Ani. Sci. Rev. 2007, 36, 23–40. [Google Scholar]

- Tölü, C.; Irmak, S.; Acikel, S.; Akbag, H.I.; Savas, T. Comparison of milk yield, milk composition and residual milk of machine and Hand-Milked in Turkish saanen Goats. J. Agric. Sci. 2016, 22, 462–470. [Google Scholar]

- Ramos, J.S.; Gomes, V.; Matazo, M.P.; Silva, C.P.C.; Baldacim, V.A.P.; Madureira, K.M. Effect of the type of milking on mammary gland examination in Saanen goats. Arq. Inst. Biol. 2020, 87, e0802018. [Google Scholar] [CrossRef]

- Kaskous, S. The effect of using quarter individual milking system “MultiLactor” on improvement of milk performance and milk quality of different dairy cows breeds in different farms. Emir. J. Food Agric. 2018, 30, 57–64. [Google Scholar] [CrossRef]

- Kaskous, S. Camel milk composition, udder health and effect of different storage times and temperatures on raw milk quality using camel milking machine “StimuLactor”. Agric. Food Sci. Res. 2019, 6, 172–181. [Google Scholar]

- Kaskous, S. Optimization of milk performance and quality in dairy farms by using a quarter individual milking system “MultiLactor”. Int. J. Environ. Agric. Biotechnol. 2020, 5, 943–952. [Google Scholar] [CrossRef]

- Franz, S.; Hofmann-Parisot, M.; Gütler, S.; Baumgartner, W. Clinical and ultrasonographic findings in the mammary gland of sheep. N. Z. Vet. J. 2003, 51, 238–243. [Google Scholar] [CrossRef]

- SAS User´s Guide: Statistics, Release version 8.0; SAS Institute INC.: Cary, NC, USA, 1999.

- Marie-Etancelin, C.; Arhainx, J.; Aurel, M.R.; Autran, P.; Bibe, B.; Jacquin, M.; Lagriffoul, G.; Pailler, F.; Porte, D.; Ricard, E.; et al. Estimates of genetic parameters for milk flow kinetics during machine milking in french Lacaune dairy sheep. In Proceedings of the 7th World Congress of Genetics Applied to Livestock Production, Montpellier, France, 19–23 August 2002. [Google Scholar]

- Merkhan, K.Y.; Alkass, J.E. Influence of udder and teat size on milk yield in black and Meriz goats. Res. Opin. Anim. Vet. Sci. 2012, 1, 601–605. [Google Scholar]

- Ampueda, J.; Combellas, J. Estimacion de la production de leche en ovejas west african. Prod. Lat. 2000, 25, 533–535. [Google Scholar]

- Arcos-Alvarez, D.; Canul-Solis, J.; Garcia-Herrera, R.; Sarmiento-Franco, L.; Pineiro-Vazquez, A.; Casanova-Lugo, F.; Tedeschi, L.O.; Gonzalez-Ronquillo, M.; Chay-Canul, A. Udder measurements and their relationship with milk yield in Pelibuey ewes. Animals 2020, 10, 518. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Billon, P.; Ronningen, O.; Sangiorgi, E.; Schuiling, E. Quantitative requirements of milking installations for small ruminants. A survey in different countries. Milking and milk production of dairy sheep and goats. In Milking and Milk Production of Dairy Sheep and Goats, Proceedings of the Sixth International Symposium on the Milking of Small Ruminants, 26 September–1 October 1998; EAAP Publication: Athens, Greece, 1999; Volume 95, pp. 209–215. [Google Scholar]

- Reinemann, D.J. Milking machine basics and special considerations for small ruminants. In Proceedings of the Dairy sheep Association for North America 21st Annual Symposium, Madison, WI, USA, 5–7 November 2015; pp. 13–15. [Google Scholar]

- Olechnowicz, J. The course of machine milking in small ruminants. In Milk Production-An Up-to-Date Overview of Animal Nutrition, Management and Health; Chapter 10; Intech: London, UK, 2012; pp. 185–216. [Google Scholar]

- Billon, P.; Marnet, P.G.; Maugras, J. Influence of pulsation parameters on milking and udder health of dairy goats. In Proceedings of the International Conference, Nitra, Slovakia, 26–28 April 2005; Volume 10, pp. 137–146. [Google Scholar]

- Gonzalo, C.; Carriedo, J.A.; Blanco, M.A.; Beneitez, E.; Juarez, M.T.; De La Fuente, L.F.; San Primitivo, F. Factors of variation influencing bulk tank somatic cell count in dairy sheep. J. Dairy Sci. 2005, 88, 969–974. [Google Scholar] [CrossRef]

- Manzur, A.; Diaz, J.-R.; Mehdid, A.; Fernandz, N.; Peris, C. Effect of mid-line or low-line milking systems on milking characteristics in goats. J. Dairy Res. 2012, 79, 375–382. [Google Scholar] [CrossRef]

- Besier, J.; Lind, O.; Bruckmaier, R.M. Dynamics of teat-end vacuum during machine milking: Types, causes and impacts on teat condition and udder health- a literature review. J. Appl. Ani. Res. 2016, 44, 263–272. [Google Scholar] [CrossRef] [Green Version]

- Caria, M.; Murgia, L.; Pazzona, A. Effect of low vacuum on sheep milking. In Proceedings of the Innovation Technology to Empower Safety, Health and Welfare in Agriculture and Agro-food Systems, International Conference, Ragusa, Italy, 15–17 September 2008. [Google Scholar]

- Sinapis, E.; Marnet, P.G.; Skapetas, B.; Hatziminaoglou, I. Vacuum level for opening the teat sphincter and the change of the teat end wall thickness during the machine milking of mountainous Greek breed (Boutsiko) ewes. Small Rum. Res. 2007, 69, 136–143. [Google Scholar] [CrossRef]

- Murgia, L.; Pazzona, A. Comparison among six milk claws for sheep milking. In Milking and Milk Production of Dairy Sheep and Goats, Proceedings of the sixth International Symposium on the Milking of Small Ruminants, 26 September–1 October 1998; EAAP Publication: Athens, Greece, 1999; Volume 95, pp. 245–247. [Google Scholar]

- Le Du, J. La machine a traite incidence des facteurs associes au fonctionnnement du manchon. Ann. Med. Vet. 1977, 121, 309–321. [Google Scholar]

| Effect | Num DF | Den DF | F-Value | p-Value |

|---|---|---|---|---|

| Sheep milking machine | ||||

| Milk jet | 3 | 139 | 64.18 | <0.0001 |

| Vacuum level | 4 | 139 | 15.95 | <0.0001 |

| Pulsation ratio | 1 | 139 | 1.82 | 0.1800 |

| Height of ML | 1 | 139 | 99.79 | <0.0001 |

| Goat milking machine | ||||

| Milk jet | 3 | 116 | 61.63 | <0.0001 |

| Vacuum level | 4 | 116 | 5.34 | 0.0003 |

| Pulsation ratio | 1 | 116 | 1.9 | 0.7650 |

| Height of ML | 1 | 116 | 19.06 | <0.0001 |

| Parameter | Sheep | Goats | ||

|---|---|---|---|---|

| N | LSMEANS ± SE | N | LSMEANS ± SE | |

| Milk Jet (mm) | ||||

| 2 | 57 | 2.91 ± 0.05 a | 54 | 3.03 ± 0.11 a |

| 2.5 | 57 | 3.85 ± 0.05 b | 54 | 3.63 ± 0.11 b |

| 3 | 54 | 4.82 ± 0.05 c | 42 | 4.47 ± 0.13 c |

| 4 | 42 | 5.51 ± 0.06 d | 24 | 5.08 ± 0.16 d |

| Vacuum (kPa) | ||||

| 32 | 33 | 3.95 ± 0.07 a | 18 | 3.66 ± 0.18 a |

| 34 | 30 | 4.16 ± 0.07 b | 33 | 3.89 ± 0.13 ae |

| 36 | 57 | 4.26 ± 0.05 b | 36 | 4.05 ± 0.13 be |

| 38 | 30 | 4.44 ± 0.07 c | 42 | 4.27 ± 0.12 cb |

| 40 | 60 | 4.55 ± 0.05 c | 45 | 4.39 ± 0.11 c |

| Milk Line Height | ||||

| Low Line | 110 | 4.51 ± 0.04 a | 90 | 4.41 ± 0.06 a |

| High Line | 100 | 4.03 ± 0.04 b | 84 | 3.70 ± 0.16 b |

| Pulsation Ratio | ||||

| 50:50 | 105 | 4.23 ± 0.05 a | 95 | 3.92 ± 0.23 a |

| 60:40 | 105 | 4.32 ± 0.03 a | 79 | 4.07 ± 0.19 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaskous, S. Laboratory Tests to Optimize the Milking Machine Settings with Air Inlet Teat Cups for Sheep and Goats. Dairy 2022, 3, 29-46. https://doi.org/10.3390/dairy3010003

Kaskous S. Laboratory Tests to Optimize the Milking Machine Settings with Air Inlet Teat Cups for Sheep and Goats. Dairy. 2022; 3(1):29-46. https://doi.org/10.3390/dairy3010003

Chicago/Turabian StyleKaskous, Shehadeh. 2022. "Laboratory Tests to Optimize the Milking Machine Settings with Air Inlet Teat Cups for Sheep and Goats" Dairy 3, no. 1: 29-46. https://doi.org/10.3390/dairy3010003

APA StyleKaskous, S. (2022). Laboratory Tests to Optimize the Milking Machine Settings with Air Inlet Teat Cups for Sheep and Goats. Dairy, 3(1), 29-46. https://doi.org/10.3390/dairy3010003