Abstract

The aim of this study was to assess the possibility of using collagen protein hydrolysate in the production of milk fermented by Bifidobacterium animalis ssp. lactis Bb-12 and Lactobacillus rhamnosus. Physicochemical and organoleptic properties were studied and microbiological analysis of fermented milk was performed on days 1 and 21 of storage. Milk with the addition of 3% collagen protein hydrolysate was pasteurized (85 °C/30 min), divided into two groups, cooled to 37 °C and inoculated: the first group with Bifidobacterium animalis ssp. lactis Bb-12, second with Lactobacillus rhamnosus. Incubation was carried out at 37 °C/10 h. After 21 days of refrigerated storage, the pH value decreased in all analyzed milk samples. Collagen protein hydrolysate was a good milk additive to increase gel hardness and reduce syneresis. Moreover, its addition did not change the taste and odour of milk fermented with the use of Bifidobacterium Bb-12 and Lactobacillus rhamnosus. Collagen protein hydrolysate favourably stimulated the survival of Bifidobacterium Bb-12 during 21 days of storage. After 21 days of cold storage in milk with collagen, the number of Lactobacillus rhamnosus cells was reduced by 0.11 log cfu g−1.

1. Introduction

Collagen, in the human body is the major component of the extracellular matrix (ECM), it makes up one-third of the total protein, and three-quarters of the skin weight. This protein is characterized by high strength and flexibility. The structure of collagen depends on its location and function [1,2]. Collagen is found in many different tissues of the body, protecting, among others, internal organs such as the kidneys, stomach and liver, forming a flexible scaffold around them. It constitutes a building material of most organs, especially skin, bones, teeth, cartilage, blood vessels and the cornea of the eye [3]. It prevents the entry of pathogenic microorganisms and toxins in the immune system [4]. Moreover, it is responsible for the continuity of cell renewal processes in the skin and maintains its proper moisture level. It stimulates cartilage cell activity and supports protective processes within the cartilage. Furthermore, collagen increases bone density and allows better absorption of minerals. In a healthy and young body, collagen undergoes systematic and regular reconstruction of about 3 kg per year. However, from the age of 25, its levels in the body begin to decrease, after 50 years of age it decreases more rapidly, and after the age of 60 its production in the body is dramatically reduced.

Within the rapid development of the functional food trend new niche markets are emerging focusing on more specific areas, such as beauty. The use of collagen became increasingly popular in dietary supplements, drinks, nutrition products for athletes or in snacking products. The use of collagen as functional food ingredient indicates that collagen peptides perform important physiological functions and have a positive effect on improving skin elasticity [5], recovering the lost cartilage [6], reducing joint pain associated with activity [7,8], strengthening tendons and ligaments [9,10,11,12] and increasing bone mineral density in postmenopausal women [13].

Fermented milk products are recognised in many regions of the world for its health properties. In comparison with fresh-unfermented milk, it is characterized by a greater absorption of proteins and fat and a higher content of many vitamins. Fermented milk has a positive effect on the digestive system, lowers blood cholesterol, and is an important component in the diet for preventing osteoporosis. Bacteria responsible for fermentation processes show healing properties, colonizing the gastrointestinal tract, they inhibit the growth of pathogenic and putrefactive bacteria [14]. Among the well-known bacteria with documented probiotic significance, we can distinguish, for instance: Bifidobacterium animalis ssp. lactis Bb-12 and Lactobacillus rhamnosus. The reported beneficial effects of ingesting these probiotic bacteria include improving intestinal health, alleviating the symptoms of lactose intolerance, and reducing the risk of various other diseases [15,16].

The purpose of the research was to evaluate the possibility of using collagen in the manufacture of milk fermented with the use of Bifidobacterium animalis ssp. lactis Bb-12 and Lactobacillus rhamnosus. Physicochemical and microbiological properties, as well as organoleptic characteristics were examined, and microbiological analysis of products was carried out on days 1 and 21 of storage.

2. Materials and Methods

2.1. Material

For this experiment 2% fat milk (Łaciate, MLEKPOL Dairy, Grajewo, Poland) and collagen-100% collagen protein hydrolysate (Intenson, Gasthaus, Germany). Two strains of probiotic bacteria were used for milk fermentation: Bifidobacterium animalis ssp. lactis Bb-12 DMS 15954 (Bifidobacterium Bb-12) (Chr. Hansen, Hoersholm, Dania) and Lactobacillus rhamnosus Lr-32™ (L. rhamnosus) (Danisco, DuPont, Copenhagen, Denmark).

2.2. Fermented Milk Manufacture

We added 3% collagen protein hydrolysate to the milk, heated it to 60 °C and homogenized it with pressure of 20 MPa (Nuoni GJJ-0.06/40, Shanghai, China). Next the milk mixture was re-pasteurized (85 °C, 30 min). After the heat treatment the milk was cooled to 37 °C. Milk–collagen mixture was divided into two lots. The first lot (A) was the milk with collagen protein hydrolysate addition, inoculated with a Bifidobacterium animalis ssp. lactis Bb-12. The second lot (C) was the milk with collagen protein hydrolysate addition, inoculated with Lactobacillus rhamnosus and the controls for this groups were milk samples without the addition of collagen protein hydrolysate (B-control Bifidobacterium Bb-12; D-control L. rhamnosus). Both groups of milk were inoculated with single starter culture, which was previously activated, according to the Szajnar et al. [17] method. Then the milk was thoroughly mixed and poured into 100 mL plastic containers and the fermentation process was carried out for 10 h at the temperature 37 °C. The probiotic fermented milk was cooled (5 °C) and evaluated on the 1st and 21st day of cold storage (5 °C). The experiment was repeated three times and all the analyses were performed in quintuplicate.

2.3. Physicochemical Properties

2.3.1. The pH and Total Acidity

The pH value was measured with the use of a pH-meter FiveEasy (Mettler Toledo, Greifensee, Switzerland). Total acidity of milk was evaluated according to the method of Jemaa et al. [18]. Fermented milk samples with phenolphthalein were titrated with 0.1 M NaOH solution. The total acidity was expressed as g L−1 of lactic acid.

2.3.2. Syneresis

Syneresis was determined using the centrifugal method according to Szajnar et al. [17]. 10 g of fermented milk was transferred into 50 mL plastic tube and centrifuged at 1790× g, 10 min, 5 °C, LC-04 CENTRIFUGE (Zenithlab, Changzhou, China). The results were converted to percentages.

2.3.3. Instrumental Texture

Texture profile analysis (TPA) was performed according to the method of Znamirowska et al. [19]. Parameters of the texture were determined using the Brookfield CT3 Texture Analyzer. (AMETEK, Berwyn, PA, USA). The test was performed on a 100 mL sample of solid state fermented milk without mixing in the plastic cup. The following settings were used: probe TA3/100 (acrylic cylinder—35 mm diameter), sample—cylinder 66.00 mm × 33.86 mm, test speed 1 mm s−1, trigger load 0.1 N table TABTKIT.

2.3.4. Microbiological Analysis

Determination of the Bifidobacterium animalis ssp. lactis Bb-12 and Lactobacillus rhamnosus was evaluated as stated by Lima et al. [20] with the use of MRS Agar (Biocorp, Warszawa, Poland). Probiotic bacterias were incubated anaerobically: 37 °C, 72 h in the vaccum desiccator and GENbox anaer (Biomerieux, Warszawa, Poland). The number of viable cell was presented as log cfu g−1.

2.3.5. Organoleptic Analysis

The panel of 10 women and 10 men (aged 25–40) was trained and performed the organoleptic analysis. The organoleptic parameters on a 9-point rating scale (1—not perceptible, 9—extremely strong) were evaluated by panelists. The presence of consistency, milky-creamy taste, fermentation taste (the taste stimulated by lactic acid and other flavour compounds produced by bacteria), sweet taste, off-taste, sour-odour, off-odour were estimated [17,21].

2.4. Statistical Analysis

From the results obtained the mean and standard deviation were calculated statistically using the Statistica v. 13.1 software (StatSoft, Tulsa, OK, USA). Significance of differences between the averages (p < 0.05) was performed with Tukey’s test.

3. Results

3.1. The pH and Total Acidity

The results of the pH and total acidity values are given in Table 1. On the first day of storage, the pH value was not significantly affected by the addition of collagen protein hydrolysate to milk fermented by Bifidobacterium Bb-12. However, in milk fermented by L. rhamnosus with the addition of collagen protein hydrolysate, a higher pH value was determined compared to its control. After 21 days of refrigerated storage, the pH value decreased in all analysed milk samples, both with the addition of collagen protein hydrolysate and their controls. The opposite effect was found for the total acidity of fermented milk. Total acidity of milk with the addition of collagen protein hydrolysate fermented by Bifidobacterium Bb-12 as well as by L. rhamnosus (A, C) was higher both on the first and the 21st day of the study compared to the controls (B, D).

Table 1.

Physicochemical properties of probiotic milk fermented with the use of Bifidobacterium Bb-12 or L. rhamnosus with collagen during storage time of 1 and 21 days.

3.2. Syneresis

Our study has shown that fermented milk had was characterised by different syneresis values depending on the Bifidobacterium Bb-12 and L. rhamnosus monoculture used in the production process. Syneresis of milk fermented by with the use of Bifidobacterium Bb-12, the control (B) and with the addition of collagen protein hydrolysate (A) was significantly lower than syneresis determined in milk fermented by L. rhamnosus, the control (D) and with the addition of collagen protein hydrolysate (C) on the first day of the study. It was noted that the addition of collagen protein hydrolysate to milk A and C reduced syneresis by approx. 2.5% in milk fermented by L. rhamnosus and approx. 2.0% in milk with Bifidobacterium Bb-12, but not significantly compared to their controls. During storage, the level of syneresis increased in all milk samples except for milk fermented by L. rhamnosus with the addition of collagen protein hydrolysate (C), where syneresis slightly decreased by about 1.0%.

3.3. Instrumental Texture

Significantly higher hardness and adhesiveness was found in milk with the addition of collagen protein hydrolysate fermented by Bifidobacterium Bb-12 and L. rhamnosus (A and C) compared to the control milk (B and D) in both research dates both on the first and on the 21st day of storage (Table 1). Moreover, no significant changes were noted in the springiness of milk samples containing Bifidobacterium Bb-12 and L. rhamnosus in both the control and milk with collagen protein hydrolysate throughout the storage period.

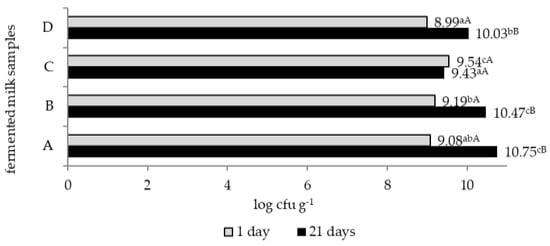

3.4. Microbiological Analysis

The survival of viable Bifidobacterium BB-12 and L. rhamnosus cells in milk samples during a 21-day storage period at 5 °C is shown in Figure 1. On the first day of the storage, the highest number of viable L. rhamnosus cells was determined in milk with the addition of collagen protein hydrolysate C. However, the addition of collagen protein hydrolysate did not differentiate the number of Bifidobacterium Bb-12 cells on day 1 of storage. After 21 days of storage. On the 21st day of research, the number of viable Bifidobacterium Bb-12 cells was significantly higher (by 1.96 log cfu g−1 in milk with collagen protein hydrolysate A) and in the fermented milk control sample milk (by 1.28 log cfu g−1, B) compared to day 1. This indicates that the addition of collagen protein hydrolysate increases the survival of Bifidobacterium Bb-12 during storage. After 21 days of storage, the number of viable cells of L. rhamnosus in the control milk D was significantly increased higher by 1.04 log cfu g−1 compared to day 1. However, in milk C with protein hydrolysate, the number of L. rhamnosus cells was reduced by 0.11 log cfu g−1 compared to day 1. In this regard, no beneficial effect of collagen protein hydrolysate on L. rhamnosus survival was found.

Figure 1.

Viable counts [log cfu g−1] in milk fermented with the use of Bifidobacterium Bb-12 or L. rhamnosus with collagen protein hydrolysate. A—milk fermented with the use of Bifidobacterium Bb-12 with collagen protein hydrolysate; B—milk fermented with the use of Bifidobacterium Bb-12 (control); C—milk fermented with the use of L. rhamnosus with collagen protein hydrolysate; D—milk fermented with the use of e L. rhamnosus (control). Means ± S.D., n = 15. A,B—mean values between 1 and 21 days of storage time characterized by different letters differ statistically significantly (p < 0.05), a–c—mean values between milk samples indicated by different letters differ statistically significantly (p < 0.05).

The number of viable Bifidobacterium Bb-12 and L. rhamnosus cells was above 8 log cfu g−1 in all milk samples and the minimum therapeutic level was maintained until the end of the storage period [22,23].

3.5. Organoleptic Analysis

All analysed milk samples fermented with the used of by Bifidobacterium Bb-12 and by L. rhamnosus, control and with the addition of collagen protein hydrolysate, did not differ significantly in parameters of organoleptic assessment on both day 1 and day 21 of assessment (Table 2). The panelists found that all samples were characterized by all milk samples having a good, compact consistency, and 3% collagen protein hydrolysate added to milk did not give a gritty, floury, gelatinous consistency of the acid curd. However, during storage, the acid curds had a slightly looser consistency associated with greater whey leakage, but these were not statistically significant differences compared to the first day of assessment. Milk samples were characterized by the milky-creamy taste, fermentation taste and fermentation odour typical of fermented beverages, the intensity of which increased with the extension of the storage time. The panelists rated sweet taste as slightly palpable and off-taste and off-odour as almost absent on both study dates.

Table 2.

The organoleptic properties of milk fermented with the use of Bifidobacterium Bb-12 or L. rhamnosus with collagen protein hydrolysate.

4. Discussion

The quality of yogurt can be adjusted with the help of various stabilizers, such as: gelatine of animal origin, natural gums such as pectins, synthetically produced carboxymethylcellulose, maize of plant origin, starch, through protective colloidal properties [24]. These additives prevent separation of various ingredients and increase viscosity to prevent separation of whey from yogurt. When preparing fermented milk, these stabilizers are used to overcome the problem associated with syneresis and give the desirable texture and stability during processing and storage. Together with extending the storage time from 1 to 21 days, the control and collagen protein hydrolysate milk samples fermented with the use of Bifidobacterium Bb-12 and L. rhamnosus were characterized by lower pH value, higher total acidity and higher acid gel hardness. Also in the studies by Lucas et al. [25] and Kavaz and Bakirci [26], it was reported that lactic acid production in probiotic yogurts increased during storage.

However, Ayub and Sadding [27] applied seven stabilizers and found that, with the exception of the use of maize starch, all other stabilizers had no significant effect on the pH value.

In our study, the addition of collagen protein hydrolysate reduced syneresis both on day 1 and day 21 of storage. However, with increasing storage time, the syneresis increased, except for milk with collagen protein hydrolysate fermented by L. rhamnosus. Panesar and Shinde [28] also confirmed the effect of storage on the syneresis of probiotic yogurt similar to that obtained in our studies, which caused the syneresis value to increase with storage time. According to Domagała [29], there is a negative relationship between yogurt hardness and susceptibility to syneresis. However, in our study, the addition of collagen protein hydrolysate reduced the syneresis of fermented milk curd while increasing the hardness of the curd. Fiszman et al. [30] showed that bovine gelatine is one of the most commonly used additives in yogurt processing, because it has a powerful ability to give yogurt products increased firmness and lower syneresis.

Gerhardt et al. [31] found that the addition of hydrolysate collagen decreased the rate of syneresis of the samples of fermented dairy drink, simultaneously improving its stability.

In our study, the hardness and adhesiveness of fermented milk was not significantly affected by the type of probiotic strain used for the fermentation process. In contrast, 3% collagen protein hydrolysate added increased hardness and adhesiveness in milk fermented both by Bifidobacterium Bb-12 and by L. rhamnosus throughout the study. Literature data report that casein hydrolysate may improve the texture and stability of yogurt by increasing the yogurt adhesiveness [32]. Oliviera et al. [33] claim that protein hydrolysates affect the texture of yogurt by changing the metabolism of primers and forming a milk protein gel. Moreover, additional probiotic cultures can give fermented dairy products a favourable acid gel texture [34].

The high survival rate of Bifidobactrium Bb-12 and Lactobacillus rhamnosus in our study can be attributed to a response specific for a probiotic strain. Collagen protein hydrolysate has been shown to be a good stimulator of growth and survival for Bifidobacterium Bb-12. However, such a relationship was not confirmed in the case of milk fermented by L. rhamnosus. The results obtained by da Mata Rigoto et al. [35] showed that hydrolysate collagen addition in probiotic beverages had a minor or no effect on Lactobacillus acidophilus culture viability. Moreover, collagen addition in dairy beverages offered functional appeal due to the continued viability of probiotic bacterias during the storage time.

Sodini et al. [36], in turn, claim that milk supplementation with peptides and amino acids can also increase the viability of probiotic organisms.

Ranadheera et al. [37] found that in food products the survival of probiotic microorganisms in addition to storage conditions is closely related to the fat concentration, the type and content of proteins, dissolved oxygen and the value of pH. Also, Iravani et al. [38] showed that the titratable acidity and low pH values of products are the main factors limiting the stability of probiotic bacteria in fermented foods. In our study, the pH value during storage significantly decreased in all analysed milk samples, but there was no significant effect of reduced pH value on the survival of the determined probiotic bacteria. According to Soomro [24], the use of milk stabilizers such as, for example, gelatine or starch has a positive effect on texture and the feeling of creamy taste. However, in our study, the addition of collagen protein hydrolysate did not differentiate the organoleptic characteristics of fermented milk [24]. A gelatine stabilizer is a translucent brittle solid, colourless or slightly yellow, produced by partial hydrolysis of collagen protein hydrolysate from animal connective tissues. Gupta and Prasad [39] found that various stabilizers (gelatine, CMC, acacia, sodium alginate and pectin) do not shape the taste of yogurt, and a good yogurt should have a smooth consistency similar to pudding. The above statements were confirmed in our study, because the use of 3% collagen protein hydrolysate in milk did not negatively affect the organoleptic characteristics of milk fermented with both Bifidobacterium Bb-12 and by L. rhamnosus. da Mata Rigoto et al. [35] obtained similar results in probiotic dairy beverages produced with hydrolysate collagen. Authors showed that hydrolysate collagen addition did not affect the apperance, aroma, flavour or texture of this beverages.

5. Conclusions

The use of collagen protein hydrolysate as an additive to milk fermented by probiotic bacteria seems to be a promising proposition for a developing new trend on the functional food market. Probiotic milk with collagen protein hydrolysate may play an important role in supplementing collagen protein hydrolysate deficiencies in the elderly and in the recovery of bone and joint injuries. Collagen protein hydrolysate has proved to be a good milk additive increasing gel hardness and reducing syneresis. Moreover, its addition did not change the taste and odour of milk fermented with the use of both Bifidobacterium Bb-12 and L. rhamnosus. Collagen protein hydrolysate favourably stimulated Bifidobacterium Bb-12 survival during storage.

Author Contributions

Conceptualization, A.Z., K.S. and M.P.; Methodology, K.S.; Software, A.Z.; Validation, A.Z.; Formal Analysis, A.Z., K.S. and M.P.; Investigation, A.Z., K.S. and M.P.; Resources, A.Z.; Data Curation, A.Z.; Writing—Original Draft Preparation, A.Z., K.S. and M.P.; Writing—Review and Editing, A.Z.; Visualization, K.S.; Supervision, A.Z.; Project Administration, M.P.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Brinckmann, J. Collagens at a glance. Top. Curr. Chem. 2005, 247, 1–6. [Google Scholar]

- Veit, G.; Kobbe, B.; Keene, D.R.; Paulsson, M.; Koch, M.; Wagener, R. Collagen XXVIII, a novel von Willebrand factor A domain-containing protein with many imperfections in the collagenous domain. J. Biol. Chem. 2006, 281, 3494–3504. [Google Scholar] [CrossRef]

- Czubak, K.; Żbikowska, H. Struktura, funkcja i znaczenie biomedyczne kolagenów. Ann. Acad. Med. Silesiensis 2014, 68, 245–254. [Google Scholar]

- Gorczyca, G. Otrzymywanie i charakterystyka nowych biomateriałów o aktywności przeciwdrobnoustrojowej na bazie chitozanu, kolagenu i żelatyny. Politech. Gdańska Wydział Chem. Gdańsk 2015. Available online: https://pbc.gda.pl/Content/57361/phd_gorczyca_grzegorz.pdf (accessed on 1 July 2020). (In Polish).

- Proksch, E.; Segger, D.; Degwert, J.; Schunck, M.; Zague, V.; Oesser, S. Oral supplementation of specific collagen peptides has beneficial effects on human skin physiology: A double-blind, placebo-controlled study. Ski. Pharmacol. Physiol. 2014, 27, 47–55. [Google Scholar] [CrossRef]

- McAlindon, T.E.; Nuite, M.; Krishnan, N.; Ruthazer, R.; Price, L.L.; Burstein, D.; Griffith, J.; Flechsenhar, K. Change in knee osteoarthritis cartilage detected by delayed gadolinium enhanced magnetic resonance imaging following treatment with collagen hydrolysate: A pilot randomized controlled trial. Osteoarthr. Cartil. 2011, 19, 399–405. [Google Scholar] [CrossRef] [PubMed]

- Zdzieblik, D.; Oesser, S.; Gollhofer, A.; Koenig, D. Corrigendum: Improvement of Activity-Related Knee Joint Discomfort Following Supplementation of Specific Collagen Peptides. Appl. Physiol. Nutr. Metab. 2017, 42, 1237. [Google Scholar] [CrossRef] [PubMed]

- Clark, K.L.; Sebastianelli, W.; Flechsenhar, K.R.; Aukermann, D.F.; Meza, F.; Millard, R.L.; Deitch, J.R.; Sherbondy, P.S.; Albert, A. 24-Week study on the use of collagen hydrolysate as a dietary supplement in athletes with activity-related joint pain. Curr. Med. Res. Opin. 2008, 24, 1485–1496. [Google Scholar] [CrossRef] [PubMed]

- Praet, S.F.E.; Purdam, C.R.; Welvaert, M.; Vlahovich, N.; Lovell, G.; Burke, L.M.; Gaida, J.E.; Manzanero, S.; Hughes, D.; Waddington, G. Oral supplementation of specific collagen peptides combined with calf-strengthening exercises enhances function and reduces pain in Achilles tendinopathy patients. Nutrients 2019, 11, 76. [Google Scholar] [CrossRef]

- Dressler, P.; Gehring, D.; Zdzieblik, D.; Oesser, S.; Gollhofer, A.; König, D. Improvement of functional ankle properties following supplementation with specific collagen peptides in athletes with chronic ankle instability. J. Sports Sci. Med. 2018, 17, 198–304. [Google Scholar] [CrossRef]

- Baar, K. Stress relaxation and targeted nutrition to treat patellar tendinopathy. Int. J. Sports Nutr. Exerc. Metab. 2019, 4, 1–5. [Google Scholar] [CrossRef]

- Zdzieblik, D.; Oesser, S.; Baumstark, M.W.; Gollhofer, A.; Konig, D. Collagen peptide supplementation in combination with resistance training improves body composition and increases muscle strength in elderly sarcopenic men: A randomised controlled trial. Br. J. Nutr. 2015, 114, 1237–1245. [Google Scholar] [CrossRef] [PubMed]

- König, D.; Oesser, S.; Scharla, S.; Zdzieblik, D.; Gollhofer, A. Specific Collagen Peptides Improve Bone Mineral Density and Bone Markers in Postmenopausal Women-A Randomized Controlled Study. Nutrients 2018, 10, 97. [Google Scholar] [CrossRef] [PubMed]

- Dietz, M. Żywność Fermentowana i Probiotyczna. Samodzielna Fermentacja Mlekowa. Trwale—Smacznie—Zdrowo; Wyd. Vital Gwarancja Zdrowia: Białystok, Polska, 2017; pp. 25–30. ISBN 978-83-65404-57-2. [Google Scholar]

- Toma, M.M.; Pokrotnieks, J. Probiotics as functional food: Microbiological and medical aspects. Acta Univ. Latv. 2006, 710, 117–129. [Google Scholar]

- Salminen, J.S.; Gueimonde, M.; Isolauri, E. Probiotics that modify disease risk. J. Nutr. 2005, 135, 1294–1298. [Google Scholar] [CrossRef] [PubMed]

- Szajnar, K.; Znamirowska, A.; Kuźniar, P. Sensory and textural properties of fermented milk with viability of Lactobacillus rhamnosus and Bifidobacterium animalis ssp. lactis Bb-12 and increased calcium concentration. Int. J. Food Prop. 2020, 23, 582–598. [Google Scholar] [CrossRef]

- Jemaa, M.B.; Falleh, H.; Neves, M.A.; Isoda, H.; Nakajima, M.; Ksouri, R. Quality Preservation of Deliberately Contaminated Milk Using Thyme Free and Nanoemulsified Essential Oils. Food Chem. 2017, 217, 726–734. [Google Scholar] [CrossRef]

- Znamirowska, A.; Szajnar, K.; Pawlos, M. Organic magnesium salts fortification in fermented goat’s milk. Int. J. Food Prop. 2019, 22, 1615–1625. [Google Scholar] [CrossRef]

- Lima, K.G.; Kruger, M.F.; Behrens, J.; Destro, M.T.; Landgraf, M.; Franco, B.D.G. Evaluation of Culture Media for Enumeration of Lactobacillus acidophilus, Lactobacillus casei and Bifidobacterium animalis in the Presence of Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus. LWT Food Sci. Technol. 2009, 42, 491–495. [Google Scholar] [CrossRef]

- PN-ISO 22935-3:2013-07. Milk and Milk Products. Guidance on a Method for Evaluation of Compliance with Product Specifications for Sensory Properties by Scoring; Polski Komitet Organizacyjny: Warszawa, Polska, 2013. (In Polish) [Google Scholar]

- Champagne, C.P.; Gardner, N.-J.; Roy, D. Challenges in the Addition of Probiotic Cultures to Foods. Crit. Rev. Food Sci. 2005, 45, 61–84. [Google Scholar] [CrossRef]

- Ashraf, R.; Shah, N.P. Selective and Differential Enumerations of Lactobacillus delbrueckii subsp. bulgaricus, Streptococcus thermophilus, Lactobacillus acidophilus, Lactobacillus casei and Bifidobacterium Spp. In Yoghurt—A Review. Int. J. Food Microbiol. 2011, 149, 194–208. [Google Scholar] [CrossRef]

- Soomro, A.H.; Dars, A.G.; Sheikh, S.A.; Khaskheli, G.S.; Magsi, A.S.; Panhwar, A.A.; Talpur, A. Effect of milk source and stabilizers on the compositional and sensorial quality of yoghurt. Pure Appl. Biol. 2016, 5, 1316–1322. [Google Scholar] [CrossRef]

- Lucas, A.; Sodini, I.; Monnet, C.; Jolivet, P.; Corrieu, G. Probiotic cell counts and acidification in fermented milks supplemented with milk protein hydrolysates. Int. Dairy J. 2004, 14, 47–53. [Google Scholar] [CrossRef]

- Kavaz, A.; Bakirci, I. Influence of inulin and demineralised whey powder addition on the organic acid profiles of probiotic yoghurts. Int. J. Dairy Technol. 2014, 67, 577–583. [Google Scholar] [CrossRef]

- Ayub, M.; Saddiq, M. Effect of different types of milk and stabilizers on the chemical composition of quality yoghurt. Sarhad J. Agric. 2003, 19, 271–278. [Google Scholar]

- Panesar, P.S.; Shinde, C. Effect of Storage on Syneresis, pH, Lactobacillus acidophilus Count, Bifidobacterium bifidum Count of Aloe vera Fortified Probiotic Yoghurt. Curr. Res. Dairy Sci. 2012, 4, 17–23. [Google Scholar] [CrossRef]

- Domagala, J. Instrumental texture, syneresis and microstructure of yoghurts prepared from goat, cow and sheep milk. Int. J. Food Prop. 2009, 12, 605–615. [Google Scholar] [CrossRef]

- Fiszman, S.M.; Lluch, M.A.; Salvador, A. Effect of addition of gelatin on microstructure of acidic milk gels and yoghurt and on their rheological properties. Int. Dairy J. 1999, 9, 895–901. [Google Scholar] [CrossRef]

- Gerhardt, Â.; Monteiro, B.W.; Gennari, A.; Lehn, D.N.; De Souza, C.F.V. Características físico-químicas e sensoriais de bebidas lácteas fermentadas utilizando soro de ricota e colágeno hidrolisado. Physicochemical and sensory characteristics of fermented dairy drink using ricotta cheese whey and hydrolyzed collagen. Rev. Inst. Laticínios Cândido Tostes 2013, 68, 41–50. [Google Scholar] [CrossRef]

- Zhao, Q.Z.; Wang, J.S.; Zhao, M.M.; Jiang, Y.M.; Chun, C. Effect of casein hydrolysates on yogurt fermentation and texture properties during storage. Food Technol. Biotechnol. 2006, 44, 429–434. [Google Scholar]

- Oliveira, M.N.; Sodini, I.; Remeuf, F.; Corrieu, G. Effect of milk supplementation and culture composition on acidification, textural properties and microbiological stability of fermented milks containing probiotic bacteria. Int. Dairy J. 2001, 11, 935–942. [Google Scholar] [CrossRef]

- Li, C.; Song, J.; Kwok, L.; Wang, J.; Dong, Y.; Yu, H.; Hou, O.; Zhang, H.; Chen, Y. Influence of Lactobacillus plantarum on yogurt fermentation properties and subsequent changes during postfermentation storage. J. Dairy Sci. 2017, 100, 2512–2525. [Google Scholar] [CrossRef]

- Da Mata Rigoto, J.; Ribeiro, T.H.S.; Stevanato, N.; Sampaio, A.R.; Ruiz, S.P.; Bolanho, B.C. Effect of açaí pulp, cheese whey, andhydrolysate collagen on the characteristics of dairy beverages containing probiotic bacteria. J. Food Process. Eng. 2019, 42, e12953. [Google Scholar] [CrossRef]

- Sodini, I.; Lucas, A.; Tissier, J.P.; Corrieu, G. Physical properties and microstructure of yoghurts supplemented with milk protein hydrolysates. Int. Dairy J. 2005, 15, 29–35. [Google Scholar] [CrossRef]

- Ranadheera, R.D.C.S.; Baines, S.K.; Adams, M.C. Importance of food in probiotic efficacy. Food Res. Int. 2010, 43, 1–7. [Google Scholar] [CrossRef]

- Iravani, S.; Korbekandi, H.; Mirmohammadi, S.V. Technology and potential applications of probiotic encapsulation in fermented milk products. J. Food Sci. Technol. 2015, 52, 4679–4696. [Google Scholar] [CrossRef] [PubMed]

- Gupta, A.; Prasad, D.N. Use of stabilizers in cultured milk products. Indian Dairym. 2000, 52, 19–24. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).