1. Introduction

Composites consist of two or more materials physically bonded together to create a new material with superior properties to the original materials [

1,

2]. They are synthesized by incorporating reinforcements, such as additives or fillers, into the matrix to design materials with enhanced desired properties [

3,

4]. The reinforced additives or fillers can be particles, short or continuous fibers, or a combination of these [

5,

6]. Composites can overcome the limitations of conventional structural materials (i.e., metals, alloys, ceramics, etc.), as they provide high strength-to-weight ratios, low densities, multi-functionalities, and tunable properties [

7]. Laminated composites (LCs) are a class of composites consisting of different materials layered or bonded together with well-defined interfaces [

8]. LCs are produced by stacking layers of different materials, which could be reinforcing particles, polymers, metallic or ceramic matrices, to produce multilayered structures with tailored physical and mechanical properties [

9,

10]. The load-bearing capacity, fatigue performance, and damage tolerance of LCs can be optimized by carefully designing the material composition, orientation, and thickness of the laminas [

11,

12]. Due to their exceptional properties, LCs are widely used materials in various industries [

13,

14]. Their superior mechanical and functional properties also make them suitable for aerospace, marine, construction, and automotive applications [

15].

Additive manufacturing (AM) processes, also known as 3D printing (3DP), offer boundless opportunities to fabricate complex and intricate geometries with a wide variety of materials [

16,

17]. AM processes provide new pathways for producing intricate structures with fine control over geometry, layer thickness, and material distribution [

18,

19], minimizing material waste and production time [

20]. Owing to these boundless flexibilities and opportunities, AM is now widely used in various industries, including automotive, medical, construction, electronics, and aerospace [

21,

22]. Based on the process principles, AM processes are broadly classified into seven categories: (1) vat photopolymerization (VPP) (which includes stereolithography (SLA) and digital light processing (DLP)), (2) material jetting (MJ), (3) material extrusion-based processes such as fused deposition modeling (FDM) or fused filament fabrication (FFF), (4) directed energy deposition (DED), (5) sheet lamination, (6) powder bed fusion (PBF), and (7) binder jetting (BJ) [

23,

24,

25]. Among different AM processes, VPP utilizes a liquid photocurable resin, which is selectively solidified by precise exposure to a light source to produce 3D structures [

26,

27]. The light source, i.e., laser (in SLA) or a digital light projector (in DLP), initiates photopolymerization reactions that convert the liquid resin into a solid structure. VPP offers exceptional resolution (often below 50 μm), smooth surface finish, and the ability to fabricate complex geometries. These attributes make VPP particularly suited for producing functional prototypes, microstructures, and biomedical components where fine detail and dimensional accuracy are critical. SLA is renowned for producing highly precise and complex structures, often surpassing FDM in terms of resolution and surface quality [

26,

28]. Further insights into the applications and advancements of SLA can be found here [

29,

30,

31].

Several studies have investigated the fabrication of laminated or sandwich materials using extrusion-based AM techniques such as FDM or FFF. Ahmed et al. [

32] proposed a hybrid laminar composite approach by adding a high-toughness layer of acrylonitrile butadiene styrene copolymer (ABS) over a carbon-reinforced poly(lactic acid) (C-PLA) sheet to improve the poor toughness of 3D-printed carbon fiber-reinforced polymer composites (CFRPs), particularly those made using FFF. The C-PLA/ABS hybrid composite was fabricated by optimizing the layer height, infill density, clad ratio, and raster angle, and subsequently tested for its impact toughness. The results revealed that adding an ABS layer to a 3D-printed C-PLA composite significantly enhances toughness, and optimizing the printing parameters can further improve mechanical performance. Yadav et al. [

33] focused on improving the tensile strength of 3D-printed parts from three materials: ABS, poly(ethene terephthalate glycol) (PETG), and a multi-material composite comprising 50% ABS and 50% PETG. They investigated how material type, infill density, and extrusion temperature affect the tensile strength of these materials and proposed a successful AI model for optimizing the printing parameters.

In another study, Rabbi et al. [

34] examined polylactic acid (PLA) and nylon-based 3D-printed bi-material and investigated the post-processing heat treatment effect on the interfacial fracture toughness. The results revealed that heat treatment profoundly influences the bonding between PLA and Nylon in 3D-printed composites, as high-temperature annealing around 160 °C dramatically strengthens the interfacial fracture toughness through improved molecular interaction and diffusion, while low-temperature annealing weakens the interfacial toughness. Wang et al. [

35] introduced a novel multi-material AM process that enables the fabrication of polymer composites in a single step. Several core geometries (rhombus, square, honeycomb, re-entrant honeycomb) were fabricated and tested for flexural performance. The rhombus core design exhibited the highest flexural stiffness, strength, and energy absorption.

Despite significant progress in AM, most LCs to date have been fabricated using extrusion-based techniques such as FDM or FFF. Although these processes are cost-effective and accessible, they often face challenges, including achieving uniform nanofiller dispersion, strong interlayer bonding, restricted resolution, and maintaining printability during the fabrication of LCs, which can affect the mechanical integrity and surface quality of the 3D-printed structures. Although the SLA technique offers superior precision, surface quality, and interlayer bonding, its use for fabricating laminated or multi-material composite structures remains very limited, as confirmed by recent reviews. For instance, Khan et al. [

9] provided an extensive overview of multi-material LCs fabricated by extrusion-based AM, identifying several related studies and emphasizing the dominance of FDM/FFF in this field. In contrast, Afridi et al. [

29] extensively reviewed SLA-based materials for diverse applications. Particle sedimentation, light attenuation during curing, and filler/resin compatibility issues were identified as key challenges of the SLA process. These limitations offer an opportunity to investigate, explore, and utilize the SLA process to fabricate LCs.

In this study, we demonstrate the use of the SLA process to fabricate laminated polymer composites to overcome the limitations of extrusion-based AM processes, i.e., challenges in high precision, strong interlayer bonding, and uniform particle distribution. In addition, the SLA is mostly utilized in the literature to fabricate single homogenous resin/filler composites, whereas we present using this cost-effective and high-resolution process to produce alternating resin/composite layers. Therefore, multilayered composites with enhanced mechanical performance and distinct multi-material layers are produced without compromising the high surface or print quality. To our knowledge, such an approach combining multi-material layering and particle reinforcement within an SLA process has received limited attention in the literature, thereby positioning this work as an early demonstration of laminated SLA composites with tunable properties.

2. Materials and Methods

2.1. Materials

The base matrix used in this study was a commercially available photocurable resin (BioMed Durable), chosen for its biocompatibility and mechanical durability. The term ‘resin’ in this study refers to a photocurable acrylate-based polymer that behaves as a thermoset after curing, unlike thermoplastic polyesters commonly used in extrusion-based 3DP. Four different particles, i.e., cobalt iron oxide (CoFe2O4), graphene (G), magnesium WE43 alloy (Mg), and iron (II,III) oxide (Fe3O4), were used as reinforcement to the photocurable resin. Two different dispersing media, dimethyl sulfoxide (DMSO) (for Mg and graphene) and oleic acid (for CoFe2O4 and Fe3O4), were used to prepare particle suspensions to prevent agglomeration and enhance interfacial compatibility. The choice of dispersing media was based on the previous experience in preparing homogenous and stable suspensions of particles. Isopropyl alcohol was used to clean and remove the uncured resin from the 3D-printed specimens. Photocurable resin was procured from FormLabs, Somerville, MA, USA. CoFe2O4, Fe3O4, oleic acid, DMSO, and IPA were procured from Sigma-Aldrich, St. Louis, MO, USA. Graphene and Mg were purchased from The Sixth Element (Changzhou) Materials Technology Co., Ltd, Changzhou, Jiangsu, China, and Nanografi Nanotechnology, Ankara, Türkiye, respectively.

2.2. Preparation of Photocurable Composite Suspensions and Stability Analysis

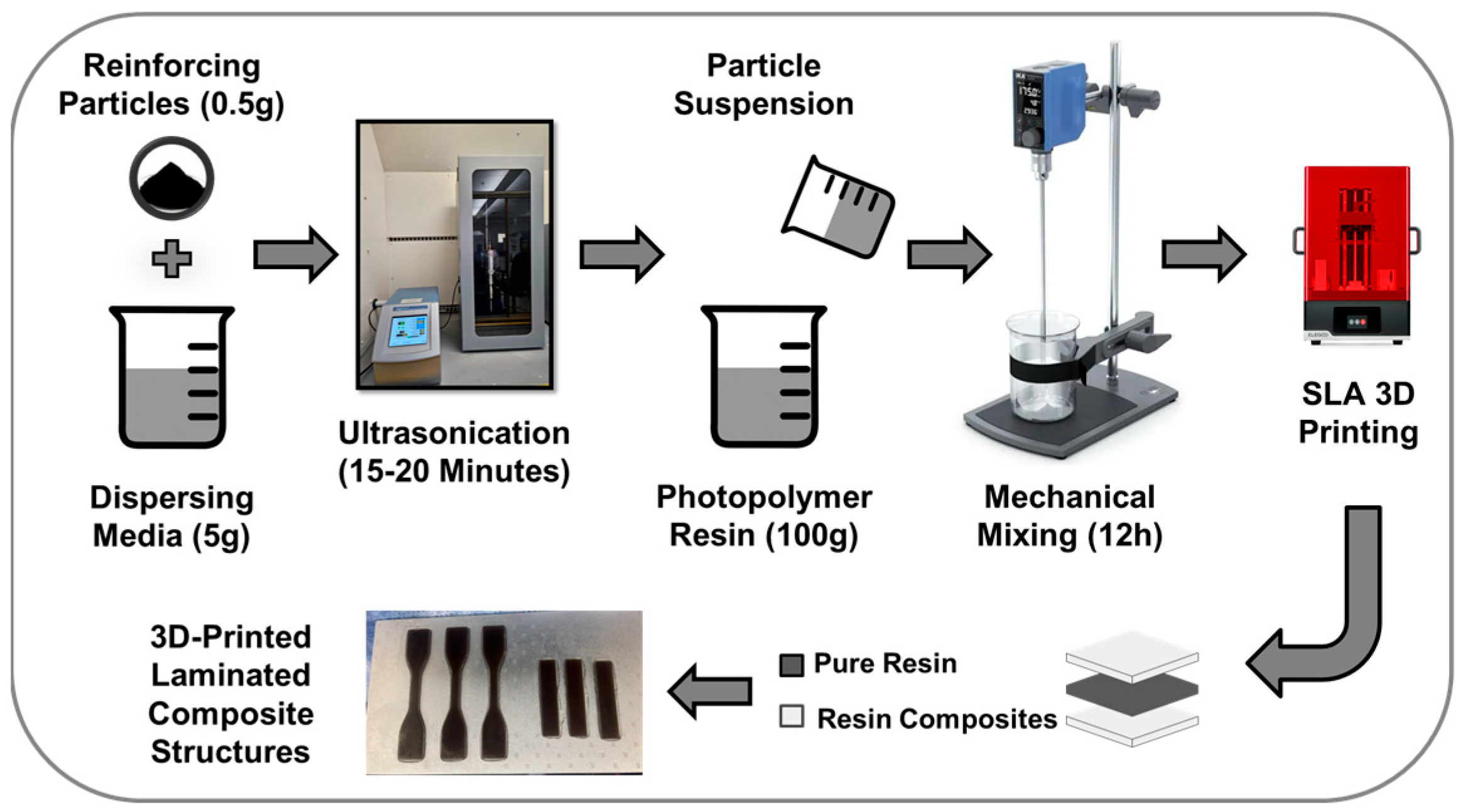

Reinforcing particles (i.e., CoFe

2O

4, graphene, Mg, and Fe

3O

4) were added to the respective dispersing media (i.e., DMSO or oleic acid). A fixed amount of 0.5 g of the particles was chosen to obtain a 0.5 wt% filler concentration and added to 5 g of the dispersing media. The selected filler content was based on the previous studies on SLA/DLP of polymer composites, which concluded that <1 wt% of filler content is optimal to maintain resin transparency, printability, and yield positive improvements in mechanical performance [

26,

27]. Particle suspensions (particles added to dispersing media) were ultrasonicated for 15–20 min to break down particle agglomerates and improve the dispersion stability of the particles before incorporation into the resin. These particle suspensions were then added to 100 g of photocurable resin (for each composite) to prepare photocurable composites. The mixtures were subjected to continuous mechanical mixing for 12 h to promote the uniform distribution of the suspended particles throughout the resin. The composite suspensions were monitored over a period of 36 h to assess their stability. Sedimentation behavior was recorded at defined intervals (2 h, 4 h, 8 h, 24 h, and 36 h). Onset of sedimentation was taken as an indicator of the time window available for effective SLA 3DP without significant particle settling.

2.3. SLA 3D Printing Process Optimization

Photocurable composites were transferred into the vat of the SLA 3D printer for the fabrication of test samples. Standard dog-bone (tensile test) and rectangular (flexural test) specimens were 3D-printed according to ASTM D638 and D790. SLA process parameters were optimized by varying the exposure time, bottom exposure time, and bottom layer count (while the layer height of 0.5 mm was kept constant), to achieve the best dimensional control and accuracy of 3D-printed parts. The design of experiments (DOE) approach was used to limit the experiments to nine unique parameter combinations. However, three identical samples were fabricated for each condition to ensure reproducibility. The G-code was modified to pause the printing process after every 1 mm of build height to fabricate LCs. At each interruption, the resin vat was replaced with either pure resin or composite resin, depending on the desired architecture. Laminated composites were produced with neat resin as the outer face material and composite resin as the core material (

Figure 1). The 3D-printed samples were removed from the build platform and washed in IPA for 15 min to remove uncured resin. Finally, UV-curing was performed (for 15 min) to ensure complete polymerization and dimensional stability.

2.4. Microscopic Analysis and Mechanical Testing

Microscopic analysis was performed on 3D-printed laminated structures to identify and ensure distinct phases of pure resin (at outer faces) and composite resin (as the core). Mark-10 universal testing machine (UTM) was used for mechanical testing (tensile and flexural). Mechanical testing was performed as per ASTM D638 and D790 standards, at a constant crosshead speed of 5 mm/min and 1.3 mm/min, for tensile and flexural tests, respectively. Load vs. displacement data were obtained for the mechanical tests and were post-processed to obtain strain vs. stress curves, and mechanical properties (i.e., tensile strength, failure strain, and Young’s/flexural modulus) were determined.

3. Results and Discussion

3.1. Stability Analysis of Photocurable Composite Suspensions

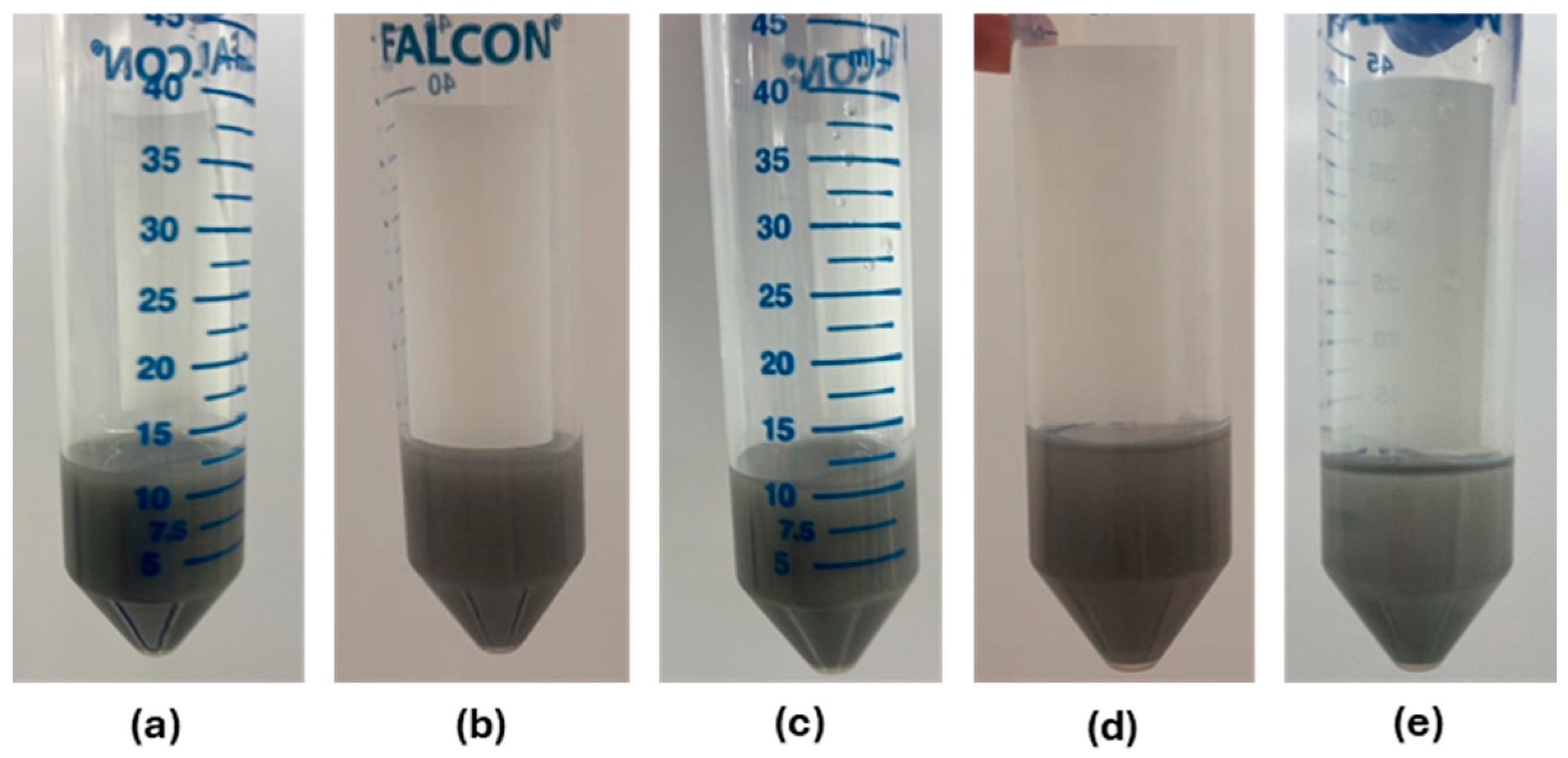

Photocurable composite suspensions were stored in the dark at room temperature to evaluate their stability over time. These suspensions were continuously monitored at specific intervals, i.e., 2 h, 4 h, 8 h, 24 h, and 36 h, to observe the particle sedimentation. The point at which the particle settling was observed was taken as the printability window of that specific composite suspension. A good dispersion without any particle sedimentation was observed for the initial 4 h for all the composite suspensions. Reinforcing particles remained stable for up to 48 h in resin/CoFe

2O

4 and resin/Fe

3O

4 composites, demonstrating excellent stability, although slight settling was observed after 36 h. However, for resin/G and resin/Mg composites, particle sedimentation was observed after 4 h, leading to complete deposition by 8 h.

Figure 2 depicts the stability analysis of the resin/Mg suspensions. Despite earlier sedimentation in two composites (i.e., resin/G and resin/Mg), the printability window (the time before particle settling) was enough to successfully 3D-print these composites.

3.2. SLA 3D Printing Process Optimization

In this study, the Elegoo Jupiter 3D printer was used to 3D-print the specimens, which operates at a 405 nm laser wavelength. As discussed in the introduction section, the addition of particles to photocurable resins alters their viscosity and optical absorption, affecting the curing performance of the 3D printer. Therefore, the 3DP parameters were systematically optimized for pure resin to ensure proper polymerization, print quality, and build plate adhesion. Three critical process parameters were selected, i.e., exposure time (10, 20, and 40 s), bottom exposure time (50, 60, and 70 s), and layer count (6, 7, and 8), while maintaining a constant layer height of 0.5 mm and experiments were conducted as per design of experiments (DOE) approach, as tabulated in

Table 1.

All 3D-printed samples were assessed for their dimensional accuracy, print quality, and build plate adhesion. The dimensions of 3D-printed samples were compared with the targeted specimen dimensions (i.e., 12 × 12 × 3 mm) using a digital caliper (±0.01 mm precision). These dimensional measurements, combined with adequate build plate adhesion and surface quality, demonstrated the optimal 3DP process parameters. A summary of the 3DP process optimization results, highlighting the successful/unsuccessful and quality of 3D prints for the resin, is presented in

Table 1.

SLA 3DP process optimization results revealed that optimal dimensional control, print quality, and build plate adhesion were observed for sample PP7. Therefore, a 0.5 mm layer height, 10 s exposure time, 50 s bottom exposure time, and an eight-layer count were found optimal for successful and high-quality 3D prints. It was also observed that higher bottom exposure times lead to overcuring of the resin, which negatively impacts the surface finish and dimensional accuracy.

3.3. Microscopic Analysis

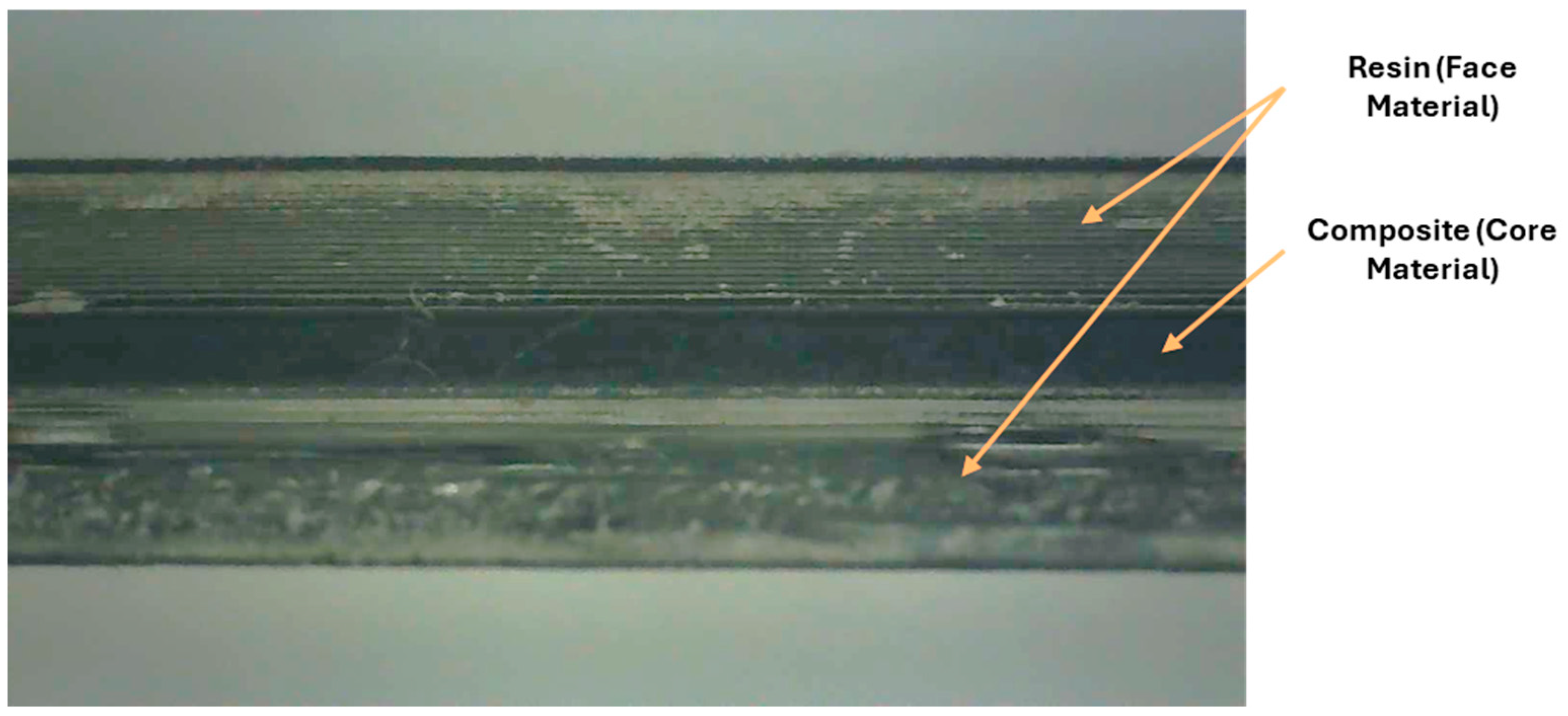

Optimized SLA process parameters were used to 3D print the laminated composite structures, and all the photocurable composites were successfully 3D-printed. The optimized SLA process was able to produce well-defined pure resin and composite layers, demonstrating the feasibility of the SLA process to produce laminated structures. In addition, a smooth transition across the interfaces was observed without any delamination or void formation.

Figure 3 presents the microscopic examination of a laminated composite, where distinct resin in the outer layers and composite in the middle section can be identified. The contrast in optical density and texture highlights the presence of reinforcing particles within the composite region, while outer layers remain transparent. The microscopic observations also confirm that reinforcing particles were confined to the desired layers only during the 3DP process.

Although

Figure 3 shows only optical micrographs, the combined evidence from optical observations, mechanical data consistency, and stability results supports adequate interfacial adhesion and filler dispersion. The absence of visible interfacial voids or delamination, together with the uniform mechanical response of multiple samples, indicates that the reinforcing particles were well dispersed within the composite layer and bonded effectively with the surrounding resin. Therefore, the optical micrographs adequately validate the laminated architecture and, when correlated with the mechanical results, confirm good interlayer bonding and effective filler incorporation.

The structural integrity of the 3D-printed laminates further validates the compatibility between the base resin and the composite formulation. These observations confirm that SLA can be effectively utilized to fabricate multilayered or functionally graded structures with controlled composition and architecture. Such laminated designs can be particularly beneficial for applications requiring a balance between mechanical strength, flexibility, and functional performance, where the composite layer contributes enhanced properties (e.g., stiffness, strength, or magnetoactive behavior), and the outer pure resin layers provide a smooth surface finish and biocompatibility. Overall, the results demonstrate the feasibility of SLA-based AM for producing complex multilayered composite systems suitable for advanced engineering and biomedical applications.

3.4. Tensile Testing

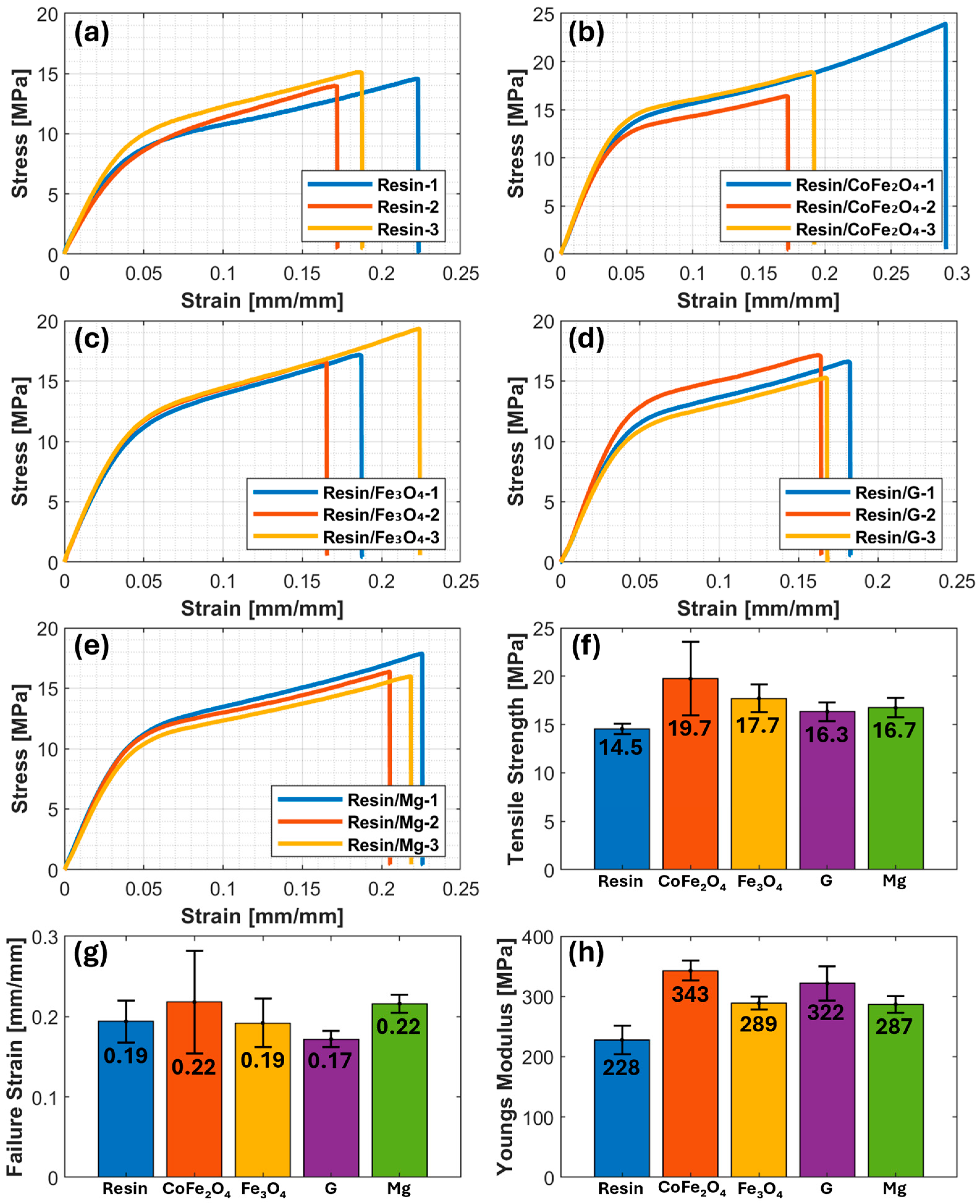

Tensile testing was conducted on at least three samples for each material and loaded until failure to obtain strain vs. stress curves.

Figure 4a–e presents the strain vs. stress behavior of all the materials tested. The failure behavior of the laminated composites under tensile loading followed a typical brittle fracture mode characteristic of photocured resins, with a sudden stress drop after the peak load.

The addition of reinforcing particles in the core layers delayed crack initiation and propagation by improving stiffness and stress transfer across the laminate interface. The uniform stress–strain response across repeated samples and the absence of interfacial fracture lines during testing further confirm the microscopic observations of strong bonding between layers. This suggests that the mechanical improvements originate from effective stress transfer across the well-adhered laminate interfaces rather than localized agglomeration effects. All the materials showed little variation within the tested samples, reflecting the consistency in the material performance.

The pure resin revealed a tensile strength of 14.55 MPa; however, the addition of composites as the core material improved their mechanical performance, as reported in

Figure 4f. A tensile strength of 19.74 MPa, 17.71 MPa, 16.33 MPa, and 16.73 MPa was recorded for resin/CoFe

2O

4, resin/Fe

3O

4, resin/G, and resin/Mg composites. Among 3D-printed laminated composites, the highest tensile strength was observed for resin/CoFe

2O

4, while the lowest average tensile strength was recorded for resin/G; yet both were considerably higher than the pure resin.

Failure strain remained mainly unaffected with the addition of the composites within the pure resin, ranging between 0.17 and 0.22 mm/mm. The highest failure strain of 0.22 mm/mm was observed for resin/CoFe

2O

4 and resin/Mg, while the lowest failure strain of 0.17 mm/mm was recorded for resin/G laminated composites, as illustrated in

Figure 4g.

The main reason for no variation in the failure strain was mainly since composites are introduced as the core sandwiched between pure resin, which positively impacts the strength and stiffness, but does not alter the strain at failure.

Figure 4h presents the comparison of Young’s modulus of all the materials tested. The pure resin revealed a Young’s modulus of 228 MPa, while the addition of composites as the core material improved their stiffness. Young’s modulus of 343 MPa, 289 MPa, 322 MPa, and 287 MPa were recorded for resin/CoFe

2O

4, resin/Fe

3O

4, resin/G, and resin/Mg composites.

A summary of the mechanical properties of SLA 3D-printed laminated composites is reported in

Table 2. Among 3D-printed laminated composites, the highest Young’s modulus was observed for resin/CoFe

2O

4, while the lowest averaged Young’s modulus was recorded for resin/Mg; yet both were considerably higher than the pure resin. Compared with the neat resin, the tensile strength improved by approximately 35.6% for the resin/CoFe

2O

4, 21.8% for resin/Fe

3O

4, 15.0% for resin/Mg, and 12.3% for resin/G.

Similarly, Young’s modulus increased by about 50.3%, 26.8%, 25.9%, and 41.2%, respectively. The consistent mechanical behavior across specimens and the absence of interfacial delamination confirm effective particle dispersion and strong interlayer adhesion, as supported by the microscopic observations in

Figure 3.

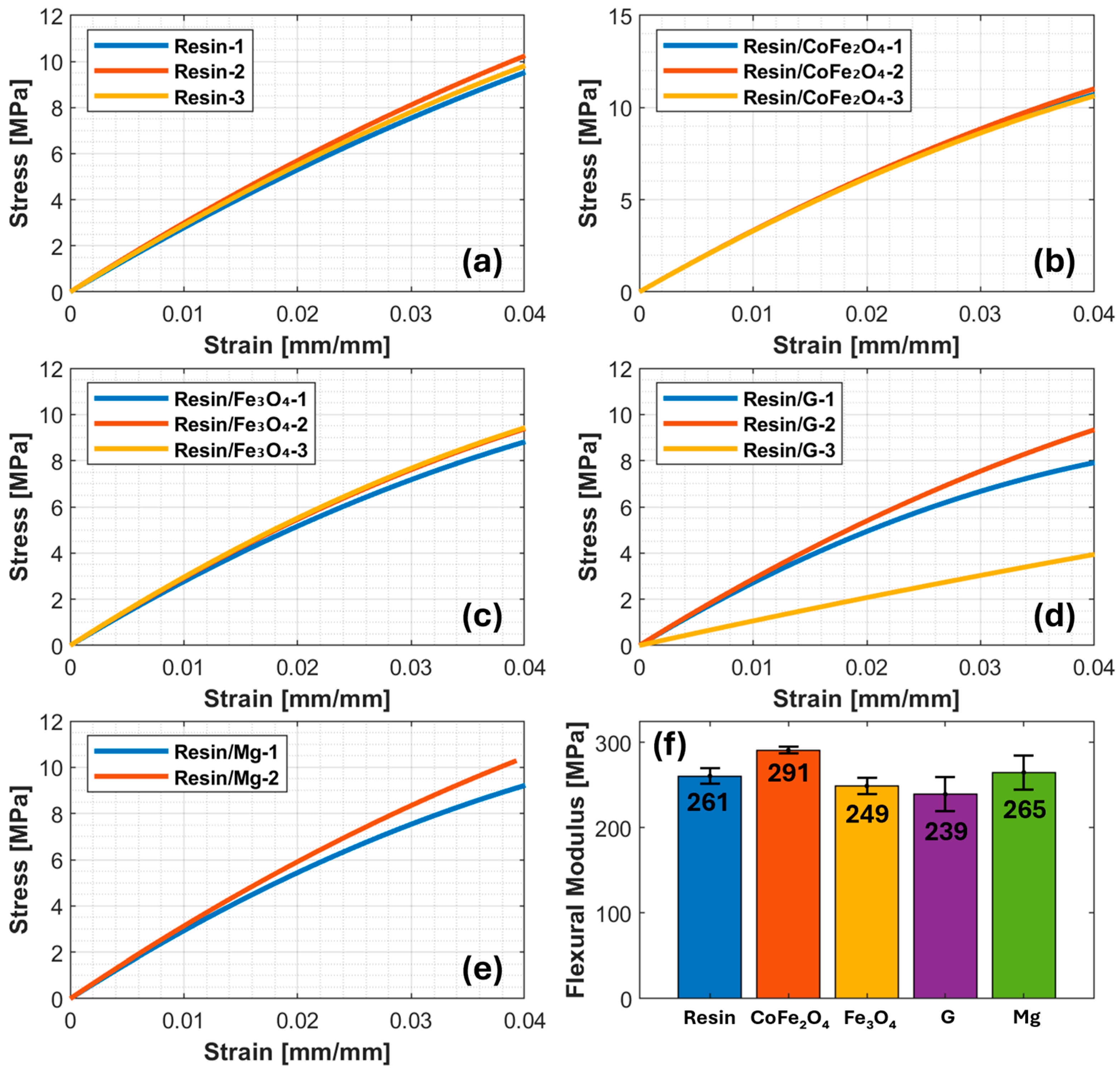

3.5. Flexural Testing

Flexural testing was performed under three-point bending conditions, and load vs. displacement data was recorded until the deflection reached two times the sample’s thickness (i.e., 6 mm); therefore, no failure was recorded.

Figure 5a–e presents the strain vs. stress behavior of all the materials tested under bending load, while

Figure 5f presents the comparison of flexural modulus among the tested materials. Resin/CoFe

2O

4 revealed the highest flexural modulus of 291 MPa, while resin/G exhibited the lowest flexural modulus of 239 MPa. Although the flexural modulus improved in the case of resin/CoFe

2O

4 composites, it remained unaffected or was negatively impacted in other materials. Only the resin/CoFe

2O

4 composite showed an ~11% increase in flexural modulus relative to the neat resin.

As flexural stresses are primarily endured by the outer resin layers, while the inner composite layer (located near the neutral axis) contributes minimally to load bearing. For this reason, the flexural modulus remained mainly unaffected, although it was lower than pure resin in the case of resin/Fe3O4 and resin/G, as the additional interfaces compromised the bending performance, and being in the middle section did not contribute to load-bearing capacity. Similar behavior has been reported for laminated composites fabricated via FDM and DLP, where the inner composite layers influence stiffness less significantly. Therefore, the addition of composites as the core within the laminated composites can contribute to the tensile performance, while for the bending/flexural performance, the introduction of composites as face materials would be more beneficial.

4. Conclusions

This study successfully demonstrates the fabrication of laminated polymer composites using the SLA 3DP technique. The integration of composite layers within pure photocurable resin resulted in structures with clear interfacial adhesion and excellent dimensional stability. Among all tested materials, the resin/CoFe2O4 laminated composite exhibited the most significant improvement, achieving a tensile strength of 19.74 MPa and a Young’s modulus of 343 MPa, corresponding to approximately 35.6% and 50.3% enhancements, respectively, compared with the neat resin (14.55 MPa, 228 MPa). However, other composites (i.e., resin/Fe3O4, resin/Mg, and resin/G) also revealed a 12–22% increase in the tensile strength. In contrast, the flexural modulus exhibited marginal improvement for resin/CoFe2O4 composites (~11% increase relative to pure resin); the rest remained either unaffected (resin/Mg) or were negatively impacted (resin/Fe3O4 and resin/G). The flexural test results demonstrated that for improved bending performance and harnessing their impact, composite layers should be positioned at the faces, as bending stresses are mainly endured by outer layers. Overall, the improvements in mechanical properties confirm that reinforcement in the laminate core effectively enhances load-bearing capacity without compromising interlayer adhesion. The findings confirm that SLA can be effectively extended beyond conventional single-material printing to fabricate functionally graded or laminated composites with tailored mechanical characteristics. This establishes a foundation for the development of high-resolution, multi-material structures for applications in biomedical devices, structural components, and smart multifunctional materials.