The Preparation of Stable MoS2 Dispersions by Using Well-Defined Polymers with Pendant Sulfide Moieties

Abstract

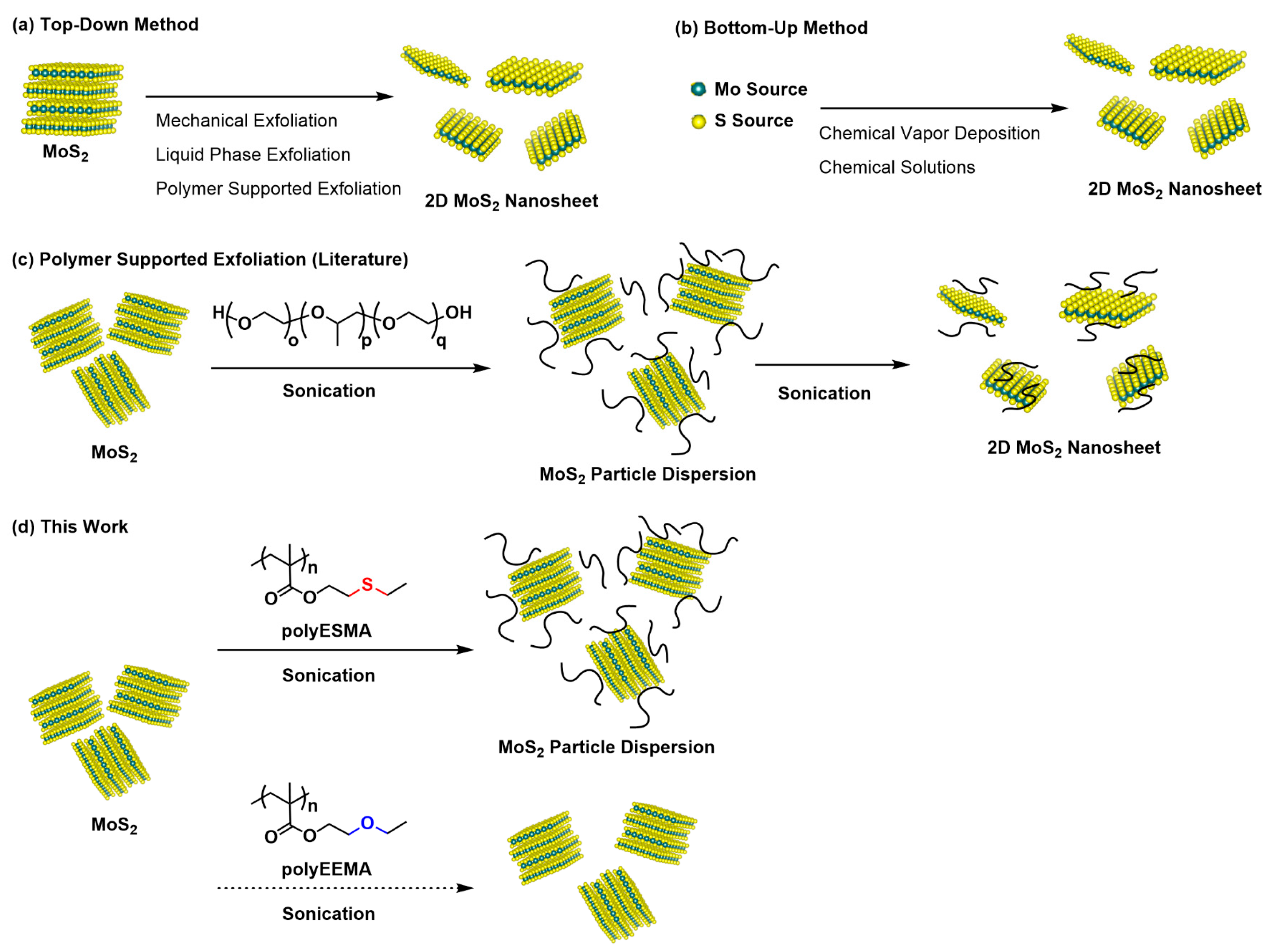

1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Methods

2.3. Synthesis of polyESMA

2.4. Synthesis of polyEEMA

2.5. Preparation of MoS2 Dispersion with polyESMA in DMSO

3. Results and Discussion

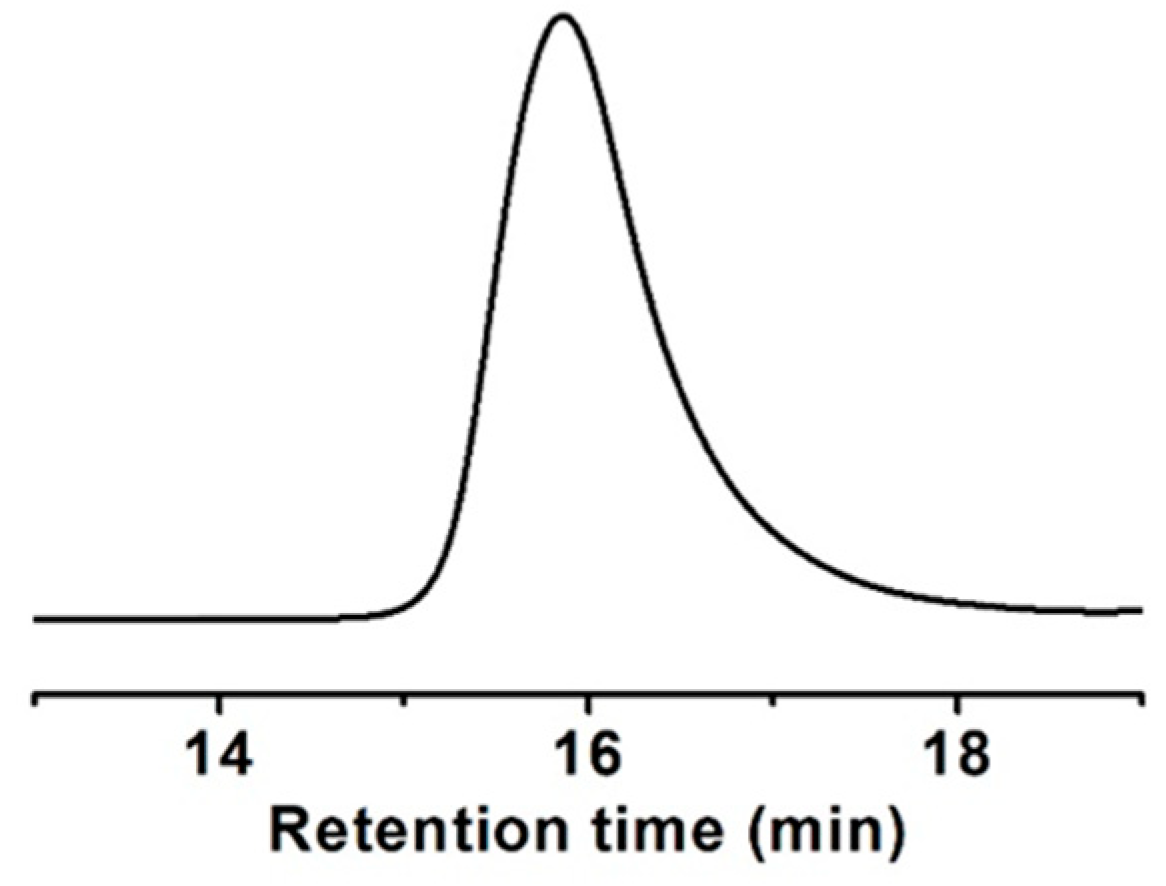

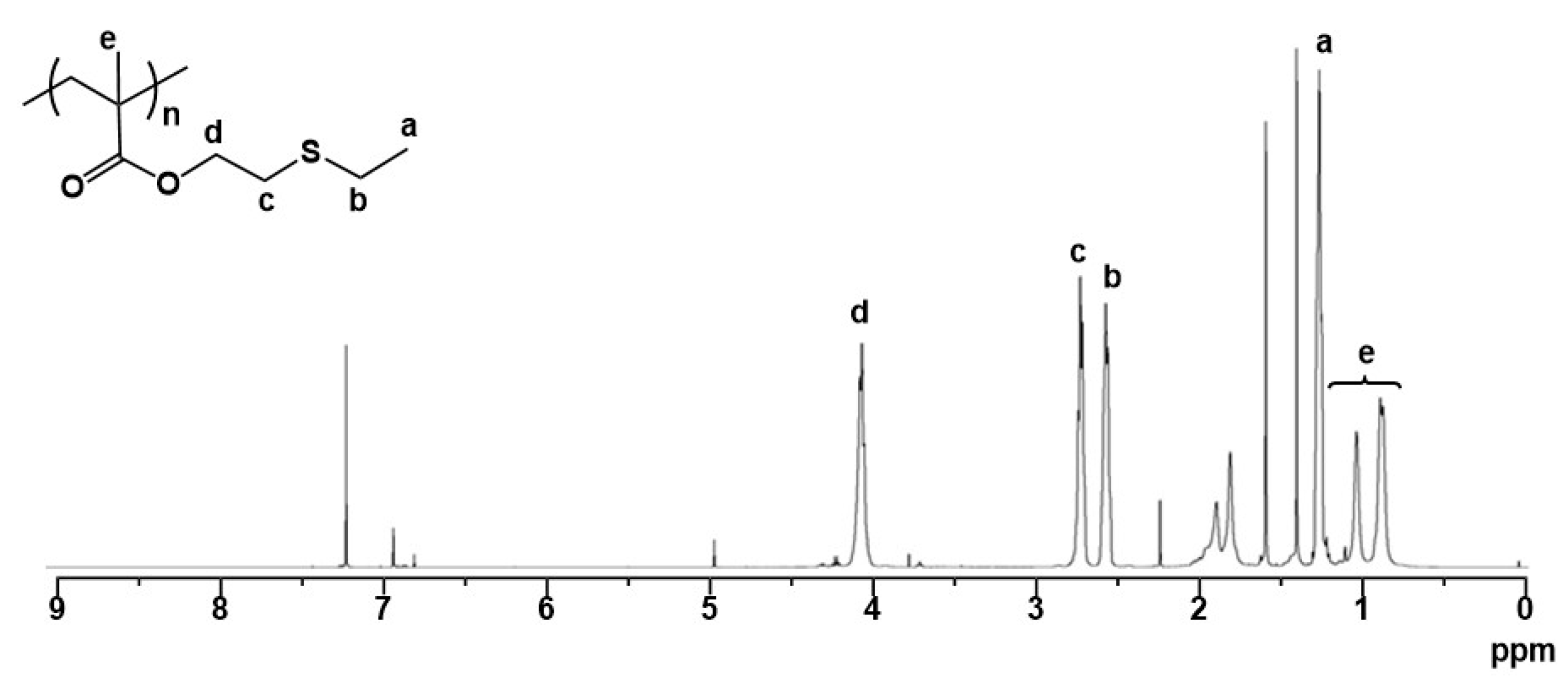

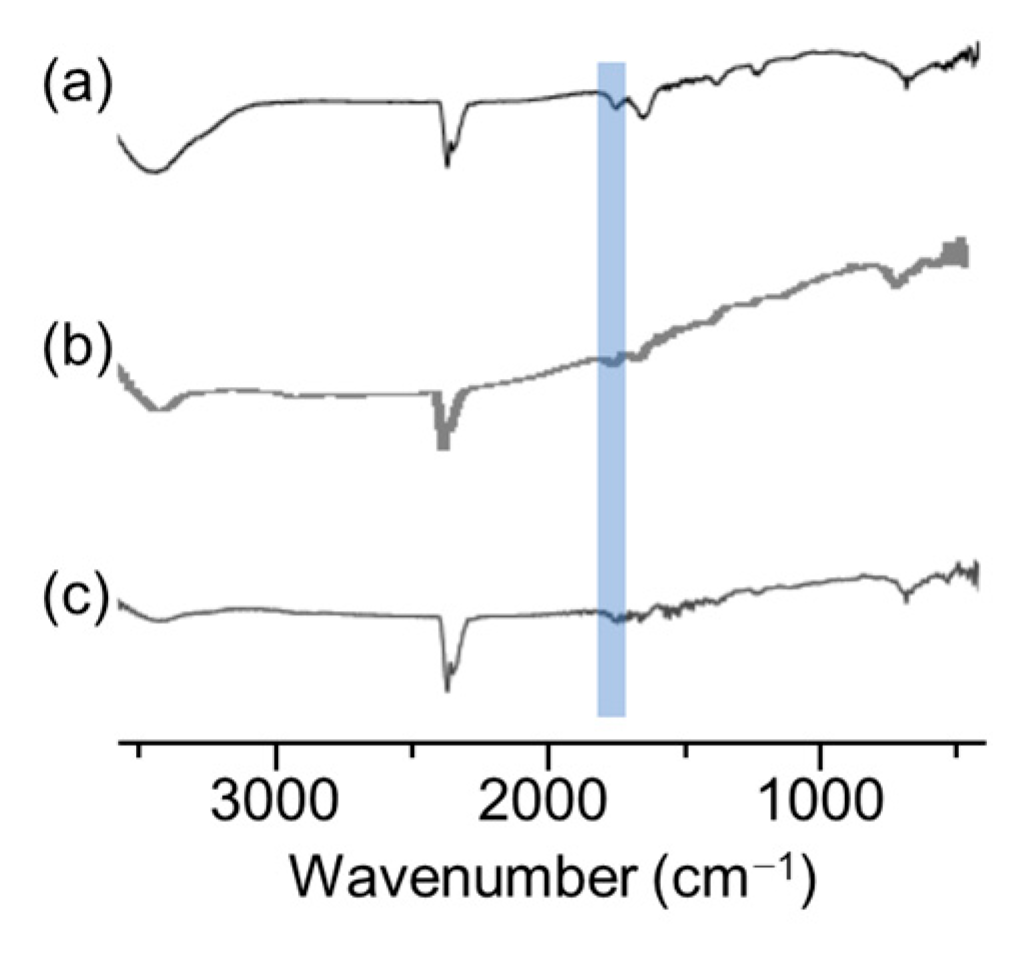

3.1. Synthesis and Characterization of ESMA and polyESMA

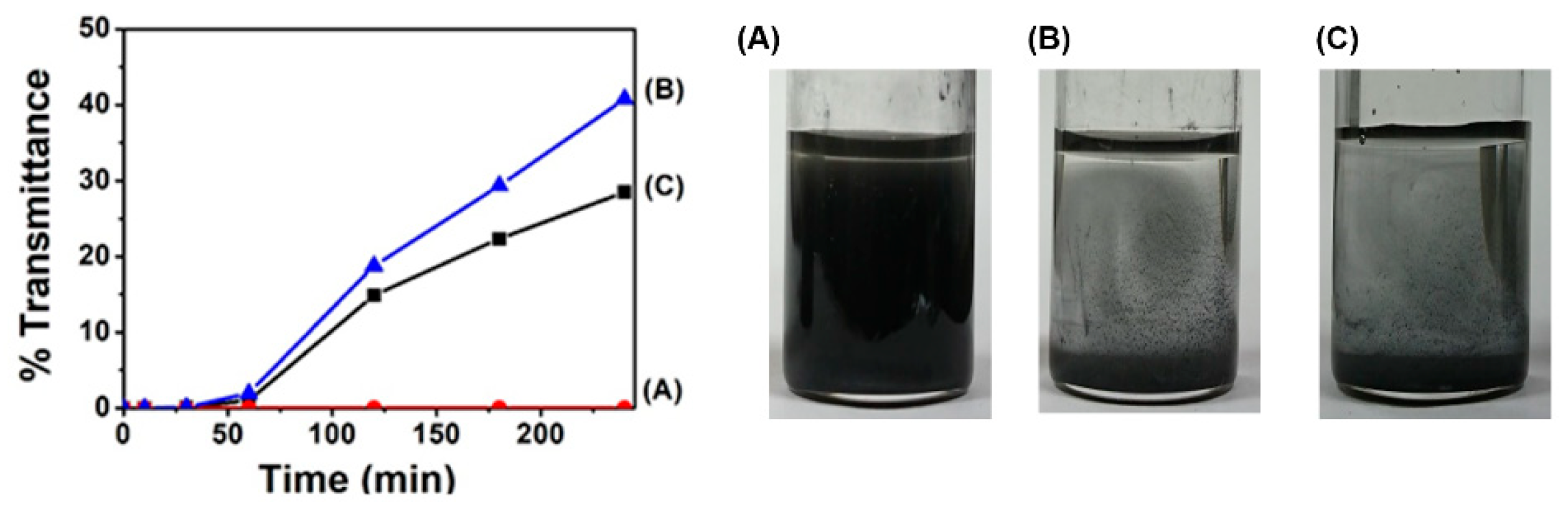

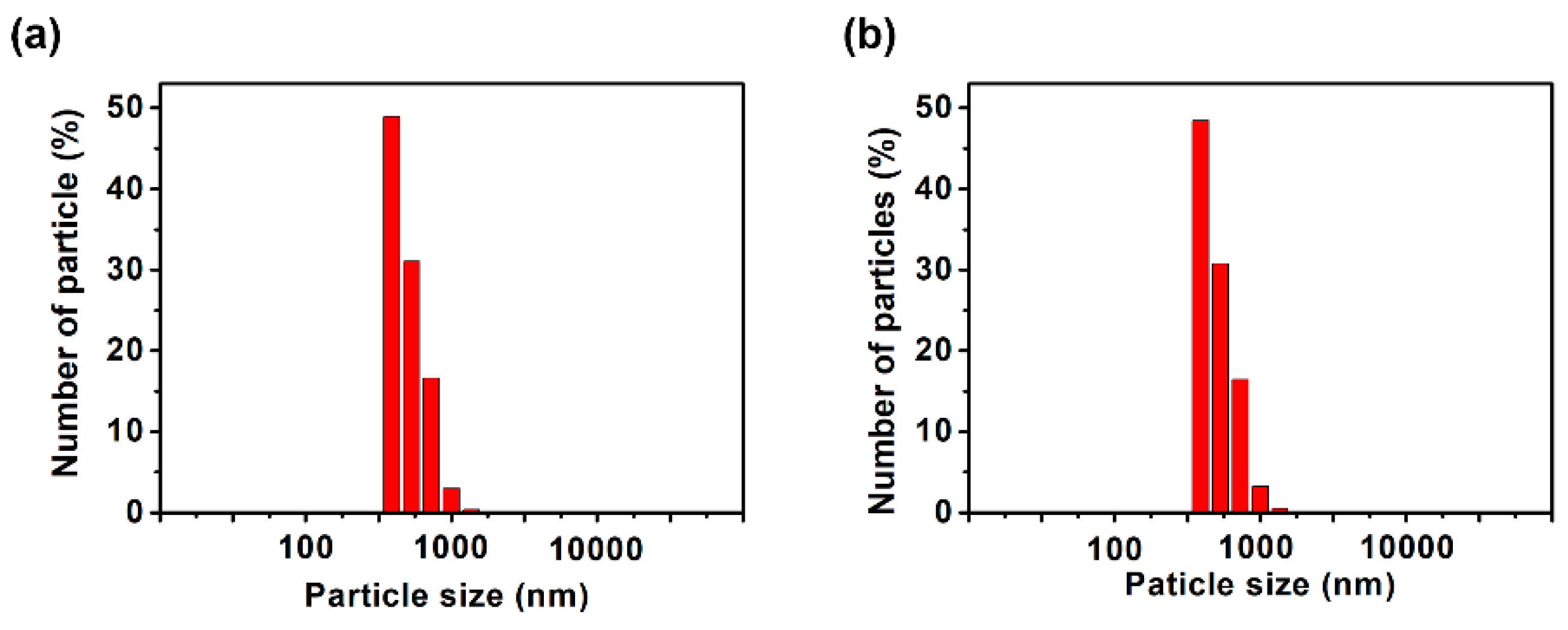

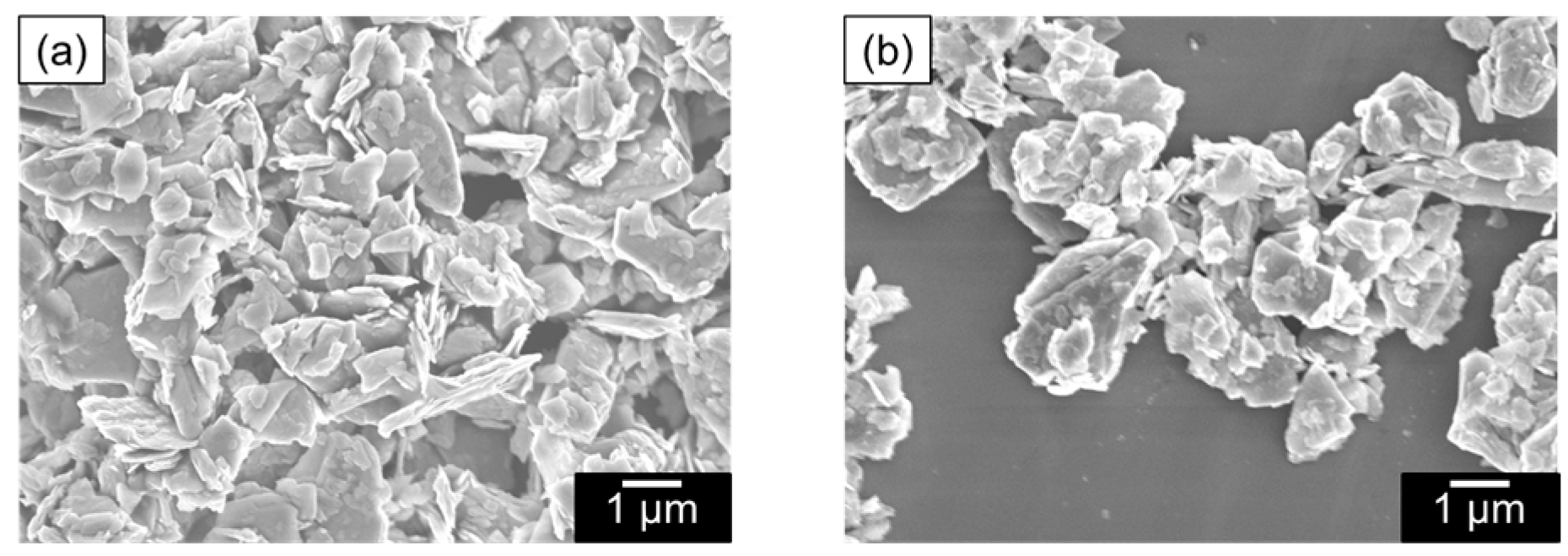

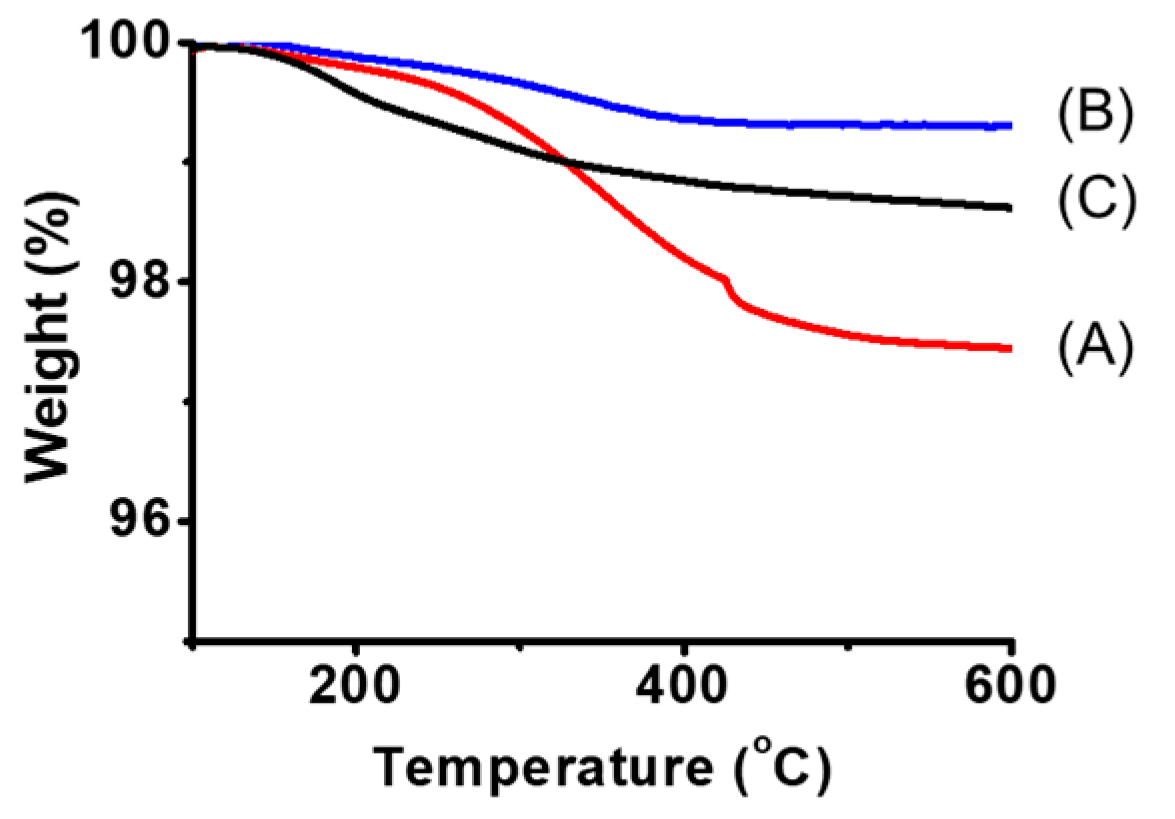

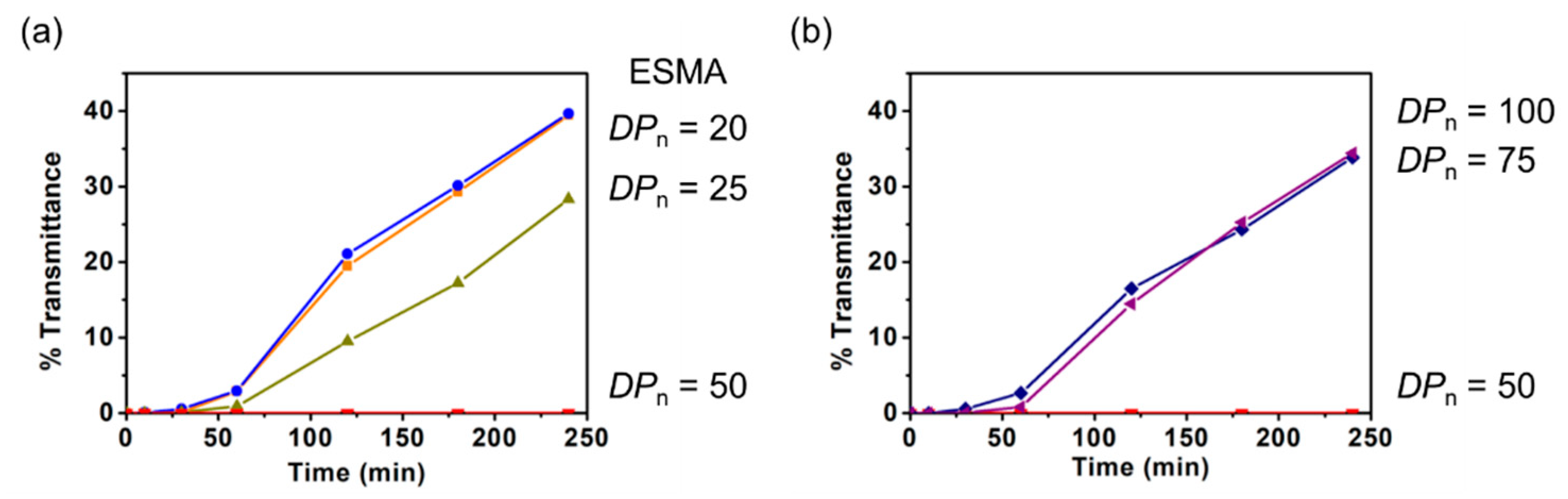

3.2. Preparation of MoS2 Dispersions with polyESMA in DMSO

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Eda, G.; Yamaguchi, H.; Voiry, D.; Fujita, T.; Chen, M.W.; Chhowalla, M. Photoluminescence from Chemically Exfoliated MoS2. Nano Lett. 2011, 11, 5111–5116. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.B.; Xu, P.T.; Zhou, D.K.; Sun, Y.F.; Li, Y.G.C.; Nguyen, M.A.T.; Terrones, M.; Mallouk, T.E. Fast and Efficient Preparation of Exfoliated 2H MoS2 Nanosheets by Sonication-Assisted Lithium Intercalation and Infrared Laser-Induced 1T to 2H Phase Reversion. Nano Lett. 2015, 15, 5956–5960. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Sutter, E.; Shi, N.N.; Zheng, J.B.; Yang, T.Z.; Englund, D.; Gao, H.J.; Sutter, P. Reliable Exfoliation of Large-Area High-Quality Flakes of Graphene and Other Two-Dimensional Materials. ACS Nano 2015, 9, 10612–10620. [Google Scholar] [CrossRef] [PubMed]

- Nicolosi, V.; Chhowalla, M.; Kanatzidis, M.G.; Strano, M.S.; Coleman, J.N. Liquid Exfoliation of Layered Materials. Science 2013, 340, 1226419. [Google Scholar] [CrossRef]

- Niu, L.Y.; Coleman, J.N.; Zhang, H.; Shin, H.; Chhowalla, M.; Zheng, Z.J. Production of Two-Dimensional Nanomaterials via Liquid-Based Direct Exfoliation. Small 2016, 12, 272–293. [Google Scholar] [CrossRef]

- Li, Y.F.; Liang, Y.L.; Robles Hernandez, F.C.R.; Deog Yoo, H.D.; An, Q.Y.; Yao, Y. Enhancing Sodium-Ion Battery Performance with Interlayer-Expanded MoS2-PEO Nanocomposites. Nano Energy 2015, 15, 453–461. [Google Scholar] [CrossRef]

- Sarkar, D.; Liu, W.; Xie, X.; Anselmo, A.C.; Mitragotri, S.; Banerjee, K. MoS2 Field-Effect Transistor for Next-Generation LabelFree Biosensors. ACS Nano 2014, 8, 3992–4003. [Google Scholar] [CrossRef]

- Wi, S.; Kim, H.; Chen, M.; Nam, H.; Guo, L.J.; Meyhofer, E.; Liang, X. Enhancement of Photovoltaic Response in Multilayer MoS2 Induced by Plasma Doping. ACS Nano 2014, 8, 5270–5281. [Google Scholar] [CrossRef]

- Wu, J.; Schmidt, H.; Amara, K.K.; Xu, X.; Eda, G.; Ozyilmaz, B. Large Thermoelectricity via Variable Range Hopping in Chemical Vapor Deposition Grown Single-Layer MoS2. Nano Lett. 2014, 14, 2730–2734. [Google Scholar] [CrossRef]

- Acerce, M.; Voiry, D.; Chhowalla, M. Metallic 1T Phase MoS2 Nanosheets as Supercapacitor Electrode Materials. Nat. Nanotechnol. 2015, 10, 313–318. [Google Scholar] [CrossRef]

- Li, H.; Wu, J.; Yin, Z.; Zhang, H. Preparation and Applications of Mechanically Exfoliated Single-Layer and Multilayer MoS2 and WSe2 Nanosheets. Acc. Chem. Res. 2014, 47, 1067–1075. [Google Scholar] [CrossRef] [PubMed]

- Cummins, D.R.; Martinez, U.; Sherehiy, A.; Kappera, R.; Martinez-Garcia, A.; Schulze, R.K.; Jasinski, J.; Zhang, J.; Gupta, R.K.; Lou, J.; et al. Efficient Hydrogen Evolution in Transition Metal Dichalcogenides via a Simple One-Step Hydrazine Reaction. Nat. Commun. 2016, 7, 11857. [Google Scholar] [CrossRef] [PubMed]

- Amani, M.; Lien, D.-H.; Kiriya, D.; Xiao, J.; Azcatl, A.; Noh, J.; Madhvapathy, S.R.; Addou, R.; Kc, S.; Dubey, M.; et al. Near-Unity Photoluminescence Quantum Yield in MoS2. Science 2015, 350, 1065–1068. [Google Scholar] [CrossRef]

- Molas, M.R.; Gołasa, K.; Bala, Ł.; Nogajewski, K.; Bartos, M.; Potemski, M.; Babiński, A. Tuning carrier concentration in a superacid treated MoS2 monolayer. Sci. Rep. 2019, 9, 1989. [Google Scholar] [CrossRef]

- Bhoyate, S.; Mhin, S.; Jeon, J.-E.; Park, K.R.; Kim, J.; Choi, W. Stable and High-Energy-Density Zn-Ion Rechargeable Batteries Based on a MoS2-Coated Zn Anode. ACS Appl. Mater. Interfaces 2020, 12, 27249–27257. [Google Scholar] [CrossRef]

- Liang, Y.; Feng, R.; Yang, S.; Ma, H.; Liang, J.; Chen, J. Rechargeable Mg Batteries with Graphene-like MoS2 Cathode and Ultrasmall Mg Nanoparticle Anode. Adv. Mater. 2011, 23, 640–643. [Google Scholar] [CrossRef]

- Samy, O.; Zeng, S.; Birowosuto, M.D.; El Moutaouakil, A. A Review on MoS2 Properties, Synthesis, Sensing Applications and Challenges. Crystals 2021, 11, 355. [Google Scholar] [CrossRef]

- Ismail, K.B.M.; Arun Kumar, M.; Mahalingam, S.; Kim, J.; Atchudan, R. Recent Advances in Molybdenum Disulfide and Its Nanocomposites for Energy Applications: Challenges and Development. Materials 2023, 16, 4471. [Google Scholar] [CrossRef] [PubMed]

- Saliba, M.; Atanas, J.P.; Howayek, T.M.; Habchi, R. Molybdenum disulfide, exfoliation methods and applications to photocatalysis: A review. Nanoscale Adv. 2023, 5, 6787–6803. [Google Scholar] [CrossRef]

- Zhang, Y.; Chang, T.-R.; Zhou, B.; Cui, Y.-T.; Yan, H.; Liu, Z.; Schmitt, F.; Lee, J.; Moore, R.; Chen, Y. Direct Observation of the Transition from Indirect to Direct Bandgap in Atomically Thin Epitaxial MoSe2. Nat. Nanotechnol. 2014, 9, 111–115. [Google Scholar] [CrossRef]

- Zhao, J.; Yu, H.; Chen, W.; Yang, R.; Zhu, J.; Liao, M.; Shi, D.; Zhang, G. Patterned Peeling 2D MoS2 off the Substrate. ACS Appl. Mater. Interfaces 2016, 8, 16546–16550. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Zhang, H.; Dong, S.H.; Liu, Y.P.; Nai, C.T.; Shin, H.S.; Jeong, H.Y.; Liu, B.; Loh, K.P. High Yield Exfoliation of Two Dimensional Chalcogenides Using Sodium Naphthalenide. Nat. Commun. 2014, 5, 2995. [Google Scholar] [CrossRef] [PubMed]

- Saha, D.; Angizi, S.; Darestani-Farahani, M.; Dalmieda, J.; Selvaganapathy, P.R.; Kruse, P. Tuning the Chemical and Mechanical Properties of Conductive MoS2 Thin Films by Surface Modification with Aryl Diazonium Salts. Langmuir 2022, 38, 3666–3675. [Google Scholar] [CrossRef] [PubMed]

- Chou, S.S.; De, M.; Kim, J.; Byun, S.; Dykstra, C.; Jin Yu, J.; Huang, J.; Dravid, V.P. Ligand Conjugation of Chemically Exfoliated MoS2. J. Am. Chem. Soc. 2013, 135, 4584–4587. [Google Scholar] [CrossRef]

- Liu, W.; Yang, X.; Zhang, Y.; Xu, M.; Chen, H. Ultra-stable two-dimensional MoS2 solution for highly efficient organic solar cells. RSC Adv. 2014, 4, 32744–32748. [Google Scholar] [CrossRef]

- Tian, R.; Jia, X.; Lan, M.; Wang, S.; Li, Y.; Yang, J.; Shao, D.; Feng, L.; Su, Q.; Song, H. Ionic Liquid Crystals Confining Ultrathin MoS2 Nanosheets: A High-Concentration and Stable Aqueous Dispersion. ACS Sustain. Chem. Eng. 2022, 10, 4186–4197. [Google Scholar] [CrossRef]

- Coleman, J.N.; Lotya, M.; O’Neill, A.; Bergin, S.D.; King, P.J.; Khan, U.; Young, K.; Gaucher, A.; De, S.; Smith, R.J.; et al. Two Dimensional Nanosheets Produced by Liquid Exfoliation of Layered Materials. Science 2011, 331, 568–571. [Google Scholar] [CrossRef]

- Dong, L.; Lin, S.; Yang, L.; Zhang, J.J.; Yang, C.; Yang, D.; Lu, H.B. Spontaneous Exfoliation and Tailoring of MoS2 in Mixed Solvents. Chem. Commun. 2014, 50, 15936–15939. [Google Scholar] [CrossRef]

- Jawaid, A.; Nepal, D.; Park, K.; Jespersen, M.; Qualley, A.; Mirau, P.; Drummy, L.F.; Vaia, R.A. Mechanism for Liquid Phase Exfoliation of MoS2. Chem. Mater. 2016, 28, 337–348. [Google Scholar] [CrossRef]

- Biswas, Y.; Dule, M.; Mandal, T.K. Poly(ionic liquid)-Promoted Solvent-Borne Efficient Exfoliation of MoS2/MoSe2 Nanosheets for Dual-Responsive Dispersion and Polymer Nanocomposites. J. Phys. Chem. C 2017, 121, 4747–4759. [Google Scholar] [CrossRef]

- Wang, X.; Wu, P. Aqueous Phase Exfoliation of Two-Dimensional Materials Assisted by Thermoresponsive Polymeric Ionic Liquid and Their Applications in Stimuli-Responsive Hydrogels and Highly Thermally Conductive Films. ACS Appl. Mater. Interfaces 2018, 10, 2504–2514. [Google Scholar] [CrossRef] [PubMed]

- Han, X.; Gao, J.; Chen, T.; Zhao, Y. Interfacial interaction and steric repulsion in polymer-assisted liquid exfoliation to produce high-quality graphene. Chem. Pap. 2020, 74, 757–765. [Google Scholar] [CrossRef]

- Feng, X.; Xing, W.; Yang, H.; Yuan, B.; Song, L.; Hu, Y.; Liew, K.M. High-Performance Poly(ethylene oxide)/Molybdenum Disulfide Nanocomposite Films: Reinforcement of Properties Based on the Gradient Interface Effect. ACS Appl. Mater. Interfaces 2015, 7, 13164–13173. [Google Scholar] [CrossRef]

- Kobayashi, K.; Masu, H.; Shuto, A.; Yamaguchi, K. Control of face-to-face π–π stacked packing arrangement of anthracene rings via chalcogen-chalcogen, Interaction: 9,10-bis(methylchalcogeno)anthracenes. Chem. Mater. 2005, 17, 6666–6673. [Google Scholar] [CrossRef]

- Silaghi-Dumitrescu, R.; Lupan, A. Weak sulfur-sulfur interactions between chemically-identical atoms. Cent. Eur. J. Chem. 2013, 11, 457–463. [Google Scholar] [CrossRef]

- Motoyanagi, J.; Matsumoto, T.; Shiotani, T.; Miki, S.; Minoda, M. Amphiphilic Star Polymers Bearing a Triphenylene Core for Novel Dispersants of Carbon Nanotubes in Polar Media. Chem. Lett. 2016, 42, 609–611. [Google Scholar] [CrossRef]

- Kameyama, T.; Takasu, A. A Vinyl Polymer Having Pendent Sulfones Prepared by Atom-Transfer Radical Polymerization of a Sulfide-Containing Methacrylate and Electrophoretic Transparent Coating on a Stainless-Steel Anode. Polym. Chem. 2015, 6, 4336–4342. [Google Scholar] [CrossRef]

- Lamkaouane, H.; Ftouhi, H.; Richard-Plouet, M.; Gautier, N.; Stephant, N.; Zazoui, M.; Addou, M.; Cattin, L.; Bernède, J.C.; Mir, Y.; et al. Efficient and Facile Synthetic Route of MoO3:MoS2 Hybrid Thin Layer via Oxidative Reaction of MoS2 Nanoflakes. Nanomaterials 2022, 12, 3171. [Google Scholar] [CrossRef]

- Jiang, Y.; Wang, J.; Wu, J.; Zhang, Y. Preparation of high-performance natural rubber/carbon black/molybdenum disulfide composite by using the premixture of epoxidized natural rubber and cysteine-modified molybdenum disulfide. Polym. Bull. 2021, 78, 1213–1230. [Google Scholar] [CrossRef]

- Kabir, M.H.; Dias, D.; Arole, K.; Bahrami, R.; Sue, H.-J.; Liang, H. Hydrophilized MoS2 as Lubricant Additive. Lubricants 2024, 12, 80. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, S.; He, Y.; Chen, C.; Zhang, C.; Xie, P.; Zhong, F.; Li, H.; Chen, J.; Li, Z. APTES Modification of Molybdenum Disulfide to Improve the Corrosion Resistance of Waterborne Epoxy Coating. Coatings 2021, 11, 178. [Google Scholar] [CrossRef]

| [ESMA]0/[EBIB]0 | Conversion a (%) | DPn b | Mn c (g mol−1) | Mw/Mn c | |

|---|---|---|---|---|---|

| polyESMA50 | 50 | 95 | 50 | 7800 | 1.20 |

| polyESMA20 | 25 | 84 | 20 | 6300 | 1.25 |

| polyESMA25 | 25 | 99 | 25 | 7100 | 1.30 |

| polyESMA75 | 85 | 88 | 75 | 13,800 | 1.16 |

| polyESMA100 | 110 | 93 | 100 | 18,400 | 1.22 |

| polyEEMA50 d | 50 | 88 | 50 | 8600 | 1.14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Motoyanagi, J.; Kawade, K.; Minoda, M. The Preparation of Stable MoS2 Dispersions by Using Well-Defined Polymers with Pendant Sulfide Moieties. Chemistry 2025, 7, 84. https://doi.org/10.3390/chemistry7030084

Motoyanagi J, Kawade K, Minoda M. The Preparation of Stable MoS2 Dispersions by Using Well-Defined Polymers with Pendant Sulfide Moieties. Chemistry. 2025; 7(3):84. https://doi.org/10.3390/chemistry7030084

Chicago/Turabian StyleMotoyanagi, Jin, Kohei Kawade, and Masahiko Minoda. 2025. "The Preparation of Stable MoS2 Dispersions by Using Well-Defined Polymers with Pendant Sulfide Moieties" Chemistry 7, no. 3: 84. https://doi.org/10.3390/chemistry7030084

APA StyleMotoyanagi, J., Kawade, K., & Minoda, M. (2025). The Preparation of Stable MoS2 Dispersions by Using Well-Defined Polymers with Pendant Sulfide Moieties. Chemistry, 7(3), 84. https://doi.org/10.3390/chemistry7030084