Liquid Phase Calorimetric Method as a Tool for Acid Strength Measurements and Application to a Variety of Sustainable Catalysts

Abstract

1. Introduction

1.1. Brief History of Calorimetry

1.2. Brief History of Adsorption

2. Brief Overview of Solid Acidity Strength

2.1. Base-TPD (Temperature Programmed Desorption)

2.2. Multinuclear Solid-State Nuclear Magnetic Resonance

2.3. FT-IR of Base Adsorption

2.4. Gas Phase Adsorption Microcalorimetry

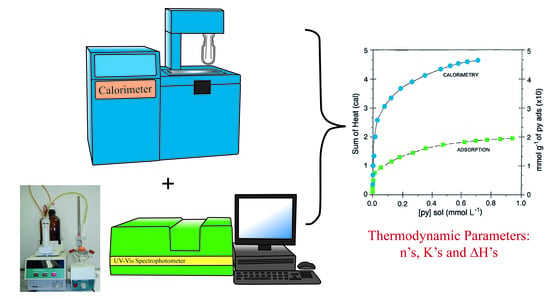

3. The Calorimetry-Adsorption (Cal-Ad) Method Proposed by Prof. Russel Drago

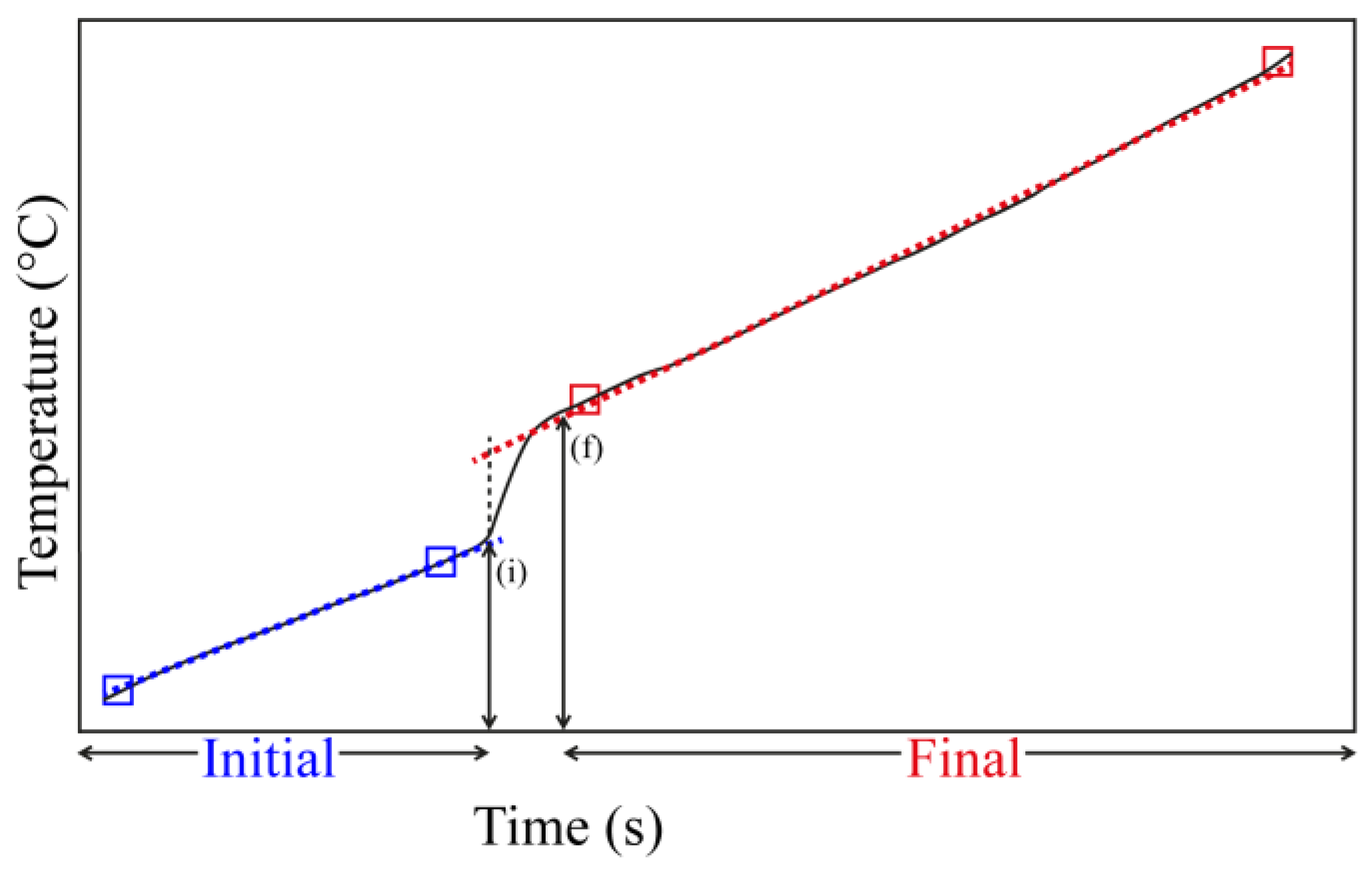

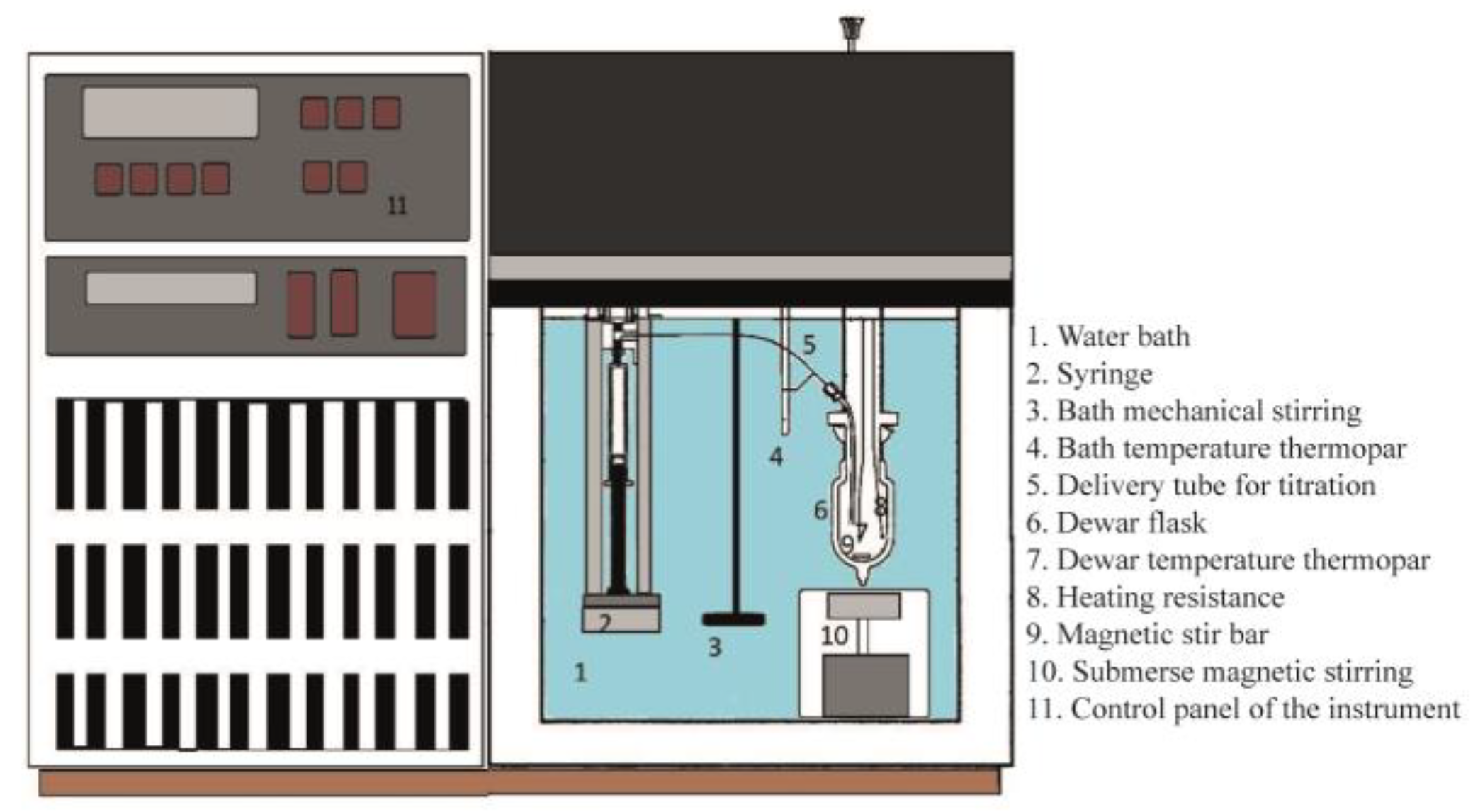

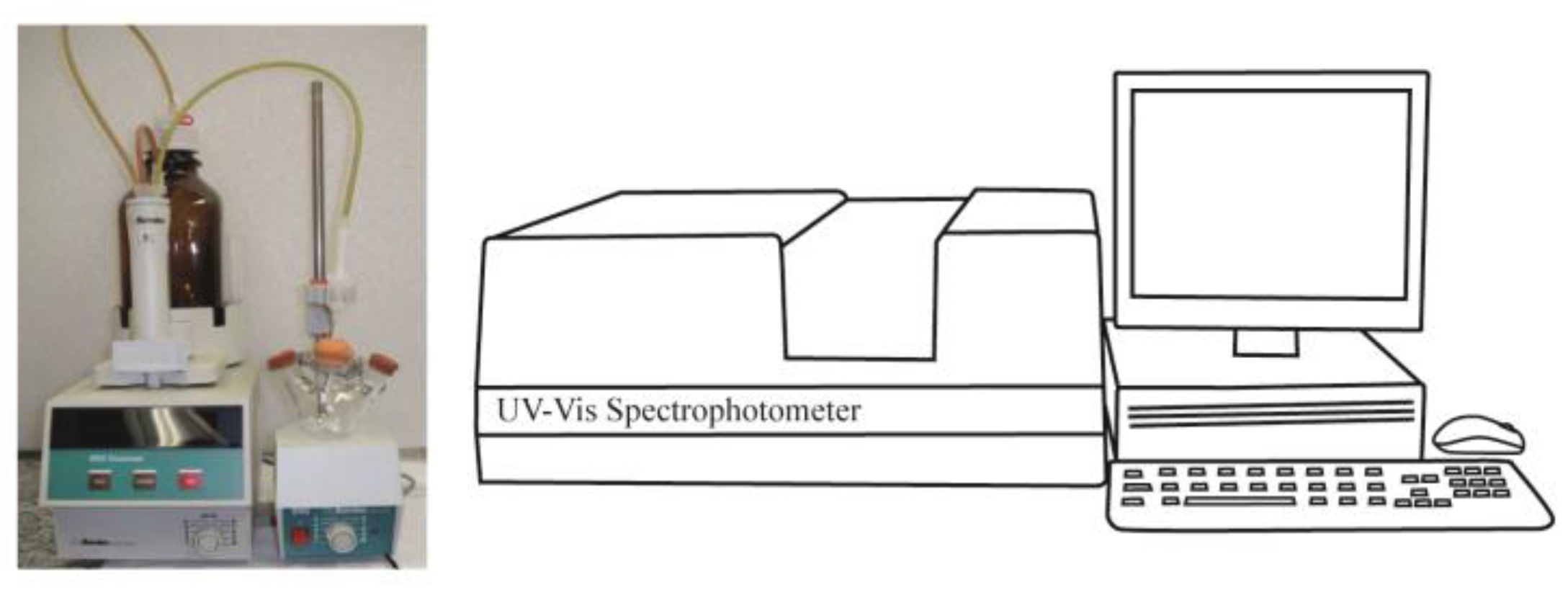

3.1. Fundamental Aspects

3.2. Experimental Procedure

3.3. Cal-Ad Analysis

3.4. Cal-Ad Calculations

4. Applications of Cal-Ad in the Characterization of Different Catalysts

4.1. Catalysts Characterized Earlier by Dragos’s Group

4.2. Zeolites

4.3. Heteropolyacids and Derivatives

4.4. Niobium-Based Catalysts

4.5. Ordered Mesoporous Silica (OMS)

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meschel, S.V. A brief history of heat measurements by calorimetry with emphasis on the thermochemistry. Calphad 2020, 68, 101714. [Google Scholar] [CrossRef]

- Swenson, H.; Stadie, N.P. Langmuir’s theory of adsorption: A centennial review. Langmuir 2019, 35, 5409–5426. [Google Scholar] [CrossRef] [PubMed]

- Foo, K.Y.; Hameed, B.H. Insights into the modeling of adsorption isotherm systems. Chem. Eng. J. 2010, 156, 2–10. [Google Scholar] [CrossRef]

- Housecroft, C.E.; Sharpe, A.G. Inorganic Chemistry, 2nd ed.; Pearson: London, UK, 2005; pp. 162–191. [Google Scholar]

- Shriver, D.F.; Atkins, P.W.; Overton, T.L.; Rourke, J.P.; Weller, M.T.; Armstrong, F.A. Química Inorgânica, 4th ed.; Editora Bookman: São Paulo, Brazil, 2008; pp. 133–162. [Google Scholar]

- Cotton, A.; Wilkinson, G.; Gaus, P. Basic Inorganic Chemistry, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1994; pp. 206–225. [Google Scholar]

- Huheey, J.E.; Keiter, E.A.; Keiter, R.L. Inorganic Chemistry, 4th ed.; Ed. Harper Collins: New York, NY, USA, 1993; pp. 318–358. [Google Scholar]

- Jolly, W.L. Modern Inorganic Chemistry; McGraw Hill International Editions: Singapore, 1986; pp. 171–211. [Google Scholar]

- Vogt, C.; Weckhuysen, B.M. The concept of active site in heterogeneous catalysis. Nat. Rev. Chem. 2022, 6, 89–111. [Google Scholar] [CrossRef] [PubMed]

- Busca, G.; Gervasini, A. Solid acids, surface acidity and heterogeneous acid catalysis. Chapter one. Adv. Catal. 2020, 67, 1–90. [Google Scholar] [CrossRef]

- Murzin, D.Y. Acid site density as a kinetic descriptor of catalytic reactions over zeolites. Chemistry 2022, 4, 1609–1623. [Google Scholar] [CrossRef]

- Paenurk, E.; Kaupmees, K.; Himmel, D.; Kütt, A.; Kaljurand, I.; Koppel, I.A.; Krossing, I.; Leito, I. A unified view to Brønsted acidity scales: Do we need solvated protons? Chem. Sci. 2017, 8, 6964–6973. [Google Scholar] [CrossRef]

- Dumeignil, F.; Paul, J.-F.; Paul, S. Heterogeneous catalysis with renewed attention: Principles, theories, and concepts. J. Chem. Educ. 2017, 94, 675–689. [Google Scholar] [CrossRef]

- Védrine, J.C. Acid–base characterization of heterogeneous catalysts: An up-to-date overview. Res. Chem. Intermed. 2015, 41, 9387–9423. [Google Scholar] [CrossRef]

- Moreno, E.L.; Rajagopal, K. Desafios da acidez na catálise em estado sólido. Quim. Nova 2009, 32, 538–542. [Google Scholar] [CrossRef]

- Busca, G. Acid catalysts in industrial hydrocarbon chemistry. Chem. Rev. 2007, 107, 5366–5410. [Google Scholar] [CrossRef] [PubMed]

- Zimmermann, Y.; Spange, S. Probing surface acidity, basicity, and dipolarity/polarizability of 12-tungstophosphoric acid by means of solvatochromic dyes. New J. Chem. 2002, 26, 1179–1184. [Google Scholar] [CrossRef]

- Kijenski, J.; Baiker, A. Acidic sites on catalyst surfaces and their determination. Catal. Today 1989, 5, 1–120. [Google Scholar] [CrossRef]

- Forni, L. Comparison of the methods for the determination of surface acidity of solid catalysts. Catal. Rev. Sci. Eng. 1974, 8, 65–115. [Google Scholar] [CrossRef]

- Mirodatos, C.; Barthomeuf, D. Acidic and cracking properties of offretite. J. Catal. 1979, 57, 136–146. [Google Scholar] [CrossRef]

- Parrilo, D.J.; Adamo, A.T.; Kokotailo, G.T.; Gorte, R.J. Amine adsorption in HZSM-5. Appl. Catal. 1990, 67, 107–118. [Google Scholar] [CrossRef]

- Tittensor, J.G.; Gorte, R.J.; Chapman, D.M. Isopropylamine adsorption for the characterization of acid sites in silica-alumina catalysts. J. Catal. 1992, 138, 714–720. [Google Scholar] [CrossRef]

- Lónyi, F.; Valyon, J. On the interpretation of the NH3-TPD patterns of H-ZSM-5 and H-mordenite. Microporous Mesoporous Mater. 2001, 47, 293–301. [Google Scholar] [CrossRef]

- Martins, G.V.A.; Berlier, G.; Bisio, C.; Coluccia, S.; Pastore, H.O.; Marchese, L. Quantification of Brønsted acid sites in microporous catalysts by a combined FTIR and NH3-TPD study. J. Phys. Chem. C 2008, 112, 7193–7200. [Google Scholar] [CrossRef]

- Luo, J.; Kamasamudram, K.; Currier, N.; Yezerets, A. NH3-TPD methodology for quantifying hydrothermal aging of Cu/SSZ-13 SCR catalysts. Chem. Eng. Sci. 2018, 190, 60–67. [Google Scholar] [CrossRef]

- Shafei, E.N.; Masudi, A.; Yamani, Z.H.; Muraza, O. Acidity modifications of nanozeolite-Y for enhanced selectivity to olefins from the steam catalytic cracking of dodecane. RSC Adv. 2022, 12, 18274. [Google Scholar] [CrossRef] [PubMed]

- Nunes, R.F.; Costa, D.; Ferraria, A.M.; Botelho do Rego, A.M.; Ribeiro, F.; Martins, Â.; Fernandes, A. Heterogenization of heteropolyacid with metal-based alumina supports for the guaiacol gas-phase hydrodeoxygenation. Molecules 2023, 28, 2245. [Google Scholar] [CrossRef] [PubMed]

- Schmal, M. Catálise Heterogênea; Editora Synergia: Rio de Janeiro, Brazil, 2011; pp. 208–250. [Google Scholar]

- Mackenzie, K.J.D.; Smith, M.E. Multinuclear Solid-State NMR of Inorganic Materials; Pergamon Materials Series: Oxford, UK, 2002; pp. 3–57. [Google Scholar]

- Drago, R.S. Physical Methods for Chemists, 2nd ed.; Saunders College Publishing: New York, NY, USA, 1992; pp. 211–352. [Google Scholar]

- Hennel, J.W.; Klinowski, J. Magic-Angle Spinning: A Historical Perspective. New Techniques in Solid-State NMR. In Topics in Current Chemistry; Klinowski, J., Ed.; Springer: Berlin/Heidelberg, Germany, 2005; Volume 246, pp. 1–14. [Google Scholar] [CrossRef]

- Polenova, T.; Gupta, R.; Goldbourt, A. Magic Angle Spinning NMR Spectroscopy: A Versatile Technique for Structural and Dynamic Analysis of Solid-Phase Systems. Anal. Chem. 2015, 87, 5458–5469. [Google Scholar] [CrossRef] [PubMed]

- Corma, A. Inorganic Solid Acids and Their Use in Acid-Catalyzed Hydrocarbon Reactions. Chem. Rev. 1995, 95, 559–614. [Google Scholar] [CrossRef]

- Zheng, A.; Huang, S.-J.; Wang, Q.; Zhang, H.; Deng, F.; Liu, S.-B. Progress in development and application of solid-state NMR for solid acid catalysis. Chin. J. Catal. 2013, 34, 436–491. [Google Scholar] [CrossRef]

- Zheng, A.; Li, S.; Liu, S.-B.; Deng, F. Acidic properties and structure−activity correlations of solid acid catalysts revealed by solid-state NMR spectroscopy. Acc. Chem. Res. 2016, 49, 655–663. [Google Scholar] [CrossRef]

- Hunger, M. Multinuclear solid-state NMR studies of acidic and non-acidic hydroxyl protons in zeolites. Solid State Nucl. Magn. Reason. 1996, 6, 1–29. [Google Scholar] [CrossRef]

- Jiang, Y.; Huang, J.; Dai, W.; Hunger, M. Solid-state nuclear magnetic resonance investigations of the nature, property, and activity of acid sites on solid catalysts. Solid State Nucl. Magn. Reason. 2011, 39, 116–141. [Google Scholar] [CrossRef]

- Li, J.; Gao, M.; Yan, W.; Yu, J. Regulation of the Si/Al ratios and Al distributions of zeolites and their impact on properties. Chem. Sci. 2023, 14, 1935–1959. [Google Scholar] [CrossRef]

- Reif, B.; Ashbrook, S.E.; Emsley, L.; Hong, M. Solid-state NMR spectroscopy. Nat. Rev. Methods Prim. 2021, 1, 2. [Google Scholar] [CrossRef]

- Brouwer, D.H.; Brouwer, C.C.; Mesa, S.; Semelhago, C.A.; Steckley, E.E.; Sun, M.P.Y.; Mikolajewski, J.G.; Baerlocher, C. Solid-state 29Si NMR spectra of pure silica zeolites for the International Zeolite Association Database of Zeolite Structures. Microporous Mesoporous Mater. 2020, 297, 110000. [Google Scholar] [CrossRef]

- Li, S.H.; Lafon, O.; Wang, W.Y.; Wang, Q.; Wang, X.X.; Li, Y.; Xu, J.; Deng, F. Recent advances of solid-state NMR spectroscopy for microporous materials. Adv. Mater. 2020, 32, 2002879. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; He, Y.; Jiao, W.; Wang, J.; Fan, W. Recent experimental and theoretical studies on Al siting/acid site distribution in zeolite framework. Curr. Opin. Chem. Eng. 2019, 23, 146–154. [Google Scholar] [CrossRef]

- Osegovic, J.P.; Drago, R.S. A solid acidity scale based on the 31P MAS-NMR shift of chemisorbed triethylphosphine Oxide. J. Catal. 1999, 182, 1–4. [Google Scholar] [CrossRef]

- Alonso, B.; Klurb, I.; Massiota, D. Studies of surfaces through molecular probe adsorption and solid-state NMR. Chem. Commun. 2002, 804–805. [Google Scholar] [CrossRef]

- Zheng, A.; Zhang, H.; Lu, X.; Liu, S.-B.; Deng, F. Theoretical predictions of 31P NMR chemical shift threshold of trimethylphosphine oxide absorbed on solid acid catalysts. J. Phys. Chem. B 2008, 112, 4496–4505. [Google Scholar] [CrossRef]

- Yi, X.; Ko, H.-H.; Deng, F.; Liu, S.-B.; Zheng, A. Solid-state 31P NMR mapping of active centers and relevant spatial correlations in solid acid catalysts. Nat. Protoc. 2020, 15, 3527–3555. [Google Scholar] [CrossRef]

- Zasukhin, D.S.; Kasyanov, I.A.; Kolyagin, Y.G.; Bulygina, A.I.; Kharas, K.C.; Ivanova, I.I. Evaluation of zeolite acidity by 31P MAS NMR spectroscopy of adsorbed phosphine oxides: Quantitative or not? ACS Omega 2022, 7, 12318–12328. [Google Scholar] [CrossRef]

- Okuhara, T.; Nishimura, T.; Watanabe, H.; Misono, M. Insoluble heteropoly compounds as highly active catalysts for liquid-phase reactions. J. Mol. Catal. 1992, 74, 247–256. [Google Scholar] [CrossRef]

- Wu, Y.; Ye, X.; Yang, X.; Wang, X.; Chu, W.; Hu, Y. Heterogenization of heteropolyacids: A general discussion on the preparation of supported acid catalysts. Ind. Eng. Chem. Res. 1996, 35, 2546–2560. [Google Scholar] [CrossRef]

- Uchida, S.; Inumaru, K.; Misono, M. States and dynamic behavior of protons and water molecules in H3PW12O40 pseudoliquid phase analyzed by solid-state MAS NMR. J. Phys. Chem. B 2000, 104, 8108–8115. [Google Scholar] [CrossRef]

- De Mattos, F.C.G.; De Carvalho, E.N.C.B.; De Freitas, E.F.; Paiva, M.F.; Ghesti, G.F.; De Macedo, J.L.; Dias, S.C.L.; Dias, J.A. Acidity and characterization of 12-tungstophosphoric acid supported on silica-alumina. J. Braz. Chem. Soc. 2017, 28, 336–347. [Google Scholar] [CrossRef]

- Rafiee, E.; Eavani, S. Heterogenization of heteropoly compounds: A review of their structure and synthesis. RSC Adv. 2016, 6, 46433–46466. [Google Scholar] [CrossRef]

- Chorkendorff, I.; Niemantsverdriet, J.W. Concepts of Modern Catalysis and Kinetics; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, The Netherlands, 2003; pp. 155–157. [Google Scholar]

- Available online: https://resources.perkinelmer.com/corporate/cmsresources/images/46-74388bro_60yearsinfraredspectroscopy.pdf (accessed on 20 March 2023).

- Vimont, A.; Travert, A.; Binet, C.; Pichon, C.; Mialane, P.; Sécheresse, F.; Lavalley, J.-C. Relationship between infrared spectra and stoichiometry of pyridine-H3PW12O40 salts using a new TGA-infrared coupling. J. Catal. 2006, 241, 221–224. [Google Scholar] [CrossRef]

- Katada, N. Analysis and interpretation of acidic nature of aluminosilicates. Mol. Catal. 2018, 458, 116–126. [Google Scholar] [CrossRef]

- Perry, E.P. An infrared study of pyridine adsorbed on acidic solids. Characterization of surface acidity. J. Catal. 1963, 2, 371–379. [Google Scholar] [CrossRef]

- Basila, M.R.; Kantner, T.R.; Rhee, K.H. The nature of the acidic sites on a silica-alumina. Characterization by infrared spectroscopic studies of trimethylamine and pyridine chemisorption. J. Phys. Chem. 1964, 68, 3197–3207. [Google Scholar] [CrossRef]

- Hughes, T.R.; White, H.M. A Study of the surface structure of decationized Y zeolite by quantitative infrared spectroscopy. J. Phys. Chem. 1967, 71, 2192–2201. [Google Scholar] [CrossRef]

- Emeis, C.A. Determination of integrated molar extinction coefficients for infrared absorption bands of pyridine adsorbed on solid acid catalysts. J. Catal. 1993, 141, 347–354. [Google Scholar] [CrossRef]

- Sadowska, K.; Góra-Marek, K.; Datka, J. Accessibility of acid sites in hierarchical zeolites: Quantitative IR studies of pivalonitrile adsorption. J. Phys. Chem. C 2013, 117, 9237–9244. [Google Scholar] [CrossRef]

- Mlekodaj, K.; Tarach, K.; Datka, J.; Góra-Marek, K.; Makowski, W. Porosity and accessibility of acid sites in desilicated ZSM-5 zeolites studied using adsorption of probe molecules. Microporous Mesoporous Mater. 2014, 183, 54–61. [Google Scholar] [CrossRef]

- Hadjiivanov, K. Identification and characterization of surface hydroxyl groups by infrared spectroscopy. Chapter two. Adv. Catal. 2014, 57, 99–318. [Google Scholar] [CrossRef]

- Adamson, A.W.; Gast, A.P. Physical Chemistry of Surfaces, 6th ed.; John Wiley & Sons, Inc.: New York, NY, USA, 2012; pp. 390–422. [Google Scholar]

- Cardona-Martinez, N.; Dumesic, J. Applications of adsorption microcalorimetry to the study of heterogeneous catalysis. Adv. Catal. 1992, 38, 149–244. [Google Scholar] [CrossRef]

- Solinas, V.; Ferino, I. Microcalorimetric characterisation of acid-basic catalysts. Catal. Today 1998, 41, 179–189. [Google Scholar] [CrossRef]

- Auroux, A. Acidity characterization by microcalorimetry and relationship with reactivity. Top. Catal. 1997, 4, 71–89. [Google Scholar] [CrossRef]

- Pierre Le Parlouër, P.L. Thermal Analysis and Calorimetry Techniques for Catalytic Investigations. In Calorimetry and Thermal Methods in Catalysis; Auroux, A., Ed.; Springer Series in Material Science; Springer: Berlin/Heidelberg, Germany, 2013; Volume 154, pp. 70–81. [Google Scholar] [CrossRef]

- Védrine, J.C.; Auroux, A.; Dejaifve, P.; Ducarme, V.; Hoser, H.; Zhou, S. Catalytic and physical properties of phosphorus-modified ZSM-5 zeolite. J. Catal. 1982, 73, 147–160. [Google Scholar] [CrossRef]

- Cardona-Martínez, N.; Dumesic, J.A. Acid strength of silica-alumina and silica studied by microcalorimetric measurements of pyridine adsorption. J. Catal. 1990, 125, 427–444. [Google Scholar] [CrossRef]

- Cardona-Martínez, N.; Dumesic, J.A. Microcalorimetric measurements of basic molecule adsorption on silica and silica-alumina. J. Catal. 1991, 128, 23–33. [Google Scholar] [CrossRef]

- Carniti, P.; Gervasini, A.; Biella, S.; Auroux, A. Intrinsic and effective acidity study of niobic acid and niobium phosphate by a multitechnique approach. Chem. Mater. 2005, 17, 6128–6136. [Google Scholar] [CrossRef]

- Kozhevnikova, E.F.; Kozhevnikov, I.V. A calorimetric study of the acidity of bulk and silica-supported heteropoly acid H3PW12O40. J. Catal. 2004, 224, 164–169. [Google Scholar] [CrossRef]

- Auroux, A.; Gervasini, A. Combined use of titration calorimetry and spectrofluorimetry for the screening of the acidity of solid catalysts in different liquids. Thermochim. Acta 2013, 567, 8–14. [Google Scholar] [CrossRef]

- Stošić, D.; Bennici, S.; Sirotin, S.; Stelmachowski, P.; Couturier, J.-L.; Dubois, J.-L.; Travert, A.; Auroux, A. Examination of acid–base properties of solid catalysts for gas phase dehydration of glycerol: FTIR and adsorption microcalorimetry studies. Catal. Today 2014, 226, 167–175. [Google Scholar] [CrossRef]

- Sánchez-Zambrano, K.S.; Vilarrasa-García, E.; Maia, D.A.S.; Bastos-Neto, M.; Rodríguez-Castellon, E.; Azevedo, D.C.S. Adsorption microcalorimetry as a tool in the characterization of amine-grafted mesoporous silicas for CO2 capture. Adsorption 2020, 26, 165–175. [Google Scholar] [CrossRef]

- Lund, C.R.F.; Tatarchuk, B.; Cardona-Martinez, N.; Hill, J.M.; Sanchez-Castillo, M.A.; Huber, G.W.; Roman-Leshkov, Y.; Simonetti, D.; Pagan-Torres, Y.; Schwartz, T.J. A Career in Catalysis: James A. Dumesic. ACS Catal. 2021, 11, 2310–2339. [Google Scholar] [CrossRef]

- Drago, R.S. Applications of Electrostatic-Covalent Models in Chemistry; Surfiside Scientific Publishers: Gainesville, FL, USA, 1994; pp. 1–308. [Google Scholar]

- Pauling, L. The nature of the chemical bond. Application of results obtained from the quantum mechanics and from a theory of paramagnetic susceptibility to the structure of molecules. J. Am. Chem. Soc. 1931, 53, 1367–1400. [Google Scholar] [CrossRef]

- Mulliken, R.S. Molecular compounds and their spectra II. J. Am. Chem. Soc. 1952, 74, 811–824. [Google Scholar] [CrossRef]

- Fowkes, F.M.; McCarthy, D.C.; Tischler, D.O. Polymer Science and Technology; Plenum Press: New York, NY, USA, 1983; Volume 27, pp. 1–27. [Google Scholar]

- Nozari, M.S.; Drago, R.S. Elimination of solvation contributions to the enthalpies of adduct formation in weakly polar solvents. II. Adducts of bis(hexafluoroacetylacetonato)copper(II). Inorg. Chem. 1972, 11, 280–283. [Google Scholar] [CrossRef]

- Nozari, M.S.; Drago, R.S. Evaluation of models and effects contributing to solvent-transfer energies. J. Am. Chem. Soc. 1972, 94, 6877–6883. [Google Scholar] [CrossRef]

- Drago, R.S.; Cundari, T.R.; Ferris, D.C. Structural and energetic analysis of gas-phase hydrated ammonium ions with relevance to the “anomalous” order in amine basicities. J. Org. Chem. 1989, 54, 1042–1047. [Google Scholar] [CrossRef]

- Drago, R.S.; Ferris, D.C.; Wong, N. A method for the analysis and prediction of gas-phase ion-molecule enthalpies. J. Am. Chem. Soc. 1990, 112, 8953–8961. [Google Scholar] [CrossRef]

- Webster, C.E.; Osegovic, J.P.; Scott, B.J.; Dias, S.C. A thermodynamic analysis of the Cal–Ad method with respect to gas–solid calorimetry. Microporous Mesoporous Mater. 1999, 31, 205–209. [Google Scholar] [CrossRef]

- Lim, Y.Y.; Drago, R.S.; Babich, M.W.; Wong, N.; Doan, P.E. Thermodynamic Studies of Donor Binding to Heterogeneous. J. Am. Chem. Soc. 1987, 109, 169–174. [Google Scholar] [CrossRef]

- Freitas, E.F. Reação de Esterificação e de Biginelli via Catálise por Polioxometalatos Impregnados em Zeólita Y. Ph.D. Dissertation, Universidade de Brasília, Brasília, Brazil, 2017. [Google Scholar]

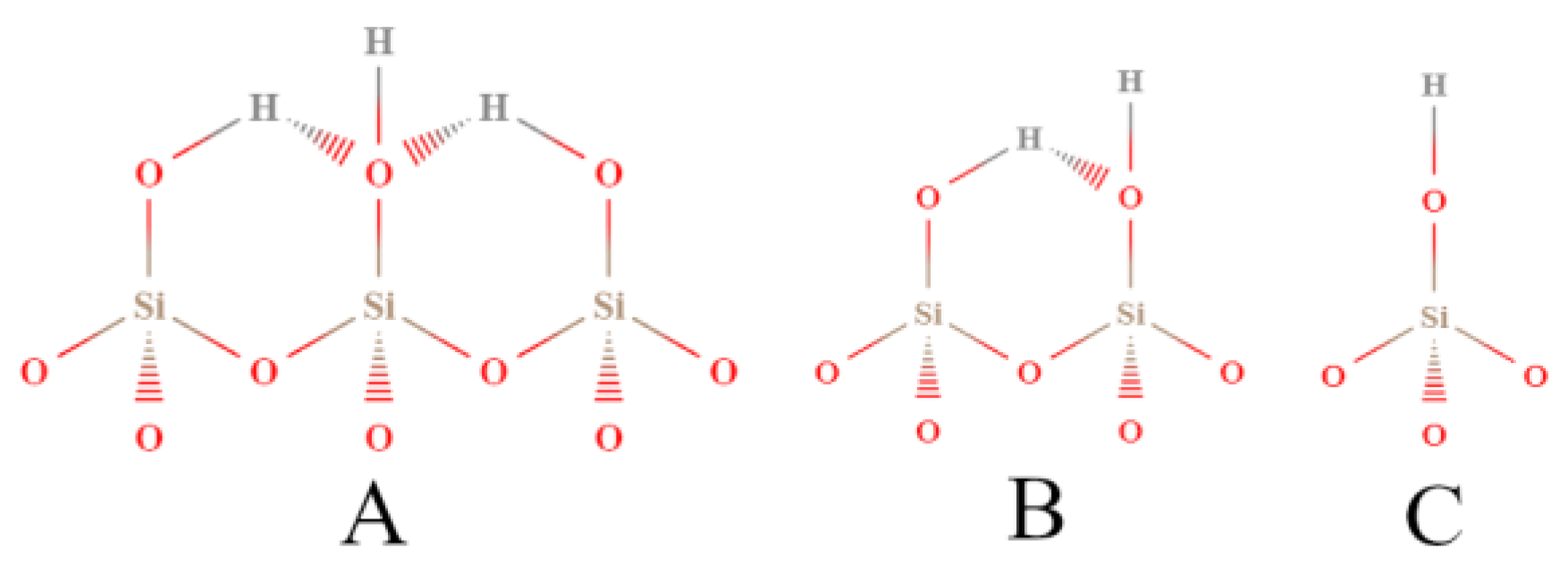

- Chronister, C.W.; Drago, R.S. Determination of Hydrogen-Bonding Acid Sites on Silica Using the Cal-Ad Method. J. Am. Chem. Soc. 1993, 115, 4793–4798. [Google Scholar] [CrossRef]

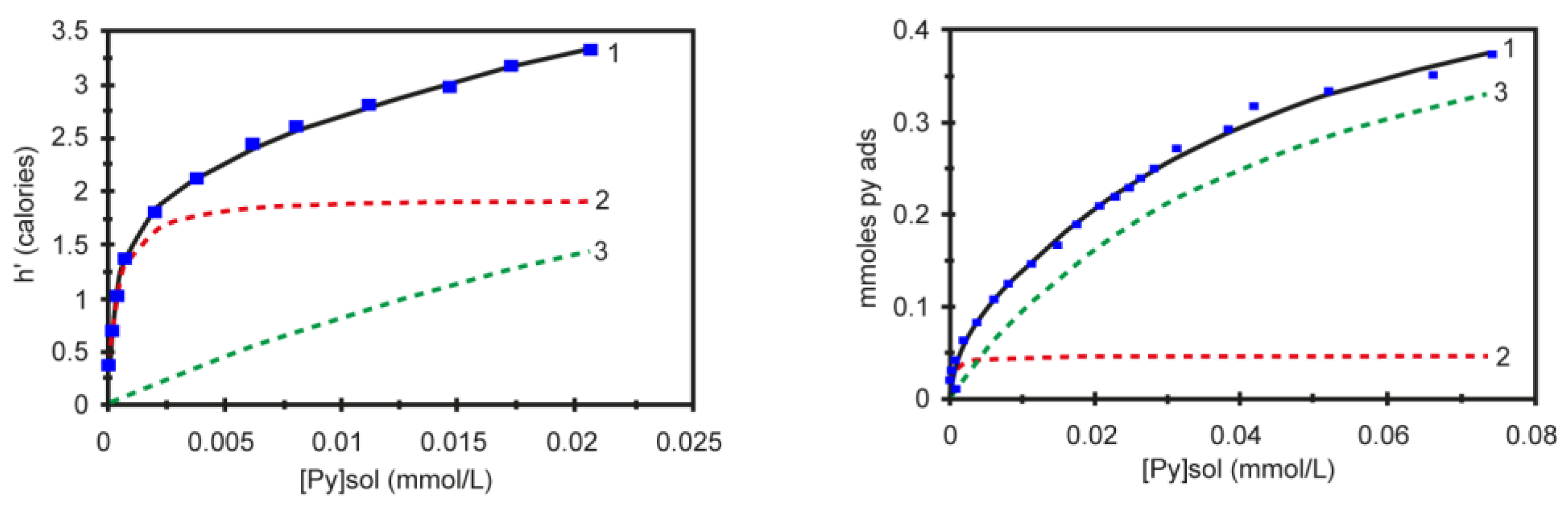

- Drago, R.S.; Dias, S.C.; Torrealba, M.; Lima, L. Calorimetric and Spectroscopic Investigation of the Acidity of HZSM-5. J. Am. Chem. Soc. 1997, 119, 4444–4452. [Google Scholar] [CrossRef]

- Anton, H.; Rorres, C. Elementary Linear Algebra: Applications Version, 11th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 2–96. [Google Scholar]

- Drago, R.S.; Kob, N. Acidity and Reactivity of Sulfated Zirconia and Metal-Doped Sulfated Zirconia. J. Phys. Chem. B 1997, 101, 3360–3364. [Google Scholar] [CrossRef]

- Kob, N.; Drago, R.S.; Young, V. Preparation, Characterization, and Acidity of a Silica Gel/Tungsten Oxide Solid Acid. Inorg. Chem. 1997, 36, 5127–5131. [Google Scholar] [CrossRef]

- Xu, T.; Kob, N.; Drago, R.S.; Nicholas, J.B.; Haw, J.F. A Solid Acid Catalyst at the Threshold of Superacid Strength: NMR, Calorimetry, and Density Functional Theory Studies of Silica-Supported Aluminum Chloride. J. Am. Chem. Soc. 1997, 119, 12231–12239. [Google Scholar] [CrossRef]

- Drago, R.S.; Dias, J.A.; Maier, T.O. An acidity scale for Brønsted acids including H3PW12O40. J. Am. Chem. Soc. 1997, 119, 7702–7710. [Google Scholar] [CrossRef]

- Hench, L.L.; West, J.K. The sol-gel process. Chem. Rev. 1990, 90, 33–72. [Google Scholar] [CrossRef]

- Jones, J.R. Review of bioactive glass: From Hench to hybrids. Acta Biomater. 2013, 9, 4457–4486. [Google Scholar] [CrossRef]

- Gomes, L.S.; Furtado, A.C.R.; Souza, M.C. A Sílica e suas Particularidades. Rev. Virtual Quim. 2018, 10, 1018–1038. [Google Scholar] [CrossRef]

- Gravelle, P.C. Calorimetry in adsorption and heterogeneous catalysis studies. Catal. Rev. 1977, 16, 37–110. [Google Scholar] [CrossRef]

- Arnett, E.M.; Cassidy, K.F. A thermochemical comparison of silica with other homogeneous and heterogeneous acids. Rev. Chem. Intermed. 1988, 9, 27–64. [Google Scholar] [CrossRef]

- Feher, F.J.; Newman, D.A. Enhanced silylation reactivity of a model for silica surfaces. J. Am. Chem. Soc. 1990, 112, 1931–1936. [Google Scholar] [CrossRef]

- Hino, H.; Arata, K. Synthesis of solid superacid catalyst with acid strength of H0 ≤ –16.04. J. Chem. Soc. Chem. Commun. 1980, 851–852. [Google Scholar] [CrossRef]

- Rao, V.; Chary, K.; Durgakumari, V.; Narayanan, S. Catalytic alkylation of phenol with methanol: Factors influencing activities and selectivities: I. Effect of different acid sites evaluated by studying the behaviour of the catalysts: γ-alumina, nafion-H, silica-alumina and phosphoric acid. Appl. Catal. 1990, 64, 83–99. [Google Scholar] [CrossRef]

- Bezouhanova, C.; Al-Zihari, M. Alkylation of phenol over simple oxides and supported vanadium oxides. Appl. Catal. 1990, 61, 89–97. [Google Scholar] [CrossRef]

- Drago, R.S.; Getty, E.E. Preparation and Catalytic Activity of a New Solid Acid Catalyst. J. Am. Chem. Soc. 1988, 110, 3311–3312. [Google Scholar] [CrossRef]

- Notari, B. Microporous crystalline titanium silicates. Adv. Catal. 1996, 41, 253–334. [Google Scholar] [CrossRef]

- Drago, R.S.; Dias, S.C.; McGilvray, J.M.; Mateus, A.L.M.L. Acidity and hydrophobicity of TS-1. J. Phys. Chem. B 1998, 102, 1508–1514. [Google Scholar] [CrossRef]

- Loureiro Dias, S.C.; de Macedo, J.L.; Dias, J.A. Acidity measurements of zeolite Y by adsorption of several probes. Phys. Chem. Chem. Phys. 2003, 5, 5574–5579. [Google Scholar] [CrossRef]

- Puente, G.; Aguiar, E.F.S.; Zontin, F.M.Z.; Camorim, V.L.D.; Sedran, U. Influence of different rare earth ions on hydrogen transfer over Y zeolite. Appl. Catal. A 2000, 197, 41–46. [Google Scholar] [CrossRef]

- Xue, M.; Chitrakar, R.; Sakane, K.; Hirotsu, T.; Ooi, K.; Yoshimura, Y.; Toba, M.; Feng, Q. Preparation of cerium-loaded Y-zeolites for removal of organic sulfur compounds from hydrodesulfurizated gasoline and diesel oil. J. Colloid Interface Sci. 2006, 298, 535–542. [Google Scholar] [CrossRef] [PubMed]

- Garcia, F.A.C.; Araújo, D.R.; Silva, J.C.M.; de Macedo, J.L.; Ghesti, G.F.; Dias, S.C.L.; Dias, J.A.; Filho, G.N.R. Effect of cerium loading on structure and morphology of modified Ce-USY zeolites. J. Braz. Chem. Soc. 2011, 22, 1894–1902. [Google Scholar] [CrossRef]

- Ghesti, G.F.; de Macedo, J.L.; Parente, V.C.I.; Dias, J.A.; Dias, S.C.L. Investigation of pyridine sorption in USY and Ce/USY zeolites by liquid phase microcalorimetry and thermogravimetry studies. Microporous Mesoporous Mater. 2007, 100, 27–34. [Google Scholar] [CrossRef]

- Webster, C.E.; Cottone, A.; Drago, R.S. Multiple equilibrium analysis description of adsorption on Na−Mordenite and H−Mordenite. J. Am. Chem. Soc. 1999, 121, 12127–12139. [Google Scholar] [CrossRef]

- de Macedo, J.L.; Dias, S.C.L.; Dias, J.A. Multiple adsorption process description of zeolite mordenite acidity. Microporous Mesoporous Mater. 2004, 72, 119–125. [Google Scholar] [CrossRef]

- Lu, T.; Yan, W.; Xu, R. Chiral zeolite beta: Structure, synthesis, and application. Inorg. Chem. Front. 2019, 6, 1938–1951. [Google Scholar] [CrossRef]

- de Macedo, J.L.; Ghesti, G.F.; Dias, J.A.; Dias, S.C.L. Liquid phase calorimetry and adsorption analyses of zeolite beta acidity. Phys. Chem. Chem. Phys. 2008, 10, 1584–1592. [Google Scholar] [CrossRef]

- Kikhtyanin, O.; Bulánek, R.; Frolich, K.; Cejka, J.; Kubicka, D. Aldol condensation of furfural with acetone over ion-exchanged and impregnated potassium BEA zeolites. J. Mol. Catal. A 2016, 424, 358–368. [Google Scholar] [CrossRef]

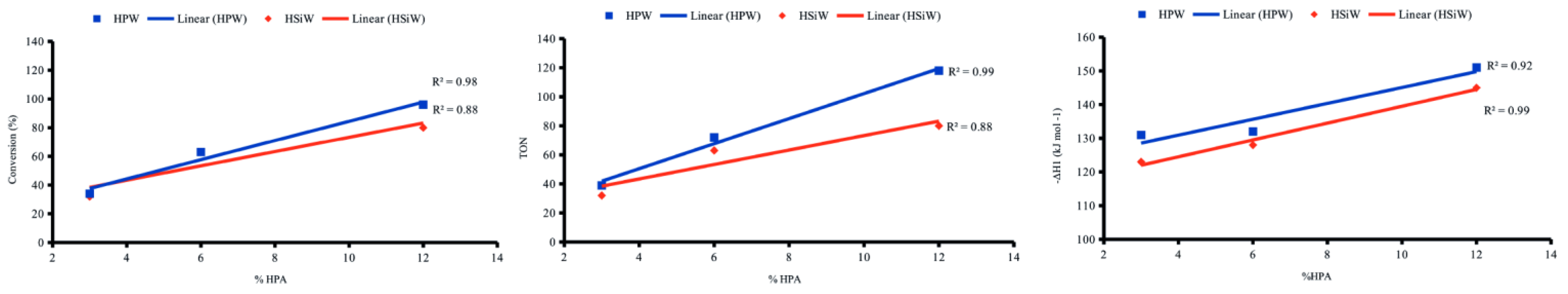

- Freitas, E.F.; Araújo, A.A.L.; Paiva, M.F.; Dias, S.C.L.; Dias, J.A. Comparative acidity of BEA and Y zeolite composites with 12-tungstophosphoric and 12-tungstosilicic acids. Mol. Catal. 2018, 458, 152–160. [Google Scholar] [CrossRef]

- Valadares, D.S.; Clemente, M.C.H.; de Freitas, E.F.; Martins, G.A.V.; Dias, J.A.; Dias, S.C.L. Niobium on BEA dealuminated zeolite for high selectivity dehydration reactions of ethanol and xylose into diethyl ether and furfural. Nanomaterials 2020, 10, 1269. [Google Scholar] [CrossRef] [PubMed]

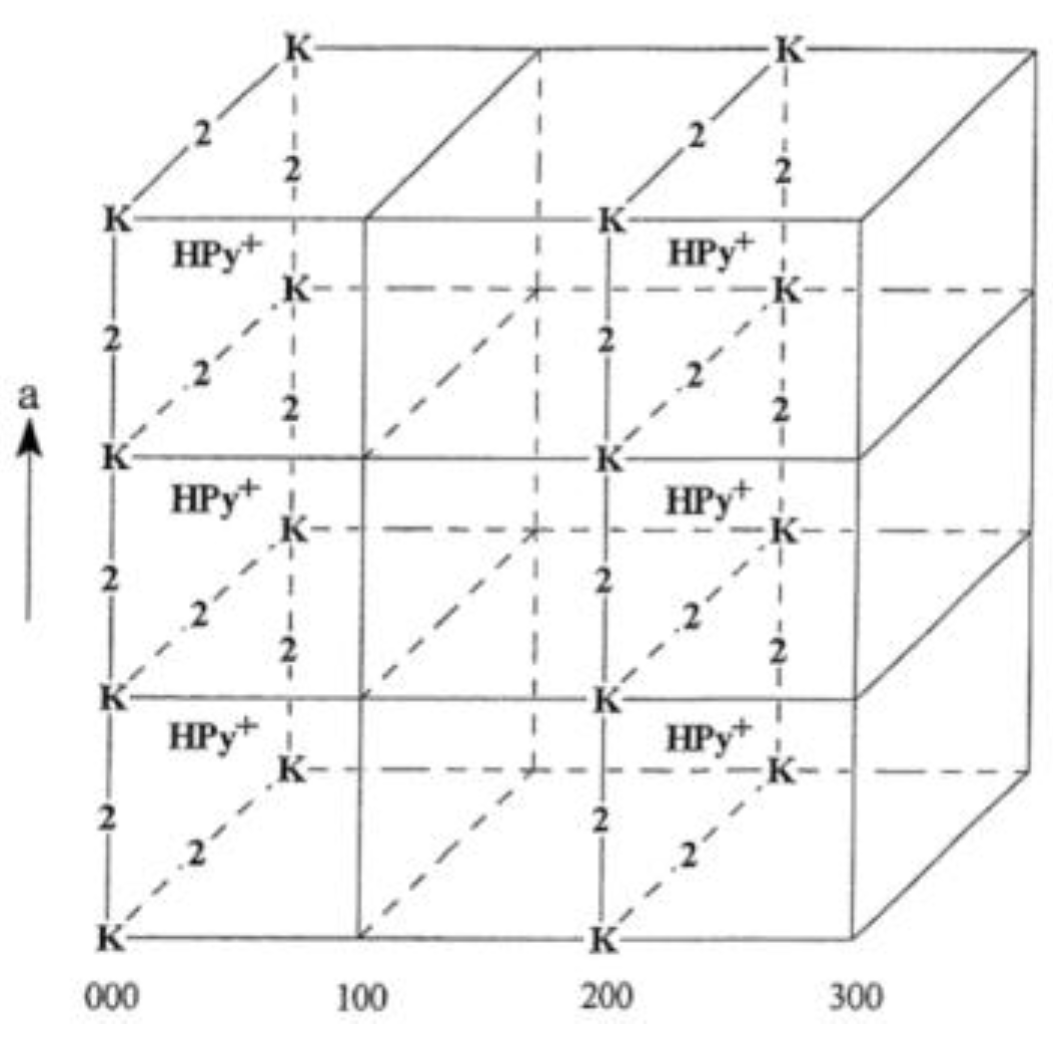

- Dias, J.A.; Osegovic, J.P.; Drago, R.S. The solid acidity of 12-tungstophosphoric acid. J. Catal. 1999, 183, 83–90. [Google Scholar] [CrossRef]

- Misono, M. Heterogeneous catalysis by heteropoly compounds of molybdenum and tungsten. Catal. Rev. Sci. Eng. 1987, 29, 269–321. [Google Scholar] [CrossRef]

- Lee, K.Y.; Arai, T.; Nakata, S.; Asaoka, S.; Okuhara, T.; Misono, M. Catalysis by heteropoly compounds. 20. An NMR study of ethanol dehydration in the pseudoliquid phase of 12-tungstophosphoric acid. J. Am. Chem. Soc. 1992, 114, 2836–2842. [Google Scholar] [CrossRef]

- Dias, J.A.; Dias, S.C.L.; Kob, N.E. Dehydration of 1-propanol using H3PW12O40 as catalyst. J. Chem. Soc. Dalton Trans. 2001, 228–231. [Google Scholar] [CrossRef]

- Dias, J.A.; Caliman, E.; Dias, S.C.L. Effects of cesium ion exchange on acidity of 12-tungstophosphoric acid. Microporous Mesoporous Mater. 2004, 76, 221–232. [Google Scholar] [CrossRef]

- Okuhara, T. Water-Tolerant Solid Acid Catalysts. Chem. Rev. 2002, 102, 3641–3666. [Google Scholar] [CrossRef]

- Corma, A.; Martínez, A.; Martínez, C. Acidic Cs+, NH4+, and K+ Salts of 12-tungstophosphoric acid as solid catalysts for isobutane/2-butene alkylation. J. Catal. 1996, 164, 422–432. [Google Scholar] [CrossRef]

- da Silva, M.J.; Rodrigues, A.A.; Lopes, N.P.G. Cesium heteropolyacid salts: Synthesis, characterization and activity of the solid and versatile heterogeneous catalysts. Chemistry 2023, 5, 662–690. [Google Scholar] [CrossRef]

- Nishimura, T.; Okuhara, T.; Misono, M. High catalytic activity of an insoluble acidic caesium salt of dodecatungstophosphoric acid for liquid-phase alkylation. Appl. Catal. 1991, 73, L7–L11. [Google Scholar] [CrossRef]

- Dias, J.A.; Dias, S.C.L.; de Macedo, J.L. Effect of acidity, structure and stability of supported 12-tungstophosphoric acid on catalytic reactions. In Environmentally Benign Catalysts for Clean Organic Reactions; Patel, A., Ed.; Springer: London, UK, 2013; pp. 165–187. [Google Scholar] [CrossRef]

- Rafiee, E.; Zolfagharifar, Z.; Joshaghani, M.; Eavani, S. Facile condensation of indole with benzaldehyde over Keggin-type heteropoly compounds: An initial effort toward catalyst design. Appl. Catal. A 2009, 365, 287–291. [Google Scholar] [CrossRef]

- Dias, J.A.; Caliman, E.; Dias, S.C.L.; Paulo, M.; de Souza, A.T.C.P. Preparation and characterization of supported H3PW12O40 on silica gel: A potential catalyst for green chemistry processes. Catal. Today 2003, 85, 39–48. [Google Scholar] [CrossRef]

- Misono, M.; Inui, T. New catalytic technologies in Japan. Catal. Today 1999, 51, 369–375. [Google Scholar] [CrossRef]

- Misono, M.; Ono, I.; Koyano, G.; Aoshima, A. Heteropolyacids. Versatile green catalysts usable in a variety of reaction media. Pure Appl. Chem. 2000, 72, 1305–1311. [Google Scholar] [CrossRef]

- Kozhevnikov, I.V. (Ed.) Catalysts for Fine Chemical Synthesis Catalysis by Polyoxometalates; John Wiley & Sons Ltd.: Chichester, UK, 2002; Volume 2, pp. 1–42. [Google Scholar]

- Zhang, Q.; Liu, X.; Deng, T.; Zhang, Y.; Ma, P. Recent progress on heteropolyacids for green fuels synthesis. Curr. Green Chem. 2019, 7, 267–281. [Google Scholar] [CrossRef]

- Na, K. Synthesis and application of zeolite catalysts. Catalysts 2021, 11, 685. [Google Scholar] [CrossRef]

- Escobar, A.M.; Blustein, G.; Luque, R.; Romanelli, G.P. Recent applications of heteropolyacids and related compounds in heterocycle synthesis. Contributions between 2010 and 2020. Catalysts 2021, 11, 291. [Google Scholar] [CrossRef]

- Dias, J.A.; Rangel, M.C.; Dias, S.C.L.; Caliman, E.; Garcia, F.A.C. Benzene transalkylation with C9+ aromatics over supported 12-tungstophosphoric acid on silica catalysts. Appl. Catal. A 2007, 328, 189–194. [Google Scholar] [CrossRef]

- Sotelo, J.L.; Calvo, L.; Velázquez, P.; Capilla, D.; Carvani, F.; Bolognini, M. A comparative study on the transalkylation of diisopropylbenzene with benzene over several zeolitic materials in supercritical CO2 and liquid phase. Appl. Catal. A 2006, 312, 194–201. [Google Scholar] [CrossRef]

- Caliman, E.; Dias, J.A.; Dias, S.C.L.; Prado, A.G.S. Solvent effect on the preparation of H3PW12O40 supported on alumina. Catal. Today 2005, 107–108, 816–825. [Google Scholar] [CrossRef]

- Caliman, E.; Dias, J.A.; Dias, S.C.L.; Garcia, F.A.C.; de Macedo, J.L.; Almeida, L.S. Preparation and characterization of H3PW12O40 supported on niobia. Microporous Mesoporous Mater. 2010, 132, 103–111. [Google Scholar] [CrossRef]

- Lefebvre, F.; Dupont, P.; Auroux, A. Study of the acidity of H3PW12O40 supported on activated carbon by microcalorimetry and methanol dehydration reaction. React. Kinet. Catal. Lett. 1995, 55, 3. [Google Scholar] [CrossRef]

- Chafran, L.S.; Campos, J.M.C.; Santos, J.S.; Sales, M.J.A.; Dias, S.C.L.; Dias, J.A. Synthesis of poly(lactic acid) by heterogeneous acid catalysis from d,l-lactic acid. J. Polym. Res. 2016, 23, 107. [Google Scholar] [CrossRef]

- Chafran, L.S.; Paiva, M.F.; França, J.O.C.; Sales, M.J.A.; Dias, S.C.L.; Dias, J.A. Preparation of PLA blends by polycondensation of d,l-lactic acid using supported 12-tungstophosphoric acid as a heterogeneous catalyst. Heliyon 2019, 5, e01810. [Google Scholar] [CrossRef]

- Rosenboom, J.-G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- de França, J.O.C.; da Silva Valadares, D.; Paiva, M.F.; Dias, S.C.L.; Dias, J.A. Polymers based on PLA from synthesis using d,l-lactic acid (or racemic lactide) and some biomedical applications: A short review. Polymers 2022, 14, 2317. [Google Scholar] [CrossRef]

- Freitas, E.F.; Paiva, M.F.; Dias, S.C.L.; Dias, J.A. Generation and characterization of catalytically active sites of heteropolyacids on zeolite Y for liquid-phase esterification. Catal. Today 2017, 289, 70–77. [Google Scholar] [CrossRef]

- Freitas, E.F.; Souza, R.Y.; Passos, S.T.A.; Dias, J.A.; Dias, S.C.L.; Neto, B.A.D. Tuning the Biginelli reaction mechanism by the ionic liquid effect: The combined role of supported heteropolyacid derivatives and acidic strength. RSC Adv. 2019, 9, 27125–27135. [Google Scholar] [CrossRef]

- Paiva, M.F.; Freitas, E.F.; de França, J.O.C.; da Silva Valadares, D.; Dias, S.C.L.; Dias, J.A. Structural and acidity analysis of heteropolyacids supported on faujasite zeolite and its effect in the esterification of oleic acid and n-butanol. Mol. Catal. 2022, 532, 112737. [Google Scholar] [CrossRef]

- Braga, V.S.; Dias, J.A.; Dias, S.C.L.; Macedo, J.L. Catalyst materials based on Nb2O5 supported on SiO2−Al2O3: preparation and structural characterization. Chem. Mater. 2005, 17, 690–695. [Google Scholar] [CrossRef]

- Nakajima, K.; Baba, Y.; Noma, R.; Kitano, M.; Kondo, J.N.; Hayashi, S.; Hara, M. Nb2O5·nH2O as a heterogeneous catalyst with water-tolerant Lewis acid sites. J. Am. Chem. Soc. 2011, 133, 4224–4227. [Google Scholar] [CrossRef] [PubMed]

- Braga, V.S.; Barros, I.C.L.; Garcia, F.A.C.; Dias, S.C.L.; Dias, J.A. Esterification of acetic acid with alcohols using supported niobium pentoxide on silica–alumina catalysts. Catal. Today 2008, 133–135, 106–112. [Google Scholar] [CrossRef]

- Braga, V.S.; Garcia, F.A.C.; Dias, S.C.L.; Dias, J.A. Copper oxide and niobium pentoxide supported on silica-alumina: Synthesis, characterization, and application on diesel soot oxidation. J. Catal. 2007, 247, 68–77. [Google Scholar] [CrossRef]

- Nowak, I.; Ziolek, M. Niobium compounds: Preparation, characterization, and application in heterogeneous catalysis. Chem. Rev. 1999, 99, 3603–3624. [Google Scholar] [CrossRef]

- Garcia, F.A.C.; Braga, V.S.; Silva, J.C.M.; Dias, J.A.; Dias, S.C.L.; Davo, J.L.B. Acidic characterization of copper oxide and niobium pentoxide supported on silica–alumina. Catal. Lett. 2007, 119, 101–107. [Google Scholar] [CrossRef]

- Clemente, M.C.H.; Valadares, D.S.; Lacava, A.B.; Barbosa, L.S.; Martins, G.A.V.; Dias, J.A.; Dias, S.C.L. Catalytic transformation conditions of ethanol on dealuminated BEA zeolites. J. Braz. Chem. Soc. 2019, 30, 2182–2190. [Google Scholar] [CrossRef]

- van Putten, R.-J.; van der Waal, J.C.; de Jong, E.; Rasrendra, C.B.; Heeres, H.J.; de Vries, J.G. Hydroxymethylfurfural, a versatile platform chemical made from renewable resources. Chem. Rev. 2013, 113, 1499–1597. [Google Scholar] [CrossRef]

- Shahbeik, H.; Peng, W.; Panahi, H.K.S.; Dehhaghi, M.; Guillemin, G.J.; Fallahi, A.; Amiri, H.; Rehan, M.; Raikwar, D.; Latine, H.; et al. Synthesis of liquid biofuels from biomass by hydrothermal gasification: A critical review. Renew. Sustain. Energy Rev. 2022, 167, 112833. [Google Scholar] [CrossRef]

- Lima, J.P.V.; Campos, P.T.A.; Paiva, M.F.; Linares, J.J.; Dias, S.C.L.; Dias, J.A. Dehydration of fructose to 5-hydroxymethylfurfural: Effects of acidity and porosity of different catalysts in the conversion, selectivity, and yield. Chemistry 2021, 3, 1189–1202. [Google Scholar] [CrossRef]

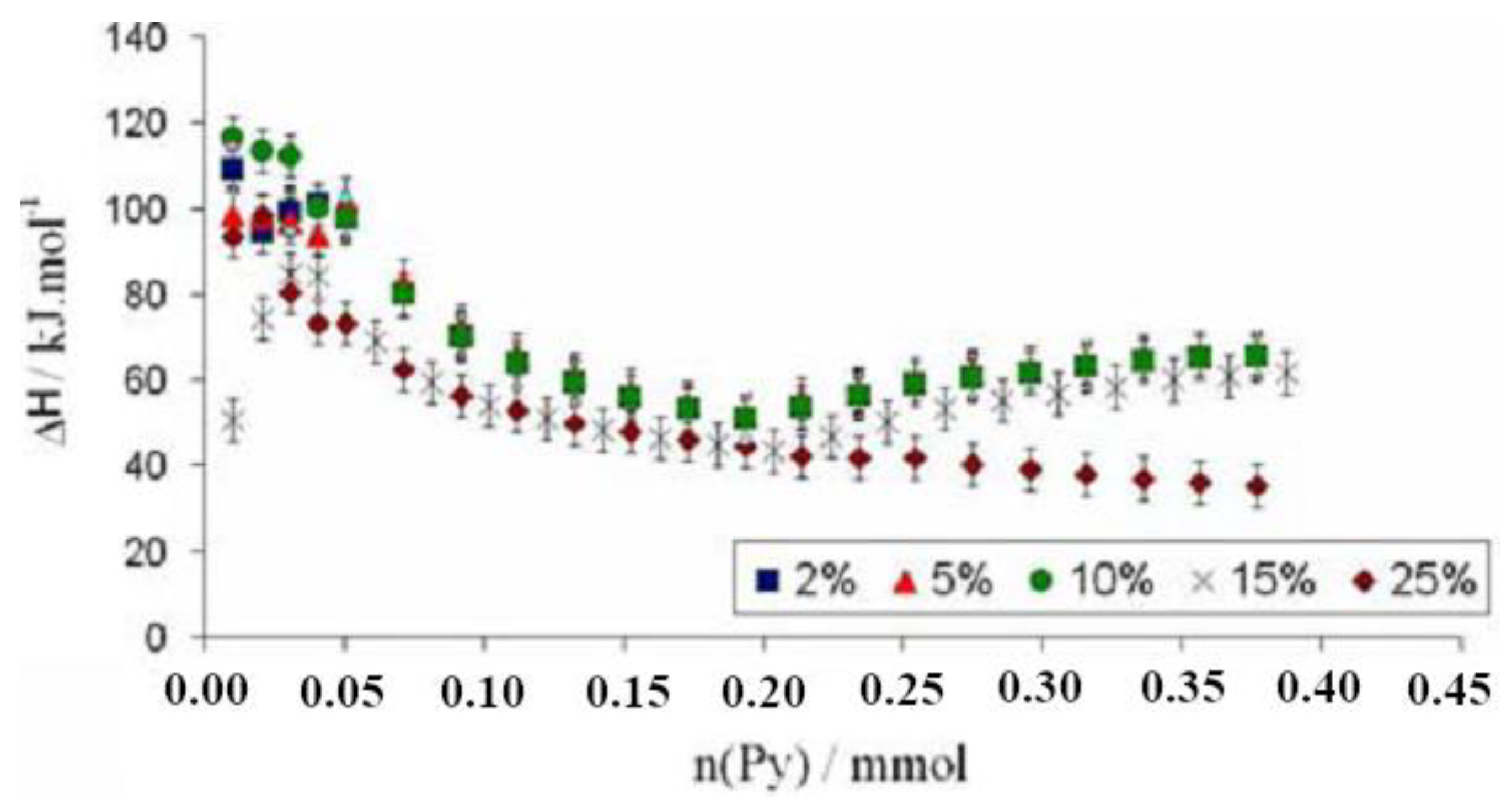

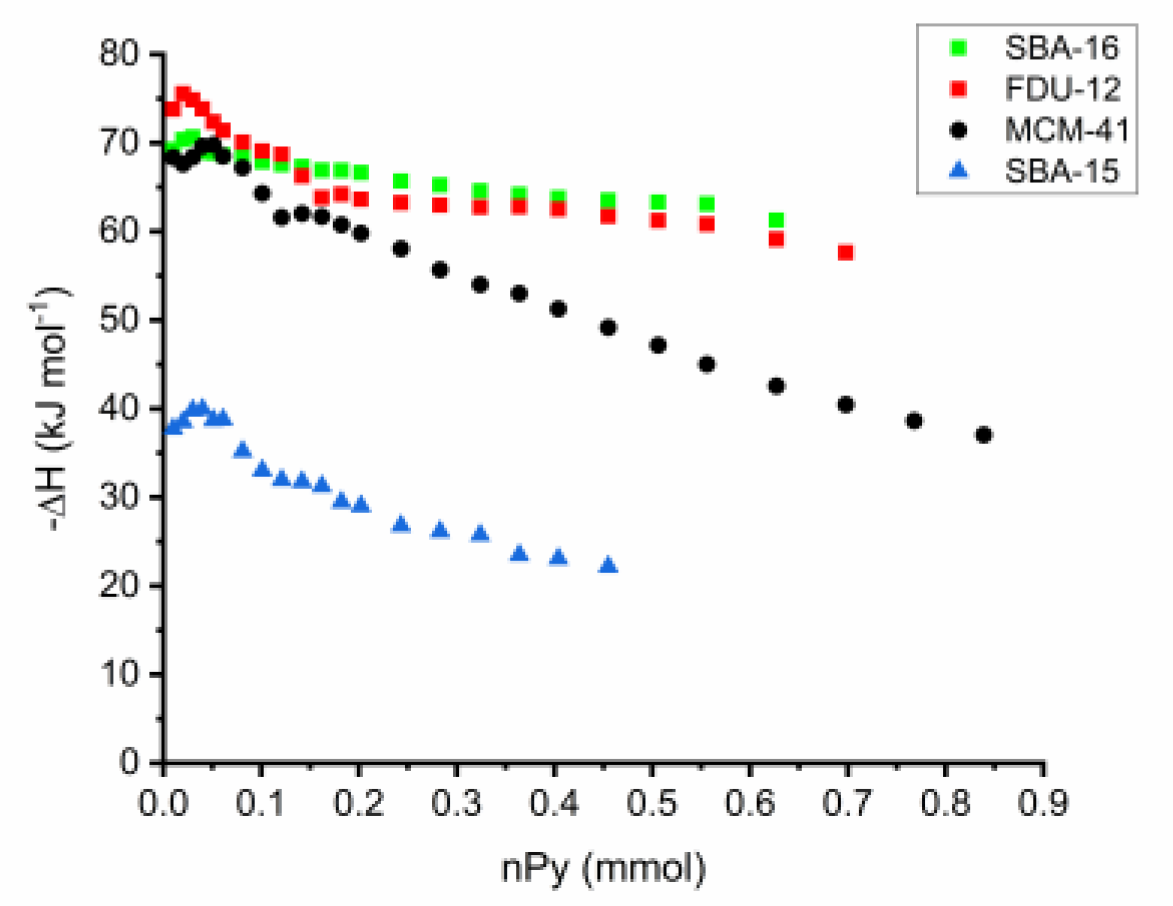

- Alves, M.R.; Paiva, M.F.; Campos, P.T.A.; de Freitas, E.F.; Clemente, M.C.H.; Martins, G.A.V.; Silveira, A.T.; da Silva, L.C.C.; Fantini, M.C.A.; Dias, S.C.L.; et al. Accessibility and strength of H-acceptor hydroxyls of ordered mesoporous silicas probed by pyridine donor. J. Porous Mater. 2020, 28, 323–335. [Google Scholar] [CrossRef]

- Meynen, V.; Cool, P.; Vansant, E.F. Verified syntheses of mesoporous materials. Microporous Mesoporous Mater. 2009, 125, 170–223. [Google Scholar] [CrossRef]

- Zhao, D. Triblock copolymer syntheses of mesoporous silica with periodic 50 to 300 angstrom pores. Science 1998, 279, 548–552. [Google Scholar] [CrossRef] [PubMed]

- Braga, P.R.S.; Costa, A.A.; de Macedo, J.L.; Ghesti, G.F.; de Souza, M.P.; Dias, J.A.; Dias, S.C.L. Liquid phase calorimetric-adsorption analysis of Si-MCM-41: Evidence of strong hydrogen-bonding sites. Microporous Mesoporous Mater. 2011, 139, 74–80. [Google Scholar] [CrossRef]

- Fan, J.; Yu, C.; Gao, F.; Lei, J.; Tian, B.; Wang, L.; Luo, Q.; Tu, B.; Zhou, W.; Zhao, D. Cubic mesoporous silica with large controllable entrance sizes and advanced adsorption properties. Angew. Chem. Int. Ed. 2003, 42, 3146–3150. [Google Scholar] [CrossRef]

- Schwanke, A.J.; Santos, A.P.B.; Bieseki, L.; Campos, P.R.P.; Pergher, S.B.C. Materiais Mesoporosos: Um Caminho Acessível; Editora da UFRN–Edufrn: Natal, Brazil, 2016; pp. 1–50. [Google Scholar]

| Catalyst (%H3PW) | SBET a (m2 g−1) | SBET b (m2 g−1) | DXRD c (nm) | −ΔHAVG (kJ mol−1) | nT (mmol g−1) | Sel(XY) (%) | Coke (%) |

|---|---|---|---|---|---|---|---|

| 8 | 74 | 23 | 12 | 85.9 | 0.078 | 0 | 1.6 |

| 15 | 63 | 60 | 15 | 100.4 | 0.159 | 3.9 | 0.3 |

| 20 | 57 | 43 | 17 | 108.8 | 0.204 | 2.8 | 1.0 |

| 25 | 40 | 20 | 18 | 116.7 | 0.252 | 0 | 2.4 |

| MOR | n.a. | n.a. | n.a. | 82.9 | 0.503 | 2.1 | 14.1 |

| Sample/Polymer | Property (Catalyst) a | Property (PLA) b | |||||

|---|---|---|---|---|---|---|---|

| # | −ΔH1 | n1 | nT | ee | Mw | ||

| 1 | d,l-lactic acid | - | - | - | 3 | - | - |

| 2 | PLA (pre-polymer) | - | - | - | 70 | 2278 | 2705 |

| 3 | PLA (no catalyst) | - | - | - | 88 | 4864 | 7408 |

| 4 | Carbon | 6 | - | - | 93 | 4893 | 9672 |

| 5 | SiO2 | 53 | 0.86 | 1.72 | 94 | 5285 | 8350 |

| 6 | Al2O3 | 64 | 0.16 | 0.41 | 84 | 5267 | 7709 |

| 7 | H3PW | 130 | 0.08 | 0.23 | 79 | 5914 | 9818 |

| 8 | 20% H3PW/C | 91 | 0.12 | 0.34 | 85 | 8469 | 15,189 |

| 9 | 20% H3PW/Al2O3 | 97 | 0.12 | 0.35 | 95 | 8161 | 14,827 |

| 10 | 20% H3PW/SiO2 | 110 | 0.09 | 0.40 | 83 | 7982 | 14,273 |

| Catalyst (Activation) | −ΔH1 | n1 | K1 | −ΔH2 | n2 | K2 | Ref. |

|---|---|---|---|---|---|---|---|

| 5% PdO/C | 54.4 | 2.5 | 2.5 × 104 | 41.8 | 3.2 | 2.9 × 102 | [87] |

| Silica (a) | 52.7 | 0.86 | 1.8 × 104 | 22.2 | 0.86 | 3.2 × 102 | [89] |

| Silica (b) | 23.0 | 1.12 | 2.5 × 104 | 13.4 | 1.30 | 5.8 × 102 | [89] |

| SZ (c) | 130.5 | 0.027 | 6.6 × 109 | 107.9 | 0.055 | 3.0 × 104 | [92] |

| SZ (d) | 62.8 | [92] | |||||

| Pt-SZ (e) | 125.5 | [92] | |||||

| SZ-Fe-Mn (e) | 108.8 | [92] | |||||

| 10.5% SG-W (b) | 132.6 | 0.065 | 6.8 × 108 | 67.8 | 0.41 | 7.1 × 102 | [93] |

| 10% SG-WO3 (f) | 114,6 | 0.016 | 1.2 × 109 | 74.5 | 0.24 | 5.8 × 103 | [93] |

| WO3 (f) | 41.8 | [93] | |||||

| H2WO4 | 71.1 | [93] | |||||

| SG-AlCl2 | 217.6 | 0.03 | 184.1 | 0.1 | [94] | ||

| HZSM-5 (g) | 176.1 | 0.042 | 4.9 × 106 | 0.52 | 2.3 × 104 | [90] | |

| TS-1 (h) | 63.2 | 0.07 | 6.7 × 105 | 2.4 | 0.31 | 1.3 × 104 | [107] |

| HY (g) | 142.6 | 0.108 | 2.1 × 108 | 74.1 | 0.22 | 1.4 × 106 | [108] |

| BEA (g) | 148.0 | 0.15 | 9 × 106 | 61.8 | 0.40 | 6 × 104 | [118] |

| DB (i) | 60 | 0.16 | 49 | 0.24 | [119] | ||

| MOR (g) | 82.9 | 0.081 | 2.7 × 107 | 36.7 | 0.422 | 3.1 × 104 | [114] |

| Ce/USY (i) | 117.2 | 0.074 | 8.7 × 105 | 87.9 | 1.117 | 7.0 × 103 | [112] |

| USY (i) | 134.0 | 0.139 | 2.0 × 108 | 101.5 | 0.737 | 2.1 × 106 | [112] |

| HPW (b) | 136.8 | 0.08 | 3.7 × 105 | 82.0 | 0.16 | 2.9 × 103 | [120] |

| 12%HPW/Y (d) | 151 | 0.32 | 36 | 0.10 | [149] | ||

| 40%HPW/Y (d) | 146 | 0.08 | [118] | ||||

| 39%HPW/BEA (d) | 144 | 0.32 | [118] | ||||

| 28%HSiW/Y (d) | 123 | 0.06 | [147] | ||||

| 8% HPW/SiO2 (b) | 87.9 | [138] | |||||

| 15% HPW/SiO2 (b) | 100.4 | [138] | |||||

| 20% HPW/SiO2 (b) | 108.8 | [138] | |||||

| 25% HPW/SiO2 (b) | 116.7 | 0.102 | 6.7 × 105 | 42.3 | 0.310 | 3.8 × 104 | [131] |

| 20% HPW/Al2O3 (b) | 94.6 | 0.152 | 1.2 × 105 | 50.2 | 0.20 | 4.9 × 103 | [140] |

| 40% HPW/Al2O3 (b) | 75.3 | [140] | |||||

| γ-Al2O3 (d) | 63.5 | 0.16 | 28.0 | 0.25 | [140] | ||

| 20% HPW/Nb2O5 (b) | 85 | 0.09 | 45 | 0.19 | [159] | ||

| 25% HPW/Nb2O5 (b) | 119.7 | 0.086 | 8.8 × 105 | 43.5 | 0.191 | 2.1 × 105 | [141] |

| 30% HPW/Nb2O5 (b) | 96.2 | [141] | |||||

| 40% HPW/Nb2O5 (b) | 87.9 | [141] | |||||

| Nb2O5 (d) | 88 | 0.06 | 50 | 0.15 | [159] | ||

| 20% HPW/C (b) | 93.7 | 0.129 | 1.2 × 107 | 29.3 | 0.210 | 8.6 × 104 | [144] |

| 20% HPW/C (h) | 91 | 0.12 | [144] | ||||

| 20% HPW/Al2O3 (h) | 97 | 0.12 | [144] | ||||

| 20% HPW/SiO2 (h) | 110 | 0.09 | [144] | ||||

| C (b) | 6 | [144] | |||||

| 10%Nb-DB (i) | 71 | 0.21 | 51 | 0.18 | [119] | ||

| 18%Nb-DB (i) | 49 | 0.24 | 42 | 0.20 | [119] | ||

| 25%Nb-DB (i) | 42 | 0.23 | 40 | 0.17 | [119] | ||

| 5% Nb2O5/Si-Al (d) | 104.6 | [152] | |||||

| 10% Nb2O5/Si-Al (d) | 113.0 | [152] | |||||

| 15% Nb2O5/Si-Al (d) | 96.2 | [152] | |||||

| 25% Nb2O5/Si-Al (d) | 83.7 | [152] | |||||

| 2% CuO/Nb2O5/Si-Al (d) | 100.4 | 64.5 | [155] | ||||

| 5% CuO/Nb2O5/Si-Al (d) | 97.9 | 64.8 | [155] | ||||

| 10% CuO/Nb2O5/Si-Al (d) | 107.5 | 64.5 | [155] | ||||

| 15% CuO/Nb2O5/Si-Al (d) | 90.8 | 39.3 | [155] | ||||

| 25% CuO/Nb2O5/Si-Al (d) | 73.2 | 60.3 | [155] | ||||

| FDU-12 (b) | 74.5 | 0.05 | 56.2 | 0.62 | [160] | ||

| SBA-16 (b) | 66.1 | 0.05 | 58.6 | 0.55 | [160] | ||

| MCM-41 (b) | 66.8 | 0.10 | 45.8 | 0.91 | [160] | ||

| SBA-15 (b) | 36.8 | 0.08 | 24.3 | 0.38 | [160] |

| Reaction | C (%)/S (%) | Catalyst | −ΔH1 (kJ/mol)/nT (mmol/g) a | Ref. |

|---|---|---|---|---|

| Ethylene/propene oligomerization | - | SG-AlCl2 | 217.6/0.13 | [94] |

| Pentane isomerization | 33% C | SZ | 130.5/0.08 | [92] |

| 1-propanol dehydration | 41% C | HPW | 136.8/0.24 | [120,123] |

| Benzene transalkylation with C9+ aromatics | 3.9% S (xylenes) | 15%HPW/SiO2 | 100.4/0.16 | [138] [131] |

| d,l-lactic acid polymerization | 100% PLA b (ee 85% PLLA) | 20%HPW/C | 91/0.34 | [143] [144] |

| d,l-lactic acid polymerization | 100% PLA b (ee 83% PLLA) | 20%HPW/SiO2 | 110/0.40 | [131] [144] |

| d,l-lactic acid polymerization | 100% PLA b (ee 95% PLLA) | 20%HPW/Al2O3 | 97/0.35 | [140] [144] |

| Biginelli (MCR) c | 99% yield | 28%HSiW/Y | 123/0.39 | [147] [148] |

| Esterification of acetic acid with n-butanol (1 h) | 77% C 83% C | 40%HPW/Y 39%HPW/BEA | 146/0.29 144/0.32 | [147] [118] |

| Esterification of oleic acid with n-butanol (1 h) | 96% C | 12%HPW/Y | 151/0.42 | [149] |

| Esterification of acetic acid with ethanol, n-butanol and isopentanol (8 h) | 83% C (ethanol) 87% C (n-butanol) 90% C (isopentanol) | 10%Nb2O5/Si-Al | 113/0.37 | [152] |

| Dehydration of ethanol (300 °C) | 100% C (ethylene) 65% C (ethylene) | HBEA DB | 105/0.62 60/0.40 | [156] [119] |

| Dehydration of ethanol (230 °C) | 97% S (DEE) d | 18%Nb-DB | 49/0.44 | [119] |

| Dehydration of xylose (water, 180 °C) | 51% C 64% S (furfural) | 18%Nb-DB | 49/0.44 | [119] |

| Dehydration of fructose (water, 120 °C) | 47.5% C 28.9% S (HMF) e | Nb2O5 | 88/0.21 | [159] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valadares, D.d.S.; de França, J.O.C.; Fernandes, R.C.; Dezaneti, L.M.; Loureiro Dias, S.C.; Dias, J.A. Liquid Phase Calorimetric Method as a Tool for Acid Strength Measurements and Application to a Variety of Sustainable Catalysts. Chemistry 2023, 5, 1138-1170. https://doi.org/10.3390/chemistry5020078

Valadares DdS, de França JOC, Fernandes RC, Dezaneti LM, Loureiro Dias SC, Dias JA. Liquid Phase Calorimetric Method as a Tool for Acid Strength Measurements and Application to a Variety of Sustainable Catalysts. Chemistry. 2023; 5(2):1138-1170. https://doi.org/10.3390/chemistry5020078

Chicago/Turabian StyleValadares, Deborah da Silva, Juliene Oliveira Campos de França, Roberto Chaves Fernandes, Luiz Marcos Dezaneti, Sílvia Cláudia Loureiro Dias, and José Alves Dias. 2023. "Liquid Phase Calorimetric Method as a Tool for Acid Strength Measurements and Application to a Variety of Sustainable Catalysts" Chemistry 5, no. 2: 1138-1170. https://doi.org/10.3390/chemistry5020078

APA StyleValadares, D. d. S., de França, J. O. C., Fernandes, R. C., Dezaneti, L. M., Loureiro Dias, S. C., & Dias, J. A. (2023). Liquid Phase Calorimetric Method as a Tool for Acid Strength Measurements and Application to a Variety of Sustainable Catalysts. Chemistry, 5(2), 1138-1170. https://doi.org/10.3390/chemistry5020078