Towards a Better Understanding of the Interaction of Fe66Cr10Nb5B19 Metallic Glass with Aluminum: Growth of Intermetallics and Formation of Kirkendall Porosity during Sintering

Abstract

1. Introduction

2. Materials and Methods

3. Results

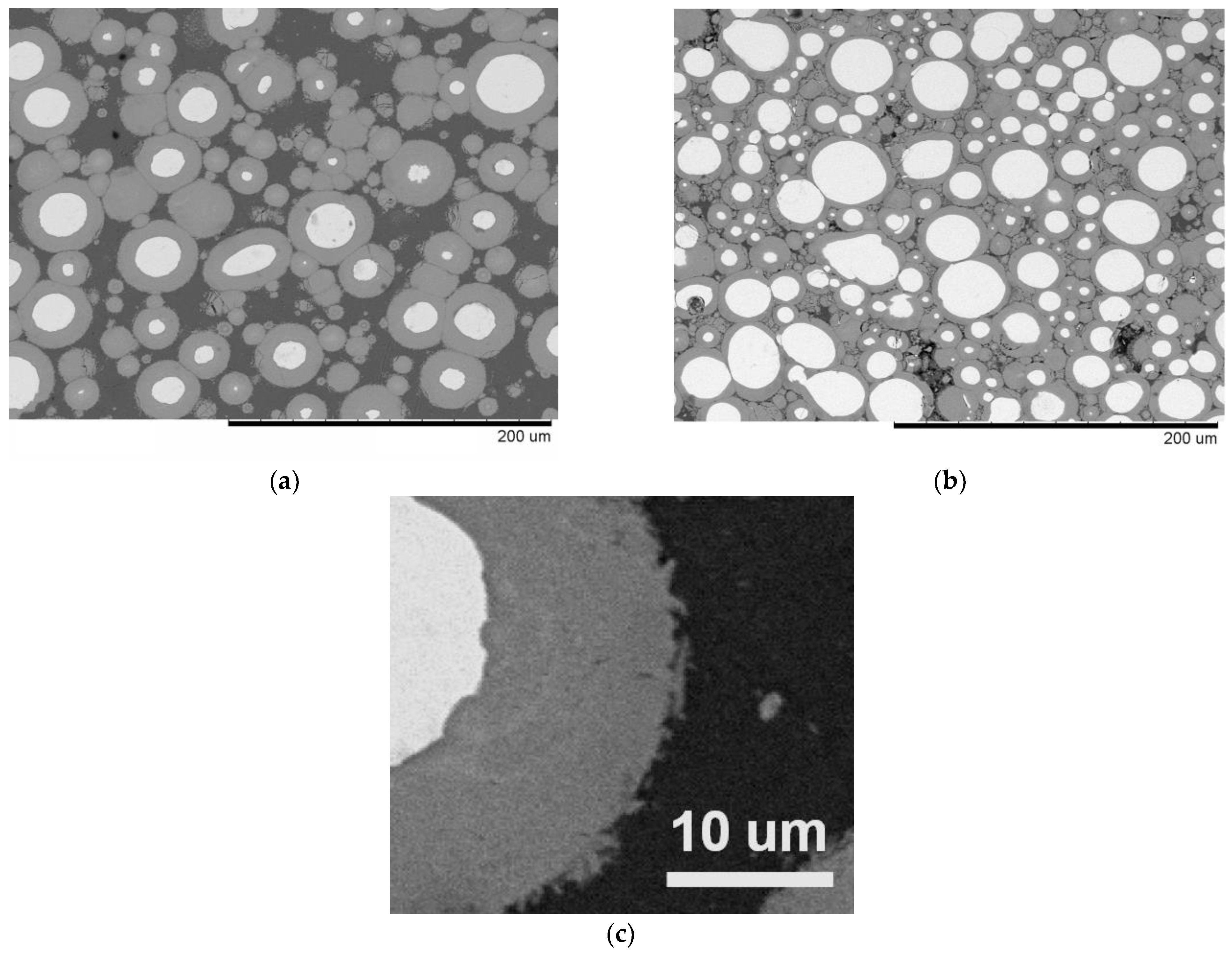

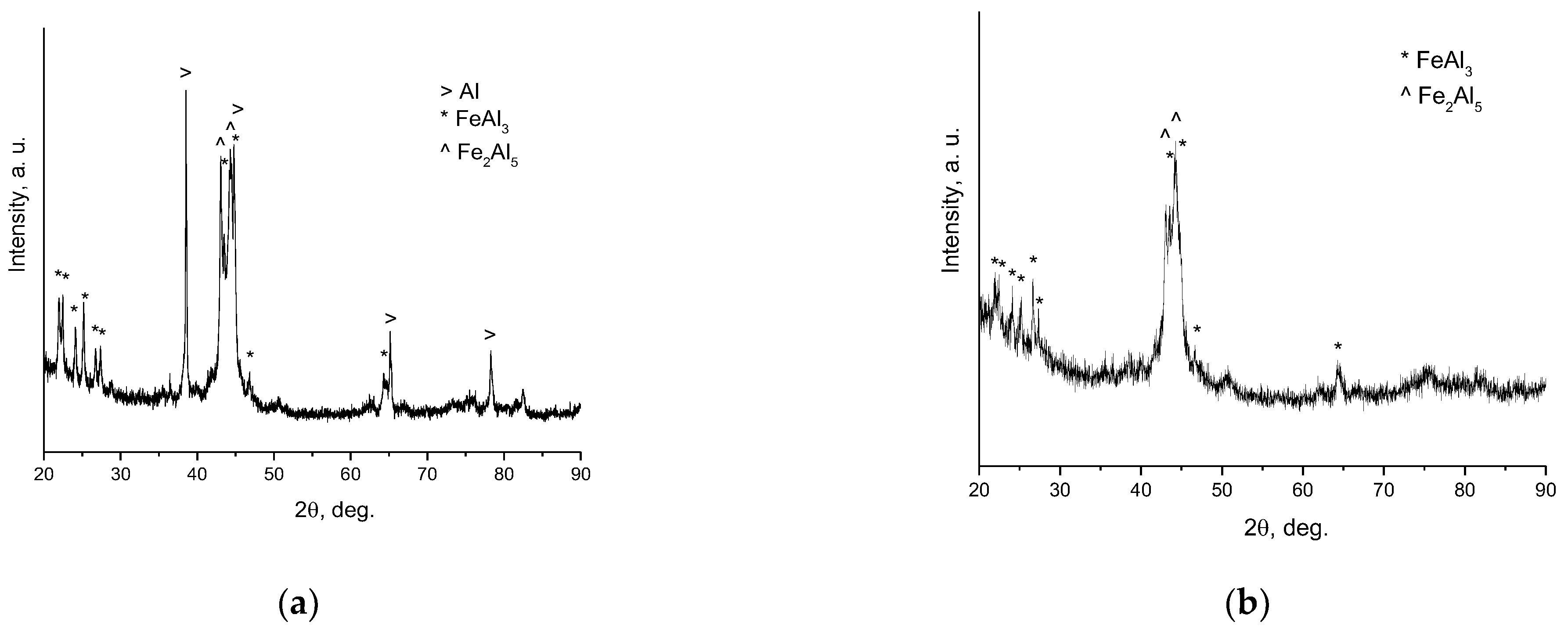

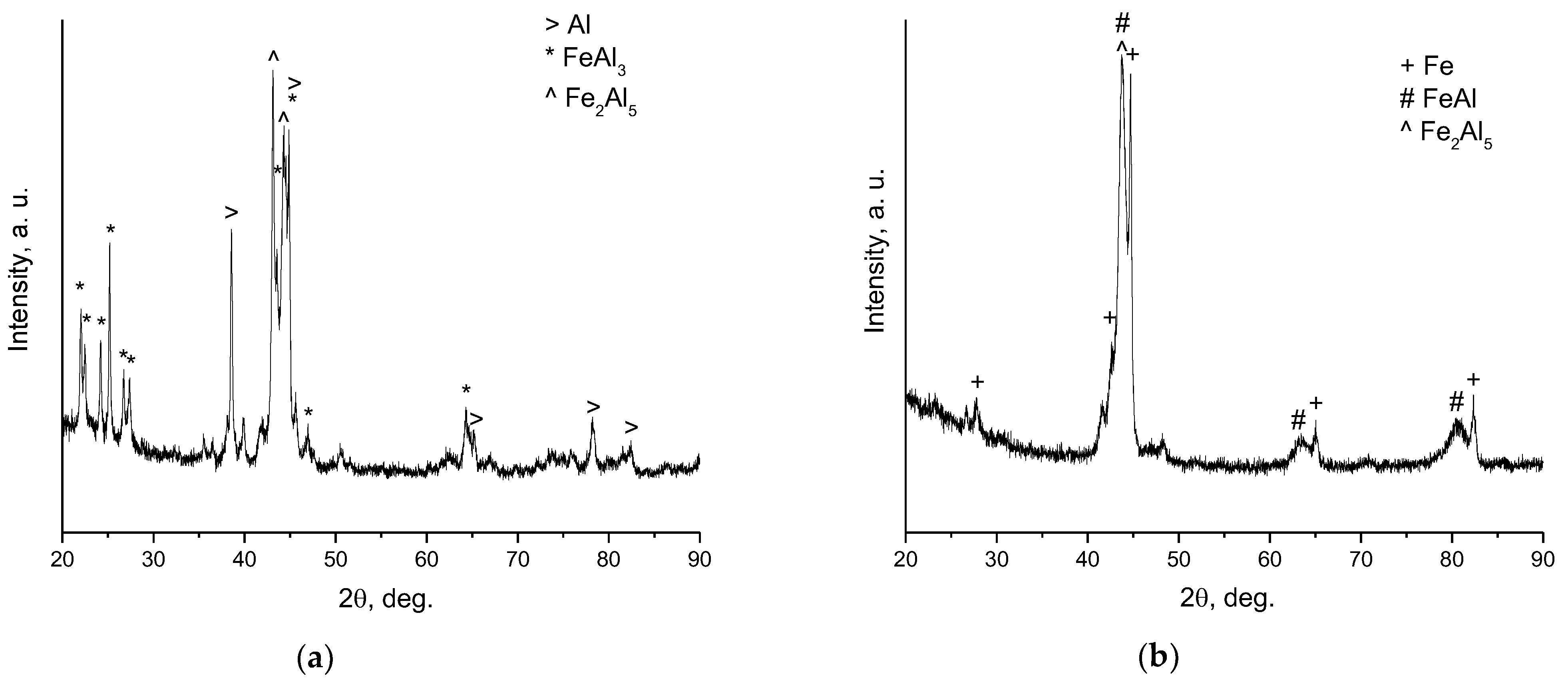

3.1. Phase Composition and Microstructural Features of Materials Obtained by Spark Plasma Sintering of Al-Fe66Cr10Nb5B19 Powder Mixtures

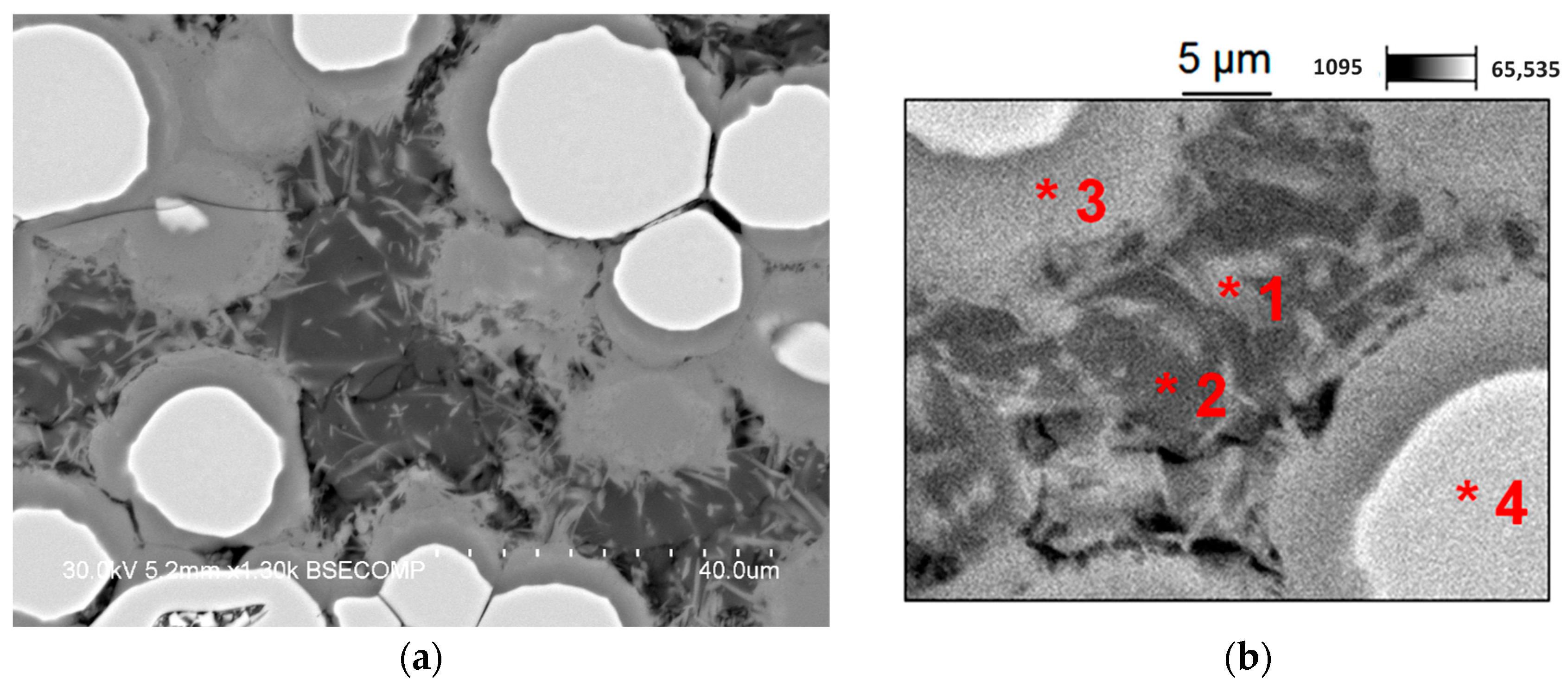

3.2. Structural Changes during Annealing of Preconsolidated Al-Fe66Cr10Nb5B19 Compacts

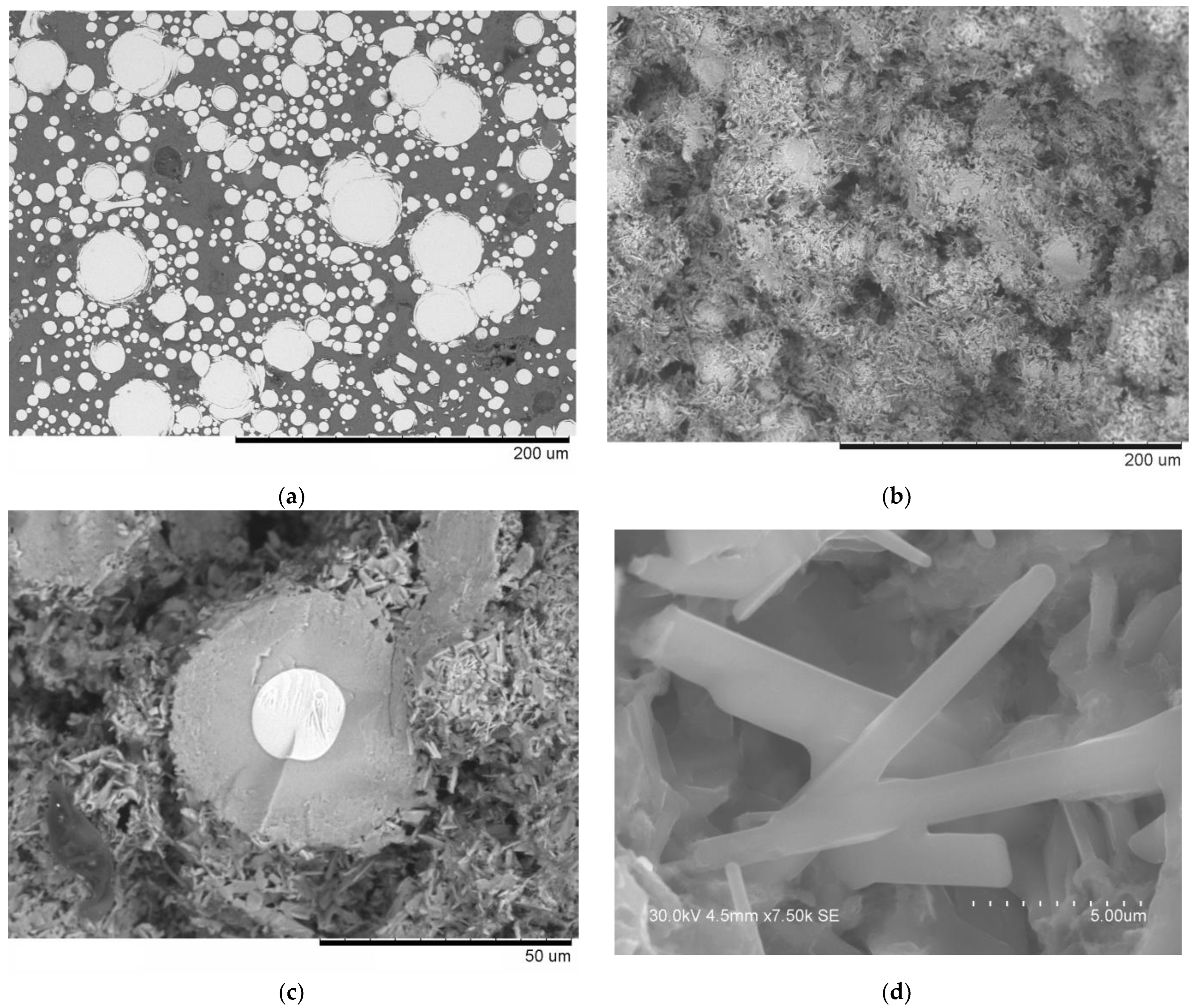

3.3. Microstructure of Materials Consolidated from Al-Fe Mixtures

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dudina, D.V.; Georgarakis, K.; Yavari, A.R. Metal matrix composites reinforced with metallic glass particles: State of the art. In Metal Matrix Composites; Davim, J.P., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2012; pp. 1–30. [Google Scholar]

- Jayalakshmi, S.; Arvind Singh, R.; Gupta, M. Metallic glasses as potential reinforcements in Al and Mg matrices: A review. Technologies 2018, 6, 40. [Google Scholar] [CrossRef]

- Georgarakis, K.; Dudina, D.V.; Kvashnin, V.I. Metallic glass-reinforced metal matrix composites: Design, interfaces and properties. Materials 2022, 15, 8278. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.; Zhang, L.C.; Zhang, W.Y.; Das, J.; Kim, K.B.; Eckert, J. Interfacial reaction during the fabrication of Ni60Nb40 metallic glass particles-reinforced Al based MMCs. Mater. Sci. Eng. A 2007, 444, 206–213. [Google Scholar] [CrossRef]

- Yu, P.; Venkataraman, S.; Das, J.; Zhang, L.C.; Zhang, W.; Eckert, J. Effect of high pressure during the fabrication on the thermal and mechanical properties of amorphous Ni60Nb40 particle-reinforced Al-based metal matrix composites. J. Mater. Res. 2007, 22, 1168–1173. [Google Scholar] [CrossRef]

- Wang, Z.; Georgarakis, K.; Nakayama, K.S.; Li, Y.; Tsarkov, A.A.; Xie, G.; Dudina, D.; Louzguine-Luzgin, D.V.; Yavari, A.R. Microstructure and mechanical behavior of metallic glass fiber-reinforced Al alloy matrix composites. Sci. Rep. 2016, 6, 24384. [Google Scholar] [CrossRef]

- Avettand-Fènoël, M.N.; Netto, N.; Simar, A.; Marinova, M.; Taillard, R. Design of a metallic glass dispersion in pure copper by friction stir processing. J. Alloys Compd. 2022, 907, 164522. [Google Scholar] [CrossRef]

- Wu, G.; Liu, C.; Brognara, A.; Ghidelli, M.; Bao, Y.; Liu, S.; Wu, X.; Xia, W.; Zhao, H.; Rao, J.; et al. Symbiotic crystal-glass alloys via dynamic chemical partitioning. Mater. Today 2021, 51, 6–14. [Google Scholar] [CrossRef]

- Fu, J.; Yang, J.; Wu, K.; Lin, H.; Wen, W.; Ruan, W.; Ren, S.; Zhang, Z.; Liang, X.; Ma, J. Metallic glue for designing composite materials with tailorable properties. Mater. Horiz. 2021, 8, 1690–1699. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Zhou, Z.Q.; Zhang, Z.B.; Park, M.H.; Yu, Q.; Li, Z.; Ma, J.; Wang, A.D.; Huang, H.G.; Song, M.; et al. Recent development of chemically complex metallic glasses: From accelerated compositional design, additive manufacturing to novel applications. Mater. Futur. 2022, 1, 012001. [Google Scholar] [CrossRef]

- Liang, X.; Zhu, X.; Li, X.; Mo, R.; Liu, Y.; Wu, K.; Ma, J. High-entropy alloy and amorphous alloy composites fabricated by ultrasonic vibrations. Sci. China Phys. Mech. Astron. 2020, 63, 116111. [Google Scholar] [CrossRef]

- Dudina, D.V.; Georgarakis, K. Core–shell particle reinforcements—A new trend in the design and development of metal matrix composites. Materials 2022, 15, 2629. [Google Scholar] [CrossRef]

- Olevsky, E.A.; Dudina, D.V. Field-Assisted Sintering: Science and Applications; Springer International Publishing: Cham, Switzerland, 2018; 425p. [Google Scholar]

- Dudina, D.V.; Georgarakis, K.; Olevsky, E.A. Progress in aluminium and magnesium matrix composites obtained by spark plasma, microwave and induction sintering. Int. Mater. Rev. 2022, in press. [Google Scholar] [CrossRef]

- Guan, H.D.; Li, C.J.; Gao, P.; Prashanth, K.G.; Tan, J.; Eckert, J.; Tao, J.M.; Yi, J.H. Aluminum matrix composites reinforced with metallic glass particles with core-shell structure. Mater. Sci. Eng. A 2020, 771, 138630. [Google Scholar] [CrossRef]

- Wang, Z.; Xie, M.S.; Zhang, W.W.; Yang, C.; Xie, G.Q.; Louzguine-Luzgin, D.V. Achieving super-high strength in an aluminum based composite by reinforcing metallic glassy flakes. Mater. Lett. 2020, 262, 127059. [Google Scholar] [CrossRef]

- Dudina, D.V.; Bokhonov, B.B.; Batraev, I.S.; Amirastanov, Y.N.; Ukhina, A.V.; Kuchumova, I.D.; Legan, M.A.; Novoselov, A.N.; Gerasimov, K.B.; Bataev, I.A.; et al. Interaction between Fe66Cr10Nb5B19 metallic glass and aluminum during spark plasma sintering. Mater. Sci. Eng. A 2021, 799, 140165. [Google Scholar] [CrossRef]

- Dudina, D.V.; Bokhonov, B.B.; Batraev, I.S.; Kvashnin, V.I.; Legan, M.A.; Novoselov, A.N.; Anisimov, A.G.; Esikov, M.A.; Ukhina, A.V.; Matvienko, A.A.; et al. Microstructure and mechanical properties of composites obtained by spark plasma sintering of Al–Fe66Cr10Nb5B19 metallic glass powder mixtures. Metals 2021, 11, 1457. [Google Scholar] [CrossRef]

- Kvashnin, V.I.; Dudina, D.V.; Ukhina, A.V.; Koga, G.Y.; Georgarakis, K. The benefit of the glassy state of reinforcing particles for the densification of aluminum matrix composites. J. Compos. Sci. 2022, 6, 135. [Google Scholar] [CrossRef]

- Kuchumova, I.D.; Batraev, I.S.; Ulianitsky, V.Y.; Shtertser, A.A.; Gerasimov, K.B.; Ukhina, A.V.; Bulina, N.V.; Bataev, I.A.; Koga, G.Y.; Guo, Y.; et al. Formation of metallic glass coatings by detonation spraying of a Fe66Cr10Nb5B19 powder. Metals 2019, 9, 846. [Google Scholar] [CrossRef]

- Koga, G.Y.; Ferreira, T.; Guo, Y.; Coimbrão, D.D.; Jorge, A.M., Jr.; Kiminami, C.S.; Bolfarini, C.; Botta, W.J. Challenges in optimizing the resistance to corrosion and wear of amorphous Fe-Cr-Nb-B alloy containing crystalline phases. J. Non-Cryst. Solids 2021, 555, 120537. [Google Scholar] [CrossRef]

- Salamon, M.; Mehrer, H. Interdiffusion, Kirkendall effect, and Al self-diffusion in iron–aluminium alloys. Z. Für Met. 2005, 96, 4–16. [Google Scholar] [CrossRef]

- Gao, H.; He, Y.; Shen, P.; Zou, J.; Xu, N.; Jiang, Y.; Huang, B.; Liu, C.T. Porous FeAl intermetallics fabricated by elemental powder reactive synthesis. Intermetallics 2009, 17, 1041–1046. [Google Scholar] [CrossRef]

- Gao, H.Y.; He, Y.H.; Shen, P.Z.; Jiang, Y.; Liu, C.T. Effect of pressure on pore structure of porous FeAl intermetallics. Adv. Powder Technol. 2015, 26, 882–886. [Google Scholar] [CrossRef]

- Springer, H.; Kostka, A.; dos Santos, J.F.; Raabe, D. Influence of intermetallic phases and Kirkendall-porosity on the mechanical properties of joints between steel and aluminium alloys. Mater. Sci. Eng. A 2011, 528, 4630–4642. [Google Scholar] [CrossRef]

- Kuchumova, I.D.; Batraev, I.S.; Ukhina, A.V.; Borisenko, T.A.; Bulanova, U.E.; Ulianitsky, V.Y.; Dudina, D.V.; Shikalov, V.S.; Kosarev, V.F.; Bataev, I.A.; et al. Processing of Fe-based alloys by detonation spraying and spark plasma sintering. J. Therm. Spray Tech. 2021, 30, 1692–1702. [Google Scholar] [CrossRef]

- Li, X.; Scherf, A.; Heilmaier, M.; Stein, F. The Al-rich part of the Fe-Al phase diagram. J. Phase Equil. Diff. 2016, 37, 162–173. [Google Scholar] [CrossRef]

- Van Alboom, A.; Lemmens, B.; Breitbach, B.; De Grave, E.; Cottenier, S.; Verbeken, K. Multi-method identification and characterization of the intermetallic surface layers of hot-dip Al-coated steel: FeAl3 or Fe4Al13 and Fe2Al5 or Fe2Al5+x. Surf. Coat. Technol. 2017, 324, 419–428. [Google Scholar] [CrossRef]

- Zhang, N.; Hu, Q.; Ding, Z.; Lu, W.; Yang, F.; Li, J. 3D morphological evolution and growth mechanism of proeutectic FeAl3 phases formed at Al/Fe interface under different cooling rates. J. Mater. Sci. Technol. 2022, 116, 83–93. [Google Scholar] [CrossRef]

- Dudina, D.V.; Vidyuk, T.M.; Gavrilov, A.I.; Ukhina, A.V.; Bokhonov, B.B.; Legan, M.A.; Matvienko, A.A.; Korchagin, M.A. Separating the reaction and spark plasma sintering effects during the formation of TiC–Cu composites from mechanically milled Ti–C–3Cu mixtures. Ceram. Int. 2021, 47, 12494–12504. [Google Scholar] [CrossRef]

- Dudina, D.V.; Grigoreva, T.F.; Devyatkina, E.T.; Vosmerikov, S.V.; Ukhina, A.V.; Markushin, V.V.; Lyakhov, N.Z. Structural features of tantalum carbide-copper composites obtained by liquid phase-assisted spark plasma sintering. Ceram. Int. 2022, 48, 32556–32560. [Google Scholar] [CrossRef]

- Itin, V.I.; Naiborodenko, Y.S. High-Temperature Synthesis of Intermetallic Compounds; Tomsk State University Publishing: Tomsk, Russia, 1989; 214p. (In Russian) [Google Scholar]

- Wang, Q.; Yang, H.; Li, X.; Zhang, G. Study of corrosion mechanism of cast iron in molten aluminum. Mater. Res. Express 2020, 7, 016534. [Google Scholar] [CrossRef]

- Chason, E.; Jadhav, N.; Pei, F. Effect of layer properties on stress evolution, intermetallic volume, and density during tin whisker formation. JOM 2011, 63, 62. [Google Scholar] [CrossRef]

- Carter, R.E. Kinetic model for solid-state reactions. J. Chem. Phys. 1961, 34, 2010–2015. [Google Scholar] [CrossRef]

- Matysik, P.; Jóźwiak, S.; Czujko, T. Characterization of low-symmetry structures from phase equilibrium of Fe-Al system—Microstructures and mechanical properties. Materials 2015, 8, 914–931. [Google Scholar] [CrossRef] [PubMed]

| Point | Concentration, at.% | ||||

|---|---|---|---|---|---|

| Al | Fe | Cr | Nb | B | |

| 1 | 89.7 ± 0.4 | 9.4 ± 0.1 | 0.9 ± 0.1 | - | - |

| 2 | 91.7 ± 0.4 | 7.1 ± 0.1 | 1.2 ± 0.1 | - | - |

| 3 | 74.7 ± 0.4 | 20.3 ± 0.2 | 4.4 ± 0.1 | 0.6 ± 0.4 | - |

| 4 | - | 80.2 ± 0.5 | 12.9 ± 0.2 | 2.2 ± 0.7 | 4.7 ± 1.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dudina, D.V.; Kvashnin, V.I.; Matvienko, A.A.; Sidelnikov, A.A.; Gavrilov, A.I.; Ukhina, A.V.; Jorge, A.M., Jr.; Georgarakis, K. Towards a Better Understanding of the Interaction of Fe66Cr10Nb5B19 Metallic Glass with Aluminum: Growth of Intermetallics and Formation of Kirkendall Porosity during Sintering. Chemistry 2023, 5, 138-150. https://doi.org/10.3390/chemistry5010011

Dudina DV, Kvashnin VI, Matvienko AA, Sidelnikov AA, Gavrilov AI, Ukhina AV, Jorge AM Jr., Georgarakis K. Towards a Better Understanding of the Interaction of Fe66Cr10Nb5B19 Metallic Glass with Aluminum: Growth of Intermetallics and Formation of Kirkendall Porosity during Sintering. Chemistry. 2023; 5(1):138-150. https://doi.org/10.3390/chemistry5010011

Chicago/Turabian StyleDudina, Dina V., Vyacheslav I. Kvashnin, Alexander A. Matvienko, Anatoly A. Sidelnikov, Alexander I. Gavrilov, Arina V. Ukhina, Alberto Moreira Jorge, Jr., and Konstantinos Georgarakis. 2023. "Towards a Better Understanding of the Interaction of Fe66Cr10Nb5B19 Metallic Glass with Aluminum: Growth of Intermetallics and Formation of Kirkendall Porosity during Sintering" Chemistry 5, no. 1: 138-150. https://doi.org/10.3390/chemistry5010011

APA StyleDudina, D. V., Kvashnin, V. I., Matvienko, A. A., Sidelnikov, A. A., Gavrilov, A. I., Ukhina, A. V., Jorge, A. M., Jr., & Georgarakis, K. (2023). Towards a Better Understanding of the Interaction of Fe66Cr10Nb5B19 Metallic Glass with Aluminum: Growth of Intermetallics and Formation of Kirkendall Porosity during Sintering. Chemistry, 5(1), 138-150. https://doi.org/10.3390/chemistry5010011