Effect of Fiber Content and Silane Treatment on the Mechanical Properties of Recycled Acrylonitrile-Butadiene-Styrene Fiber Composites

Abstract

1. Introduction

2. Materials and Methods

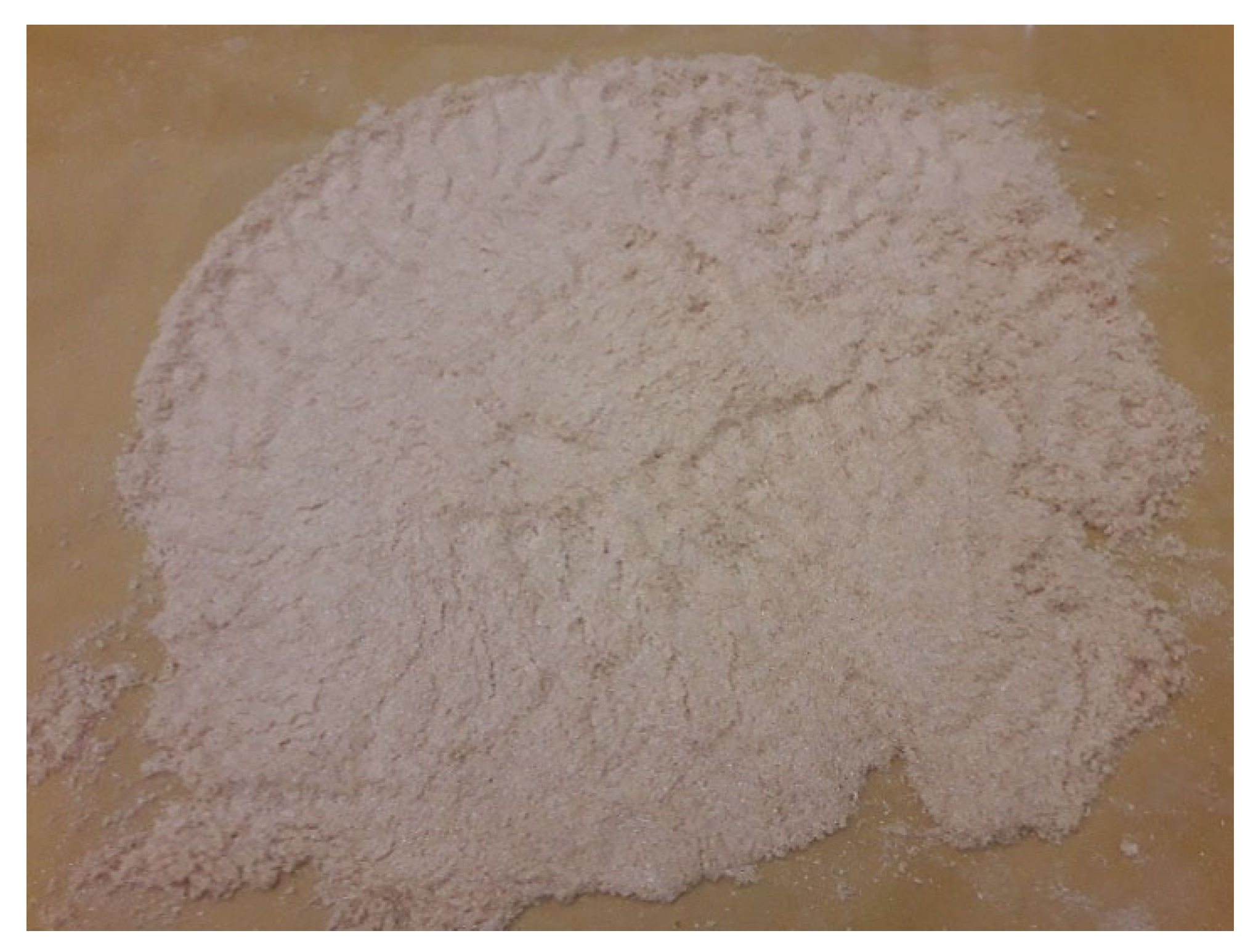

2.1. Materials

2.2. Silane Treatment

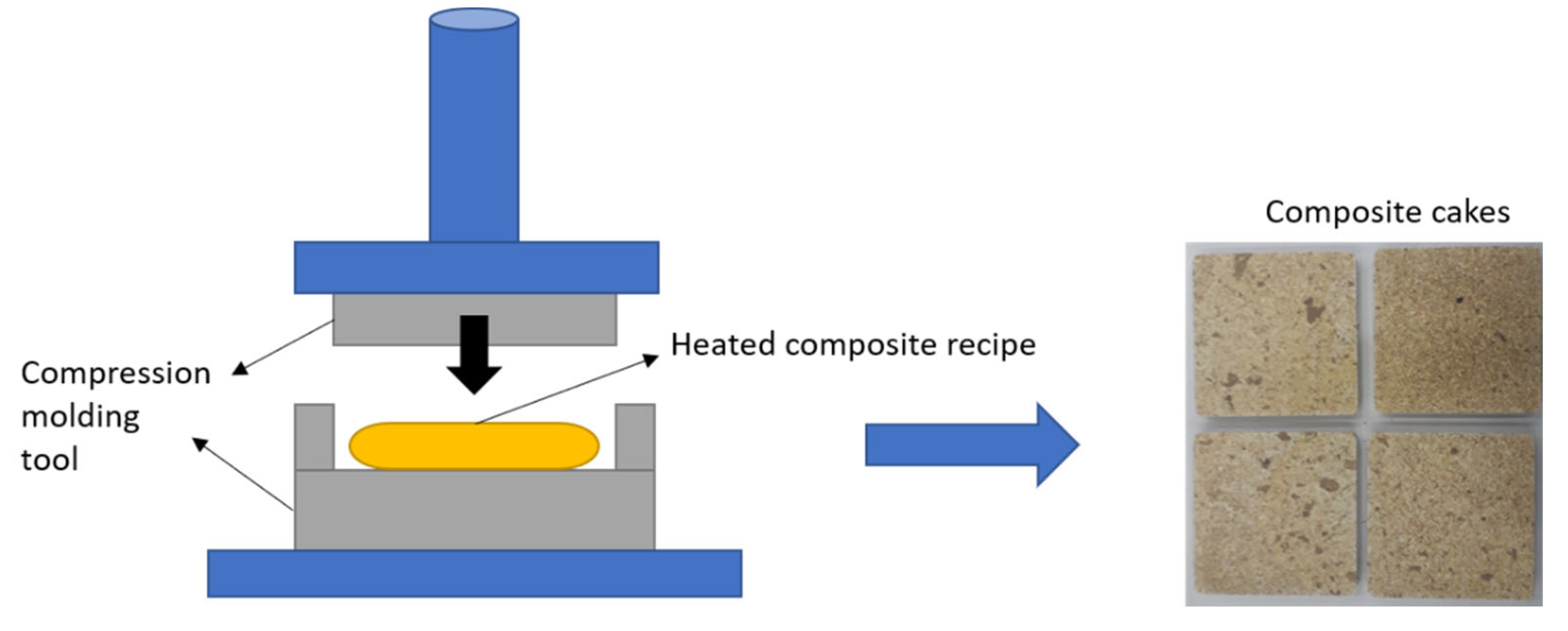

2.3. Composite Preparation

2.4. Mechanical Properties Testing

2.5. Surface Morphology Analysis

2.6. Statistical Analysis

3. Results

3.1. Wood Fiber Composites

3.2. Palmyra Fiber Composites

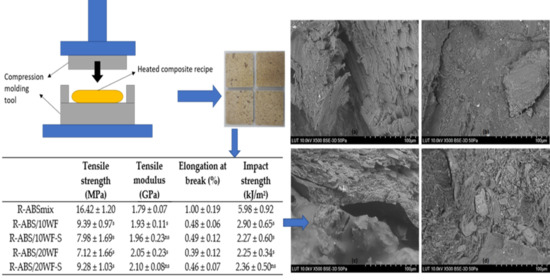

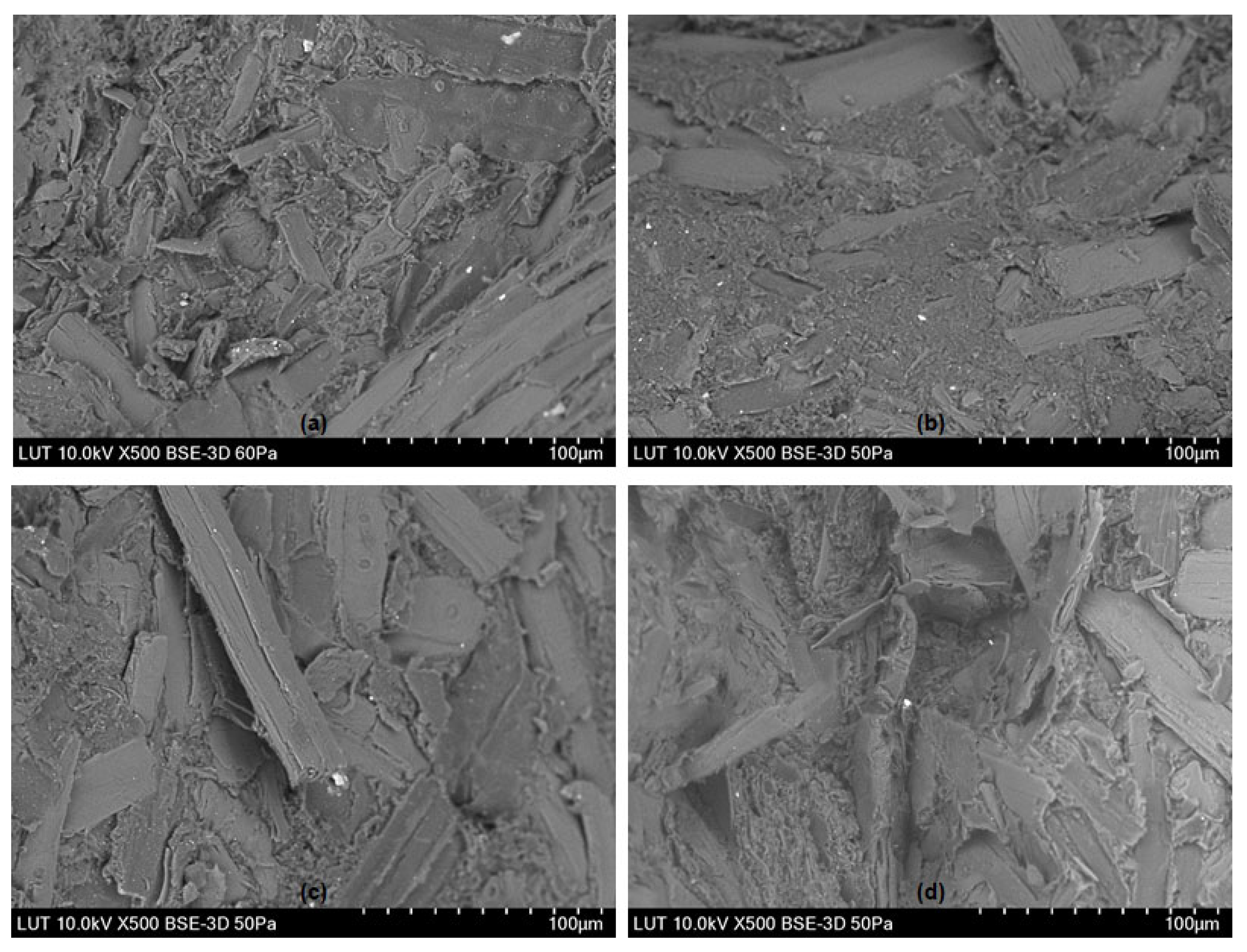

3.3. Morphological Investigations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Sample Availability

References

- Arslan, C.; Dogan, M. The effects of fiber silane modification on the mechanical performance of chopped basalt fiber/ABS composites. J. Thermoplast. Compos. Mater. 2020, 33, 1449–1465. [Google Scholar] [CrossRef]

- Neher, B.; Bhuiyan, M.M.R.; Kabir, H.; Qadir, M.R.; Gafur, M.A.; Ahmed, F. Study of Mechanical and Physical Properties of Palm Fiber Reinforced Acrylonitrile Butadiene Styrene Composite. Mater. Sci. Appl. 2014, 5, 39–45. [Google Scholar] [CrossRef]

- Nikmatin, S.; Syafiuddin, A.; Irwanto, D.A.Y. Properties of Oil Palm Empty Fruit Bunch-Filled Recycled Acrylonitrile Butadiene Styrene Composites: Effect of Shapes and Filler Loadings with Random Orientation. BioResources 2016, 12, 1090–1101. [Google Scholar] [CrossRef]

- Threepopnatkul, P.; Teppinta, W.; Sombatsompop, N. Effect of co-monomer ratio in ABS and wood content on processing and properties in wood/ABS composites. Fibers Polym. 2011, 12, 1007–1013. [Google Scholar] [CrossRef]

- Platt, D.K. Engineering and High Performance Plastics Market Report; Smithers Rapra Technology: Birmingham, UK, 2003. [Google Scholar]

- Margolis, J.M. Engineering Plastics Handbook; McGraw-Hill: New York, NY, USA, 2006; ISBN 9780071457675. [Google Scholar]

- Ma, L.; He, H.; Jiang, C.; Zhou, L.; Luo, Y.; Jia, D. Effect of Alkali Treatment on Structure and Mechanical Properties of Acrylonitrile-Butadiene-Styrene/Bamboo Fiber Composites. J. Macromol. Sci. Part B Phys. 2012, 51, 2232–2244. [Google Scholar] [CrossRef]

- Suryadi, G.S.; Nikmatin, S.; Sudaryanto; Irmansyah; Sukaryo, S.G. Surface free energy analysis of oil palm empty fruit bunches fiber reinforced biocomposites. IOP Conf. Ser. Earth Environ. Sci. 2017, 65, 012044. [Google Scholar] [CrossRef]

- Ashby, M.F. Material profiles. In Materials and the Environment, 2nd ed.; Ashby, M.F., Ed.; Butterworth-Heinemann: Boston, MA, USA, 2013; pp. 459–595. [Google Scholar]

- Naik, T.R.; Singh, S.S.; Huber, C.O.; Brodersen, B.S. Use of post-consumer waste plastics in cement-based composites. Cem. Concr. Res. 1996, 26, 1489–1492. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; AL-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef]

- Marzouk, O.Y.; Dheilly, R.M.; Queneudec, M. Valorization of post-consumer waste plastic in cementitious concrete composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef]

- Kuo, P.-Y.; Wang, S.-Y.; Chen, J.-H.; Hsueh, H.-C.; Tsai, M.-J. Effects of material compositions on the mechanical properties of wood–plastic composites manufactured by injection molding. Mater. Des. 2009, 30, 3489–3496. [Google Scholar] [CrossRef]

- Farsi, M. Thermoplastic Matrix Reinforced with Natural Fibers: A Study on Interfacial Behavior. In Some Critical Issues for Injection Molding; Wang, J., Ed.; IntechOpen: Rijeka, Croatia, 2012; pp. 225–250. [Google Scholar]

- Chotirat, L.; Chaochanchaikul, K.; Sombatsompop, N. On adhesion mechanisms and interfacial strength in acrylonitrile–butadiene–styrene/wood sawdust composites. Int. J. Adhes. Adhes. 2007, 27, 669–678. [Google Scholar] [CrossRef]

- Kimchiang, P.; Threepopnatkul, P.; Sombatsompop, N. Influence of Functionalized silanes on Mechanical Properties of Wood Sawdust Reinforced ABS Composites. In Proceedings of the Processing and Fabrication of Advanced Materials XIX, Auckland, New Zealand, 14–17 January 2011; pp. 998–1005. [Google Scholar]

- Threepopnatkul, P.; Krachang, T.; Teerawattananon, W.; Suriyaphaparkorn, K.; Kulsetthanchalee, C. Study of surface treatment of pineapple leaf fiber (PALF) on performance of PALF/ABS composites. In Proceedings of the 15th European Conference on Composite Materials, Venice, Italy, 24–28 June 2012; pp. 1–7. [Google Scholar]

- Anandjiwala, R.D.; Blouw, S. Composites from bast fibres-Prospects and potential in the changing market environment. J. Nat. Fibers 2007, 4, 91–901. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. J. Miner. Met. Mater. Soc. 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Yeh, S.K.; Agarwal, S.; Gupta, R.K. Wood-plastic composites formulated with virgin and recycled ABS. Compos. Sci. Technol. 2009, 69, 2225–2230. [Google Scholar] [CrossRef]

- Liang, R.; Gupta, R.K. The effect of residual impurities on the rheological and mechanical properties of engineering polymers separated from mixed plastics. In Proceedings of the SPE 59th Annual Technical Conference, Dallas, TX, USA, 6–10 May 2001; pp. 2753–2757. [Google Scholar]

- Liang, R.; Gupta, R.K. Processing and characterization of recycled PC/ABS blends with high recycle content. In Proceedings of the SPE 60th Annual Technical Conference, San Francisco, CA, USA, 10–15 June 2002; pp. 2948–2952. [Google Scholar]

- Chauhan, V.; Kärki, T.; Varis, J. Review of natural fiber-reinforced engineering plastic composites, their applications in the transportation sector and processing techniques. J. Thermoplast. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- Thiruchitrambalam, M.; Logesh, M.; Shanmugam, D.; Muthukumar, S. The physical, chemical properties of untreated and chemically treated palmyra palm leaf fibres. Int. J. Eng. Technol. 2018, 7, 582–585. [Google Scholar]

- Nwabanne, J.; Igbokwe, P.; Ezeonyebuchi, E. Effect of palmyra palm fiber filler on properties of natural rubber vulcanizate. World J. Eng. 2014, 11, 565–574. [Google Scholar] [CrossRef]

- Reddy, K.O.R.; Maheswari, C.U.; Reddy, K.O.R.; Shukla, M.; Muzenda, E.; Rajulu, A.V. Effect of Chemical Treatment and Fiber Loading on Mechanical Properties of Borassus (Toddy Palm) Fiber/Epoxy Composites. Int. J. Polym. Anal. Charact. 2015, 20, 612. [Google Scholar] [CrossRef]

- Räisänen, T.; Athanassiadis, D. Basic Chemical Composition of the Biomass Components of Pine, Spruce and Birch. Available online: http://www.biofuelregion.se/UserFiles/file/Forest%20Refine/1_2_IS_2013-01-31_Basic_chemical_composition.pdf (accessed on 25 October 2021).

- Wang, Q.; Zhang, Y.; Liang, W.; Wang, J.; Chen, Y. Effect of silane treatment on mechanical properties and thermal behavior of bamboo fibers reinforced polypropylene composites. J. Eng. Fiber. Fabr. 2020, 15, 1558925020958195. [Google Scholar] [CrossRef]

- Rehman, M.M.; Zeeshan, M.; Shaker, K.; Nawab, Y. Effect of micro-crystalline cellulose particles on mechanical properties of alkaline treated jute fabric reinforced green epoxy composite. Cellulose 2019, 26, 9057–9069. [Google Scholar] [CrossRef]

- Bledzki, A.; Al-Mamun, D.A.; Lucka-Gabor, M.M.; Gutowski, V. The effects of acetylation on properties of flax fibre and its polypropylene composites. eXPRESS Polym. Lett. 2008, 2, 413–422. [Google Scholar] [CrossRef]

- De Prez, J.; Van Vuure, A.W.; Ivens, J.; Aerts, G.; Van de Voorde, I. Enzymatic treatment of flax for use in composites. Biotechnol. Rep. (Amst. Neth.) 2018, 20, e00294. [Google Scholar] [CrossRef] [PubMed]

- Uehara, T.; Sakata, I. Effect of corona discharge treatment on cellulose prepared from beech wood. J. Appl. Polym. Sci. 1990, 41, 1695–1706. [Google Scholar] [CrossRef]

- Sèbe, G.; Brook, M.A. Hydrophobization of wood surfaces: Covalent grafting of silicone polymers. Wood Sci. Technol. 2001, 35, 269–282. [Google Scholar] [CrossRef]

- Ali, A.; Shaker, K.; Nawab, Y.; Jabbar, M.; Hussain, T.; Militky, J.; Baheti, V. Hydrophobic treatment of natural fibers and their composites—A review. J. Ind. Text. 2016, 47, 2153–2183. [Google Scholar] [CrossRef]

- Väntsi, O.; Kärki, T. Different coupling agents in wood-polypropylene composites containing recycled mineral wool: A comparison of the effects. J. Reinf. Plast. Compos. 2015, 34, 879–895. [Google Scholar] [CrossRef]

- Orue, A.; Jauregi, A.; Unsuain, U.; Labidi, J.; Eceiza, A.; Arbelaiz, A. The effect of alkaline and silane treatments on mechanical properties and breakage of sisal fibers and poly(lactic acid)/sisal fiber composites. Compos. Part A Appl. Sci. Manuf. 2016, 84, 186–195. [Google Scholar] [CrossRef]

- Neher, B.; Nova, N.; Hossain, R.; Gafur, M.; Ahmed, F. Fabrication and Characterization on Physico-Mechanical and Structural Properties of Sawdust Reinforced Acrylonitrile Butadiene Styrene (ABS) Composites. Mater. Sci. Appl. 2020, 11, 644–658. [Google Scholar] [CrossRef]

- Martins, J.N.; Klohn, T.G.; Bianchi, O.; Fiorio, R.; Freire, E. Dynamic mechanical, thermal, and morphological study of ABS/textile fiber composites. Polym. Bull. 2010, 64, 497–510. [Google Scholar] [CrossRef]

- Demir, H.; Atikler, U.; Balköse, D.; Tihminlioǧlu, F. The effect of fiber surface treatments on the tensile and water sorption properties of polypropylene–luffa fiber composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 447–456. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Velmurugan, R.; Manikandan, V. Mechanical properties of palmyra/glass fiber hybrid composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2216–2226. [Google Scholar] [CrossRef]

- Kim, T.-W.; Lee, S.-Y.; Chun, S.-J.; Doh, G.-H.; Paik, K.-H. Effect of silane coupling on the fundamental properties of wood flour reinforced polypropylene composites. J. Compos. Mater. 2011, 45, 1595–1605. [Google Scholar] [CrossRef]

- Lv, S.; Tan, H.; Gu, J.; Zhang, Y. Silane Modified Wood Flour Blended with Poly(lactic acid) and its Effects on Composite Performance. BioResources 2015, 10, 5426–5439. [Google Scholar] [CrossRef]

- Zhou, L.; Guo, C.; Li, L. Influence of ammonium polyphosphate modified with 3-(methylacryloxyl) propyltrimethoxy silane on mechanical and thermal properties of wood flour–polypropylene composites. J. Appl. Polym. Sci. 2011, 122, 849–855. [Google Scholar] [CrossRef]

- Raj, R.G.; Kokta, B.V.; Daneault, C. Polypropylene-Wood Fiber Composites: Effect of Fiber Treatment on Mechanical Properties. Int. J. Polym. Mater. Polym. Biomater. 1989, 12, 239–250. [Google Scholar] [CrossRef]

- Eng, C.C.; Ibrahim, N.; Zainuddin, N.; Ariffin, H.; Yunus, W. Chemical Modification of Oil Palm Mesocarp Fiber by Methacrylate Silane: Effects on Morphology, Mechanical, and Dynamic Mechanical Properties of Biodegradable Hybrid Composites. Bioresources 2015, 11, 861–872. [Google Scholar] [CrossRef]

- Srinivasababu, N.; Kumar, J.S.; Reddy, K.V.K. Mechanical and Dielectric Properties of PTSL FRP Composites. Adv. Mater. Res. 2012, 585, 311–316. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Jawaid, M.; Ishak, M.R.; Sapuan, S.M.; Sapuan, S.M. Effect of Alkali and Silane Treatments on Mechanical and Interfacial Bonding Strength of Sugar Palm Fibers with Thermoplastic Polyurethane. J. Nat. Fibers 2018, 15, 251–261. [Google Scholar] [CrossRef]

- Abu Bakar, A.; Hassan, A.; Mohd Yusof, A.F. Mechanical Properties of Silane and Zirconate Coupling Agent-Treated Oil Palm Empty Fruit Bunch Fiber-Filled Acrylic-Impact Modified Poly (Vinyl Chloride) Composites. Polym. Plast. Technol. Eng. 2010, 49, 1563–1570. [Google Scholar] [CrossRef]

- Nnaemeka, A.A.; Kamardeen, A.O. Effect of Silane Treatment on the Impact Strength Properties of Oil Palm Empty Fruit Bunch Fiber-Reinforced Polyester Composites. World J. Eng. Pure Appl. Sci. 2011, 1, 40. [Google Scholar]

| Spruce [27] | Palmyra [24] | |

|---|---|---|

| Cellulose (%) | 42.00 | 58.58 |

| Hemicellulose (%) | 27.30 | 22.80 |

| Lignin (%) | 27.40 | 13.48 |

| Extractives and Wax (%) | 2.00 | 0.53 |

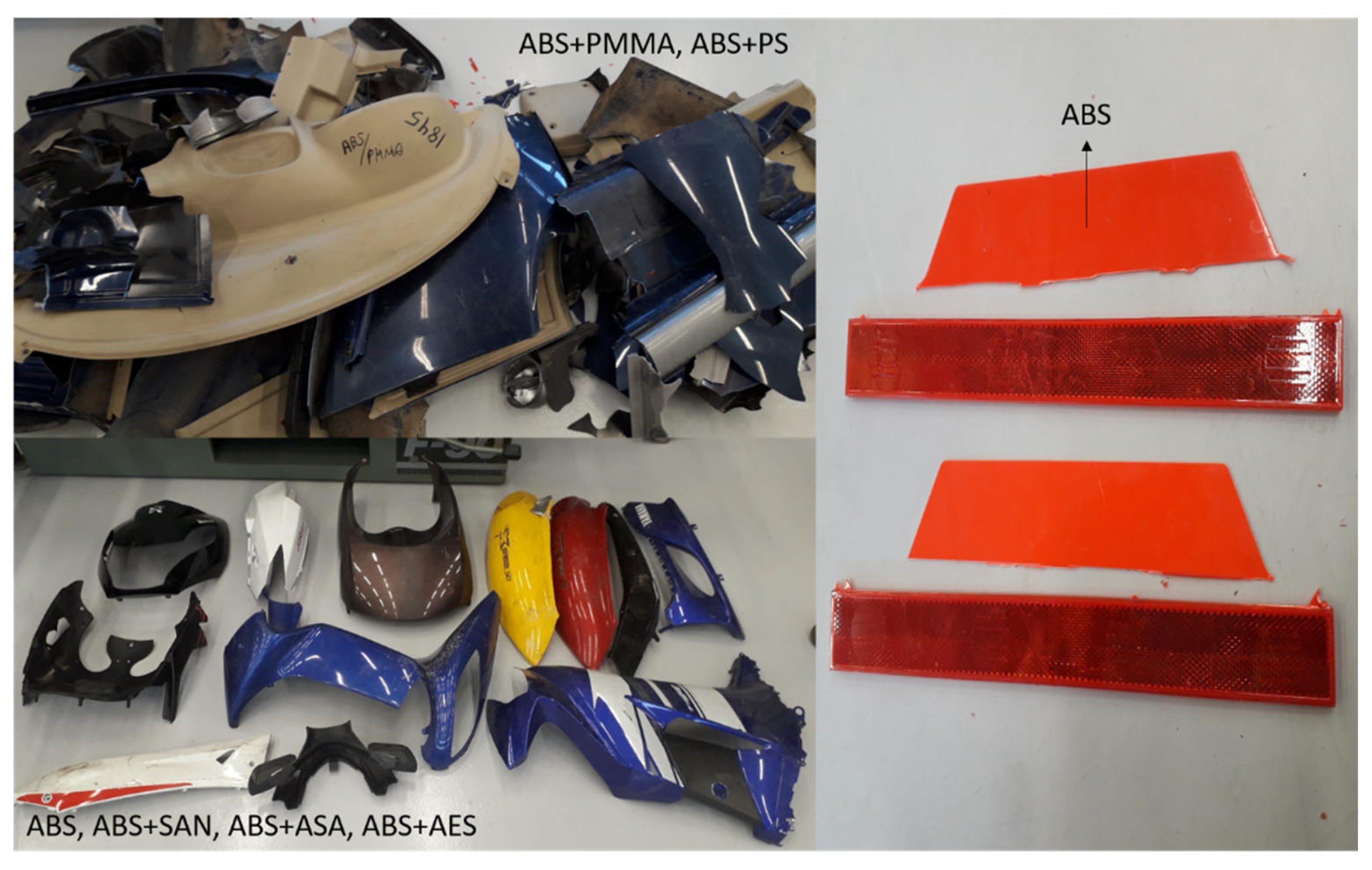

| Polymer Type | Weight (kg) | Composition (%) |

|---|---|---|

| ABS | 63.47 | 80.77 |

| ABS + SAN | 1.38 | 1.75 |

| ABS + ASA | 3.62 | 4.61 |

| ABS + AES | 1.25 | 1.59 |

| ABS + PMMA | 6.04 | 7.69 |

| ABS + PS | 2.82 | 3.59 |

| Total | 78.58 |

| Designation | Fiber | Polymer (%) | Fiber (%) | Lubricant (%) | Silane (%) | Density (kg/m3) |

|---|---|---|---|---|---|---|

| R-ABS/10WF | Wood | 87 | 10 | 3 | - | 1067 |

| R-ABS/10WF-S | Wood | 84 | 10 | 3 | 3 | 1079 |

| R-ABS/20WF | Wood | 77 | 20 | 3 | - | 1074 |

| R-ABS/20WF-S | Wood | 74 | 20 | 3 | 3 | 1083 |

| R-ABS/10PF | Palmyra | 87 | 10 | 3 | - | 1082 |

| R-ABS/10PF-S | Palmyra | 84 | 10 | 3 | 3 | 1068 |

| R-ABS/20PF | Palmyra | 77 | 20 | 3 | - | 1067 |

| R-ABS/20PF-S | Palmyra | 74 | 20 | 3 | 3 | 1087 |

| Tensile Strength (MPa) | Tensile Modulus (GPa) | Elongation at Break (%) | Impact Strength (kJ/m2) | |

|---|---|---|---|---|

| R-ABSmix | 16.42 ± 1.20 | 1.79 ± 0.07 | 1.00 ± 0.19 | 5.98 ± 0.92 |

| R-ABS/10WF | 9.39 ± 0.97 s | 1.93 ± 0.11 s | 0.48 ± 0.06 | 2.90 ± 0.65 s |

| R-ABS/10WF-S | 7.98 ± 1.69 s | 1.96 ± 0.23 ns | 0.49 ± 0.12 | 2.27 ± 0.60 s |

| R-ABS/20WF | 7.12 ± 1.66 s | 2.05 ± 0.23 s | 0.39 ± 0.12 | 2.25 ± 0.34 s |

| R-ABS/20WF-S | 9.28 ± 1.03 s | 2.10 ± 0.08 ns | 0.46 ± 0.07 | 2.36 ± 0.50 ns |

| Tensile Strength (MPa) | Tensile Modulus (GPa) | Elongation at Break (%) | Impact Strength (kJ/m2) | |

|---|---|---|---|---|

| R-ABSmix | 16.42 ± 1.20 | 1.79 ± 0.07 | 1.00 ± 0.19 | 5.98 ± 0.92 |

| R-ABS/10PF | 6.26 ± 1.97 s | 1.82 ± 0.34 ns | 0.41 ± 0.12 | 2.27 ± 0.52 s |

| R-ABS/10PF-S | 10.04 ± 2.79 s | 1.92 ± 0.12 ns | 0.76 ± 0.20 | 3.12 ± 0.87 s |

| R-ABS/20PF | 6.04 ± 1.83 s | 1.88 ± 0.13 ns | 0.48 ± 0.27 | 2.41 ± 0.67 s |

| R-ABS/20PF-S | 8.55 ± 0.74 s | 2.00 ± 0.10 ns | 0.52 ± 0.13 | 2.47 ± 0.63 ns |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chauhan, V.; Kärki, T.; Varis, J. Effect of Fiber Content and Silane Treatment on the Mechanical Properties of Recycled Acrylonitrile-Butadiene-Styrene Fiber Composites. Chemistry 2021, 3, 1258-1270. https://doi.org/10.3390/chemistry3040091

Chauhan V, Kärki T, Varis J. Effect of Fiber Content and Silane Treatment on the Mechanical Properties of Recycled Acrylonitrile-Butadiene-Styrene Fiber Composites. Chemistry. 2021; 3(4):1258-1270. https://doi.org/10.3390/chemistry3040091

Chicago/Turabian StyleChauhan, Vardaan, Timo Kärki, and Juha Varis. 2021. "Effect of Fiber Content and Silane Treatment on the Mechanical Properties of Recycled Acrylonitrile-Butadiene-Styrene Fiber Composites" Chemistry 3, no. 4: 1258-1270. https://doi.org/10.3390/chemistry3040091

APA StyleChauhan, V., Kärki, T., & Varis, J. (2021). Effect of Fiber Content and Silane Treatment on the Mechanical Properties of Recycled Acrylonitrile-Butadiene-Styrene Fiber Composites. Chemistry, 3(4), 1258-1270. https://doi.org/10.3390/chemistry3040091