Hybrid Digital Twin for Phytotron Microclimate Control: Integrating Physics-Based Modeling and IoT Sensor Networks

Abstract

1. Introduction

- Physical level—sensors, actuators and IoT devices;

- Communication level—protocols and interfaces for data transmission;

- Digital level—virtual representation of the farm;

- Analytical level—algorithms and models for data processing;

- Application level—user interfaces and decision support tools.

- Physical modeling—mathematical models that simulate environmental dynamics, plant growth, and resource flows based on established scientific principles;

- Agent-based modeling—simulations where individual components are represented as autonomous agents;

- Discrete-event simulation: models representing system changes at discrete time moments;

- Hybrid approaches: combinations of several modeling methods.

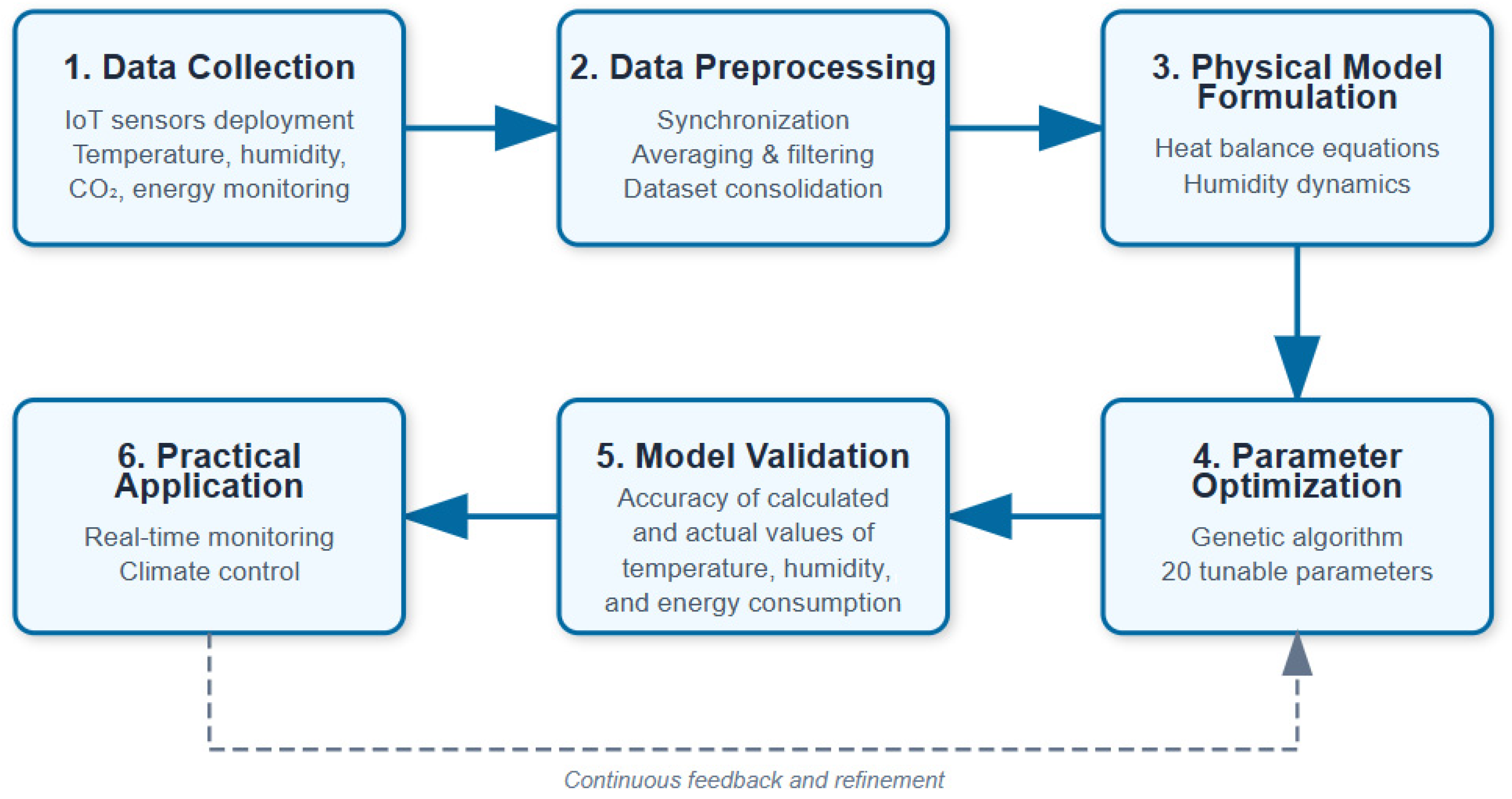

2. Materials and Methods

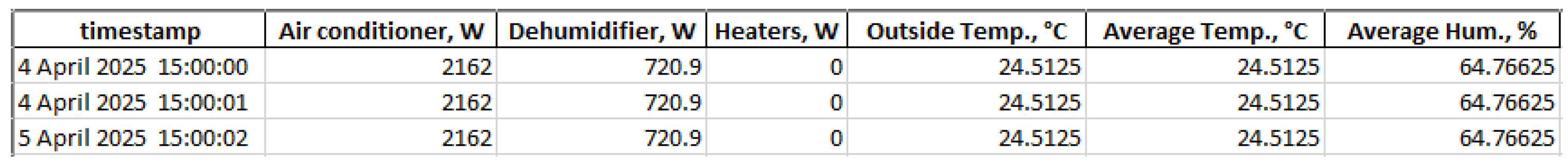

2.1. Basic Equations of the Microclimate Model in the Phytotron

- Selection, in which the fittest individuals are retained based on the objective function;

- Crossover, which recombines parameter values from selected individuals;

- Mutation, which introduces random variations to maintain diversity and avoid premature convergence.

- Thermophysical parameters:

- Conditional vapor coefficient—determines the effective thermal mass of water in the system;

- External heat-loss coefficient—governs heat transfer through the enclosing structures.

- Temperature parameters:

- Daytime temperature setpoint—target temperature during daytime;

- Nighttime temperature setpoint—target system temperature during nighttime.

- Air-conditioning parameters:

- Base COP for cooling of the air conditioner—efficiency of the unit in cooling mode;

- Base COP for heating of the air conditioner—efficiency of the unit in heating mode;

- Air-conditioner control coefficient—governs the response of the unit to deviations from the setpoint.

- Humidity parameters:

- Air-conditioner dehumidification coefficient—effect of the air conditioner on reducing humidity;

- Baseline plant transpiration rate—intensity of moisture release by the plants;

- Dehumidifier capacity—dehumidification efficiency per unit of power;

- Humidity setpoint for the air conditioner—target relative humidity level.

- Heater parameters:

- Heater efficiency—effectiveness of converting electrical energy into heat;

- Heater control adjustment coefficient—governs the heater’s response to deviations from the setpoint.

- Diurnal cycle parameters:

- Transpiration cycle amplitude—variation in plant transpiration intensity over a 24 h period;

- Transpiration cycle phase shift—phase offset of the transpiration cycle relative to the lighting cycle;

- Transpiration cycle duration—length of the transpiration variation cycle.

- External influence parameters:

- External temperature influence coefficient—degree to which changes in external temperature affect the system;

- Time delay of external temperature influence—lag in the effect of external temperature changes;

- Dependence of AC COP on external temperature (cooling)—variation in cooling efficiency with ambient temperature;

- Dependence of AC COP on external temperature (heating)—variation in heating efficiency with ambient temperature.

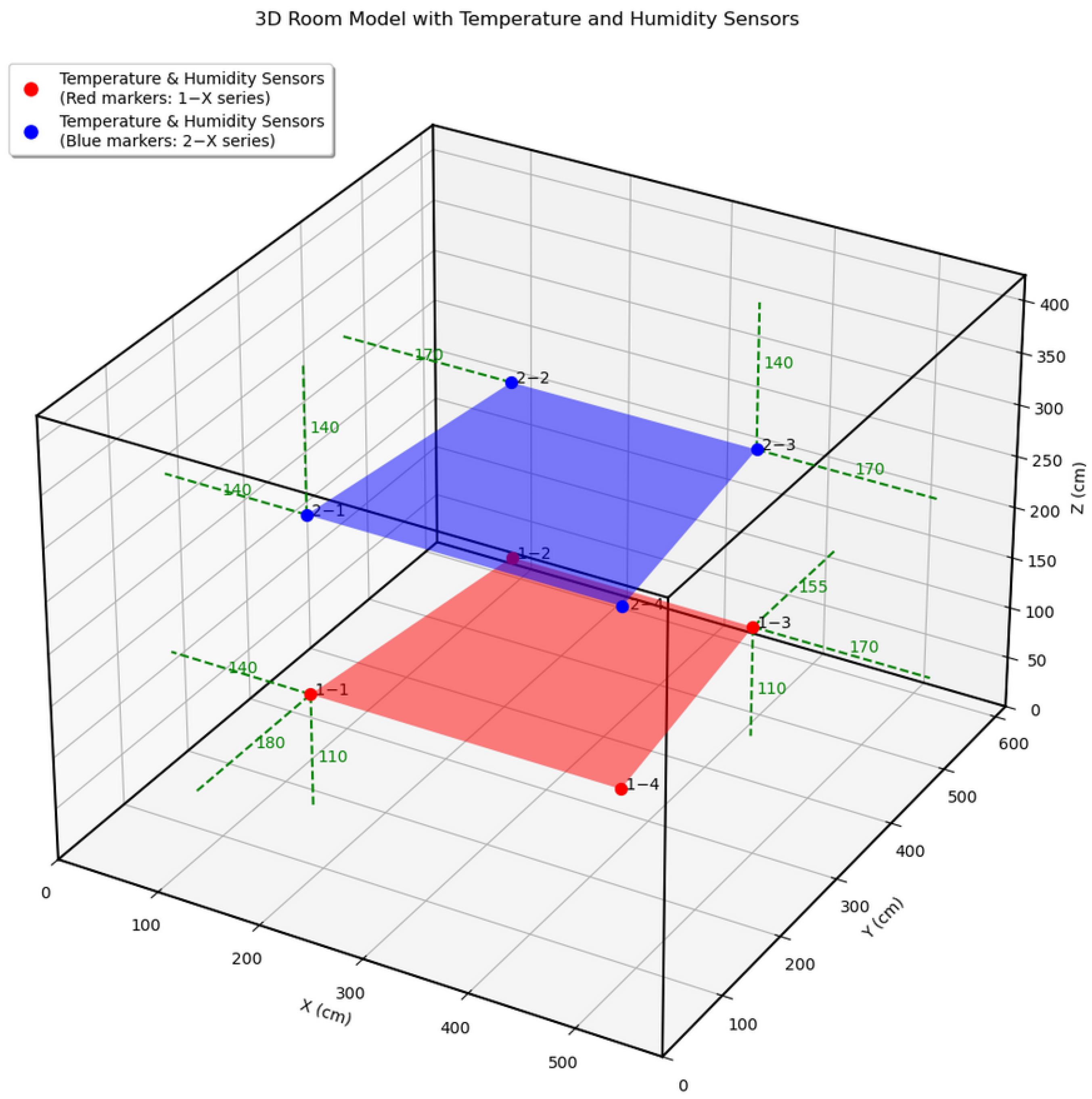

- Requirements, risks, and constraints of the microclimate monitoring system

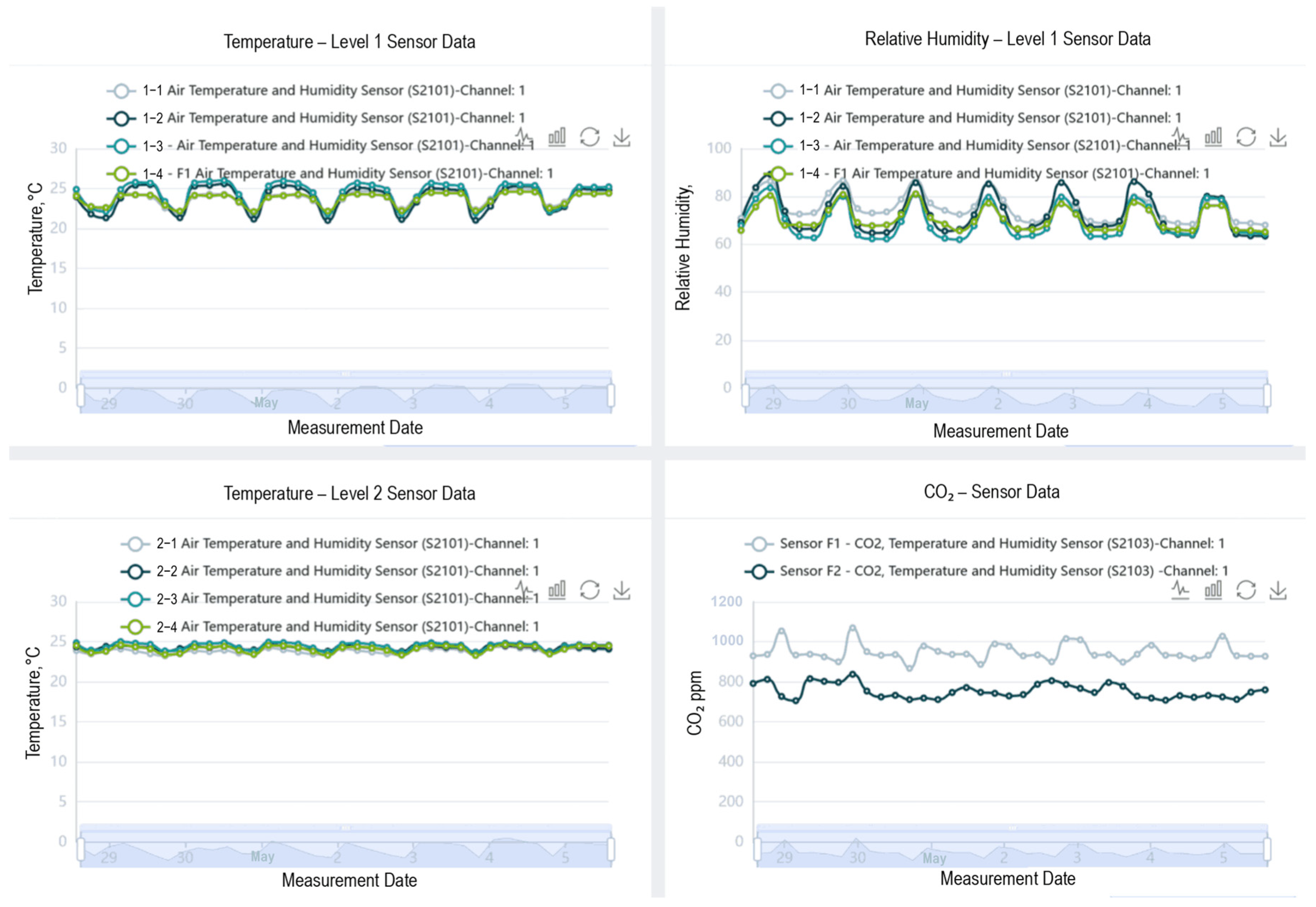

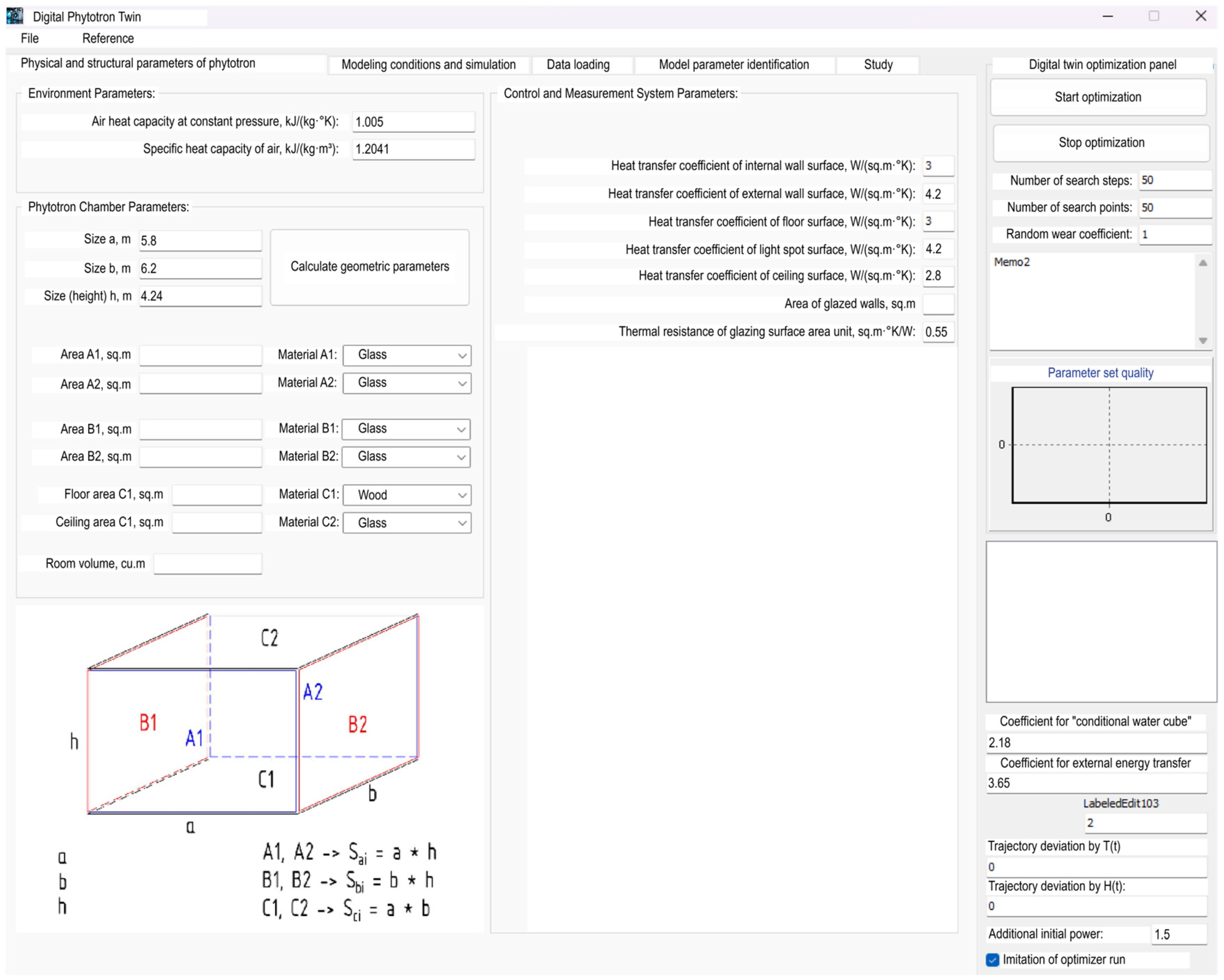

- Temperature and relative humidity at eight equidistant locations inside the chamber;

- CO2 concentration at a single air intake point within the chamber;

- Ambient temperature and humidity outside the chamber;

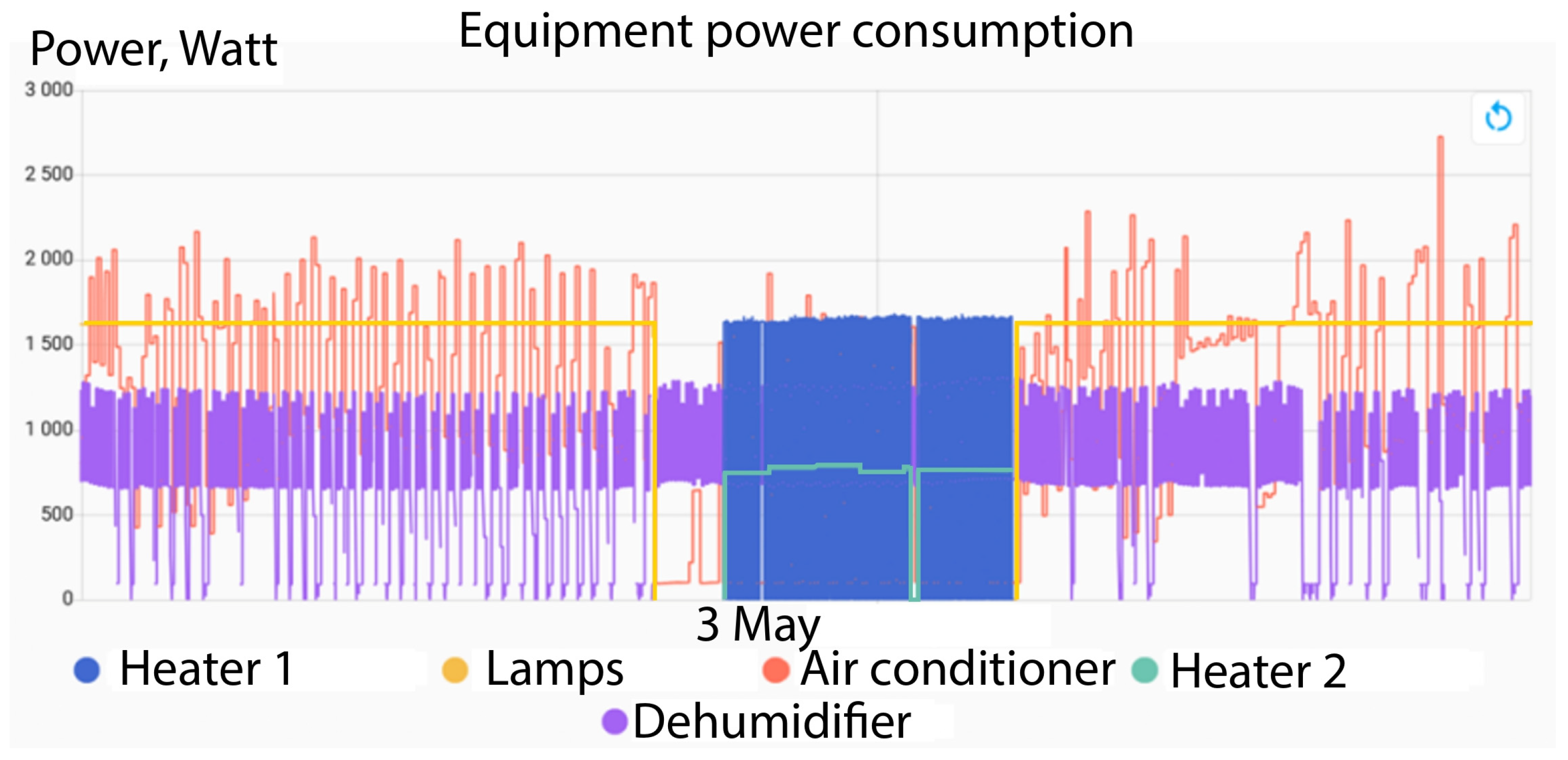

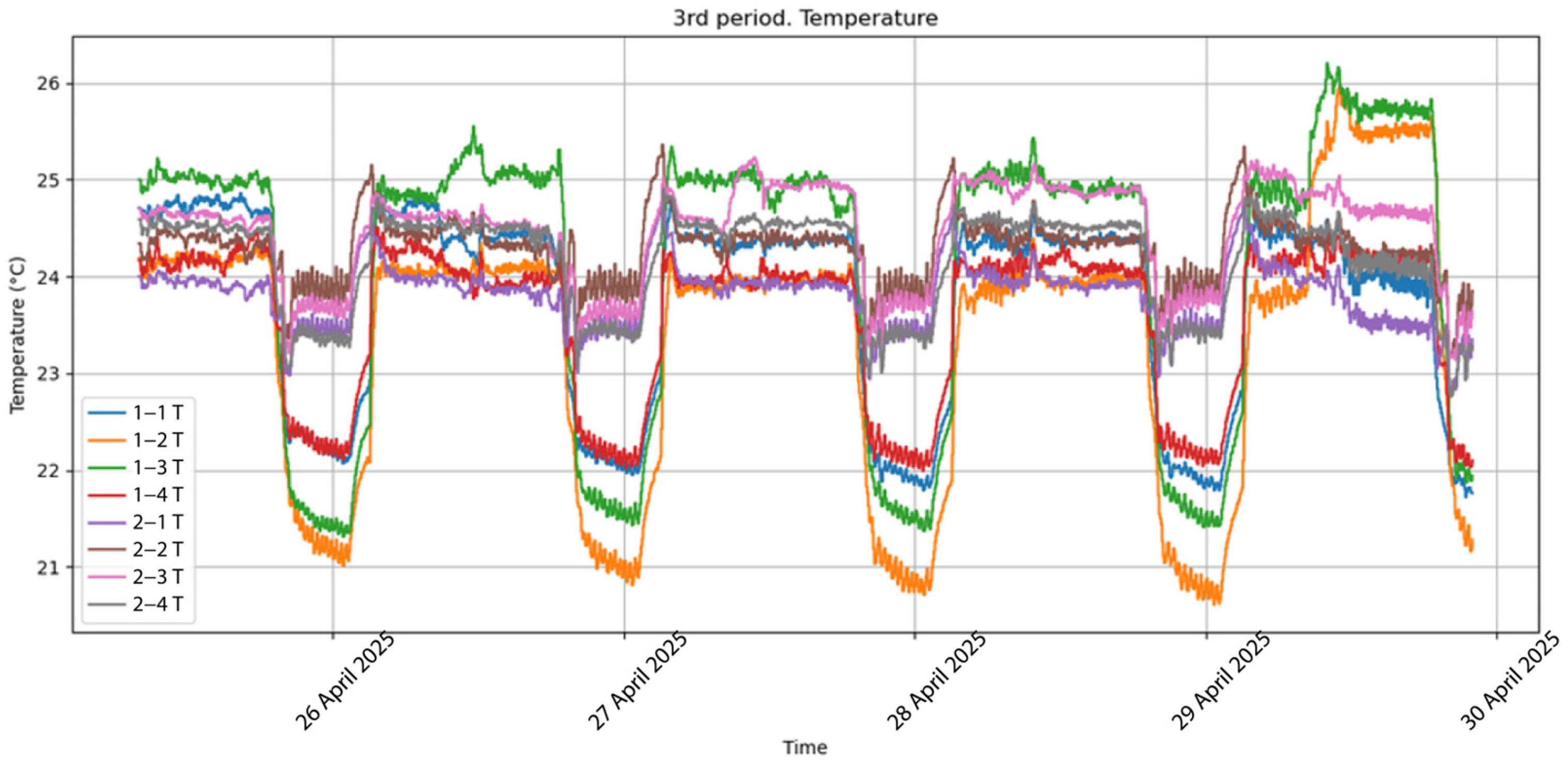

- Electrical energy consumption of the phytotron equipment.

- Air-conditioning system used to regulate temperature, humidity, and air quality;

- Electric heater and convector, primarily used for temperature control in the evening;

- Air dehumidifier for humidity control;

- Grow-light lamps, which generate substantial heat and therefore directly influence temperature and humidity.

- Deployment within the phytotron without altering plant-growth processes, microclimatic dynamics, or equipment operation;

- Automatic, synchronized acquisition of temperature, humidity, and equipment energy use data at specified time points without human intervention;

- Unlimited retention of collected data;

- Export of data in a format suitable for downstream processing.

- User-friendly interface for system monitoring and inspection of recorded parameters at defined intervals;

- Rapid and straightforward deployment of the data-acquisition system;

- Scalability to support deployment in facilities of varying sizes.

- Sensors for data collection;

- Server for storage and processing of received data.

- Desynchronization of sensor data intervals. To address this, interpolation may be applied to align data to fixed time points. However, interpolation can introduce modeling inaccuracies, which may necessitate shortening the interval between sampling points.

- Inaccuracy of acquired data. Mitigation requires using precise, calibrated sensors, applying real-time data filtering, and rejecting measurements outside acceptable bounds.

- Data loss during certain periods. Outages caused by factors unrelated to the data-collection system (e.g., power failures) or partial/full system downtime due to component failure or lost sensor connectivity. The usual remedy is to exclude these periods from model-building datasets.

- The phytotron is assumed to be a turnkey plant-growth facility, where modifying existing hardware or processes is impractical.

- Access to phytotron equipment is limited, imposing a requirement that the monitoring system be non-intrusive and entirely independent of the plant-growth infrastructure.

- Use of Wi-Fi or Zigbee sensors with manufacturer-provided cloud services. The main drawback of this approach is the inability to perform full data acquisition and export the raw measurements needed for model development. Most sensor vendors limit their platforms to real-time monitoring dashboards and do not offer functionality for downstream data processing.

- Use of LoRaWAN technology with professional-grade sensors. This approach is well suited to our system, since vendors typically provide extensive tooling for data control, processing, and export, perfectly matching our needs. The primary disadvantage is the higher capital cost associated with more specialized industrial hardware.

- Use of off-the-shelf sensors combined with third-party software rather than vendor platforms. A number of open-source and commercial applications can replace or extend the functionality offered by sensor manufacturers. For example, Home Assistant is a popular IoT automation platform that can ingest data from inexpensive consumer devices and provide advanced data-processing workflows. The trade-offs are a steeper learning curve and potentially lower reliability or usability, since these software solutions are not officially supported by the hardware vendors.

2.2. Architecture of the Phytotron Microclimate Data-Acquisition System Using SenseCAP LoRaWAN

- SenseCAP S2101-LoRaWAN® Air temperature and humidity sensor. A battery-powered, IP66-rated wireless air-temperature and humidity sensor with a measurement range of −40 °C to 85 °C and 0–100% RH. It features built-in Bluetooth and supports Over-the-Air configuration and remote management via a mobile app. Commonly used in Smart Farming, Smart Yard, and Smart City deployments.

- SenseCAP S2103 LoRaWAN® CO2, temperature, and humidity sensor. A battery-powered, IP66-rated wireless sensor for CO2 (400–10,000 ppm), air temperature (−40 °C to 85 °C), and relative humidity (0–100%).

- SenseCAP Outdoor gateway. The central LoRaWAN® gateway for the SenseCAP network, which aggregates data from multiple SenseCAP sensors and forwards it to the cloud platform via LTE or Ethernet. Designed for high reliability and performance in large-scale deployments, it employs mutual authentication and AES encryption across the network. The IP66-rated enclosure and extended operating temperature range make it suitable for industrial use. Internally, it combines a Cortex-A8 1 GHz processor with an SX1301 LoRa® concentrator chip. It supports EU868, US915, CN470, and other regional frequency plans at up to +27 dBm output power.

- SenseCAP S2120 8-in-1 LoRaWAN Weather sensor. A compact weather station that measures air temperature, humidity, wind speed and direction, rainfall intensity, ambient light intensity, UV index, and barometric pressure. Suitable for horticulture, agriculture, meteorology, urban environmental monitoring, and other applications. Low maintenance is ensured by its ultra-low power consumption, reliable operation, and built-in Bluetooth for Over-the-Air configuration and remote management.

2.3. System for Energy Consumption Data Acquisition Using Smart-Home Sensors and Home Assistant

- Tuya smart plugs into which the dehumidifier, convector, and electric heater are connected. These plugs include built-in power-measurement sensors.

- Taxnele TVPS1-63FW multifunction smart voltage relays (Yueqing Taixin Electric Co., Ltd., Yueqing, Zhejiang Province, China), inserted in the circuits of the air conditioner and the grow-light lamps.

- Orange Pi 5 Ultra—a single-board computer (Shenzhen Xunlong Software Co., Ltd., Shenzhen, China) running Home Assistant software OS 11.0, which handles data collection and storage. The board is based on the Rockchip RK3588, featuring eight cores (four Cortex-A76 at 2.4 GHz and four Cortex-A55 at 1.8 GHz) and 64 GB of eMMC storage. This configuration delivers high performance and sufficient network throughput for the task. Home Assistant is deployed via Docker on the Orange Pi, which ingests data from the smart plugs and relays and stores it locally; no cloud services are used.

2.4. Data Analysis and Software Development Approach

3. Results and Discussion

3.1. Object of Modeling

3.2. Monitoring System

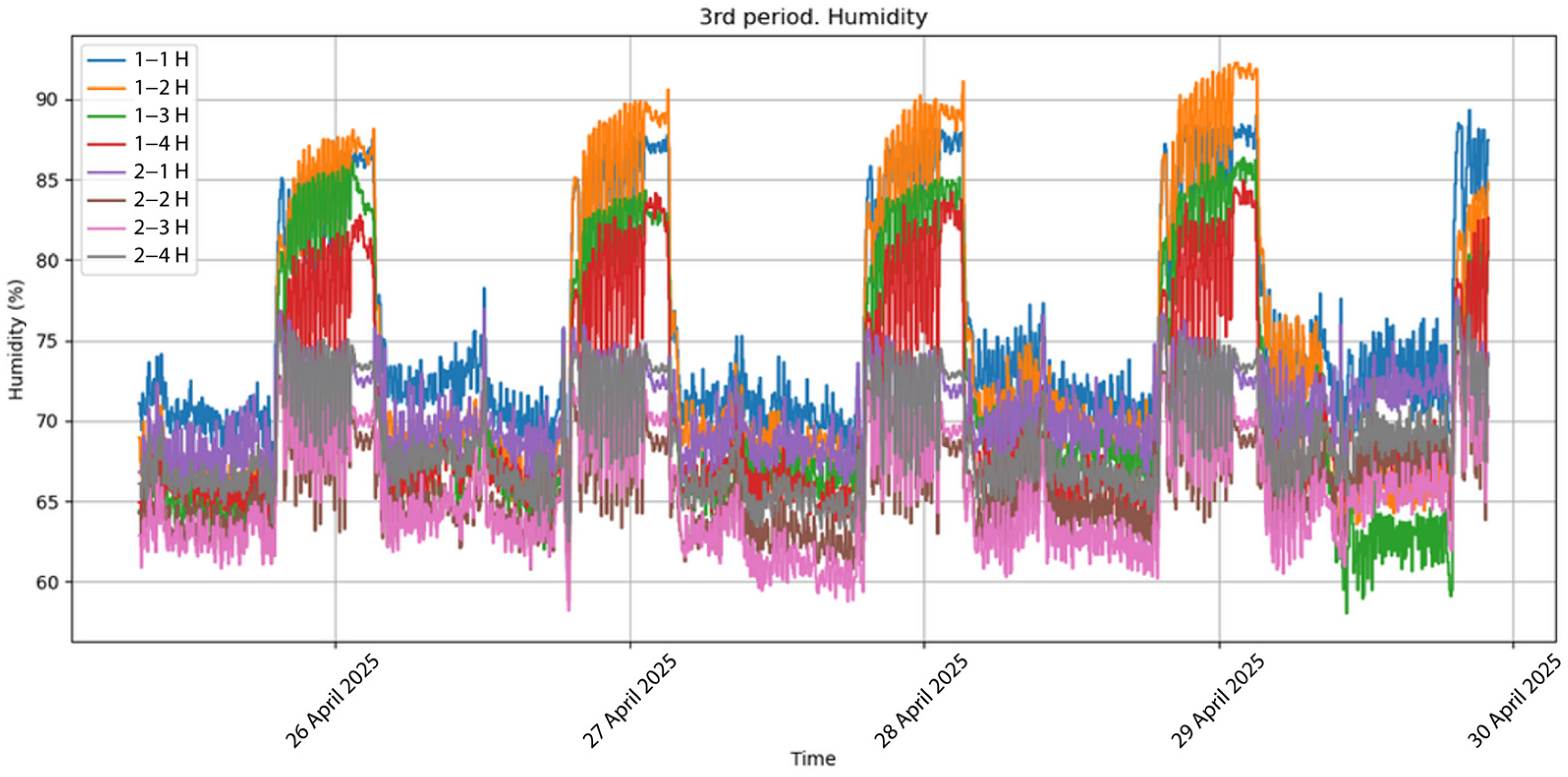

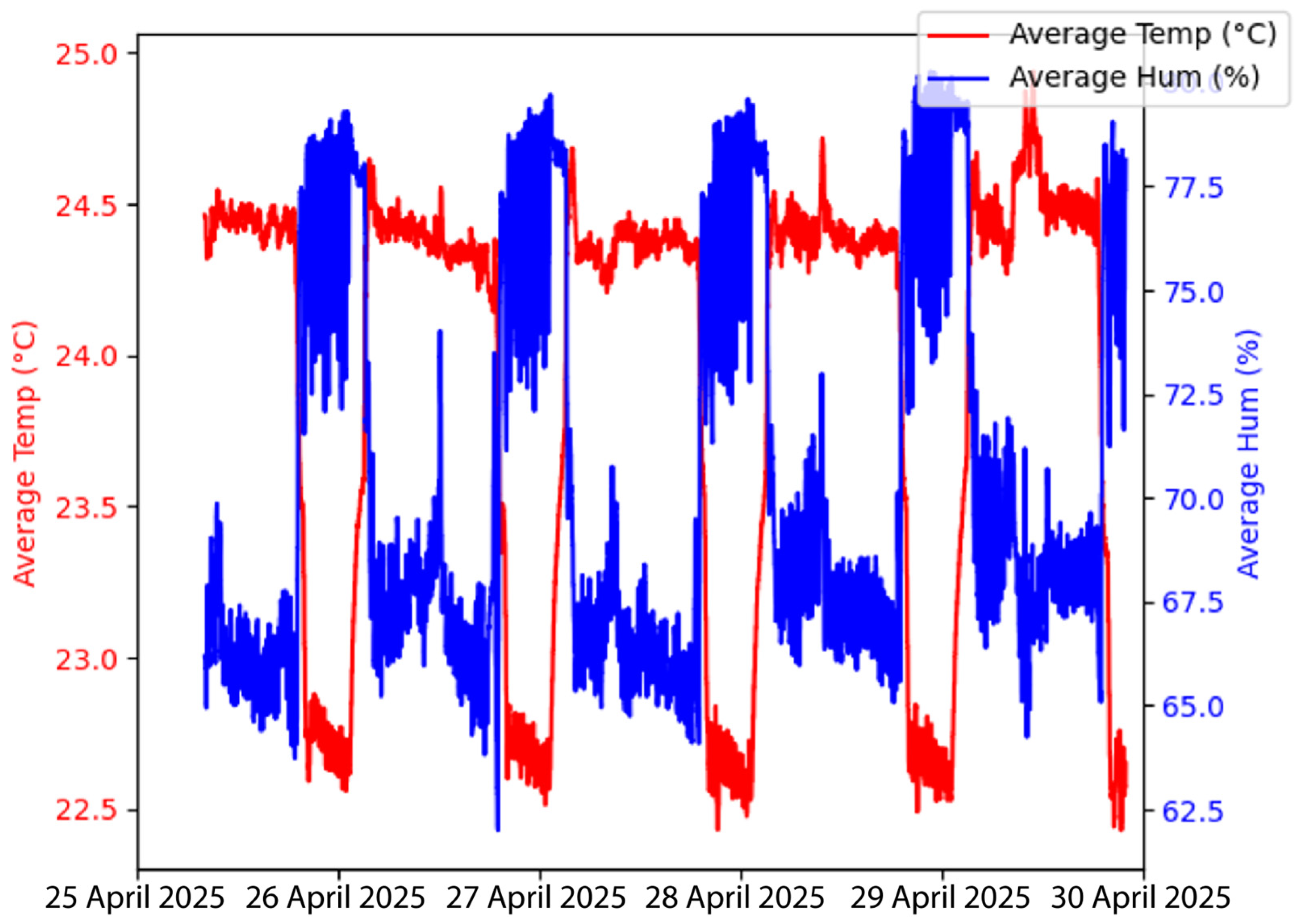

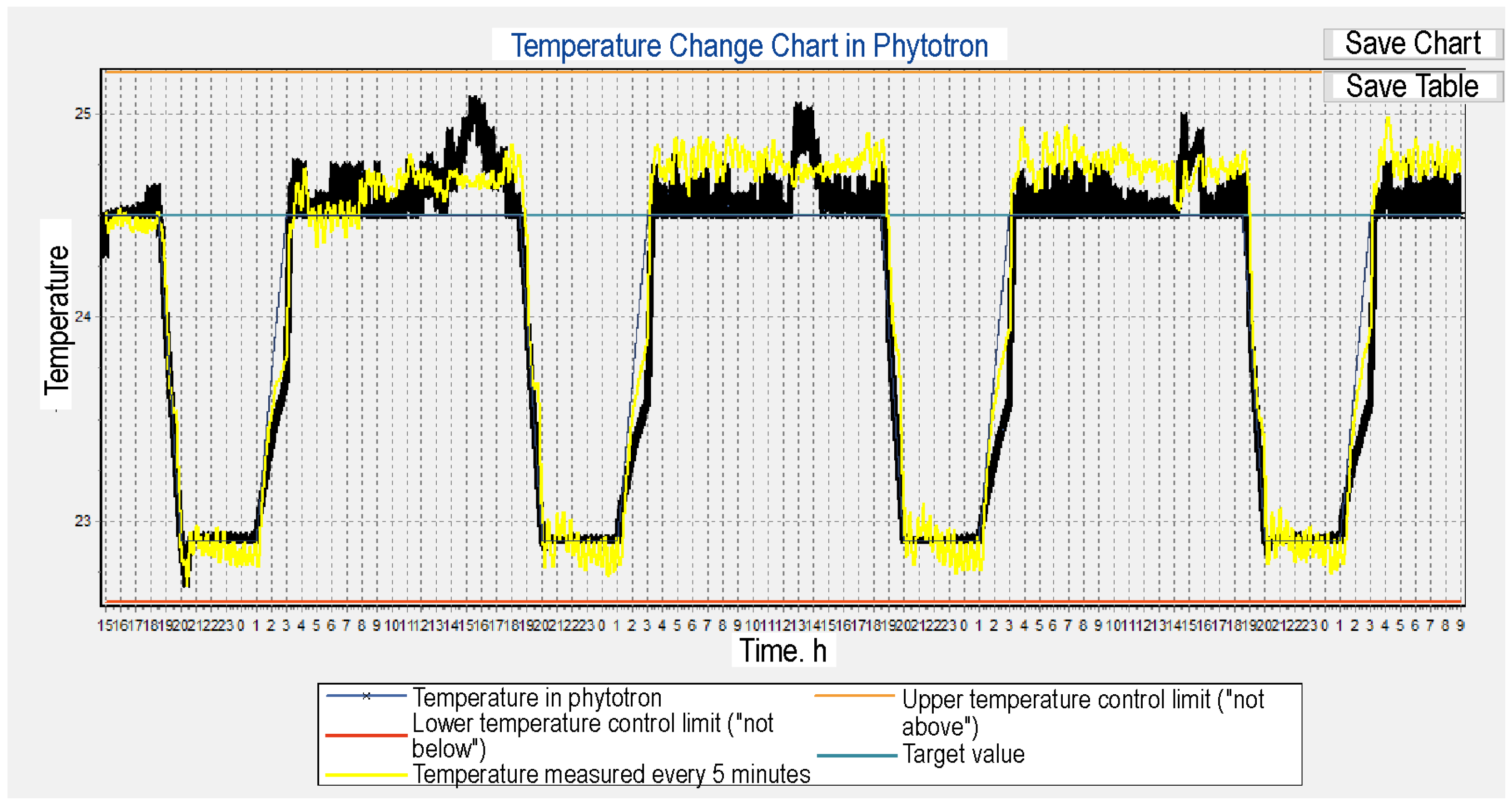

3.3. Analysis of Collected Data and Validation of the Computational Model

3.4. Model Generalizability and Adaptation

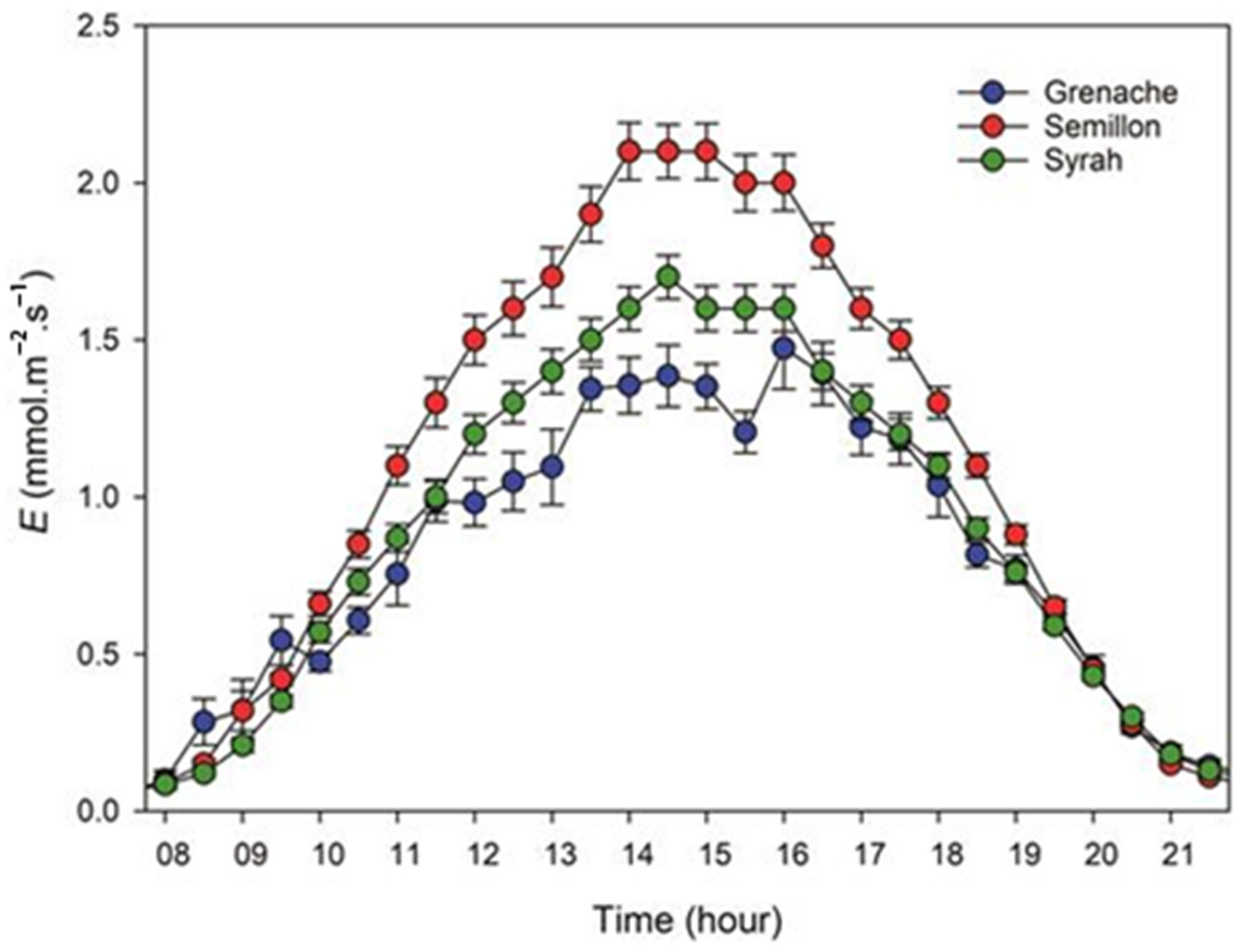

- The transpiration model (Equation (9)) can be adapted for different crops by varying the values of Itransp, Atransp, and Lcycle based on species-specific physiological data.

- The model’s heat balance Equations (1)–(3) scale linearly with room volume and surface area, making them applicable to a variety of facilities, from small research chambers to commercial-scale vertical farms.

- The outside temperature model (Equation (10)) can incorporate regional climate data, with the tdelay value adjusted based on local building thermal mass characteristics.

- The energy models (Equations (11)–(15)) use common power ratings and efficiency factors, allowing for substitution of different HVAC systems, lighting technologies, and dehumidification equipment.

3.5. Economic Analysis

- LoRaWAN sensors (8 × S2101 + 1 × S2103): ~USD 1200;

- Gateway and weather station: ~USD 800;

- Smart plugs and meters: ~USD400;

- Orange Pi 5 and software development: ~USD 500.

- Total initial cost: ~USD 2900

- Dynamically adjusting the temperature setpoint depending on the growth stage of plants;

- Predictive control to minimize the cycling of HVAC systems;

- Optimizing the LED spectrum depending on environmental conditions.

3.6. Comparison with Existing Microclimate Control Approaches

- Ensure the accuracy of the calculation optimization parameters at first;

- Computational requirements are reduced compared to CFD or ML methods;

- Practical cost is reduced due to the use of commercial Internet sensors;

- Adaptability, at first, is possible to take into account the optimization of genetic algorithms.

3.7. Future Work

- Developing mechanisms for remote firmware updates of sensors and controllers and for automated database aggregation;

- Introducing predictive modeling based on machine learning to forecast microclimate parameters and plant-growth dynamics [47];

- Reducing overall energy consumption via adaptive control of LED lighting, air conditioning, and dehumidification based on analytical predictors. Shifting from static setpoints to dynamic profiles will improve system efficiency without compromising yield [48];

- Implementing an additional control loop to ensure real-time operation with feedback on environmental quality;

- Investigating the integration of computer-vision and image-processing technologies for automatic plant-health monitoring or verification of personnel operations;

- Applying nonparametric system identification methods to achieve more accurate approximation of system characteristics, even in the absence of detailed initial-state information, thereby simplifying model validation and improving model quality;

- Optimizing production from a business-process perspective. Resource allocation strategies that maximize satisfaction of multiple product consumer demands will require long-term production planning (over months or years) and agile adaptation to changing market conditions [49];

- Developing and testing resilience mechanisms: periodic sensor calibration, LoRaWAN packet loss monitoring, and channel redundancy, as well as a strategy for automatic switching to backup controllers in the event of a node outage;

- Extending the current single-zone model to a spatially resolved digital twin—initially via a simple 2 × 2 grid of zones and subsequently through CFD-based approximations—to capture shelf- and row-level microclimatic variations and improve local control fidelity;

- Investigating the comparative effectiveness of passive homogenization methods (e.g., perforated or lattice inlet surfaces) versus active ventilation strategies. A systematic evaluation of these approaches in terms of airflow uniformity, energy efficiency, and cost will provide further guidance for practical deployment in large-scale vertical farming facilities;

- Expanding calibration periods to cover longer datasets (minimum 1–3 months) and introduce multi-objective optimization that balances energy efficiency with equipment longevity and minimizes negative control pulsations (e.g., amplitude of compressor switching cycles).

4. Conclusions

- Development of a microclimate model. A comprehensive system of heat-balance, humidity, and energy-consumption equations was formulated, accounting for all climate-control systems and plant transpiration.

- Implementation of a distributed monitoring system. A scalable IoT architecture based on LoRaWAN and Wi-Fi technologies was deployed, enabling data collection for temperature, humidity, CO2, and equipment power use.

- Hybrid model validation. A genetic algorithm (GA)—an evolutionary optimization method—was employed to optimize the model parameters against real monitoring data, achieving high predictive accuracy (0.1 °C temperature deviation, 2% humidity deviation).

- Verification of energy-efficiency predictions. The optimized model predicted total energy consumption with 99.5% accuracy, confirming its suitability for resource-usage optimization.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

Abbreviations

| IoT | Internet of things |

| CFD | Computational fluid dynamics |

| LoRaWAN | Long-range wide-area network |

| Wi-Fi | Wireless fidelity |

| LED | Light-emitting diode |

| CO2 | Carbon dioxide |

| GPS | Global positioning system |

| HA | Home Assistant |

| ISM | Industrial, scientific, and medical (bands) |

| AES | Advanced encryption standard |

| DT | Digital twin |

| NB-IoT | Narrowband Internet of Things |

| RMSE | Root mean square error |

| GA | Genetic algorithm |

References

- Zhang, R.; Zhu, H.; Chang, Q.; Mao, Q. A Comprehensive Review of Digital Twins Technology in Agriculture. Agriculture 2025, 15, 903. [Google Scholar] [CrossRef]

- Rathor, A.S.; Choudhury, S.; Sharma, A.; Nautiyal, P.; Shah, G. Empowering vertical farming through IoT and AI-Driven technologies: A comprehensive review. Heliyon 2024, 10, 34998. [Google Scholar] [CrossRef]

- Costa, G.P.; Sakata, G.Y.A.; Oliveira, L.F.P.D.; Chaves, M.E.; Duarte, L.F.; Matulovic, M.; Buzo, R.F.; Morais, F.J. FarmSync: Ecosystem for Environmental Monitoring of Barns in Agribusiness. AgriEngineering 2025, 7, 124. [Google Scholar] [CrossRef]

- Stamford, J.D.; Stevens, J.; Mullineaux, P.M.; Lawson, T. LED lighting: A grower’s guide to light spectra. HortScience 2023, 58, 180–196. [Google Scholar] [CrossRef]

- Pereira, J.; Gomes, M.G. Lighting strategies in vertical urban farming for enhancement of plant productivity and energy consumption. Appl. Energy 2025, 377, 124669. [Google Scholar] [CrossRef]

- Rahman, H.; Shah, U.M.; Riaz, S.M.; Kifayat, K.; Moqurrab, S.A.; Yoo, J. Digital twin framework for smart greenhouse management using next-gen mobile networks and machine learning. Future Gener. Comput. Syst. 2024, 156, 285–300. [Google Scholar] [CrossRef]

- Chaux, J.D.; Sanchez-Londono, D.; Barbieri, G. A digital twin architecture to optimize productivity within controlled environment agriculture. Appl. Sci. 2021, 11, 8875. [Google Scholar] [CrossRef]

- Monteiro, J.; Barata, J.; Veloso, M.; Veloso, L.; Nunes, J. A scalable digital twin for vertical farming. J. Ambient Intell. Humaniz. Comput. 2023, 14, 13981–13996. [Google Scholar] [CrossRef]

- Bersani, F.; Capra, A.; Rovai, M.; Francini, A.; Al-Sharmouri, N.; Orsini, F.; Gianquinto, G. Internet of Things approaches for monitoring and control of smart greenhouses in Industry 4.0. Energies 2022, 15, 3834. [Google Scholar] [CrossRef]

- Saad, M.H.M.; Hamdan, N.M.; Sarker, M.R. State of the art of urban smart vertical farming automation system: Advanced topologies, issues and recommendations. Electronics 2021, 10, 1422. [Google Scholar] [CrossRef]

- Farooq, M.S.; Riaz, S.; Abid, A.; Abid, K.; Naeem, M.A. A Survey on the Role of IoT in Agriculture for the Implementation of Smart Farming. IEEE Access 2019, 7, 156237–156271. [Google Scholar] [CrossRef]

- Ariesen-Verschuur, N.; Verdouw, C.; Tekinerdogan, B. Digital Twins in greenhouse horticulture: A review. Comput. Electron. Agric. 2022, 199, 107183. [Google Scholar] [CrossRef]

- Avşar, E.; Mowla, M.N. Wireless communication protocols in smart agriculture: A review on applications, challenges and future trends. Ad Hoc Netw. 2022, 136, 102982. [Google Scholar] [CrossRef]

- Singh, N.; Sharma, A.K.; Sarkar, I.; Prabhu, S.; Chadaga, K. IoT-based greenhouse technologies for enhanced crop production: A comprehensive study of monitoring, control, and communication techniques. Syst. Sci. Control. Eng. 2024, 12, 2306825. [Google Scholar] [CrossRef]

- Platero-Horcajadas, M.; Pardo-Pina, S.; Cámara-Zapata, J.M.; Brenes-Carranza, J.A.; Ferrández-Pastor, F.J. Enhancing Greenhouse Efficiency: Integrating IoT and Reinforcement Learning for Optimized Climate Control. Sensors 2024, 24, 8109. [Google Scholar] [CrossRef] [PubMed]

- Sowmya, C.; Anand, M.; Indu Rani, C.; Amuthaselvi, G.; Janaki, P. Recent developments and inventive approaches in vertical farming. Front. Sustain. Food Syst. 2024, 8, 1400787. [Google Scholar] [CrossRef]

- Escribà-Gelonch, M.; Liang, S.; van Schalkwyk, P.; Fisk, I.; Long, N.V.D.; Hessel, V. Digital twins in agriculture: Orchestration and applications. J. Agric. Food Chem. 2024, 72, 10737–10752. [Google Scholar] [CrossRef]

- Verdouw, C.; Beulens, A.; van der Voort, M.; Verloop, C.; Tromp, S. Digital twins in smart farming. Agric. Syst. 2020, 189, 103046. [Google Scholar] [CrossRef]

- Conti, Z.X.; Ward, R.; Choudhary, R. Energy Modelling and Forecasting for an Underground Agricultural Farm using a Higher Order Dynamic Mode Decomposition Approach. arXiv 2023, arXiv:2306.15089. [Google Scholar] [CrossRef]

- Nasirahmadi, S.; Hensel, O. Toward the next generation of digitalization in agriculture based on digital twin paradigm: A comprehensive review. Sensors 2022, 22, 498. [Google Scholar] [CrossRef]

- Shrivastava, A.; Nayak, C.K.; Dilip, R.; Samal, S.R.; Rout, S.; Ashfaque, S.M. Automatic robotic system design and development for vertical hydroponic farming using IoT and big data analysis. Mater. Today Proc. 2023, 80, 3546–3553. [Google Scholar] [CrossRef]

- Morella, P.; Lambán, M.P.; Royo, J.; Sánchez, J.C. Vertical Farming Monitoring: How Does It Work and How Much Does It Cost? Sensors 2023, 23, 3502. [Google Scholar] [CrossRef] [PubMed]

- Peladarinos, N.; Piromalis, D.D.; Cheimaras, V.; Tserepas, E.; Munteanu, A.; Papageorgas, P. Enhancing Smart Agriculture by Implementing Digital Twins: A Comprehensive Review. Sensors 2023, 23, 7128. [Google Scholar] [CrossRef] [PubMed]

- Purcell, W.; Neubauer, T. Digital Twins in Agriculture: A State-of-the-art review. Smart Agric. Technol. 2023, 3, 100094. [Google Scholar] [CrossRef]

- Slob, N.; Hurst, W. Digital Twins and Industry 4.0 Technologies for Agricultural Greenhouses. Smart Cities 2022, 5, 1179–1192. [Google Scholar] [CrossRef]

- Kalyani, Y.; Vorster, L.; Whetton, R.; Collier, R. Application scenarios of digital twins for smart crop farming through cloud–fog–edge infrastructure. Future Internet 2024, 16, 100. [Google Scholar] [CrossRef]

- Bournet, P.E.; Rojano, F. Advances of Computational Fluid Dynamics (CFD) applications in agricultural building modelling: Research, applications and challenges. Comput. Electron. Agric. 2022, 201, 107277. [Google Scholar] [CrossRef]

- Sezer, N.; Yoonus, H.; Zhan, D.; Wang, L.L.; Hassan, I.G.; Rahman, M.A. Urban microclimate and building energy models: A review of the latest progress in coupling strategies. Renew. Sustain. Energy Rev. 2023, 184, 113577. [Google Scholar] [CrossRef]

- Mirzaei, P.A. CFD modeling of micro and urban climates: Problems to be solved in the new decade. Sustain. Cities Soc. 2021, 69, 102839. [Google Scholar] [CrossRef]

- Singh, M.C.; Yousuf, A.; Singh, J.P. Greenhouse microclimate modeling under cropped conditions-A review. Res. Environ. Life Sci. 2016, 9, 1552–1557. [Google Scholar]

- Kang, L.; Zhang, Y.; Kacira, M.; van Hooff, T. CFD simulation of air distributions in a small multi-layer vertical farm: Impact of computational and physical parameters. Biosyst. Eng. 2024, 243, 148–174. [Google Scholar] [CrossRef]

- Zhang, Y.; Kacira, M. Analysis of climate uniformity in indoor plant factory system with computational fluid dynamics (CFD). Biosyst. Eng. 2022, 220, 73–86. [Google Scholar] [CrossRef]

- Zhang, Y.; Kacira, M.; An, L. A CFD study on improving air flow uniformity in indoor plant factory system. Biosyst. Eng. 2016, 147, 193–205. [Google Scholar] [CrossRef]

- Plas, W.; De Paepe, M. Using CFD to improve flow conditions in vertical farms using realistic plant geometries. In Acta Horticulturae 1369, Proceedings of the XXXI International Horticultural Congress (IHC2022): International Symposium on Advances in Vertical Farming, Angers, France, 14–20 August 2022; International Society for Horticultural Science (ISHS): Leuven, Belgium, 2022; Volume 1369, pp. 49–56. [Google Scholar]

- Pylianidis, C.; Osinga, S.; Athanasiadis, I.N. Introducing digital twins to agriculture. Comput. Electron. Agric. 2021, 184, 105942. [Google Scholar] [CrossRef]

- Lin, Y.; Huang, T.; Yang, W.; Hu, X.; Li, C. A review on the impact of outdoor environment on indoor thermal environment. Buildings 2023, 13, 2600. [Google Scholar] [CrossRef]

- Hou, Y.; Cao, B.; Zhu, Y.; Zhang, H.; Yang, L.; Duanmu, L.; Lian, Z.; Zhang, Y.; Zhai, Y.; Wang, Z.; et al. Temporal and spatial heterogeneity of indoor and outdoor temperatures and their relationship with thermal sensation from a global perspective. Environ. Int. 2023, 179, 108174. [Google Scholar] [CrossRef]

- World Meteorological Organization (WMO). Guide to Instruments and Methods of Observation; (WMO-No. 8); WMO: Geneva, Switzerland, 2021. [Google Scholar]

- Dayer, S.; Herrera, J.C.; Dai, Z.; Burlett, R.; Lamarque, L.J.; Delzon, S.; Bortolami, G.; Cochard, H.; Gambetta, G.A. The sequence and thresholds of leaf hydraulic traits underlying grapevine varietal differences in drought tolerance. J. Exp. Bot. 2020, 71, 4333–4344. [Google Scholar] [CrossRef]

- Játiva, P.P.; Soto, I.; Azurdia-Meza, C.A.; Sánchez, I.; Wang, R.; Kern, W. Hybrid Digital Twin Model for Greenhouse and Underground Environments. IEEE Access 2024, 12, 73906–73924. [Google Scholar] [CrossRef]

- Codeluppi, G.; Cilfone, A.; Davoli, L.; Ferrari, G. LoRaFarM: A LoRaWAN-Based Smart Farming Modular IoT Architecture. Sensors 2020, 20, 2028. [Google Scholar] [CrossRef]

- Tekinerdogan, B.; Verdouw, C. Systems architecture design pattern catalog for developing digital twins. Sensors 2020, 20, 5103. [Google Scholar] [CrossRef]

- Jans-Singh, M.; Leeming, K.; Choudhary, R.; Girolami, M. Digital twin of an urban-integrated hydroponic farm. Data-Centric Eng. 2020, 1, e20. [Google Scholar] [CrossRef]

- Zainali, S.; Qadir, O.; Parlak, S.C.; Lu, S.M.; Avelin, A.; Stridh, B.; Campana, P.E. Computational fluid dynamics modelling of microclimate for a vertical agrivoltaic system. Energy Nexus 2023, 9, 100173. [Google Scholar] [CrossRef]

- Ardabili, S.; Mosavi, A.; Mahmoudi, A.; Gundoshmian, T.M.; Nosratabadi, S.; Várkonyi-Kóczy, A.R. Modelling temperature variation of mushroom growing hall using artificial neural networks. In Engineering for Sustainable Future, Proceedings of the International Conference on Global Research and Education, Budapest, Hungary, Balatonfüred, Hungary, 4–7 September 2019; Springer International Publishing: Cham, Switzerland, 2020; pp. 33–45. [Google Scholar]

- Chen, S.; Liu, A.; Tang, F.; Hou, P.; Lu, Y.; Yuan, P. A Review of Environmental Control Strategies and Models for Modern Agricultural Greenhouses. Sensors 2025, 25, 1388. [Google Scholar] [CrossRef]

- Thwin, K.M.M.; Horanont, T.; Phatrapornnant, T. Machine-Learning Microclimate Forecasting for Adaptive Equipment Control via Web Integration in Open-Ventilated Greenhouses. AgriEngineering 2024, 6, 2845–2869. [Google Scholar] [CrossRef]

- Kaiser, E.; Kusuma, P.; Vialet-Chabrand, S.; Folta, K.; Liu, Y.; Poorter, H.; Woning, N.; Shrestha, S.; Ciarreta, A.; van Brenk, J.; et al. Vertical farming goes dynamic: Optimizing resource use efficiency, product quality, and energy costs. Front. Sci. 2024, 2, 1411259. [Google Scholar] [CrossRef]

- Luo, Y.; Ball, P. Adaptive production strategy in vertical farm digital twins with Q-learning algorithms. Sci. Rep. 2025, 15, 15129. [Google Scholar] [CrossRef]

| Time Interval | Mean Temperature Deviation, °C | Mean Humidity Deviation, % |

|---|---|---|

| First period (72 h) | 0.08 | 1.9 |

| Second period (90 h) | 0.09 | 2.4 |

| Third period (110 h) | 0.10 | 2.2 |

| Time Interval | Calculated Accumulated Energy Consumption (kWh) | Actual Accumulated Energy Consumption (kWh) | Relative Error, % |

|---|---|---|---|

| First period (72 h) | 474.3 | 476.8 | 0.52 |

| Second period (90 h) | 602.8 | 601.2 | 0.26 |

| Third period (110 h) | 748.7 | 752.9 | 0.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bukhtoyarov, V.V.; Nekrasov, I.S.; Timofeenko, I.A.; Gorodov, A.A.; Kartushinskii, S.A.; Trofimov, Y.V.; Lishik, S.I. Hybrid Digital Twin for Phytotron Microclimate Control: Integrating Physics-Based Modeling and IoT Sensor Networks. AgriEngineering 2025, 7, 285. https://doi.org/10.3390/agriengineering7090285

Bukhtoyarov VV, Nekrasov IS, Timofeenko IA, Gorodov AA, Kartushinskii SA, Trofimov YV, Lishik SI. Hybrid Digital Twin for Phytotron Microclimate Control: Integrating Physics-Based Modeling and IoT Sensor Networks. AgriEngineering. 2025; 7(9):285. https://doi.org/10.3390/agriengineering7090285

Chicago/Turabian StyleBukhtoyarov, Vladimir V., Ivan S. Nekrasov, Ivan A. Timofeenko, Alexey A. Gorodov, Stanislav A. Kartushinskii, Yury V. Trofimov, and Sergey I. Lishik. 2025. "Hybrid Digital Twin for Phytotron Microclimate Control: Integrating Physics-Based Modeling and IoT Sensor Networks" AgriEngineering 7, no. 9: 285. https://doi.org/10.3390/agriengineering7090285

APA StyleBukhtoyarov, V. V., Nekrasov, I. S., Timofeenko, I. A., Gorodov, A. A., Kartushinskii, S. A., Trofimov, Y. V., & Lishik, S. I. (2025). Hybrid Digital Twin for Phytotron Microclimate Control: Integrating Physics-Based Modeling and IoT Sensor Networks. AgriEngineering, 7(9), 285. https://doi.org/10.3390/agriengineering7090285