Carbon Footprint of Crop Rotation Systems and Mitigation Options for Net Zeroing Greenhouse Gas Balance in Farms of Central Brazil

Abstract

1. Introduction

2. Material and Methods

3. Results and Discussion

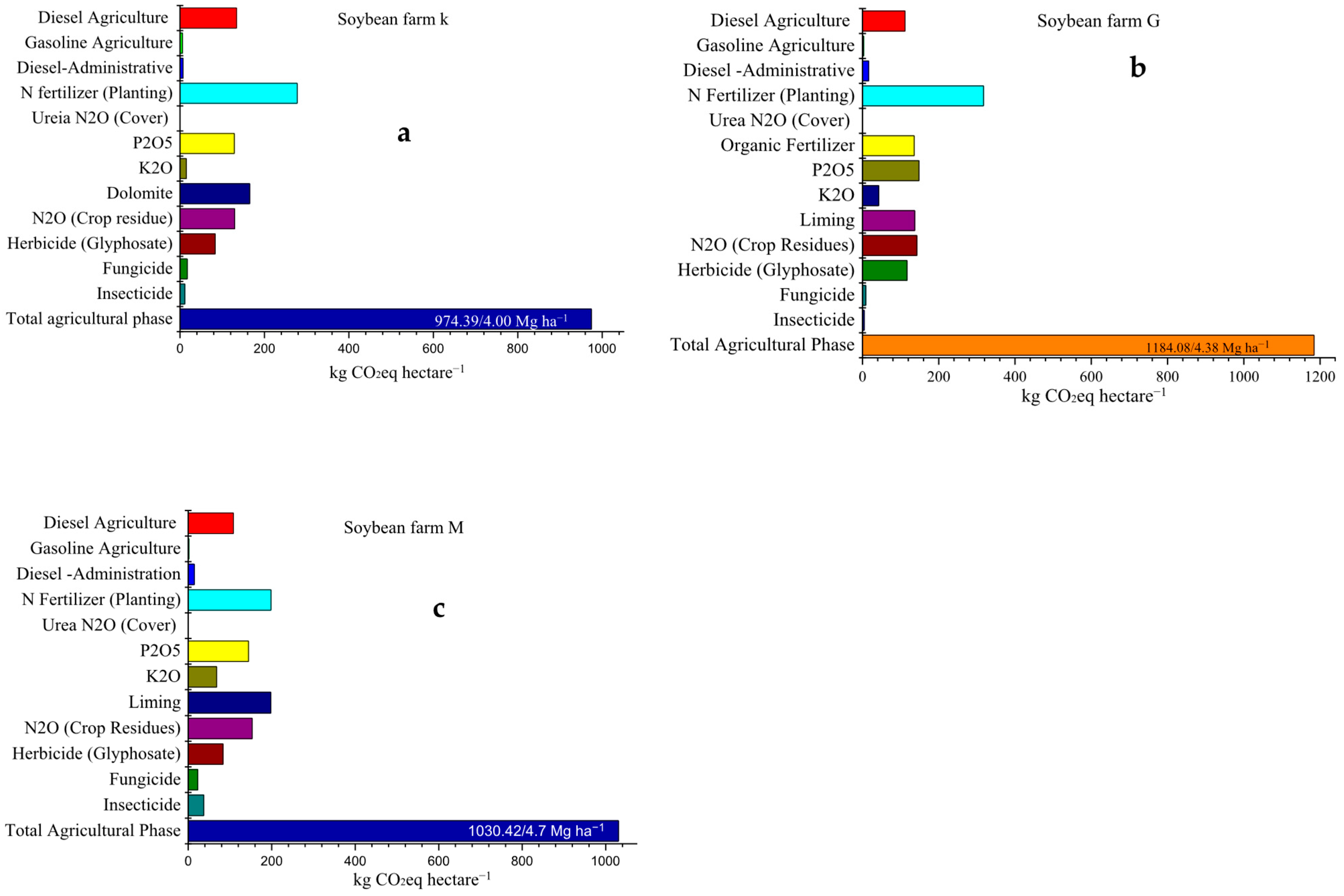

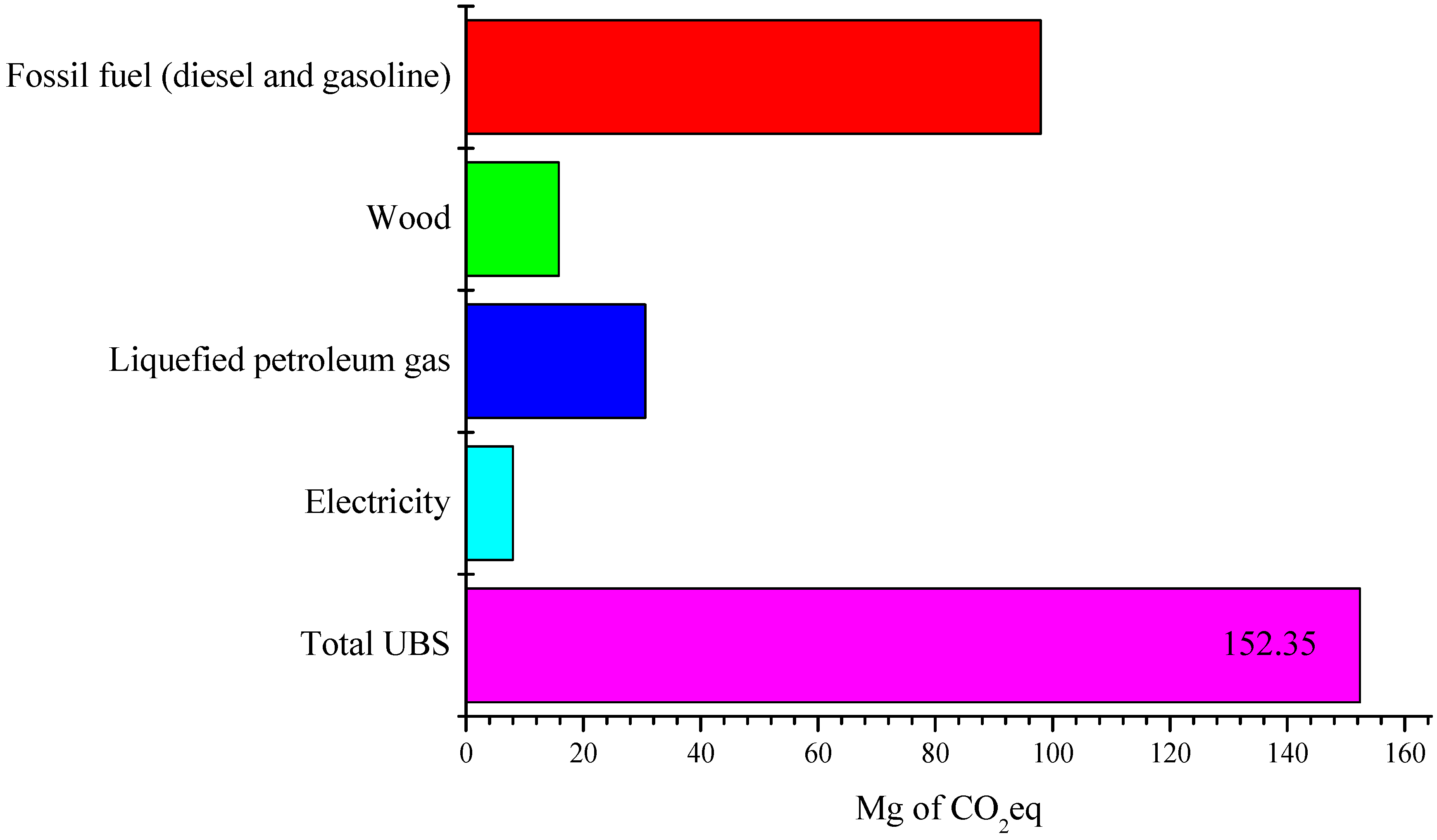

3.1. GHG Emission from Soybean Seed Production

Emission of Soybean Seed Production: Agricultural Phase, Seed Transport and Seed Processing Phase

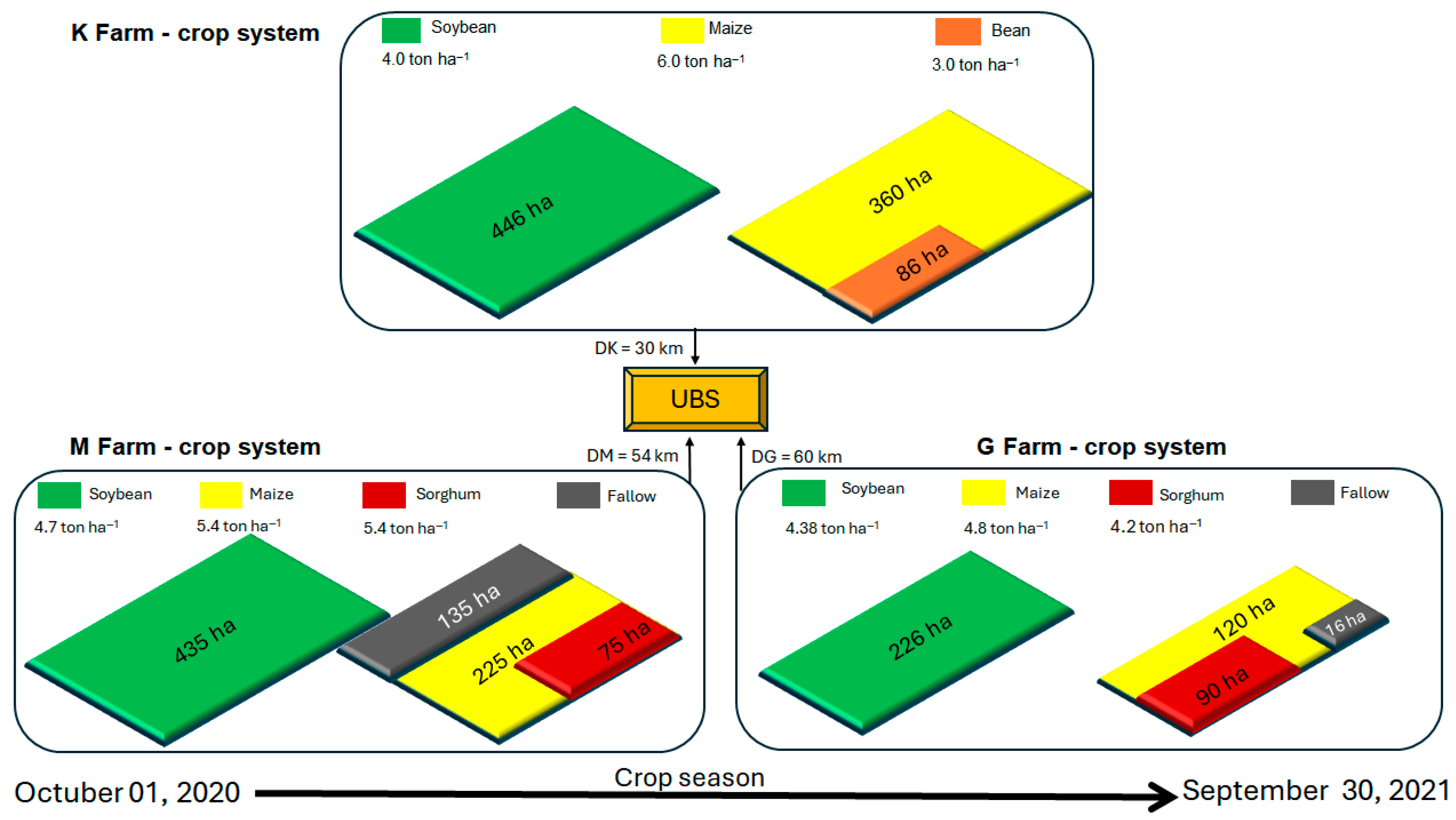

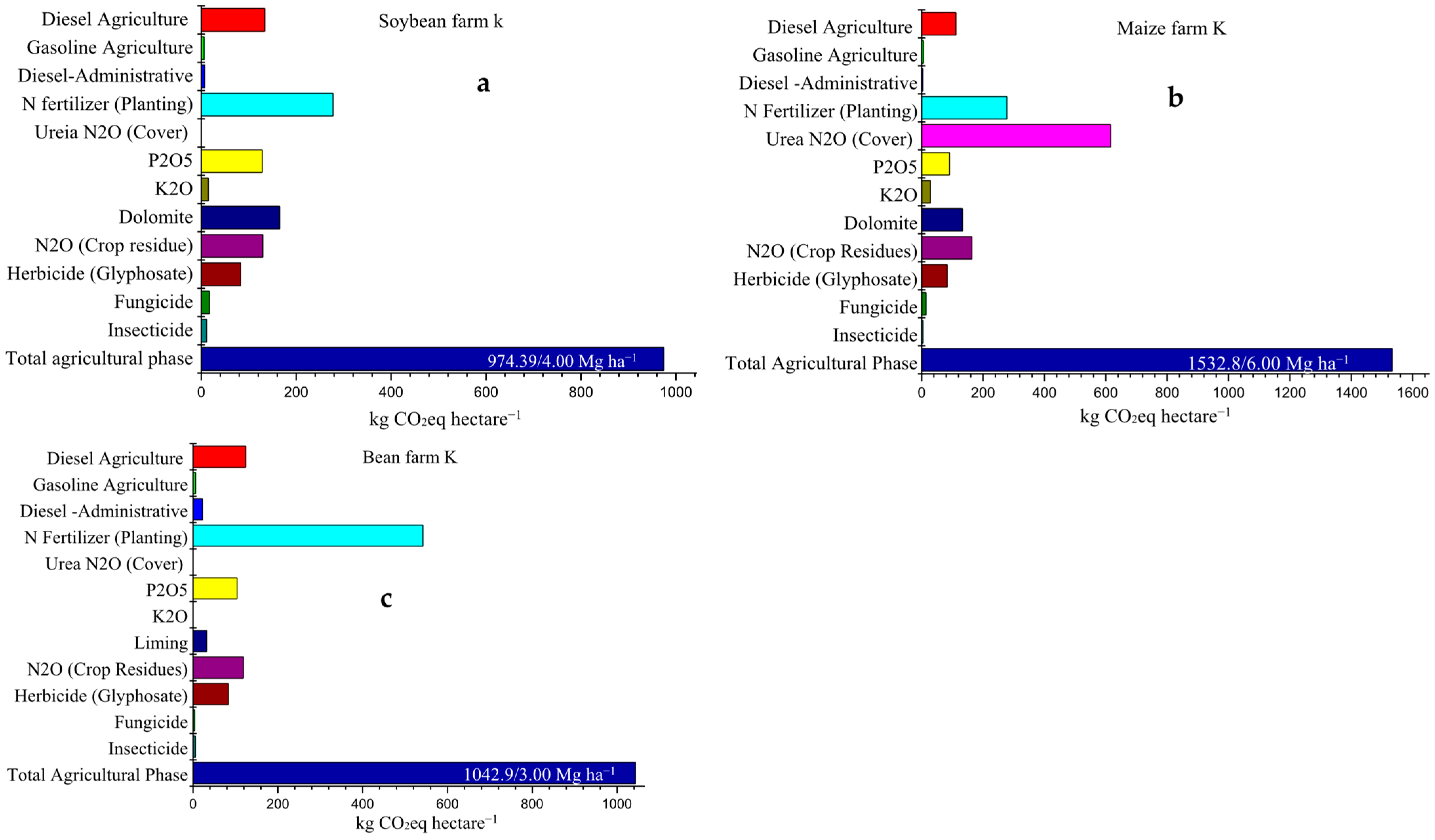

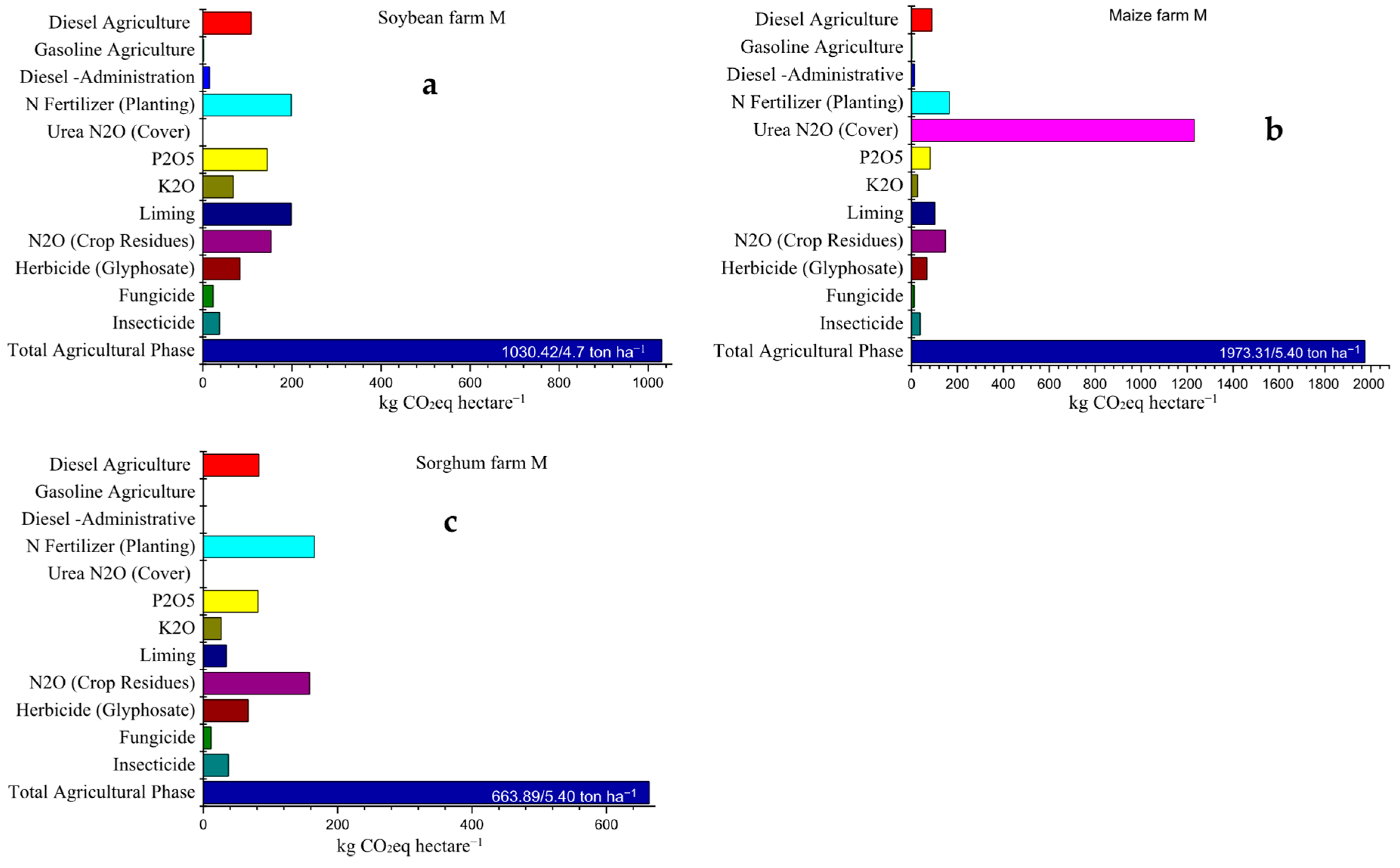

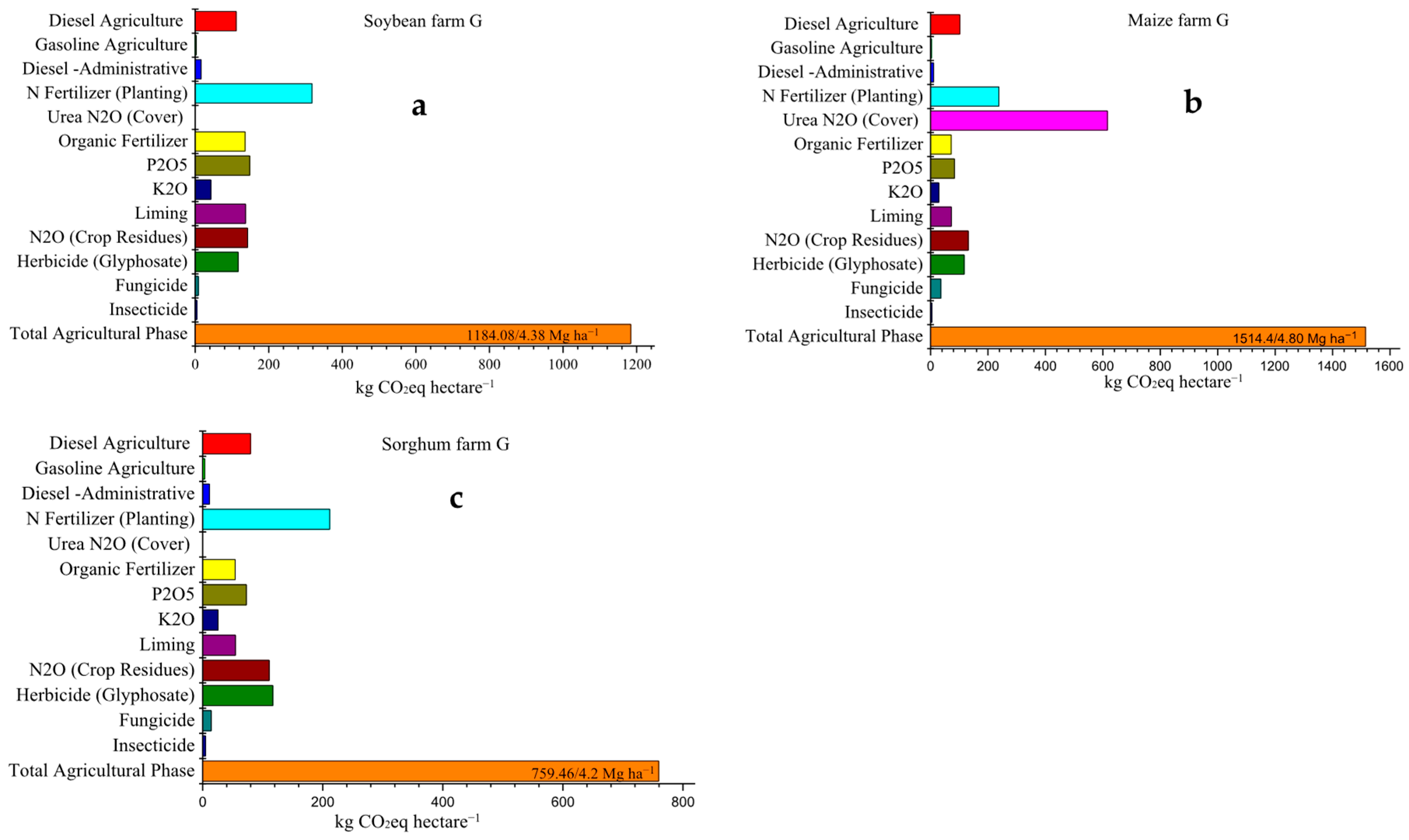

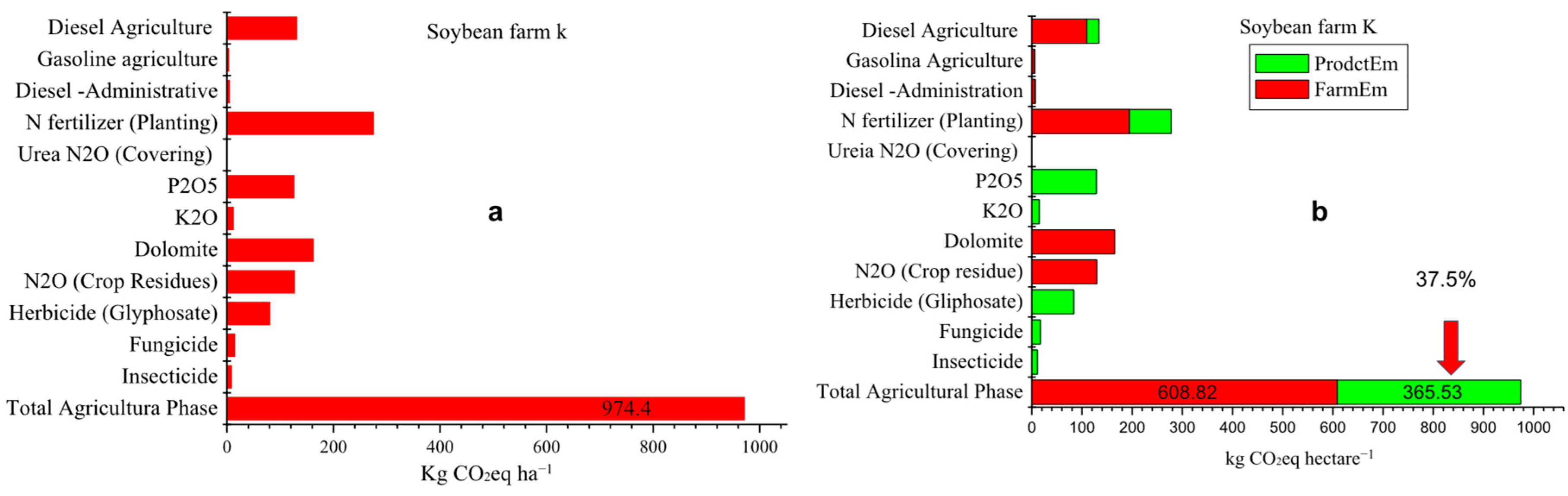

3.2. GHG Emission and C Footprint of Soybean and Crops in Rotations—The Agricultural System Analysis for Farms K, M and G

4. GHG Mitigation Options for Soybean and Respective Crop Rotations

4.1. Emission Reduction from Fertilizers Use

4.2. Pathways to Offset Emissions from Agricultural Production

4.2.1. Soil C Sequestration

4.2.2. Biomass C Sequestration to Offset GHG Emissions

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Nabuurs, G.-J.; Mrabet, R.; Hatab, A.A.; Bustamante, M.; Clark, H.; Havlík, P.; House, J.; Mbow, C.; Ninan, K.N.; Popp, A.; et al. Agriculture, Forestry and Other Land Uses (AFOLU). In IPCC, 2022: Climate Change 2022: Mitigation of Climate Change. Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Shukla, P.R., Skea, J., Slade, R., Al Khourdajie, A., van Diemen, R., McCollum, D., Pathak, M., Some, S., Vyas, P., Fradera, R., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Future Earth; The Earth League; WCRP. 10 New Insights in Climate Science 2023/2024. Stockholm. 2023. Available online: https://10insightsclimate.science/wp-content/uploads/2023/12/10NICS-2023-Report_digital.pdf (accessed on 5 May 2025).

- FAO. The State of Agricultural Commodity Markets 2015–2016. Trade and Food Security: Achieving a Better Balance Between National Priorities and the Collective Good; Food and Agriculture Organization: Rome, Italy, 2015. [Google Scholar]

- Escobar, N.; Tizado, E.J.; zu Ermgassen, E.K.H.J.; Löfgren, P.; Börner, J.; Godar, J. Spatially-explicit footprints of agricultural commodities: Mapping carbon emissions embodied in Brazil’s soy exports. Glob. Environ. Chang. 2020, 62, 102067. [Google Scholar] [CrossRef]

- Smeets, E.M.W.; Bouwmanw, L.F.; Stehfest, E.; van Vuuren, D.P.; Posthuma, A. Contribution of N2O to the greenhouse gas balance of first-generation biofuels. Glob. Chang. Biol. 2009, 15, 1–23. [Google Scholar] [CrossRef]

- Kendall, A.; Chang, B. Estimating life cycle greenhouse gas emissions from corn–ethanol: A critical review of current U.S. practices. J. Clean. Prod. 2009, 17, 1175–1182. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Regional variations in greenhouse gas emissions of biobased products in the United States—Corn-based ethanol and soybean oil. Int. J. Life Cycle Assess. 2009, 14, 540–546. [Google Scholar] [CrossRef]

- Castanheira, É.G.; Freire, F. Greenhouse gas assessment of soybean production: Implications of land use change and different cultivation systems. J. Clean. Prod. 2013, 54, 49–60. [Google Scholar] [CrossRef]

- Arias, P.A.; Bellouin, N.; Coppola, E.; Jones, R.G.; Krinner, G.; Marotzk, J.; Naik, V.; Palmer, M.D.; Plattner, G.-K.; Rogelj, J.; et al. Technical Summary. In Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Berger, S., Caud, N., Chen, Y., Goldfarb, L., Gomis, M.I., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021; pp. 33–144. [Google Scholar] [CrossRef]

- IPCC. Guidelines for National Greenhouse Gas Inventories. In IPCC National Greenhouse Gas Inventories Programme; EgglesMg, S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Forest Land; Institute for Global Environmental Strategies (IGES): Hayama, Japan, 2006; Chapter 4; p. 664. Available online: https://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/4_Volume4/V4_04_Ch4_Forest_Land.pdf (accessed on 10 April 2024).

- IPCC. Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. 2019. Available online: https://www.ipcc.ch/report/2019-refinement-to-the-2006-ipcc-guidelines-for-national-greenhouse-gas-inventories/ (accessed on 5 June 2024).

- de Figueiredo, E.B.; Panosso, A.R.; Romão, R.; La Scala, N., Jr. Research Greenhouse gas emission associated with sugar production in southern Brazil. Carbon Balance Manag. 2010, 5, 3. [Google Scholar] [CrossRef] [PubMed]

- de Figueiredo, E.B.; La Scala, N., Jr. Greenhouse gas balance due to the conversion of sugarcane areas from burned to green harvest in Brazil. Agric. Ecosyst. Environ. 2011, 141, 77–85. [Google Scholar] [CrossRef]

- de Figueiredo, E.B.; Jayasundara, S.; Bordonal, R.d.O.; Berchielli, T.T.; Reis, R.A.; Wagner-Riddle, C.; La Scala, N., Jr. Greenhouse gas balance and carbon footprint of beef cattle in three contrasting pasture-management systems in Brazil. J. Clean. Prod. 2017, 142, 420–431. [Google Scholar] [CrossRef]

- Bordonal, R.d.O.; Lal, R.; Aguiar, D.A.; de Figueiredo, E.B.; Perillo, L.I.; Adami, M.; Rudorff, B.F.T.; La Scala, N. Greenhouse gas balance from cultivation and direct land use change of recently established sugarcane (Saccharum officinarum) plantation in south-central Brazil. Renew. Sustain. Energy Rev. 2015, 52, 547–556. [Google Scholar] [CrossRef]

- Perillo, L.I.; Bordonal, R.D.O.; De Figueiredo, E.B.; Moitinho, M.R.; Aguiar, D.A.; Rudorff, B.F.T.; Panosso, A.R.; La Scala, N. Avoiding burning practice and its consequences on the greenhouse gas emission in sugarcane areas southern Brazil. Environ. Sci. Pollut. Res. 2022, 29, 719–730. [Google Scholar] [CrossRef]

- SEEG. Sistema de Estimativas de Emissões e Remoções de Gases de Efeito Estufa. 2024. Available online: https://seeg.eco.br/relatorios/ (accessed on 20 November 2024).

- Gov.br. Brazilian Ministry of Agriculture and Livestock. Low Carbon Agriculture Plan 2025. Available online: https://www.gov.br/agricultura/pt-br/assuntos/sustentabilidade/planoabc-abcmais/abc/metas-do-abc (accessed on 18 June 2025).

- IPCC. Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S., Qin, D., Manning, M., Chen, Z., Marquis, M., Averyt, K.B., Tignor, M., Miller, H.L., Eds.; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- MCTI. Emissões Corporativas. Ministério da Ciência, Tecnologia e İnovação, Brazil. 2019. Available online: https://www.gov.br/mcti/pt-br/acompanhe-o-mcti/sirene/dados-e-ferramentas/fatores-de-emissao (accessed on 15 February 2024).

- CETESB. Emissões Veiculares no Estado de São Paulo. 2014. Available online: https://repositorio.cetesb.sp.gov.br/handle/123456789/2878 (accessed on 15 February 2024).

- Macedo, I.C.; Seabra, J.E.; Silva, J.E.A.R. Greenhouse gases emissions in the production and use of ethanol from sugarcane in Brazil: The 2005/2006 averages and a prediction for 2020. Biomass Bioenergy 2008, 32, 582–595. [Google Scholar] [CrossRef]

- Don, A.; Seidel, F.; Leifeld, J.; Kätterer, T.; Martin, M.; Pellerin, S.; Emde, D.; Seitz, D.; Chenu, C. Carbon sequestration in soils and climate change mitigation—Definitions and pitfalls. Glob. Chang. Biol. 2024, 30, e16983. [Google Scholar] [CrossRef]

- Griscom, B.W.; Adams, J.; Ellis, P.W.; Houghton, R.A.; Lomax, G.; Miteva, D.A.; Schlesinger, W.H.; Shoch, D.; Siikamäki, J.V.; Smith, P.; et al. Natural climate solutions. Proc. Natl. Acad. Sci. USA 2017, 114, 11645–11650. [Google Scholar] [CrossRef]

- Lucić, R.; Raposo, M.; Chervinska, A.; Domingos, T.; Teixeira, R.F. Global Greenhouse Gas Emissions and Land Use Impacts of Soybean Production: Systematic Review and Analysis. Sustainability 2025, 17, 3396. [Google Scholar] [CrossRef]

- EPE. Empresa de Pesquisa Energética. 2024. Available online: https://www.epe.gov.br/sites-pt/publicacoes-dados-abertos/publicacoes/PublicacoesArquivos/publicacao-819/topico-723/BEN2024.pdf (accessed on 15 October 2024).

- Barbosa, J.Z.; Hungria, M.; Sena, J.V.S.; Poggere, G.; dos Reis, A.R.; Corrêa, R.S. Meta-analysis reveals benefits of co-inoculation of soybean with Azospirillum brasilense and Bradyrhizobium spp. in Brazil. Appl. Soil Ecol. 2021, 163, 103913. [Google Scholar] [CrossRef]

- Ciampitti, I.A.; Salvagiotti, F. New insights into soybean biological nitrogen fixation. Agron. J. 2018, 110, 1185–1196. [Google Scholar] [CrossRef]

- Cheng, K.; Yan, M.; Nayak, D.; Pan, G.X.; Smith, P.; Zheng, J.F.; Zheng, J.W. Carbon footprint of crop production in China: An analysis of National Statistics data. J. Agric. Sci. 2014, 153, 422–431. [Google Scholar] [CrossRef]

- Barbosa, J.Z.; Roberto, L.A.; Hungria, M.; Corrêa, R.S.; Magri, E.; Correia, T.D. Meta-analysis of maize responses to Azospirillum brasilense inoculation in Brazil: Benefits and lessons to improve inoculation efficiency. Appl. Soil Ecol. 2022, 170, 104276. [Google Scholar] [CrossRef]

- Yang, Y.; Zou, J.; Huang, W.; Olesen, J.E.; Li, W.; Rees, R.M.; Harrison, M.T.; Feng, B.; Feng, Y.; Chen, F.; et al. Drivers of soybean-based rotations synergistically increase crop productivity and reduce GHG emissions. Agric. Ecosyst. Environ. 2024, 372, 109094. [Google Scholar] [CrossRef]

- Bohórquez-Sánchez, C.E.; de Castro, S.A.Q.; Carvalho, J.L.N.; Tenelli, S.; Ferraz-Almeida, R.; Sermarini, R.A.; Otto, R. Legume growth and straw retention in sugarcane fields: Effects on crop yield, C and N storage in the central-south Brazil. Agric. Ecosyst. Environ. 2023, 347, 108374. [Google Scholar] [CrossRef]

- Cherubim, M.R. Guia Prático de Plantas de Cobertura: Espécies, Manejo e İmpacto na Saúde do Solo. 2022. Available online: https://www.livrosabertos.abcd.usp.br/portaldelivrosUSP/catalog/book/1340 (accessed on 23 April 2025).

- Telles, T.S.; Nogueira, M.A.; Hungria, M. Economic Value of Biological Nitrogen Fixation in Soybean Crops in Brazil. Environ. Technol. Innov. 2023, 31, 103158. [Google Scholar] [CrossRef]

- Debiasi, H.; Franchini, J.C.; Coelho, A.E.; Balbinot Junior, A.A. Cover Crops Increase the Yield and Profitability of Soybean–Wheat Cropping Systems in Southern Brazil. Int. J. Plant Prod. 2025, 19, 183–195. [Google Scholar] [CrossRef]

- GHG Protocol. The Greenhouse Gas Protocol: A Corporate Accounting and Reporting Standard, Revised Edition; World Resources Institute and World Business Council for Sustainable Development: Washington, DC, USA, 2004; ISBN 1-56973-568-9. Available online: https://ghgprotocol.org/corporate-standard (accessed on 1 June 2025).

- Menegat, S.; Ledo, A.; Tirado, R. Greenhouse Gas Emissions from Global Production and Use of Nitrogen Synthetic Fertilisers in Agriculture. Sci. Rep. 2022, 12, 14490. [Google Scholar] [CrossRef]

- Bondeau, A.; Smith, P.C.; Zaehle, S.; Scharphoff, S.; Lucht, W.; Cramer, W.; Gerten, D.; Lotze-Campen, H.; Müller, C.; Reichstein, M.; et al. Modelling the role of agriculture for the 20th century global terrestrial carbon balance. Glob. Chang. Biol. 2007, 13, 679–706. [Google Scholar] [CrossRef]

- Lal, R. Soil Carbon Sequestration for Sustaining Agricultural Production and Improving the Environment with Particular Reference to Brazil. J. Sustain. Agric. 2005, 26, 23–42. [Google Scholar] [CrossRef]

- Bayer, C.; Martin-Neto, L.; Mielniczuk, J.; Pavinato, A.; Dieckow, J. Carbon sequestration in two Brazilian Cerrado soils under no-till. Soil Tillage Res. 2006, 86, 237–245. [Google Scholar] [CrossRef]

- Carvalho, L.N.; Cerri, C.E.P.; Feigl, B.J.; Píccolo, M.C.; Godinho, V.P.; Cerri, C.C. Carbon Sequestration in Agricultural Soils in the Cerrado Region of the Brazilian Amazon. Soil Tillage Res. 2009, 103, 342–349. [Google Scholar] [CrossRef]

- La Scala Junior, N.; De Figueiredo, E.B.; Panosso, A.R. A review on soil carbon accumulation due to the management change of major Brazilian agricultural activities. Braz. J. Biol. 2012, 72, 775–785. [Google Scholar] [CrossRef]

- Cerri, C.E.P.; Damian, J.M.; Alves, P.A.; Cerri, D.G.P.; Cherubin, M.R. On-farm greenhouse gas emissions and soil carbon stocks of a soybean-maize system. Nutr. Cycl. Agroecosyst. 2024, 128, 309–324. [Google Scholar] [CrossRef]

- Miranda, E.; Carmo, J.; Couto, E.; Camargo, P. Long-Term Changes in Soil Carbon Stocks in the Brazilian Cerrado Under Commercial Soybean. Land Degrad. Dev. 2016, 27, 1586–1594. [Google Scholar] [CrossRef]

- Dias, F.P.M.; Leandro, W.M.; Fernandes, P.M.; Xavier, F.A.Z. Impact of short-term land-use change on soil organic carbon dynamics in transitional agro-ecosystems: A case study in the Brazilian Cerrado. Carbon Manag. 2022, 13, 238–248. [Google Scholar] [CrossRef]

- Oliveira, D.M.S.; Freitas, D.A.F.; Cherubin, M.R.; Cerri, C.E.P. Crop, livestock, and forestry integration to reconcile soil health, food production, and climate change mitigation in the Brazilian Cerrado: A review. Geoderma Reg. 2024, 37, e00796. [Google Scholar] [CrossRef]

- Almeida, L.L.S.; Frazão, L.A.; Lessa, T.A.M.; Fernandes, L.A.; Veloso, A.L.C.; Lana, A.M.Q.; de Souza, I.A.; Pegoraro, R.F.; Ferreira, E.A. Soil Carbon and Nitrogen Stocks and the Quality of Soil Organic Matter under Silvopastoral Systems in the Brazilian Cerrado. Soil Tillage Res. 2021, 205, 104785. [Google Scholar] [CrossRef]

- UNFCCC. Views on the Range of Topics and Other Relevant Information Relating to Reducing Emissions from Deforestation in Developing Countries. Submissions from Parties. United Nations Framework Convention on Climate Change. 2007. Available online: http://unfccc.int/resource/docs/2007/sbsta/eng/misc03.pdf (accessed on 21 May 2022).

- UNFCCC. Views on Land Use, Land-Use Change and Forestry Issues Referred to in Decision 2/CMP.7, Paragraphs 5–7. Submissions from Parties and Admitted Observer Organizations 12–18. United Nations Framework Convention on Climate Change. 2013. Available online: http://go.nature.com/hLAtTN (accessed on 18 December 2022).

- IPCC. Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Smith, P., Bustamante, M., Eds.; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- de Melo, A.C.; Durigan, G. Carbon Sequestration by Planted Riparian Forests in Paranapanema Valley, SP, Brazil. Sci. Florest. 2006, 71, 149–154. [Google Scholar]

- Stape, J.L.; Binkley, D.; Ryan, M.G. Eucalyptus production and the supply, use and efficiency of use of water, light and nitrogen across a geographic gradient in Brazil. For. Ecol. Manag. 2004, 193, 17–31. [Google Scholar] [CrossRef]

- Pezzopane, J.R.M.; Bosi, C.; Bernardi, A.C.C.B.; Muller, M.D.; de Oliveira, P.P.A. Managing eucalyptus trees in agroforestry systems: Productivity parameters and PAR transmittance. Agric. Ecosyst. Environ. 2021, 312, 107350. [Google Scholar] [CrossRef]

- Oliveira, D.M.S.; Oliveira, P.P.A.; Bernardi, A.C.C.; Pezzopane, J.R.M.; Bosi, C.; Júnior, F.P.; Tadini, A.M.; Martin-Neto, L.; Rodrigues, P.H.M. Potential of integrated trees-pasture-based systems for GHG emission mitigation and improving soil carbon dynamics 824 in the Atlantic Forest biome, Southeastern of Brazil. Eur. J. Agron. 2024, 158, 127219. [Google Scholar] [CrossRef]

- Monteiro, A.; Barreto-Mendes, L.; Fanchone, A.; Morgavi, D.P.; Pedreira, B.C.; Magalhães, C.A.S.; Adibe, L.A.L.; Eugène, M. Crop-livestock-forestry systems as a strategy for mitigating greenhouse gas emissions and enhancing the sustainability of forage-based livestock systems in the Amazon biome. Sci. Total. Environ. 2024, 906, 167396. [Google Scholar] [CrossRef] [PubMed]

- Dos Reis, J.C.; Kamoi, M.Y.T.; Michetti, M.; Wruck, F.J.; de Aragão Ribeiro Rodrigues, R.; de Farias Neto, A.L. Economic and environmental impacts of integrated systems adoption in Brazilian agriculture-forest frontier. Agrofor. Syst. 2023, 97, 847–863. [Google Scholar] [CrossRef]

- Ministry of Agriculture, Livestock and Food Supply. Plan for Adaptation and Low Carbon Emission in Agriculture: Strategic Vision for a New Cycle—ABC+ 2020–2030; MAPA: Brasília, Brazil, 2021. Available online: https://www.gov.br/agricultura/pt-br/assuntos/sustentabilidade/planoabc-abcmais (accessed on 20 May 2025).

- Ministry of Agriculture, Livestock and Food Supply. Federal Government Launches 2025–2026 Harvest Plan with R$ 516.2 Billion to Boost Brazilian Agribusiness. Government of Brazil. 30 June 2025. Available online: https://www.gov.br/agricultura/pt-br/assuntos/noticias/governo-federal-lanca-plano-safra-2025-2026-com-r-516-2-bilhoes-para-impulsionar-o-agro-brasileiro (accessed on 25 June 2025).

| Sector | Emission sources |

| Agriculture | |

| Diesel and gasoline from agricultural operations and labor transport CO2 | |

| CH4 | |

| N2O | |

| Direct and indirect emissions from N2O | |

| -N Synthetic fertilizer | |

| -N from organic composts | |

| -N from agricultural residues | |

| -Emissions from herbicides, fungicides and insecticides | |

| Transports | |

| Diesel emission from farms until UBS CO2 | |

| CH4 | |

| N2O | |

| UBS (Seed processing plant) | |

| Emission from Liquefied Petroleum Gas (LPG)) | |

| Emission from electricity use | |

| Firewood burning emission—soybean drying | |

| Diesel and gasoline from labors transport |

| Parameters and Inputs | Farm K | Farm M | Farm G | |

| Units | Amount | Amount | Amount | |

| Production area (Soybean) | Hectares | 446 | 435 | 226 |

| Total production (grains—soybean) | Mg | 1784 | 2036 | 989.8 |

| Soybean Production | Bags (60 kg) | 29,733 | 33,933 | 16,496 |

| Productivity | Bags 60 kg ha−1 | 66.7 | 78 | 73 |

| Fertilizers | Formula | 07.33.07 | 05.37.00 | 11.52.00 |

| kg | 300 | 300 | 220 | |

| N fertilizer | kg N ha−1 | 21 | 15 | 24.2 |

| P2O5 | kg ha−1 | 99 | 111 | 114.4 |

| K2O | kg ha−1 | 21 | 96 | 60 |

| Pesticides (active ingredient) | kg or L a.i. ha−1 | |||

| Glyphosate | kg | 2.5 | 2.0 | 3.5 |

| Insecticide | L ha−1 | Metoxyfenozide | Bifenthrin/carbosulfan | Acetamiprid/bifenthrin |

| 0.6 | 0.5 | 0.25 | ||

| Fungicides | L ha−1 | Pyraclostrobin/fluxapiroxid | Pyraclostrobin/fluxapiroxid | Picoxystrobin/benzovindiflupyr |

| 1.2 | 0.4 | 0.6 | ||

| Lime (dolomitic) | Mg ha−1 | 0.750 | 0.450 | 0.288 |

| Diesel (Agricultural phase) | L ha−1 | 39 | 34 | 35 |

| Diesel (Administrative) | L | 1000 | 2000 | 1150 |

| Gasoline (Transport—home to farm) | L | 2000 | 280 | 250 |

| Diesel (Grain transport—farm to UBS *) | L | 1982 | 4018 | 1650 |

| Crop Rotation Systems | Crop Yield | Area | Crop/Fallow Emission | Crop Cf | System Cf | C to Offset Emissions |

|---|---|---|---|---|---|---|

| Farm K (Soybean) | 4.00 | 446 | 974.4 | 243.6 | 2413 | 657.4 |

| Farm K (Maize) | 6.00 | 360 | 1532.9 | 255.5 | ||

| Farm K (Bean) | 3.00 | 86 | 1042.6 | 347.6 | ||

| Farm M (Soybean) | 4.70 | 435 | 1030.4 | 219.2 | 2209 | 601.9 |

| Farm M (Sorghum) | 5.40 | 225 | 663.9 | 122.9 | ||

| Farm M (Maize)) | 5.40 | 135 | 1973.3 | 365.4 | ||

| Farm M (Fallow) | 75 | 663.9 | - | |||

| Farm G (Soybean) | 4.40 | 226 | 1184.1 | 269.1 | 2096 | 571.1 |

| Farm G (Sorghum) | 4.20 | 90 | 759.6 | 180.9 | ||

| Farm G (Maize) | 4.80 | 120 | 1514.4 | 315.5 | ||

| Farm G (Fallow) | 16 | 155.5 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Figueiredo, E.B. Carbon Footprint of Crop Rotation Systems and Mitigation Options for Net Zeroing Greenhouse Gas Balance in Farms of Central Brazil. AgriEngineering 2025, 7, 258. https://doi.org/10.3390/agriengineering7080258

de Figueiredo EB. Carbon Footprint of Crop Rotation Systems and Mitigation Options for Net Zeroing Greenhouse Gas Balance in Farms of Central Brazil. AgriEngineering. 2025; 7(8):258. https://doi.org/10.3390/agriengineering7080258

Chicago/Turabian Stylede Figueiredo, Eduardo Barretto. 2025. "Carbon Footprint of Crop Rotation Systems and Mitigation Options for Net Zeroing Greenhouse Gas Balance in Farms of Central Brazil" AgriEngineering 7, no. 8: 258. https://doi.org/10.3390/agriengineering7080258

APA Stylede Figueiredo, E. B. (2025). Carbon Footprint of Crop Rotation Systems and Mitigation Options for Net Zeroing Greenhouse Gas Balance in Farms of Central Brazil. AgriEngineering, 7(8), 258. https://doi.org/10.3390/agriengineering7080258