1. Introduction

In recent years, viticulture has undergone a profound transformation, becoming a predominantly mechanized agricultural system. Technological advancements have been integrated across the entire production chain—from vineyard establishment and canopy management to grape harvesting and post-harvest processing [

1,

2]. This shift has brought significant improvements in operational efficiency and consistency, enabling producers to manage vineyards with greater precision while reducing dependence on manual labor. Mechanization has also emerged as a strategic response to two of the sector’s most pressing challenges: the increasing scarcity of seasonal agricultural workers and the growing unpredictability of climatic conditions [

1,

2]. Tools such as automated harvesters, GPS-guided machinery, and precision irrigation systems help minimize human error, optimize resource use, and contribute to more stable yields and improved grape quality. Furthermore, mechanization facilitates real-time monitoring and data collection, which supports decision-making processes related to crop management and environmental adaptation, ultimately bolstering the resilience and sustainability of viticultural practices in the face of evolving climatic challenges [

1,

2].

Grape harvesting is one of the most critical stages in both wine and table grape production, as it directly affects crop quality, economic efficiency, and overall sustainability in viticulture [

2,

3,

4]. The method chosen for harvesting—manual or mechanized—plays a pivotal role, with each approach offering distinct advantages and limitations. Manual harvesting enables greater selectivity and tends to preserve grape integrity, particularly for premium varieties. Conversely, mechanized harvesting, while efficient, may lead to increased mechanical stress in some cultivars, especially those with delicate skin. In recent decades, the adoption of mechanized methods has surged, driven by technological advancements and the diminishing availability of skilled agricultural labor, thereby reshaping production strategies in the modern vineyard [

2,

3,

4].

The selection of the optimal harvesting method is contingent upon a range of factors, including the unique characteristics of the vineyard, the technological resources available, and the specific objectives of the producer [

5]. In this context, site-specific variables—such as terrain, microclimate, and vine architecture—play a critical role in determining whether manual or mechanized harvesting is more appropriate [

5]. Additionally, the timing of the harvest emerges as a crucial parameter that must be precisely calibrated to capture the grapes at their optimal ripeness, thereby maximizing both yield quality and overall economic return [

5].

Manual harvesting offers significant advantages in viticulture by enabling the collection of grapes from areas inaccessible to machines, such as steep slopes or irregular terrains that exceed operational limits [

6]. This method ensures that high-quality grapes from challenging vineyard sections are harvested, while also allowing workers to selectively assess ripeness and health at the cluster level, which is an essential factor in producing premium wines [

6]. Although manual harvesting is more labor-intensive and time-consuming, its benefits in preserving grape quality and unique terroir characteristics often outweigh the additional costs, ultimately enhancing the final wine product [

6]. Another notable advantage of manual harvesting is the intrinsic human capability to sort grapes with a high level of precision. Skilled workers can visually and tactilely assess the health, ripeness, and overall quality of each grape cluster, thereby ensuring that only the best fruit is selected for processing [

6]. This selective sorting not only minimizes the inclusion of unripe or damaged grapes but also reduces the risk of contamination by extraneous materials such as leaves or stems, which can negatively affect must quality. Consequently, the careful manual selection process contributes significantly to achieving the desired sensory and chemical characteristics in the final wine product, particularly for premium varieties where quality is paramount [

4]. Manual techniques offer notable robustness in the face of seasonal variations by enabling tailored selection and handling of grapes even under less-than-optimal growing conditions. This flexibility can contribute to maintaining grape quality and supports consistent production, particularly in variable growing conditions. Wines obtained through manual harvesting are often perceived as better expressing terroir nuances, especially in small-scale, premium viticulture contexts [

7].

Harvesting represents a pivotal stage in the winemaking process, as it determines the moment when grapes are removed from the vine at their peak physiological and technological maturity. The timing of this operation is essential, since even slight delays can compromise the desired balance of sugars, acids, and phenolic compounds. In this context, mechanical harvesting has become a practical tool for managing the tight harvest window, particularly in vineyards cultivated on a larger scale [

8,

9]. Mechanized systems can support timely responses to optimal ripening windows, particularly in large-scale vineyards. Manual harvesting is generally more suitable for thin-skinned or aromatic varieties, where gentle handling is critical to preserve phenolic and aromatic integrity. Their capacity to handle large volumes in a short period reduces the risk of over-ripening and maintains uniformity in grape intake, which is critical for consistent wine production. Furthermore, mechanization allows for more precise timing and uniformity in the selection process, contributing to the overall stability of production and cost savings, thereby supporting the scalability and economic viability of modern viticultural practices [

10,

11]. However, for premium wines and vineyards in challenging terrains, manual harvesting remains a viable option [

10,

11]. In addition, research indicates that mechanized harvesting can alter the phenolic composition and aroma compounds of wines, which may subsequently affect the sensory properties and overall quality of the final product [

12]. This potential compromise in quality makes manual harvesting indispensable when the preservation of delicate flavor profiles is paramount. Furthermore, targeted manual selection can help ensure that only the optimal grapes are used, thereby maintaining the integrity and complexity that define high-end wines [

12].

Historically, mechanical harvesting was plagued by several drawbacks. Not only did it indiscriminately collect all the grapes, but it also often resulted in the inclusion of extraneous materials such as leaves and vine shoots in the harvest bins, thereby compromising the quality of the must and contributing to a negative perception of mechanization. However, recent technological advancements have significantly refined the process, enhancing both the selectivity and efficiency of mechanical harvesters and mitigating many of the issues that once marred their reputation [

7,

13]. Modern harvesters now incorporate sensors and adjustable settings that allow for better discrimination between ripe grapes and unwanted debris. This innovation has improved the overall quality of the harvested product, reducing the need for extensive post-harvest sorting. Consequently, the enhanced precision of current mechanized systems is gradually restoring confidence in their ability to meet the rigorous standards of premium winemaking [

7,

13].

With precise adjustments, mechanical harvesters can now pick individual berries, ensuring that only the desired grapes are collected, for example, at the peak of their ripeness [

14]. Advanced sensor technologies allow these machines to assess grape maturity in real time, aligning the harvesting process with the optimal sugar and acidity profiles. Furthermore, the refined systems reduce mechanical stress on the fruit, preserving grape skin integrity and aromatic compounds [

14]. Consequently, this targeted approach minimizes oxidation and improves the chemical balance of the must, ultimately contributing to enhanced wine quality [

14]. The advanced settings allow for the elimination of grapes affected by rot or those that have not yet reached full maturity, ensuring that only the highest-quality fruit is harvested. Moreover, the high efficiency of modern harvesters minimizes the time between harvesting and processing in the winery to just a few minutes, significantly reducing the risk of must oxidation [

15]. Another key advantage of mechanical harvesting is its ability to operate during night-time, which helps preserve the grapes’ delicate aromas and overall quality. Additionally, the ability to fine-tune mechanical parameters further optimizes the harvesting process, ensuring that operational conditions are closely aligned with the specific requirements of different grape varieties [

15].

The aim of this study is to systematically investigate the impact of harvesting methods—manual versus mechanized—on the composition of must and, consequently, on wine quality, by analyzing how these techniques influence essential physicochemical parameters and the organoleptic characteristics of the final products. In addition, the study addresses the differences in economic efficiency between manual and mechanized harvesting, highlighting that, within the context of Romanian viticulture, mechanization is advantageous for large-scale commercial production, where cost reduction is crucial, while manual harvesting remains particularly relevant for producing high-quality wines in sensitive grape varieties or terroir-driven production systems. This research is highly innovative, as it provides quantifiable data on how these methods affect must composition, thereby contributing to the optimization of agricultural management decisions and the development of sustainable and competitive production models. We hypothesize that manual harvesting will result in superior must quality for sensitive grape varieties due to lower physical damage, while mechanized harvesting will offer increased economic efficiency, albeit with a potential trade-off in certain enological characteristics.

2. Materials and Methods

2.1. Grape Varieties and Location

In this study, two distinct harvesting methods—manual and mechanized—were applied to selected grape varieties (

Figure 1, see also

Section 2.2). Four grape varieties were investigated: Fetească Regală and Sauvignon Blanc, representing white wine cultivars; Muscat Ottonel, an aromatic variety; and Pinot Noir, a red wine cultivar.

The experimental vineyard is situated in the Târnave viticultural area (latitude 46.2° N, longitude 24.5° E), at an elevation of 350 m, on a gently sloping southern exposure. The vineyard was planted in 2015 with a spacing of 2.2 m between rows and 1.2 m between vines. The rows are oriented east–west to optimize sunlight exposure throughout the day. For this study, 12 consecutive rows were allocated per grape variety. From these, 3 rows were randomly selected for manual harvesting and 3 for mechanized harvesting, ensuring that all selected rows were located within the central part of the plot to minimize edge effects and soil variability. All selected rows had identical vine age, rootstock, and training system (Guyot), and were maintained under the same agro-technical conditions.

To provide a clearer understanding of the vineyard’s experimental layout and the distribution of treatments, a schematic diagram has been included as

Supplementary Figure S1. This illustration shows the east–west orientation of the rows, the spatial distribution of the vines, and the allocation of manual and mechanized harvesting treatments. For each grape variety, twelve consecutive rows were designated; three were randomly selected for manual harvesting and three for mechanized harvesting. These rows were positioned centrally within each block to reduce border effects and environmental variability. All experimental units shared identical characteristics in terms of vine age, rootstock, training system (Guyot), and agro-technical practices, ensuring consistency and comparability throughout the study.

These varieties were selected either for their prevalence in the vineyards of Târnave (Fetească Regală and Sauvignon Blanc) or for their distinctive morphological characteristics (as exemplified by Muscat Ottonel). The research was conducted in the Târnave region, an ideal setting in which the unique pedoclimatic conditions influencing vine cultivation were thoroughly examined and analyzed. This setting enabled a comprehensive evaluation of how the applied harvesting techniques affect grape quality, thereby providing insights into their implications for producing high-quality wines under distinct environmental conditions.

After vinification, the study proceeded with an in-depth analysis to assess how the different harvesting methods affected the quality of both the must and the resulting wine. This phase involved a comprehensive evaluation of various chemical, sensory, and physical parameters, including sugar and acid levels, phenolic profiles, and aromatic compound composition. By comparing these metrics across samples obtained via manual and mechanized harvesting, the study aimed to determine whether the harvesting technique exerts a significant influence on the overall quality and stability of the final product.

2.2. Vinification

To initiate the harvesting process, the technological maturity of the grape varieties was rigorously assessed. This assessment was based on the evaluation of accumulated sugar levels, ensuring that the grapes had reached an optimal state for winemaking. Specifically, a grape variety was considered technologically mature when the sugar concentration remained stable over a period of three consecutive days, indicating that sufficient sugar accumulation had occurred for the desired fermentation process [

16]. After confirming technological maturity, we determined the optimal harvest date by analyzing two critical parameters, the glucose-acidimetric index and the maximal weight of a sample of 100 berries, both of which are tailored to the characteristics of each grape variety. The glucose-acidimetric index provides a reliable indicator of the balance between sugar and acidity, which is essential for achieving the desired wine profile, while the measurement of berry weight serves as an additional quality control parameter, reflecting the fruit’s overall development and suitability for processing. This methodical approach ensures that grapes are harvested at the precise moment when their chemical and physical attributes are best aligned with the winemaking objectives, thereby enhancing the consistency and quality of the final wine product.

2.3. Grape Harvesting and Winemaking

Two distinct harvesting techniques—manual and mechanized—were employed to ensure both quality control and operational efficiency. We manually harvested grapes using precision tools such as shears and knives, to carefully cut the peduncle and minimize damage to the grape clusters. Then, we promptly placed them into containers for transporting to the winery, where they were emptied into hoppers for further processing. Mechanized harvesting was performed using advanced equipment, including Gregoire G8 self-propelled grape harvesters (models 119, 121, 326, and 330), as well as other combine harvesters such as Pellenc 4560, Pellenc 100, Pellenc 8590 (manufactured by Pellenc S.A.S., Pertuis, Vaucluse, France) and Gregoire G3 (manufactured by Grégoire S.A., Cognac, Charente, France). These machines were grouped into three categories to optimize operational efficiency and adapt to specific vineyard conditions. A GPS monitoring system provided real-time data for integrated field management, enabling continuous and precise harvesting throughout the day. The grouping was based on the generation of technology, level of automation, and grape-handling precision. Group I included older mechanical harvesters with basic vibration systems and minimal protective features. Group II consisted of intermediate models offering partial selectivity and moderate improvements in preserving grape integrity. Group III represented the most advanced harvesters, equipped with onboard destemming systems, real-time sensors, and shock-absorption technology to significantly reduce berry damage. This classification facilitated a more structured and comparative analysis of the relationship between harvester technology and both enological and economic performance. The overall harvesting process included phases of cleaning, maintenance, and equipment servicing, with harvesting activities conducted for approximately 18 h per day. This integrated approach reflects the technological advancements in modern viticulture and highlights the practical balance between traditional and mechanized methods in achieving optimal grape quality and operational efficiency.

Winemaking followed standardized protocols for white wine production, with all operations carried out in a dedicated vinification cellar. Grapes were first gently crushed and destemmed to obtain high-quality must while preserving fruit integrity. The must then underwent clarification through settling and racking to remove suspended solids. Clarified must was transferred to temperature-controlled fermentation tanks, where a selected yeast strain was inoculated to initiate controlled fermentation. Key parameters such as temperature, sugar content, and acidity were monitored throughout the process. After fermentation, standard post-fermentation procedures—including cold stabilization, fining, and filtration—were applied to improve wine clarity, stability, and sensory profile. All operations were carried out under strict hygienic conditions to ensure that the final product met high-quality standards and expressed the distinct characteristics of premium white wines [

17].

The fermentation process was conducted at a controlled temperature between 16 and 18 °C to preserve aromatic freshness. Saccharomyces cerevisiae var. bayanus (commercial strain) was used due to its reliability, low production of off-flavors, and strong fermentation kinetics, particularly suitable for white wine production. To ensure microbiological stability and limit oxidation, sulfur dioxide (as potassium metabisulfite) was added immediately after pressing at a dose of 50 mg/L. Post-fermentation, additional SO2 was applied to maintain free SO2 levels between 25 and 30 mg/L, consistent with OIV standards for white wines.

2.4. Must and Wine Analysis Methods

The physicochemical characteristics of the must and wine were assessed using well-established, standardized methods in accordance with protocols recommended by the International Organisation of Vine and Wine (OIV). These procedures are widely recognized in the scientific community for ensuring accuracy, consistency, and comparability across studies [

18].

For grape must, the analysis included the determination of reducing sugars, total acidity, sulfur dioxide content, pH, and concentrations of malic and tartaric acids. In addition, levels of inorganic, organic, and total nitrogen were measured, alongside potassium, catechin, and total polyphenols. For the finished wines, assessments involved measuring alcohol content, reducing sugar, total and volatile acidity, sulfur dioxide levels, and pH. Further analysis included the quantification of malic, lactic, and tartaric acids, as well as density, non-reducing extract, and total dry extract. Ethanol concentration was determined by distillation. The final value was calculated based on the mass and density of the distillate and expressed as a volume percentage (vol%) at 20 °C [

19,

20].

The determination of reducing sugars was carried out using the OIV reference method for reducing substances, based on iodometric titration (Luff-Schoorl method). First, the samples were clarified with neutral lead acetate to remove interfering compounds. During the reaction, reducing sugars convert heated Cu

2+ ions into Cu

+, resulting in the formation of copper(I) oxide. The remaining Cu

2+ ions then react with potassium iodide, releasing free iodine. This iodine is titrated using a standard sodium thiosulfate solution. The amount of liberated iodine indicates the extent of the reduction reaction and serves as the endpoint for the titration. The final sugar concentration is expressed in grams per liter (g/L). This method is widely recognized for its accuracy, sensitivity, and reproducibility, making it a reliable tool for assessing must ripeness and fermentative potential [

17,

21].

Total and volatile acidities were determined according to the reference methods of the International Organisation of Vine and Wine (OIV). Total acidity was measured by potentiometric titration using bromothymol blue as an indicator. Results were expressed in grams per liter, either as sulfuric acid (H

2SO

4) or tartaric acid (C

4H

6O

6) equivalents [

22]. Volatile acidity analysis began with the removal of dissolved carbon dioxide (CO

2) from the sample. The sample was then subjected to steam distillation, followed by titration with a standard sodium hydroxide solution. The results were expressed as grams of acetic acid (CH

3COOH) per liter [

23]. Sulfur dioxide (SO

2) was determined using two OIV-approved methods. Free SO

2 was measured by direct iodometric titration in the presence of EDTA. Total SO

2 was determined after hydrolysis with sodium hydroxide, followed by iodometric titration [

24].

Malic acid was measured using the chromotropic acid colorimetric method. This technique is based on the formation of a colored complex, the intensity of which is directly proportional to the malic acid concentration in the sample. Tartaric acid was quantified by gravimetric analysis. Results were expressed as potassium racemate. Potassium content was measured using spectrophotometric analysis, a method recognized for its high precision and sensitivity. Total nitrogen was measured using the standard Kjeldahl method. In this procedure, the sample is mineralized with concentrated sulfuric acid at approximately 330 °C, converting all nitrogenous compounds into ammonia. The released ammonia is then distilled under alkaline conditions and titrated with hydrochloric acid. Final results were expressed in mg/L [

25]. Inorganic nitrogen (ammonia nitrogen) was measured separately through distillation, followed by titration with hydrochloric acid. Organic nitrogen was calculated as the difference between total nitrogen and inorganic nitrogen.

The non-reducing dry extract was obtained by evaporating a measured volume of wine at 100 °C. This process removes all water and volatile substances, leaving only the non-volatile solids. The remaining residue represents the total non-reducing dry extract in the wine. This parameter is considered essential for evaluating wine quality, as it reflects the concentration of stable dissolved components.

Total dry extract was obtained by evaporating a measured volume of wine at 100 °C until a constant mass was reached. This ensured the complete removal of water and volatile compounds. The remaining residue represented the total dry extract, which includes both organic and inorganic non-volatile substances. These compounds contribute significantly to the wine’s structure, mouthfeel, and overall sensory quality. The method offers a reliable and reproducible way to quantify the solid content of wine. It is widely used in quality control and formulation adjustments during the winemaking process [

26].

Catechin content was determined through a three-step process involving extraction, separation, and quantification by spectrophotometric analysis. First, catechins were extracted from the sample using a suitable solvent to ensure high recovery. The extract was then purified using a chromatographic method to separate catechins from other polyphenolic compounds. Finally, the isolated catechins were quantified with a spectrophotometer. Concentrations were calculated based on calibration curves prepared from standard catechin solutions. This method is widely used due to its sensitivity, accuracy, and reproducibility in measuring catechin levels in wine and must.

Total polyphenol content was measured using the Folin–Ciocâlteu colorimetric method. Diluted must samples were treated with specific Folin–Ciocâlteu reagents to initiate the reaction. In the presence of phenolic compounds, a blue complex formed as a result of the interaction with the phosphotungstate-molybdate reagent. The intensity of this blue coloration was measured spectrophotometrically at 765 nm. Results were expressed as milligrams per liter (mg/L) of total polyphenols [

27].

Density was measured using the pycnometer method at a controlled temperature of 20 °C. The pycnometer was first weighed empty, then filled with the wine sample and weighed again. All measurements were carried out under stable temperature conditions to ensure accuracy. The density was calculated by dividing the mass of the liquid by the known volume of the pycnometer. This method is widely recognized for its precision and reproducibility and is essential for assessing wine composition and quality. pH values were determined using a laboratory pH meter equipped with a wine-adapted electrode. The measurement followed the potentiometric method.

Table S1 presents the validation of all analytical methods used in this study. It includes key parameters such as limits of detection (LOD) and quantification (LOQ), as well as precision expressed as repeatability and reproducibility (RSD%). For example, the Luff-Schoorl method used for determining reducing sugars showed an LOD of 0.5 g/L and an LOQ of 1.0 g/L. The repeatability and reproducibility values were 2.5% and 3.5%, respectively. Similar validation data were reported for the other methods, including potentiometric and spectrophotometric techniques, all in accordance with OIV standards. This thorough validation ensures the accuracy, sensitivity, and reproducibility of the analytical results, providing a strong scientific basis for evaluating must and wine quality.

2.5. Statistical Analysis

This study rigorously evaluated viticulture harvesting methods, ensuring precise and reliable results. Each experiment was replicated three times, and data are presented as mean ± standard deviation. Statistical analyses, including descriptive statistics and ANOVA, were conducted using Excel (Office 365), XLSTAT (Office 365), and SPSS (version 24), with Duncan’s test employed for mean separation at a significance level of p ≤ 0.005. This comprehensive approach allowed for the assessment of significant differences in both product quality and economic efficiency, ensuring the findings’ practical relevance for optimizing production processes. The results, reported with high scientific precision, provide a clear understanding of harvesting methods’ impact on viticulture outcomes. Before performing ANOVA, the assumption of homogeneity of variance was tested using Levene’s test. The test showed no significant differences in variance across groups (p > 0.05), thereby confirming that the ANOVA assumption was met. Where applicable, data were also screened for normality using descriptive statistics and visual inspection (e.g., histograms and Q-Q plots).

3. Results

The method of grape harvesting—manual or mechanical—significantly influences the quality of must and the resulting wine. Each approach offers distinct advantages and challenges that can impact the final product. Manual harvesting allows workers to selectively pick grape clusters, ensuring that only ripe and healthy grapes are collected. This meticulous selection minimizes the inclusion of unripe or diseased grapes, which can adversely affect the flavor and quality of the wine. Additionally, gentle handling during manual harvesting reduces the risk of grape skin breakage, thereby decreasing premature oxidation and preserving the grape’s aromatic compounds. This method is particularly advantageous for grape varieties with thin and sensitive skins that are prone to damage.

Mechanical harvesting offers efficiency and speed, making it especially beneficial for large vineyards or regions facing labor shortages. Modern mechanical harvesters operate by shaking the vines to dislodge grapes, which are then collected. While technological advancements have improved the precision of these machines, challenges remain. Mechanical harvesters may inadvertently collect unripe grapes, leaves, and other debris, potentially introducing unwanted flavors or increasing astringency in the wine. Moreover, the mechanical process can cause grape skin breakage, leading to oxidation and loss of aromatic qualities, which are undesirable, particularly in the production of white and sparkling wines [

1]. The choice between manual and mechanical harvesting significantly impacts the quality of must and wine. Manual harvesting offers precise selection and gentle handling, ensuring high-quality grape collection, but it is labor-intensive and time-consuming. Conversely, mechanical harvesting provides efficiency and cost-effectiveness but may compromise grape selection and increase the risk of oxidation.

3.1. Advanced Evaluation of Must Composition: The Impact of Harveting Method on Key Physicochemical and Oenological Parameters

The analysis of the results reveals significant differences in reducing sugar content among the studied grape varieties and between the harvesting methods employed. The reducing sugar content varied significantly among the four grape varieties, both for mechanized and manual harvesting. Pinot Noir recorded the highest values of reducing sugar (219.67 ± 0.58 g/L for mechanized harvesting and 224.20 ± 4.48 g/L for manual harvesting), suggesting a superior accumulation of sugars compared to the other varieties. Conversely, Sauvignon Blanc exhibited the lowest values (203.55 ± 2.13 g/L mechanized and 207.63 ± 3.04 g/L manual), which aligns with the known characteristics of this variety, recognized for its higher acidity and lower sugar content (

Table 1). Muscat Ottonel and Feteasca Regală displayed intermediate values, with relatively smaller variations between the harvesting methods, which may indicate that these varieties are less affected by the harvesting technique in terms of sugar composition. In Pinot Noir, the reducing sugar content was consistently higher when grapes were harvested manually compared to mechanical methods. This difference highlights the sensitivity of this variety to the harvesting technique. Manual harvesting allows for greater selectivity and gentler handling, which helps preserve sugar accumulation in berries. These findings are in line with previous studies emphasizing that mechanical harvesting may reduce sugar content due to berry damage and mixed ripeness levels. While mechanized harvesting offers operational efficiency, manual methods remain preferable for preserving optimal sugar profiles in sensitive varieties intended for high-quality wine production. For example, in the case of Pinot Noir, the difference between manual and mechanized harvesting is approximately 4.5 g/L, while for Sauvignon Blanc, it is 4.08 g/L. These differences could be attributed to the more selective nature of manual harvesting, which allows for the collection of grapes at optimal ripeness. Mechanized harvesting, on the other hand, is a faster process and less selective, potentially including grapes at different ripening stages, which may explain the slight reduction in sugar content. In the case of Muscat Ottonel, the differences between harvesting methods are negligible (209.98 ± 1.06 g/L mechanized vs. 209.18 ± 11.16 g/L manual), suggesting that this variety is less affected by the method of harvesting. The reported

p-values (4.119 and 12.078) and significance level (***) indicate that the observed differences are statistically significant. This confirms that both grape variety and harvesting method have a significant impact on the reducing sugar content. Our results indicate that the method of grape harvesting significantly influences the reducing sugar content, with manually harvested grapes consistently exhibiting higher sugar levels than those harvested mechanically. The observed differences in reducing sugar content between harvesting methods are also supported by international guidelines, which emphasize the importance of monitoring and controlling sugar levels in grapes at the time of harvest to ensure the desired oenological outcomes [

28]. This aligns with previous research, such as the study by the International Organization of Vine and Wine [

29], which emphasizes that manual harvesting allows for selective grape picking, reducing berry damage and preserving sugar integrity [

29]. Similarly, a metabolomics study on grape varieties cultivated in Xinjiang, China [

2], highlighted that sugar accumulation is highly sensitive to handling techniques, reinforcing the idea that mechanical harvesting may lead to slight sugar loss due to increased physical stress on the berries [

2]. These findings suggest that while mechanized harvesting offers efficiency, manual methods. These findings suggest that while mechanized harvesting offers efficiency and scalability, manual methods provide superior control over fruit selection, thereby better preserving sugar concentrations and minimizing biochemical degradation during harvest. In our study, we observed that manual harvesting generally resulted in lower total acidity (TA) levels across various grape varieties compared to mechanized harvesting. For instance, Muscat Ottonel exhibited a TA of 4.89 ± 0.24 g/L H

2SO

4 with manual harvesting, whereas mechanized harvesting yielded a higher TA of 5.59 ± 0.14 g/L H

2SO

4. This trend aligns with findings from other research, which suggest that manual harvesting, due to its gentle handling of grape clusters, may lead to reduced berry damage and, consequently, lower TA levels. In contrast, mechanized harvesting, while efficient, can cause increased berry injury, potentially leading to higher TA levels. These observations underscore the impact of harvesting methods on grape acidity, with manual harvesting favoring lower acidity levels, which can influence the sensory attributes and overall quality of the resulting wines. These findings are consistent with prior research on Merlot grapes, which demonstrated that manual harvesting can positively influence wine composition by reducing berry damage and preserving favorable biochemical characteristics, including sugar and acidity levels [

30]. Kaltbach et al. (2022) [

30] reported that wines produced from manually harvested grapes showed more balanced profiles, with improved sugar retention and lower total acidity compared to those obtained through mechanical harvesting, reinforcing the idea that harvest method plays a crucial role in determining grape and wine quality. The results indicate that the total acidity of grapes is significantly influenced by both the grape variety and the harvesting method. Among the studied varieties, Feteasca Regală exhibited the highest total acidity values, while Muscat Ottonel had the lowest. In terms of harvesting method, mechanized harvesting generally resulted in higher acidity levels compared to manual harvesting. This is likely due to the increased exposure of berries to oxidative processes and potential cellular damage during mechanical collection, which may lead to a higher concentration of organic acids. These findings align with previous research, such as the study, which demonstrated that mechanically harvested grapes tend to retain higher acidity due to minimal dehydration and prolonged exposure to metabolic changes post-harvest [

31]. Similarly, Kaltbach et al. (2022) [

30] found that manually harvested grapes, particularly in warm climates, tend to have lower acidity due to selective picking of riper berries with more sugar and less acid [

32]. These comparative insights reinforce the observed trends in our study and highlight the role of harvest technique in shaping grape acidity, a critical parameter in winemaking. Our results indicate significant differences in total acidity (g/L C

4H

6O

6) among grape varieties and between harvesting methods. Mechanized harvesting preserved higher acidity levels, with Sauvignon Blanc showing the highest values (9.06 ± 0.05 g/L mechanized vs. 8.59 ± 0.22 g/L manual), while Muscat Ottonel exhibited the lowest (8.37 ± 0.01 g/L mechanized vs. 7.61 ± 0.07 g/L manual). This suggests that mechanical harvesting includes less ripe berries with higher acidity, whereas manual harvesting favors riper grapes with lower acid content. These findings align with Kontoudakis et al. (2010) [

31], who reported that mechanically harvested grapes tend to retain more acidity due to a wider range of berry maturities, influencing must composition and final wine characteristics. The results demonstrate significant differences in both free and total SO

2 content across grape varieties and harvesting methods. Sauvignon Blanc and Feteasca Regală exhibited the highest total SO

2 levels, with 25.00 ± 0.44 mg/L and 25.00 ± 0.01 mg/L under mechanized harvesting, which slightly increased to 25.98 ± 1.17 mg/L and remaining at 25.00 ± 0.01 mg/L, respectively, under manual harvesting. Conversely, Pinot Noir had the lowest total SO

2 content, with 20.26 ± 0.80 mg/L for mechanized harvesting and 20.63 ± 0.81 mg/L for manual harvesting. Regarding free SO

2, Muscat Ottonel had the highest level under mechanized harvesting (7.00 ± 0.01 mg/L), whereas Sauvignon Blanc showed the highest value under manual harvesting (6.02 ± 0.13 mg/L). In contrast, Pinot Noir exhibited the lowest free SO

2 concentration, with 2.00 ± 0.01 mg/L under both harvesting methods. The observed differences suggest that mechanized harvesting, which can cause greater berry damage and oxidation, may lead to an increased need for SO

2 to maintain stability. Manual harvesting, by preserving berry integrity, may contribute to slightly lower total SO

2 levels, except in cases like Sauvignon Blanc, where free SO

2 is higher, likely due to differences in grape physiology and oxidation potential. These findings align with prior research indicating that grape handling significantly influences SO

2 retention, with manual harvesting often providing better control over oxidative processes (Kontoudakis et al., 2011) [

32]. The statistical significance (

p < 0.001) confirms the strong impact of both grape variety and harvesting method on SO

2 composition, emphasizing the importance of harvest techniques in optimizing wine quality and stability. There is a relatively small but notable difference in pH across varieties and harvesting methods. Sauvignon Blanc and Feteasca Regală show the lowest pH values (~3.16–3.19), while Muscat Ottonel has the highest (~3.45–3.54). This suggests that Muscat Ottonel grapes tend to be less acidic, aligning with findings from previous studies on aromatic varieties. The differences between mechanized and manual harvesting are minor, indicating that pH is less influenced by the harvesting method.

Malic acid levels show more pronounced variation. Feteasca Regală contains the highest malic acid concentration (3.93 g/L for mechanized and 3.74 g/L for manual harvesting), while Muscat Ottonel has the lowest (2.83 g/L for mechanized and 2.71 g/L for manual). Generally, manually harvested grapes have lower malic acid content, which aligns with research indicating that selective manual harvesting often results in riper grapes with lower malic acid due to increased respiration during ripening (Kontoudakis et al., 2011) [

32]. The statistical significance (

p < 0.001) confirms that harvesting method plays a role in malic acid concentration. Tartaric acid, a crucial determinant of wine stability and freshness, also varies significantly (

p < 0.001). Sauvignon Blanc shows the highest levels (5.92 g/L for manual vs. 5.45 g/L for mechanized), whereas Feteasca Regală and Pinot Noir have the lowest (~4.86–4.97 g/L). Manual harvesting tends to increase tartaric acid content in Sauvignon Blanc but slightly reduces it in other varieties, suggesting that the variety-specific ripening process may influence this trend. These findings align with existing research on acidity modulation in grapes and its role in wine quality (Kontoudakis et al., 2011) [

32], and Ramos et al., 2017 [

33]. The results emphasize that grape variety has a stronger influence on pH and acidity than the harvesting method, but manual selection tends to enhance grape maturity, affecting acidity composition.

The present study highlights the impact of harvesting methods on the potassium and nitrogen content of grape must across different varieties. The results indicate that mechanized harvesting consistently leads to higher potassium levels compared to manual harvesting. For example, in Sauvignon Blanc, potassium concentration was significantly higher in mechanized harvesting (1219.67 ± 11.02 mg/L) than in manual harvesting (827.67 ± 23.50 mg/L). Similar trends were observed in Feteasca Regală (1217.67 ± 16.26 mg/L vs. 1111.67 ± 12.90 mg/L) and Pinot Noir (1057.33 ± 22.12 mg/L vs. 937.00 ± 15.39 mg/L). These findings align with previous research indicating that potassium levels in grape must are influenced by vineyard practices, grape variety, and berry integrity at harvest. Elevated potassium content can influence wine acidity by increasing pH, potentially affecting wine stability and sensory characteristics [

34]. In terms of nitrogen composition, mechanized harvesting also resulted in higher concentrations of organic and inorganic nitrogen, which are critical for yeast metabolism during fermentation. Muscat Ottonel, for instance, exhibited higher total nitrogen levels in mechanized harvesting (306.33 ± 5.03 mg/L) than in manual harvesting (253.33 ± 11.59 mg/L). Similarly, Pinot Noir showed total nitrogen levels of 265.33 ± 8.08 mg/L in mechanized harvesting versus 224.00 ± 11.14 mg/L in manual harvesting. The increase in nitrogenous compounds in mechanically harvested grapes could be due to a greater release of intracellular nutrients from damaged grape skins and pulp. While higher nitrogen availability can promote fermentation efficiency, excessive nitrogen may also influence the sensory profile of wine, leading to the production of unwanted volatile compounds [

35]. Overall, these findings suggest that harvesting methods significantly impact the chemical composition of grape must, influencing both potassium and nitrogen content. Mechanized harvesting appears to enhance the extraction of minerals and nutrients, which can have both beneficial and detrimental effects on wine quality, depending on the desired wine style. These results emphasize the importance of selecting appropriate harvesting techniques to optimize grape composition and fermentation performance. Our study highlights significant differences in catechin and polyphenol content in grape must as influenced by harvesting methods. Catechins, important flavonoids contributing to wine astringency and antioxidant properties, were consistently higher in mechanized harvesting compared to manual harvesting. For example, Pinot Noir exhibited the highest catechin concentration with mechanized harvesting (108.33 ± 3.06 mg/L), while manual harvesting resulted in lower values (86.33 ± 11.32 mg/L). Although statistically significant, these differences in catechin levels also have practical implications, as higher catechin concentrations may enhance the wine’s antioxidant capacity and contribute to better aging potential and mouthfeel, particularly in red varieties such as Pinot Noir. Similar trends were observed for Feteasca Regală (59.00 ± 3.00 mg/L vs. 45.33 ± 5.51 mg/L) and Muscat Ottonel (43.00 ± 2.00 mg/L vs. 35.67 ± 8.33 mg/L). These findings align with previous research indicating that mechanized harvesting increases catechin extraction due to the physical impact on grape skins, leading to greater release of phenolic compounds [

36].

Total polyphenol content followed a similar pattern, with significantly higher values recorded for mechanized harvesting. Pinot Noir must contained 782.00 ± 7.94 mg/L polyphenols when harvested mechanically, compared to 745.33 ± 9.50 mg/L with manual harvesting. Likewise, Feteasca Regală and Muscat Ottonel showed higher polyphenol levels with mechanized harvesting (561.67 ± 14.84 mg/L and 509.00 ± 2.00 mg/L, respectively) than manual harvesting (426.33 ± 8.39 mg/L and 428.33 ± 6.51 mg/L, respectively). These differences are consistent with studies showing that mechanical harvesting promotes the extraction of polyphenolic compounds, particularly in red grape varieties where skin maceration plays a crucial role [

37]. However, excessive polyphenol extraction can also influence wine bitterness and oxidative stability, which must be carefully managed during vinification.

3.2. Comprehensive Assessment of Wine Quality: The Influence of Harvesting Method on Essential Physicochemical and Oenological Characteristics

The analysis of alcohol concentration in must from different grape varieties harvested using both mechanized and manual methods reveals significant variations, particularly in manually harvested grapes (

p = 2.743), whereas differences in mechanized harvesting are less pronounced (

p = 0.579). Among the mechanized harvesting group, Pinot Noir (12.33 ± 0.21%) and Muscat Ottonel (12.29 ± 0.07%) exhibited the highest alcohol concentrations, while Sauvignon Blanc (12.03 ± 0.12%) and Feteasca Regală (12.11 ± 0.20%) showed slightly lower values. However, manual harvesting led to a more noticeable increase in alcohol content, particularly in Pinot Noir (13.13 ± 0.26%), suggesting that selective grape picking during manual harvesting may favor riper berries with higher sugar content, ultimately resulting in increased alcohol levels. Similarly, Muscat Ottonel (12.35 ± 0.05%) and Feteasca Regală (12.28 ± 0.28%) demonstrated slightly higher alcohol content in manually harvested samples compared to their mechanized counterparts. These differences can be attributed to the varying sugar content in each grape variety, as higher sugar levels during fermentation generally result in increased alcohol production. The results align with findings by Kontoudakis et al. (2011) [

32], who reported that grape maturity and composition significantly impact alcohol formation in wine. Additionally, variations in grape physiology and climatic adaptation may also contribute to these observed differences [

38]. The influence of mechanized harvesting on alcohol content remains a subject of debate. While some studies suggest that mechanized methods may lead to a more homogenous grape selection, potentially affecting sugar content and subsequent alcohol levels [

38], our findings indicate that the differences observed are more likely driven by intrinsic varietal characteristics rather than the harvesting method itself. Further studies comparing manual and mechanized harvesting under controlled conditions could provide deeper insights into these effects (

Table 2).

The analysis of residual sugar content in must from different grape varieties harvested using mechanized and manual methods reveals statistically significant variations (

p = 9.400 for mechanized harvesting,

p = 0.709 for manual harvesting). For mechanized harvesting, Feteasca Regală exhibited the highest residual sugar content (3.58 ± 0.15 g/L), followed by Sauvignon Blanc (2.54 ± 0.33 g/L) and Pinot Noir (1.99 ± 0.05 g/L), while Muscat Ottonel had the lowest value (1.51 ± 0.14 g/L). In contrast, manual harvesting led to more balanced sugar retention across varieties, with Feteasca Regală (2.64 ± 0.46 g/L) and Muscat Ottonel (2.26 ± 0.26 g/L) showing slightly higher values, while Sauvignon Blanc (1.67 ± 0.11 g/L) recorded the lowest residual sugar content. These differences suggest that mechanized harvesting may lead to increased sugar retention in some varieties, potentially due to mechanical stress affecting grape integrity and fermentation dynamics. Conversely, manual harvesting, which ensures better grape selection, may favor a more uniform fermentation process with lower residual sugar. Similar trends have been observed in studies analyzing the impact of harvesting methods on fermentation efficiency and sugar metabolism [

37,

38]. Further investigations into yeast activity and enzymatic degradation during fermentation could provide deeper insights into these variations.

The analysis of total and volatile acidity in must from different grape varieties harvested through mechanized and manual methods reveals statistically significant variations (p < 0.001 for all parameters). Although statistically significant, the observed difference in SO2 concentration is within the normal range for white wines and does not pose technological or sensory concerns. For total acidity expressed as H2SO4, Pinot Noir exhibited the highest values (5.35 ± 0.25 g/L for mechanized and 5.12 ± 0.18 g/L for manual harvesting), followed by Feteasca Regală (4.70 ± 0.47 g/L, 4.87 ± 0.08 g/L) and Sauvignon Blanc (4.63 ± 0.13 g/L, 4.65 ± 0.14 g/L). The lowest values were recorded for Muscat Ottonel (4.28 ± 0.25 g/L, 4.14 ± 0.02 g/L). A similar pattern was observed for total acidity expressed as C4H6O6, where Pinot Noir had the highest acidity (8.05 ± 0.06 g/L mechanized, 7.53 ± 0.33 g/L manual), while Muscat Ottonel recorded the lowest (6.55 ± 0.26 g/L mechanized, 6.62 ± 0.15 g/L manual). These results suggest that Pinot Noir retains more acidity regardless of the harvesting method, a factor that could enhance its freshness and aging potential. For volatile acidity, which is crucial for sensory quality, Pinot Noir again displayed the highest values (0.32 ± 0.04 g/L CH3COOH for mechanized harvesting and 0.26 ± 0.10 g/L for manual harvesting), while Sauvignon Blanc showed the lowest (0.20 ± 0.01 g/L for both harvesting methods). The relatively higher volatile acidity in mechanized-harvested musts, particularly for Muscat Ottonel and Pinot Noir, may be attributed to greater oxidation and microbial activity due to the handling process.

While the differences between mechanized and manual harvesting were minimal in most cases, certain trends emerged. Manual harvesting tended to slightly reduce total acidity in Pinot Noir and Sauvignon Blanc but increased it in Feteasca Regală. This could be related to better grape selection, leading to variations in organic acid composition. Mechanized harvesting resulted in slightly higher volatile acidity across all varieties, suggesting that increased exposure to oxygen and possible microbial contamination might influence the development of acetic acid precursors. These findings align with previous studies highlighting the impact of harvesting methods on acidity retention and volatile acidity formation in must and wine [

37,

38]. Understanding these variations is essential for optimizing harvest strategies, particularly for varieties like Pinot Noir and Feteasca Regală, where acidity management is critical for wine balance and stability.

The analysis of SO

2 concentrations in must from different grape varieties, harvested through both mechanized and manual methods, highlights significant variations (

p < 0.01 for free SO

2 and

p < 0.001 for total SO

2). These differences are crucial, as sulfur dioxide plays a key role in microbial stability and oxidation prevention during winemaking. Sauvignon Blanc recorded the highest free SO

2 levels (25.00 ± 2.00 mg/L for mechanized, 27.67 ± 1.53 mg/L for manual), followed by Pinot Noir (24.00 ± 2.65 mg/L mechanized, 23.00 ± 2.65 mg/L manual). The lowest values were observed in Muscat Ottonel (14.67 ± 1.53 mg/L mechanized, 20.33 ± 1.53 mg/L manual), indicating a potentially higher susceptibility to oxidation. Similarly, total SO

2 was highest in Sauvignon Blanc (67.67 ± 1.53 mg/L mechanized, 71.00 ± 6.56 mg/L manual), while Feteasca Regală showed the lowest values (55.67 ± 0.58 mg/L mechanized, 62.67 ± 2.08 mg/L manual). These results suggest that Sauvignon Blanc and Pinot Noir require higher SO

2 protection due to their composition and oxidation potential. Manual harvesting tended to result in slightly higher SO

2 levels across all varieties, with Sauvignon Blanc showing the most notable increase (+2.67 mg/L free SO

2, +3.33 mg/L total SO

2). This may be attributed to better grape integrity during manual picking, reducing oxidation and microbial load, which, in turn, allows for more effective SO

2 binding. Conversely, mechanized harvesting, which often causes berry breakage, led to lower free SO

2 levels, possibly due to increased binding with oxidation byproducts and fermentation precursors. These findings align with previous studies indicating that grape variety and handling methods significantly affect SO

2 retention and efficacy in must and wine [

38,

39]. Managing SO

2 levels is essential for maintaining wine stability and sensory properties, particularly for aromatic and oxidation-sensitive varieties like Sauvignon Blanc and Muscat Ottonel.

Among the analyzed varieties, Muscat Ottonel exhibited the highest pH values (3.36 ± 0.26 for mechanized, 3.22 ± 0.11 for manual harvesting), suggesting lower acidity compared to other grapes. In contrast, Feteasca Regală had the lowest pH values (3.21 ± 0.10 for mechanized, 3.09 ± 0.02 for manual harvesting), indicating higher acidity, which may contribute to greater freshness and longevity in the final wine. Sauvignon Blanc and Pinot Noir fell within an intermediate range (3.16–3.19 for mechanized, 3.17–3.18 for manual harvesting). Manual harvesting was associated with slightly lower pH values in most cases, particularly for Feteasca Regală (3.09 manual vs. 3.21 mechanized) and Pinot Noir (3.17 manual vs. 3.19 mechanized). This could be attributed to reduced berry damage and lower oxidation levels, which help preserve acidity. Conversely, mechanized harvesting, which can cause berry rupture and exposure to oxygen, might lead to minor acid degradation and a slight pH increase. These results are consistent with previous studies (Marcuzzo et al., 2021 [

37]; Kontoudakis et al., 2011 [

32]), which indicate that grape handling and variety-specific buffering capacity influence must pH. Since lower pH contributes to microbial stability and color intensity, the findings suggest that careful SO

2 management is particularly important for high-pH musts like Muscat Ottonel to prevent oxidation and microbial growth.

The analysis of malic acid concentration in must from different grape varieties reveals significant differences between mechanized and manual harvesting methods (

p ***). Sauvignon Blanc (3.70 ± 0.05 g/L) and Feteasca Regală (3.77 ± 0.25 g/L) exhibited the highest malic acid levels under mechanized harvesting, whereas manual harvesting resulted in lower concentrations, particularly for Sauvignon Blanc (2.86 ± 0.26 g/L) and Muscat Ottonel (2.34 ± 0.15 g/L). Mechanized harvesting may retain more malic acid, likely because of how grapes are handled and how metabolism changes after harvest. Interestingly, lactic acid was below the limit of detection (BLD) in all samples, indicating the absence of malolactic fermentation at this stage. Since malolactic fermentation converts malic acid into lactic acid, its absence implies that the musts retain their natural acidity, which is crucial for freshness and stability in white wines. These findings align with previous studies, such as those by Kontoudakis et al. (2011) [

32] and Piccardo et al. (2019) [

38], which discuss how grape maturity and processing conditions influence acidity and stability in musts and wines.

The analysis of tartaric acid levels in musts from different grape varieties subjected to mechanized and manual harvesting methods reveals significant differences. Mechanized harvesting generally resulted in higher levels of tartaric acid in Pinot Noir (4.68 ± 0.25 g/L) compared to manual harvesting (4.28 ± 0.15 g/L), reflecting a clear effect of harvesting method on the acid profile of this variety. In contrast, Sauvignon Blanc showed a higher tartaric acid concentration in the manually harvested grapes (3.91 ± 0.48 g/L) compared to mechanized harvesting (3.66 ± 0.25 g/L). Muscat Ottonel and Feteasca Regală both exhibited relatively stable tartaric acid concentrations across both harvesting methods, with values slightly decreasing under manual harvesting, especially for Feteasca Regală (3.55 ± 0.39 g/L) compared to mechanized harvesting (3.70 ± 0.15 g/L). These results underline that while some grape varieties, such as Pinot Noir, show a notable impact of harvesting method on tartaric acid, others may be less sensitive, suggesting potential variability depending on the grape variety.

The analysis of the physicochemical properties of musts, including density, non-reducing dry extract, and total dry extract from different grape varieties harvested using mechanized and manual methods, reveals significant differences in all parameters assessed. For density at 20 °C, Pinot Noir exhibited the highest values for both harvesting methods, with mechanized harvesting showing 0.9952 ± 0.001 g/cm3, while manual harvesting yielded 0.9995 ± 0.04 g/cm3. This indicates a slight increase in density under manual harvesting. In contrast, Sauvignon Blanc showed the lowest density in mechanized harvesting (0.9918 ± 0.001 g/cm3), with a marginal increase in the manual harvesting method (0.9922 ± 0.001 g/cm3). Regarding the non-reducing dry extract (a measure of the concentration of dissolved solids excluding reducing sugars), Pinot Noir again had the highest values across both harvesting methods (mechanized: 18.63 ± 0.97 g/L, manual: 19.16 ± 0.52 g/L). On the other hand, Sauvignon Blanc had the lowest levels of non-reducing dry extract, particularly in mechanized harvesting (17.16 ± 1.46 g/L), which were consistent with lower concentrations in manual harvesting (17.35 ± 1.06 g/L). The total dry extract, which includes all dissolved solids in the must, followed a similar trend to the non-reducing dry extract. Pinot Noir once again showed the highest values for both harvesting methods (mechanized: 20.77 ± 0.36 g/L, manual: 21.55 ± 0.62 g/L). Conversely, Sauvignon Blanc exhibited the lowest total dry extract concentrations, 19.52 ± 0.77 g/L with mechanized harvesting and 18.91 ± 1.25 g/L with manual harvesting.

These results suggest that Pinot Noir grapes are associated with higher concentrations of solids, both reducing and non-reducing, compared to other varieties, and this may be indicative of a higher potential for wine body and mouthfeel. Meanwhile, Sauvignon Blanc and other varieties like Muscat Ottonel and Feteasca Regală tend to show lower extractive values, which might influence their flavor profile and structure. The significant differences observed for each parameter (

p-values ranging from 6.471 to 22.065, all with

p < 0.05) confirm that the harvesting method and grape variety play a critical role in the must’s physicochemical composition, impacting the final wine characteristics. This study aligns with the existing literature on the impact of grape variety and harvesting methods on must composition, particularly in the context of wine stability and quality (Kontoudakis et al., 2011) [

32]. These findings are valuable for winemakers aiming to optimize their processes for specific grape varieties and desired wine qualities.

3.3. Exploring the Influence of Harvesting Techniques on Must Composition and Wine Quality

In this study, four grape varieties were selected: Fetească Regală and Sauvignon Blanc for white wines, and the aromatic Muscat Ottonel and Pinot Noir for red wines. These varieties were chosen due to their prominence in the vineyard plantations of the Târnave region, which is known for its favorable terroir for these types of grapes.

Both Fetească Regală and Sauvignon Blanc are widely cultivated for their high acidity and aromatic profiles, making them ideal for producing crisp, refreshing white wines. Pinot Noir is a well-known red variety that thrives in cooler climates, while Muscat Ottonel is a distinctive aromatic variety known for its floral and fruity characteristics, commonly used in sweet and semi-sweet wines. Two distinct harvesting methods were employed: manual harvesting and mechanized harvesting. Manual harvesting was performed by hand, using scissors or knives to cut the grape bunches, which were then placed into buckets or crates. These crates were carefully transported to the winery and emptied into reception hoppers. This method has several advantages, primarily due to its selectivity. Manual harvesting allows for a meticulous sorting process in the vineyard, where only the ripe and healthy berries are selected, thus minimizing the risk of contaminants like leaves, stems, or damaged grapes. Additionally, manual harvesting is ideal for vineyards with uneven terrain or rows that are difficult to access with machinery (

Figure 2).

On the other hand, mechanized harvesting was carried out using self-propelled harvesters, equipped with a beater system that efficiently detaches grapes from the vines. The system utilizes a series of 12–14 beaters that vibrate to separate the grapes from the bunches, with the frequency of oscillation adjusted according to grape variety, ripeness, and the harvester’s forward speed. In this study, the harvesting was conducted at a speed of 2.8 km/h and a frequency of 440 beats per minute. Mechanized harvesting is widely used due to its speed, labor efficiency, and cost-effectiveness. However, it tends to be more aggressive, as the mechanical process can cause more damage to the grapes, leading to broken skins and exposed pulp. This increases the likelihood of oxidation, which can result in higher acidity and undesirable sensory characteristics in the wine.

The physicochemical composition of the must, which forms the basis of the wine, is highly influenced by the harvesting method. Acidity, sugar levels, extracts, and phenolic compounds are some of the primary factors that shape the quality of the must and, consequently, the wine. The results observed in this study revealed significant differences in these parameters based on the method of harvesting.

For example, total acidity levels in musts from mechanically harvested grapes were found to be generally higher than those from manually harvested grapes, particularly in Sauvignon Blanc and Pinot Noir. The mechanical harvesting process tends to increase the mechanical stress on the berries, which can lead to the release of more phenolic compounds, including acids. As a result, the must from mechanically harvested grapes exhibited higher levels of volatile acidity and tartaric acid, which contributed to a more acidic final wine. In contrast, manual harvesting helped preserve the natural balance of acids in the grapes, resulting in musts with more controlled acidity levels. Further analysis revealed that total dry extract in wines from mechanically harvested musts was higher compared to wines made from manually harvested grapes. This increase in dry extract suggests that the more aggressive mechanical harvesting led to a higher extraction of compounds from the skins and seeds, which include tannins, phenolics, and other macromolecules. These compounds, while beneficial for aging and stability, contribute to a more astringent mouthfeel and may give the wine a harsher structure upon immediate consumption. Wines produced from manually harvested grapes, in contrast, exhibited smoother tannins, indicative of lower extraction, which is often associated with wines that are more approachable in their youth (Gutiérrez-Escobar et al., 2021) [

39]. Moreover, the sulfur dioxide (SO

2) levels required for stabilizing the wines were higher in wines from mechanically harvested grapes. This is because the mechanical harvesting process, by causing more damage to the grapes, increases the risk of oxidation and the development of volatile compounds like acetic acid, which are typically undesirable in wine production (Gutiérrez-Escobar et al., 2021) [

39]. Therefore, to prevent further oxidation and microbial spoilage, higher amounts of SO

2 were needed in the fermentation process for wines made from mechanically harvested musts.

The Sauvignon Blanc and Muscat Ottonel varieties demonstrated a remarkable contrast in their response to the harvesting method. Sauvignon Blanc, known for its naturally high acidity, performed well under both harvesting techniques, although wines made from mechanically harvested grapes tended to have higher acidity, which is characteristic of the more aggressive mechanical process. On the other hand, Muscat Ottonel, which has a more aromatic profile, seemed to retain better aromatic compounds when manually harvested. This indicates that manual harvesting is more suited to aromatic varieties that benefit from careful handling to preserve volatile esters and terpenes that contribute to their fragrance and flavor. In contrast, the Pinot Noir variety, which is highly sensitive to handling, showed the most dramatic differences between the two methods. Manual harvesting proved to be far more suitable for maintaining the delicate balance of phenolic compounds and acidity required for quality Pinot Noir production. The more aggressive mechanical harvesting method caused increased berry damage, which led to the breakdown of anthocyanins and tannins, resulting in wines with less desirable color and flavor profiles.

The higher catechin and total polyphenol concentrations observed in mechanically harvested grapes—particularly in red cultivars like Pinot Noir—can have important enological consequences. On one hand, these compounds contribute to enhanced antioxidant stability, which may support improved aging potential by protecting against oxidative degradation. On the other hand, excessive catechin levels may lead to increased bitterness and astringency, especially in wines with shorter maceration periods or lacking sufficient phenolic balance. Therefore, while mechanical harvesting can provide phenolic richness beneficial for long-term storage, careful vinification management (e.g., adjusted maceration time, fining) is essential to mitigate undesirable sensory effects.

3.4. Economic Efficiency of Manual vs. Mechanized Grape Harvesting: A Comparative Analysis

In this analysis, we aim to compare the economic efficiency of manual and mechanized grape harvesting methods, focusing on various factors such as labor costs, productivity, and additional costs associated with each method. By carefully analyzing these elements, we seek to provide valuable recommendations for the viticulture sector in Romania, where these harvesting methods are commonly employed.

Manual Harvesting: Cost Breakdown

Productivity per Worker:

In the context of manual harvesting, a single worker typically collects 600 kg of grapes per day, working 7 h. However, this productivity is subject to fluctuation due to several factors, including grape variety, vineyard conditions, and weather. It is important to note that, in some cases, a worker may collect between 400 kg and 800 kg of grapes per day depending on these factors.

Labor Cost:

The total cost of labor for one worker is 210 RON per day (gross salary), which includes all taxes to be paid to the state. After deductions, the net salary for the worker is 140 RON per day. For the purpose of this analysis, we will focus on the gross salary of 210 RON, as it reflects the actual cost to the employer.

Conversion: At an exchange rate of approximately 1 EUR = 4.9 RON (rate at the time of writing):

210 RON = 42.86 EUR (gross per worker per day).

Productivity per Hectare (Fetească Neagră Example):

Considering an average yield of 8000 kg of grapes per hectare for the Fetească Neagră variety, the number of working days required to harvest one hectare is calculated as

8000 kg/600 kg per worker = 13.33 days.

Therefore, the total labor cost per hectare for harvesting is as follows:

13.33 days × 210 RON = 2800 RON per hectare or 571.43 EUR per hectare.

Additional Costs:

Transportation of Workers to the Vineyard: The cost of transporting workers to the vineyard is 500 RON per day for the rental of a microbus, excluding VAT.

500 RON = 102.04 EUR per day.

Transportation of Grapes: Using a tractor to transport grapes consumes approximately 12 L of diesel per day. Given the price of diesel at 7 RON per liter, the daily cost of fuel for transporting grapes is 12 L × 7 RON = 84 RON per day or 17.14 EUR.

Total Cost for Manual Harvesting: Since the number of days required for harvesting one hectare is 13.33, we can calculate the following:

Worker transportation: 500 RON/day × 13.33 days = 6665 RON or 1358.67 EUR.

Tractor transportation: 84 RON/day × 13.33 days = 1127 RON or 229.59 EUR.

Thus, the total additional costs associated with manual harvesting are as follows:

6665 RON (worker transport) + 1127 RON (grape transport) = 7792 RON or 1591.27 EUR.

Total Cost for Manual Harvesting:

Combining labor costs and additional costs:

2800 RON (labor) + 7792 RON (additional costs) = 10,592 RON per hectare or 2161.84 EUR per hectare.

Mechanized Harvesting: Cost Breakdown

Harvesting Service Cost:

For mechanized harvesting, the cost is generally fixed at 2500 RON per hectare, excluding VAT. This cost remains the same regardless of the amount of grapes harvested per hectare (whether it is 6 tons or 20 tons).

2500 RON = 510.20 EUR per hectare.

Additional Costs:

Tractor Transportation of Grapes: Similar to the manual harvesting method, the tractor used for transporting the grapes consumes about 15 L of diesel per day. With diesel priced at 7 RON per liter, the daily cost for transporting grapes is 15 L × 7 RON = 105 RON per day or 21.43 EUR per day.

Since mechanized harvesting typically requires only one day of work per hectare, the cost for transporting the grapes will be

105 RON or 21.43 EUR.

Total Cost for Mechanized Harvesting:

Combining the harvesting service cost and additional transport costs:

2500 RON (harvesting service) + 105 RON (transportation) = 2605 RON per hectare or 531.63 EUR per hectare.

Comparison of Manual vs. Mechanized Harvesting Costs:

Manual Harvesting:

Total cost per hectare: 10,592 RON or 2161.84 EUR.

Mechanized Harvesting:

Total cost per hectare: 2605 RON or 531.63 EUR.

Clearly, mechanized harvesting is significantly more cost-effective than manual harvesting. The total cost for mechanized harvesting is approximately 75% lower than the cost of manual harvesting. This difference is primarily due to the lower labor costs associated with mechanized harvesting, as well as the reduction in transportation and other associated costs.

Implications for Viticulture in Romania: Labor Costs and Efficiency: While mechanized harvesting is much cheaper, it is essential to consider the potential trade-off in terms of quality. Manual harvesting offers a more selective picking process, which ensures only the healthiest and ripest grapes are harvested. This method is particularly advantageous for high-quality wines, where maintaining the integrity of the grapes is crucial. On the other hand, mechanized harvesting, while more cost-efficient, may lead to the harvesting of under-ripe or over-ripe grapes, as well as the inclusion of leaves and stems, which could negatively affect the wine’s quality. Moreover, the increased mechanical stress during the harvesting process may result in the extraction of higher levels of tannins, which can contribute to a more astringent taste and potentially lower the overall drinkability of the wine.

The following table presents a comparative summary of key economic indicators associated with manual and mechanized grape harvesting under the specific conditions of Romanian viticulture. The data include labor cost per ton, fuel consumption and maintenance expenses, equipment depreciation or rental costs, and the resulting total estimated cost per ton of harvested grapes. These quantified elements allow for a more nuanced understanding of the cost-efficiency trade-offs between traditional and modern harvesting approaches. By aggregating these variables, the table highlights the financial advantages of mechanized harvesting for large-scale operations, while also underscoring the higher labor demands and precision associated with manual techniques. This synthesis supports informed decision-making regarding harvesting strategies, especially when balancing production scale, wine quality expectations, and budget constraints (

Table 3).

Impact on Wine Quality: For grape varieties like Pinot Noir, which require a more delicate handling process due to their sensitivity, manual harvesting may be essential to preserve their flavor profile and ensure the final wine has the desired balance of acidity, sugar content, and phenolic compounds. Conversely, for more robust grape varieties such as Sauvignon Blanc or Merlot, which tend to have thicker skins and higher acidity, mechanized harvesting may be more suitable, as they are generally more resilient to the harsher handling methods. For premium wines, particularly those with delicate or aromatic varieties, manual harvesting should be prioritized, despite the higher cost. This method allows for more precise grape selection, reducing the risk of oxidation and contamination, and ensuring that the wine reflects the true characteristics of the grape variety. For bulk wine production, where cost efficiency is more critical, mechanized harvesting is a viable solution. It can significantly reduce labor costs, improve harvesting efficiency, and be particularly advantageous for large-scale vineyards with robust grape varieties. Hybrid Approach: In some cases, a hybrid approach may be adopted, where the initial pass through the vineyard is mechanized to gather the majority of the harvest, followed by manual sorting and selection to ensure the highest-quality grapes are used for the final wine production.

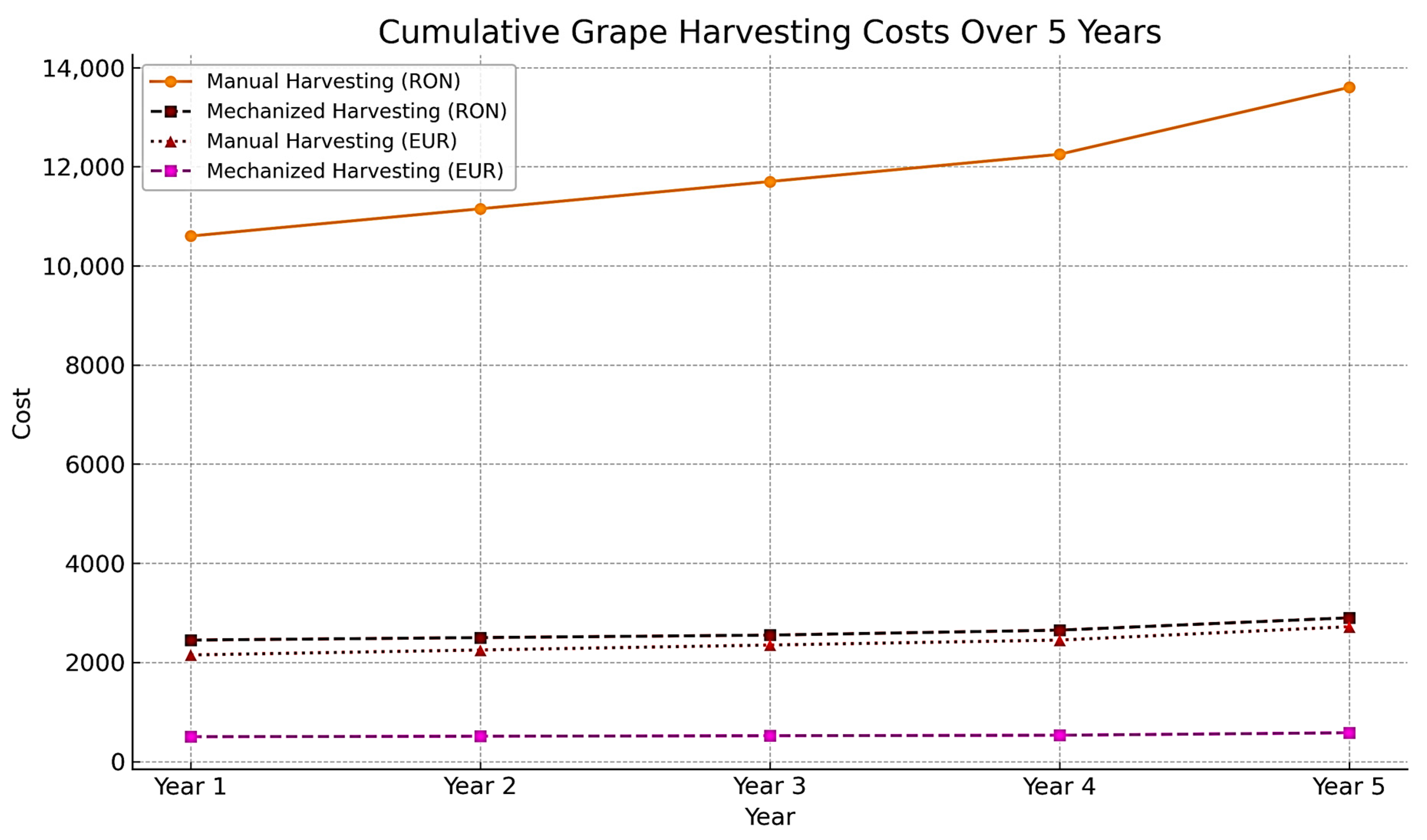

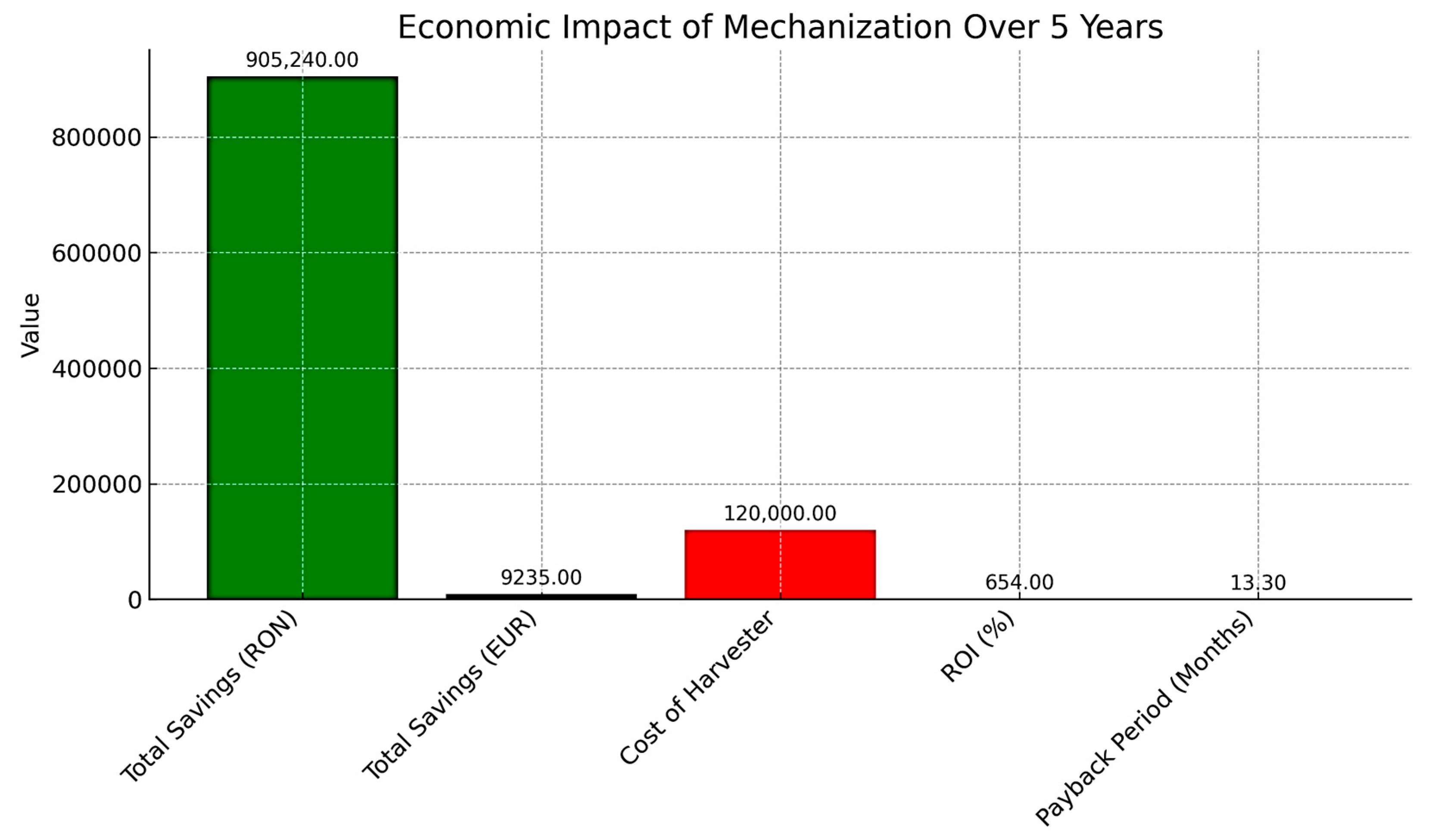

Figure 3 displays a comparative economic analysis of manual versus mechanized grape harvesting, with cost breakdowns per hectare in RON and EUR. The data clearly highlight substantial savings with mechanized harvesting, primarily due to lower labor and transportation costs, which is essential for optimizing vineyard management in modern viticulture.

3.5. Cost Structure and Labor Efficiency: Key Metrics in Manual vs. Mechanized Grape Harvesting

A forward-looking economic analysis of grape harvesting costs was conducted, comparing manual and mechanized methods over a five-year period. This projection, based on prevailing industry trends and economic indicators, anticipates a steady increase in labor-related expenses. In particular, manual harvesting costs are expected to rise by approximately 5% annually due to escalating wages, persistent labor shortages, and increased regulatory compliance costs. These assumptions reflect not only the inflationary pressures in rural labor markets but also the growing challenges in recruiting seasonal workers for viticulture, especially in countries like Romania, where urban migration and an aging population have significantly reduced the available workforce. In contrast, mechanized harvesting costs are projected to grow at a slower annual rate of 3%, a figure that incorporates modest increases in fuel prices, periodic maintenance, spare parts replacement, and machinery depreciation. The lower growth rate reflects the scalability and energy efficiency improvements in modern agricultural equipment, as well as the reduced dependency on human labor. Furthermore, mechanization benefits from economies of scale: as technology becomes more widespread and competitive, upfront capital investments tend to be amortized over larger vineyard areas and longer timeframes, effectively diluting per-hectare costs.

By modeling these divergent growth rates over five years, the analysis aims to capture the long-term financial implications for vineyard operators. The results indicate that while both cost categories are expected to increase, the gap between manual and mechanized harvesting will widen significantly. In year five, manual harvesting is projected to reach a cost of 13,525 RON (approximately 2760 EUR) per hectare, compared to 3016 RON (615 EUR) per hectare for mechanized harvesting. This differential represents a cumulative savings of 10,509 RON (2145 EUR) per hectare in favor of mechanization—an increasingly compelling argument for its adoption in regions facing rising labor pressures.

At the end of the five-year projection period, the cumulative financial impact of rising operational costs highlights a clear economic divergence between manual and mechanized grape harvesting. Specifically, manual harvesting is anticipated to reach a total cost of approximately 13,525 RON (2760 EUR) per hectare, whereas mechanized harvesting is expected to incur a significantly lower cost of about 3016 RON (615 EUR) per hectare. This results in a substantial cost gap of 10,509 RON (2145 EUR) per hectare, favoring mechanized practices.

This widening cost differential is primarily driven by the compounding nature of labor cost increases, which are assumed to rise at an annual rate of 5%. Given the labor-intensive nature of manual harvesting, even modest wage inflation substantially affects total expenditures. In contrast, mechanized harvesting, while incurring expenses related to fuel, maintenance, and machinery depreciation, is projected to increase at a more conservative rate of 3% annually. This slower growth trajectory underscores the long-term cost stability associated with mechanical solutions.