Simulation and Optimization Experiment of Seven-Link Planting Mechanism Based on Discrete Element Method and Multibody Dynamics (DEM–MBD) Coupling

Abstract

1. Introduction

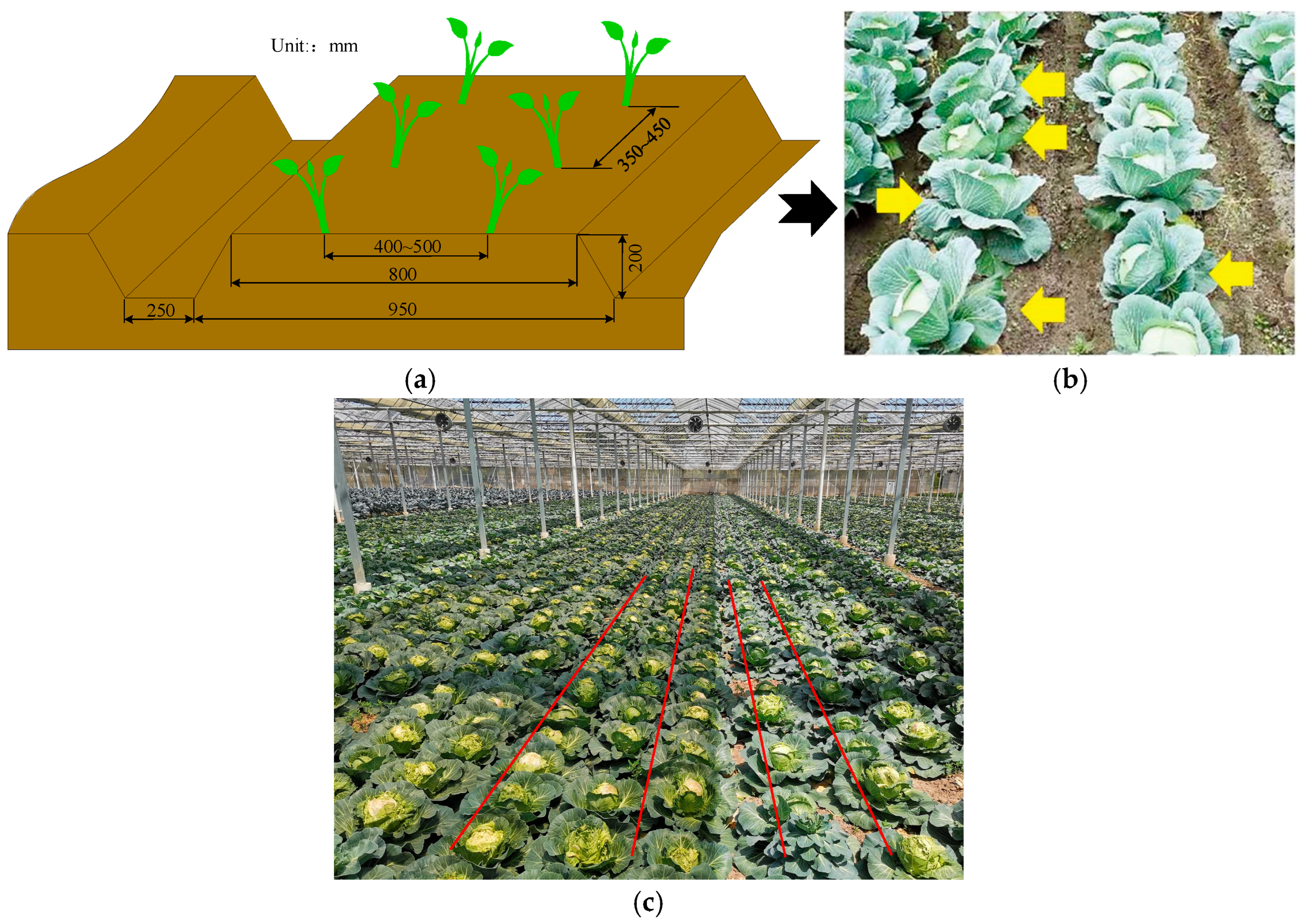

2. Materials and Methods

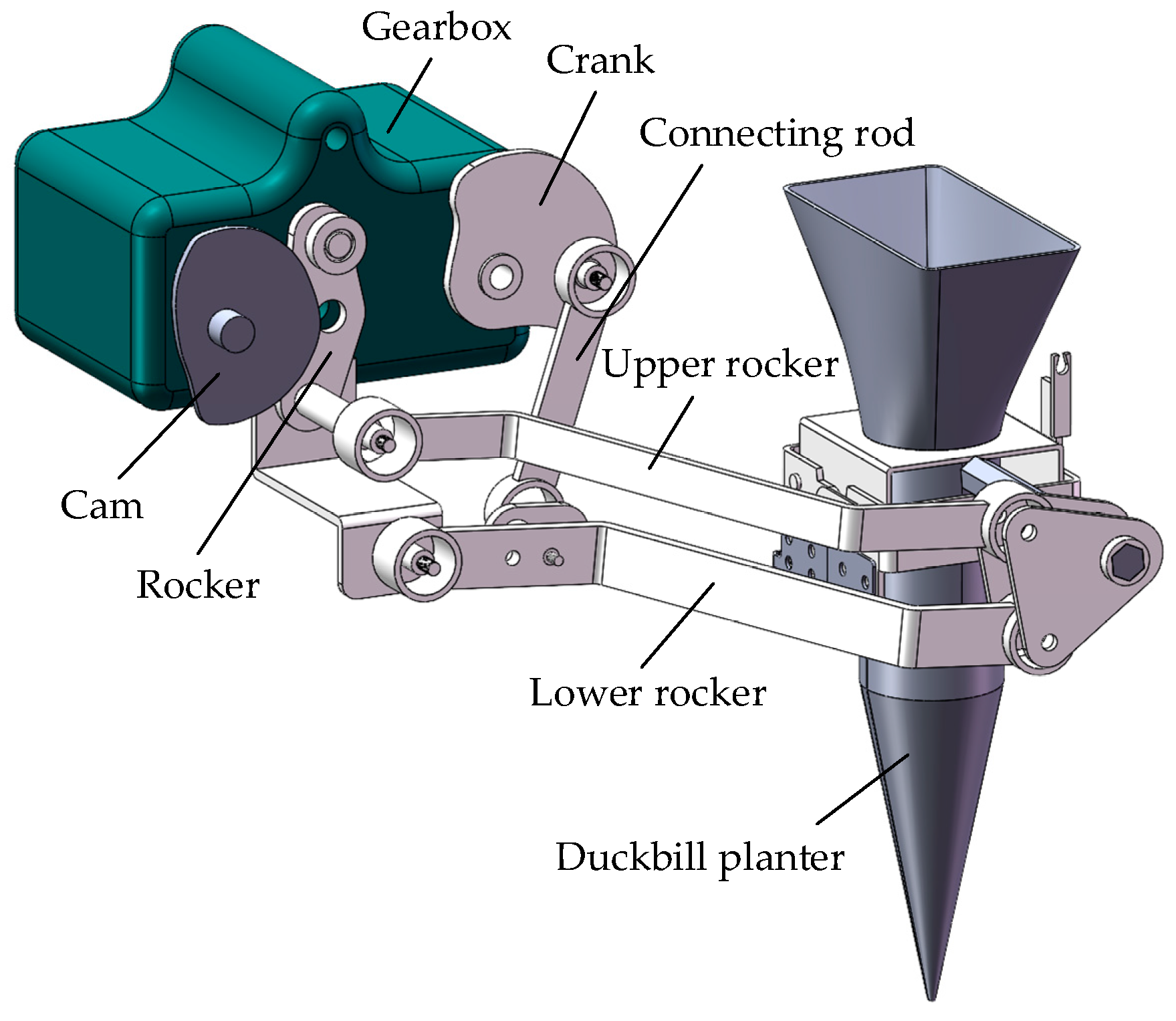

2.1. Prototype Components

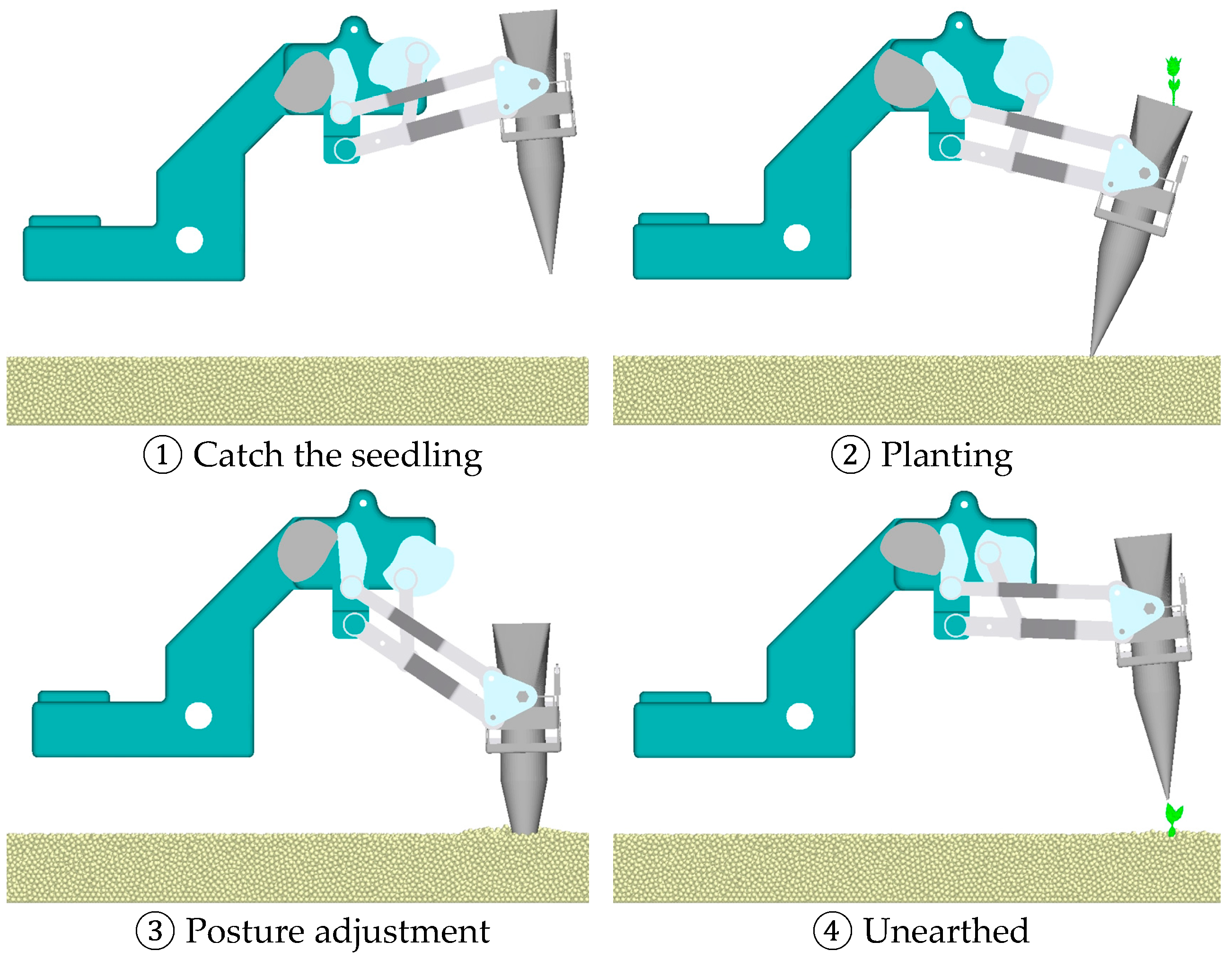

2.2. Working Principle

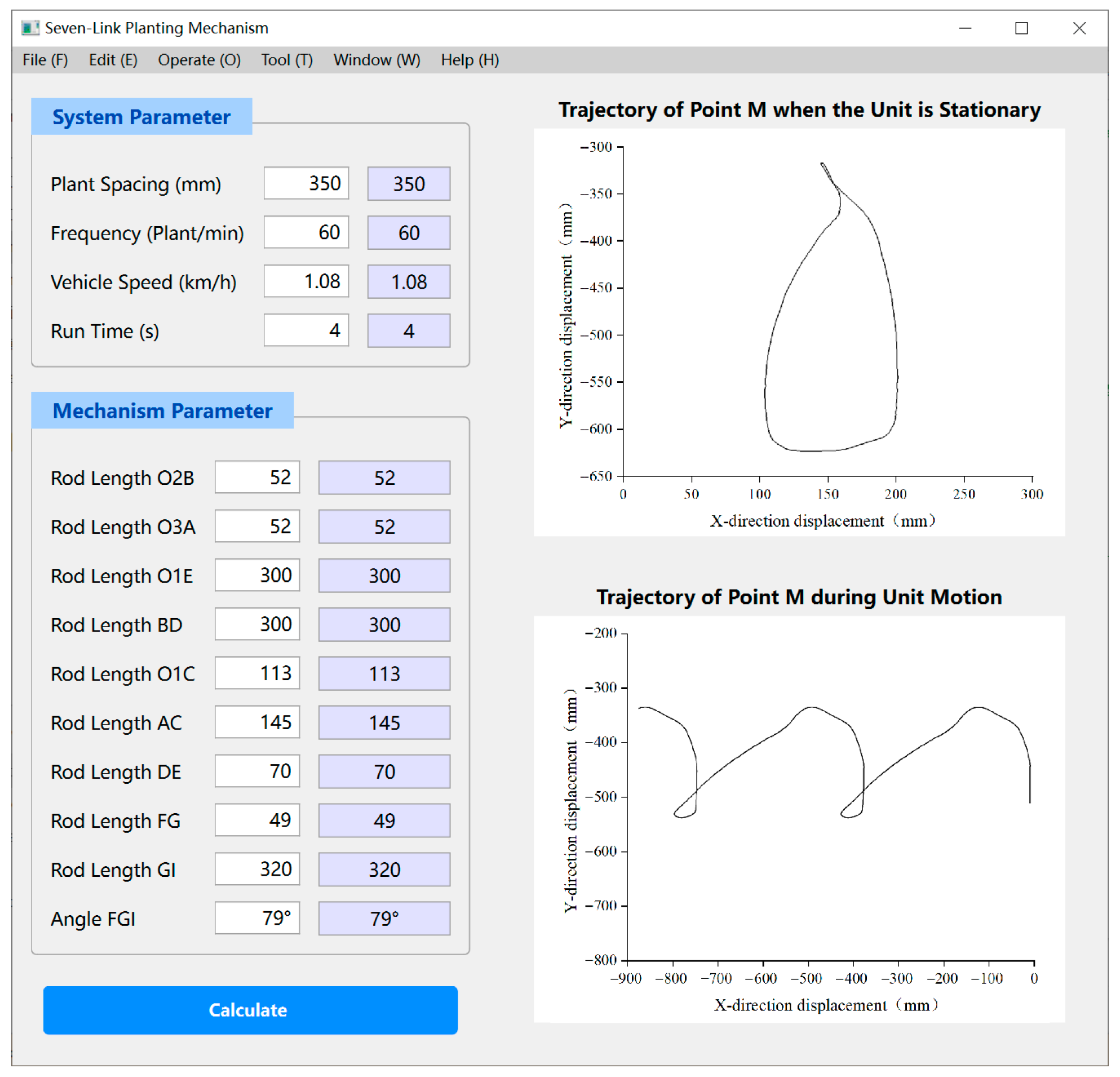

2.3. Mathematical Modeling Establishment and Linkage Optimization

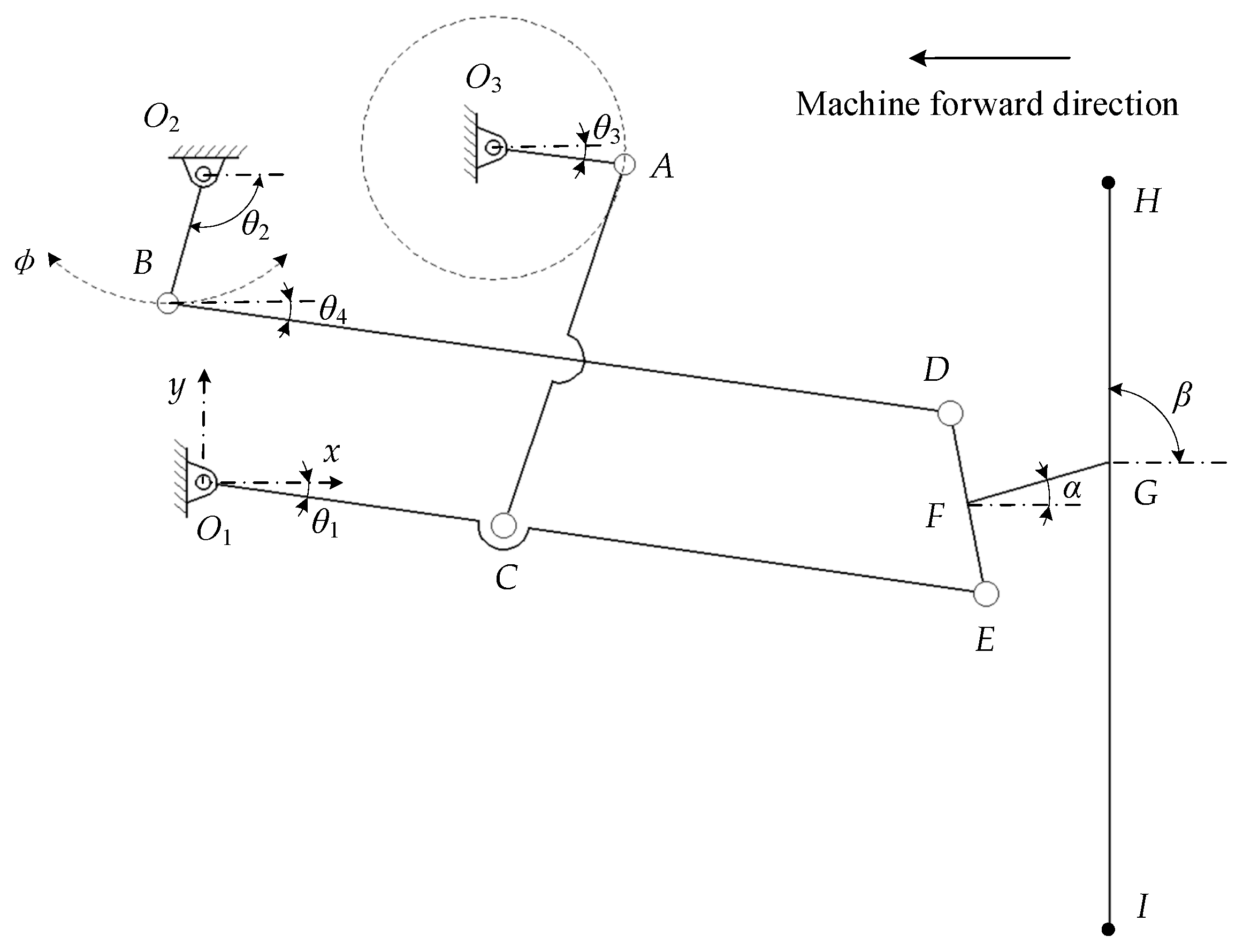

2.3.1. Establishment of Kinematic Model

2.3.2. Constraints

2.3.3. Linkage Optimization

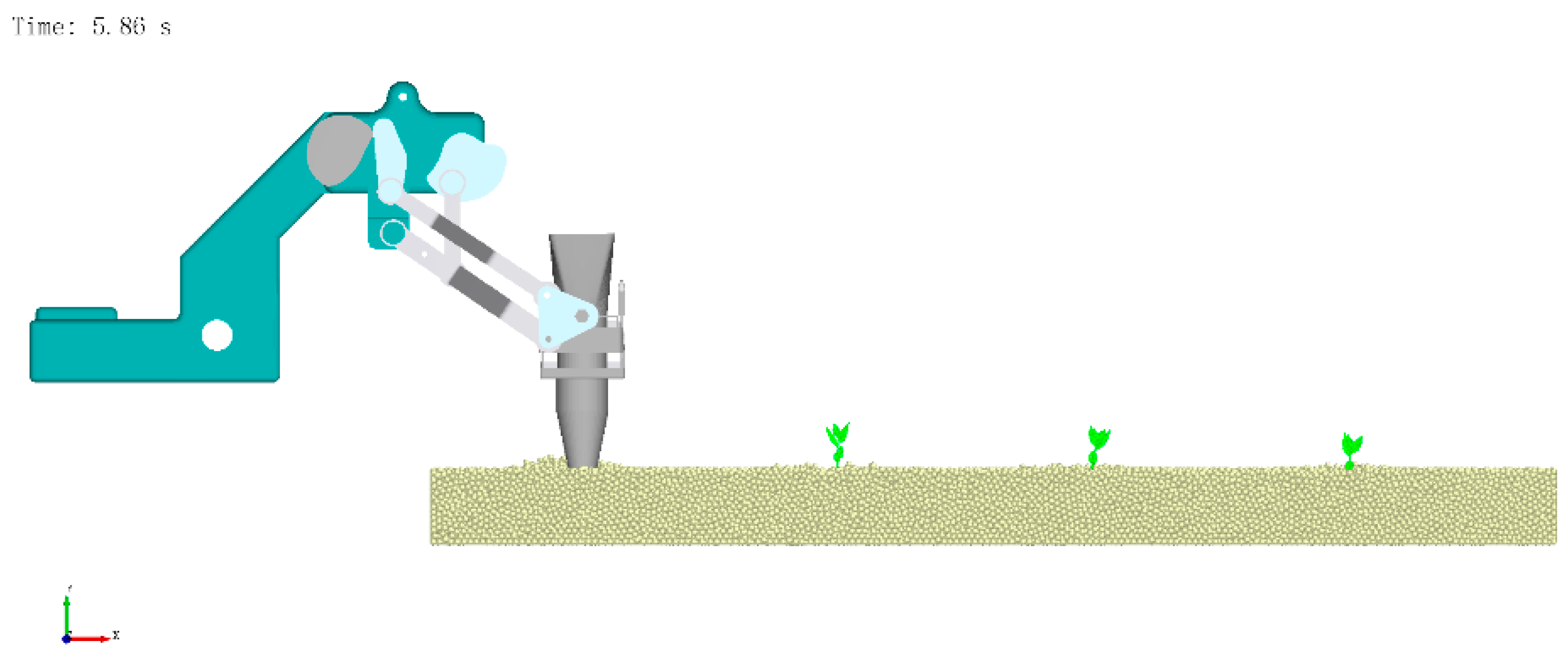

2.4. Establishment of DEM–MBD Coupling Simulation Model

2.5. Test Factors and Evaluation Indicators

3. Results and Discussion

3.1. Test Results

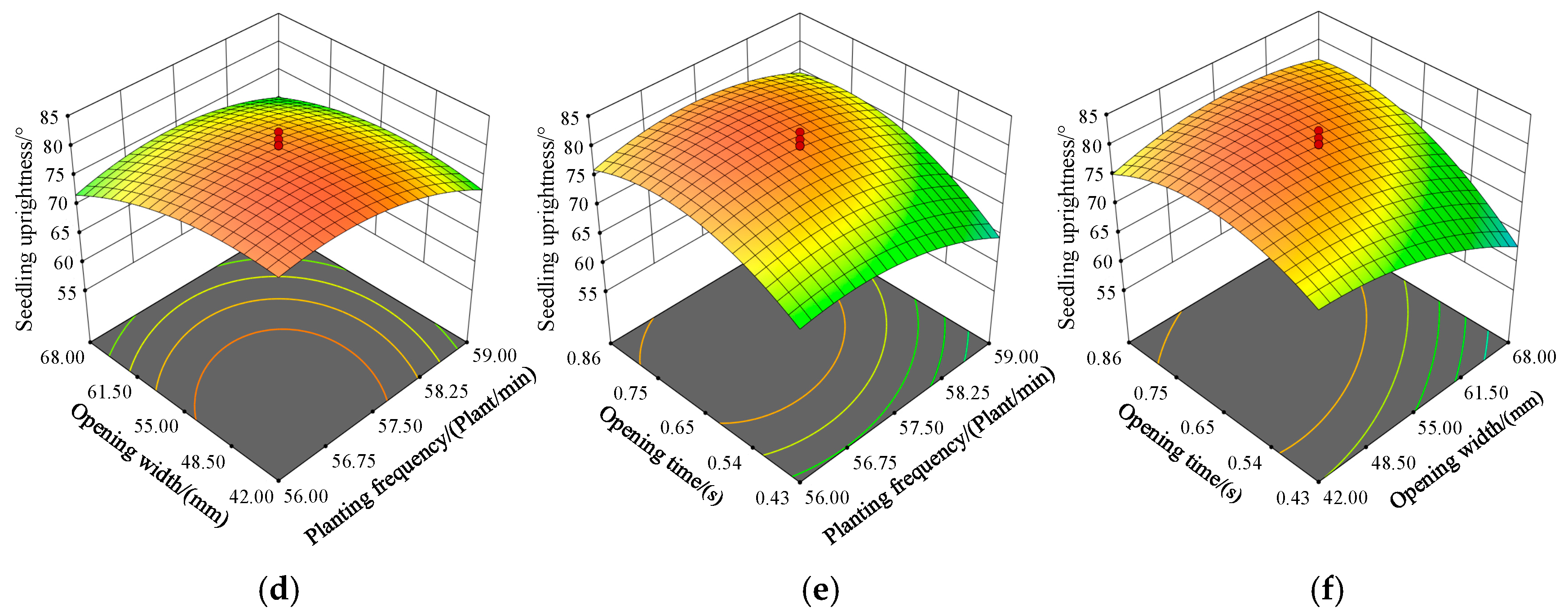

3.2. Results Analysis

3.3. Parameter Optimization

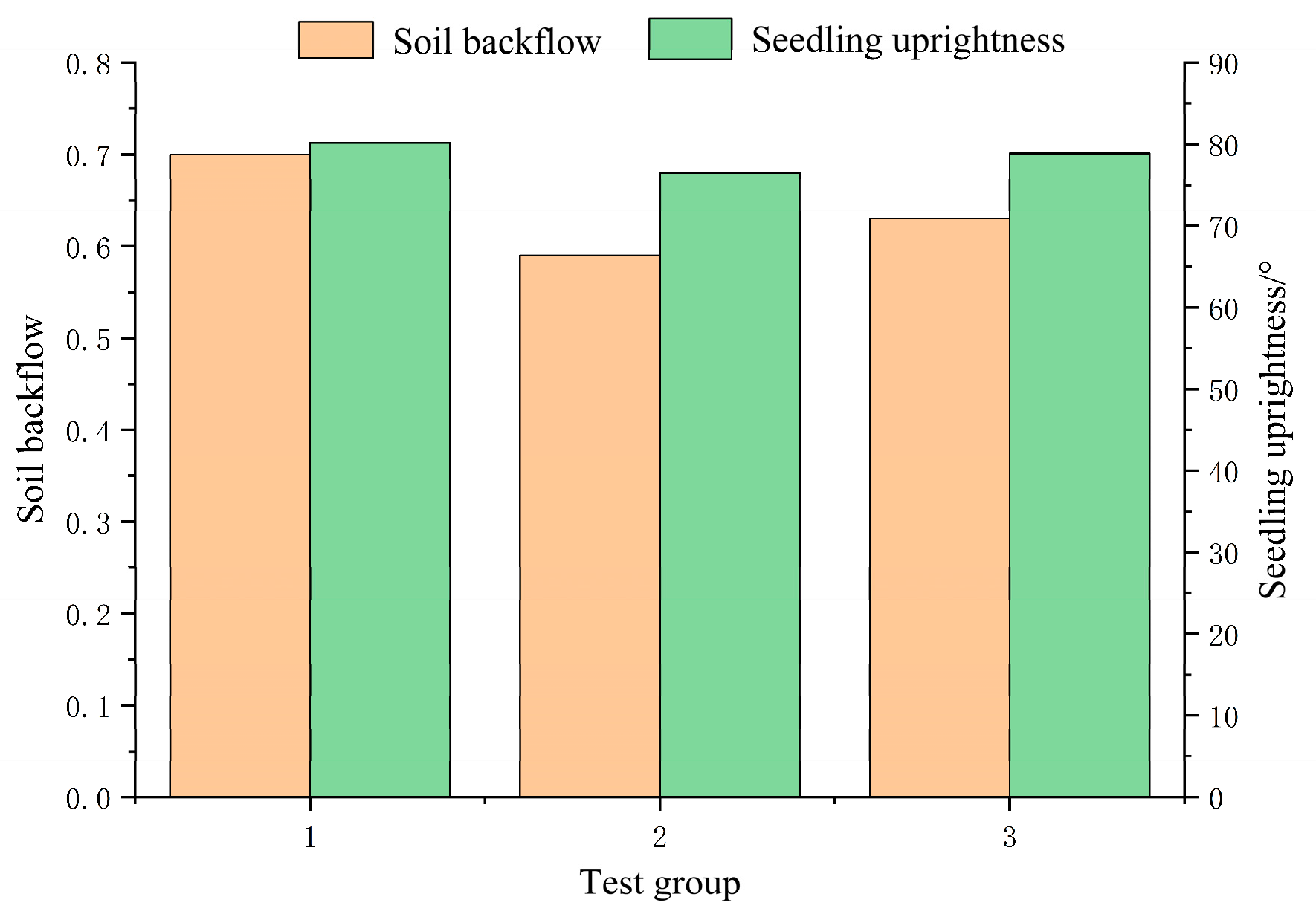

3.4. Field Test

3.5. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yan, H.; Liu, C.; Li, P.; Chen, R.; Zhou, H. Design and experiment of duckbill planting device with adjustable static trajectory for planting vegetable transplanters. Trans. Chin. Soc. Agric. Mach. 2023, 54, 71–81. [Google Scholar]

- Yu, G.; Wang, L.; Sun, L.; Zhao, X.; Ye, C. Progress in research on mechanised transplanting technology and equipment for large fields. Trans. Chin. Soc. Agric. Mach. 2022, 53, 1–20. (In Chinese) [Google Scholar]

- Zheng, J.; Huang, H. Progress and suggestions on full mechanization of rapeseed production in the middle reaches of the Yangtze River. Chin. J. Oil Crop Sci. 2024, 46, 245–259. [Google Scholar]

- Cui, Z.; Guan, C.; Yang, Y.; Gao, Q.; Chen, Y. Research status of vegetable mechanized transplanting technology and equipment. J. Chin. Agric. Mech. 2020, 41, 85–92. (In Chinese) [Google Scholar]

- Cui, Z.; Guan, C.; Xu, T.; Yang, Y.; Xu, B.; Chen, Y. Development status of technology and equipment of substrate block seedling cultivation and transplanting. J. Chin. Agric. Mech. 2021, 43, 29–34. (In Chinese) [Google Scholar]

- Song, J.; Zhang, Y.; Wang, Z.; Li, K.; Cui, Z. Design and experiment of asymmetrical planting implement for garlic upright planter. Trans. Chin. Soc. Agric. Mach. 2024, 55, 116–128, 261. [Google Scholar]

- Wang, Y.; He, Z.; Wang, J.; Wu, C.; Yu, G.; Tang, Y. Experiment on transplanting performanceof automatic vegetable pot seedling transplanter for dry land. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2018, 34, 19–25, (In Chinese with English Abstract). [Google Scholar]

- Liu, C. Design and Experiment of Reciprocating Duckbill Planting Device. Master’s Thesis, Chinese Academy of Agricultural Mechanization Sciences, Beijing, China, 2023. [Google Scholar]

- Yang, Q.; Zhu, M.; Jia, C.; Li, Z.; He, W.; Hu, J. Simulation and experiment of hole forming performance on the membrane of hanging cup planter of high-speed transplanter for pot seedling. J. Chin. Agric. Mech. 2022, 43, 1–7. [Google Scholar]

- Liu, Y. Damage Mechanism of Vegetable Pot Transplanting Pot and Optimization and Experiment of Planter Cavitation Movement. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2019. [Google Scholar]

- Han, C.; Xiao, L.; Xu, Y.; Zhang, J.; Li, H. Design and experiment of automatic seedling transplanting machine for pepper hole. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2021, 37, 20–29. [Google Scholar]

- Yin, Z. Design and Experiment of Planting Mechanism of Automatic Tomato Transplanter. Master’s Thesis, Sichuan Agricultural University, Ya’an, China, 2022. [Google Scholar]

- Li, H.; He, T.; Liu, H.; Shi, S.; Zhou, J.; Liu, X.; Wang, B. Development of cutting transplanting machine on film of sweet potato in hilly region. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2023, 39, 26–35. [Google Scholar]

- Maraveas, C.; Tsigkas, N.; Bartzanas, T. Agricultural process simulation using discrete element method: A review. Comput. Electron. Agric. 2025, 237, 110733. [Google Scholar] [CrossRef]

- He, Y.; Li, S.; Yang, X.; Yan, H.; Wang, W. Motion analysis and performance test of cam swing-rod type planting mechanism. Trans. CSAE 2016, 32, 34–41. [Google Scholar]

- Yin, W.; Liu, H.; Hu, F.; Yan, H.; Guo, D.; Wu, Y. Optimization design and experiment of eight-linkage planting mechanism of dryland transplanter. Trans. Chin. Soc. Agric. Mach. 2020, 51, 51–60. [Google Scholar]

- Xiao, M.; Sun, S.; Luo, H.; Wu, W.; Luo, J. Kinematics analysis and experiment of double parallel multi-pole planting mechanism. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2014, 30, 25–33. [Google Scholar]

- Liao, Q.; Liu, M.; Zhang, Z.; Hu, X. Multi-objective optimization design of double-five-bar planting mechanism of rape pot seedling transplanter. Trans. Chin. Soc. Agric. Mach. 2015, 46, 49–56. [Google Scholar]

- Cui, Z.; Guan, C.; Xu, T.; Fu, Q.; Chen, Y. Design and experiment of double-row chain planting device for cabbage substrate block seedlings. Trans. Chin. Soc. Agric. Mach. 2023, 54, 46–54. (In Chinese) [Google Scholar]

- Zhao, Y. Design and Experimental Study of the Planting Mechanism of Electric Tobacco Transplanter. Master’s Thesis, Kunming University of Science and Technology, Kunming, China, 2024. [Google Scholar]

- Ankit, S.; Sanjay, K. Current developments in vegetable transplanters in developing countries: A comprehensive review. Int. J. Veg. Sci. 2022, 28, 417–440. [Google Scholar] [CrossRef]

- Li, H.; Cao, W.; Li, S.; Liu, J.; Chen, B.; Ma, X. Development of 2ZXM-2 automatic plastic filmmulching plug seedling transplanter for vegetable. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 23–33. (In Chinese) [Google Scholar]

- Li, P.; Yan, H.; Wang, P.; Li, L.; Wu, H. Optimization and test of small plant spacing planting mechanism rod for transplanter. Trans. Chin. Soc. Agric. Mach. 2020, 51, 72–78. [Google Scholar]

- Chen, L. Optimization Design and Experiment of Self-Propelled Vegetable Transplanting Machine Planting Device. Master’s Thesis, Shandong Agricultural University, Taian, China, 2024. [Google Scholar]

- Mao, P.; Li, J.; Zhang, S.; Xu, R. Kinematic analysis of seven-rod planting mechanism of seedling transplanter—Based on MATLAB. J. Agric. Mech. Res. 2013, 35, 59–62. [Google Scholar]

- Xu, G.; Song, Y.; Chu, R.; Jian, S.; Qiu, X.; Gao, Q. Dynamic optimization design and experiment of five-bar transplanting mechanism, with counterweight for Salvia, miltiorrhiza. J. Chin. Agric. Mech. 2022, 43, 15–21. [Google Scholar]

- Jin, Y.; Hu, J.; Lü, J.; Yao, M.; Liu, W. Design and Experiment of Multi-blade Duck Bill Planting Mechanism for Automatic Vegetable Transplanter. Trans. Chin. Soc. Agric. Mach. 2024, 55, 217–229. [Google Scholar]

- Hou, J.; Zhang, E.; Zhang, K.; Li, Y. Optimization Design and Test of Seedling Picking and Throwing Device of Plug Seeding Transplanter Based on DEM-MFBD. Trans. Chin. Soc. Agric. Mach. 2023, 54, 46–57, 87. [Google Scholar]

- Jia, C. Study on the Interaction Mechanism Between the Hanging Cup Planter and Soil of High-Speed Transplanter for Plug Seedling Based on DEM. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2021. [Google Scholar]

- Department of Agricultural Mechanization, Ministry of Agriculture and Rural Affairs. Vegetable Transplanter: DG/T 283-2023; China Agriculture Press: Beijing, China, 2023.

| Parameters | Seeding | Soil | Planting Device |

|---|---|---|---|

| Density (kg/m3) | 1000 | 2800 | 7800 |

| Poisson’s ratio | 0.25 | 0.25 | 0.25 |

| Shear modulus (pa) | 1 × 106 | 1 × 106 | 1 × 108 |

| Parameters | Seeding–Seeding | Seeding–Soil | Seeding–Plant Device | Soil–Soil | Soil–Planting Device |

|---|---|---|---|---|---|

| Static friction coefficient | 0.5 | 0.5 | 0.1 | 0.5 | 0.1 |

| Rolling friction coefficient | 0.01 | 0.1 | 0.01 | 0.01 | 0.01 |

| Impact recovery coefficient | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Level | Factors | ||

|---|---|---|---|

| Planting Frequency X1/(plant/min) | Opening Width X2/(mm) | Opening Time X3/(s) | |

| 1.682 | 60.00 | 70.00 | 0.90 |

| 1 | 59.00 | 68.00 | 0.86 |

| 0 | 57.50 | 55.00 | 0.65 |

| −1 | 56.00 | 42.00 | 0.43 |

| −1.682 | 55.00 | 40.00 | 0.40 |

| No. | Planting Frequency X1/(Plant/min) | Opening Width X2/(mm) | Opening Time X3/(s) | Soil Backflow Y1 | Seedling Uprightness Y2/(°) |

|---|---|---|---|---|---|

| 1 | −1 | −1 | −1 | 0.59 (0.05) | 78.53 (0.59) |

| 2 | 1 | −1 | −1 | 0.47 (0.08) | 67.23 (1.36) |

| 3 | −1 | 1 | −1 | 0.45 (0.09) | 62.85 (1.54) |

| 4 | 1 | 1 | −1 | 0.43 (0.06) | 57.47 (2.61) |

| 5 | −1 | −1 | 1 | 0.72 (0.02) | 75.24 (0.58) |

| 6 | 1 | −1 | 1 | 0.65 (0.06) | 70.15 (0.93) |

| 7 | −1 | 1 | 1 | 0.54 (0.07) | 73.54 (0.76) |

| 8 | 1 | 1 | 1 | 0.52 (0.04) | 73.43 (0.68) |

| 9 | −1.682 | 0 | 0 | 0.59 (0.04) | 71.84 (0.92) |

| 10 | 1.682 | 0 | 0 | 0.55 (0.05) | 67.12 (1.15) |

| 11 | 0 | −1.682 | 0 | 0.6 (0.06) | 74.66 (0.79) |

| 12 | 0 | 1.682 | 0 | 0.45 (0.09) | 67.49 (1.24) |

| 13 | 0 | 0 | −1.682 | 0.52 (0.07) | 58.96 (2.53) |

| 14 | 0 | 0 | 1.682 | 0.7 (0.01) | 72.51 (0.66) |

| 15 | 0 | 0 | 0 | 0.67 (0.03) | 80.33 (0.25) |

| 16 | 0 | 0 | 0 | 0.64 (0.05) | 79.15 (0.38) |

| 17 | 0 | 0 | 0 | 0.65 (0.04) | 78.47 (0.49) |

| 18 | 0 | 0 | 0 | 0.63 (0.05) | 82.43 (0.17) |

| 19 | 0 | 0 | 0 | 0.67 (0.03) | 80.19 (0.41) |

| 20 | 0 | 0 | 0 | 0.63 (0.04) | 78.37 (0.65) |

| 21 | 0 | 0 | 0 | 0.65 (0.06) | 81.26 (0.57) |

| 22 | 0 | 0 | 0 | 0.62 (0.03) | 79.51 (0.48) |

| 23 | 0 | 0 | 0 | 0.65 (0.05) | 80.24 (0.32) |

| Source | Y1 | Y2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SS | DF | MS | F | p | SS | DF | MS | F | p | |

| Model | 0.1502 | 9 | 0.0167 | 37.66 | <0.0001 ** | 1102.46 | 9 | 122.50 | 47.74 | <0.0001 ** |

| X1 | 0.0065 | 1 | 0.0065 | 14.60 | 0.0021 ** | 65.10 | 1 | 65.10 | 25.37 | 0.0002 ** |

| X2 | 0.0403 | 1 | 0.0403 | 91.03 | <0.0001 ** | 94.47 | 1 | 94.47 | 36.81 | <0.0001 ** |

| X3 | 0.0460 | 1 | 0.0460 | 103.83 | <0.0001 ** | 176.30 | 1 | 176.30 | 68.70 | <0.0001 ** |

| X1X2 | 0.0028 | 1 | 0.0028 | 6.35 | 0.0256 * | 14.85 | 1 | 14.85 | 5.79 | 0.0317 * |

| X1X3 | 0.0003 | 1 | 0.0003 | 0.7051 | 0.4162 | 16.47 | 1 | 16.47 | 6.42 | 0.0249 * |

| X2X3 | 0.0021 | 1 | 0.0021 | 4.77 | 0.0479 * | 91.26 | 1 | 91.26 | 35.56 | <0.0001 ** |

| X12 | 0.0146 | 1 | 0.0146 | 32.96 | <0.0001 ** | 179.40 | 1 | 179.40 | 69.91 | <0.0001 ** |

| X22 | 0.0340 | 1 | 0.0340 | 76.63 | <0.0001 ** | 124.24 | 1 | 124.24 | 48.41 | <0.0001 ** |

| X32 | 0.0042 | 1 | 0.0042 | 9.38 | 0.0091 ** | 348.64 | 1 | 348.64 | 135.86 | <0.0001 ** |

| Residual | 0.0058 | 13 | 0.0004 | 33.36 | 13 | 2.57 | ||||

| Lack of fit | 0.0033 | 5 | 0.0007 | 2.21 | 0.1530 | 19.70 | 5 | 3.94 | 2.31 | 0.1402 |

| Error | 0.0024 | 8 | 0.0003 | 13.66 | 8 | 1.71 | ||||

| Total | 0.1560 | 22 | 1135.82 | 22 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, Z.; Fu, J.; Wang, Y.; Yang, Y.; Song, J.; Lu, K.; Huang, X.; Liang, H.; Xu, B.; Zhao, W.; et al. Simulation and Optimization Experiment of Seven-Link Planting Mechanism Based on Discrete Element Method and Multibody Dynamics (DEM–MBD) Coupling. AgriEngineering 2025, 7, 357. https://doi.org/10.3390/agriengineering7110357

Cui Z, Fu J, Wang Y, Yang Y, Song J, Lu K, Huang X, Liang H, Xu B, Zhao W, et al. Simulation and Optimization Experiment of Seven-Link Planting Mechanism Based on Discrete Element Method and Multibody Dynamics (DEM–MBD) Coupling. AgriEngineering. 2025; 7(11):357. https://doi.org/10.3390/agriengineering7110357

Chicago/Turabian StyleCui, Zhichao, Jingjing Fu, Yundong Wang, Yating Yang, Jingling Song, Kangping Lu, Xingchang Huang, Hongli Liang, Binxing Xu, Weisong Zhao, and et al. 2025. "Simulation and Optimization Experiment of Seven-Link Planting Mechanism Based on Discrete Element Method and Multibody Dynamics (DEM–MBD) Coupling" AgriEngineering 7, no. 11: 357. https://doi.org/10.3390/agriengineering7110357

APA StyleCui, Z., Fu, J., Wang, Y., Yang, Y., Song, J., Lu, K., Huang, X., Liang, H., Xu, B., Zhao, W., Chen, Y., Guan, C., & Zhang, C. (2025). Simulation and Optimization Experiment of Seven-Link Planting Mechanism Based on Discrete Element Method and Multibody Dynamics (DEM–MBD) Coupling. AgriEngineering, 7(11), 357. https://doi.org/10.3390/agriengineering7110357