Advancing Intercropping of Drought-Resistant Oilseed Crops: Mechanized Harvesting

Abstract

1. Introduction

2. Materials and Methods

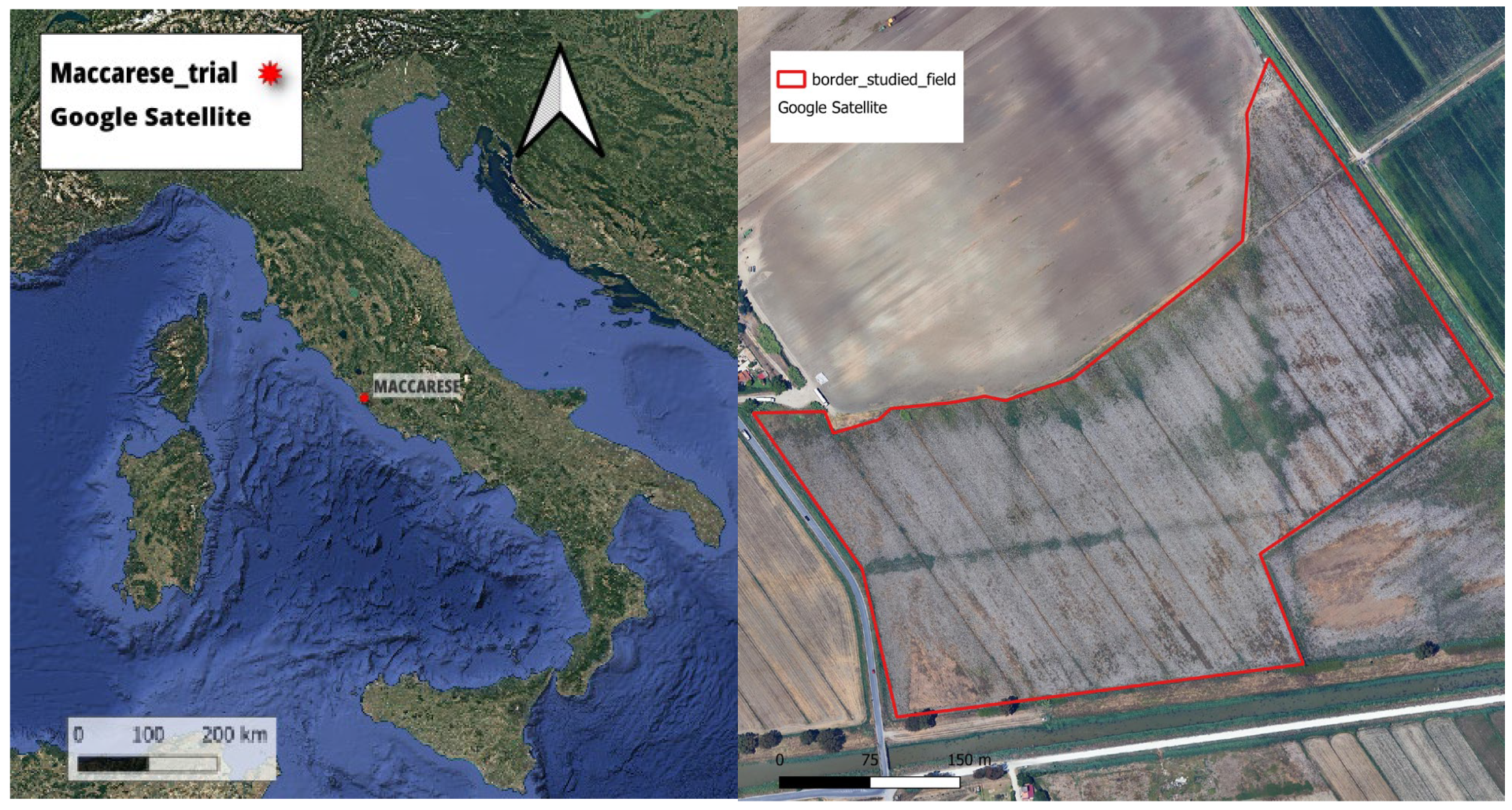

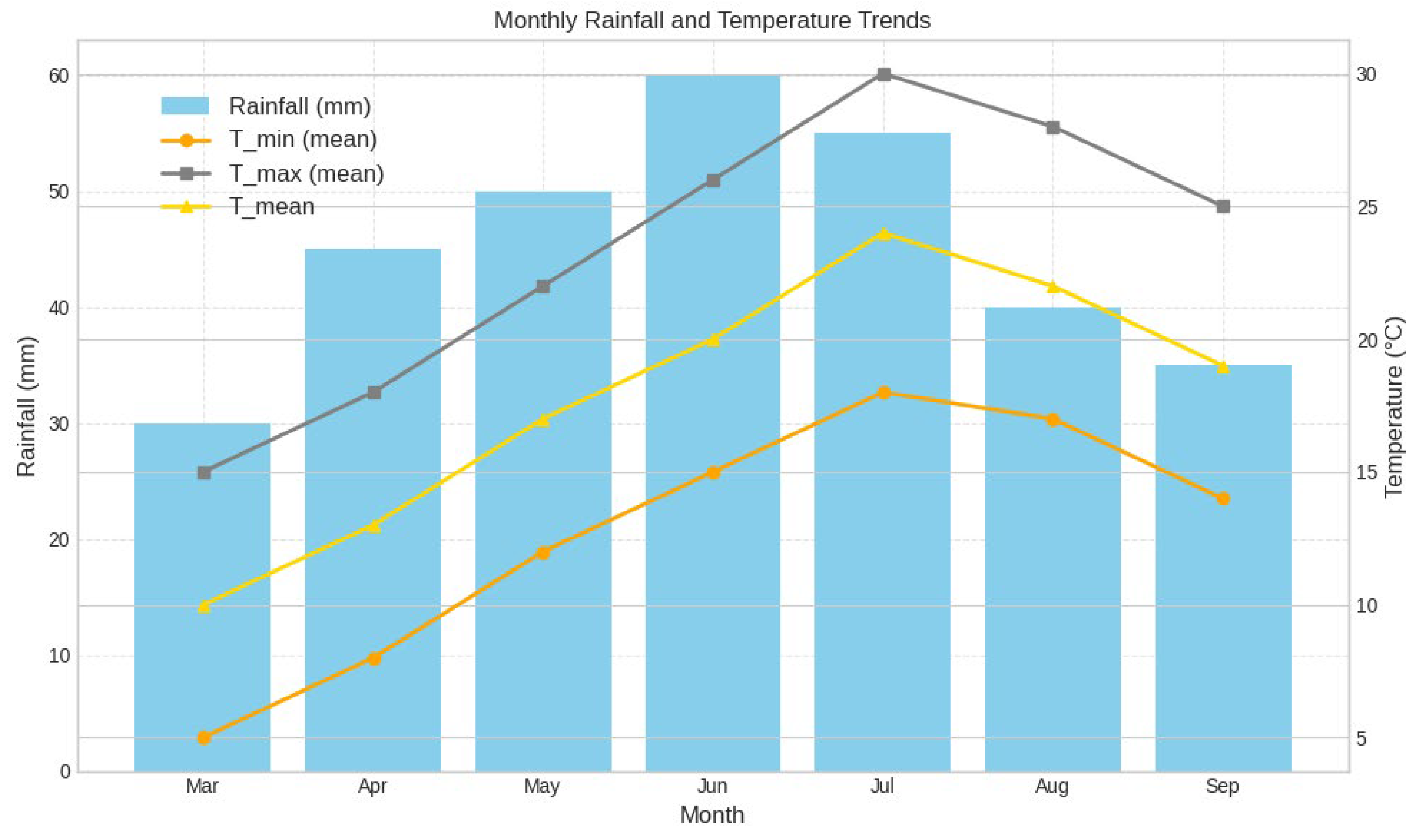

2.1. Study Area

2.2. Cardoon (Cynara cardunculus L.), 2022

2.3. Intercropping, 2023

2.4. Safflower (Carthamus tinctorius L.), 2024

2.5. Pre-Harvest Tests and Biomass Caracterization

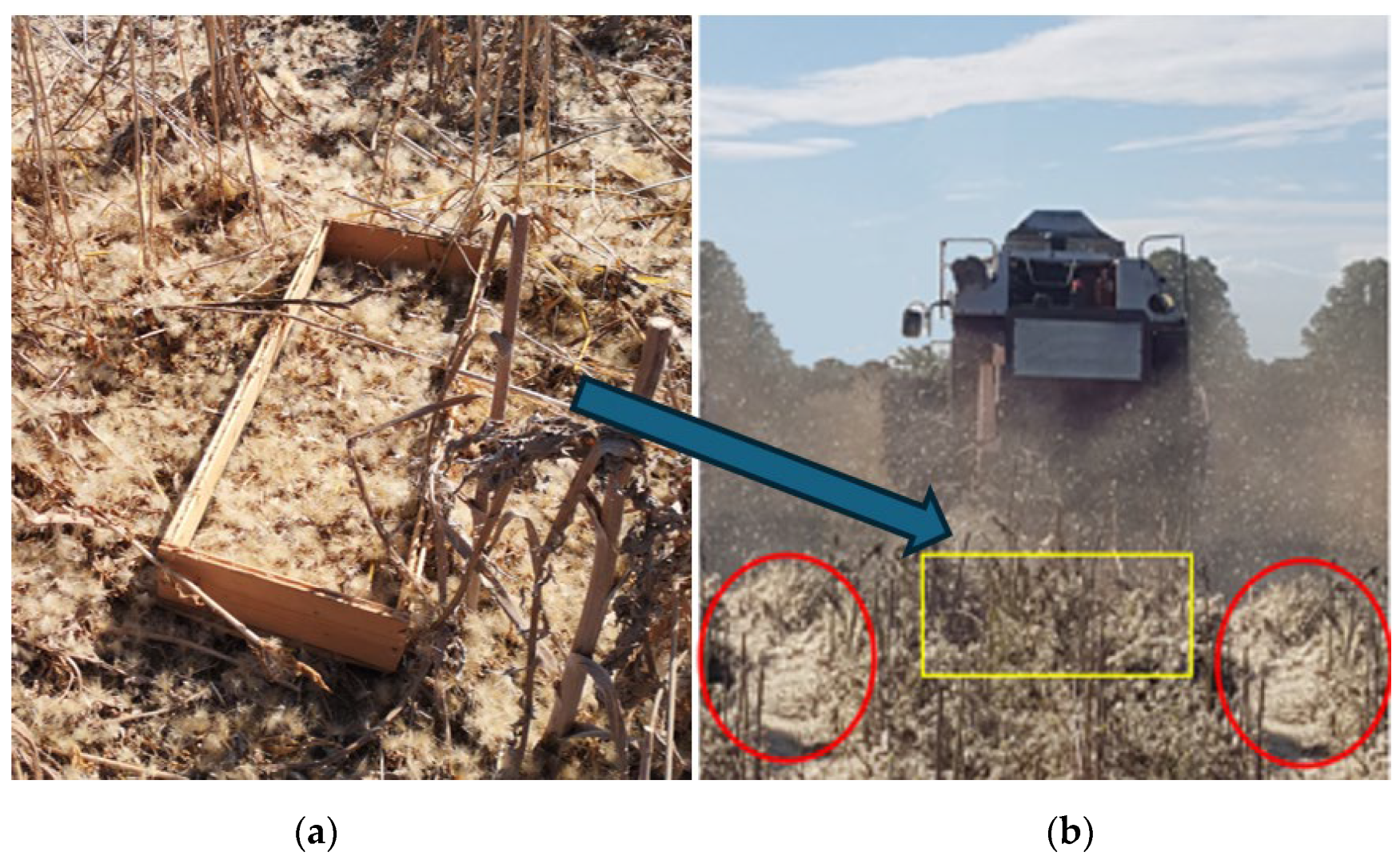

2.6. Combine Harvesting

2.7. Evaluation of the Harvesting Performance and Costs

- TFC: Working speed × cutting bar width.

- EFC: Harvested surface/working times (effective working time + maneuvers time, avoidable delay time + unavoidable delay time + accessory time).

- FE: (Harvested surface/working times)/(working speed × cutting bar width).

2.8. Crop Yield and Seed Losses Evaluation

2.9. Land Equivalent Ratio (LER)

- YIS = yield of intercropped safflower;

- YDS = yield of monoculture safflower;

- YIC = yield of intercropped cardoon;

- YDC = yield of monoculture cardoon.

2.10. Statistical Analysis

3. Results

3.1. Pre-Harvest Tests

3.2. Harvesting Performance and Costs

3.3. Crop Yield and Seed Losses

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mathanker, S.K.; Hansen, A.C. Harvesting System Design and Performance. In Engineering and Science of Biomass Feedstock Production and Provision; Springer: Berlin/Heidelberg, Germany, 2014; pp. 85–139. [Google Scholar]

- Alkaabi, G.A. Synthesis a Mechanical Harvester to Increase Performance Efficiency and Reduce Losses. Int. J. Res. Agron. 2024, 7, 309–312. [Google Scholar] [CrossRef]

- Gupta, G.S.R.; Awat, C.; Basediya, A.L. Comparative Performance of Different Methods of Harvesting of Wheat Crop in Western Madhya Pradesh, India. Int. J. Curr. Microbiol. Appl. Sci. 2020, 9, 2223–2228. [Google Scholar] [CrossRef]

- Marcelino, S.; Gaspar, P.; do Paço, A.; Lima, T.; Monteiro, A.; Franco, J.; Santos, E.; Campos, R.; Lopes, C. Towards Sustainable Agriculture: A Critical Analysis of Agrobiodiversity Assessment Methods and Recommendations for Effective Implementation. Appl. Sci. 2024, 14, 2622. [Google Scholar] [CrossRef]

- Méndez-Zambrano, P.V.; Tierra Pérez, L.P.; Ureta Valdez, R.E.; Flores Orozco, Á.P. Technological Innovations for Agricultural Production from an Environmental Perspective: A Review. Sustainability 2023, 15, 16100. [Google Scholar] [CrossRef]

- Biggs, S.; Justice, S. Rural and Agricultural Mechanization: A History of the Spread of Small Engines in Selected Asian Countries. In IFPRI Discussion Papers 1443; International Food Policy Research Institute (IFPRI): Washington, DC, USA, 2015. [Google Scholar]

- Takeshima, H.; Nin-Pratt, A.; Diao, X. Mechanization and Agricultural Technology Evolution, Agricultural Intensification in Sub-Saharan Africa: Typology of Agricultural Mechanization in Nigeria. Am. J. Agric. Econ. 2013, 95, 1230–1236. [Google Scholar] [CrossRef]

- Bigot, Y.; Bigot, Y.; Binswanger, H.P. Agricultural Mechanization and the Evolution of Farming Systems in Sub-Saharan Africa; Johns Hopkins University Press: Baltimore, MD, USA, 1987; ISBN 080183502X. [Google Scholar]

- Bacsi, Z.; Szálteleki, P.; Bánhegyi, G. The Impact of Agricultural Land Use Patterns on Natural Vegetation, Plant, and Livestock Diversity in the European Union. Heritage 2025, 8, 83. [Google Scholar] [CrossRef]

- Buzhdygan, O.Y.; Petermann, J.S. Multitrophic Biodiversity Enhances Ecosystem Functions, Services and Ecological Intensification in Agriculture. J. Plant Ecol. 2023, 16, rtad019. [Google Scholar] [CrossRef]

- Chaudhuri, S.; Roy, M.; McDonald, L.M.; Emendack, Y. Reflections on Farmers’ Social Networks: A Means for Sustainable Agricultural Development? Environ. Dev. Sustain. 2021, 23, 2973–3008. [Google Scholar] [CrossRef]

- Monteleone, B.; Borzí, I.; Bonaccorso, B.; Martina, M. Quantifying Crop Vulnerability to Weather-Related Extreme Events and Climate Change through Vulnerability Curves. Nat. Hazards 2023, 116, 2761–2796. [Google Scholar] [CrossRef]

- Wu, Y.; Meng, S.; Liu, C.; Gao, W.; Liang, X.-Z. A Bibliometric Analysis of Research for Climate Impact on Agriculture. Front. Sustain. Food Syst. 2023, 7, 1191305. [Google Scholar] [CrossRef]

- Annie, M.; Pal, R.K.; Gawai, A.S.; Sharma, A. Assessing the Impact of Climate Change on Agricultural Production Using Crop Simulation Model. Int. J. Environ. Clim. Change 2023, 13, 538–550. [Google Scholar] [CrossRef]

- Kopeć, P. Climate Change—The Rise of Climate-Resilient Crops. Plants 2024, 13, 490. [Google Scholar] [CrossRef] [PubMed]

- Altieri, M.A.; Nicholls, C.I.; Henao, A.; Lana, M.A. Agroecology and the Design of Climate Change-Resilient Farming Systems. Agron. Sustain. Dev. 2015, 35, 869–890. [Google Scholar] [CrossRef]

- Nasiro, K. Cropping Systems Diversification as an Approach to Enhancing Crop Productivity: A Review. Plant 2024, 12, 48–65. [Google Scholar] [CrossRef]

- Hufnagel, J.; Reckling, M.; Ewert, F. Diverse Approaches to Crop Diversification in Agricultural Research. A Review. Agron. Sustain. Dev. 2020, 40, 14. [Google Scholar] [CrossRef]

- Assefa, Y.; Yadav, S.; Mondal, M.K.; Bhattacharya, J.; Parvin, R.; Sarker, S.R.; Rahman, M.; Sutradhar, A.; Prasad, P.V.V.; Bhandari, H.; et al. Crop Diversification in Rice-Based Systems in the Polders of Bangladesh: Yield Stability, Profitability, and Associated Risk. Agric. Syst. 2021, 187, 102986. [Google Scholar] [CrossRef]

- Beillouin, D.; Ben-Ari, T.; Malézieux, E.; Seufert, V.; Makowski, D. Positive but Variable Effects of Crop Diversification on Biodiversity and Ecosystem Services. Glob. Change Biol. 2021, 27, 4697–4710. [Google Scholar] [CrossRef]

- Isbell, F.; Adler, P.R.; Eisenhauer, N.; Fornara, D.; Kimmel, K.; Kremen, C.; Letourneau, D.K.; Liebman, M.; Polley, H.W.; Quijas, S.; et al. Benefits of Increasing Plant Diversity in Sustainable Agroecosystems. J. Ecol. 2017, 105, 871–879. [Google Scholar] [CrossRef]

- Yu, R.-P.; Yang, H.; Xing, Y.; Zhang, W.-P.; Lambers, H.; Li, L. Belowground Processes and Sustainability in Agroecosystems with Intercropping. Plant Soil 2022, 476, 263–288. [Google Scholar] [CrossRef]

- Yu, R.-P.; Dresbøll, D.B.; Finckh, M.R.; Justes, E.; van der Werf, W.; Fletcher, A.; Carlsson, G.; Li, L. Intercropping: Ecosystem Functioning and Sustainable Agriculture. Plant Soil 2025, 506, 1–6. [Google Scholar] [CrossRef]

- Laroche, G.; Domon, G.; Gélinas, N.; Doyon, M.; Olivier, A. Integrating Agroforestry Intercropping Systems in Contrasted Agricultural Landscapes: A SWOT-AHP Analysis of Stakeholders’ Perceptions. Agrofor. Syst. 2019, 93, 947–959. [Google Scholar] [CrossRef]

- Jensen, E.S.; Carlsson, G.; Hauggaard-Nielsen, H. Intercropping of Grain Legumes and Cereals Improves the Use of Soil N Resources and Reduces the Requirement for Synthetic Fertilizer N: A Global-Scale Analysis. Agron. Sustain. Dev. 2020, 40, 5. [Google Scholar] [CrossRef]

- Gu, C.; Bastiaans, L.; Anten, N.P.R.; Makowski, D.; van der Werf, W. Annual Intercropping Suppresses Weeds: A Meta-Analysis. Agric. Ecosyst. Environ. 2021, 322, 107658. [Google Scholar] [CrossRef]

- Stomph, T.; Dordas, C.; Baranger, A.; de Rijk, J.; Dong, B.; Evers, J.; Gu, C.; Li, L.; Simon, J.; Jensen, E.S.; et al. Designing Intercrops for High Yield, Yield Stability and Efficient Use of Resources: Are There Principles? Adv. Agron. 2020, 160, 1–50. [Google Scholar]

- Deng, Y.-H.; Liao, J.-D.; Hei, Z.-W.; Liang, K.-M.; Wei, H.; Zhang, J.-E.; Xiang, H.-M. Rice Intercropping with Water Mimosa (Neptunia oleracea Lour.) Could Alleviate the Negative Effects of Simulated Nitrogen Deposition on Rice and Soil. Plant Soil 2025, 506, 503–523. [Google Scholar] [CrossRef]

- Li, C.; Hoffland, E.; Kuyper, T.W.; Yu, Y.; Zhang, C.; Li, H.; Zhang, F.; van der Werf, W. Syndromes of Production in Intercropping Impact Yield Gains. Nat. Plants 2020, 6, 653–660. [Google Scholar] [CrossRef] [PubMed]

- FIRST2RUN project, Flagship demonstration of an integrated biorefinery for dry crops sustainable exploitation towards biobased materials production, Circular Bio-based Europe Joint Undertaking. Available online: https://www.first2run.eu/ (accessed on 25 October 2024).

- Pari, L.; Cozzolino, L.; Marsac, S.; Hermet, L.; Bergonzoli, S. Effect of Swathing or Direct Combining on Yield, Seed Losses and Costs of Camelina. Agronomy 2024, 14, 325. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, G.; Liu, M.; Zhao, Y.; Dong, Q.; Zhou, F. Analysis of the Causes of Cutter Loss in Mechanized Oilseed Rape Harvesting and Experimental Research. J. Agric. Vet. Sci. 2023, 16, 7–17. [Google Scholar] [CrossRef]

- Theodoridis, A.; Melfou, K. Productivity and Efficiency of Agricultural and Livestock Systems. Agriculture 2025, 15, 1977. [Google Scholar] [CrossRef]

- Von Cossel, M.; Lewandowski, I.; Elbersen, B.; Staritsky, I.; Van Eupen, M.; Iqbal, Y.; Mantel, S.; Scordia, D.; Testa, G.; Cosentino, S.L.; et al. Marginal Agricultural Land Low-Input Systems for Biomass Production. Energies 2019, 12, 3123. [Google Scholar] [CrossRef]

- D’Avino, L.; Di Bene, C.; Farina, R.; Razza, F. Introduction of Cardoon (Cynara cardunculus L.) in a Rainfed Rotation to Improve Soil Organic Carbon Stock in Marginal Lands. Agronomy 2020, 10, 946. [Google Scholar] [CrossRef]

- Toscano, V.; Sollima, L.; Genovese, C.; Melilli, M.G.; Raccuia, S.A. Pilot Plant System for Biodiesel and Pellet Production from Cardoon: Technical and Economic Feasibility. In Proceedings of the IX International Symposium on Artichoke, Cardoon and Their Wild Relatives 1147, La Plata, Argentina, 29 September–2 October 2015; pp. 429–442. [Google Scholar]

- MIDAS Project—Marginal land Industrial Crops and Innovative Biobased Value Chains is a Horizon Europe Innovation Action. Available online: https://www.midas-bioeconomy.eu/ (accessed on 25 October 2024).

- Vasilakoglou, I.; Dhima, K. Potential of Two Cardoon Varieties to Produce Biomass and Oil under Reduced Irrigation and Weed Control Inputs. Biomass Bioenergy 2014, 63, 177–186. [Google Scholar] [CrossRef]

- Mauro, R.P.; Sortino, O.; Pesce, G.R.; Agnello, M.; Lombardo, S.; Pandino, G.; Mauromicale, G. Exploitability of Cultivated and Wild Cardoon as Long-Term, Low-Input Energy Crops. Ital. J. Agron. 2015, 10, 44–46. [Google Scholar] [CrossRef]

- Velez, Z.; Campinho, M.A.; Guerra, Â.R.; García, L.; Ramos, P.; Guerreiro, O.; Felício, L.; Schmitt, F.; Duarte, M. Biological Characterization of Cynara cardunculus l. Methanolic Extracts: Antioxidant, Anti-Proliferative, Anti-Migratory and Anti-Angiogenic Activities. Agriculture 2012, 2, 472–492. [Google Scholar] [CrossRef]

- Pappalardo, H.D.; Toscano, V.; Puglia, G.D.; Genovese, C.; Raccuia, S.A. Cynara cardunculus L. as a Multipurpose Crop for Plant Secondary Metabolites Production in Marginal Stressed Lands. Front. Plant Sci. 2020, 11, 240. [Google Scholar] [CrossRef]

- Gongora, B.; Melegari de Souza, S.N.; Bassegio, D.; Santos, R.F.; Siqueira, J.A.C.; Bariccatti, R.A.; Gurgacz, F.; Secco, D.; Tokura, L.K.; Sequinel, R. Comparison of Emissions and Engine Performance of Safflower and Commercial Biodiesels. Ind. Crops Prod. 2022, 179, 114680. [Google Scholar] [CrossRef]

- Pari, L.; Bergonzoli, S.; Cozzolino, L.; Baldi, G.M.; Falce, M.; Alexopoulou, E. Mechanical Harvesting of Marginal Land and Agroforestry Field: New Insights from Safflower for Bio-Product Production. Agronomy 2024, 14, 2268. [Google Scholar] [CrossRef]

- Pari, L.; Alfano, V.; Acampora, A.; Del Giudice, A.; Scarfone, A.; Sanzone, E. Harvesting and Separation of Different Plant Fractions in Cynara cardunculus L. In Perennial Biomass Crops for a Resource-Constrained World; Springer: Berlin/Heidelberg, Germany, 2016; pp. 261–271. [Google Scholar]

- Bolohan, C.; Marin, D.I.; Mihalache, M.; Ilie, L.; Oprea, A.C. Research on Cynara cardunculus l. species under the conditions of southeastern romania area. Agronomy 2016, 56, 429–432. [Google Scholar] [CrossRef]

- Gominho, J.; Lourenço, A.; Curt, M.D.; Fernández, J.; Pereira, H. Cynara cardunculus in Large Scale Cultivation. A Case Study in Portugal. Chem. Eng. Trans. 2014, 37, 529–534. [Google Scholar] [CrossRef]

- ISO 18400-205; Soil Quality—Sampling—Part 205: Guidance on the Procedure for Investigation of Natural, near-Natural and Cultivated Sites. International Organization for Standardization ISO: Geneva, Switzerland, 2018.

- Rate, F.A. Wireless Vantage Pro2TM & Vantage Pro2TM Plus Stations. Available online: https://www.davisinstruments.com/collections/wireless-vantage-pro2-and-vantage-pro2-plus-weather-stations (accessed on 10 July 2025).

- Sałata, A.; Nurzyńska-Wierdak, R.; Lombardo, S.; Pandino, G.; Mauromicale, G.; Ibáñez-Asensio, S.; Moreno-Ramón, H.; Kalisz, A. Polyphenol Profile, Antioxidant Activity and Yield of Cynara cardunculus Altilis in Response to Nitrogen Fertilisation. Agronomy 2024, 14, 739. [Google Scholar] [CrossRef]

- Ebrahimian, E.; Seyyedi, S.M.; Bybordi, A.; Damalas, C.A. Seed Yield and Oil Quality of Sunflower, Safflower, and Sesame under Different Levels of Irrigation Water Availability. Agric. Water Manag. 2019, 218, 149–157. [Google Scholar] [CrossRef]

- Shahid, M.; Jaradat, A.; Rao, N.K. Safflower: A Multipurpose Crop for the Marginal Lands. In Emerging Research in Alternative Crops; Springer: Berlin/Heidelberg, Germany, 2020; pp. 279–294. ISBN 978-3-030-41386-6. [Google Scholar]

- ISO 18134-2:2017; Solid Biobuels Determination of Moisture Content—Oven Dry Method—Part 2 Total Moisture—Simplified Method. International Organization for Standardization ISO: Geneva, Switzerland, 2017.

- Latterini, F.; Stefanoni, W.; Sebastiano, S.; Baldi, G.M.; Pari, L. Evaluating the Suitability of a Combine Harvester Equipped with the Sunflower Header to Harvest Cardoon Seeds: A Case Study in Central Italy. Agronomy 2020, 10, 1981. [Google Scholar] [CrossRef]

- Ruiz-Altisent, M.; Ortiz-Cañavate, J.; Valero, C. Fruit and Vegetables Harvesting Systems. In Production Practices and Quality Assessment of Food Crops; Springer: Berlin/Heidelberg, Germany, 2004; Volume 1, pp. 261–285. [Google Scholar]

- Lachuga, Y.F.; Bur’yanov, A.I.; Pakhomov, V.I.; Chervyakov, I.V. Adaptation of Threshing Devices to Physical and Mechanical Characteristics of Harvested Crops. Russ. Agric. Sci. 2020, 46, 198–201. [Google Scholar] [CrossRef]

- Ebadian, M.; Shedden, M.E.; Webb, E.; Searcy, E.M.; Sokhansanj, S. Impact of Parcel Size, Field Shape, Crop Yield, Storage Location, and Collection Equipment on the Performance of Single-Pass Cut-and-Chip Harvest System in Commercial Shrub Willow Fields. In BioEnergy Research; Springer: Berlin/Heidelberg, Germany, 2018; Volume 11, pp. 1–15. [Google Scholar] [CrossRef]

- Stefanoni, W.; Latterini, F.; Malkogiannidis, V.; Salpiggidis, V.; Alexopoulou, E.; Pari, L. Mechanical Harvesting of Castor Bean (Ricinus communis L.) with a Combine Harvester Equipped with Two Different Headers: A Comparison of Working Performance. Energies 2022, 15, 2999. [Google Scholar] [CrossRef]

- Reith, S.; Frisch, J.; Winkler, B. Revision of the Working Time Classification to Optimize Work Processes in Modern Agriculture. Chem. Eng. Trans. 2017, 58, 121–126. [Google Scholar]

- Pari, L.; Assirelli, A.; Suardi, A.; Civitarese, V.; Del Giudice, A.; Santangelo, E. Seed Losses during the Harvesting of Oilseed Rape (Brassica napus L.) at on-Farm Scale. J. Agric. Eng. 2013, 44, 633–636. [Google Scholar] [CrossRef]

- Assirelli, A.; Pignedoli, S. Costo Di Esercizio Delle Macchine Agricole. Cent. Ric. Prod. Anim. (CRPA) 2005, 5, 1–10. [Google Scholar]

- Suardi, A.; Stefanoni, W.; Bergonzoli, S.; Latterini, F.; Jonsson, N.; Pari, L. Comparison between Two Strategies for the Collection of Wheat Residue after Mechanical Harvesting: Performance and Cost Analysis. Sustainability 2020, 12, 4936. [Google Scholar] [CrossRef]

- Banca d’Italia Banca d’Italia Lending Rate. Available online: https://Www.Bancaditalia.It/ (accessed on 11 October 2020).

- American Society of Agricultural Engineers. American Society of Agricultural Engineers ASAE Standard D497.4. Agriculture Machinery Management Data. American Society of Agricultural Engineers: Joseph, MI, USA, 2003; pp. 373–380. [Google Scholar]

- Zustovi, R.; Landschoot, S.; Dewitte, K.; Verlinden, G.; Dubey, R.; Maenhout, S.; Haesaert, G. Intercropping Indices Evaluation on Grain Legume-Small Grain Cereals Mixture: A Critical Meta-Analysis Review. Agron. Sustain. Dev. 2024, 44, 5. [Google Scholar] [CrossRef]

- Wenda-Piesik, A.; Synowiec, A. Productive and Ecological Aspects of Mixed Cropping System. Agriculture 2021, 11, 395. [Google Scholar] [CrossRef]

- Klima, K.; Synowiec, A.; Puła, J.; Chowaniak, M.; Pużyńska, K.; Gala-Czekaj, D.; Kliszcz, A.; Galbas, P.; Jop, B.; Dąbkowska, T.; et al. Long-Term Productive, Competitive, and Economic Aspects of Spring Cereal Mixtures in Integrated and Organic Crop Rotations. Agriculture 2020, 10, 231. [Google Scholar] [CrossRef]

- Scianna, J.; Zentner, D.; Pokorny, M.; Majeski, M.; Noack, R. Impact of Cover Crop Seeding Rate on Stand Establishment and Aboveground Biomass Production. In USDA Final Study Report; USDA: Washington, DC, USA, 2022. [Google Scholar]

- Vertucci, C.W.; Roos, E.E. Seed Moisture Content, Storage, Viability and Vigor. Seed Sci. Res. 1991, 1, 277–279. [Google Scholar]

- Smith, M.R.; Rao, I.M.; Merchant, A. Source-Sink Relationships in Crop Plants and Their Influence on Yield Development and Nutritional Quality. Front. Plant Sci. 2018, 9, 1889. [Google Scholar] [CrossRef]

- Quezada, T. Protective Agriculture Production Series: Plant Density Recommendations. Virginia Cooperative Extension: Blacksburg, VA, USA, 2023; pp. 1–8. [Google Scholar]

- Brooker, R.; Pakeman, R.J.; Hewison, R.L.; Mitchell, C.; Newton, A.C.; Neilson, R.; Raubach, S.; Shaw, P.D.; Verrall, S.; Karley, A.J. Crop Mixtures: Yield Responses to Climate and Management and Impacts on Seed and Soil Chemical Composition in a Scottish-Based Study. Plant Soil 2024, 1–19. [Google Scholar] [CrossRef]

- Roberts, E.H. Loss of Viability and Crop Yields. In Viability of Seeds; Springer: Berlin/Heidelberg, Germany, 1972; pp. 307–320. [Google Scholar]

- Brown, J.; Davis, J.B.; Erickson, D.A.; Brown, A.P. Effects of Swathing on Yield and Quality of Spring Canola in Northern Idaho. J. Prod. Agric. 1999, 12, 33–37. [Google Scholar] [CrossRef]

- Engbersen, N.; Brooker, R.W.; Stefan, L.; Studer, B.; Schöb, C. Temporal Differentiation of Resource Capture and Biomass Accumulation as a Driver of Yield Increase in Intercropping. Front. Plant Sci. 2021, 12, 668803. [Google Scholar] [CrossRef]

- Pari, L.; Latterini, F.; Stefanoni, W. Herbaceous Oil Crops, a Review on Mechanical Harvesting State of the Art. Agriculture 2020, 10, 309. [Google Scholar] [CrossRef]

| Parameters | Measures Unit | Value | ||

|---|---|---|---|---|

| Combine Harvester | Power | kw | 176 | |

| Investment | EUR | 250,000 | ||

| Service life | year | 10 | ||

| Service life | h | 3000 | ||

| Inflation | (1 + i)n | 5.22 | ||

| Resale | % | 60.34 | ||

| Resale | EUR | 47,157.71 | ||

| Depreciation | EUR | 202,842.3 | ||

| Annual usage | h/year | 300 | ||

| Interest rate | % | 2.5 | ||

| Worker salary | EUR× h−1 | 12.19 | ||

| Manpower | n° | 1 | ||

| Fixed costs | Ownership costs | (V0 − Vr)/n | EUR yr−1 | 20,284.23 |

| Interests | Mean (V0;Vr) × r | EUR yr−1 | 3714.47 | |

| Value of the shelter | EUR yr−1 | 30 | ||

| Insurance costs | 0.25% | EUR yr−1 | 625 | |

| Various expenses * | EUR yr−1 | 655 | ||

| Total annual fixed costs | Qr + Qi + Qv | EUR yr−1 | 24,653.7 | |

| Total fixed costs | Qfa/Ui | EUR h−1 | 82.18 | |

| Variable costs | Repair factor | % | 60 | |

| Repairs and maintenance | EUR h−1 | 50 | ||

| Fuel cost | EUR lt−1 | 0.91 | ||

| Fuel consumption | lt h−1 | 26.6 | ||

| Fuel consumption | EUR h−1 | 24.21 | ||

| Lubricant cost | EUR lt−1 | 3.03 | ||

| Lubricant consumption | lt h−1 | 0.32 | ||

| Lubricant consumption | EUR h−1 | 0.97 | ||

| Manpower costs | EUR h−1 | 12.19 | ||

| Total variable costs | EUR h−1 | 87.37 | ||

| Total annual costs | Ui × qu + Qfa | EUR yr−1 | 50,863.89 | |

| Total hourly costs | EUR h−1 | 169.55 | ||

| Treatment | Plant Density (N × m2) | Biomass * (Mg ha−1) | Straw * (Mg ha−1) | Seed Moisture (%) | Straw Moisture (%) |

|---|---|---|---|---|---|

| DC | 14.20 ± 3.27 a | 21.47 ± 4.43 a | 20.02 ± 4.10 a | 5.82 ± 0.04 a | 26.75 ± 10.10 a |

| IC | 11.20 ± 1.64 a | 14.49 ± 3.16 b | 13.32 ± 1.47 b | 5.91 ± 0.27 a | 26.36 ± 11.58 a |

| DS | 46.20 ± 8.70 b | 13.08 ± 4.09 a | 11.67 ± 3.97 b | 9.40 ± 0.29 b | 34.70 ± 2.95 a |

| IS | 9.00 ± 4.30 a | 8.47 ± 1.97 b | 8.22 ± 1.10 b | 8.62 ± 0.77 b | 34.46 ± 5.98 a |

| IT | 20.20 ± 3.27 a | 22.96 ± 2.23 a | 21.53 ± 2.57 a | 7.27 ± 0.35 b | 30.41 ± 5.68 a |

| LSD (α = 0.05) | 6.26 | 4.27 | 3.75 | 0.54 | 10.18 |

| Treatment | Working Speed (ha h−1) | Theoretical Field Capacity (ha h−1) | Effective Field Capacity (ha h−1) | Cutting Height (cm) | Field Efficiency (FE %) | Harvesting Cost (EUR ha−1) | Total Cost (EUR) |

|---|---|---|---|---|---|---|---|

| DC | 6.35 ± 2.11 a | 3.05 ± 1.01 a | 2.56 ± 0.65 a | 57.42 ± 2.62 a | 85 ± 0.06 a | 70.24 | 1241.19 |

| DS | 3.92 ± 0.11 b | 2.35 ± 0.06 a | 1.98 ± 0.06 ab | 45.10 ± 2.75 b | 84 ± 0.01 a | 90.66 | 1602.04 |

| IT | 3.81 ± 0.66 b | 2.09 ± 0.36 a | 1.82 ± 0.26 b | 49.20 ± 3.09 b | 87 ± 0.04 a | 98.61 | 1742.52 |

| LSD (α = 0.05) | 1.25 | 0.72 | 0.61 | 3.85 | 1.02 | / | / |

| Treatment | PSY (Mg × ha−1) | CHL (Mg × ha−1) | IHL (Mg × ha−1) | THL (Mg × ha−1) | ESY* (Mg × ha−1) | ESL* (Mg × ha−1) |

|---|---|---|---|---|---|---|

| DC | 1.448 ± 0.710 a | 0.106 ± 0.158 a | 0.007 ± 0.003 a | 0.114 ± 0.158 a | 1.247 | 0.201 |

| IC | 1.175 ± 0.233 a | 0.260 ± 0.137 b | 0.080 ± 0.036 b | 0.340 ± 0.142 c | 0.748 | - |

| DS | 1.415 ± 0.161 a | - | 0.011 ± 0.001 a | 0.011 ± 0.001 b | 1.394 | 0.02 |

| IS | 0.247 ± 0.109 b | 0.009 ± 0.001 c | 0.020 ± 0.006 a | 0.029 ± 0.006 b | 0.249 | - |

| IT | 1.422 ± 0.325 a | 0.269 ± 0.136 b | 0.100 ± 0.037 b | 0.369 ± 0.143 c | 0.997 | 0.425 |

| LSD | 0.682 | - | 0.042 | 0.208 | - | - |

| Parameter | LER |

|---|---|

| Biomass | 1.32 |

| Potential Seed Yield (PSY) | 0.99 |

| Effective Seed Yield (ESY) | 0.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cozzolino, L.; Bergonzoli, S.; Baldi, G.M.; Falce, M.; Pari, L. Advancing Intercropping of Drought-Resistant Oilseed Crops: Mechanized Harvesting. AgriEngineering 2025, 7, 330. https://doi.org/10.3390/agriengineering7100330

Cozzolino L, Bergonzoli S, Baldi GM, Falce M, Pari L. Advancing Intercropping of Drought-Resistant Oilseed Crops: Mechanized Harvesting. AgriEngineering. 2025; 7(10):330. https://doi.org/10.3390/agriengineering7100330

Chicago/Turabian StyleCozzolino, Luca, Simone Bergonzoli, Gian Maria Baldi, Michele Falce, and Luigi Pari. 2025. "Advancing Intercropping of Drought-Resistant Oilseed Crops: Mechanized Harvesting" AgriEngineering 7, no. 10: 330. https://doi.org/10.3390/agriengineering7100330

APA StyleCozzolino, L., Bergonzoli, S., Baldi, G. M., Falce, M., & Pari, L. (2025). Advancing Intercropping of Drought-Resistant Oilseed Crops: Mechanized Harvesting. AgriEngineering, 7(10), 330. https://doi.org/10.3390/agriengineering7100330