Abstract

Cereal grain crops are used as main food and raw feed materials all over the world. Among cereal crops, wheat occupies a leading place as the most valuable crop. Harvesting is the most energy-intensive stage in wheat cultivation. Therefore, improving technologies and tools to reduce energy costs in this process is an urgent task. A new stripping and threshing unit for harvesting cereal crops has been developed, allowing the harvesting of grain at both full maturity and in the early stages of maturity, when the grain has an increased content of protein and amino acids and is a valuable raw feed material. The new unit consists of a stripping and threshing unit. The stripping unit consists of a stripping drum and stripping combs. The threshing unit contains replaceable decks that collide with the grain, separating it from the ear; an auger for transporting the heap to the unloading device; and a blade beater with a cut-off shield. Wheat grain in the early stages of maturity has a strong connection with the ear, as a result of which harvesting such grain can be energy-intensive and impractical. In this regard, the purpose of this research was to study the dynamics of changes in the energy intensity of the wheat grain harvesting process during ripening and to compare the energy intensity of the harvesting process with the new unit with the energy intensity of a combine harvester. The methodology is based on measuring torque on the shaft of the stripping and threshing unit. The results show that the power required for stripping by the new unit is reduced from 8–10 kW to 2–4 kW, which is 2.5–4 times lower. The difference in power values between harvesting at the hard wax ripeness stage and full ripeness is only 1–1.5 kW, indicating the feasibility of harvesting grain at this stage.

1. Introduction

Grain is a fundamental resource for populations worldwide, serving as a vital feed and food source. According to FAO [1] forecasts for 2024, global grain production will reach 2.9 billion tons, a 0.3% increase from the previous year. In 2023, grain crops made up 17% of the global market, with wheat accounting for 24%. Improving the quality of grain production, processing, and utilization in food and feed industries is crucial for agricultural profitability and efficiency.

By 2033, global grain production is expected to increase to 3.2 billion tons, primarily due to higher corn and wheat production. The main exporters of corn are the United States and Brazil, while the Russian Federation is the largest wheat exporter, accounting for 20% of the global volume [2]. In Russia, wheat made up 70% of the total grain harvest in 2023, followed by barley (16%) and corn (7%).

As wheat grain ripens, it gradually loses its connection with the ear, with daily losses averaging 1.5–2% [3]. According to [4], the process of self-shedding occurs starting from the third day after full ripening and increases, according to various sources, by 0.25–0.50% daily. On the fifth day, losses are 1.5%; on the tenth day—5%; on the fifteenth day—9%; on the twentieth day—up to 20%; and on the twenty-sixth day—up to 50%. If harvesting is not performed in a timely manner (within 10–12 days), a significant portion of the crop is lost as a result of self-shedding: according to various sources [3,4,5], losses can reach 15–20 million tons per year. These are large losses that can be avoided by harvesting within 10–12 days. However, to meet the established deadlines, it is necessary to use a large volume of grain harvesting equipment, which is often in short supply due to the seasonality of its use. Grain harvesters are expensive, specialized equipment that is used, as a rule, two times a year: in the summer when harvesting cereal crops and in the fall when harvesting sunflower, corn, sorghum, and other crops. Purchasing a large number of combines to reduce the load on the technology park of agricultural organizations is economically unprofitable so the issue of creating a universal technical means used throughout the calendar year, for example, a tractor with which various technical means can be aggregated, is relevant.

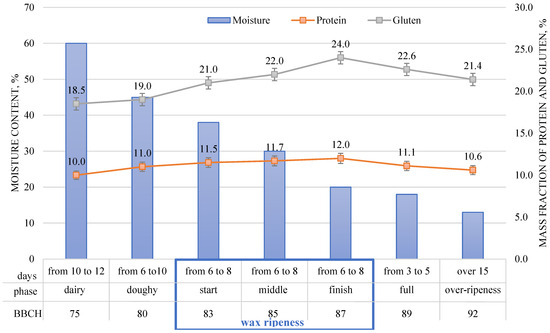

A potential solution is harvesting grain before it reaches full maturity. Paper [6] presents the results of a study on the influence of the stage of wheat grain maturation on the ensiling process. This study showed that wheat at the milk ripeness stage had a higher yield of lactic acid, better nutritional composition, and better quality of silage fermentation compared to the flowering stage. The results of a study of changes in the amino acid composition of wheat grain during maturation [7] showed that the highest amino acid content is found at the wax ripeness stage and that the amino acid content decreases by the beginning of full maturity. The highest protein and gluten content in wheat grain is also observed at the wax ripeness stage [7,8,9,10] (Figure 1). The figure shows the phenological stage of plant development according to the BBCH scale.

Figure 1.

Changes in the properties of wheat grain during maturation.

Thus, when harvesting wheat grain at the wax stage of ripeness (6 days before full ripeness), it is possible to shorten the time of harvesting grain after full ripeness and reduce losses from self-shedding without increasing the number of grain harvesting equipment. Wheat grain at the early stages of ripeness is a valuable raw feed material that can be used as silage or processed into a feed additive [11].

Traditional combine harvesting is characterized by a fairly high degree of grain injury—up to 20–30% of the total threshed grain mass [12,13,14]. In modern new-generation combines, the degree of grain damage is significantly lower but nevertheless remains quite high, which negatively affects its quality. Injured grain has a low germination rate, and pathogenic microorganisms develop in the cracks formed during storage. This often does not allow obtaining high-quality seed material, and when a certain level of mycotoxin concentration is reached, the grain becomes unsuitable not only for the production of bakery products but also for animal feed.

The design of modern grain harvesters implements the method of threshing and primary separation of the harvested heap. The threshing process is one of the most energy-intensive grain harvesting processes, with 80% of the energy spent on threshing and grinding the straw and only 7% on separating the grain from the ear. Despite numerous studies on improving the threshing process and the working parts of threshing devices [14,15,16,17], which directly mechanically impact the ear and the grains in it, it is impossible to achieve a significant reduction in energy costs for separating the grain from the ear and significantly reduce grain injury. As a result of studying the process of impact mechanical threshing, researchers [12,13,18,19] came to the conclusion that this method has exhausted its potential for improvement since when using it, it is impossible to avoid the impact effect that damages the grain. Therefore, it is necessary to develop fundamentally new methods for separating grain from the ear—eliminating the direct mechanical impact of the working bodies on the grains themselves—and also allowing the harvesting of grain at the wax ripeness stage, when the wheat grain has a strong connection with the ear [20] and cannot be harvested with a classic combine.

For this purpose, theoretical studies were conducted [20] that made it possible to determine the optimal parameters of the machine for energy-efficient grain extraction from the ear (including at early stages of maturity) and to develop a unit that allows harvesting wheat at different stages of maturity using the combing method and extracting the grain remaining in the ear in the post-threshing chamber. The post-threshing chamber is made of a polymer material that reduces the degree of grain injury [18].

Since the grain of wheat in the early stages of maturity has a strong connection with the ear, then, presumably, the energy intensity of the process of harvesting such grain can be energy-consuming and unprofitable. The purpose of this study is to examine the energy intensity of the process of harvesting grain at different stages of maturity by a harvesting unit using the stripping method on the root and to compare its energy intensity with a classic grain harvesting combine.

2. Materials and Methods

2.1. Stripping and Threshing Unit for Harvesting Cereal Crops

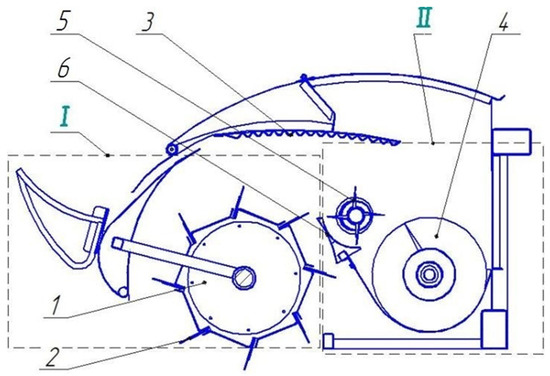

The new unit [21] includes a stripping drum with combs, a threshing unit II, and a means for moving the threshed grain along a tubular conveyor with a rotating impeller with a drive. Above the stripping drum in the direction of movement of the stripped heap, replaceable decks with a curvilinear ribbed surface were installed, and between the stripping drum and the means for moving the threshed grain along the tubular conveyor, a blade beater with a cutting shield was installed. Figure 2 shows a diagram of the trailed stripping and threshing unit for cereal crops.

Figure 2.

Scheme of the combing and threshing parts of the unit for harvesting cereal crops: I—combing unit; II—threshing block; 1—stripping drum; 2—combing combs; 3—replaceable decks; 4—auger; 5—paddle beater; 6—cut-off shield.

The stripping and threshing unit for harvesting grain crops operates as follows. During the forward movement of the unit, each stripping comb—part 2—of the stripping drum—part 1—(Figure 2) grabs a row of stalks of grain crops and strips the ear from the bottom up. The stripped heap, reflected from the stripping combs, under the action of the centrifugal forces of the stripping drum and the suction air flow created by the blade beater—part 5—is directed to the profile surfaces of the replaceable decks—part 3—which perform the threshing.

Threshing with the release of free grain occurs due to the progressive oscillatory movement of the combed heap by means of its interaction with the curvilinear ribbed surface of the replaceable deck under the air support created by the blade beater. When the resulting combed heap with threshed grain passes through the air flow created by the blade beater, light impurities with windage are separated and blown out together with the excess air.

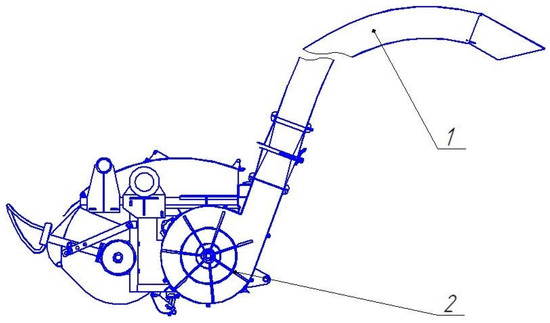

After this, the combed heap, which is a mixture of threshed grain and chaff, is directed by the auger (Figure 2, part 4), rotating impeller (Figure 3, part 2), and tubular conveyor (Figure 3, part 1) into a container for collecting the grain heap of wheat.

Figure 3.

A means for moving threshed grain along a tubular conveyor: 1—tubular conveyor; 2—impeller.

The implementation of replaceable decks with a curved ribbed surface—such as trapezoidal, wavy, or triangular—and the installation of a blade beater with a cutting shield facilitate the threshing of the combed heap with minimal energy costs, reducing grain loss due to the suction ventilation effect created by the blade beater.

The proposed technical solution, implemented in the form of a stripping and threshing unit, can be used as a mounted device on combines with serial and newly developed threshing devices or as a trailed harvesting unit when harvesting grain crops with final threshing of the heap at a stationary location.

The studies to determine the energy intensity of the process of harvesting wheat of different stages of maturity were conducted on soft winter wheat of the variety Lydia (awned, easy to thresh) and the variety Kaprizulya (awnless, rigid) selected by the Agrarian Scientific Center “Donskoy” of the Russian Federation. The varieties were located in the same field, which indicates similar growing conditions. The field was leveled, and the slope was no more than 1°.

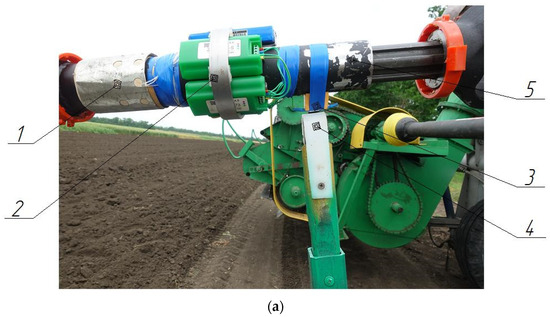

The stripping and threshing unit for harvesting grain crops was attached to the MTZ-80 tractor. The general appearance of the stripping and threshing unit for harvesting grain crops is shown in Figure 4. The length of the harvesting part is 2 m (laboratory and field sample).

Figure 4.

Harvesting wheat with a stripping and threshing unit: (a) harvesting winter wheat of the Lydia variety before the full stage of maturity (awned variety, BBCH stage 80); (b) harvesting winter wheat of the Kaprizulya variety in the full stage of maturity (awnless variety, stage 89 on the BBCH scale).

2.2. Methodology for Analyzing the Energy Intensity of the Wheat Grain Harvesting Process at Different Stages of Maturity Using a Stripping and Threshing Unit

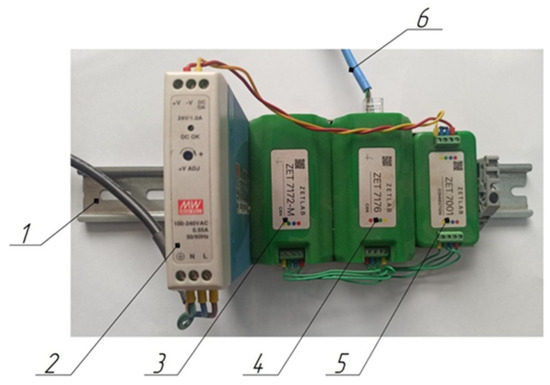

Energy consumption during the harvesting process was studied by measuring the torque on the drive shaft of the stripping and threshing unit. The torque was studied using the ZetLab measuring complex. The sensitive element of the system is a strain gauge bridge, which responds to shaft deformation. The strain gauge bridge consists of four general-purpose foil constantan uniaxial strain gauges of the 2FKP series [22]. The strain gauge configuration is full-bridge (4 active elements). Data from the strain gauges were fed to the ZET 7111 measuring module and then recorded on the ZET 7173 recorder installed on the shaft. Data was transmitted via a radio channel using the ZET 7172 telemetry system, consisting of two modules: ZET 7172-S (installed on the unit shaft, receiving information and converting the CAN interface into a radio channel) and 7172-M (receiving a signal from the measured object and converting the CAN interface for transmission to a PC). Next, via the ZET 7176 interface converter and the ZET 7001 measuring line connector (Figure 5), the information was sent to a PC for further processing in the Torque Measurement program from ZetLab.

Figure 5.

ZetLab measuring complex installed on a field measuring station: 1—base; 2—power adapter from 220 V network; 3—ZET 7172-M module; 4—ZET 7176 module; 5—ZET 7001 module; 6—cable for connecting to a laptop.

Figure 6 shows the torque measurement equipment mounted on the drive shaft of a trailed harvesting unit prior to measurement.

Figure 6.

Installed ZetLab measuring complex (a) 1—strain gauges; 2—ZetLab measuring complex; 3—reed switch sensor; 4—magnet; 5—drive shaft. and general view of the stripping and threshing unit for harvesting cereal crops (b).

After determining the torque, calculate the value of power spent on combing , produced according to Formula (1).

where —torque, N·m; —angular velocity, rpm.

The general power, , required to perform the technological process of harvesting cereal crops using a stripping and threshing unit can be determined from Formula (2) [23]:

where —the power expended in the combing process (determined experimentally), kW; —power expended on driving the remaining working parts of the stripping and threshing unit (we take this according to the values of power at idle speed, determined experimentally), kW; —power spent on rolling the tractor and unit across the field at a working speed of 7 km/h, kW.

Power spent on rolling the tractor and unit across the field at a working speed of 7 km/h, kW is determined by Formula (3):

where —tractor gravity, kN; —tractor rolling coefficient (0.07) [23]; —gravity force of the stripping and threshing unit together with the maximum load of the replaceable container, kN; —rolling coefficient of the stripping and threshing unit (assuming it is equal to 0.07 for the tractor); —operating speed of the stripping and threshing unit, km/h (all studies were conducted at a unit speed of 7 km/h).

Tractor gravity and the stripping and threshing unit are determined from Formula (4):

where —tractor weight, tons (MTZ-80 tractor weight—3.7 tons); —acceleration of gravity, 9.8 m/s2; —weight of the stripping and threshing unit together with the maximum load of the replaceable container, tons (3.11 tons according to the design documentation for the stripping and threshing unit).

Then, the power expended on rolling the tractor and the unit across the field , will be equal, as follows:

The power required to roll the tractor and the unit across the field was kept constant for all operating modes of the stripping and threshing unit.

The harvesting was carried out by the unit in 6 stages: the doughy stage (stage 80 on the BBCH scale), early phase of wax ripeness (stage 83 on the BBCH scale), middle of wax ripeness (stage 85 on the BBCH scale), hard wax ripeness (stage 87 on the BBCH scale), full ripening (stage 89 on the BBCH scale), overmaturity (stage 92 on the BBCH scale). The choice of stages is based on the results of studies of changes in the quality of wheat grain (amino acid composition, protein, and gluten), which shows that at the wax ripeness stage, the grain has the highest quality indicators for the entire growing season. In this regard, it is advisable to study the energy intensity of the grain harvesting process at the wax ripeness stage, as well as to study the dynamics of changes in the energy intensity of the harvesting process during the transition from milk to wax ripeness (stage 80 on the BBCH scale). Figure 7 shows the stages of grain ripening from milk to full maturity.

Figure 7.

Grain maturation stages from milk to full maturity [24]: 71, 73—early milk maturity; 75—middle milk maturity; 77—late milk maturity; 83—early wax maturity; 85—middle wax maturity (soft wax maturity); 87—hard wax maturity; 91, 92—after full maturity (overmaturity, grains begin to crumble).

Before conducting the research, the mass fraction of the moisture in the grain was analyzed using the Adam PMB-53 moisture analyzer, the operating principle of which is based on drying the sample under study. This method allows for a short time in the field to analyze the mass fraction of moisture and obtain reliable results with an error of ±0.05% for a sample weight of 10–50 g (in accordance with the device passport). The values of power spent on idle were determined by turning on the engine, bringing it to operating speed, and measuring the torque on the unit shaft (Figure 6) without entering the grain mass.

3. Results

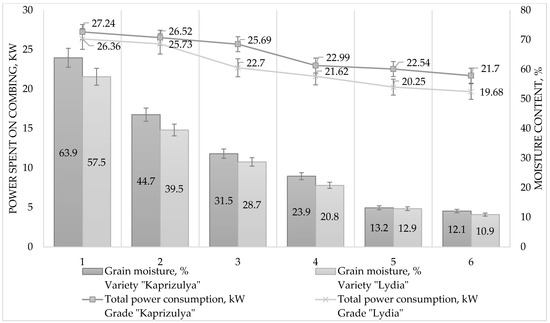

According to the results of this study, the values of power spent on idle running were 8.57 ± 0.27 kW. The results of the study of changes in the power spent on stripping and the mass fraction of moisture in wheat grain depending on the ripening phase are presented in Table 1 and Table 2 and Figure 7. Table 1 and Table 2 present the values of power spent directly on the stripping process, as well as power costs (calculated using Formula (2)). Also, for subsequent comparison of the stripping unit with a classic grain harvester, calculations of the power per 1 m of the stripping unit’s capture were made.

Table 1.

Power spent on combing and mass fraction of moisture in grain of wheat of the Kaprizulya variety (awnless, rigid) depending on the ripening phase.

Table 2.

Power spent on combing and mass fraction of moisture in wheat grain of the Lydia variety (awned, easy to thresh) depending on the ripening phase.

The results of this study presented in Table 1 show that a sharp jump in the change in power values occurs when the grain transitions from the mid-wax ripeness stage (stage 85 on the BBCH scale) to the hard wax ripeness stage (stage 87 on the BBCH scale). The difference in power values between the two stages is about 3.5 kW. The difference in power values at other transition stages is 0.45–0.84 kW. The difference in power values between the hard wax ripeness stage and the full ripening stage is less than 1 kW, which indicates a low excess of energy costs when harvesting wheat grain before full ripeness. The dynamics of changes in the mass fraction of moisture in the grain of the Kaprizulya wheat variety during the transition from one phase to another was 19.2%, 13.2%, 8.0%, 10.2%, and 1.1%, respectively. A sharp change in the mass fraction of moisture occurs during the transition from milky (dough-like) ripeness to waxy. Then, at the waxy ripeness stage, the change in the mass fraction of moisture occurs uniformly. A sharp jump in moisture occurs during the transition from waxy ripeness to the stage of full ripeness.

A sharp change in the power values of winter wheat of the Lydia variety occurs during the transition from the early wax ripeness stage (stage 83 on the BBCH scale) to the middle wax ripeness stage (stage 85 on the BBCH scale). The difference in the power values spent on towing between the two stages is about 3 kW. In comparison with the rigid variety—the winter wheat of the Kaprizulya variety (Table 1)—a sharp decrease in the power values of the Lydia wheat variety occurs earlier. At the late wax ripeness stage (stage 87 on the BBCH scale), when wheat grain has the highest nutritional value, the power values required for harvesting Lydia wheat grain are 1.3 kW less than those of the rigid Kaprizulya variety. The difference in the power values between the hard wax ripeness stage and the full ripening stage of Lydia wheat is about 1.5 kW (Figure 8).

Figure 8.

Results of this study of changes in the mass fraction of moisture and the power required for harvesting grain of winter wheat varieties Kaprizulya and Lydia: 1—doughy stage (stage 80 on the BBCH scale); 2—early phase of wax ripeness (stage 83 on the BBCH scale); 3—middle of wax ripeness (stage 85 on the BBCH scale); 4—hard wax ripeness (stage 87 on the BBCH scale); 5—full ripeness (stage 89 on the BBCH scale); 6—overmaturity (stage 92 on the BBCH scale).

After full maturity, the change in the mass fraction of moisture in the grain of both studied varieties and the values of power required for their harvesting by the stripping method occurs insignificantly as follows: within 1–2% for the mass fraction of moisture and 0.6–0.8 kW for power. The productivity of the stripping and threshing unit per 1 m of capture in terms of yield in the phase of full maturity for the Lydia variety was 5.5 t/h of net time, for the Kaprizulya variety it was 8.1 t/h of net time with the unit moving at a speed of 7 km/h.

4. Discussion

To compare the energy consumption of the wheat grain harvesting process with a new stripper–threshing unit and a grain harvester with a classic header, where the grain mass is cut with a stripper header, the Acros 530 combine harvester manufactured by Rostselmash LLC, Rostov-on-Don, the Russian Federation, was selected for comparison. The comparison will be carried out based on the value of the total power required to perform the technological process of harvesting fully ripened grain crops using the grain harvesting equipment listed above. The total power that the Acros 530 grain harvester consumed during the technological process of harvesting fully ripened wheat grain can be calculated using Formula (5):

where —power consumed in the cutting process, kW (according to sources [4,23,25,26] 7.0 kW for a header with a cutting width of 7 m);—power consumed to drive the threshing drum, kW; —power spent on driving the remaining working parts of the grain harvester, kW (for Acros 530 we will take 60 kW [25,26]; —power required to move a grain harvester across a field, kW.

The value of the power expended on the drive of the threshing drum can be determined by Formula (6) [25]:

where —power spent on threshing grain mass, kW (Formula (7)); —power spent on idle running of the threshing drum, kW (Formula (8)).

where —mass feed per second, kg/s (for the Acros 530 combine—8 m/s [25,26]); and —coefficients depending on the condition and variety of the crop and the design parameters of the threshing device (for a drum-deck apparatus = 100–120 and = 8–10) [25]; —speed of movement of the whips, m/s (we take the value of 30.0 m/s) [25].

Power consumed by the threshing drum in idle mode is determined by Formula (8) [25]:

where —coefficient of friction forces (for beat drums = 0.87 N for every 100 kg of drum weight (Acros 530 harvester drum weight—370 kg); —coefficient depending on the air density, shape, and size of the rotating parts of the drum (for beat drums = 0.072 N·s2/m2); —length of the beater drum, m (1.5 m).

Let us perform calculations using Formulas (6)–(8).

The power required to move a combine harvester across the field is determined by Formula (9):

where —the force expended by the combine for rolling, N; —combine harvester speed, m/s; —efficiency of the combine harvester chassis transmission ( = 0.87); —slip coefficient ( = 0.96) [25].

For the combine harvester speed, , we will determine it according to the manufacturer’s recommendations, taking into account the varietal characteristics and yield of the harvested crops using Formula (10):

where —productivity, main time threshing machine (for Acros 530 we will take 8 kg/s [26]), kg/s; —amount of biological mass per unit area (grain + straw: variety Kaprizulya 1.617 kg/m2, Lydia 2.135 kg/m2), kg/m2; —header width (7 m), m; —header capture coefficient (0.97).

For harvesting winter wheat of the Kaprizulya variety, the recommended combine speed is as follows:

For the Lydia variety, the recommended speed is as follows:

The force expended by the combine for rolling , can be determined by Formula (11):

where —rolling resistance coefficient ( = 0.10—stubble after harvesting grain); = —combine harvester gravity, kN; —mass of the combine with the mass of grain in the combine bunker, tons (22 tons); —field slope, °.

The force expended by the combine for rolling will be equal, as follows:

Then, the power required to move the combine harvester across the field, , when harvesting wheat of the Kaprizulya variety will be equal, as follows:

For the Lydia variety, the calculation is the following:

Total power of the Acros 530 grain harvester consumed during the technological process of harvesting fully ripe wheat grain is equal, as follows:

For the Kaprizulya variety:

For the Lydia variety:

When using the Acros 530 grain harvester with a stripper header, the power values will decrease when it processes straw [27,28,29,30,31] since the main part of the straw will remain in the field, and only an insignificant part of it will enter the threshing drum. The ratio of grain to non-grain part of the crop will decrease to 1.0:0.1–1.0:0.5 (for a combine using a continuous-cut header, the ratio of grain to non-grain mass varies in the range of 1.0:1.0–1.0:2.2 depending on the varietal characteristics and natural and climatic conditions). With a decrease in straw content, the power consumption of the chopping drum will decrease by 50–80% [27,28,29,30,31] since the bulk of the non-grain part is chaff, ear rods, and a small amount of plant stems. At the same time, the straw walker will operate with minimal power consumption for idle running. As a result, the total power consumed for the harvesting process by a grain harvester with a stripper header is lower by an average of 20% compared to a straight-cut header [27,28,29,30,31]. Power values for harvesting grain with a combine harvester with a stripper header, , are determined by Formula (12):

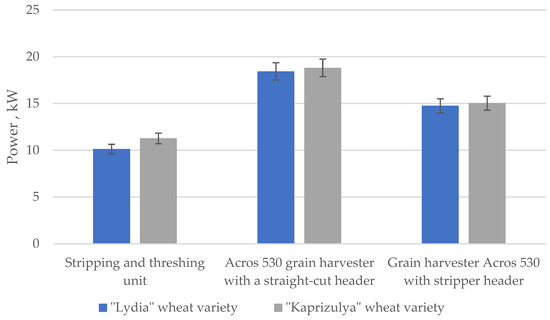

Using the above analysis and data from literary sources [4,23,25,26], we will compare the energy costs for harvesting wheat when it reaches full maturity and for harvesting with a moisture content of less than 14% using various methods given in Table 3.

Table 3.

Comparison of power values when harvesting wheat grain using different methods and technical means.

Grain harvesting with a classic combine with a straight-cut header is the most energy-intensive. The power spent on the harvesting process is 1.7 times higher than the power of a stripper–threshing unit for harvesting cereal crops. The power spent on harvesting with a combine with a stripper header is 1.5 times higher than when harvesting with a stripper–threshing unit. The difference in power values—depending on the wheat variety being harvested—varies slightly, within 0.28–1.14 kW per 1 m of the header (Figure 9).

Figure 9.

Comparative characteristics of the influence of the grain harvesting method and wheat variety on the value of power expended in the harvesting process.

The product obtained after the stripping and threshing unit (wheat grain heap) must be processed at a stationary facility: the grain heap of full maturity must be cleaned of impurities or the grain heap of early ripeness wheat must be processed into a feed additive (Figure 10) [7,32].

Figure 10.

Grain heap of winter soft wheat of the Kaprizulya variety: (a)—hard wax ripeness; (b)—full ripeness.

This will incur additional energy costs. However, when cleaning or processing the grain heap of wheat at a stationary facility, electricity is used, which is cheaper than motor fuel. In addition, the use of motor fuel has a negative impact on the environment, increasing the amount of greenhouse gases [33,34,35].

5. Conclusions

The conducted research on the energy intensity of the wheat grain harvesting process by the new stripping and threshing unit proved its efficiency as a low-energy-intensive means capable of harvesting grain at different stages of maturity. Grain harvesting at the early stages of maturity obtains highly valuable raw feed materials (with increased content of protein, gluten, and amino acids), reduces the load on the technology parks of agricultural organizations, and completes harvesting operations within agro-technological timeframes. The change in the values of power spent on the grain mass stripping process, depending on the ripening stage, occurs from 8–10 kW (the stage of early wax ripeness—80 on the BBCH scale) to 2–4 kW (the stage after the onset of full ripeness—92 on the BBCH scale), i.e., 2.5–4 times depending on the wheat variety. The highest content of nutrients in wheat grain is contained in the stage of hard wax ripeness (stage 87 on the BBCH scale). The power for harvesting grain at this stage is only 1–1.5 kW higher than at the stage of full ripening (stage 89 on the BBCH scale). The wheat variety affects the energy intensity of the harvesting process: the power value spent on harvesting winter wheat of the rigid variety Kaprizulya is 1.3 kW higher than that of the easy-threshing variety Lydia.

A comparison of the power values expended in the harvesting process by a stripper–threshing unit, a combine with a classic straight-cut header, and a combine with a stripper header showed the following:

- -

- Harvesting grain with a classic combine with a straight-cut header is the most energy-intensive;

- -

- The power consumed in the harvesting process is 1.7 times higher than the power of the stripping and threshing unit for harvesting cereal crops;

- -

- The power expended on harvesting with a combine with a stripper header is 1.5 times higher than when harvesting with a stripper–threshing unit;

- -

- The difference in power values depending on the harvested wheat variety varies slightly, within 0.28–1.14 kW per 1 m of the header.

In further studies, it is planned to apply the developed unit to other cereal crops, such as barley (a crop often used in compound feed production) and perennial cereal crops (winter wheat (trititrigia) of the “Pamyati Lyubimova” variety and gray wheat grass of the “Sova” variety), which have a number of advantages over annual crops (drought resistance, frost resistance, prevention of soil erosion, etc.). These crops differ in physical and mechanical properties as well as in the structure of the grain (especially gray wheat grass), and additional studies are needed for their high-quality harvesting. Research will also be conducted on the development and testing of an industrial sample with a harvesting part width of 7 m or more.

Author Contributions

Conceptualization, V.P. and D.R.; methodology, S.K.; software, S.K.; investigation, D.R. and S.K.; resources, V.P.; data curation, D.R. and T.M.; writing—original draft preparation, V.P., D.R., S.K. and T.M.; writing—review and editing, S.K. and T.M.; visualization, D.R. and T.M.; supervision, V.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work is carried out as part of the project, “Development of a new technology for differentiated harvesting of cereal crops” (FZNE-2024-0014), Ministry of Science and Higher Education of the Russian Federation.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- FAO’s Cereal Supply and Demand Brief. Available online: https://www.fao.org/worldfoodsituation/csdb/en/ (accessed on 5 July 2024).

- OECD/FAO. OECD-FAO Agricultural Outlook 2024–2033, Paris and Rome. 2024. Available online: https://doi.org/10.1787/4c5d2cfb-en (accessed on 5 July 2024).

- Saker, S.; Levshin, A.G. Analysis of losses during wheat harvesting. In Proceedings of the All-Russian Scientific Conference of Young Scientists and Specialists with International Participation, Dedicated to the 155th Anniversary of the Birth of N.N. Khudyakov, Moscow, Russia, 7–9 June 2021; Volume 1, pp. 215–218. (In Russian). [Google Scholar]

- Berenshtein, I.B.; Gonchar, I.V. Technical and economic efficiency of two-phase harvesting of grain (spike) crops with post-harvest utilization of straw. News Agric. Sci. Tavrida 2017, 11, 51–60. (In Russian) [Google Scholar]

- Buryanov, A.I.; Goryachev, Y.O.; Buryanov, M.A. Efficiency of grain crop harvesting technology by combine stripping. Tract. Agric. Mach. 2016, 9, 34–39. (In Russian) [Google Scholar] [CrossRef]

- Xu, L.; Tang, G.; Wu, D.; Han, Y.; Zhang, J. Effects of tillage and maturity stage on the yield, nutritive composition, and silage fermentation quality of whole-crop wheat. Front. Plant Sci. 2024, 15, 1357442. [Google Scholar] [CrossRef] [PubMed]

- Lachuga, Y.F.; Meskhi, B.C.; Pakhomov, V.I.; Rudoy, D.V.; Kambulov, S.I.; Maltseva, T.A. Study of Changes in the Amino Acid Composition of Spiked Cereals during the Ripening Process. Eng. Technol. Syst. 2023, 33, 508–523. [Google Scholar] [CrossRef]

- Berihuete-Azorín, M.; Stika, H.-P.; Hallama, M.; Valamoti, S.M. Distinguishing ripe spelt from processed green spelt (Grünkern) grains: Methodological aspects and the case of early La Tène Hochdorf (Vaihingen a.d. Enz, Germany). J. Archaeol. Sci. 2020, 118, 105143. [Google Scholar] [CrossRef]

- Kraska, P.; Andruszczak, S.; Dziki, D.; Stocki, M.; Stocka, N.; Kwiecińska-Poppe, E.; Różyło, K.; Gierasimiuk, P. Green grain of spelt (Triticum aestivum ssp. spelta) harvested at the stage of milk-dough as a rich source of valuable nutrients. Emir. J. Food Agric. 2019, 31, 263–270. [Google Scholar] [CrossRef]

- Marti, A.; Rahardjo, C.P.; Ismail, B. Insights Into Perennial Crops as Potential Food Source. Encycl. Food Secur. Sustain. 2019, 2, 400–405. [Google Scholar] [CrossRef]

- Salami, S.A.; O’Grady, M.N.; Luciano, G.; Priolo, A.; McGee, M.; Moloney, A.P.; Kerry, J.P. Fatty acid composition, shelf-life and eating quality of beef from steers fed corn or wheat dried distillers’ grains with solubles in a concentrate supplement to grass silage. Meat Sci. 2021, 173, 108381. [Google Scholar] [CrossRef]

- Khazaei, J.; Shahbazi, F.; Massah, J.; Nikravesh, M.; Kianmehr, M. Evaluation and Modeling of Physical and Physiological Damage to Wheat Seeds under Successive Impact Loadings: Mathematical and Neural Networks Modeling. Crop Sci. 2008, 48, 1532–1544. [Google Scholar] [CrossRef]

- Majid, Y.; Feizollah, S.; Kianoosh, H. Crop Yield and Physicochemical Properties of Wheat Grains as Affected by Tillage Systems. Sustainability 2021, 13, 4781. [Google Scholar] [CrossRef]

- Zhou, Y.; Gao, J.; Hui, Y.; Wang, X.; Liu, J.; Zhang, Y.; Wang, Q. Accurate modelling and fracture characteristics of wheat grains. J. Stored Prod. Res. 2024, 105, 102249. [Google Scholar] [CrossRef]

- Yuan, L.; He, X.; Zhu, C.; Wang, W.; Wang, M.; Wu, S. Design and test of tangential and longitudinal-axial threshing and separating unit for wheat. Results Eng. 2024, 21, 101774. [Google Scholar] [CrossRef]

- Liang, Z.; Wada, M.E. Development of cleaning systems for combine harvesters: A review. Biosyst. Eng. 2023, 236, 79–102. [Google Scholar] [CrossRef]

- Ni, X.; Liu, K.; Zhou, X.; Mao, X.; Chen, D.; Wang, S. Unsupervised anomaly analysis-based manufacturing quality test and grading method for combine harvesters. Comput. Electron. Agric. 2023, 210, 107898. [Google Scholar] [CrossRef]

- Pakhomov, V.I.; Braginets, S.V.; Bakhchevnikov, O.N.; Benova, E.V.; Rukhlyada, A.I. Experimental Data of the Ear Threshing Process in a Pneumatic Device. Eng. Technol. Syst. 2020, 30, 111–132. [Google Scholar] [CrossRef]

- Safaei, F.A.; Rezaei, N.A.; Feizollah, S.; Sadegh, M.-F. The Effects of Simulated Vibration Stress on Plant Height and Some Physical and Mechanical Properties of Coleus blumei Benth. Int. J. Hortic. Sci. Technol. 2019, 6, 273–282. [Google Scholar] [CrossRef]

- Meskhi, B.; Rudoy, D.; Lachuga, Y.; Pakhomov, V.; Soloviev, A.; Matrosov, A.; Panfilov, I.; Maltseva, T. Finite Element and Applied Models of the Stem with Spike Deformation. Agriculture 2021, 11, 1147. [Google Scholar] [CrossRef]

- Lachuga, Y.F.; Meskhi, B.C.; Pakhomov, V.I.; Rudoy, D.V. Harvesting Machine. Patent of the Russian Federation No 206314 U1, 6 September 2021. [Google Scholar]

- Strain Gauges of the 2FKP Series. Available online: https://zetlab.com/shop/datchiki/tensodatchiki/tenzorezistoryi/2fkp/ (accessed on 23 August 2024).

- Lezhenkin, A.N. Methodology of Formation of Energy- and Resource-Saving Technology of Harvesting Grain Crops in Conditions of Farms: On the Example of Ukraine. Ph.D. Thesis, V.P. Goryachkin Moscow State Agroengineering University, Saint Petersburg, Russia, 2008; 503p. [Google Scholar]

- Diagnostics of Winter Wheat Development Stages according to the BBCH Scale. Methodological Manual. Available online: https://pesticidy.by/diagnostika-stadij-razvitiya-ozimoj-pshenitsy-po-shkale-vvsn-metodicheskoe-posobie/ (accessed on 23 August 2024).

- Bakhterev, A.A.; Iovlev, G.A.; Nesgovorov, A.G. Improving the process of threshing grain crops. Theory Pract. World Sci. 2017, 10, 51–60. (In Russian) [Google Scholar]

- Official Website of the Rostselmash Plant [Electronic Resource]. Available online: https://rostselmash.com/ (accessed on 26 July 2024).

- Lachuga, Y.F.; Pakhomov, V.I.; Buryanov, A.I. Oches: Technology, technique, prospects. In The Collection of Scientific Papers of the International Scientific and Methodological Conference “Innovative Technologies in Science and Education”; DSTU: Rostov-on-Don, Russia, 2013; pp. 47–50. (In Russian) [Google Scholar]

- Lovchikov, A.P. Improving grain quality during harvesting with combines. News OSAU 2005, 7, 141–143. (In Russian) [Google Scholar]

- Ozherelyev, V.N.; Popov, V.B. Innovations in the process of separating grain from the ear. Bull. Gomel State Tech. Univ. Named After P.O. Sukhoi. 2017, 4, 26–35. (In Russian) [Google Scholar]

- Mkrtchyan, S.R.; Ignatov, V.D.; Zhalnin, E.V.; Struzhkin, N.I. Stripping headers: State and development prospects. Agric. Mach. Technol. 2013, 4, 18–21. [Google Scholar]

- Tado, C.J.M.; Wacker, P.; Kutzbach, H.D.; Suministrado, D.C. Development of Stripper Harvesters: A Review. J. Agric. Eng. Res. 1998, 71, 103–112. [Google Scholar] [CrossRef]

- Rudoy, D.V. Results of testing compound feed with grain heap of wheat of early stages of maturity. Polythematic Online Electron. Sci. J. Kuban State Agrar. Univ. (Sci. J. KubSAU) 2023, 4, 1882304013. [Google Scholar] [CrossRef]

- Castelein, R.B.; Broeze, J.; Kok, M.G.; Axmann, H.B.; Guo, X.; Soethoudt, J.M. Mechanization in rice farming reduces greenhouse gas emissions, food losses, and constitutes a positive business case for smallholder farmers—Results from a controlled experiment in Nigeria. Clean. Eng. Technol. 2022, 8, 100487. [Google Scholar] [CrossRef]

- Kumar, T.; Kundu, M.S.; Jha, R.K. Impact of crop rotation and tillage operations on mitigating greenhouse gas emissions and evaluation of sustainability index in rice- wheat-green gram cropping system of north Bihar. J. Environ. Manag. 2024, 366, 121689. [Google Scholar] [CrossRef] [PubMed]

- Braglia, M.; Paco, F.D.; Gabbrielli, R.; Grassi, C.; Marrazzini, L. Greenhouse gas Emissions Deployment (GED): A novel Lean method for mitigating greenhouse gas emissions in industrial environment. Sustain. Prod. Consum. 2024, 48, 29–45. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).