A Multi-Function Novel Crop Seeder for the Management of Residues and Mechanized Sowing of Wheat in a Single Path

Abstract

1. Introduction

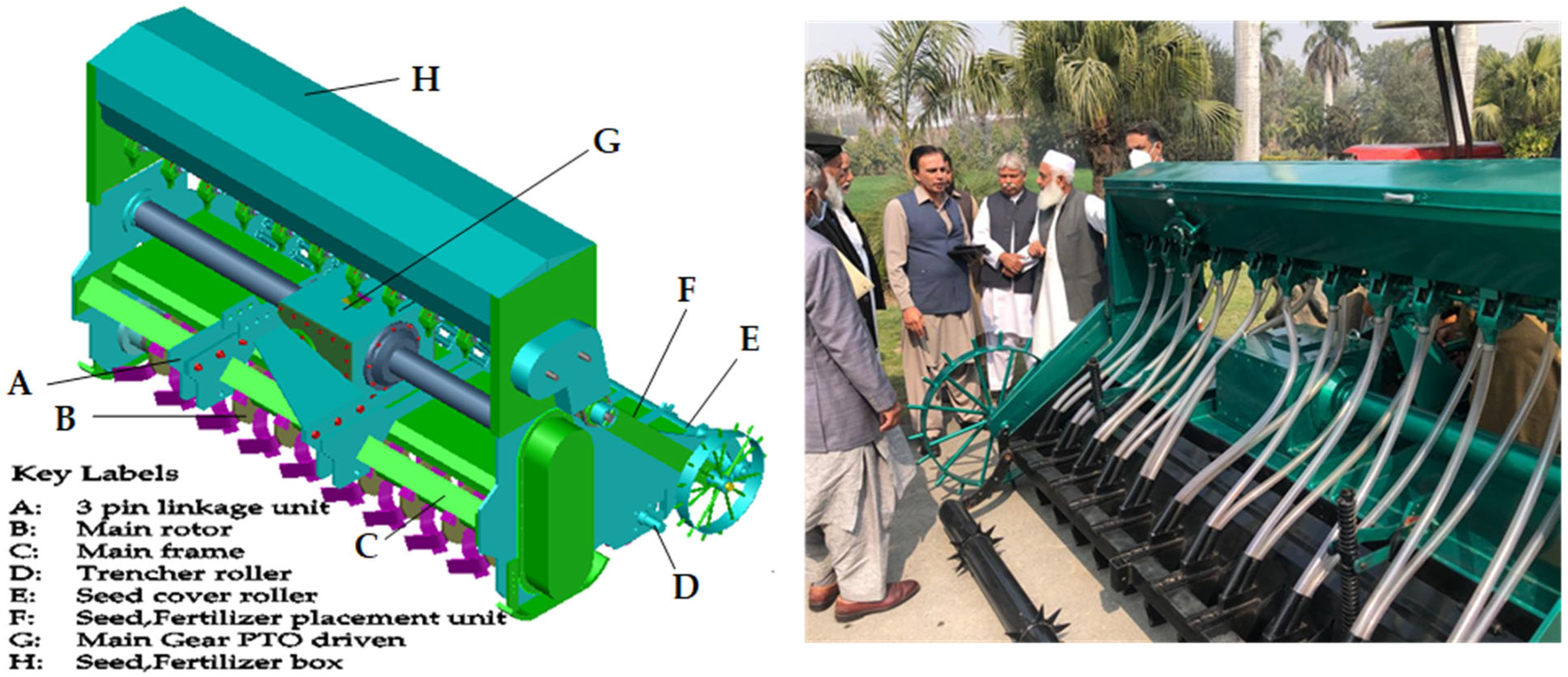

2. Materials and Methods

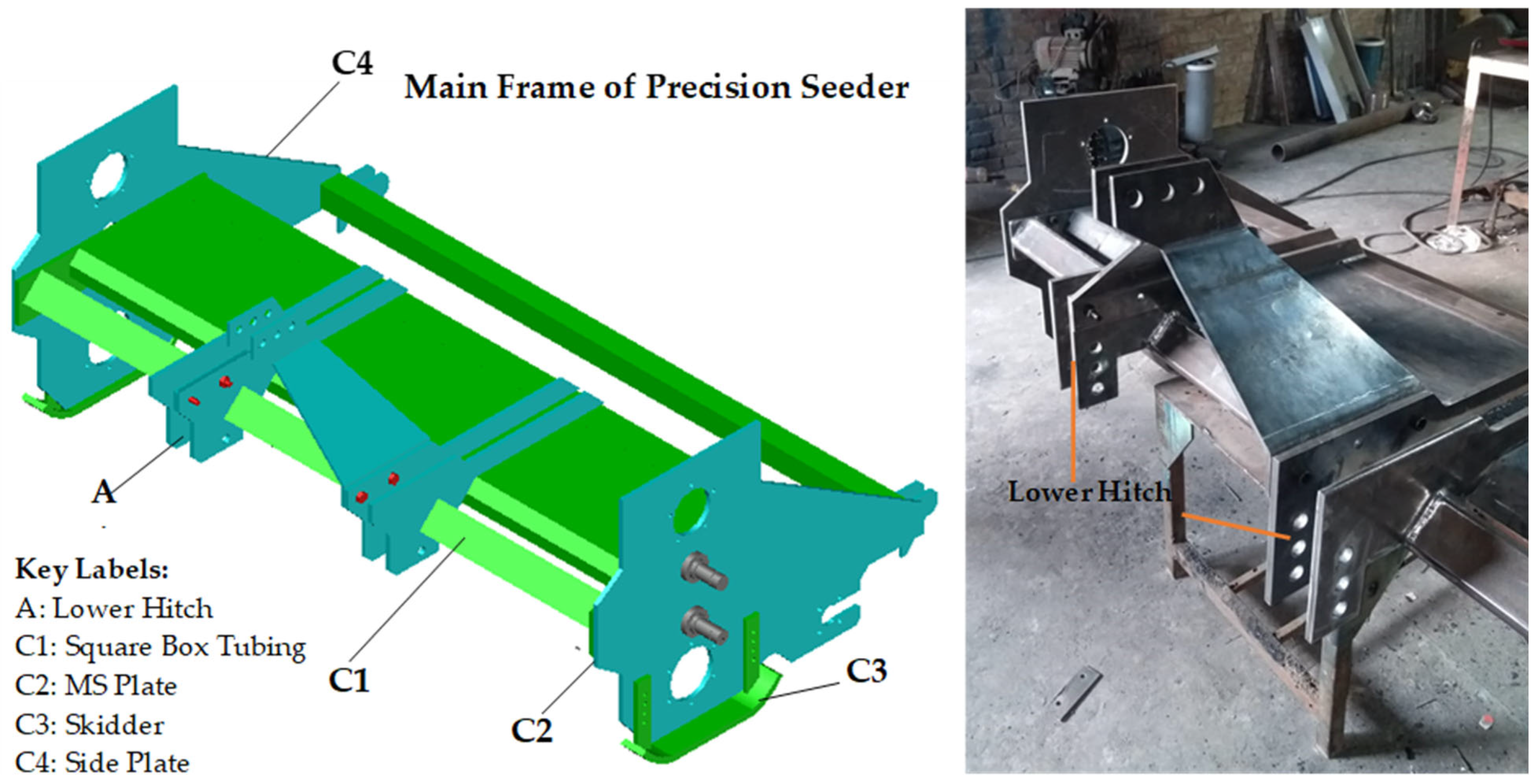

2.1. Main Frame

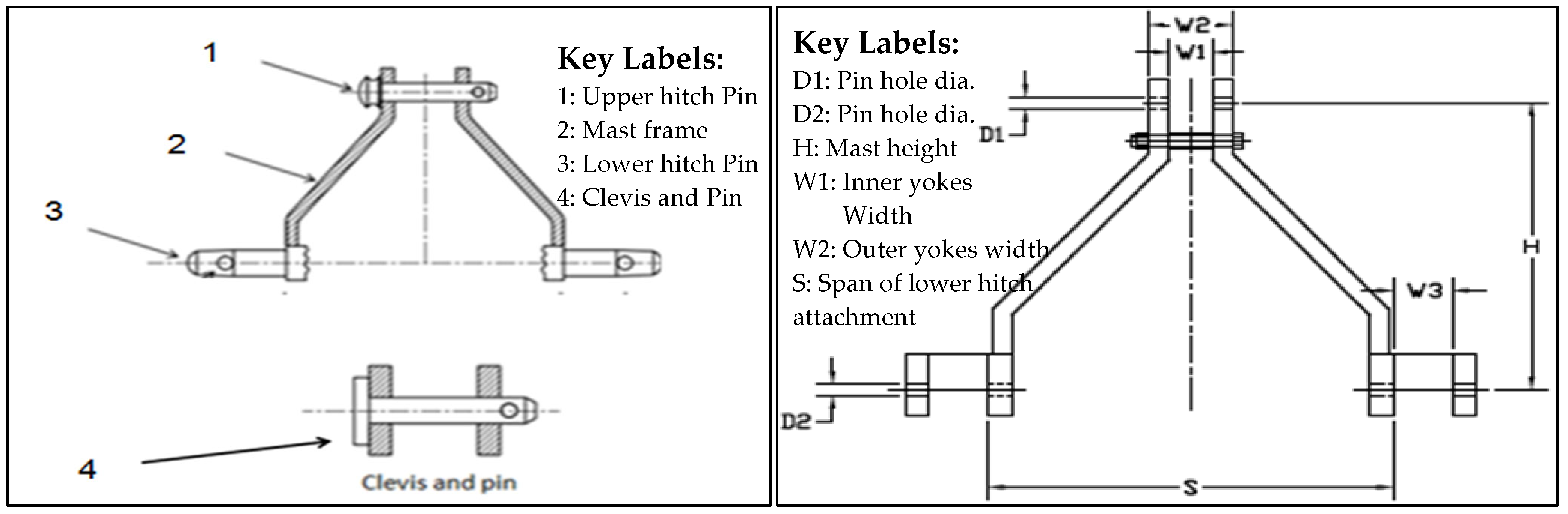

2.2. Three-Point Hitch System

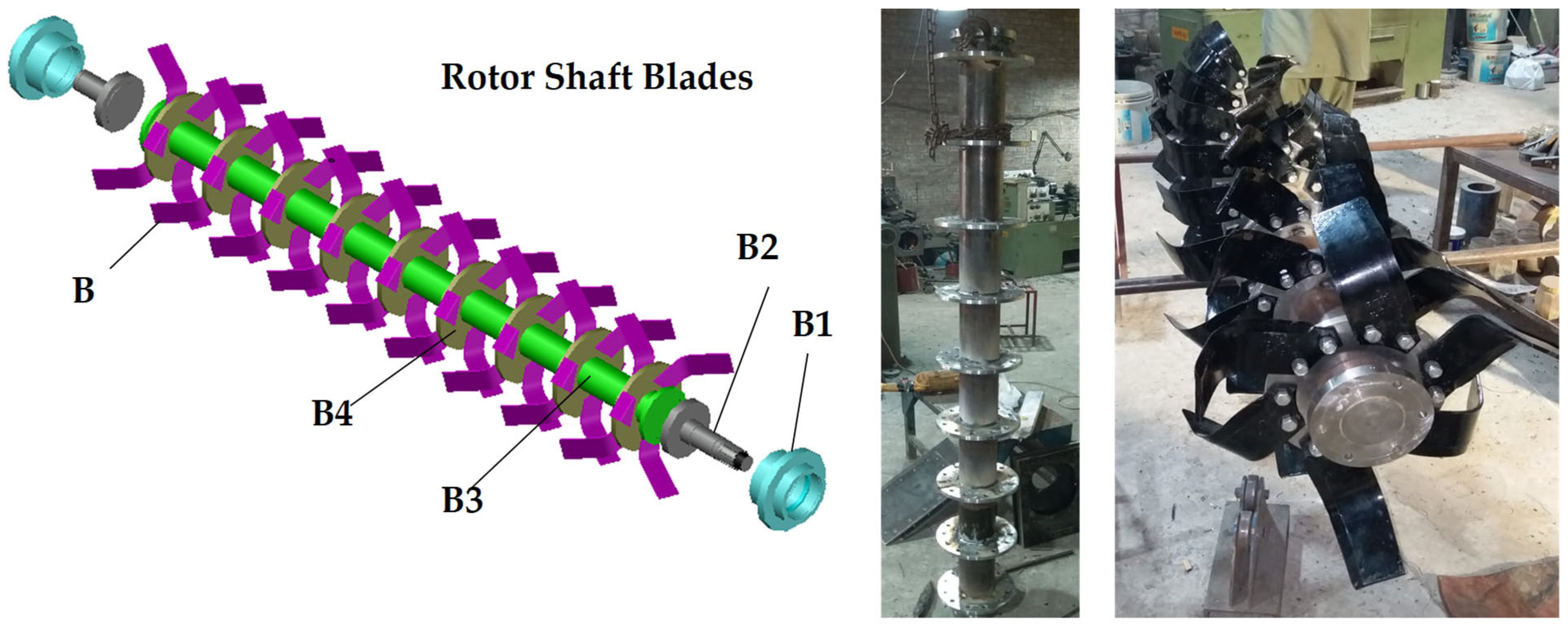

2.3. Rotor Blade

Rotor Design Parameters

- Ws = Total specific work of rotor

- W0 = Static-specific work

- Wb = Dynamic work

- V = Forward speed of tractor (m/s)

- U = Rotor peripheral velocity (m/s)

- K0 = Specific resistance of soil (kg/dm3)

- C0 = Coefficient proportion of soil type and machine parameter

- λ = Coefficient of proportion

- d = Rotor diameter (mm)

- Ms = Maximum amount of torque on rotor axle (N·mm)

- τ = Shear stress on rotor axle (N/mm2)

- k = Coefficient for concentration of stress

- Sy = Safety factor

- Ks = Max. tangent force on rotor (Mpa)

- R = Rotor radius (mm)

- Cs = Reliability factor, i.e., non-rocky soil = 1.5, rocky soil = 2

- Nc = Tractor power (HP)

- ηc = Tractor PTO efficiency (0.85)

- ηz = Coefficient of reserved tractor power (0.7–0.8)

- Umin = Min. linear velocity of rotor (m/s)

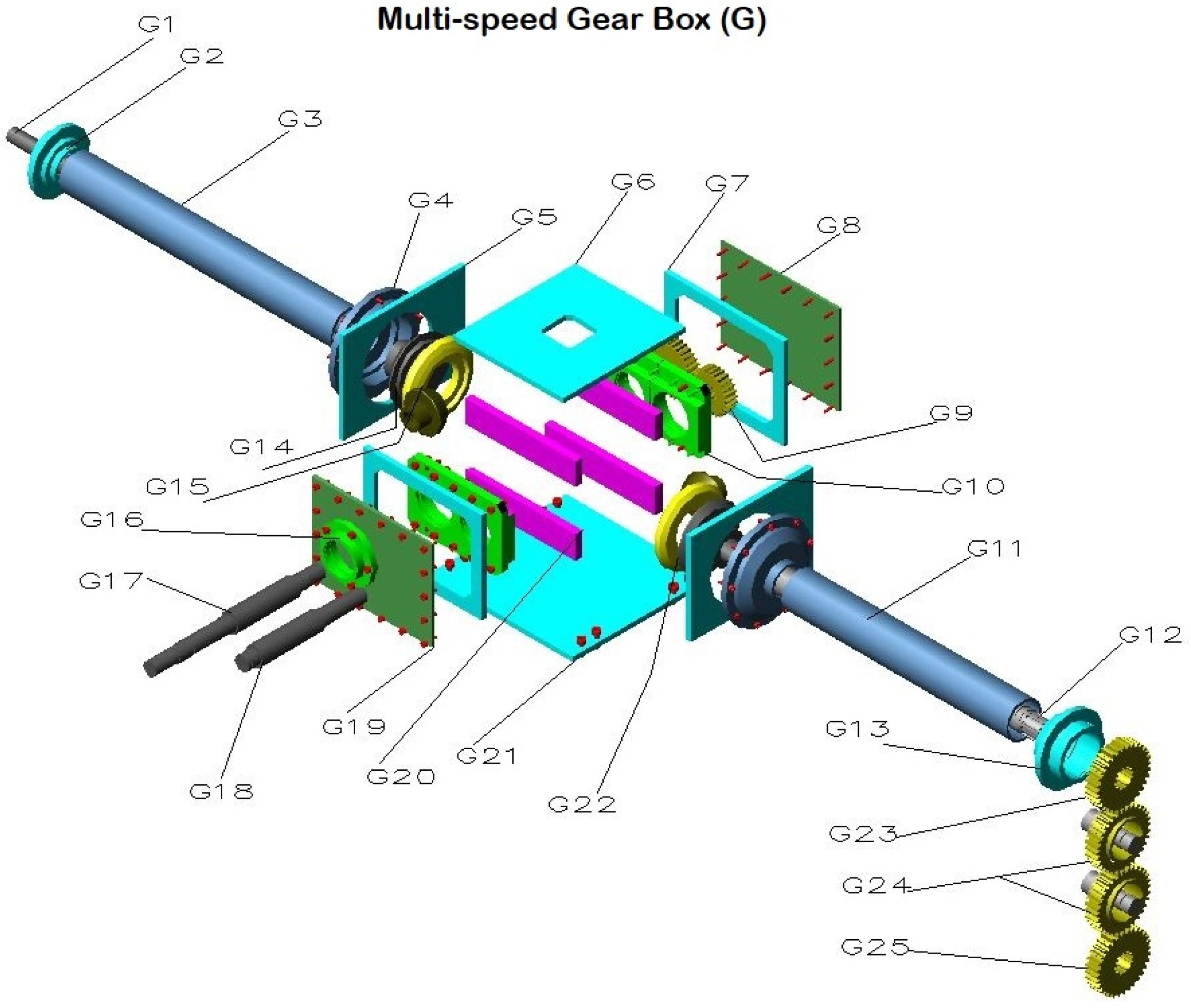

2.4. Multi-Speed Gear Box

2.5. Trencher Plates

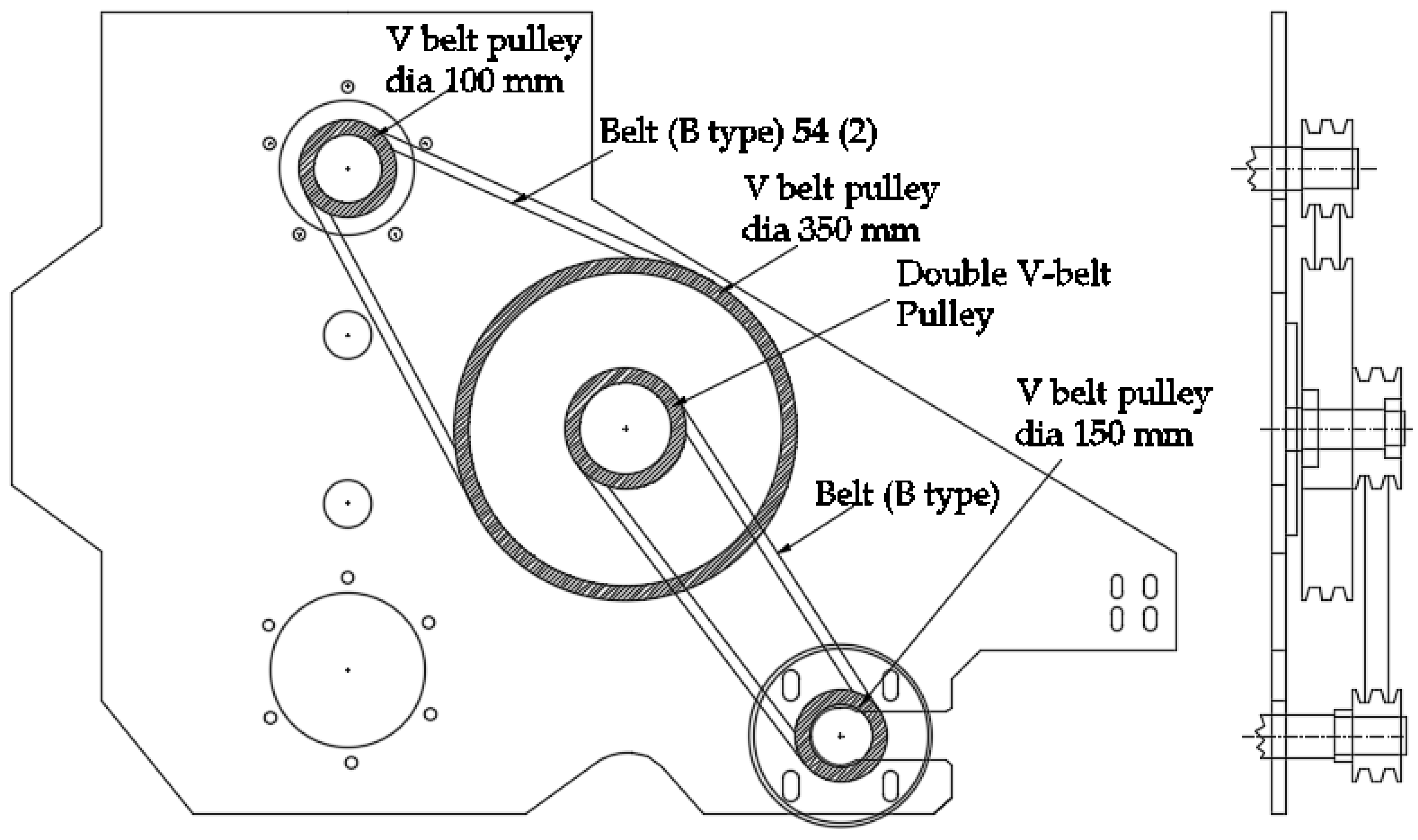

2.6. Power Transmission

- i.

- Timing belt and pulley:

- ii.

- V-belt and pulley:

- iii.

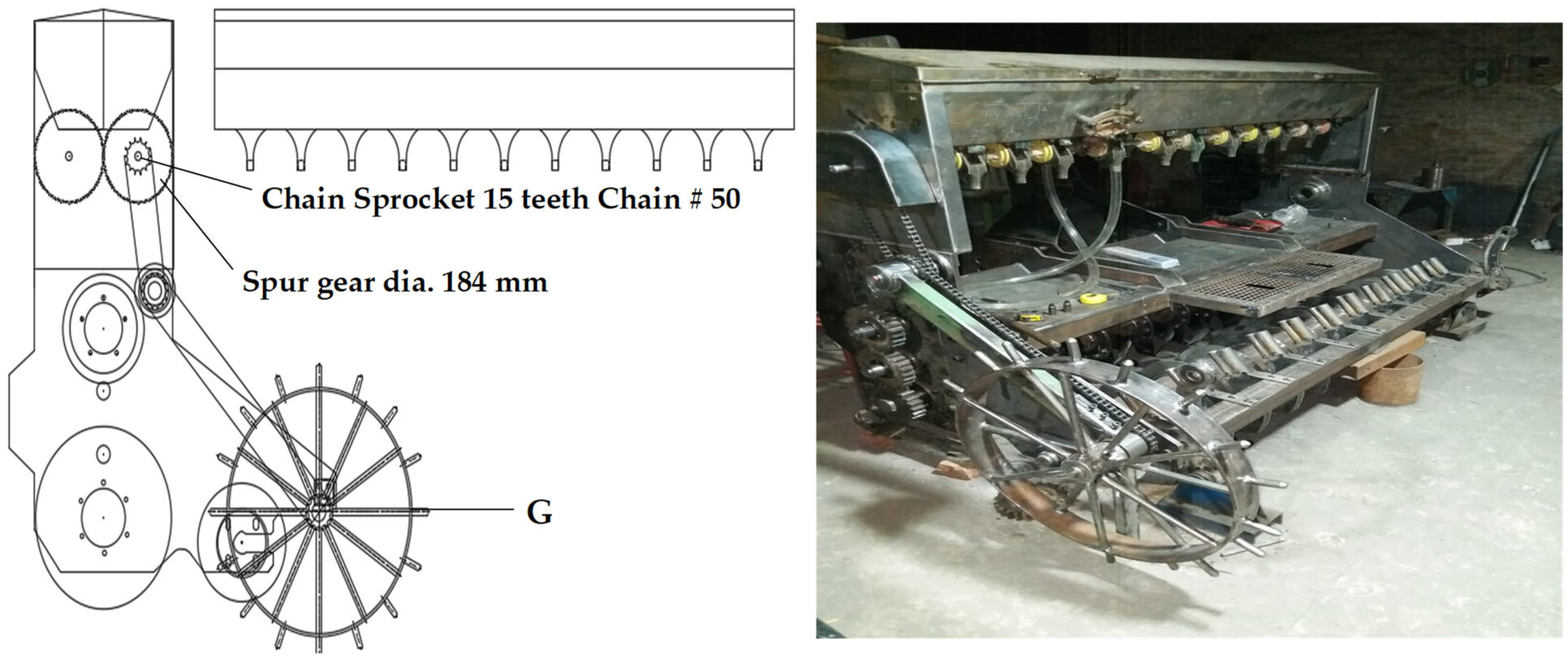

- Gear System:

- iv.

- Chain and Sprocket:

- v.

- Star Wheels:

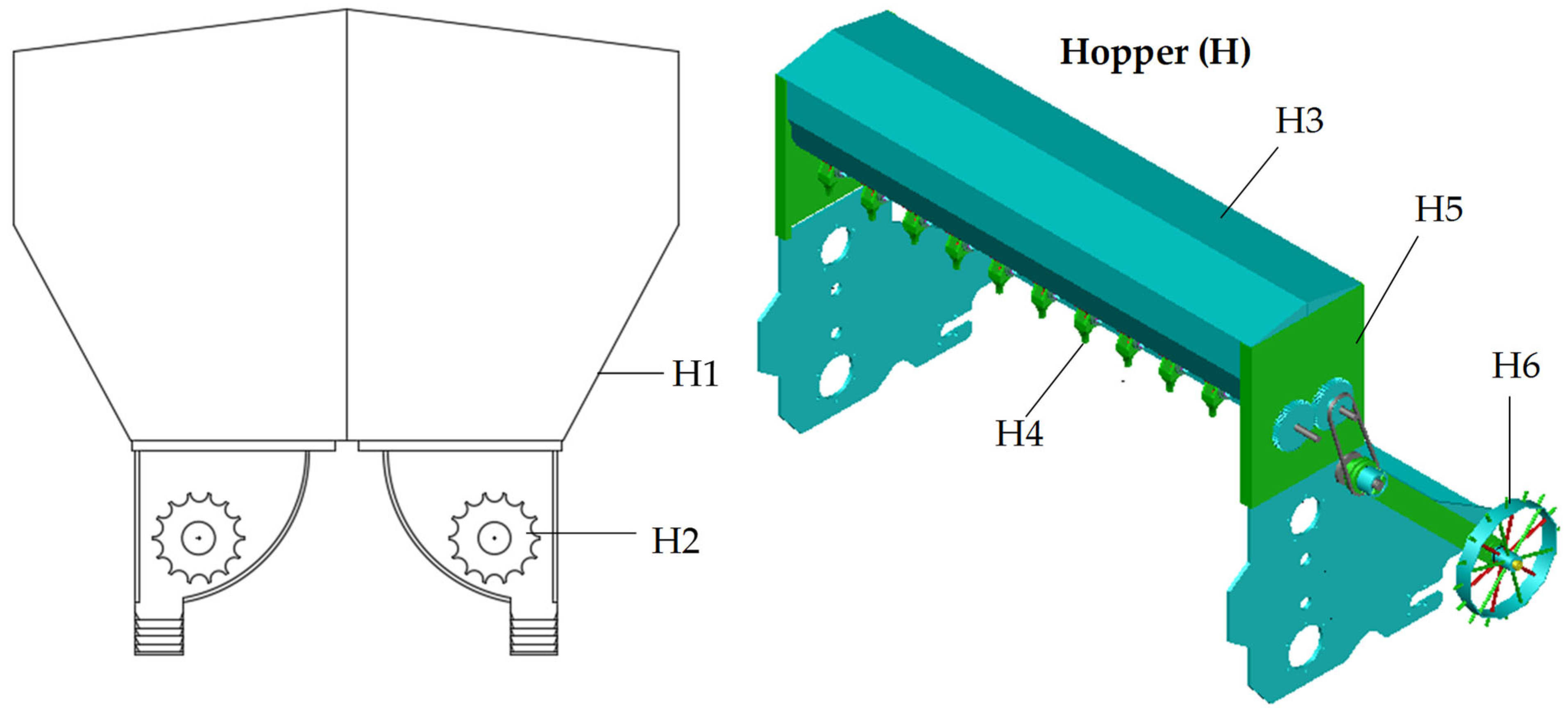

2.7. Seeder Units

2.8. Seed and Fertilizer Distribution

2.9. Seed and Fertilizer Calibration

- (i = 1, 2, 3, …, n)

- Ms = Mass of seed/fertilizer collected under each fluted roller (kg)

- n = Number of fluted rollers on the seeder

- Ws = Width of the seeder (m)

- Cgw = Circumference of the ground wheel (m)

- N = Number of ground-wheel revolutions, e.g., 10

2.10. Draft Measurement

- Pdb = Drawbar power (HP)

- V = Forward speed of the tractor (km/h)

- Db = Drawbar force (kN)

- a = Working depth (cm)

- b = Seeder working width (mm)

- Da = Avg. specific resistance

2.11. Field Efficiency

- St = Forward speed of tractor during operation with the seeder (km·h−1)

- Ws = Working width of the seeder (m)

2.12. Cost Analysis

3. Results and Discuss

3.1. Laboratory Testing

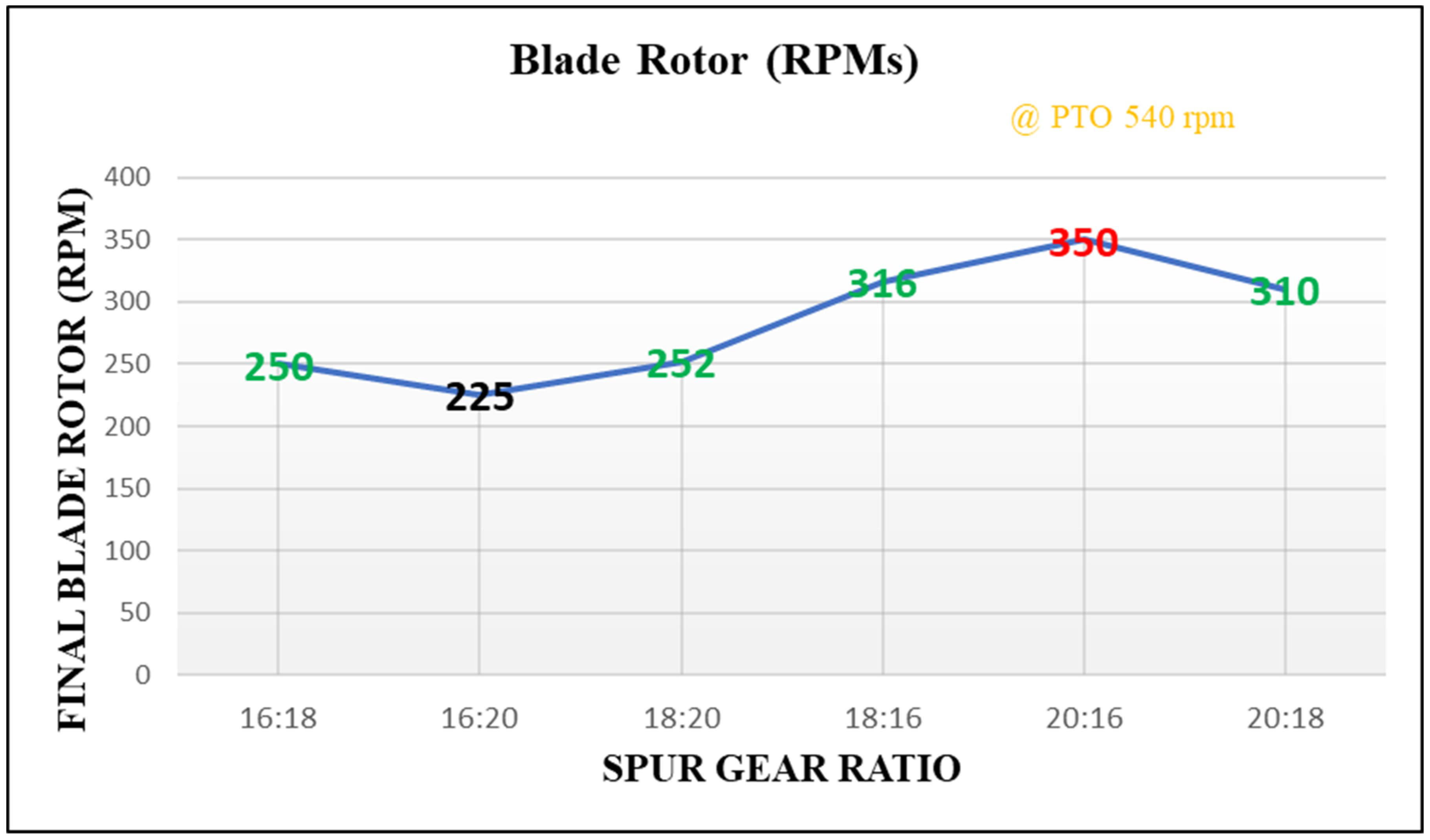

3.1.1. Blade Rotor RPM

3.1.2. Trencher Plates Rotor

3.2. Field Testing

3.2.1. Blade Rotor RPM

3.2.2. Trencher Rotor Speed

3.3. Seed and Fertilizer Calibration

3.4. Field Efficiency

3.5. Wheel Slippage

3.6. Cost Analysis

3.7. Precision Seeding

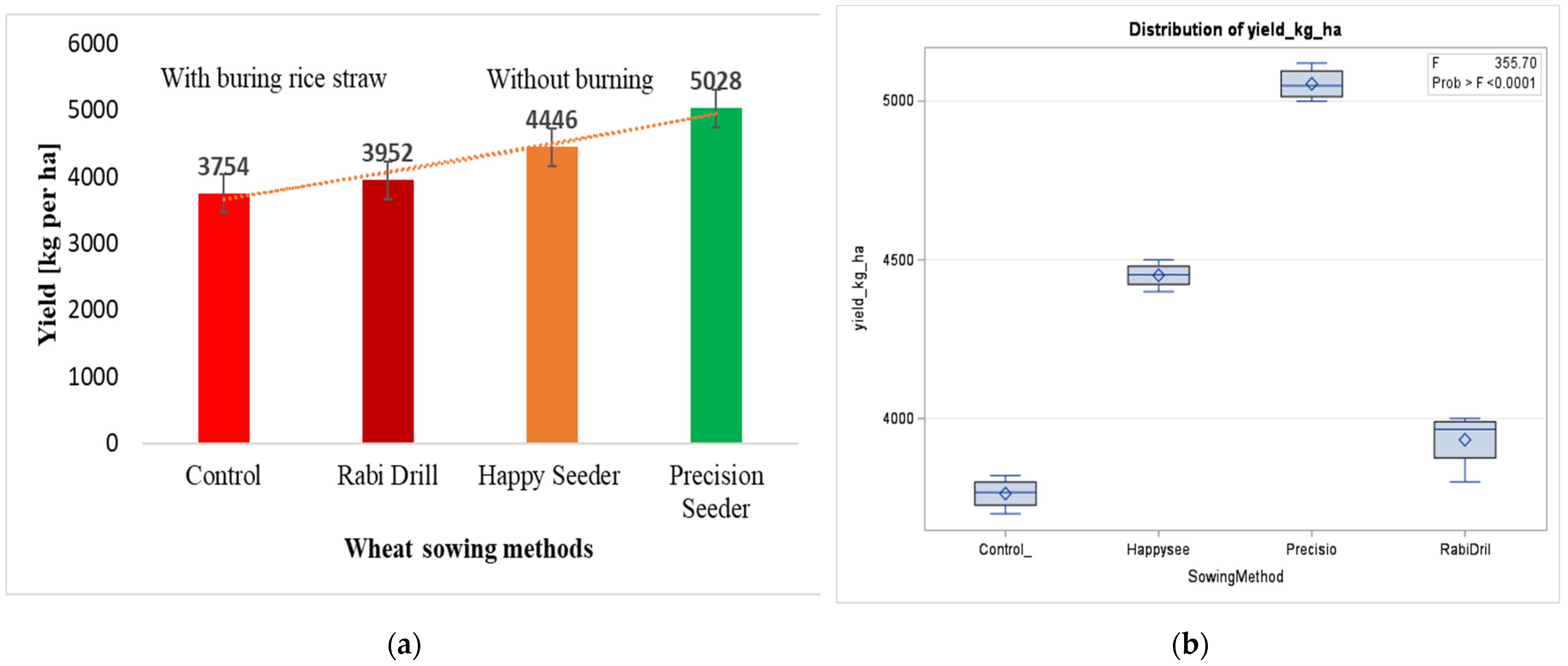

3.8. Vegetative Growth/Yield

Wheat Yield Comparison under Different Sowing Methods

4. Conclusions

- Wheat sowing is achieved in a single pass without burning or removal of rice residue by incorporating rice straw and stubble directly into the soil profile ahead of the trenching units.

- This seeder requires less tractor power (75 HP) to operate compared to other advanced multi-operation seeders via the introduction of a novel multi-gear box transmission.

- The operational cost of 40.68 USD/ha is lower than conventional tillage and reported a significantly (α = 0.01) higher yield (5028 kg/ha) versus conventional methods of tillage and drilling (3952 kg/ha) in rice–wheat cropping systems.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Food and Agriculture—Statistical Yearbook 2022; FAO: Rome, Italy, 2022; ISBN 978-92-5-136930-2.

- Erenstein, O.; Jaleta, M.; Mottaleb, K.A.; Sonder, K.; Donovan, J.; Braun, H.-J. Global Trends in Wheat Production, Consumption and Trade. In Wheat Improvement: Food Security in a Changing Climate; Reynolds, M.P., Braun, H.-J., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 47–66. ISBN 978-3-030-90673-3. [Google Scholar]

- Su, D.; Qiao, Y.; Kong, H.; Sukkarieh, S. Real Time Detection of Inter-Row Ryegrass in Wheat Farms Using Deep Learning. Biosyst. Eng. 2021, 204, 198–211. [Google Scholar] [CrossRef]

- World Population Clock: 8.1 Billion People (LIVE, 2023)—Worldometer. Available online: https://www.worldometers.info/world-population/ (accessed on 5 October 2023).

- Shah, B.H.; Hamid, F.S.; Islam, S.U.; Ahmed, N.; Ahmad, F.; Khan, N.; Zaman, Q.U. Evaluation of Elite Rice (Oryza sativa L.) Lines for Yield and Yield Components. PJAR 2020, 33, 1–191. [Google Scholar] [CrossRef][Green Version]

- Martin Goal 2: Zero Hunger. United Nations Sustainable Development. Available online: https://www.un.org/sustainabledevelopment/hunger/ (accessed on 18 June 2024).

- United Nations. Department of Economic and Social Affairs The Sustainable Development Goals Report 2023: Special Edition; The Sustainable Development Goals Report; United Nations: San Francisco, CA, USA, 2023; ISBN 978-92-1-002491-4. [Google Scholar]

- Share of Economic Sectors in the Global Gross Domestic Product (GDP) from 2011 to 2021. Available online: https://www.statista.com/statistics/256563/share-of-economic-sectors-in-the-global-gross-domestic-product/ (accessed on 5 October 2023).

- Ministry of Finance | Government of Pakistan |. Available online: https://www.finance.gov.pk/survey_2022.html (accessed on 5 October 2023).

- Liu, K.; Harrison, M.T.; Wang, B.; Yang, R.; Yan, H.; Zou, J.; Liu, D.L.; Meinke, H.; Tian, X.; Ma, S.; et al. Designing High-Yielding Wheat Crops under Late Sowing: A Case Study in Southern China. Agron. Sustain. Dev. 2022, 42, 29. [Google Scholar] [CrossRef]

- McDonald, A.J.; Riha, S.J.; Duxbury, J.M.; Steenhuis, T.S.; Lauren, J.G. Soil Physical Responses to Novel Rice Cultural Practices in the Rice–Wheat System: Comparative Evidence from a Swelling Soil in Nepal. Soil Tillage Res. 2006, 86, 163–175. [Google Scholar] [CrossRef]

- Balwinder-Singh; Humphreys, E.; Gaydon, D.S. Sudhir-Yadav Options for Increasing the Productivity of the Rice–Wheat System of North West India While Reducing Groundwater Depletion. Part 2. Is Conservation Agriculture the Answer? Field Crops Res. 2015, 173, 81–94. [Google Scholar] [CrossRef]

- Ferdows, M.N.; Rahman, M.A.; Ali, M.R.; Hanif, M.A.; Tabriz, S.S.; Hossen, M.S.; Rokonuzzaman, M. Development and Performance Evaluation of Low-Cost 2WT-Operated Earthing-Up Machine for Sugarcane Cultivation in Bangladesh. AgriEngineering 2023, 5, 1327–1346. [Google Scholar] [CrossRef]

- Bhatt, R.; Kukal, S.S.; Busari, M.A.; Arora, S.; Yadav, M. Sustainability Issues on Rice–Wheat Cropping System. Int. Soil Water Conserv. Res. 2016, 4, 64–74. [Google Scholar] [CrossRef]

- Upadhyay, G.; Raheman, H. Comparative Analysis of Tillage in Sandy Clay Loam Soil by Free Rolling and Powered Disc Harrow. Eng. Agric. Environ. Food 2019, 12, 118–125. [Google Scholar] [CrossRef]

- Tadić, V.; Gligorević, K.; Mileusnić, Z.; Miodragović, R.; Hajmiler, M.; Radočaj, D. Agricultural Engineering Technologies in the Control of Frost Damage in Permanent Plantations. AgriEngineering 2023, 5, 2079–2111. [Google Scholar] [CrossRef]

- Singh, G.; Jalota, S.K.; Sidhu, B.S. Soil Physical and Hydraulic Properties in a Rice-Wheat Cropping System in India: Effects of Rice-Straw Management. Soil Use Manag. 2005, 21, 17–21. [Google Scholar] [CrossRef]

- Liu, C.; Wang, L.; Cocq, K.L.; Chang, C.; Li, Z.; Chen, F.; Liu, Y.; Wu, L. Climate Change and Environmental Impacts on and Adaptation Strategies for Production in Wheat-Rice Rotations in Southern China. Agric. For. Meteorol. 2020, 292–293, 108136. [Google Scholar] [CrossRef]

- Timsina, J.; Jat, M.L.; Majumdar, K. Rice-Maize Systems of South Asia: Current Status, Future Prospects and Research Priorities for Nutrient Management. Plant Soil 2010, 335, 65–82. [Google Scholar] [CrossRef]

- Capinera, J.L. Relationships between Insect Pests and Weeds: An Evolutionary Perspective. Weed Sci. 2005, 53, 892–901. [Google Scholar] [CrossRef]

- Goswami, S.B.; Mondal, R.; Mandi, S.K. Crop Residue Management Options in Rice–Rice System: A Review. Arch. Agron. Soil Sci. 2020, 66, 1218–1234. [Google Scholar] [CrossRef]

- FAO. Remote Sensing for Space-Time Mapping of Smog in Punjab and Identification of the Underlying Causes Using Geographic Information System (R-SMOG); FAO: Rome, Italy, 2020; ISBN 978-92-5-131960-4. [Google Scholar]

- Sharma, A.; Brar, A.S. Wheat Drilling Directly in Combine Harvested Paddy Fields: A Comparative Input-Output Energy Analysis. J. Biosyst. Eng. 2022, 47, 370–385. [Google Scholar] [CrossRef]

- Badagliacca, G.; Messina, G.; Praticò, S.; Lo Presti, E.; Preiti, G.; Monti, M.; Modica, G. Multispectral Vegetation Indices and Machine Learning Approaches for Durum Wheat (Triticum durum Desf.) Yield Prediction across Different Varieties. AgriEngineering 2023, 5, 2032–2048. [Google Scholar] [CrossRef]

- Ghosh, S.; Das, T.K.; Rana, K.S.; Biswas, D.R.; Das, D.K.; Singh, G.; Bhattacharyya, R.; Datta, D.; Rathi, N.; Bhatia, A. Energy Budgeting and Carbon Footprint of Contrasting Tillage and Residue Management Scenarios in Rice-Wheat Cropping System. Soil Tillage Res. 2022, 223, 105445. [Google Scholar] [CrossRef]

- Nigon, C.M.; Shinners, K.J.; Friede, J.C. An Apparatus and Method for Evaluating Particle-Size Distribution of Small Grain Crop Residues. AgriEngineering 2022, 4, 1016–1029. [Google Scholar] [CrossRef]

- Li, C.; Tang, Y.; McHugh, A.D.; Wu, X.; Liu, M.; Li, M.; Xiong, T.; Ling, D.; Tang, Q.; Liao, M.; et al. Development and Performance Evaluation of a Wet-Resistant Strip-till Seeder for Sowing Wheat Following Rice. Biosyst. Eng. 2022, 220, 146–158. [Google Scholar] [CrossRef]

- Liu, X.; Peng, C.; Zhang, W.; Li, S.; An, T.; Xu, Y.; Ge, Z.; Xie, N.; Wang, J. Subsoiling Tillage with Straw Incorporation Improves Soil Microbial Community Characteristics in the Whole Cultivated Layers: A One-Year Study. Soil Tillage Res. 2022, 215, 105188. [Google Scholar] [CrossRef]

- Kornecki, T.S.; Kichler, C.M. Influence of Recurrent Rolling/Crimping of a Cereal Rye/Crimson Clover Cover Crop on No-Till Bush Bean Yield. AgriEngineering 2022, 4, 855–870. [Google Scholar] [CrossRef]

- Zhuo, S.-N.; Ren, H.-Y.; Xie, G.-J.; Xing, D.-F.; Liu, B.-F. Conversion Mechanism of Biomass to Nano Zero-Valent Iron Biochar: Iron Phase Transfer and in Situ Reduction. Engineering 2023, 21, 124–134. [Google Scholar] [CrossRef]

- Sahbeni, G.; Székely, B.; Musyimi, P.K.; Timár, G.; Sahajpal, R. Crop Yield Estimation Using Sentinel-3 SLSTR, Soil Data, and Topographic Features Combined with Machine Learning Modeling: A Case Study of Nepal. AgriEngineering 2023, 5, 1766–1788. [Google Scholar] [CrossRef]

- Chu, J.; Guo, X.; Zheng, F.; Zhang, X.; Dai, X.; He, M. Effect of Delayed Sowing on Grain Number, Grain Weight, and Protein Concentration of Wheat Grains at Specific Positions within Spikes. J. Integr. Agric. 2023, 22, 2359–2369. [Google Scholar] [CrossRef]

- Kirthiga, S.M.; Patel, N.R. In-Season Wheat Yield Forecasting at High Resolution Using Regional Climate Model and Crop Model. AgriEngineering 2022, 4, 1054–1075. [Google Scholar] [CrossRef]

- Ma, C.; Liu, Y.; Wang, J.; Xue, L.; Hou, P.; Xue, L.; Yang, L. Warming Increase the N2O Emissions from Wheat Fields but Reduce the Wheat Yield in a Rice-Wheat Rotation System. Agric. Ecosyst. Environ. 2022, 337, 108064. [Google Scholar] [CrossRef]

- Nazim Ud Dowla, M.A.N.; Edwards, I.; O’Hara, G.; Islam, S.; Ma, W. Developing Wheat for Improved Yield and Adaptation Under a Changing Climate: Optimization of a Few Key Genes. Engineering 2018, 4, 514–522. [Google Scholar] [CrossRef]

- Yaseen, M.U.; Ashraf, M.; Munir, A. Development and Performance Evalution of Solar Assisted Milk Pasteurizer by Using Vacuum Tube Collector. Pak. J. Agric. Sci. 2019, 56, 693–700. [Google Scholar] [CrossRef]

- Luo, W.; Chen, X.; Guo, K.; Qin, M.; Wu, F.; Gu, F.; Hu, Z. Optimization and Accuracy Analysis of a Soil–Planter Model during the Sowing Period of Wheat after a Rice Stubble Based Discrete Element Method. Agriculture 2023, 13, 2036. [Google Scholar] [CrossRef]

- Cui, N.; Pozzobon, V. Food-Grade Cultivation of Saccharomyces Cerevisiae from Potato Waste. AgriEngineering 2022, 4, 951–968. [Google Scholar] [CrossRef]

- Toscano, P.; Cutini, M.; Filisetti, A.; Premoli, E.; Porcu, M.; Catalano, N.; Bisaglia, C.; Brambilla, M. Workability Assessment of Different Stony Soils by Soil–Planter Interface Noise and Acceleration Measurement. AgriEngineering 2022, 4, 1139–1152. [Google Scholar] [CrossRef]

- Priori, S.; Zanini, M.; Falcioni, V.; Casa, R. Topsoil Vertical Gradient in Different Tillage Systems: An Analytical Review. Soil Tillage Res. 2024, 236, 105947. [Google Scholar] [CrossRef]

- Bhaduri, D.; Purakayastha, T.J. Long-Term Tillage, Water and Nutrient Management in Rice-Wheat Cropping System: Assessment and Response of Soil Quality. Soil Tillage Res. 2014, 144, 83–95. [Google Scholar] [CrossRef]

- Shorstkii, I.; Sosnin, M.; Mounassar, E.H.A.; Bindrich, U.; Heinz, V.; Aganovic, K. The Effect of High-Pressure Pre-Soaking on the Water Absorption, Gelatinization Properties, and Microstructural Properties of Wheat Grains. AgriEngineering 2022, 4, 1153–1163. [Google Scholar] [CrossRef]

- Manpreet-Singh; Chaleka, A.T.; Goyal, R.; Gupta, N.; Singh, A.; Singh, M.; Sharma, S.; Dixit, A.K.; Malik, A.; Al-Ansari, N.; et al. PAU Smart Seeder: A Novel Way Forward for Rice Residue Management in North-West India. Sci Rep 2024, 14, 11747. [Google Scholar] [CrossRef] [PubMed]

- Jaidka, M.; Sharma, M.; Sandhu, P.S. Evaluation of Rice Residue Management Options in District Shaheed Bhagat Singh Nagar of Punjab—A Survey. Agricul. Res. Jour. 2020, 57, 358. [Google Scholar] [CrossRef]

- Kirandeep; Sharma, M.; Singh, R. Effect of Different Sowing Techniques and Varieties on Yield of Wheat (Triticum aestivum L.). J. Krishi Vigyan 2020, 9, 92–98. [Google Scholar] [CrossRef]

- Choudhary, S.; Upadhyay, G.; Patel, B.; Naresh; Jain, M. Energy Requirements and Tillage Performance Under Different Active Tillage Treatments in Sandy Loam Soil. J. Biosyst. Eng. 2021, 46, 353–364. [Google Scholar] [CrossRef]

- Mooventhan, P.; Singh, S.R.K.; Venkatesan, P.; Dixit, A.; Sharma, K.C.; Sivalingam, P.N.; Gupta, A.K.; Singh, U.; Kaushal, P. Happy Seeder—A Promising Technology In Conservation Agriculture. Har. Dhara 2018, 1, 27–29. [Google Scholar]

- Fernandez-Gallego, J.A.; Kefauver, S.C.; Gutiérrez, N.A.; Nieto-Taladriz, M.T.; Araus, J.L. Wheat Ear Counting In-Field Conditions: High Throughput and Low-Cost Approach Using RGB Images. Plant Methods 2018, 14, 22. [Google Scholar] [CrossRef]

- Bindu; Sharma, M.; Manan, J. Ways and Means of Paddy Straw Management: A Review. J. Rev. Agric. Allied Fields 2018, 1, 1–8. [Google Scholar] [CrossRef]

- Grahmann, K.; Honsdorf, N.; Crossa, J.; Alvarado Beltrán, G.; Govaerts, B.; Verhulst, N. Dry Sowing Reduced Durum Wheat Performance under Irrigated Conservation Agriculture. Field Crops Res. 2021, 274, 108310. [Google Scholar] [CrossRef]

- Sidhu, H.S.; Manpreet-Singh; Humphreys, E.; Yadvinder-Singh; Balwinder-Singh; Dhillon, S.S.; Blackwell, J.; Bector, V.; Malkeet-Singh; Sarbjeet-Singh. The Happy Seeder Enables Direct Drilling of Wheat into Rice Stubble. Aust. J. Exp. Agric. 2007, 47, 844–854. [Google Scholar] [CrossRef]

- Bishnoi, R.; Kumar, V.; Bishnoi, D.K.; Meena, M.S. Economics of Super Seeder Technique of Wheat Cultivation in Haryana. IJECC 2023, 13, 574–582. [Google Scholar] [CrossRef]

- Dhanda, S.; Yadav, A.; Yadav, D.B.; Chauhan, B.S. Emerging Issues and Potential Opportunities in the Rice–Wheat Cropping System of North-Western India. Front. Plant Sci. 2022, 13, 832683. [Google Scholar] [CrossRef] [PubMed]

- Latif, M.T.; Hussain, M.; Zohaib, A.; Hassan, I. Performance Evaluation of Super Seeder for Wheat Sowing in Rice-Wheat Cropping System of Pakistan. SJA 2024, 40, 109. [Google Scholar] [CrossRef]

- Salokhe, V.M.; Hanif Miah, M.; Hoki, M. Effect of Blade Type on Power Requirement and Puddling Quality of a Rotavator in Wet Clay Soil. J. Terramechanics 1993, 30, 337–350. [Google Scholar] [CrossRef]

- Sokolowski, A.C.; Prack McCormick, B.; De Grazia, J.; Wolski, J.E.; Rodríguez, H.A.; Rodríguez-Frers, E.P.; Gagey, M.C.; Debelis, S.P.; Paladino, I.R.; Barrios, M.B. Tillage and No-Tillage Effects on Physical and Chemical Properties of an Argiaquoll Soil under Long-Term Crop Rotation in Buenos Aires, Argentina. Int. Soil Water Conserv. Res. 2020, 8, 185–194. [Google Scholar] [CrossRef]

- New MF 375 Tractor for Sale in Pakistan. Import Now. Available online: https://www.masseyferguson.com.pk/details-mf-375.html (accessed on 18 June 2024).

- Mollazade, K.; Ahmadi, H.; Alimardani, R. Optimal Design of Rotary Tiller. Int. J. Agric. Biol. Eng. 2009, 2, 1–7. [Google Scholar] [CrossRef]

- Daood, K. Mechanics of Materials by B. J. 7th. 2013. Available online: https://www.academia.edu/35205827/Mechanics_of_Materials_By_B_J_7th (accessed on 18 June 2024).

- Domek, G.; Kołodziej, A.; Dudziak, M.; Woźniak, T. Identification of the Quality of Timing Belt Pulleys. Procedia Eng. 2017, 177, 275–280. [Google Scholar] [CrossRef]

- Hirasawa, K.; Kataoka, T.; Kubo, T. Relationship between Required Power and PTO Speed in Rotary Tiller. IFAC Proc. Vol. 2013, 46, 141–146. [Google Scholar] [CrossRef]

- Conwell, J.C.; Johnson, G.E. Design, Construction and Instrumentation of a Machine to Measure Tension and Impact Forces in Roller Chain Drives. Mech. Mach. Theory 1996, 31, 525–531. [Google Scholar] [CrossRef]

- RNAM Test Codes and Procedures for Farm Machinery. Tech. Ser. Reg. Netw. Agric. Mach. 1983, 12, 297.

- Balta, B.; Sonmez, F.O.; Cengiz, A. Speed Losses in V-Ribbed Belt Drives. Mech. Mach. Theory 2015, 86, 1–14. [Google Scholar] [CrossRef]

- Yaseen, M.U.; Saddique, G.; Ashraf, M.; Yasmeen, Z.; Ahmad, S. Design, development and testing of mobile sprinkler raingun for smart irrigation in arid zone-based crops. J. Agric. Res. 2019, 57, 103–112. [Google Scholar]

- Smith, D.W.; Sims, B.G.; O’Neill, D.H. Testing and Evaluation of Agricultural Machinery and Equipment: Principles and Practices; FAO Agricultural Services Bulletin; Food and Agriculture Organization of the United Nations: Rome, Italy, 1994; ISBN 978-92-5-103458-3. [Google Scholar]

- Sun, J.; Zhang, Y.; Zhang, Y.; Li, P.; Teng, G. Precision Seeding Compensation and Positioning Based on Multisensors. Sensors 2022, 22, 7228. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Jiang, Y.; Wang, X.; Thuy, N.T.D.; Yu, H. A Mechanical Model of Single Wheat Straw with Failure Characteristics Based on Discrete Element Method. Biosyst. Eng. 2023, 230, 1–15. [Google Scholar] [CrossRef]

- Wang, F.; Li, F.; Mohan, V.; Dudley, R.; Gu, D.; Bryant, R. An Unsupervised Automatic Measurement of Wheat Spike Dimensions in Dense 3D Point Clouds for Field Application. Biosyst. Eng. 2022, 223, 103–114. [Google Scholar] [CrossRef]

| A. GENERAL: | ||

| 1. | Application | For sowing of the wheat crop in a single path by crushing and incorporating the rice residue into the soil after combine harvesting |

| 2. | Type | Tractor rear mounted |

| 3. | Linkage type | Cat-II |

| 4. | Number of rows | 11 |

| 5. | Row spacing | 190 mm (Fixed) |

| 6. | Seed and fertilizer hopper Capacity | 100 kg each |

| 7. | Working width | 2040 mm |

| 8. | Power | 75 Hp tractor |

| 9. | Effective field capacity | 0.35 ha/h |

| B. OVERALL DIMENSIONS: | ||

| 10. | Width | 2575 mm ± 20 mm |

| 11. | Length | 1775 mm ± 20 mm |

| 12. | Height | 1650 mm ± 10 mm |

| 13. | Weight | 950 kg |

| C. MAIN FRAME: | ||

| 14. | Side plates | MS plate 1210 × 835 mm, thickness 12 mm |

| 15. | Top cover | MS plate 2145 × 530 mm, thickness 4 mm MS Square pipe 100 × 100 mm, thickness 6 mm, length 2145 mm MS plate 700 × 140 mm, thickness 15 mm |

| 16. | 3-pin linkage system “A” frame | MS plate 566 × 320 mm, thickness 10 mm Top link hole size 26 mm |

| 17. | Lower links attachment | MS plate 862 × 285 mm, thickness 15 mm Lower links hole, size 29 mm |

| 18. | Coulter disk | Coulter disk, diameter 508 mm |

| 19. | Skidders | MS plate, 18 mm thickness |

| D. MAIN GEAR | ||

| 20. | Gear box | Gray cast iron |

| 21. | PTO shaft (main shaft) | Medium carbon steel shaft, diameter 65 mm |

| 22. | Gear coupling | MS plate, diameter 200 mm, thickness 95 mm |

| 23. | Gear set | Crown wheel and gear 13/25 Super gear 16, 18, and 20 teeth easily attachable/de-attachable on the gear main shaft |

| 24. | Bearing and oil seal | As per shafts and hub designs |

| 25. | Back and side plate | Backplate grey cast iron as per gear body Side plate grey cast iron as per bearing size Front plate grey cast iron as per bearing size |

| 26. | Side drive gear (rotor) | Medium carbon steel axle shaft, diameter 65 mm, length 1000 mm |

| E. ROTOR & BLADE | ||

| 27. | Rotor shaft | MS pipe, outer diameter 90 mm, wall thickness 7 mm, and length 1915 mm |

| 28. | Blade mounting plates | MS plate, diameter 260 mm thickness, 12 mm (09 Nos) hole as per blade |

| 29. | Blade | “C”-type blade hardness, 50 HRC (54 Nos) |

| 30. | Bearing Hub & Bearing | MS bearing hub as per 6313 bearing along with oil seal Bearing 6313 (04 Nos) double bearings on both sides Oil seal 65 × 120 × 10 (04 Nos) Bearing lock as per bearing 6313 (outer, inner) Oil lubrication on both sides of the rotor |

| 31. | Bearing shaft | MS shaft of rotor as per design Spline work as per side gear |

| 32. | Side drive Gears Transmission | 04 Nos. of spur gears along with 02 carrier gear 23 teeth spur gear fitted on main axle shaft, 65 mm spline as per gear 24 teeth carrier gear (02 Nos.) Bearings 6309 (04 Nos) |

| 33. | Side Gear oil cover | MS sheet cover, 3 mm thickness as per design |

| F. TRENCHER ROLLER | ||

| 34. | Trencher pipe | MS pipe, outer diameter 190 mm, wall thickness 4 mm, and length 2120 mm |

| 35. | Trencher plate | MS plate, diameter 340 mm, bore 190 mm, thickness 40 mm as per design (V-shaped) 11 Nos. of plate (ground driven) |

| 36. | Bearing shaft | MS shaft, diameter 50 mm, length as per design |

| 37. | Bearing | UCF 209 (02 Nos) |

| 38. | Trencher scraping plate | MS plate 2140 × 350 mm, thickness 4 mm, fitted with hinge as per design |

| G. SEED AND FERTILIZER BOX: | ||

| 39. | Seed and fertilizer hopper | MS sheet, 18 SWG Hopper, length 2100 mm Capacity 100 kg each (seed and fertilizer) Fitted on side plate as per design (MS channel 50 × 516 mm and length 700 mm), wall thickness 3 mm |

| 40. | Seed and fertilizer distributors | PPRC material as per wheat drill (11,11 Nos.) |

| 41. | Drive wheel (ground wheel) | Diameter 685 mm along with respective accessories, viz, chain sprockets, bearing hub, bearings, shaft, etc. MS flat 63 mm, thickness 8 mm MS shaft, 15 mm as per design |

| H. SEEDER UNITS | ||

| 42. | Seed and fertilizer placement units | MS sheet, thickness 3 mm as per design 11 Nos. of seeder unit Fitted with trencher plate as per design |

| 43. | Seed and fertilizer tubes | Transparent plastic pipe, 25 mm wall, thickness 3 mm |

| 44. | Seed and fertilizer cover roller | Diameter 102 mm and length 2100 mm as per design |

| Tractor PTO Shaft (RPM) | Spur Gear Ratio | Pinion and Crown Gear | Final Blade Rotor (RPM) |

|---|---|---|---|

| 540 | 16:18 | 13/25 | 250 |

| 540 | 16:20 | 13/25 | 225 |

| 540 | 18:20 | 13/25 | 252 |

| 540 | 18:16 | 13/25 | 316 |

| 540 | 20:16 | 13/25 | 350 |

| 540 | 20:18 | 13/25 | 310 |

| Power Transmission System (PTS) | Gear Box Rotation Speed (rpm) | PTS Ratio | Trencher Rotor (rpm) | |

|---|---|---|---|---|

| Timing Belt and Pulleys (TBP) | 280 | 150/225 | - | 187 |

| V-Belt and Pulleys (VBP) | 280 | 100/350 | 125/150 | 67 |

| Sprocket Chain (SC) | 280 | 130/190 | - | 192 |

| Spur Gear (SG) | 280 | 11/25 | 25/23 | 134 |

| Star Wheels (SW) | - | - | - | 32 |

| Power Transmission System (PTS) | Gear Box Rotation Speed (rpm) | PTS Ratio | Trencher Rotor (rpm) | Result | |

|---|---|---|---|---|---|

| Timing Belt and Pulleys (TBP) | 280 | 150/225 | - | 187 | Failed due to breakage of timing belt |

| V-Belt and Pulleys (VBP) | 280 | 100/350 | 125/150 | 67 | Failed due to breakage of V-belt |

| Sprocket Chain (SC) | 280 | 130/190 | - | 192 | Failed due to Chain collapse |

| Spur Gear (SG) | 280 | 11/25 | 25/23 | 134 | Heavy torque load on tractor |

| Star Wheels (SW) | - | - | - | 32 | Good |

| Gear | Speed (km·h−1) | Straw Load (t/ha) | Straw Crushing Efficiency (%) |

|---|---|---|---|

| First low | 2.05 | 8 | 90.2 |

| Second low | 3.4 | 8 | 82.5 |

| Third low | 4.7 | 8 | 73.8 |

| Fixed Parameters (Precision Seeder) | ||||

|---|---|---|---|---|

| Items | Units | Value | ||

| Purchase/Capital Price of Seeder (P) | USD | 3900 | ||

| Salvage Value (S) = @ 10% of P | % | 390 | ||

| Operational Life (N) | Total life in years | year | 10 | |

| Life in hour per year | h/year | 320 | ||

| Total life in hours | h | 3200 | ||

| Rate of Interest (r) at Current Rate | % | 13.75 | ||

| Insurance Rate (i) at Current Rate | % | 2 | ||

| Rate of Taxes (t) at Current Rate | % | 10 | ||

| Shelter and Housing Rate (h) | % | 1 | ||

| R and M Rate (m) | % | 5 | ||

| Wages of Labour | USD·h−1 | 0.85 | ||

| Rate of Fuel | USD·L−1 | 1.12 | ||

| Test/Field Data | ||||

| Field Capacity | ha·h−1 | 0.4 | ||

| Fuel Consumption | L·h−1 | 8.5 | ||

| Labour Required | No. | 2 | ||

| Operational Cost | ||||

| Annual Fixed Cost | Variable Cost | |||

| Depreciation (D) = (P − S)/N | 351 | Fuel Consumption Cost | 9.52 | |

| Interest (R) = {(P + S)/2 × (r/100)}, r @ 13.75% | 294.9375 | Lubrication Cost, 10% F.C | 0.952 | |

| Insurance (I) = (P + S)/2 × (i/100) | 42.9 | Wages of Labour | 1.7 | |

| Tax (T) = (P) × (t/100) | 390 | Variable Cost, USD per h | 12.172 | |

| Housing (H) = P × (h/100) | 39 | Variable Cost, USD per ha | 30.43 | |

| Maintenance (M) = P × (m/100) | 195 | |||

| Annual Fixed Cost (AFC) = D + R + I + T + H + M | 1312.838 | |||

| Hourly Fixed Cost = AFC/N (h year−1) | 4.102617 | |||

| Total Fixed Cost, USD per ha | 10.25654 | |||

| Total Operational Cost, (fixed + variable) | USD/h | 16.27 | ||

| Total Operational Cost in hectare | USD/ha | 40.68 | ||

| OLS Regression Results | |||||

|---|---|---|---|---|---|

| Dep. Variable: | Plant_count | R-squared: | 0.968 | ||

| Model: | OLS | Adj. R-squared: | 0.961 | ||

| Method: | Least Squares | F-statistic: | 150.8 | ||

| No. Observations: | 13 | ||||

| Df Residuals: | 10 | ||||

| Df Model: | 2 | ||||

| coef | std err | t | p > |t| | [0.025 0.975] | |

| Intercept (β0) | −39.3078 | 16.698 | −2.354 | 0.040 | −76.513 −2.102 |

| Seed_depth_cm (β1) | 7.3802 | 2.099 | 3.515 | 0.006 | 2.702 12.058 |

| Coefficient_of_Uniformity (β2) | 283.7959 | 18.653 | 15.214 | 0.001 | 242.234 325.358 |

| Wheat yield with different methods of sowing The ANOVA Procedure Dependent Variable: yield_kg_ha | |||||

| Source | DF | Sum of Squares | Mean Squares | F Value | Pr > F |

| Model | 3 | 4,058,968.75 | 1,352,989.58 | 355.70 | <0.0001 |

| Error | 12 | 45,645.00 | 3803.75 | ||

| Corrected Total | 15 | 4,104,613.75 | |||

| R-Square | Coeff Var | Root MSE | Yield_kg_ha Mean | ||

| 0.988 | 1.434 | 61.6745 | 4300.625 | ||

| Source | DF | Anova SS | Mean Squares | F Value | Pr > F |

| Sowing Method | 3 | 4,058,968.75 | 1,352,989.583 | 355.70 | <0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yaseen, M.U.; Ahmad, S.; Ahmad, M.; Long, J.M.; Raza, H.A.; Iftekhar, H.; Ameer, S.; Ogunbiyi, D. A Multi-Function Novel Crop Seeder for the Management of Residues and Mechanized Sowing of Wheat in a Single Path. AgriEngineering 2024, 6, 2445-2469. https://doi.org/10.3390/agriengineering6030143

Yaseen MU, Ahmad S, Ahmad M, Long JM, Raza HA, Iftekhar H, Ameer S, Ogunbiyi D. A Multi-Function Novel Crop Seeder for the Management of Residues and Mechanized Sowing of Wheat in a Single Path. AgriEngineering. 2024; 6(3):2445-2469. https://doi.org/10.3390/agriengineering6030143

Chicago/Turabian StyleYaseen, Muhammad Usama, Shahzad Ahmad, Maqsood Ahmad, John M. Long, Hafiz Ali Raza, Hassan Iftekhar, Sikander Ameer, and Dabira Ogunbiyi. 2024. "A Multi-Function Novel Crop Seeder for the Management of Residues and Mechanized Sowing of Wheat in a Single Path" AgriEngineering 6, no. 3: 2445-2469. https://doi.org/10.3390/agriengineering6030143

APA StyleYaseen, M. U., Ahmad, S., Ahmad, M., Long, J. M., Raza, H. A., Iftekhar, H., Ameer, S., & Ogunbiyi, D. (2024). A Multi-Function Novel Crop Seeder for the Management of Residues and Mechanized Sowing of Wheat in a Single Path. AgriEngineering, 6(3), 2445-2469. https://doi.org/10.3390/agriengineering6030143