Theoretical Study of the Motion of a Cut Sugar Beet Tops Particle along the Inner Surface of the Conveying and Unloading System of a Topping Machine

Abstract

1. Introduction

2. Materials and Methods

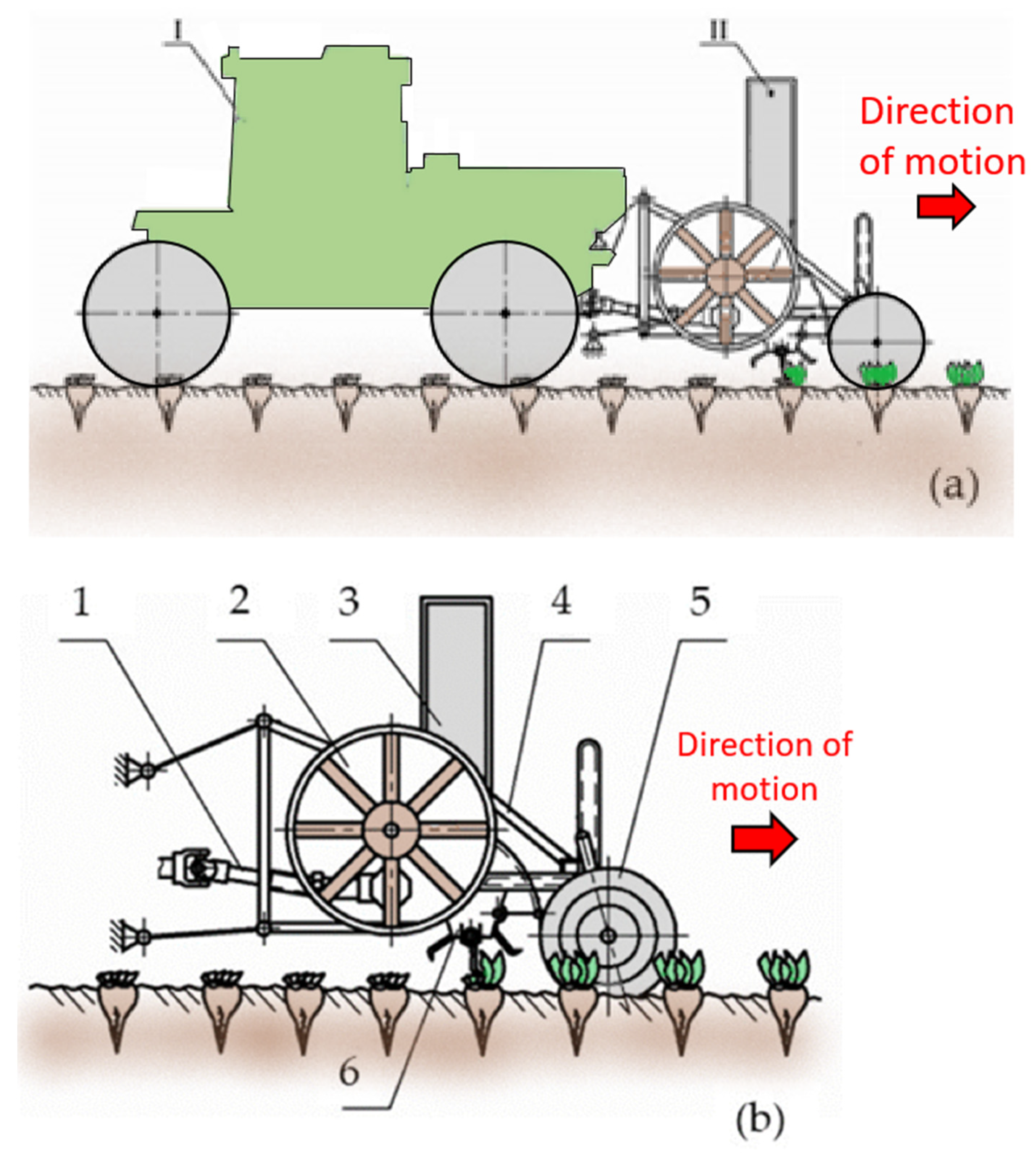

2.1. The New Front-Mounted Tractor Beet Topper Machine

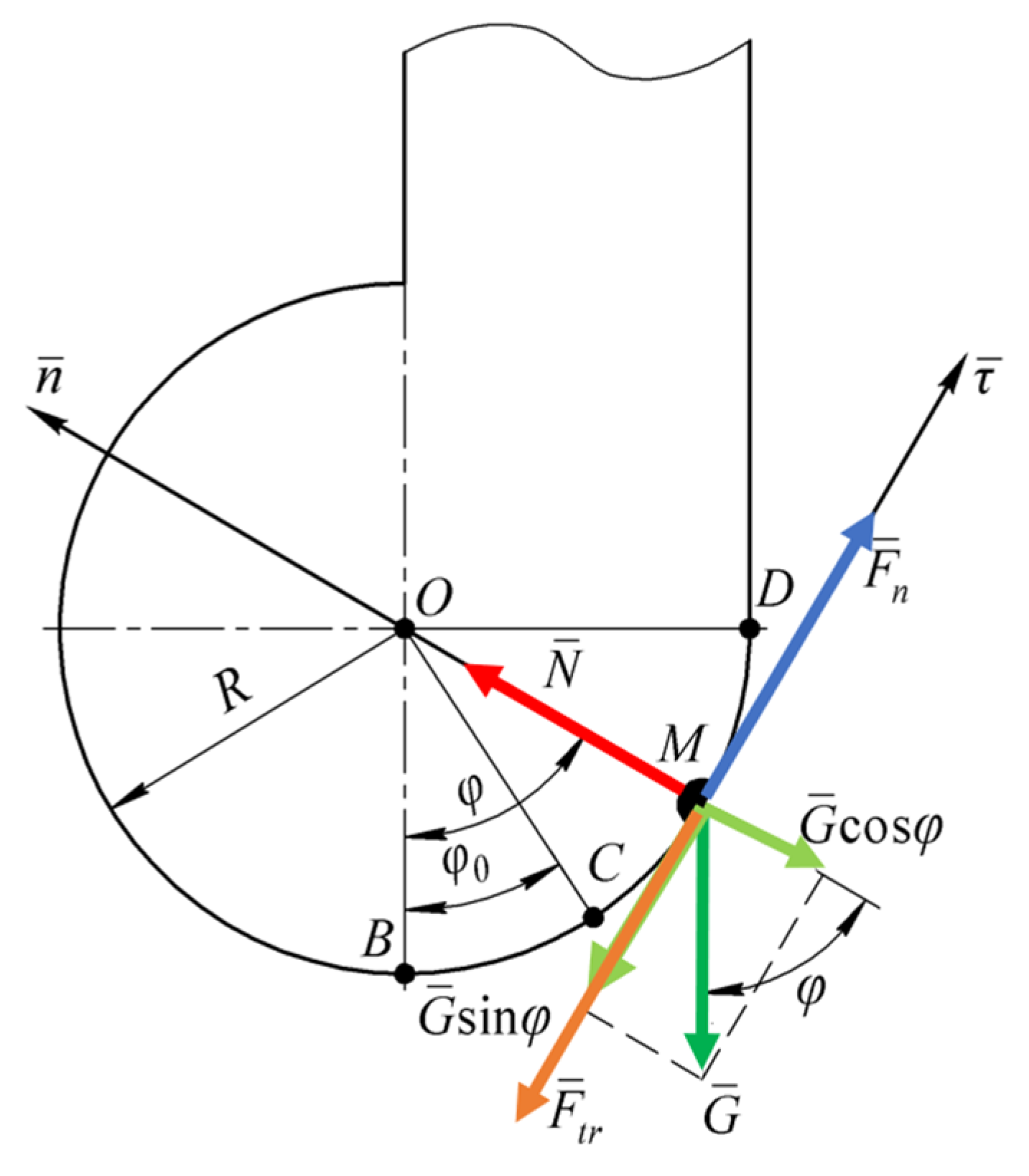

2.2. Mathematical Model of Motion of Particle M along the Cylindrical Section of the Conveying and Unloading System

- ○

- The weight force of particle M, whose magnitude is given by:

- ○

- The normal reaction of the inner surface of the cylindrical section, whose magnitude will be determined later.

- ○

- The sliding friction force of particle M along the inner surface of the cylindrical section, whose magnitude is given by:

- ○

- The aerodynamic force of the airflow, generated by the rotating blade of the thrower, which works as a fan. This force is determined according to the following equation [20]:

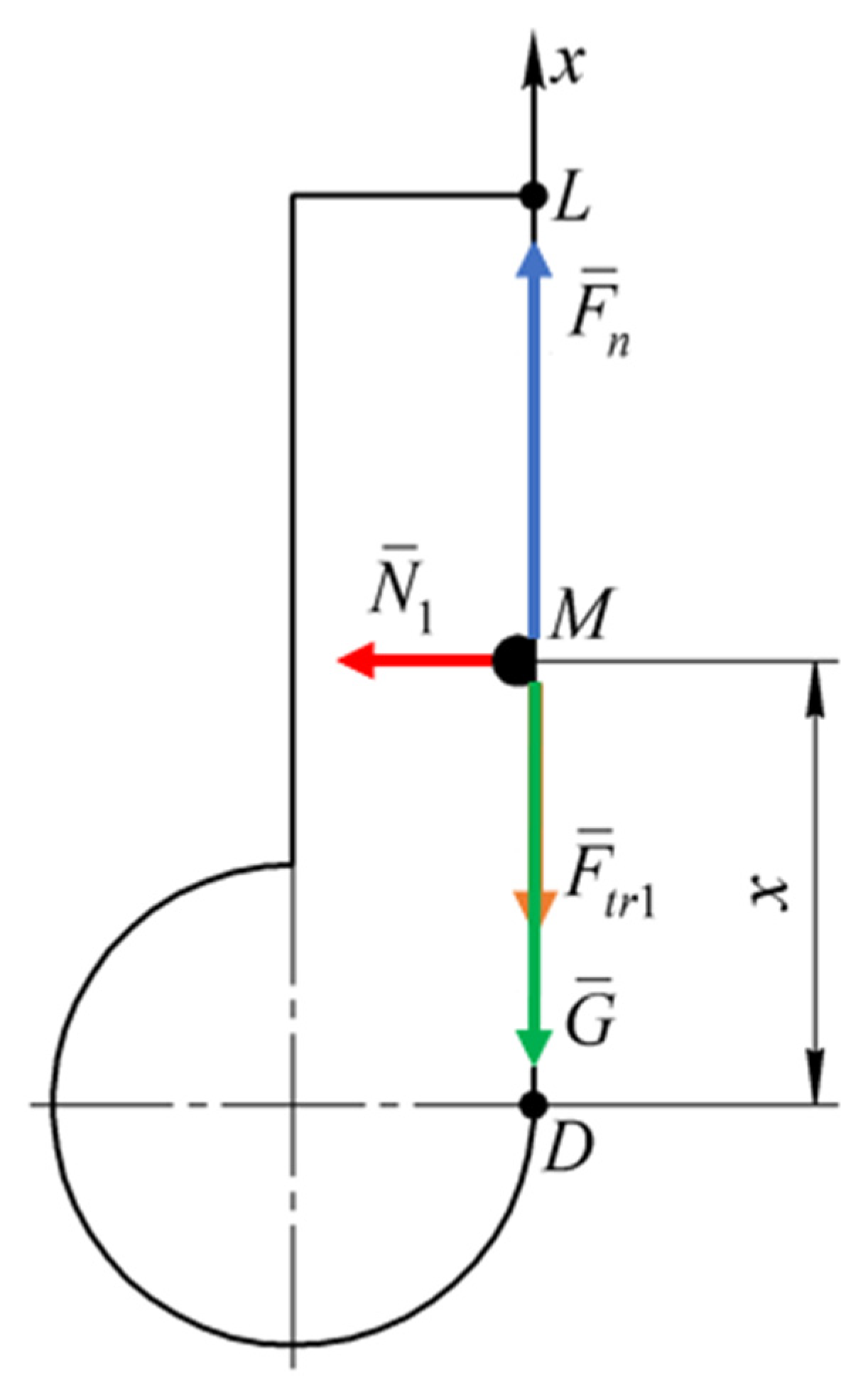

2.3. Mathematical Model of Motion of Particle M along the Discharge Chute

3. Results

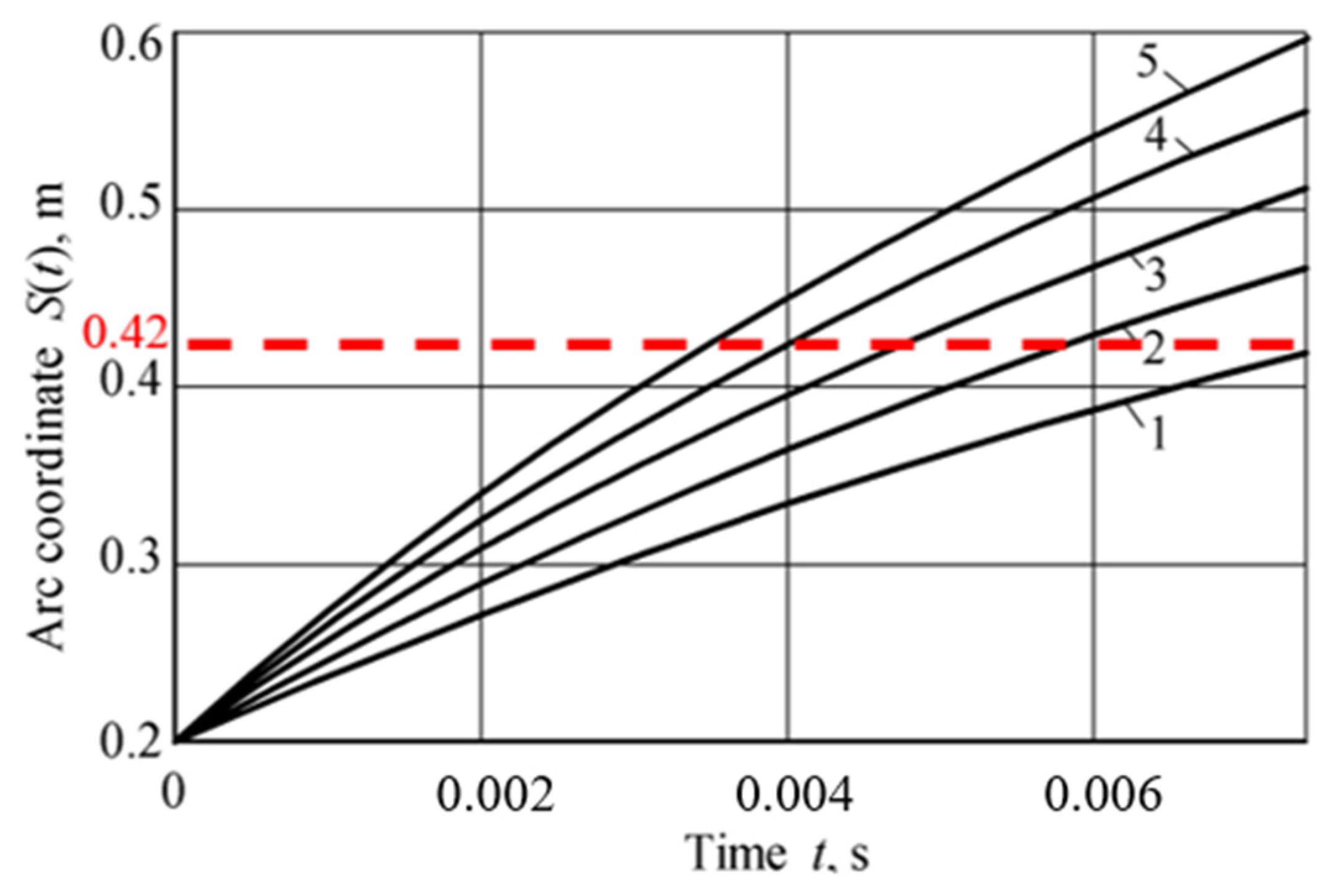

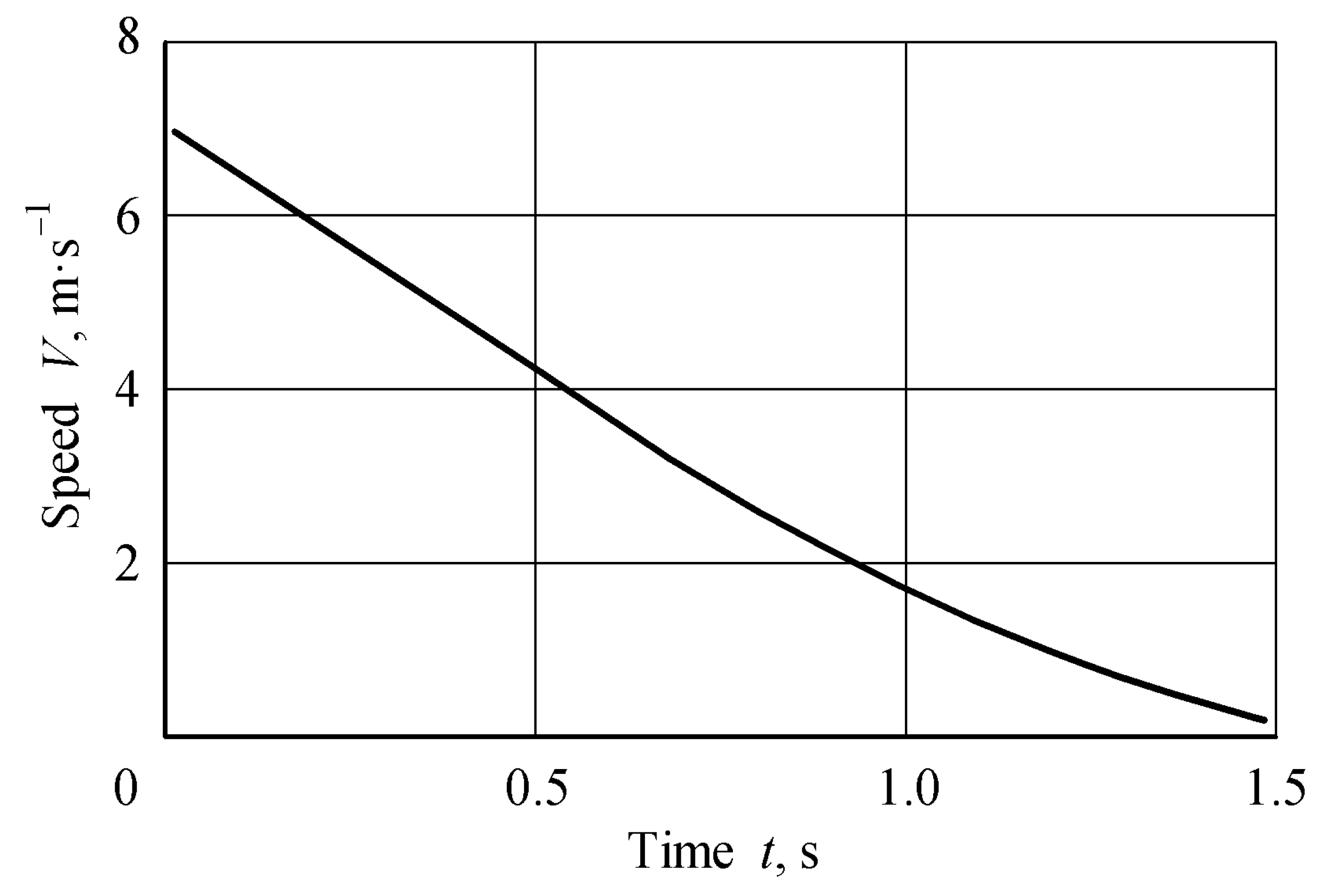

3.1. Cylindrical Section of the Conveying and Unloading System

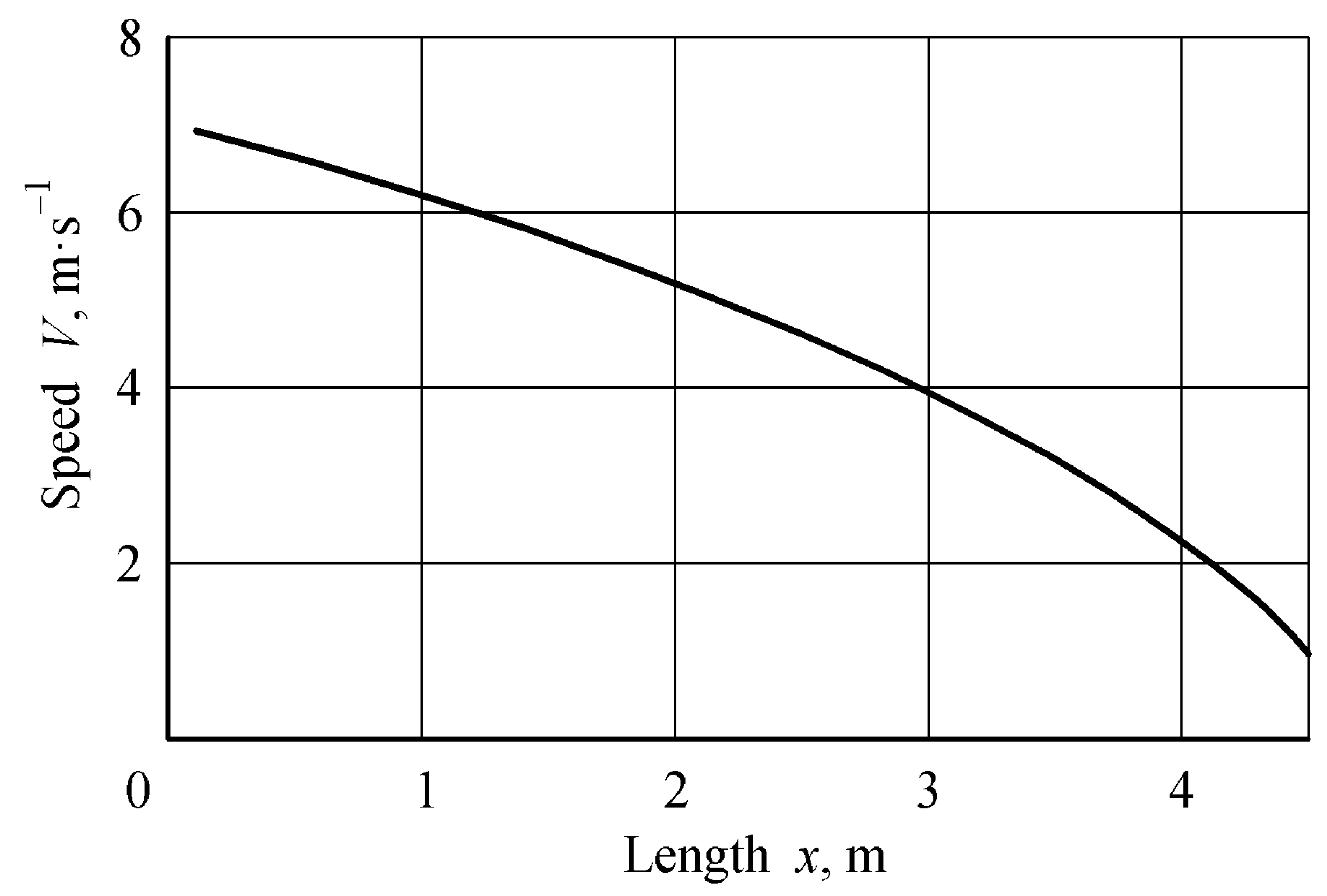

3.2. Straight-Line Section of the Conveying and Unloading System

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| M | cut sugar beet top particle |

| φ | angular coordinate |

| B | initial position of M in the inner surface of the cylindrical section |

| C | point of the cylindrical section when M leaves the thrower blade |

| D | final position of M in the inner surface of the cylindrical section and initial position of M in the inner surface of the straight-line section (discharge chute) |

| R | radius of the cylindrical section |

| S | arc length described by M during its motion along the cylindrical section |

| t0 | time when M is in C |

| φ0 | angular coordinate at t0 |

| arc length when M is in C | |

| arc length when M is in D | |

| local coordinate system | |

| m | mass of the cut beet top particle |

| gravity acceleration | |

| f | friction coefficient |

| speed of air flow | |

| speed of M | |

| absolute speed at which the cut beet tops particle M has left the thrower blade | |

| absolute speed at which the cut beet tops particle M enters the discharge chute | |

| absolute speed at which the cut beet tops particle M leaves the discharge chute | |

| k | coefficient affected by the physical and mechanical properties of M |

| dimensionless coefficient affected by the shape and the cross-sectional area of M | |

| cross-sectional area of M | |

| air density | |

| motion acceleration of M | |

| tangential acceleration of M (vector intensity) | |

| speed of M (vector intensity) | |

| normal acceleration of M (vector intensity) |

References

- Jones, P.D.; Lister, D.H.; Jaggard, K.W.; Pidgeon, J.D. Future Climate Impact on the Productivity of Sugar Beet (Beta vulgaris L.) in Europe. Clim. Chang. 2003, 58, 93–108. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Hemayati, S.S.; Tabatabaei, M.; Aghbashlo, M.; Mahmoudi, S.B. A review on beet sugar industry with a focus on implementation of waste-to-energy strategy for power supply. Renew. Sustain. Energy Rev. 2019, 103, 423–442. [Google Scholar] [CrossRef]

- Fairtrade Foundation. Available online: https://www.fairtrade.org.uk/wp-content/uploads/legacy/Fairtrade-and-Sugar-Briefing-Jan13.pdf (accessed on 8 January 2024).

- Muir, B.M.; Anderson, A.R. Development and Diversification of Sugar Beet in Europe. Sugar Tech 2022, 24, 992–1009. [Google Scholar] [CrossRef]

- OECD; FAO. OECD-FAO Agricultural Outlook 2022–2031; OECD Publishing: Paris, France, 2022. [CrossRef]

- Maksakov, V. The Haulm, Pulp and Melissa when Feeding Animals; Urozhaj: Kyiv, Ukraine, 1993; 145p. (In Russian) [Google Scholar]

- Møller, A.H.; Hammershøj, M.; Dos Passos, N.H.M.; Tanambell, H.; Stødkilde, L.; Ambye-Jensen, M.; Danielsen, M.; Jensen, S.K.; Dalsgaard, T.K. Biorefinery of green biomass—How to extract and evaluate high quality leaf protein for food? J. Agric. Food Chem. 2021, 69, 14341–14357. [Google Scholar] [CrossRef] [PubMed]

- Tuğrul, K.M. Mechanization in Sugar Beet Cultivation. In Sugar Beet Cultivation, Management and Processing, 1st ed.; Misra, V., Srivastava, S., Mall, A.K., Eds.; Springer: Singapore, 2022; pp. 473–502. [Google Scholar] [CrossRef]

- Brouwer, B.; Paillart, M.J.M.; Bruins, M.E.; Wissink, E.; de Vries, M.N.; Mensink, M.; Bode-Mocking, H.; Liese, W.; Geerdink, P.; van Echtelt, E.M.H.; et al. The impact of wounding and postharvest storage conditions on retention of soluble protein in sugar beet leaves. J. Food Sci. 2023, 88, 1580–1594. [Google Scholar] [CrossRef] [PubMed]

- Hoffmann, C.M.; Schnepel, K. Susceptibility to root tip breakage increases storage losses of sugar beet genotypes. Sugar Ind. 2016, 141, 625–632. [Google Scholar] [CrossRef]

- Mail, M.F.; Maja, J.M.; Marshall, M.; Cutulle, M.; Miller, G.; Barnes, E. Agricultural Harvesting Robot Concept Design and System Components: A Review. AgriEngineering 2023, 5, 777–800. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, D. Parameter optimization and test on auto guide device for disc type sugar beet harvester. Trans. Chin. Soc. Agric. Eng. 2015, 31, 27–33. [Google Scholar]

- Anelli, F.; Annunziato, A.; Godfrey, M.; Loconsole, A.M.; Holmes, C.; Prudenzano, F. Effects of Curvature on Flexible Bragg Grating in Off-Axis Core: Theory and Experiment. J. Light. Technol. 2023, 41, 2904–2910. [Google Scholar] [CrossRef]

- Davidson, J.; Bhusal, S.; Mo, C.; Karkee, M.; Zhang, Q. Robotic Manipulation for Specialty Crop Harvesting: A Review of Manipulator and End-Effector Technologies. Glob. J. Agric. Allied Sci. 2020, 2, 25–41. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Wilczek, U.; Hensel, O. Sugar Beet Damage Detection during Harvesting Using Different Convolutional Neural Network Models. Agriculture 2021, 11, 1111. [Google Scholar] [CrossRef]

- Osipov, A.; Shumaev, V.; Ekielski, A.; Gataullin, T.; Suvorov, S.; Mishurov, S.; Gataullin, S. Identification and classification of mechanical damage during continuous harvesting of root crops using computer vision methods. IEEE Access 2022, 10, 28885–28894. [Google Scholar] [CrossRef]

- Ihnatiev, Y. Theoretical substantiation of topping parameters without sugar beet head copying. Mech. Agric. Conserv. Resour. 2016, 62, 10–12. [Google Scholar]

- Bulgakov, V.; Pascuzzi, S.; Anifantis, A.S.; Santoro, F. Oscillations Analysis of Front-Mounted Beet Topper Machine for Biomass Harvesting. Energies 2019, 12, 2774. [Google Scholar] [CrossRef]

- Fugate, K.K.; Ribeiro, W.S.; Lulai, E.C.; Deckard, E.L.; Finger, F.L. Cold temperature delays wound healing in postharvest sugar beet roots. Front. Plant Sci. 2016, 7, 499. [Google Scholar] [CrossRef]

- Bentini, M.; Caprara, C.; Rondelli, V.; Caliceti, M. The use of an electronic beet to evaluate sugar beet damage at various forward speeds of a mechanical harvester. Trans. ASAE 2002, 45, 547. [Google Scholar] [CrossRef]

- Kołodziej, P.; Gołacki, K.; Boryga, M. Impact characteristics of sugar beet root during postharvest storage. Int. Agrophys. 2019, 33, 355–361. [Google Scholar] [CrossRef]

- Bulgakov, V.; Pascuzzi, S.; Ivanovs, S.; Santoro, F.; Anifantis, A.S.; Ihnatiev, I. Performance assessment of front-mounted beet topper machine for biomass harvesting. Energies 2020, 13, 3524. [Google Scholar] [CrossRef]

- Khelemendik, N.M. Directions and Methods for the Development of New Operating Tools of Agricultural Machines. A Monograph; Ahrarna Nauka: Kyiv, Ukraine, 2001; 280p. (In Ukrainian) [Google Scholar]

- Pogorelyj, L.V.; Tat’yanko, N.V. Beet Harvesting Machines: History, Design, Theory, Forecast; Phoenix: Kyiv, Ukraine, 2004; 232p. (In Russian) [Google Scholar]

- Vasilenko, P.M. Introduction to Agricultural Mechanics; Silhosposvita: Kyiv, Ukraine, 1996; 252p. (In Russian) [Google Scholar]

- Vasilenko, P.M. The Theory of a Particle Movement along Rough Surfaces of the Agricultural Machines; UASKhN: Kyiv, Ukraine, 1990; 284p. (In Russian) [Google Scholar]

- Bulgakov, V.; Pascuzzi, S.; Adamchuk, V.; Kuvachov, V.; Nozdrovicky, L. Theoretical study of transverse offsets of wide span tractor working implements and their influence on damage to row crops. Agriculture 2019, 9, 144. [Google Scholar] [CrossRef]

- Knaifl, O. Simulation of a sugar beet topper. Mech. Mach. Theory 1978, 13, 95–106. [Google Scholar] [CrossRef]

- Lilleboe, D. Optimizing defoliator & harvester performance. Sugarbeet Grow. 2014, 53, 6–13. [Google Scholar]

- Jobbágy, J.; Gabaj, D.; Árvay, J. Evaluation of selected agro-physical properties of a root vegetable. Acta Technol. Agric. 2011, 14, 61–66. [Google Scholar]

- Lammers, S.; Olaf, P.; Olaf, R. Defoliation of sugar beets—Assessment of quality and gain in delivered beet mass. Landtechnik 2010, 65, 464–467. [Google Scholar]

- Ivančan, S.; Sito, S.; Fabijanić, G. Factors of the quality of performance of sugar beet combine harvesters. Bodenkultur 2002, 53, 161–166. [Google Scholar]

- Nadykto, V.; Arak, M.; Olt, J. Theoretical research into the frictional slipping of wheel-type undercarriage taking into account the limitation of their impact on the soil. Agron. Res. 2015, 13, 148–157. [Google Scholar]

- Xin, J.; Xinwu, D.; Shiguang, W.; Jiangtao, J.; Xiang, D.; Dongyang, W. Design and Experiment of Stems Cutting Device for Carrot Harvester. Trans. Chin. Soc. Agric. Mach. 2016, 47, 82–89. [Google Scholar]

- Yang, K.; Zhaoyang Yu, Z.; Luo, W.; Fan, J.; Yuyao Li, Y.; Gu, F.; Zhang, Y.; Wang, S.; Peng, B.; Hu, Z. Experiment and Study of Garlic Root Cutting Based on Continuous Force Feedback. Agronomy 2023, 13, 835. [Google Scholar] [CrossRef]

- Tang, H.; Jiang, Y.; Wang, J.; Guan, R.; Zhou, W. Bionic Design and Parameter Optimization of Rotating and Fixed Stem- and Leaf-Cutting Devices for Carrot Combine Harvesters. Math. Probl. Eng. 2021, 2021, 8873965. [Google Scholar] [CrossRef]

- Gao, X.; Zhou, Z.; Xu, Y.; Yu, Y.; Su, Y.; Cui, T. Numerical simulation of particle motion characteristics in quantitative seed feeding system. Powder Technol. 2020, 367, 643–658. [Google Scholar] [CrossRef]

- Movchan, S.; Dereza, O.; Mazilin, S.; Dereza, S. Study of hydromechanical parameters part of the water solutions household in running flows. In Modern Development Paths of Agricultural Production; Springer: Cham, Switzerland, 2019; pp. 145–160. [Google Scholar] [CrossRef]

- Kibble, T.; Berkshire, F. Classical Mechanics, 5th ed.; Imperial College Press: London, UK, 2004; 478p, ISBN 978-1-86094-424-6. [Google Scholar]

- Bulgakov, V.; Holovach, I.; Ivanovs, S.; Aboltins, A.; Trokhaniak, O.; Ihnatiev, Y.; Ruzhylo, M. Theory of Movement of the Sugar Beet Tops in Loading Mechanism, Taking into Account the Influence of the Air Flow. Appl. Sci. 2023, 13, 11233. [Google Scholar] [CrossRef]

- Wang, F.Y.; Zhang, Z.Y.; Pan, Y.F.; Yun, Y.L.; Wang, D.W. Optimized design of the 4TSQ-2 sugar beet top cutting machine. Int. J. Agric. Biol. Eng. 2022, 13, 111–116. [Google Scholar] [CrossRef]

- Abdollahian-Noghabi, M.; Zadeh, M.R.O. Effect of harvesting operation procedure duration on the yield loss of sugar beet in Dezful, Iran. Int. Sugar J. 2005, 107, 354–356. [Google Scholar]

- Ayres, G.E. An Evaluation of Machinery Systems for Harvesting the Total Corn Plant; Iowa State University: Ames, IA, USA, 1973. [Google Scholar]

- Sokhansanj, S.; Mani, S.; Turhollow, A.; Kumar, A.; Bransby, D.; Lynd, L.; Laser, M. Large-scale production, harvest and logistics of switchgrass (Panicum virgatum L.)—Current technology and envisioning a mature technology. Biofuels Bioprod. Biorefining 2009, 3, 124–141. [Google Scholar] [CrossRef]

- Venendaal, R.; Jørgensen, U.; Foster, C.A. European energy crops: A synthesis. Biomass Bioenergy 1997, 13, 147–185. [Google Scholar] [CrossRef]

- Abdel Mawla, H.A.; Yehia, I.; El Lithy, A.M.; Faisal, A. An appropriate sugar-beet harvesting mechanization for big-scale project. Misr J. Agric. Eng. 2012, 29, 1213–1238. [Google Scholar] [CrossRef]

| Machinery | Speed | Performance | Advantages | Limitations |

|---|---|---|---|---|

| 1. Forage harvesters (trailed) [43] | 2.3 ÷ 3.3 m·s–1 | 50 ÷ 90·103 kg·h–1 | The slatted system ensures the unloading of corn in any condition. | Design complexity, high energy consumption. |

| 2. Hay mowers (trailer) [44] | up to 3.0 m·s–1 | 2.5 ÷ 4.5 ha·h–1 | Cut and unload in a windrow on the ground. | Additional technical and operating costs for further collection or pressing of the roll |

| 3. Mower-choppers (trailer) [45] | up to 2.2 m·s–1 | 15 ÷ 18·103 kg·h–1 | Cut and unload in a windrow the remains of sunflower, sorghum, potato tops, corn, and grass. | Difficult to operate, since the unit has a trailer connected to the rear to collect the mown mass. |

| 4. Topper removal machines (self-propelled) [46] | 1.8 ÷ 2.5 m·s–1 | 1.0 ÷ 1.3 ha·h–1 | No conditions for the unloading system clogging at any moisture content. | Design complexity, high energy consumption due to the presence of a slatted unloading system. |

| 5. Design presented in the article | 2.5 ÷ 3.0 m·s–1 | up to 2.0 ha·h–1 (considering a working width of 1.35 m, three rows of sugar beet crops) | Simplicity of construction, and operational reliability. | A decrease or a complete stop in unloading process may occur because of accumulation of wet mass of tops which can clog the thrower. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pascuzzi, S.; Bulgakov, V.; Holovach, I.; Ivanovs, S.; Aboltins, A.; Ihnatiev, Y.; Rucins, A.; Trokhaniak, O.; Paciolla, F. Theoretical Study of the Motion of a Cut Sugar Beet Tops Particle along the Inner Surface of the Conveying and Unloading System of a Topping Machine. AgriEngineering 2024, 6, 409-422. https://doi.org/10.3390/agriengineering6010025

Pascuzzi S, Bulgakov V, Holovach I, Ivanovs S, Aboltins A, Ihnatiev Y, Rucins A, Trokhaniak O, Paciolla F. Theoretical Study of the Motion of a Cut Sugar Beet Tops Particle along the Inner Surface of the Conveying and Unloading System of a Topping Machine. AgriEngineering. 2024; 6(1):409-422. https://doi.org/10.3390/agriengineering6010025

Chicago/Turabian StylePascuzzi, Simone, Volodymyr Bulgakov, Ivan Holovach, Semjons Ivanovs, Aivars Aboltins, Yevhen Ihnatiev, Adolfs Rucins, Oleksandra Trokhaniak, and Francesco Paciolla. 2024. "Theoretical Study of the Motion of a Cut Sugar Beet Tops Particle along the Inner Surface of the Conveying and Unloading System of a Topping Machine" AgriEngineering 6, no. 1: 409-422. https://doi.org/10.3390/agriengineering6010025

APA StylePascuzzi, S., Bulgakov, V., Holovach, I., Ivanovs, S., Aboltins, A., Ihnatiev, Y., Rucins, A., Trokhaniak, O., & Paciolla, F. (2024). Theoretical Study of the Motion of a Cut Sugar Beet Tops Particle along the Inner Surface of the Conveying and Unloading System of a Topping Machine. AgriEngineering, 6(1), 409-422. https://doi.org/10.3390/agriengineering6010025