Bridging the Implementation Gap between Pomace Waste and Large-Scale Baker’s Yeast Production

Abstract

:1. Introduction

- (1)

- Climate neutral Europe; introducing the European Climate Law with the goal of reducing the greenhouse gas emissions;

- (2)

- Clean energy transition by securing an affordable energy supply, developing a new energy market and prioritizing energy efficiency;

- (3)

- New industrial strategies to promote a sustainable and circular economic model;

- (4)

- Energy and resource efficiency in construction and renovating;

- (5)

- Transition towards sustainable and smart transportation;

- (6)

- Reaching a pollution-free environment with zero toxicity;

- (7)

- “Farm to fork strategy”—environmentally sustainable food system;

- (8)

- Conserving and re-establishing ecosystems and biodiversity.

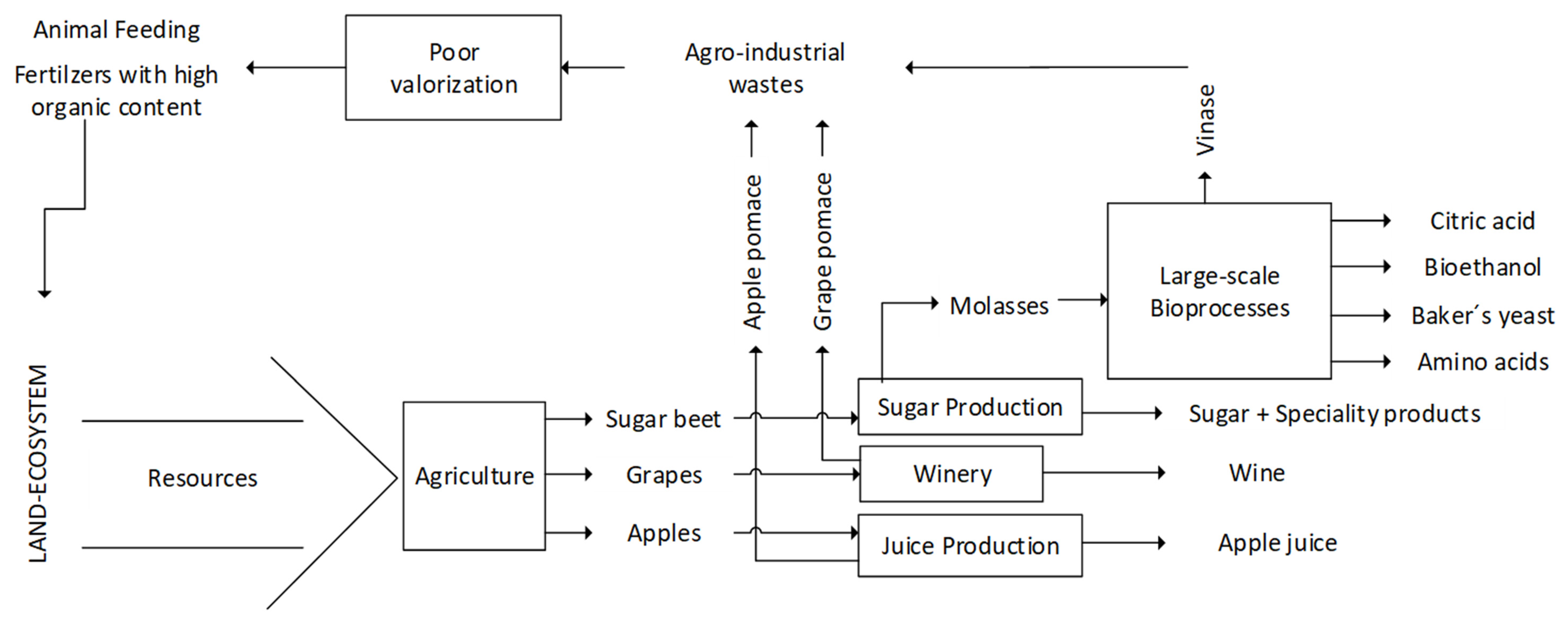

2. Recent Advances in Sustainable Valorization of Apple and Grape Pomace as Problematic Agro-Industrial Wastes

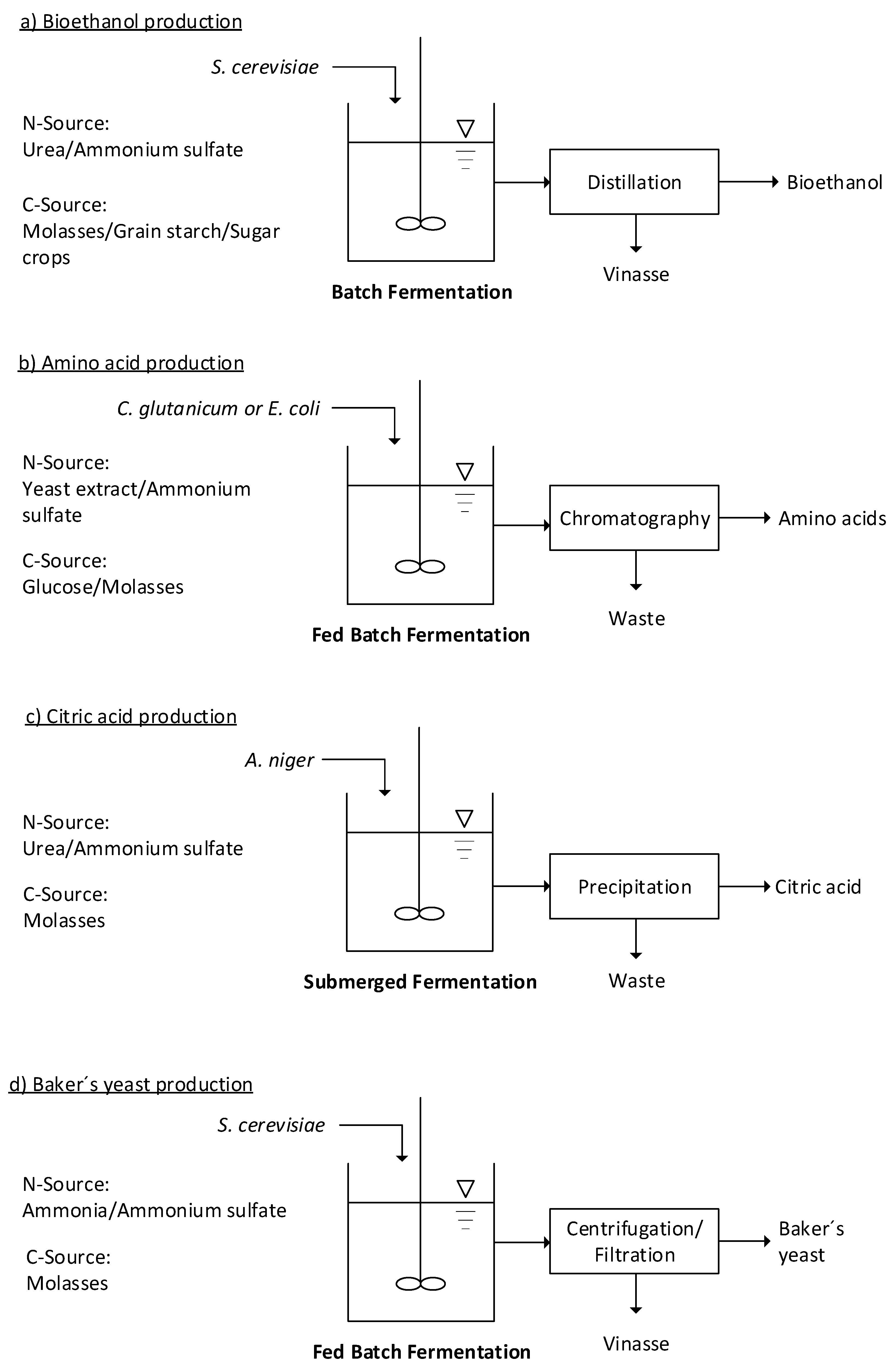

3. The Lack of Sustainability in Large-Scale Bioprocesses: Baker’s Yeast Production as a Representative Example

| Waste | Application | Literature |

|---|---|---|

| Grape pomace | As source of bioactive compounds (phenolics) used in pharmaceutical, cosmetic and food industries | [7,35,36,37,38,39] |

| As source of dietary fiber (as dietary supplement, dough improver, alternative source of antioxidants and dietary fiber for yogurt, for the fortification of meat and fish products) | [7,11,36,40,41,42] | |

| In the production of bioethanol | [39,43,44,45] | |

| In the production of baker’s yeast | [10,46] | |

| In the production of lactic acid | [47,48] | |

| Apple pomace | Green extraction of bioactive compounds: | [49,50,51,52,53] |

| [6,25,26,27,28,49,50,54,55,56,57,58,59,60] | |

| [6,49,58] | |

| As solid biofuel | [25,27,28] | |

| As source of dietary fiber (used in baked food products) | [61,62,63] | |

| As functional ingredient in food products: | [6] | |

| [6,26,58,60,64,65] | |

| [6,50,54,64,66,67,68] | |

| [6,24,61,69] | |

| In the production of citric acid | [6,26,70,71,72,73,74] | |

| In the production of baker’s yeast | [25,75,76] |

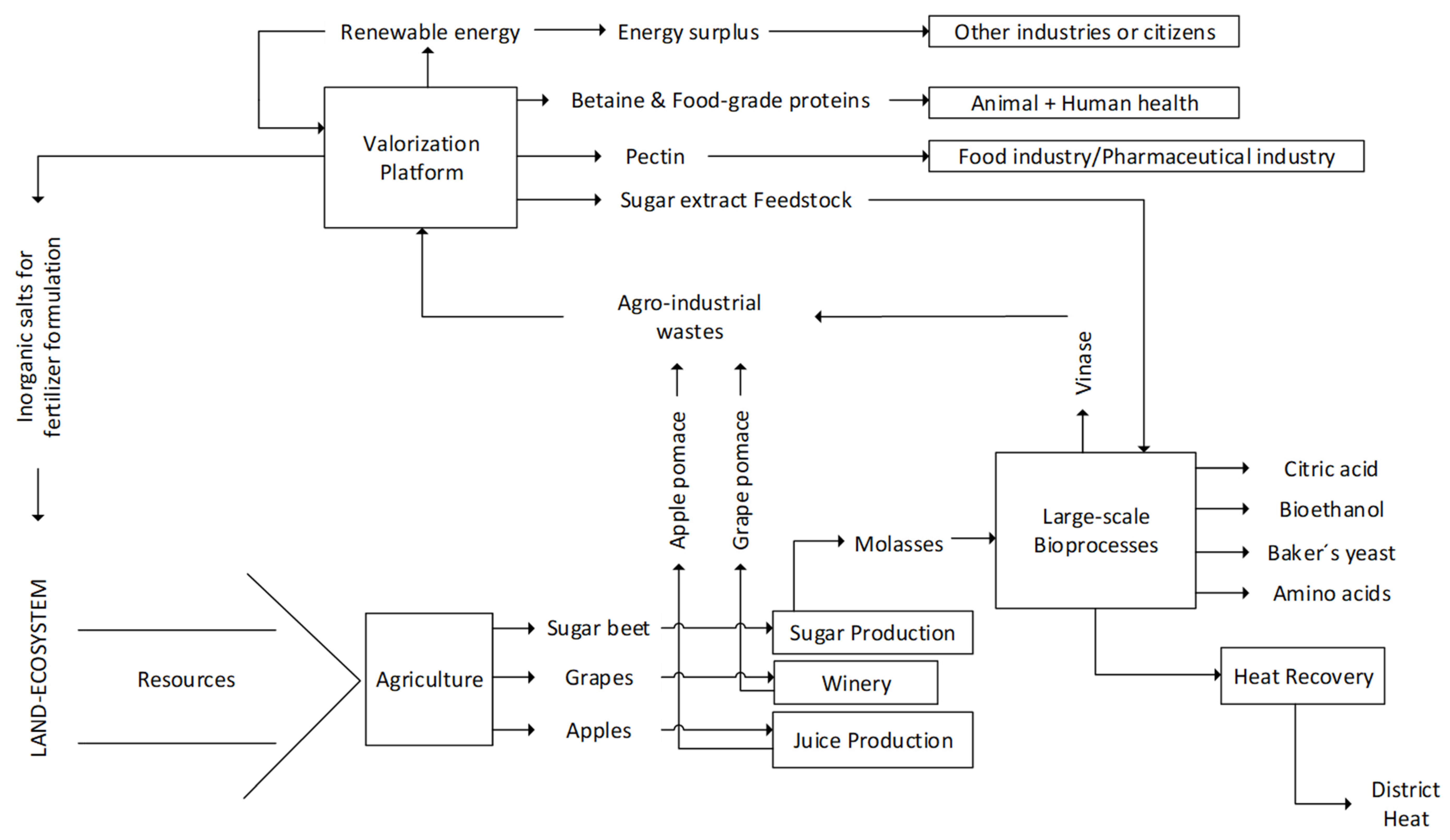

4. Centralized Valorization Platforms as Well as a Close Collaboration between Academia and Industry Are Crucial to Bridge the Gap between Agro-Industrial Wastes and Large-Scale Bio-Industries

5. Conclusions

- -

- Openness and mentality changes, especially in companies involved in the bioproduction of one main product. New expertise and financial risks are often associated with the extension of a product portfolio. This move is often uncomfortable for small- and middle-sized companies, which then become new players in existing or novel markets. Centralized valorization platforms can play a crucial role in overwhelming the valorization chain and accelerating the transition towards a circular economy.

- -

- Adequate policies to ensure the correct balance between the pressure to enforce, engage and consolidate the transition and the support to encourage companies to take risks and develop new market opportunities.

- -

- Academic research plays a vital role for the establishment and the acceleration of transition towards a sustainable circular economy. However, the conversion of research outputs into innovation necessitates a close and trustful collaboration between academic and industrial partners. Prior to the project start, academic researchers should have a deep understanding of the workflow of the companies involved in the research with a special focus on the current constraints associated with the market dynamics, and the product quality standards.

Author Contributions

Funding

Conflicts of Interest

References

- Schunz, S. The ‘European Green Deal’—A Paradigm Shift? Transformations in the European Union’s Sustainability Meta-Discourse. Polit. Res. Exch. 2022, 4, 2085121. [Google Scholar] [CrossRef]

- Kougias, I.; Taylor, N.; Kakoulaki, G.; Jäger-Waldau, A. The Role of Photovoltaics for the European Green Deal and the Recovery Plan. Renew. Sustain. Energy Rev. 2021, 144, 111017. [Google Scholar] [CrossRef]

- Gheuens, J. The European Green Deal. Mak. Eur. Green. Deal. Work. 2023, 15–28. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 29 November 2023).

- European Commission. Farm to Fork Strategy. Available online: https://food.ec.europa.eu/horizontal-topics/farm-fork-strategy_en (accessed on 29 November 2023).

- Asif, M.; Javaid, T.; Razzaq, Z.U.; Khan, M.K.I.; Maan, A.A.; Yousaf, S.; Usman, A.; Shahid, S. Sustainable Utilization of Apple Pomace and Its Emerging Potential for Development of Functional Foods. Environ. Sci. Pollut. Res. 2023, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Bordiga, M.; Travaglia, F.; Locatelli, M. Valorisation of Grape Pomace: An Approach That Is Increasingly Reaching Its Maturity—A Review. Int. J. Food Sci. Technol. 2019, 54, 933–942. [Google Scholar] [CrossRef]

- FAO Global Fruit Production in 2019, by Selected Variety (in Million Metric Tons). Available online: https://www.statista.com/statistics/262266/global-production-of-fresh-fruit/ (accessed on 29 November 2023).

- Maicas, S.; Mateo, J.J. Sustainability of Wine Production. Sustainability 2020, 12, 559. [Google Scholar] [CrossRef]

- Lisičar Vukušić, J.; Millenautzki, T.; Reichert, L.; Saaid, A.M.; Müller, L.; Clavijo, L.; Hof, J.; Mösche, M.; Barbe, S. Conversion of Problematic Winery Waste into Valuable Substrate for Baker’s Yeast Production and Solid Biofuel: A Circular Economy Approach. Food Technol. Biotechnol. 2023, 61, 1–19. [Google Scholar] [CrossRef]

- Antonić, B.; Jančíková, S.; Dordević, D.; Tremlová, B. Grape Pomace Valorization: A Systematic Review and Meta-Analysis. Foods 2020, 9, 1627. [Google Scholar] [CrossRef]

- Gómez-Brandón, M.; Lores, M.; Insam, H.; Domínguez, J. Strategies for Recycling and Valorization of Grape Marc. Crit. Rev. Biotechnol. 2019, 39, 437–450. [Google Scholar] [CrossRef]

- Soceanu, A.; Dobrinas, S.; Sirbu, A.; Manea, N.; Popescu, V. Economic Aspects of Waste Recovery in the Wine Industry. A Multidisciplinary Approach. Sci. Total Environ. 2021, 759, 143543. [Google Scholar] [CrossRef]

- Ardente, F.; Beccali, G.; Cellura, M.; Marvuglia, A. POEMS: A Case Study of an Italian Wine-Producing Firm. Environ. Manag. 2006, 38, 350–364. [Google Scholar] [CrossRef] [PubMed]

- Kariyapperuma, N.; Collins, E. Family Logics and Environmental Sustainability: A Study of the New Zealand Wine Industry. Bus. Strategy Environ. 2021, 30, 3626–3650. [Google Scholar] [CrossRef]

- Gilinsky, A.; Newton, S.K.; Vega, R.F. Sustainability in the Global Wine Industry: Concepts and Cases. Agric. Agric. Sci. Procedia 2016, 8, 37–49. [Google Scholar] [CrossRef]

- Baiano, A. An Overview on Sustainability in the Wine Production Chain. Beverages 2021, 7, 15. [Google Scholar] [CrossRef]

- Golicic, S.L.; Flint, D.J.; Signori, P. Building Business Sustainability through Resilience in the Wine Industry. Int. J. Wine Bus. Res. 2017, 29, 74–97. [Google Scholar] [CrossRef]

- Flores, S.S. What Is Sustainability in the Wine World? A Cross-Country Analysis of Wine Sustainability Frameworks. J. Clean. Prod. 2018, 172, 2301–2312. [Google Scholar] [CrossRef]

- Bandinelli, R.; Acuti, D.; Fani, V.; Bindi, B.; Aiello, G. Environmental Practices in the Wine Industry: An Overview of the Italian Market. Br. Food J. 2020, 122, 1625–1646. [Google Scholar] [CrossRef]

- Bhushan, S.; Kalia, K.; Sharma, M.; Singh, B.; Ahuja, P.S. Processing of Apple Pomace for Bioactive Molecules. Crit. Rev. Biotechnol. 2008, 28, 285–296. [Google Scholar] [CrossRef]

- Palmonari, A.; Cavallini, D.; Sniffen, C.J.; Fernandes, L.; Holder, P.; Fagioli, L.; Fusaro, I.; Biagi, G.; Formigoni, A.; Mammi, L. Short Communication: Characterization of Molasses Chemical Composition. J. Dairy Sci. 2020, 103, 6244–6249. [Google Scholar] [CrossRef]

- Lisičar Vukušić, J.; Millenautzki, T.; Sedaghati, M.; Schallenberg, M.; Müller, P.; Hof, J.; Mösche, M.; Barbe, S. Fractionation of Baker’s Yeast Vinasse via Ultrafiltration: Assessment of Feasibility. Int. J. Food Sci. Technol. 2019, 54, 1794–1803. [Google Scholar] [CrossRef]

- Lyu, F.; Luiz, S.F.; Azeredo, D.R.P.; Cruz, A.G.; Ajlouni, S.; Ranadheera, C.S. Apple Pomace as a Functional and Healthy Ingredient in Food Products: A Review. Processes 2020, 8, 319. [Google Scholar] [CrossRef]

- Lisičar Vukušić, J.; Millenautzki, T.; Cieplik, R.; Obst, V.; Saaid, A.M.; Clavijo, L.; Zlatanovic, S.; Hof, J.; Mösche, M.; Barbe, S. Reshaping Apple Juice Production into a Zero Discharge Biorefinery Process. Waste Biomass Valorization 2021, 12, 3617–3627. [Google Scholar] [CrossRef]

- Gorawala, P.; Mandhatri, S. Apple Pomace: Source of Value Added Products. In Agricultural Research Updates; Prathames, G., Mandhatri, S., Eds.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2014; Volume 8, pp. 167–203. ISBN 978-1-63321-485-9. [Google Scholar]

- Gołębiewska, E.; Kalinowska, M.; Yildiz, G. Sustainable Use of Apple Pomace (AP) in Different Industrial Sectors. Materials 2022, 15, 1788. [Google Scholar] [CrossRef] [PubMed]

- Shalini, R.; Gupta, D.K. Utilization of Pomace from Apple Processing Industries: A Review. J. Food Sci. Technol. 2010, 47, 365–371. [Google Scholar] [CrossRef] [PubMed]

- Pereira, C.L.F.; Ortega, E. Sustainability Assessment of Large-Scale Ethanol Production from Sugarcane. J. Clean. Prod. 2010, 18, 77–82. [Google Scholar] [CrossRef]

- Wu, B.; Wang, Y.-W.; Dai, Y.-H.; Song, C.; Zhu, Q.-L.; Qin, H.; Tan, F.-R.; Chen, H.-C.; Dai, L.-C.; Hu, G.-Q.; et al. Current Status and Future Prospective of Bio-Ethanol Industry in China. Renew. Sustain. Energy Rev. 2021, 145, 111079. [Google Scholar] [CrossRef]

- Karp, S.G.; Medina, J.D.C.; Letti, L.A.J.; Woiciechowski, A.L.; De Carvalho, J.C.; Schmitt, C.C.; De Oliveira Penha, R.; Kumlehn, G.S.; Soccol, C.R. Bioeconomy and Biofuels: The Case of Sugarcane Ethanol in Brazil. Biofuels Bioprod. Biorefining 2021, 15, 899–912. [Google Scholar] [CrossRef]

- Behera, B.C.; Mishra, R.; Mohapatra, S. Microbial Citric Acid: Production, Properties, Application, and Future Perspectives. Food Front. 2021, 2, 62–76. [Google Scholar] [CrossRef]

- Yokota, A.; Ikeda, M. (Eds.) Amino Acid Fermentation; Advances in Biochemical Engineering/Biotechnology; Springer: Tokyo, Japan, 2017; Volume 159, ISBN 978-4-431-56518-5. [Google Scholar]

- Wendisch, V.F. Metabolic Engineering Advances and Prospects for Amino Acid Production. Metab. Eng. 2020, 58, 17–34. [Google Scholar] [CrossRef]

- Ferreira, S.M.; Santos, L. A Potential Valorization Strategy of Wine Industry By-Products and Their Application in Cosmetics—Case Study: Grape Pomace and Grapeseed. Molecules 2022, 27, 969. [Google Scholar] [CrossRef]

- Fontana, A.R.; Antoniolli, A.; Bottini, R. Grape Pomace as a Sustainable Source of Bioactive Compounds: Extraction, Characterization, and Biotechnological Applications of Phenolics. J. Agric. Food Chem. 2013, 61, 8987–9003. [Google Scholar] [CrossRef] [PubMed]

- Ferri, M.; Vannini, M.; Ehrnell, M.; Eliasson, L.; Xanthakis, E.; Monari, S.; Sisti, L.; Marchese, P.; Celli, A.; Tassoni, A. From Winery Waste to Bioactive Compounds and New Polymeric Biocomposites: A Contribution to the Circular Economy Concept. J. Adv. Res. 2020, 24, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Ioannou, L.A.; Puma, G.L.; Fatta-Kassinos, D. Treatment of Winery Wastewater by Physicochemical, Biological and Advanced Processes: A Review. J. Hazard. Mater. 2015, 286, 343–368. [Google Scholar] [CrossRef] [PubMed]

- Corbin, K.R.; Hsieh, Y.S.Y.; Betts, N.S.; Byrt, C.S.; Henderson, M.; Stork, J.; DeBolt, S.; Fincher, G.B.; Burton, R.A. Grape Marc as a Source of Carbohydrates for Bioethanol: Chemical Composition, Pre-Treatment and Saccharification. Bioresour. Technol. 2015, 193, 76–83. [Google Scholar] [CrossRef]

- Valiente, C.; Arrigoni, E.; Esteban, R.M.; Amado, R. Grape Pomace as a Potential Food Fiber. J. Food Sci. 1995, 60, 818–820. [Google Scholar] [CrossRef]

- Iuga, M.; Mironeasa, S. Potential of Grape Byproducts as Functional Ingredients in Baked Goods and Pasta. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2473–2505. [Google Scholar] [CrossRef]

- García-Lomillo, J.; González-SanJosé, M.L. Applications of Wine Pomace in the Food Industry: Approaches and Functions. Compr. Rev. Food Sci. Food Saf. 2017, 16, 3–22. [Google Scholar] [CrossRef]

- Energy, C.; Technologies, P. (Eds.) Food Waste to Green Fuel: Trend & Development; Springer: Berlin/Heidelberg, Germany, 2022; ISBN 978-981-19081-2-5. [Google Scholar]

- Rodríguez, L.A.; Toro, M.E.; Vazquez, F.; Correa-Daneri, M.L.; Gouiric, S.C.; Vallejo, M.D. Bioethanol Production from Grape and Sugar Beet Pomaces by Solid-State Fermentation. Int. J. Hydrogen Energy 2010, 35, 5914–5917. [Google Scholar] [CrossRef]

- Sirohi, R.; Tarafdar, A.; Singh, S.; Negi, T.; Gaur, V.K.; Gnansounou, E.; Bharathiraja, B. Green Processing and Biotechnological Potential of Grape Pomace: Current Trends and Opportunities for Sustainable Biorefinery. Bioresour. Technol. 2020, 314, 123771. [Google Scholar] [CrossRef]

- Lo Curto, R.B.; Tripodo, M.M. Yeast Production from Virgin Grape Marc. Bioresour. Technol. 2001, 78, 5–9. [Google Scholar] [CrossRef]

- Rivera, O.M.P.; Moldes, A.B.; Torrado, A.M.; Domínguez, J.M. Lactic Acid and Biosurfactants Production from Hydrolyzed Distilled Grape Marc. Process Biochem. 2007, 42, 1010–1020. [Google Scholar] [CrossRef]

- Campanella, D.; Rizzello, C.G.; Fasciano, C.; Gambacorta, G.; Pinto, D.; Marzani, B.; Scarano, N.; De Angelis, M.; Gobbetti, M. Exploitation of Grape Marc as Functional Substrate for Lactic Acid Bacteria and Bifidobacteria Growth and Enhanced Antioxidant Activity. Food Microbiol. 2017, 65, 25–35. [Google Scholar] [CrossRef] [PubMed]

- Putra, N.R.; Rizkiyah, D.N.; Abdul Aziz, A.H.; Che Yunus, M.A.; Veza, I.; Harny, I.; Tirta, A. Waste to Wealth of Apple Pomace Valorization by Past and Current Extraction Processes: A Review. Sustainability 2023, 15, 830. [Google Scholar] [CrossRef]

- Costa, J.M.; Ampese, L.C.; Ziero, H.D.D.; Sganzerla, W.G.; Forster-Carneiro, T. Apple Pomace Biorefinery: Integrated Approaches for the Production of Bioenergy, Biochemicals, and Value-Added Products—An Updated Review. J. Environ. Chem. Eng. 2022, 10, 108358. [Google Scholar] [CrossRef]

- Rashid, R.; Wani, S.M.; Manzoor, S.; Masoodi, F.A.; Dar, M.M. Green Extraction of Bioactive Compounds from Apple Pomace by Ultrasound Assisted Natural Deep Eutectic Solvent Extraction: Optimisation, Comparison and Bioactivity. Food Chem. 2023, 398, 133871. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Poojary, M.M.; Choudhary, A.; Rai, D.K.; Tiwari, B.K. Comparison of Selected Clean and Green Extraction Technologies for Biomolecules from Apple Pomace. Electrophoresis 2018, 39, 1934–1945. [Google Scholar] [CrossRef]

- Wijngaard, H.; Brunton, N. The Optimization of Extraction of Antioxidants from Apple Pomace by Pressurized Liquids. J. Agric. Food Chem. 2009, 57, 10625–10631. [Google Scholar] [CrossRef]

- Sobczak, P.; Nadulski, R.; Kobus, Z.; Zawiślak, K. Technology for Apple Pomace Utilization within a Sustainable Development Policy Framework. Sustainability 2022, 14, 5470. [Google Scholar] [CrossRef]

- de Oliveira, T.C.G.; Sganzerla, W.G.; Ampese, L.C.; Sforça, B.P.; Goldbeck, R.; Forster-Carneiro, T. Sustainable Valorization of Apple Waste in a Biorefinery: A Bibliometric Analysis. Biofuels Bioprod. Biorefining 2022, 16, 891–919. [Google Scholar] [CrossRef]

- Pyanikova, E.A.; Kovaleva, A.E.; Ovchinnikova, E.V.; Afanasieva, L.A. Researching the Possibility of Using Recycled Apple Raw Materials to Create Functional Food Products. IOP Conf. Ser. Earth Environ. Sci. 2021, 677, 6–11. [Google Scholar] [CrossRef]

- Kodagoda, K.; Marapana, R. Utilization of Fruit Processing By-Products for Industrial Applications: A Review. Int. J. Food Sci. Nutr. 2017, 2, 24–30. [Google Scholar]

- Guardia, L.; Suárez, L.; Querejeta, N.; Rodríguez Madrera, R.; Suárez, B.; Centeno, T.A. Apple Waste: A Sustainable Source of Carbon Materials and Valuable Compounds. ACS Sustain. Chem. Eng. 2019, 7, 17335–17343. [Google Scholar] [CrossRef]

- Reis, S.F.; Rai, D.K.; Abu-Ghannam, N. Apple Pomace as a Potential Ingredient for the Development of New Functional Foods. Int. J. Food Sci. Technol. 2014, 49, 1743–1750. [Google Scholar] [CrossRef]

- Sudha, M.L. Apple Pomace (By-Product of Fruit Juice Industry) as a Flour Fortification Strategy; Elsevier Inc.: Amsterdam, The Netherlands, 2011; ISBN 978-0-12-380886-8. [Google Scholar]

- Wang, H.J.; Thomas, R.L. Direct Use of Apple Pomace in Bakery Products. J. Food Sci. 1989, 54, 618–620. [Google Scholar] [CrossRef]

- Masoodi, F.A.; Sharma, B.; Chauhan, G.S. Use of Apple Pomace as a Source of Dietary Fiber in Cakes. Plant Foods Hum. Nutr. 2002, 57, 121–128. [Google Scholar] [CrossRef] [PubMed]

- Sudha, M.L.; Baskaran, V.; Leelavathi, K. Apple Pomace as a Source of Dietary Fiber and Polyphenols and Its Effect on the Rheological Characteristics and Cake Making. Food Chem. 2007, 104, 686–692. [Google Scholar] [CrossRef]

- Muntean, M.V.; Fărcaş, A.C.; Medeleanu, M.; Salanţă, L.C.; Borşa, A. A Sustainable Approach for the Development of Innovative Products from Fruit and Vegetable By-Products. Sustainability 2022, 14, 10862. [Google Scholar] [CrossRef]

- Wang, X.; Kristo, E.; LaPointe, G. The Effect of Apple Pomace on the Texture, Rheology and Microstructure of Set Type Yogurt. Food Hydrocoll. 2019, 91, 83–91. [Google Scholar] [CrossRef]

- Younis, K.; Ahmad, S. Waste Utilization of Apple Pomace as a Source of Functional Ingredient in Buffalo Meat Sausage. Cogent Food Agric. 2015, 1, 1119397. [Google Scholar] [CrossRef]

- Lantto, R.; Plathin, P.; Niemistö, M.; Buchert, J.; Autio, K. Effects of Transglutaminase, Tyrosinase and Freeze-Dried Apple Pomace Powder on Gel Forming and Structure of Pork Meat. LWT 2006, 39, 1117–1124. [Google Scholar] [CrossRef]

- Rather, S.A.; Akhter, R.; Masoodi, F.A.; Gani, A.; Wani, S.M. Utilization of Apple Pomace Powder as a Fat Replacer in Goshtaba: A Traditional Meat Product of Jammu and Kashmir, India. J. Food Meas. Charact. 2015, 9, 389–399. [Google Scholar] [CrossRef]

- Issar, K.; Sharma, P.C.; Gupta, A. Utilization of Apple Pomace in the Preparation of Fiber-Enriched Acidophilus. J. Food Process. Preserv. 2017, 41, e13098. [Google Scholar] [CrossRef]

- Dhillon, G.S.; Brar, S.K.; Verma, M.; Tyagi, R.D. Utilization of Different Agro-Industrial Wastes for Sustainable Bioproduction of Citric Acid by Aspergillus Niger. Biochem. Eng. J. 2011, 54, 83–92. [Google Scholar] [CrossRef]

- Dhillon, G.S.; Brar, S.K.; Verma, M.; Tyagi, R.D. Apple Pomace Ultrafiltration Sludge—A Novel Substrate for Fungal Bioproduction of Citric Acid: Optimisation Studies. Food Chem. 2011, 128, 864–871. [Google Scholar] [CrossRef]

- Hang, Y.D.; Woodams, E.E. Solid State Fermentation of Apple Pomace for Citric Acid Production. MIRCEN J. Appl. Microbiol. Biotechnol. 1986, 2, 283–287. [Google Scholar] [CrossRef]

- Hoseyini, M.; Asefi, N.; Mozaffari, M. Production of Citric Acid from Apple Pomace by Using Surface Culture Method. Agric. J. 2011, 6, 226–230. [Google Scholar] [CrossRef]

- Kumar, D.; Verma, R.; Bhalla, T.C. Citric Acid Production by Aspergillus Niger van. Tieghem MTCC 281 Using Waste Apple Pomace as a Substrate. J. Food Sci. Technol. 2010, 47, 458–460. [Google Scholar] [CrossRef]

- Bhushan, S.; Joshi, V.K. Baker’s Yeast Production under Fed Batch Culture from Apple Pomace. J. Sci. Ind. Res. 2006, 65, 72–76. [Google Scholar]

- Joshi, V.K.; Bhushan, S. Apple Pomace Utilization for the Production of Baker’s Yeast: Effect of Substrate Concentrations and Growth Stimulators. Indian J. Biotechnol. 2003, 2, 220–226. [Google Scholar]

- Reed, G.; Nagodawithana, T.W. Baker’s Yeast Production; Reed, G., Ed.; Springer: Dordrecht, The Netherlands, 2018. [Google Scholar]

- Trivedi, N.B.; Jacobson, G.K.; Tesch, W.; Friend, J.P. Industrial Production of Bakers’ Yeast. Crit. Rev. Biotechnol. 1986, 4, 75–109. [Google Scholar] [CrossRef]

- Flynn, G.; Adams, M.R. An Industrial Profile of Yeast Production; Tropical Products Institute: London, UK, 1981. [Google Scholar]

- Grba, S. Proizvodnja Pekarskog Kvasca. In Kvasci u Biotehnološkoj Proizvodnji; Ranić, I., Ed.; Plejada: Zagreb, Croatia, 2010; pp. 265–300. [Google Scholar]

- Lisičar, J.; Scheper, T.; Barbe, S. Turning Industrial Baker’s Yeast Manufacture into a Powerful Zero Discharge Multipurpose Bioprocess. Ind. Biotechnol. 2017, 13, 184–191. [Google Scholar] [CrossRef]

- Lisicar, J.; Scheper, T.; Barbe, S. Industrial Baker’s Yeast Fermentation: From Manufacture to Integrated Sustainability. J. Biotechnol. 2017, 256, S23–S24. [Google Scholar] [CrossRef]

- Mamun-Or-Rashid, A.N.M.; Lucy, T.T.; Md Pramanik, K. Isolation, Identification, Optimization of Baker’s Yeast from Natural Sources, Scale-Up Production Using Molasses as a Cheap Carbohydrate Source, and Evaluation for Bread Production. Appl. Microbiol. 2022, 2, 516–533. [Google Scholar] [CrossRef]

- Igwegbe, C.A.; Obiora-Okafo, I.A.; Iwuozor, K.O.; Ghosh, S.; Kurniawan, S.B.; Rangabhashiyam, S.; Kanaoujiya, R.; Ighalo, J.O. Treatment Technologies for Bakers’ Yeast Production Wastewater. Environ. Sci. Pollut. Res. 2022, 29, 11004–11026. [Google Scholar] [CrossRef]

- Yusof, A.H.; Dailin, D.J.; Low, L.Z.M.I.; Abg Zaidel, D.N.; El Enshasy, H. Potential Application of Pineapple Waste as a Fermentation Substrate in Yeast Production. Int. J. Sci. Technol. Res. 2020, 9, 1933–1937. [Google Scholar]

- Nancib, N.; Nancib, A.; Boudrant, J. Use of Waste Date Products in the Fermentative Formation of Baker’s Yeast Biomass by Saccharomyces cerevisiae. Bioresour. Technol. 1997, 60, 67–71. [Google Scholar] [CrossRef]

- Diboune, N.; Nancib, A.; Nancib, N.; Aníbal, J.; Boudrant, J. Utilization of Prickly Pear Waste for Baker’s Yeast Production. Biotechnol. Appl. Biochem. 2019, 66, 744–754. [Google Scholar] [CrossRef]

- Gengec, E.; Kobya, M.; Demirbas, E.; Akyol, A.; Oktor, K. Optimization of Baker’s Yeast Wastewater Using Response Surface Methodology by Electrocoagulation. Desalination 2012, 286, 200–209. [Google Scholar] [CrossRef]

- Xu, Y.; Cao, W.; Cui, J.; Shen, F.; Luo, J.; Wan, Y. Developing a Sustainable Process for the Cleaner Production of Baker’s Yeast: An Approach towards Waste Management by an Integrated Fermentation and Membrane Separation Process. J. Environ. Manag. 2022, 323, 116197. [Google Scholar] [CrossRef]

- Angumeenal, A.R.; Venkappayya, D. An Overview of Citric Acid Production. LWT 2013, 50, 367–370. [Google Scholar] [CrossRef]

- Mordenti, A.L.; Giaretta, E.; Campidonico, L.; Parazza, P.; Formigoni, A. A Review Regarding the Use of Molasses in Animal Nutrition. Animals 2021, 11, 115. [Google Scholar] [CrossRef] [PubMed]

- Dogbe, E.S.; Mandegari, M.; Görgens, J.F. Revitalizing the Sugarcane Industry by Adding Value to A-Molasses in Biorefineries. Biofuels Bioprod. Biorefining 2020, 14, 1089–1140. [Google Scholar] [CrossRef]

- Moraes, B.S.; Triolo, J.M.; Lecona, V.P.; Zaiat, M.; Sommer, S.G. Biogas Production within the Bioethanol Production Chain: Use of Co-Substrates for Anaerobic Digestion of Sugar Beet Vinasse. Bioresour. Technol. 2015, 190, 227–234. [Google Scholar] [CrossRef] [PubMed]

- Carpanez, T.G.; Moreira, V.R.; Assis, I.R.; Amaral, M.C.S. Sugarcane Vinasse as Organo-Mineral Fertilizers Feedstock: Opportunities and Environmental Risks. Sci. Total Environ. 2022, 832, 154998. [Google Scholar] [CrossRef] [PubMed]

- Lisičar Vukušić, J.; Millenautzki, T.; Saaid, A.M.; Reichert, L.; Barbe, S. New Feedstocks for Bioethanol Production. In Book of Proceedings of STEPsCON 2018; TH Köln: Leverkusen, Germany, 2018. [Google Scholar]

- Lisičar Vukušić, J.; Kneer, A.; Mösche, M.; Barbe, S. Turning Industrial Aerobic Fermentation Plants into Thermal Power Stations. Int. J. Energy Res. 2019, 43, 544–551. [Google Scholar] [CrossRef]

- Lisičar, J.; Sedaghati, M.; Hof, J.; Mösche, M.; Barbe, S. Full Mass Balance Analysis During Industrial Baker’s Yeast Fermentation Shows New Perspectives for Biomolecule Recovery. Ind. Biotechnol. 2019, 15, 303–310. [Google Scholar] [CrossRef]

- Cai, B. Study of Membrane Separation Processes of a Betaine-like Medicinal Solution. Desalination 2006, 191, 432–437. [Google Scholar] [CrossRef]

- Silva, S.C.D.; Moravia, M.C.S.A.; Couto, C.F. Combined Process of Ultrafiltration and Nanofiltration for Vinasse Treatment with and without Pre-Coagulation. J. Water Process Eng. 2020, 36, 101326. [Google Scholar] [CrossRef]

- Hosseinipour, E.; Karimi, S.; Barbe, S.; Park, K.; Davies, P.A. Hybrid Semi-Batch/Batch Reverse Osmosis (HSBRO) for Use in Zero Liquid Discharge (ZLD) Applications. Desalination 2022, 544, 116126. [Google Scholar] [CrossRef]

| Component | Grape Pomace (g/100 g DM) [11] | Apple Pomace (g/100 g DM) * | Cane Molasses (g/100 g DM) ** | Beet Molasses (g/100 g DM) ** | Vinasse (g/100 g DM) *** |

|---|---|---|---|---|---|

| Ash | 1.73–9.10 | 0.54–6.58 | 13.14–20.99 | 8.79–25.02 | 27.02 |

| Protein | 3.57–14.17 | 3.21–6.12 | 2.86–11.99 | 14.47–21.10 | 21.71 |

| Fat | 1.14–13.90 | 1.30–4.21 | – | – | – |

| TDF | 17.28–88.70 | 5.07–55.15 | – | – | – |

| TPC | 0.28–8.70 | – | – | – | – |

| Sucrose | – | 4.10–6.26 | 50.48–86.67 | 62.88–89.38 | – |

| Fructose | 0.38–8.91 | 21.48–43.50 | 2.96–18.39 | 0.01–1.18 | – |

| Glucose | 0.21–26.34 | 21.05–21.26 | 1.67–15.54 | 0.03–2.65 | – |

| Pectin | – | 3.78–16.48 | – | – | – |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lisičar Vukušić, J.; Millenautzki, T.; Barbe, S. Bridging the Implementation Gap between Pomace Waste and Large-Scale Baker’s Yeast Production. AgriEngineering 2023, 5, 2238-2252. https://doi.org/10.3390/agriengineering5040137

Lisičar Vukušić J, Millenautzki T, Barbe S. Bridging the Implementation Gap between Pomace Waste and Large-Scale Baker’s Yeast Production. AgriEngineering. 2023; 5(4):2238-2252. https://doi.org/10.3390/agriengineering5040137

Chicago/Turabian StyleLisičar Vukušić, Josipa, Thomas Millenautzki, and Stéphan Barbe. 2023. "Bridging the Implementation Gap between Pomace Waste and Large-Scale Baker’s Yeast Production" AgriEngineering 5, no. 4: 2238-2252. https://doi.org/10.3390/agriengineering5040137

APA StyleLisičar Vukušić, J., Millenautzki, T., & Barbe, S. (2023). Bridging the Implementation Gap between Pomace Waste and Large-Scale Baker’s Yeast Production. AgriEngineering, 5(4), 2238-2252. https://doi.org/10.3390/agriengineering5040137